1. Introduction

Major countries worldwide are adopting various greenhouse gas (GHG) reduction policies as the awareness of climate change issues increases, including declarations of achieving carbon neutrality by 2050. Furthermore, as global supply chain instability intensifies alongside climate change, the Republic of Korea, a nation with limited natural resources, has proposed the ‘Promotion of Circular Economy’ as one of its strategies to achieve carbon neutrality by 2050 [

1].

The traditional linear economy, defined as “a sequence of processes from the acquisition of raw materials to manufacturing, use, and disposal,” neglects the concept of recycling, leading to resource depletion and environmental pollution [

2]. In contrast, the circular economy emphasizes the reuse, remanufacturing, and recycling of materials from waste generated during the production process and end-of-life products. Among these, remanufacturing is increasingly being recognized as a critical tool for advancing the circular economy and related industries [

3].

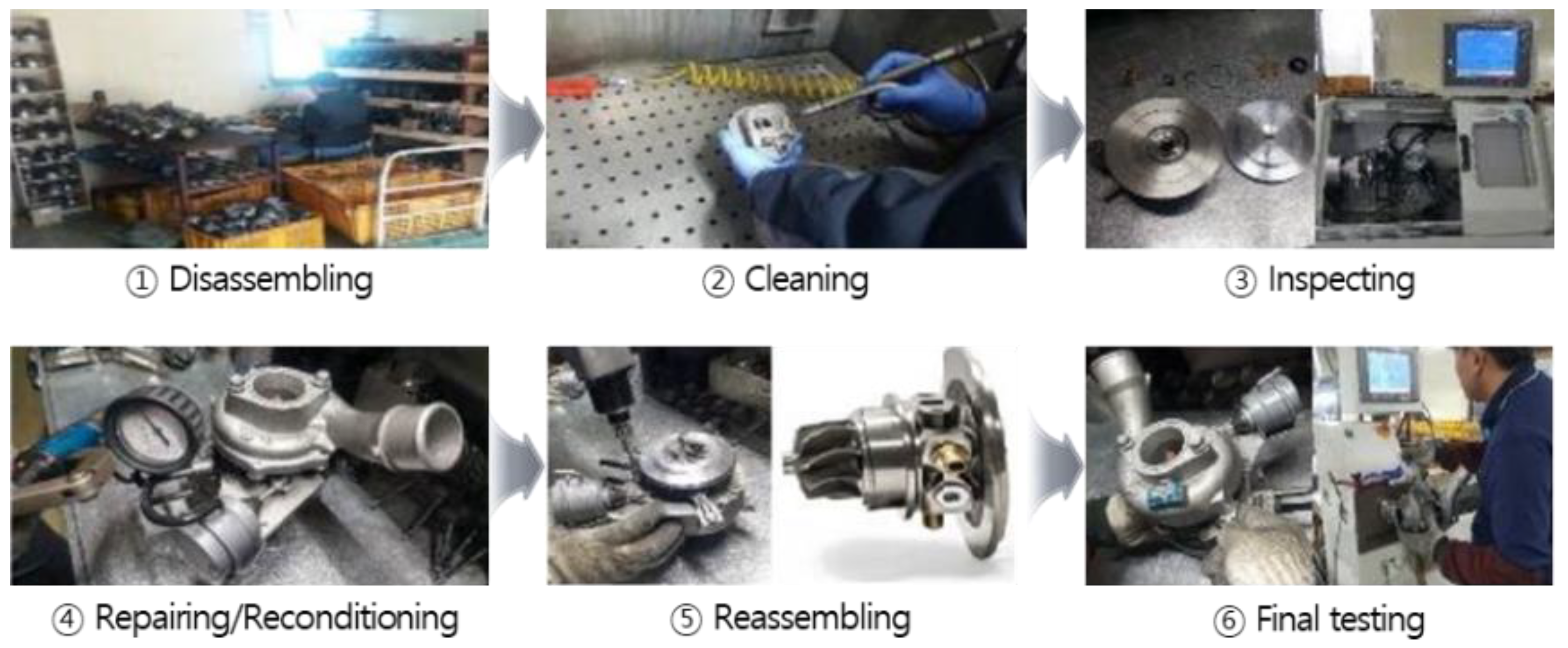

Remanufacturing involves disassembling, cleaning, inspecting, repairing, reconditioning, and reassembling used products to restore or enhance their original performance. These remanufactured products are then re-commercialized. In the resource circulation sector, remanufacturing has significant potential to reduce raw material usage and costs by minimizing the natural resources and energy required for production while demonstrating superior environmental and economic performance [

4].

In Korea, the 「Act on the Promotion of the Conversion into Environment-Friendly Industrial Structure」 introduces the circular economy concept, establishes certification for remanufactured product quality, and mandates labeling for these products [

5]. These measures aim to promote the market launch of remanufactured products across various sectors and invigorate the remanufacturing industry through consumer protection measures such as labeling and quality certification.

The remanufacturing sector in Korea includes automotive parts, toner cartridges, construction machinery components, and machine tools. As of 2017, the market size of the remanufacturing industry was approximately 1 trillion won(approximately 885 million USD), reflecting approximately 30% growth compared to 2010 [

6]. Among these, the automotive parts remanufacturing market is the most active, accounting for approximately 80% of the total remanufacturing market [

7].

According to automotive remanufacturing companies, turbochargers, primarily composed of cast iron, have been identified as the largest item in the automotive parts remanufacturing sector, accounting for approximately 20% of revenue. The steel industry, which produces and utilizes cast iron, contributes approximately 30% of GHG emissions in the industrial sector in the Republic of Korea [

8]. As a result, remanufacturing turbochargers is expected to reduce GHG emissions significantly due to savings in raw materials and energy compared to other automotive parts.

Gao et al. [

9] evaluated the environmental performance of turbocharger remanufacturing through a Life Cycle Assessment (LCA). They analyzed the processes from raw material production to manufacturing and assembly to compare the environmental benefits of remanufactured turbochargers with those of new ones. On the other hand, Gao et al. [

9] assumed that all components of the turbocharger were 100% remanufactured without considering the end-of-life stage. This assumption resulted in an inflated assessment of the environmental benefits and served as a significant variable in the LCA results, suggesting the need for a more realistic reflection.

Lee et al. [

10] rectified the limitations of Gao et al.‘s study by reflecting the actual remanufacturing ratio of core parts to analyze the GHG reduction effects of remanufactured products compared to brand-new products during a one-time remanufacturing cycle. Although turbochargers are one of the most actively traded automotive components and can go through multiple remanufacturing processes, Lee et al. [

10] didn’t consider the environmental benefits of such repeated remanufacturing cycles for turbochargers.

Therefore, this study examined the accumulated annual GHG emissions associated with multiple remanufacturing cycles (more than three times for turbochargers) and assessed the resulting GHG reduction effects based on this analysis.

2. Turbocharger Components and Remanufacturing Process

2.1. Turbocharger Components

A turbocharger is an auxiliary device that improves the engine output by compressing and supplying additional air to the cylinders. Heat resistance and durability are essential owing to the high thermal shock generated during this process. Therefore, turbochargers are made primarily of cast iron.

Figure 1 shows the six components of a turbocharger, including the intake housing, exhaust housing, bearing housing, turbine wheel, variable nozzle turbine (VNT), and actuator.

2.2. Turbocharger Remanufacturing Process

Figure 2 shows the turbocharger remanufacturing process. The remanufacturing procedure involves separating the collected used product (core parts) and cleaning, inspecting, and repairing them. Finally, the core parts are integrated with new components to assemble a complete turbocharger, which is then inspected.

3. Research Procedure

The LCA method was used to analyze the GHG reduction effects associated with multiple remanufacturing of turbochargers. LCA quantified the resources and energy used, as well as the pollutants emitted throughout the life cycle of the product. This allows an assessment of the environmental impact and exploring potential improvements [

11,

12].

Figure 3 presents the research procedure, including Goal Definition and Scope, Life Cycle Inventory Analysis, Life Cycle Impact Assessment, and Reduction Effect Analysis.

4. Research Method

4.1. Goal Definition and Scope

This study examined the accumulated annual GHG reduction effects resulting from multiple remanufacturing of turbochargers. The target is the 4A480 turbocharger model used in the Hyundai Grand Starex (or commercial vehicles such as iLoad and iMax) [

13,

14], and the functional unit is one turbocharger. The life cycle of turbochargers depends on the driving conditions, engine load, and maintenance practices [

15]. In particular, turbochargers may experience accelerated wear when operating in high-temperature and high-pressure environments for extended periods, making it difficult to generalize their life cycle [

16,

17]. Generally, the average life cycle of a turbocharger is at least 150,000 miles (approximately 240,000 km) [

18].

According to remanufacturers, turbocharger replacements typically occur approximately every three years due to the mileage and engine usage conditions in commercial vehicles. The life cycle of a vehicle is approximately 15 years. Approximately five turbochargers are used during this period, considering the replacement cycle of turbochargers. However, a turbocharger can be remanufactured up to three or more times.

Based on these circumstances, this study analyzes the GHG reduction effects of turbocharger remanufacturing up to three times.

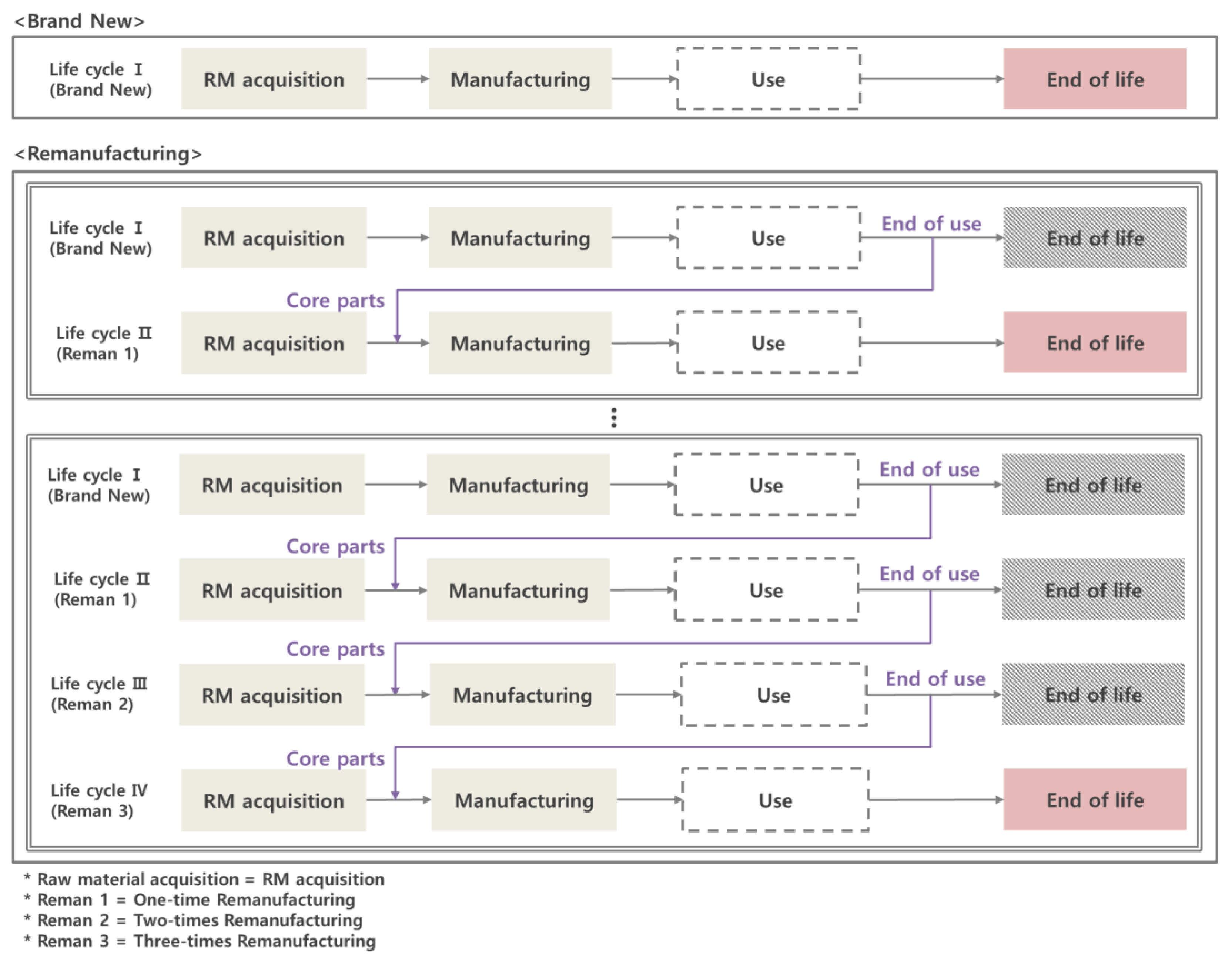

The system boundary encompasses a cradle-to-grave approach, covering all stages from raw material acquisition to end-of-use/life (

Figure 4). Using cut-off criteria, the study excluded the transportation stage from the system boundary because of its minimal contribution to GHG emissions, while the use stage was excluded because of the high variability of consumer usage patterns, making it difficult to generalize.

The life cycle of a brand-new product included the stage of raw material acquisition and manufacturing, and end-of-use/life. In contrast, the life cycle of remanufactured products included the life cycle of the previous product and the remanufacturing process itself, encompassing the same stage of raw material acquisition, manufacturing, and end-of-use/life as a brand-new product.

Remanufacturers collect used turbocharger(core parts) and disassemble them. They then clean, inspect, and repair the core parts. Consequently, in the case of remanufactured products, the raw material acquisition stage can be replaced with core parts, and components discarded from used products are disposed of within the remanufacturing life cycle. As a result, remanufacturing avoids the end-of-life of the previous life cycle and produces an extended process that includes multiple life cycles.

Hence, remanufacturing is a special stage that extends the life cycle of a product. For example, if a brand-new turbocharger ends after three years, a turbocharger that has undergone three remanufacturing cycles could last for up to twelve years. A significant advantage of remanufacturing is that it reduces the use of new resources because the core parts are used as the primary raw material, extending the product life.

4.2. Life Cycle Inventory Analysis

4.2.1. Raw Material Acquisition Stage

Table 1 lists the component materials and weight data used in manufacturing a brand-new turbocharger. The major materials include cast iron, silicone, aluminum alloy, stainless steel, and carbon steel. The intake housing, exhaust housing, and bearing housing of the CHRA consist of 95% cast iron and 5% silicone. The turbine wheel & other parts and VNT of the CHRA use 100% aluminum alloy, and the actuator is composed of 50% stainless steel and 50% carbon steel.

Table 2 lists the Input/Output data for multiple remanufacturing turbochargers. The data for the materials and weights of one-time remanufacturing (remanufacturing 1) are cited from Lee et al. [

10]. The Input/Output data of the two- and three-times remanufactured turbochargers (remanufacturing 2 and 3) are based on the internal data from specialized turbocharger remanufacturers.

For remanufacturing 1, the usage ratio of the core parts was approximately 64.08%, which decreased to 60.33% and 55.57% with remanufacturing 2 and 3, respectively. Hence, the damage rate of the core parts increases with repeated remanufacturing, reducing their use ratio compared to remanufacturing 1.

The decrease in the use of core parts was attributed primarily to turbocharger failures, often resulting from oil leaks. These leaks occur when engine oil escapes due to improper assembly between components, inadequate sealing, or aging. In addition, turbocharger failures are caused by defects within the turbocharger itself. For example, defects in the turbine wheel & other parts can cause damage to the inner walls of the intake and exhaust housing, and the exhaust housing combined with the VNT experiences shrinkage fitting caused by heat and cooling, making disassembly difficult over time to time. Consequently, some damaged components must be replaced with new ones.

4.2.2. Manufacturing and End-of-Use/Life Stage

In the manufacturing stage, this study used the electricity consumption data of brand-new turbocharger manufacturing and turbocharger remanufacturing from Gao et al. [

9] and Lee et al. [

10]. The electricity used to produce one turbocharger is 4.16 kWh for new products and 0.67 kWh for the remanufactured products.

In the end-of-use/life stage, this study referred to and processed the waste statistics data provided by KEITI [

21] and applied the recycling, incineration, and landfill rates for waste metal and waste synthetic rubber, as listed in

Table 3. This study classified cast iron, stainless steel, carbon steel, and aluminum as “Waste metal” and silicone as “Waste synthetic rubber,” and applied their respective recycling, incineration, and landfill rates. The ‘others’ category was excluded because it involves intermediate treatment rather than final disposal.

4.2.3. Life Cycle Inventory Database

The Life Cycle Inventory Database (LCI DB) aims to apply site-specific data. On the other hand, this study used the LCI DB provided by the Ministry of Trade, Industry, and Energy, the Ministry of Environment [

22], and Ecoinvent [

23] because of the difficulty in collecting on-site data.

Table 4 lists the LCI DB for the Raw and subsidiary materials.

5. Impact Assessment Results

5.1. GHG Emissions for a Brand New Turbocharger (Life Cycle I)

Table 5 lists the results of GHG emissions generated during the life cycle of a brand-new turbocharger (Life Cycle I). When a brand-new turbocharger reaches the end-of-life, it generates 19.6 gCO

2eq. In contrast, it produces 19.5 gCO

2eq. in GHG emissions when a brand-new turbocharger is remanufactured (end-of-use).

In the raw material acquisition stage, GHG contributions are significant in the order of the exhaust housing, turbine wheel & other parts, and VNT, while the actuator shows the lowest contribution. The exhaust housing accounts for approximately 42% of the total weight, resulting in high emissions. The turbine wheel & other parts and VNT constitute approximately 10% and 8% of the total weight, respectively. On the other hand, the emission factor for aluminum alloy production in these components is approximately two to four times higher than that of cast iron and silicone. Therefore, they contribute significantly to GHG emissions, second only to exhaust housing.

In the end-of-use/life stage, GHG contributions were significant in the order of the exhaust housing, bearing housing, and turbine wheel & other parts. In contrast, the actuator made the lowest contribution. The analysis suggests that, consistent with the above results, the weight proportion and the emission factor of aluminum alloy contribute significantly.

5.2. GHG Emissions for the Remanufactured Turbocharger (Life Cycle II-IV)

Table 6 lists the GHG emissions generated by multiple remanufacturing. When the remanufactured product reached the end-of-life, the GHG emissions generated for remanufacturing 1 (Life Cycle II), 2 (Life Cycle III), and 3 (Life Cycle IV) were 9.74 gCO

2eq., 10.6 gCO

2eq., and 11.5 gCO

2eq., respectively.

In contrast, when the remanufactured product was remanufactured again (end-of-use), the GHG emissions for remanufacturing 1 (Life Cycle II) and 2 (Life Cycle III) were 9.67 gCO2eq. and 10.5 gCO2eq., respectively.

The analysis showed that emissions increased by approximately 8% with each multiple remanufacturing (Life Cycle III-IV) compared to the one-time remanufacturing (Life Cycle II). This increase occurred because repeated remanufacturing led to a higher damage rate of the core parts because of durability issues, leading to a decrease in the remanufacturing rate.

5.3. GHG Emissions for Multiple Remanufactured Turbocharger

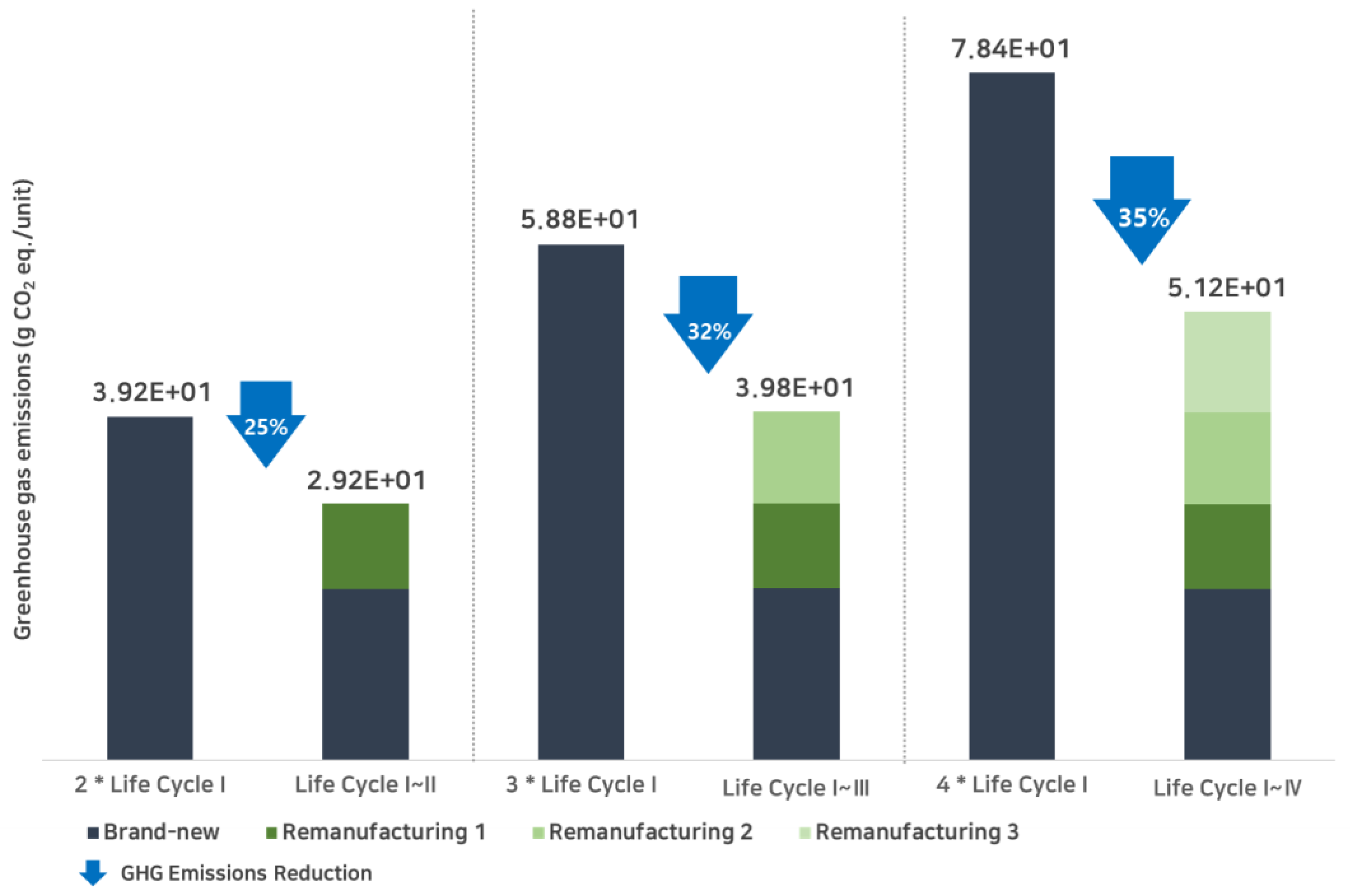

Figure 5 shows the GHG emissions resulting from multiple remanufactured turbochargers, based on the comparative analysis between brand-new and remanufactured products presented in the study by Lee et al.

The GHG emissions generated for Life Cycle I were 19.6 gCO2eq., 39.2 gCO2eq., and 58.8 gCO2eq., while Life CycleⅡ, Ⅲ, and Ⅳ were 9.7 gCO2eq., 20.2 gCO2eq., and 31.7 gCO2eq., respectively. Compared to Life Cycle I, these emission reductions indicate approximately 50%, 48%, and 46%, respectively.

However, as remanufacturing is repeated, the durability of core parts decreases, leading to higher damage rates and reduced usage. Consequently, the demand for new parts rises, diminishing the GHG reduction effect.

As in Lee et al.‘s study, comparing brand-new and remanufactured products does not fully capture the key advantage of remanufacturing.

This advantage lies in its ability to extend the product life cycle by using core parts as primary raw materials and reducing the consumption of new resources.

Therefore, it is important to consider the environmental impact of remanufacturing within an expanded process where brand-new products are included in the entire life cycle. Since core parts from used products are sourced from new products, evaluating the environmental impact of remanufacturing requirements includes brand-new products in the life cycle assessment. This approach helps in accurately determining the accumulated GHG emissions.

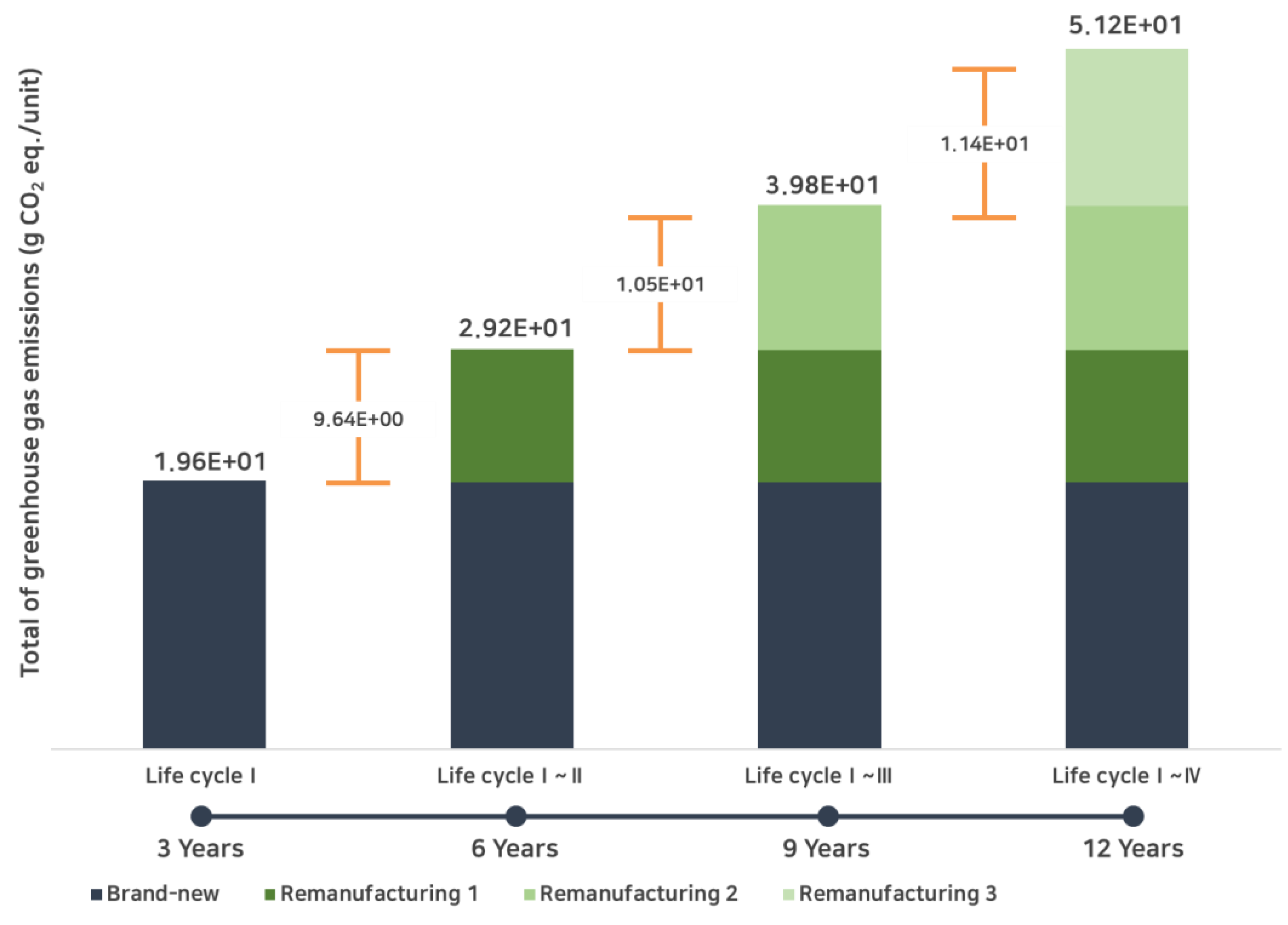

5.4. Accumulated GHG Emissions for Multiple Remanufactured Turbocharger

Figure 6 shows the accumulated GHG emissions from multiple remanufacturing of turbochargers. The life of a brand-new turbocharger (Life cycleⅠ) was three years; the life of a turbocharger involving multiple remanufacturing was extended to six, nine, and 12 years for Life Cycles II, III, and IV, respectively. The accumulated GHG emissions for Life Cycles I, II, III, and IV were 19.6 gCO

2eq., 29.2 gCO

2eq., 39.8 gCO

2eq., and 51.2 gCO

2eq., respectively.

As the turbocharger underwent repeated remanufacturing, accumulated GHG emissions increased. GHG emissions are by approximately 9.64 gCO2eq., 10.5 gCO2eq., and 11.4 gCO2eq.. This increase occurred because repeated remanufacturing increases the damage rate of inner parts because of durability issues, leading to a decrease in the use of core parts. As a result, the increased use of new components during multiple remanufacturing cycles also increased GHG emissions.

GHG emissions increased as the remanufacturing process was repeated. Simultaneously, the remanufacturing process extended the life of a product to a maximum of 12 years. Multiple remanufacturing processes use the core parts as primary raw materials, reducing the need for new raw materials. Therefore, when a turbocharger is in use or replaced, selecting a remanufacturing product allows up to 12 years of use for a single turbocharger.

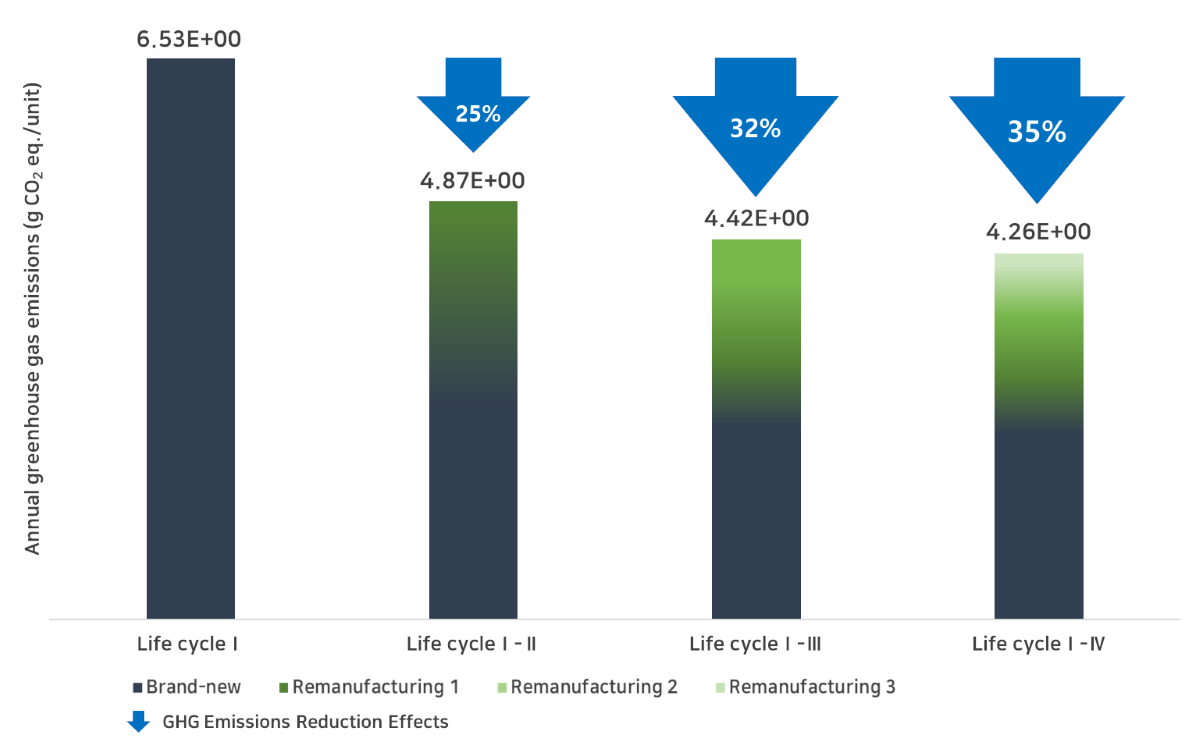

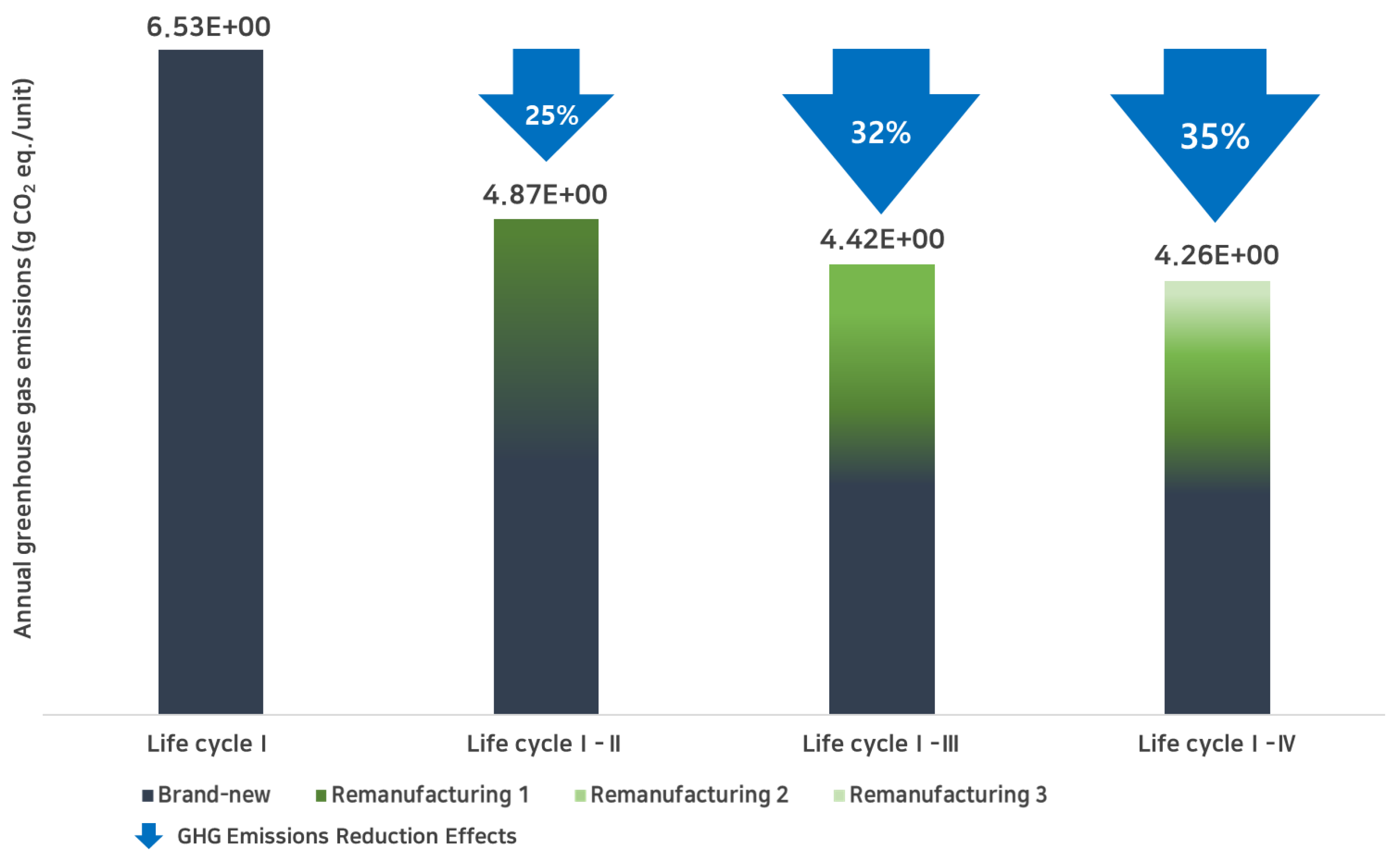

5.5. Accumulated Annual GHG Emissions for Multiple Remanufactured Turbocharger

The difference in life resulting from the number of remanufacturing cycles makes it challenging to compare and analyze the environmental impacts of products when based solely on accumulated GHG emissions. For example, a brand-new turbocharger has a life of three years, while a turbocharger that has been remanufactured three times can attain a life of up to 12 years. Therefore, evaluating these products based solely on accumulated GHG emissions, without considering their differing life, is inappropriate, overlooking the substantial environmental benefits of remanufacturing. Accordingly, this study calculated the accumulated annual GHG emissions decrease. Accumulated annual GHG emissions from all scenarios of the turbocharger life cycle to compare the emissions generated by each product over the same period, as shown in

Figure 7.

As a result, GHG emissions decrease progressively with repeated remanufacturing. The accumulated annual GHG emissions for Life Cycles I, II, III, and IV were 6.53 gCO2eq, 4.87 gCO2eq, 4.42 gCO2eq, and 4.26 gCO2eq, respectively. Compared to Life Cycle I, these accumulated annual emission reductions indicate approximately 25%, 32%, and 35%, respectively.

These results suggest that multiple remanufactured products effectively reduce GHG emissions compared to brand-new products. In particular, the product life is extended as remanufacturing occurs repeatedly, and accumulated annual GHG emissions decrease. Hence, multiple remanufacturing processes contribute to reducing GHGs and conserving resources. The result contributes significantly to sustainability.

6. Conclusion

This study analyzed the accumulated annual GHG emissions reduction effects associated with multiple remanufactured turbochargers. The findings of the study are as follows.

① The GHG emissions for multiple remanufactured turbochargers are as follows:

a) As in Lee et al.‘s study, comparing brand-new and remanufactured products shows that multiple remanufacturing of turbochargers leads to a diminishing GHG reduction effect.

b) However, such comparisons didn’t consider a key advantage of remanufacturing, which is the reuse of core parts to reduce the need for new resources and extend the product life cycle.

c) Therefore, to accurately assess the environmental impact of remanufacturing, it is necessary to include the life cycle of brand-new products. Since core parts in remanufactured products originate from brand-new ones, they should be included within the system boundary. This approach allows for a more precise calculation of accumulated GHG emissions.

② The accumulated GHG emissions from multiple remanufactured turbochargers are as follows:

a) Accumulated GHG emissions for Life Cycles I, II, III, and IV were 19.6 gCO2eq, 29.2 gCO2eq, 39.8 gCO2eq, and 51.2 gCO2eq, respectively.

b) Although GHG emissions increased with repeated remanufacturing, the product lifespan was extended up to 12 years. The lifespans of Life Cycles I (brand-new product), II, III, and IV were three, six, nine, and 12 years, respectively.

c) The differences in life cycle of turbochargers resulting from the number of remanufacturing makes it challenging to compare and analyze the environmental impacts of products based solely on accumulated GHG emissions. Therefore, this study also evaluated the annual GHG emissions to provide a more comprehensive understanding.

③ The accumulated annual GHG emissions resulting from multiple remanufacturing of turbochargers are as follows:

a) The accumulated annual GHG emissions for Life Cycle I, II, III, and IV were 6.53 gCO2eq, 4.87 gCO2eq, 4.42 gCO2eq, and 4.26 gCO2eq, respectively.

b) These results indicate reduction effects of approximately 25%, 32%, and 35% for Life Cycles II, III, and IV, respectively, compared to Life Cycle I, confirming that repeated remanufacturing contributes to lower GHG emissions.

c) Hence, multiple remanufactured products effectively reduced GHG emissions compared to brand-new products. In particular, the product life increases as remanufacturing occurs repeatedly, and annual GHG emissions decrease.

d) These results suggest that multiple remanufacturing processes can significantly enhance the circular economy and promote sustainability. Multiple remanufacturing helps reduce resource consumption and conserve resources by minimizing resource consumption and enhancing economic efficiency by extending the product life.

The LCA method was used to analyze the accumulated annual GHG emissions and the corresponding reduction effects associated with multiple remanufacturing processes applied to turbochargers. The findings provide a practical perspective on the remanufacturing industry, showing that enhancing the remanufacturing rate of products with high steel content, such as turbochargers, can be an effective strategy for reducing GHG emissions in the steel sector.

On the other hand, the proportion of parts that are completely discarded or replaced with new parts may increase when the damage rate of specific components is high during the remanufacturing processes or when remanufacturing occurs repeatedly. Improving restoration technologies are essential for minimizing the rate of new replacements and maximizing the GHG reduction effects of remanufacturing. Technologies currently used in remanufacturing, such as laser cladding [

24] and 3D printing [

25], exemplify the advanced technologies required for this purpose.

The importance of the remanufacturing industry in the pursuit of carbon neutrality and a circular economy is attracting increasing attention. Hence, the results of this study can serve as a valuable model for understanding GHG emission reduction effects of multiple remanufacturing across various industrial sectors, providing practical resources for environmental improvement strategies.

Author Contributions

Conceptualization, D.Y.K.; methodology, D.Y.K. and J.H.L.; software, D.Y.K.; validation, J.H.L. and H.Y.K.; formal analysis, D.Y.K.; investigation, J.H.L.; resources, D.Y.K.; data curation, H.Y.K.; writing—original draft preparation, D.Y.K.; writing—review and editing, D.Y.K., J.H.L. and H.Y.K.; visualization, D.Y.K.; supervision, H.Y.K. and Y.W.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning(KETEP) grant funded by the Korean government(MOTIE) (No. 20214000000520, Human Resource Development Project in Circular Remanufacturing Industry)

Data Availability Statement

The original contributions presented in the study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ministry of Environment, 「2050 Carbon neutrality」 Promotion strategy, Korea, 2020; pp. 1-12.

- Kim, J. S. , Jun, Y. S., Jun, J. H., et al. Transition from Linear Economy to Circular Economy, Resources Recycling, JKIRR, 2021; 30(3), pp. 3-17.

- Lacy, P. , Long J., Spindler W. The Circular Economy Handbook, England. 2020. [Google Scholar]

- Kang H., Y. , Chung N. H., Hwang Y. W., Remanufacturing engineering, Yejark, Korea. 2022. [Google Scholar]

- Kang H., Y. , Kim Y. C., Lee I. S. Current Status and Promotional Measures of Domestic and Overseas Remanufacturing Industry, KIRR, 2012; Volume 4, pp. 3-5.

- Korea Ministry of Government Legislation, Korea Law Information Center, 「ACT ON THE PROMOTION OF THE CONVERSION INTO ENVIRONMENT-FRIENDLY INDUSTRIAL STRUCTURE」.

- Kim, Y. C, Korea Institute of Energy Technology Evaluation and Planning, https://www.ketep.re.kr/contents/siteMain.do, Remanufacturing technology and market strategy for net zero by 2050, April 9, 2024. 2050. [Google Scholar]

- Korea Institute of Energy Research, Climate Technology Strategy Office, “Decarbonizing the Steel Industry”, Korea. 2021.

- Wang Gao, Tao Li, Zijue Tang, et al. Investigation on the Comparative Life Cycle Assessment between Newly Manufacturing and Remanufacturing Turbochargers, CIRP, 2017; Volume 61, pp. 750-755.

- Lee, J. H. , Kang H. Y., Kim Y. W., et al. Analysis of the life cycle environmental impact reductions of remanufactured turbochargers, IJREM, 2023; Volume 13, pp. 187-206.

- International Organization for Standardization, ISO 14040, in Environmental management-Life cycle assessment - Principles and framework. 2011.

- International Standard confirmed, ISO 14044, Environmental management-Life cycle assessment-Requirements and guidelines. 2006.

- TurboTotal GmbH, Hyundai Starex CRDI Turbocharger 28200-4A480, https://www.turbo-total.com/en/hyundai-starex-crdi-turbocharger-28200-4a480-1623.

- GCG Turbochargers Australia Pty Ltd., Turbo Charger BV43 Hyundai iLoad/iMax 120kw D4CB 2008-2012 28200-4A480 Exchange, https://gcg.com.au/borg-warner-turbo-charger-bv43-hyundai-iload-2.5ltr-28200-4a480—08-2012-bw53039880145tex.html.

- Schweizer, B. Total instability of turbocharger rotors—physical explanation of the dynamic failure of rotors with full-floating ring bearings, J. Sound Vib., 2009; Volume 328, pp. 156–190.

- Vasudev, H. , Thakur, L., & Bansal, A. High Temperature Oxidation and Wear Resistant Bi-Layer Coating for Turbocharger Housing. IntechOpen. 2017. [Google Scholar] [CrossRef]

- Tammineni, N. M. , & Mutra, R. R. A review on recent advancements in an automotive turbocharger rotor system supported on the ball bearings, oil film, and oil-free bearings. J. Braz. Soc. Mech. Sci. Eng., 2023 Volume 9, 481.

- Tanaka, M. , Hori, Y. Stability Characteristics of floating bush bearings, J. Lubr. Technol., 1972; Volume 94, pp. 248–256.

- Korea Environmental Industry and Technology Institute, Environmental Product Declaration, https://ecosq.or.kr/websquare.do#w2xPath=/cm/main/index.xml, April 7, 2024.

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 1995: The Science of Climate Change. Cambridge University Press. 1996.

- Ministry of Environment, National waste generation and disposal status, https://www.recycling-info.or.kr/rrs/main.do, April 7, 2024.

- Ministry of Environment, National waste generation and disposal status, https://ecosq.or.kr/websquare.do#w2xPath=/ui/cer/ic/oh/ICOH110M01.xml&valVl=tabs1&menuSn=20018000, April 9, 2024.

- Ecoinvent, https://ecoquery.ecoinvent.org/3.10/cutoff/search, April 9, 2024.

- Ma, W. , Hu, T., Zhang C., Chen Q. Adaptive remanufacturing for freeform surface parts based on linear laser scanner and robotic laser cladding, 2025; Volume 91, 102855.

- Kim C., K. , Cho D. W., Kim S., et al., High-Throughput Metal 3D Printing Pen Enabled by a Continuous Molten Droplet Transfer, Adv Sci, 2023; Volume 6, pp. 1-11.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).