1. Introduction

The maritime industry is undergoing a significant transformation driven by advancements in digital technologies, with parametric design and automation playing pivotal roles in modern ship design processes. Traditionally, ship design has been a labor-intensive and time-consuming task, requiring detailed manual adjustments for each design iteration. However, the integration of Computer-Aided Ship Design (CASD) tools has revolutionized this process by enabling designers to rapidly create, modify, and optimize ship models.

Parametric design introduces a flexible approach, allowing ship geometries to be defined by adjustable parameters, which facilitates quicker adaptation to design changes and enhances the overall efficiency of the design process. Automation, on the other hand, reduces the reliance on repetitive manual tasks, optimizes design performance, and improves workflow efficiency, paving the way for more complex and accurate ship designs.

It reviews the great developments in the areas of parametric modeling and automation systems, their current role in shipbuilding, problems, and potential. It also looks at emergent trends in the use of artificial intelligence and machine learning that in the future may be able to play a catalytic role in innovation related to ship design. It gives an all-inclusive overview, explaining the status as well as the future trajectory that will be traversed by fully automated workflows in ship design.

2. Literature Review

The use of parametric modeling tools has resulted in considerable breakthroughs in ship hull design, simplifying the complicated geometry involved. It also enhances speed and flexibility in early-stage ship design. Bole and Forrest [

1] presented the development of the Paramarine system, which made possible the integration of parametric hull generation with model analysis for fast exploration of design concepts. Abt et al. [

2] extended this to include a parametric definition language that allows for quick variations of hulls, contributing to the concept of "one-week ship design”.

Zhang, Kim, and Bahatmaka [

3] developed a new approach for the complete automation of creating and editing bulbous bows with NURBS surfaces while performing hydrodynamic optimizations related to fuel-efficient designs.

Guilcher and Laurens [

4] further developed the set of parametric tools by introducing the NEMO plugin for Rhino/Grasshopper, adding hydrostatic calculations and data export, which improved the interoperability of the tool with such programs as NAVCAD and MARS2000. Katsoulis, Wang, and Kaklis [

5] presented TshipPM-a T-spline-based modeler-enabling higher flexibility and accuracy in performing the modeling of complex geometries. Thakur,

Saxena and Roy [

6] applied generative AI to hull optimization, using machine learning algorithms in concert with the "SHIP-D" dataset as drivers for innovative designs.

Indeed, this new direction in ship design promises great possibilities regarding far broader explorations of design spaces and effective integrations of multidisciplinary optimization objectives. What is common in all these discussed studies is the great influence of using parametric tools and other emerging technologies on enhancing efficiency and precision in the current workflow related to ship design.

3. Case Studies

3.1. Case Study 1: PARAMARINE: Early-Stage Design Module

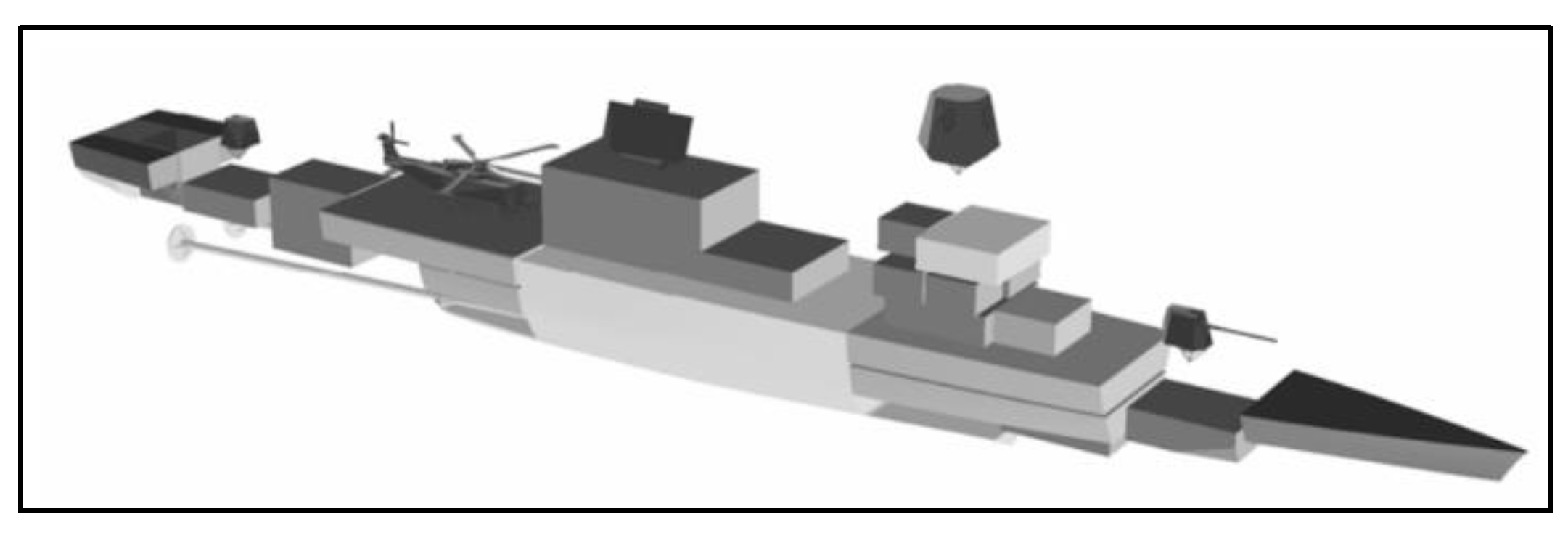

Paramarine is an integrated ship design system using the "Functional Building Block" methodology, developed using modern object-oriented techniques based on the Parasolid modeling library. In the hierarchy, its building blocks are represented with a tree structure, each block possessing both the visualization geometry and functional characteristics that can be moved interactively to achieve the best arrangement shown in

Figure 1.

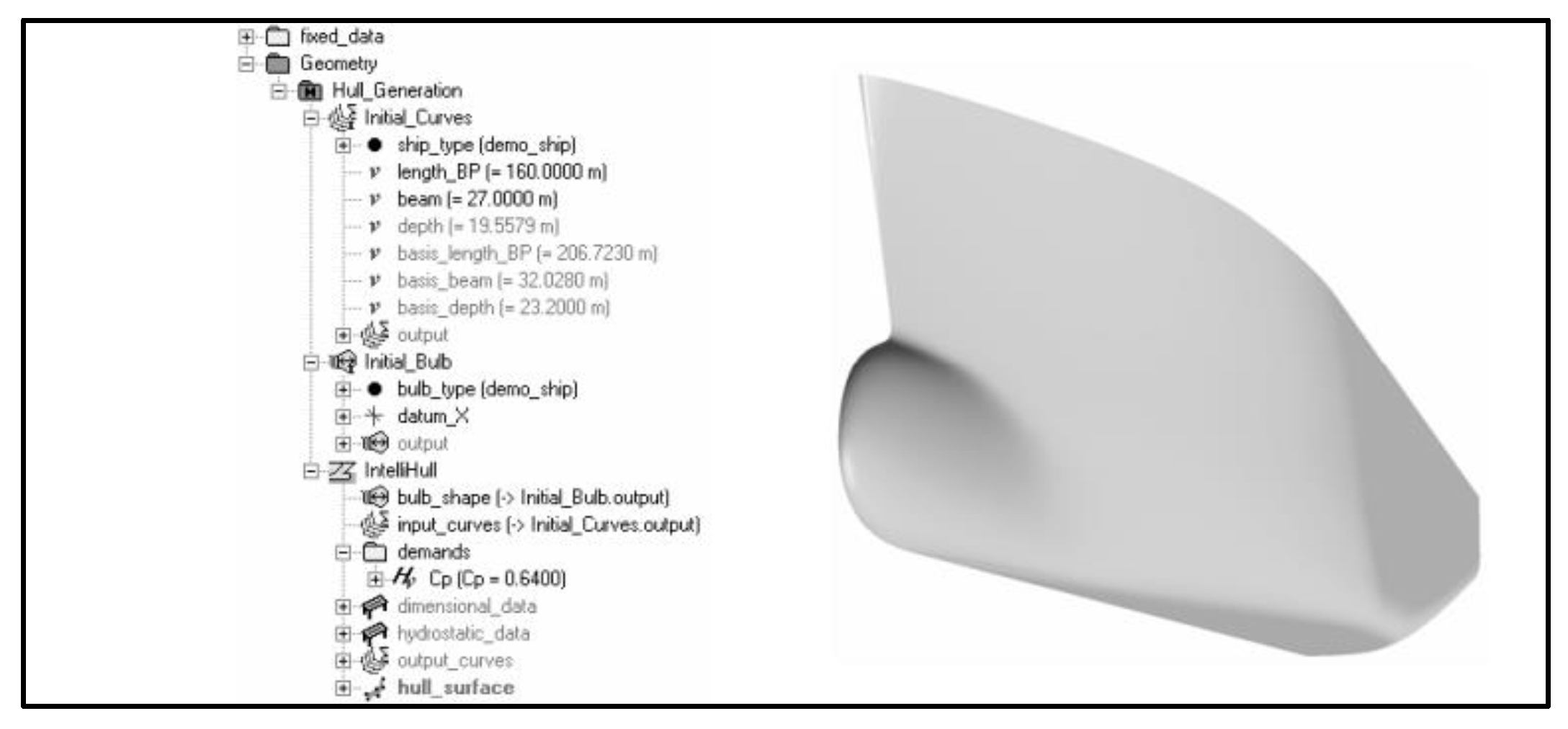

Also, Paramarine has 3 types of hull generator tools.

QuickHull – Generation and modification of Frigate type hull forms.

IntelliHull – Generation of conventional ship-type hull forms.

Hull Generator – A parametric hull surface design tool shown in

Figure 2.

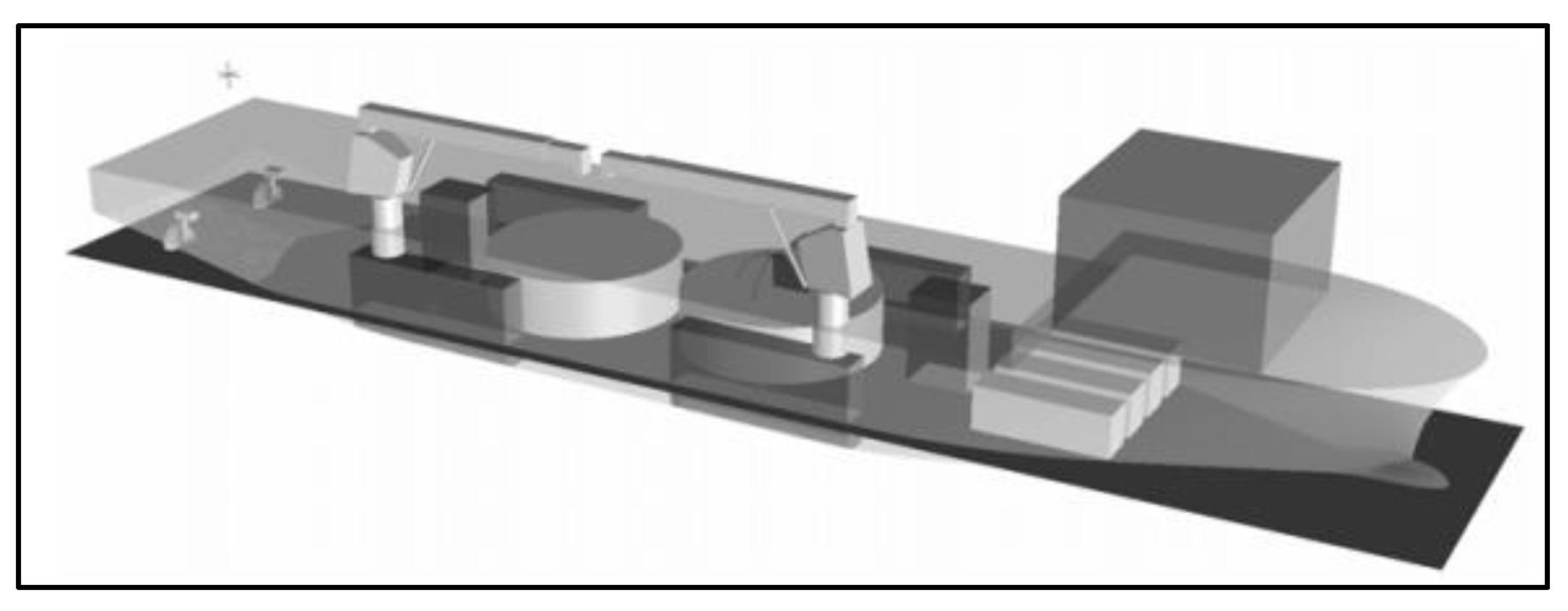

A complex ship model can be composed of functional building blocks and a parametric hull; an example is shown in

Figure 3. Additional structure can also be added to complete the design for manufacture.

The only problem is that this is a very inconvenient platform, and access isn’t even provided. Hull generation depends upon a methodology that can always be enhanced by including more parameters.

3.2. Case Study 2: FRIENDSHIP Modeler

The FRIENDSHIP-Modeler system is based on parametric principles. It is based on a parametric curve generation technique for hull optimization, developed by Harries and Abt (1997).

In the FRIENDSHIP model, minimal input is necessary to define the shapes of the midship section. For instance, by supplying merely the beam at the design waterline, the software can determine additional dimensions such as draft, beam, and freeboard. Further details may be provided, such as changing the deadrise parameter, or a flat part at the bottom of the shape. The next step in this phase is the optimization of form; hence, it is also allowed to change the topology of the design. Lastly, when the model file is produced after the small number of parameters are considered, a full geometric representation may be output shown in

Figure 4, if so desired.

It can be further characterized by various parameters, which include the slope of the buttock, the position of the apex of the bulb, and the length and height of the fairing extending into the bare hull.

The inverse model simplifies the setup process and allows tuning to become very fine. The technique is far more dynamic compared to traditional methods; it requires further development in managing the transitions of abstraction and detail in the design. Further development is attained by embedding hull elements, AI-driven automation, multi-disciplinary optimization, and cloud collaboration that will improve the usability of the solution for modern shipbuilding.

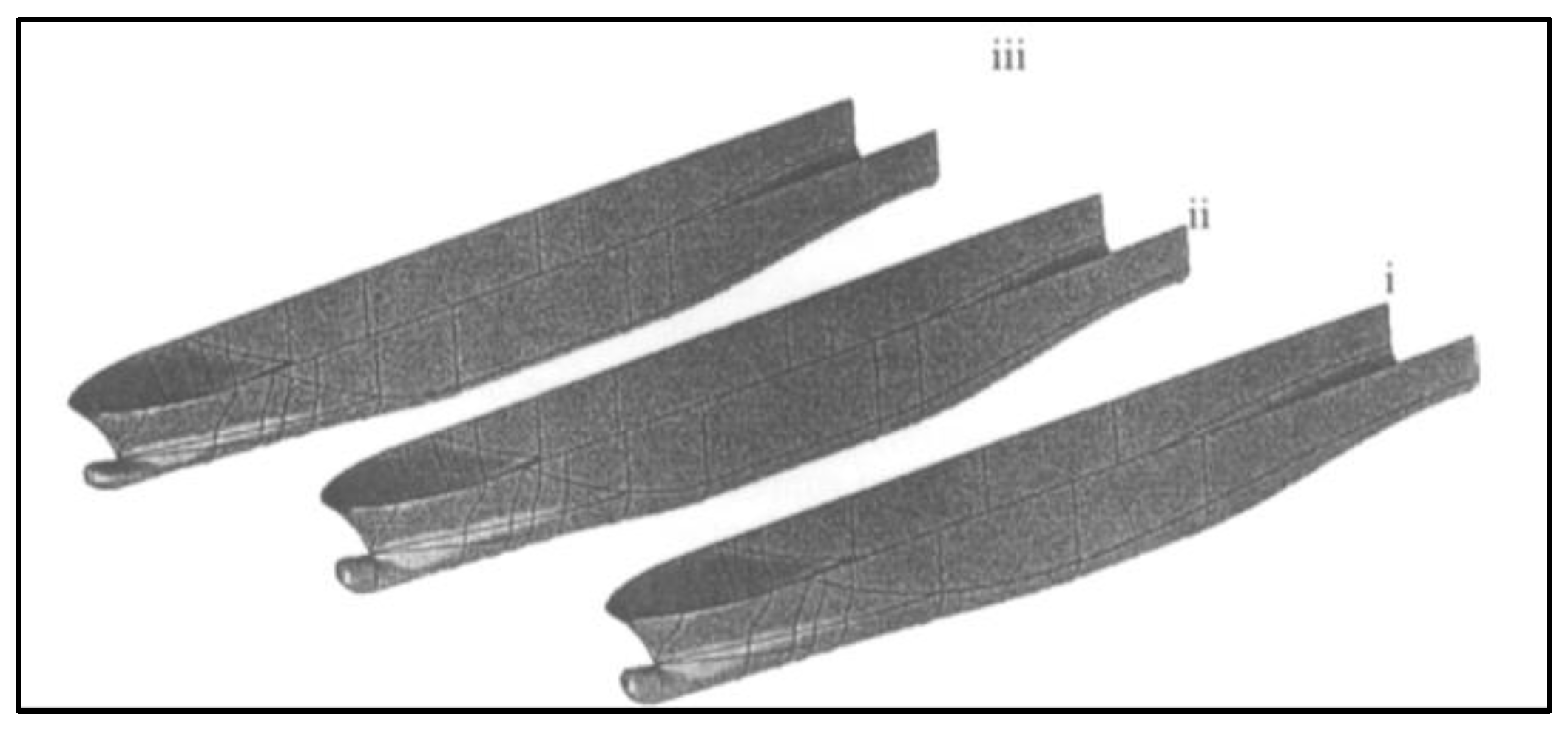

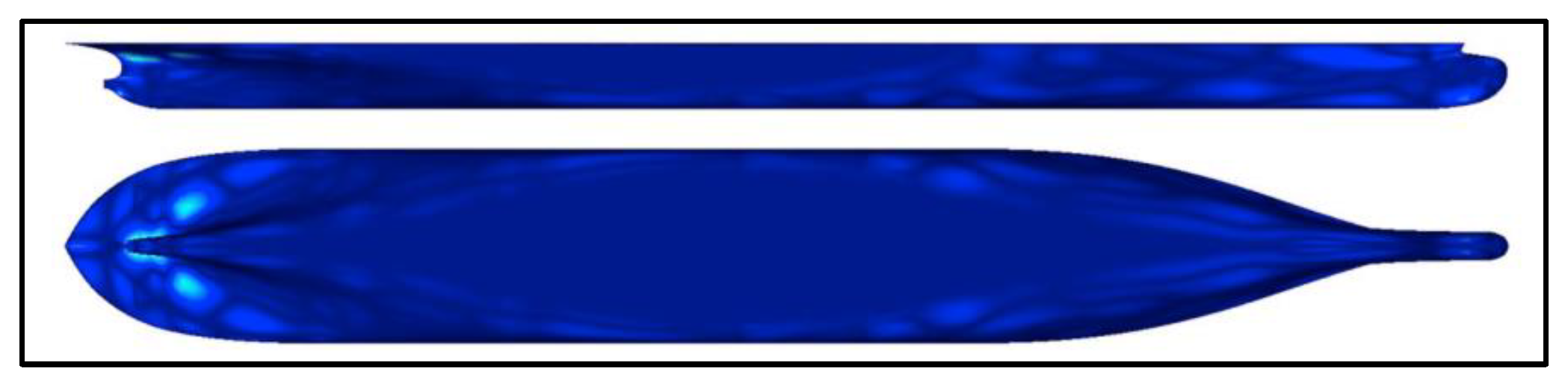

3.3. Case Study 3: TshipPM

TshipPM is a new advanced parametric model addressed to ship hull design. It gives more flexibility in modeling complex regions such as bow, stern, and transitions from midship. It uses 27 parameters; the basic dimensions are Lwl, B, and T, while the nondimensional parameters are between 0 and 1. The parameters are interconnected to make a coherent control cage for Rhino5 and T-splines. The process flow chart is shown in

Figure 5. This yielded surfaces with a total of only 196 control points that enable a rich design space at low computational cost. Extensive testing has shown the stability of TshipPM; large variations of parameters produce valid, non-self-intersecting geometries.

The model generates G1-continuous surfaces, reducing curvature problems for smoother hulls shown in

Figure 6. It remains stable with major parameter changes, preventing self-intersections.

However, these are not able to model flat areas like sides and bottom correctly; the deviations of SAC from KCS hull are more compared to that by CAESES.

It could improve by reducing complex vertices that affect surface smoothness. Automating input would boost usability for hull reconstruction.

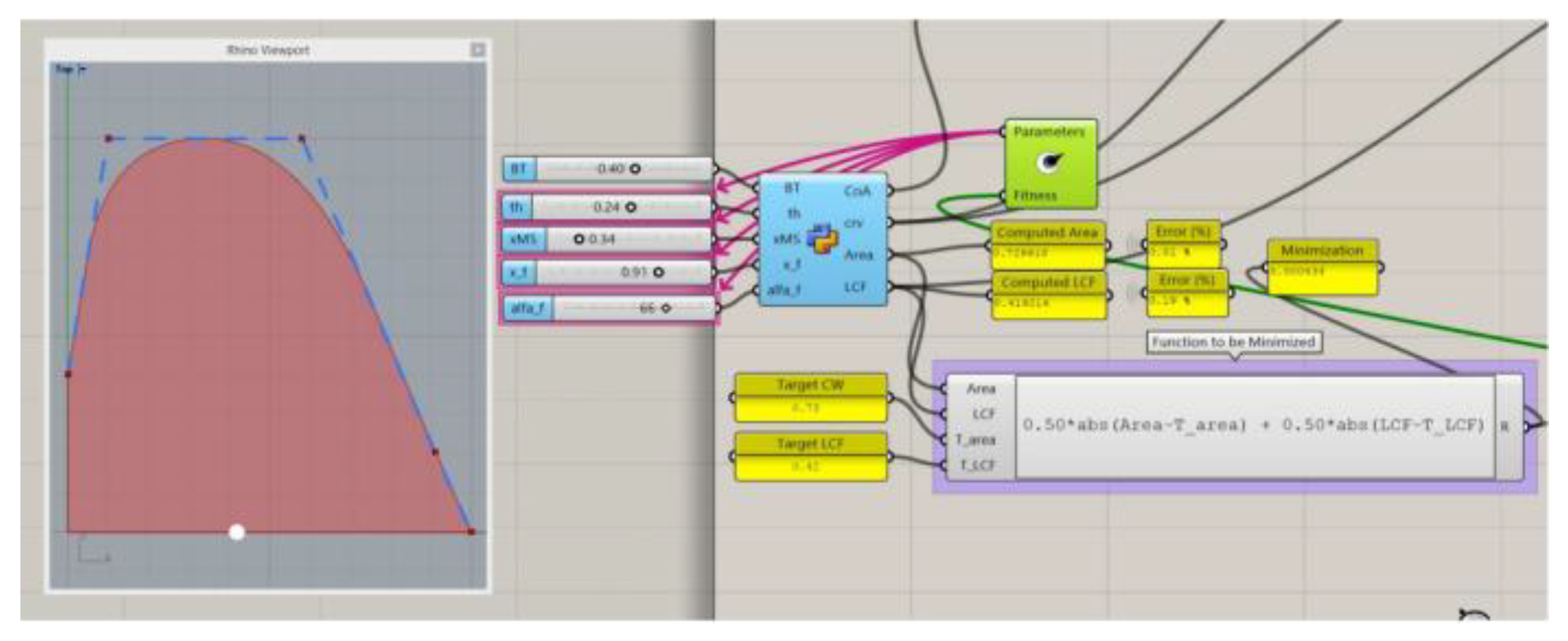

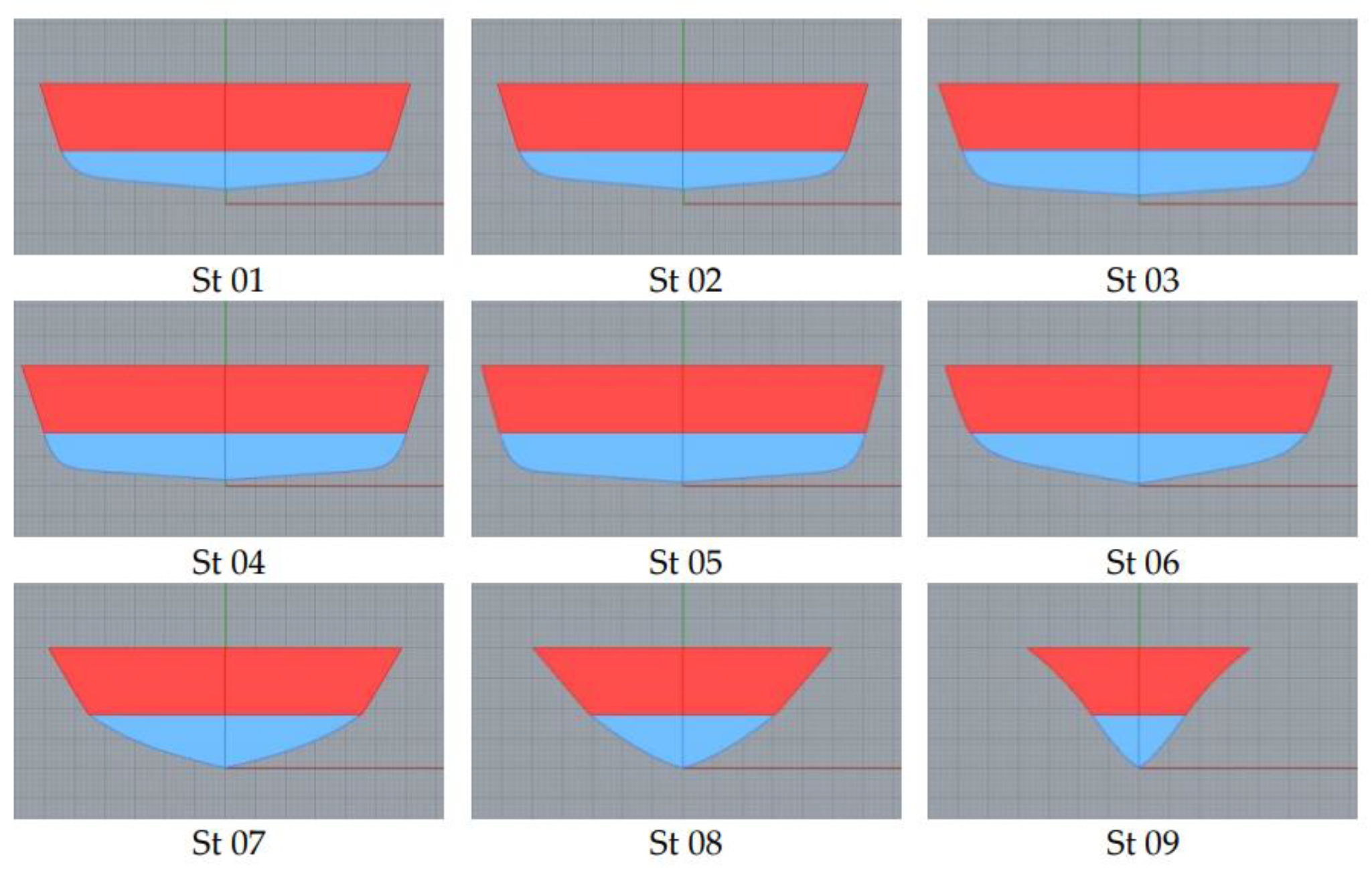

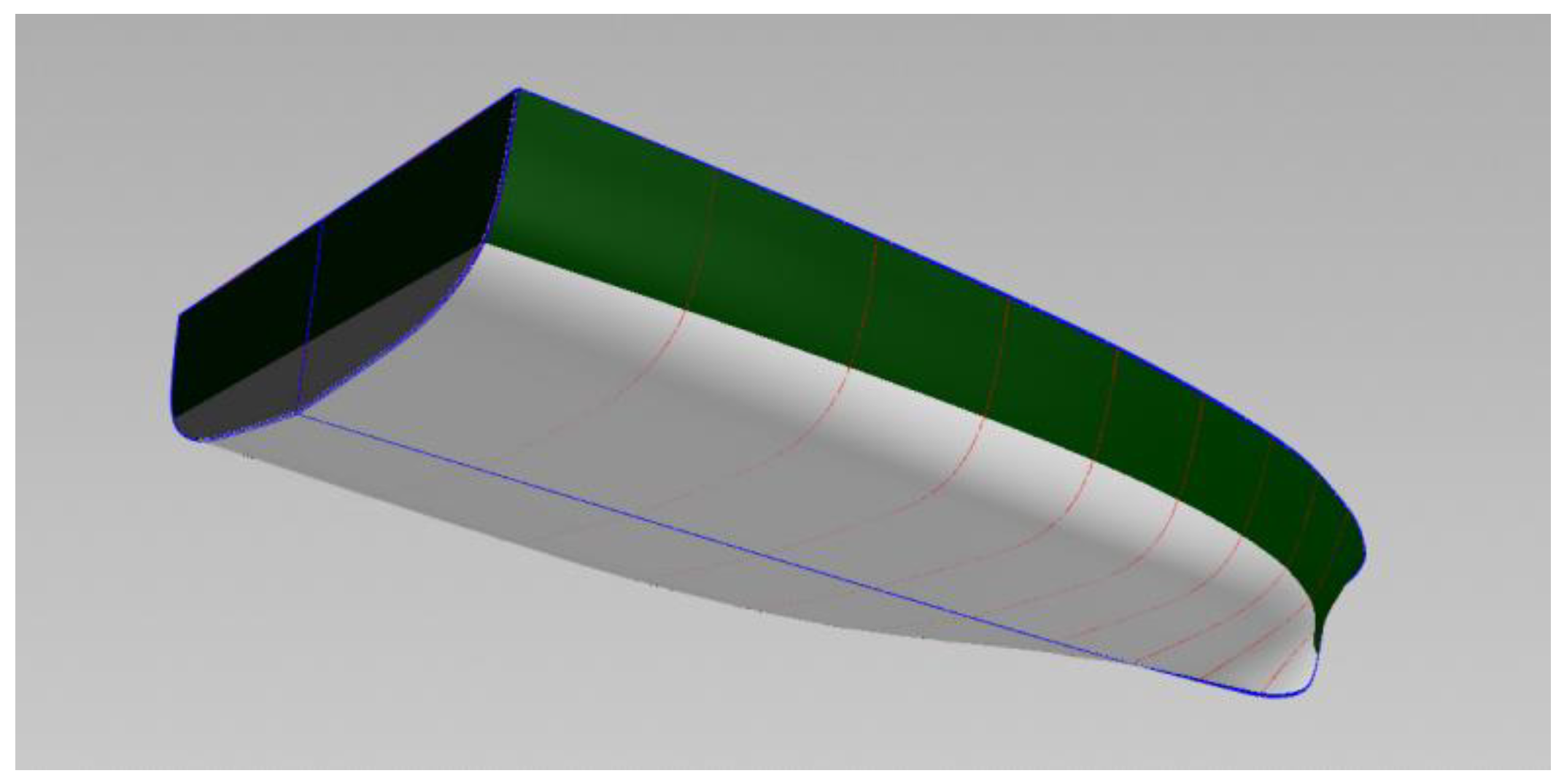

3.4. Case Study 4: Grasshopper

Rhino’s parametric design plug-in is embedded for control of the key geometric parameters to immediately manipulate the hull. The SAC of the vessel including the keel line, deck line, and water line were drawn using a B-spline curve shown in

Figure 7. Key parameters were defined: displacement, water plane area, LCB and LCF each of them linked to geometric properties of a hull-easy to change by using the Grasshopper slide directly. Each parameter was changed using a slider, and local and global changes in hull shape were observed in real-time. This script generates the cross sections (shown in

Figure 8) of the hull and then lofts them to get the hull surface shown in

Figure 9. Another script from Zhang and Kim [

3] can create a bulbous bow. There is also a script called Nemo [

4], which calculates the hydrostatics of the ship hull. Integration of all these scripts can make Rhino 3D fully parametric in ship design software.

However, there are certain shortcomings. The use of Rhino becomes cumbersome as too many parameters get involved.

3.5. Case Study 5: Generative AI

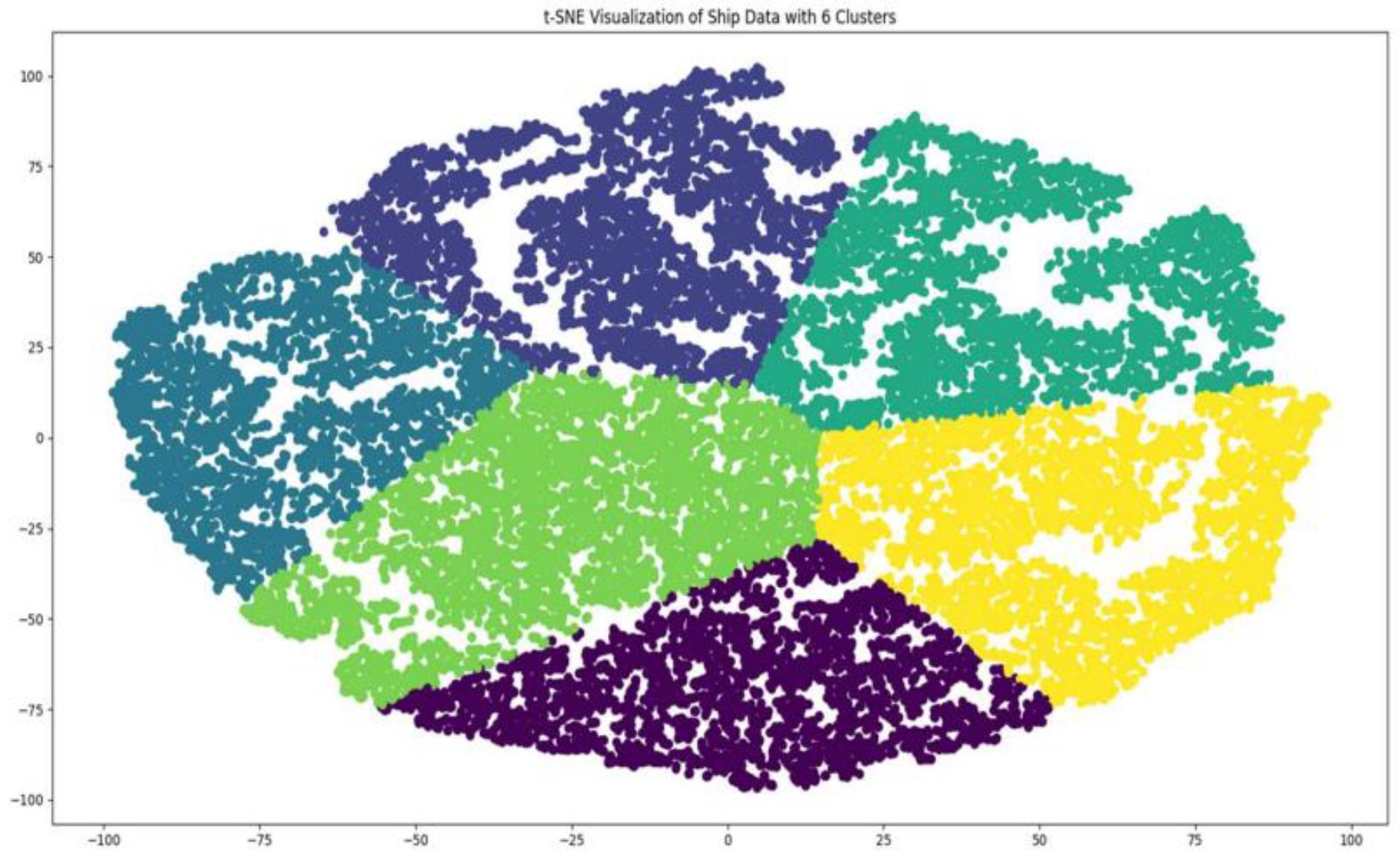

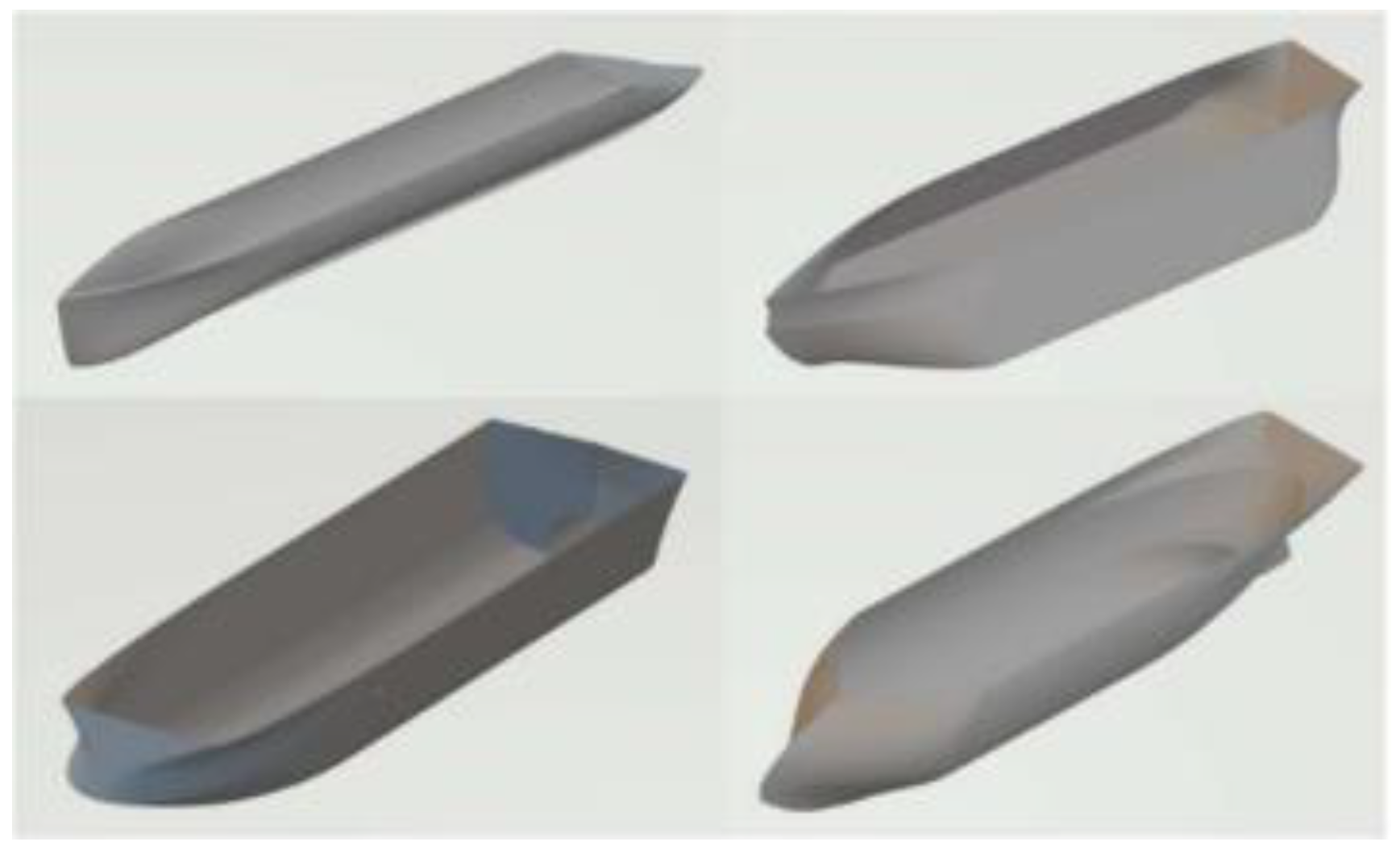

A generative model then utilized the "SHIP-D" database, developed by Bagazinski and Ahmed [

7], which contained 30,000 hull forms defined by 45 parameters. The t-SNE algorithm was applied to reduce the dimensionality for visualization of the dataset shown in

Figure 10, while K-means clustering helped to discover six optimal clusters. Later, a generative model would learn to find patterns in data and create similar traits. A GMM then sorted the data and produced new hull designs with unique variations shown in

Figure 11. It also consists of 45 parameters of those new hulls that are now available for use.

It allows the derivation of new forms of hulls, according to constraints provided by a user, and helps him in choosing feasible designs.

The designs were checked against uniqueness, while no feasibility check was required because the original dataset itself already satisfied the feasibility constraints. The key benefits the generative approach provides over the conventional approach is offering multi-disciplinary optimization.

However, this AI relies on the diversity of the original dataset and cannot generate designs outside existing data. New designs could face unforeseen issues despite prior validations.

A broader dataset could enhance creativity. Stronger validation of new designs is needed. Also, better feedback mechanisms could enhance effectiveness.

4. Result & Discussion

The results of the above case studies show the following developments in parametric ship design: indeed, each case study has proved the usability issues of different optimization techniques, although not so accessible and having fewer modifying parameters than FRI, the method is useful at the early design stage. TshipPM enables the modification of smooth geometries in real time but becomes cumbersome to handle for excessively high numbers of parameters and failures in consideration of flat regions. While the generative model-smart ship database was based on sets of pre-existing data, new designs and optimizations are generated by means of artificial intelligence.

The paper discusses issues like the harmonization of the adaptability of the tools at a parametric level with functionality, an area that introduces many complexities in TshipPM for design. AI technologies in development require larger datasets, more validation, and thus more robust innovative designs. Surface smoothness and geometric control become very crucial, especially when dealing with complex structures. It is very important to enhance usability through cloud collaboration and automation, as emphasized in FRI.

6. Future Work

In future the management of parameters should be easier, the AI capability increased, and the validation of ship design tools improved. Automation of processes will further increase ease of use, while growing AI datasets will spark further innovation. Better validation will turn new hull forms into practical use. Further development of cloud collaboration and multi-disciplinary optimization will enhance teamwork and efficiency in shipbuilding.

7. Conclusion

Overall, the case studies illustrate a promising yet evolving landscape in the domain of ship design tools. Paramarine, FRIENDSHIP Modeler, and TshipPM each possess unique strengths in the realms of early-stage design, parametric optimization, and real-time geometry control. Nevertheless, there exists potential for enhancement in areas including user-friendliness, AI implementation, and surface geometry management. In this respect, the further development of corresponding tools must be related to their flexibility and robustness of operation for covering the demands of modern shipbuilding with new designs, up to usability and collaboration.

8. Acknowledgement

This review paper was prepared solely by the author independently. No external assistance and funding were needed. The author declares no known conflict of interest. No new data was generated or analyzed in this study. All data discussed in this review are derived from previously published studies, which are cited in the reference list. While efforts have been made to ensure that the information contained in this is accurate and reliable, any mistake or omission is entirely at the discretion of the author.

This review paper does not involve original research, human subjects, or animal studies. Therefore, no ethics approval was required.

References

- M. Bole and C. Forrest, “Early Stage Integrated Parametric Ship Design,” Proc. ICCAS, 2005. Available: https://intellihull.com/downloads/Iccas05.pdf.

- C. Abt, S. D. Bade, L. Birk, and S. Harries, “Parametric Hull Form Design — A Step Towards One Week Ship Design,” Practical Design of Ships and Other Floating Structures, pp. 67–74, 2001. [CrossRef]

- Y. Zhang, D.-J. Kim, and Aldias Bahatmaka, “Parametric Method Using Grasshopper for Bulbous Bow Generation,” Aug. 2018. [CrossRef]

- P.-M. Guilcher and J.-M. Laurens, “Mathieu VENOT Development of Rhino / Grasshopper tools for Ship Design Graduation project report Nemo,” 2018. Accessed: Oct. 24, 2024. [Online]. Available: https://mathieuvenot.com/assets/venot-mathieu_stage- rapport.pdf.

- T. Katsoulis, X. Wang, and P. D. Kaklis, “A T-splines-based parametric modeler for computer-aided ship design,” Ocean Engineering, vol. 191, p. 106433, Nov. 2019. [CrossRef]

- S. Thakur, N. V. Saxena, and P. S. Roy, “Generative AI in Ship Design,” arXiv (Cornell University), Aug. 2024. [CrossRef]

- N. J. Bagazinski and F. Ahmed, “Ship-D: Ship Hull Dataset for Design Optimization Using Machine Learning,” arXiv (Cornell University), Aug. 2023. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).