1. Introduction

The sustainable use of natural resources and waste recycling from economic activities are two primary environmental goals. The directive [

1] establishes the fundamental concepts and definitions underpinning waste management practices throughout the European Union. It emphasises the principles of recycling and recovery, laying the foundation for effective waste processing in member states. The regulation [

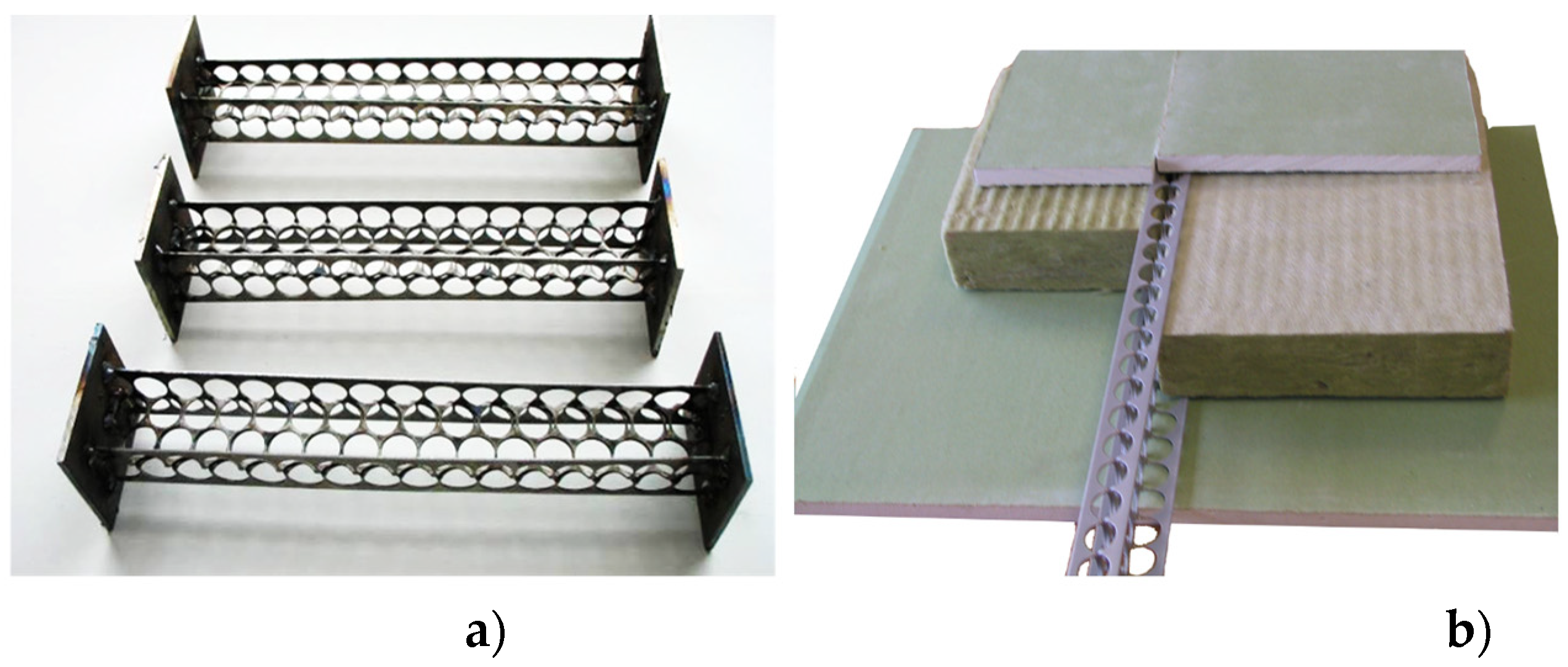

2] outlines the criteria determining when specific scrap metals are no longer classified as waste. This is crucial for facilitating recycling operations and clarifying the legal status of recycled materials under the Waste Framework Directive. Studies show that global raw material consumption reached 90 billion tonnes in 2017 and may quadruple by 2050 [

3]. Simultaneously, a significant portion of solid inorganic waste comprises various metallic materials. Much waste from punched steel is in tape form rather than sheets. In mechanical engineering, this material is generated during the stamping of components (

Figure 1).

Technologies for the recycling and repurposing of metallic materials are advancing; however, studies conducted by the European Commission indicate that the rise in material recovery is negligible relative to the escalating demand for metallic resources. Consequently, there is a pressing necessity for heightened public awareness and the innovation of new solutions for the reutilization of metallic materials.

The building industry is expanding swiftly due to the rising demand for materials. The construction sector has been identified as a priority area for this transition, not only because it is fundamental to the economic system, providing approximately 9% of the EU's GDP, but also because it is a significant source of employment [

4]. The construction sector can thus catalyse the more efficient utilisation of raw materials and the resolution of metal and other waste recycling issues. The primary strategies for enhancing the efficiency of metal raw material utilisation include advancing recycling technologies, optimising manufacturing structures during the design phase, and re-utilising scrap, of which up to 90% can be reintegrated into the life cycle.

Circular Economy (CE) and the 3Rs strategy (Reduce, Reuse, and Recycle) have gained significant traction recently, particularly in the manufacturing and construction industries. This approach addresses the growing global waste generation problem, projected to increase from 2.02 billion tons in 2016 to 3.4 billion tons by 2050 [

5]. In the steel sector, there's a growing emphasis on reusing and recycling byproducts to achieve the ambitious "zero waste" goal [

6]. This trend is particularly relevant given the large quantities of metal scraps, including iron and steel, generated from manufacturing machining processes [

7]. Innovative approaches to steel waste recycling are also being explored. For instance, the use of punched metal straps as replacements for main steel rebars in regular concrete beams has been investigated, demonstrating the viability and advantages of this alternative [

8]. Furthermore, research is being conducted on sustainable lifecycle management of perforated metal materials, proposing new technologies for recycling or reuse [

9]. This reflects a broader trend towards finding creative and sustainable applications for various forms of steel waste. The research groups are investigating composite materials comprising a reinforcing structure as fibres embedded in different polymers as a matrix. Fiber-reinforced polymers (FRPs) have emerged as a promising alternative to traditional steel reinforcement in various construction applications. FRP bars as compression reinforcement in columns have gained significant attention. A critical review [

10] highlights the potential of FRP-reinforced columns and suggests that code authorities should recognise FRP used in compression members. This recommendation is based on an analysis of existing research and the accuracy of various design approaches in predicting FRP-reinforced column behaviour. FRP composites have demonstrated versatility in strengthening, repairing, and retrofitting multiple structures. [

11] provides an overview of FRP composites as strengthening materials in the construction industry, focusing on engineering aspects and design characteristics. The review concludes that FRP techniques will likely remain preferred for numerous projects involving bridges, buildings, and historical monuments. The application of FRP composites extends to both new and existing concrete structures. [

12] discusses the use of FRP composites as reinforcement in concrete structures, noting their effectiveness in increasing the flexural capacity of reinforced concrete column-beam joints. Experimental studies have further validated the benefits of FRP in structural applications. [

13] investigated the behaviour of FRP-steel-confined concrete columns under reversed cyclic lateral loads. The research demonstrated that increasing the number of FRP layers improved various structural behaviours, including yield load and displacement, peak load and displacement, ultimate load and displacement, and ductility coefficient. The applications of FRP composites extend beyond reinforcement and strengthening. [

14] focuses on the structural applications of FRP composites as major load-carrying members in aggressive environments, demonstrating their versatility and durability in challenging conditions.

While FRP offers numerous advantages, steel remains widely used in industrial applications due to its excellent mechanical properties. However, steel's poor corrosion resistance in chloride-containing environments is a significant drawback. [

15] explores the use of epoxy-based polymer coatings as an effective anti-corrosive solution for steel, highlighting their unique mechanical properties, superior adhesion, good thermal stability, and excellent corrosion and chemical resistance. The use of fibre-reinforced polymer (FRP) composites and steel-polymer sandwich structures in civil engineering applications has gained significant attention due to their unique properties and potential advantages over traditional materials. This review synthesises recent research on these advanced materials, focusing on their structural applications, corrosion resistance, and mechanical properties. FRP composites have shown promise in various structural applications, particularly column members. [

16] provides a comprehensive review of FRP materials used in column applications for new and existing construction, identifying knowledge gaps and areas for further research. This work highlights the growing interest in FRP as an alternative to traditional construction materials. One of the key advantages of FRP composites is their corrosion resistance. [

17] investigates the structural behaviour and corrosion resistance of hybrid FRP-wrapped steel bars for reinforced concrete structures. The study demonstrates that FRP-wrapped steel reinforcing bars exhibit high corrosion resistance, potentially addressing a significant challenge in conventional steel-reinforced structures.

The importance of corrosion protection for steel elements, particularly in façade systems, is emphasised in [

18]. This review likely explores various methods and technologies for protecting steel elements from corrosion in building envelopes.

Steel-polymer sandwich composites represent another area of interest in advanced construction materials. [

19] examines the effects of interfacial adhesion on the tensile strength of these composites. By systematically varying the interfacial adhesion, the study evaluates its impact on mechanical properties, providing insights into optimising these composite structures. The formability of steel-polymer sandwich composites is explored in [

20], which introduces a new forming limit diagram that considers both delamination and fracture. This research investigates the effect of interfacial adhesion on the formability of sandwich composites, contributing to a better understanding of their manufacturing processes and structural integrity. The work [

21] addresses the damping performance of lightweight steel/polymer/steel sandwich composites, focusing on the interface between heterogeneous materials. This study highlights the importance of considering interfacial properties in assessing the dynamic behaviour of these composite structures.

The punched steel waste can be utilised to produce various profiles subjected to compression and bending forces. These profiles may be employed as structural components for walls and panels (

Figure 2.). Punched steel tape can be used for fasteners, providing mechanical connections in composite timber-concrete structural members [

22].

The issue of stress concentration coefficients should be considered separately in each case where punched steel waste is used as load-carrying components of structural members. Correct determination of the stress concentration coefficient influences structural member dimensioning and total structural material consumption. Correspondingly, the structural efficiency of load-carrying members based on punched metal materials (PMM) depends on total structural material consumption and the stress concentration coefficient. Therefore, the current investigation aims to increase the structural efficiency of PMM, which are waste materials obtained during the stamping process in mechanical engineering. The possibility of decreasing the stress concentration coefficient should be investigated. The results should be verified through laboratory experiments and finite element (FE) models.

2. Materials and Methods

2.1. Laboratory Specimens for Determining the Coefficient of Stress Concentration

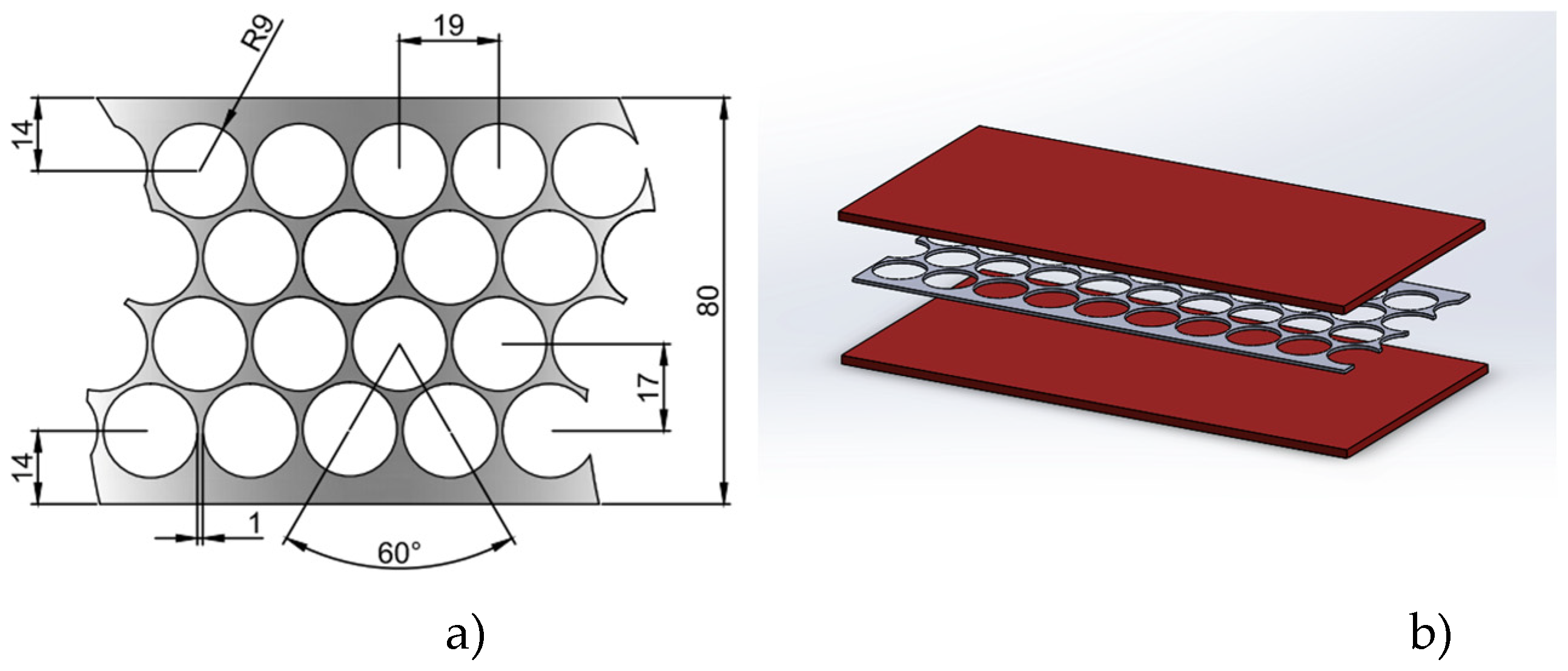

A composite load-carrying element based on PMM waste is considered the object of investigation for determining the stress concentration coefficient. Due to design load actions, the composite load-carrying element was developed to withstand tension forces acting in different structures. For example, it can be used as a tie-bar in timber and composite arches and as a bracing member. The composite load-bearing element is based on a punched steel tape of grade LPM-4, produced by JSC "Ditton Driving Chain Factory" (Daugavpils, Latvia). The punched steel tape is embedded in a polymer matrix. The geometric parameters of the tape and a total view of the composite load-carrying structural element are shown in

Figure 3.

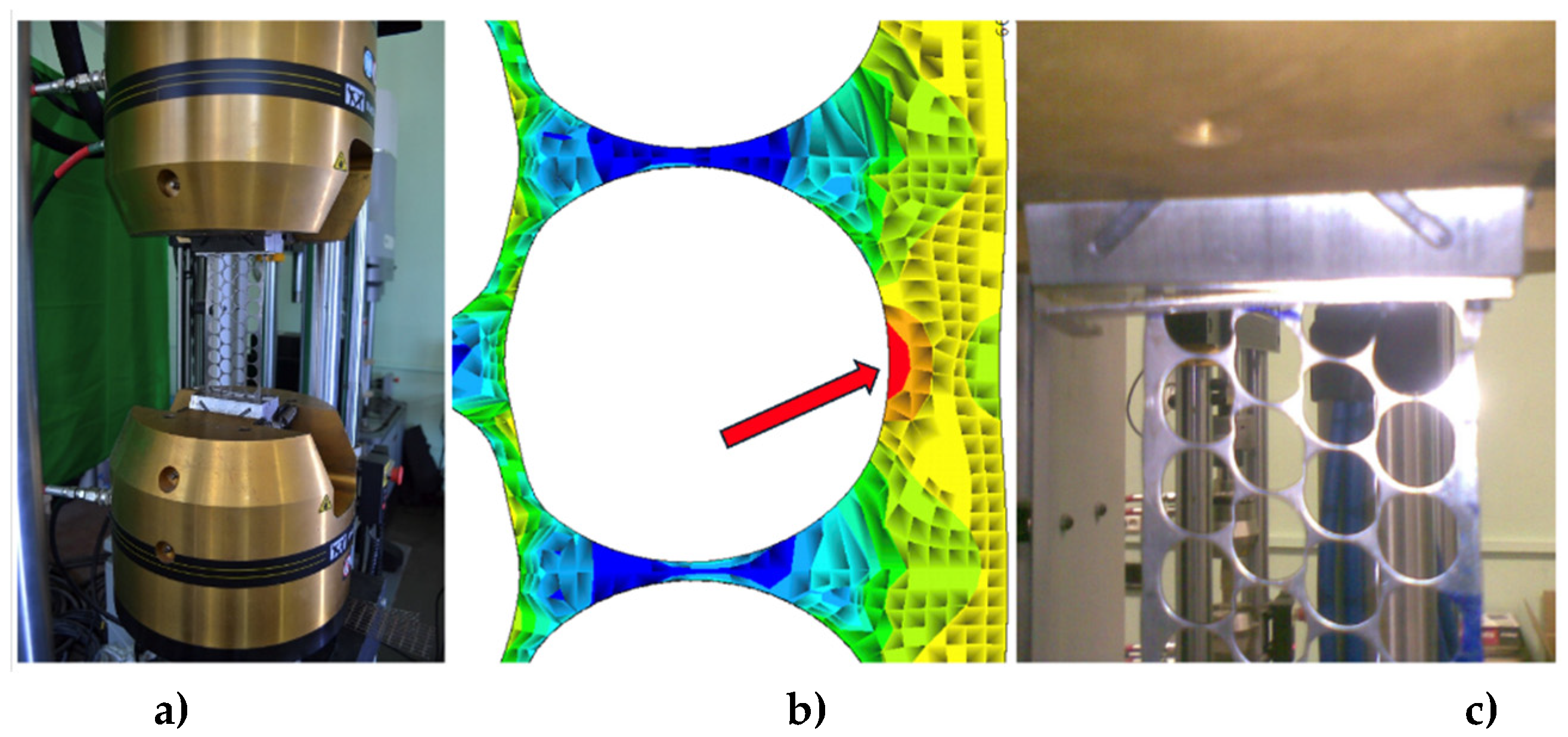

Mechanical properties of the punched steel tape of grade LPM-4 were determined by laboratory experiments. Specimens with dimensions 300 x 80 x 1.5 mm were loaded until collapse using the testing device INSTRON 8802 (

Figure 4a)

The zone of maximum normal stress concentration and the failure mode of the punched steel tape specimen are shown in Figures 4 b) and c). The normal stress distribution in the punched steel tape specimen was determined by the FE model described in sub-chapter 4.1. The maximum load-carrying capacity of the specimens and their strain in tension were 5.54 kN and 3.93%, respectively. The average values of the maximum tensile stress and modulus of elasticity were 220.65 MPa and 130.05 GPa, respectively. Technical thermoplastic polypropylene Polystone® P grey homopolymer, produced by the German company Rochling, was considered the matrix material. Its density, modulus of elasticity, and tensile strength are 0.91 g/cm³, 1.3 GPa, and 32 MPa, respectively. The laboratory specimens were prepared using a hot press (

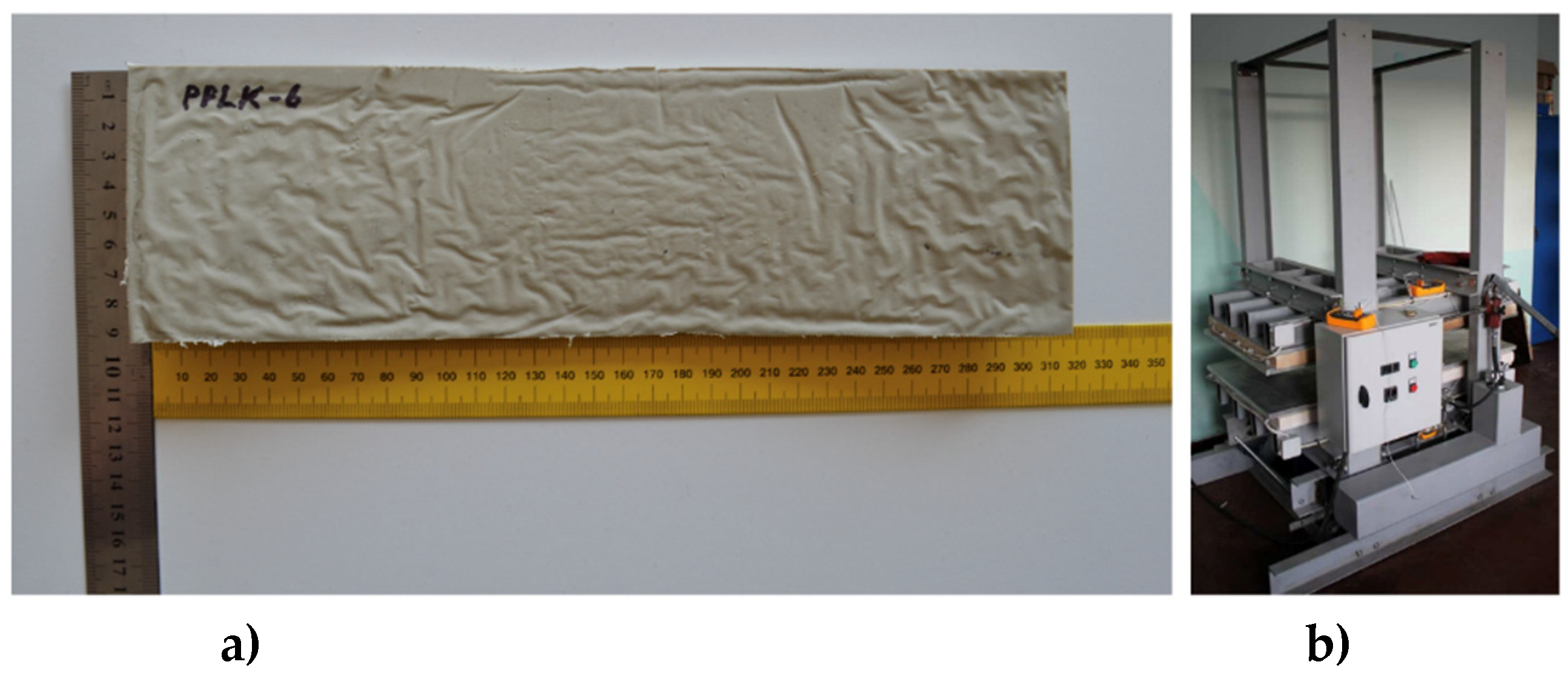

Figure 5). The press is designed for products with a maximum of 1200 x 600 x 600 mm dimensions. The maximum permissible temperature of the slabs for the contact surface is +350°C. The dimensions of the prepared laboratory specimens were 310 x 90 x 6.30 mm.

Polypropylene samples were prepared with dimensions of 310 x 90 x 3 mm. The sheet size was chosen to exceed the dimensions of the punched steel tape LPM-4 samples, ensuring that the LPM-4 samples were fused with the polymer around the entire perimeter. The polypropylene sheet was 5 mm wider than the punched steel tape LPM-4 sheet on each of the four sides. Polypropylene and punched steel tape LPM-4 samples were assembled before compression to form a multi-layer sandwich according to the principle "polypropylene - punched steel tape - polypropylene". The sandwich was wrapped in heat-resistant food paper to limit polypropylene leakage and protect the hot press plates. As the melting point of polypropylene ranges from 162 to 167°C, the press was set to heat up to 210°C, ensuring that the press plates' surface reaches 180°C. This is sufficient to melt the polypropylene. A test pressing was carried out to select the correct melt-pressing mode, during which the required plate pressure and specimen ageing time were determined. It was thus determined that for the compression of the specimens and the interlocking of the polypropylene sheets on all sides, the following regime should be ensured:

• Compress the sample to a load of 9.5 kN (5 bar) and hold until the pressure begins to drop due to melting of the polypropylene;

• Increase the load to 9.5 kN and expect it to decrease again;

• Increase the load to 19 kN (10 bar) on the third pass and hold the sample until the total compression time reaches 2 minutes;

• Unload and remove the sample from the press;

• The press plates shall be interconnected before a new specimen is pressed, and the temperature shall be returned to a predetermined level.

Six composite laboratory specimens (

Figure 5a) were prepared. The composite specimens were designated PPLK-1 to PPLK-6. Five composite specimens (PPLK-1, PPLK-3 – PPLK-6) were used in the experiment to investigate the coefficient of stress concentration. The sixth one (PPLK-2) was used to test the hot press parameters described above during specimen preparation.

2.2. Laboratory Experiment

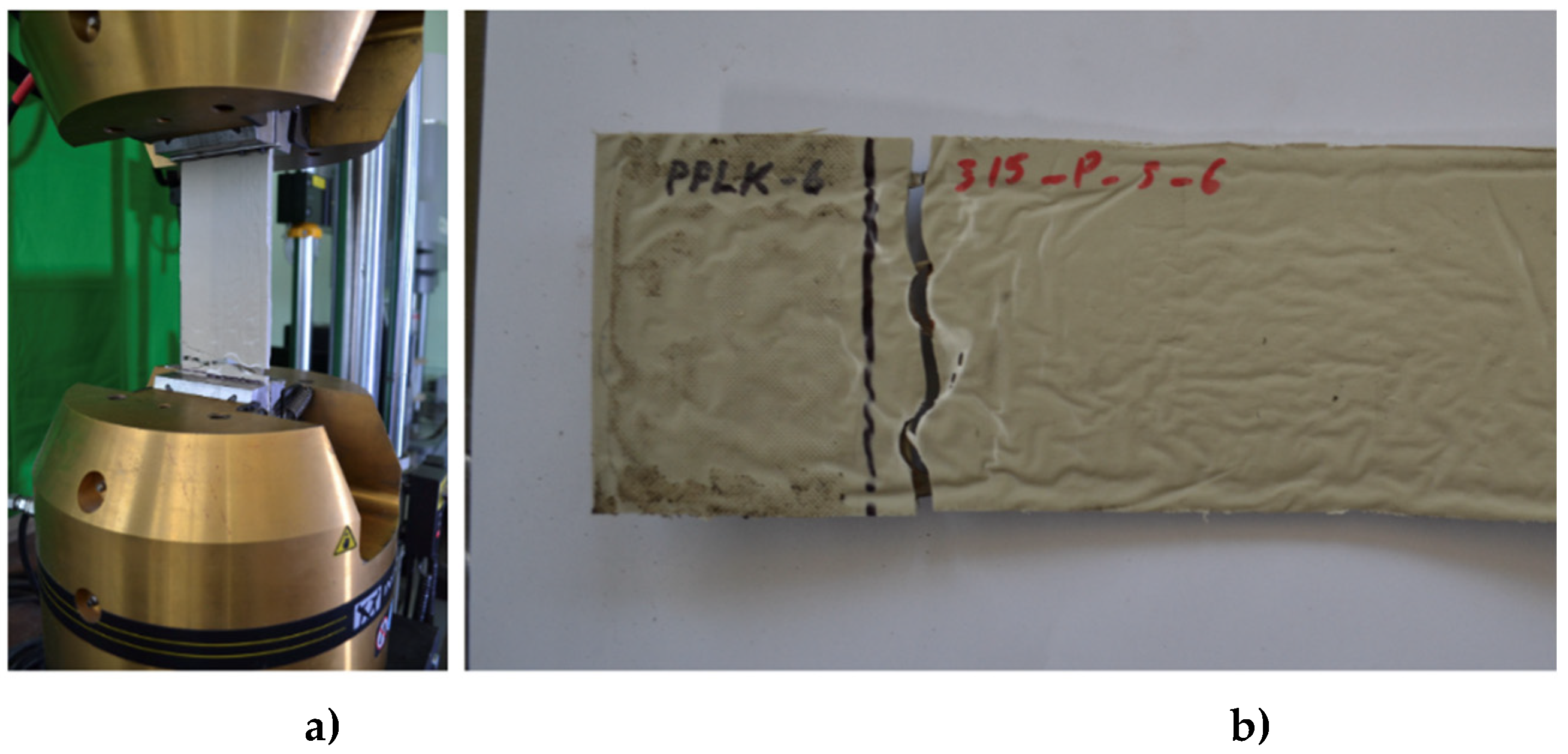

The laboratory experiment was conducted using the testing device INSTRON 8802 (

Figure 6a). The composite specimens' fixation length in the testing device was 60 mm on each side. The composite specimens' working zone length was 180 mm (

Figure 6a). The loading velocity of the composite specimens was 5 mm/min.

All five composite specimens (PPLK-1, PPLK-3 – PPLK-6) were loaded with a breaking force until failure. The shape of specimen PPLK-6 after its failure is shown in

Figure 6b). The same mode of failure was observed for all five specimens. Zones of specimen failure were observed quite close to the fixation zones in the testing device but always within the working zone of the specimens. It was noted that the polymer matrix and punched steel tape component broke simultaneously.

2.3. Analysis of Laboratory Samples

The analysis of the laboratory specimens was joined with determining their load-carrying capacity and modulus of elasticity.

The load-carrying capacity of the laboratory specimens PPLK was determined based on the principle of proportional summation. This means that the load-carrying capacity of the laboratory specimens was determined as the sum of the polypropylene and steel load-carrying capacities, as shown in equation (1):

Where:

Ft, max,pplk - load-carrying capacity of laboratorian specimens, kN; Ft, max, pp - load-carrying capacity of polypropylene component, kN; Ft, max, pl - load-carrying capacity of punched steel tape component, kN.

The maximum load-carrying capacity of the laboratory specimen was equal to 19.19 kN. The maximum load-carrying capacities of the polypropylene and punched steel tape components were equal to 6.83 kN and 5.53 kN, respectively.

As the composite (PPLK) is composed of transversely isotropic materials, the final product was assumed to be transversely isotropic. In the case of a transversely isotropic material, the elastic modulus was determined using Equations (2) and (3).

Where:

E1 – approximate value of the modulus of elasticity of the laboratorian specimen, taking into account the different materials percentages (volume fractions), GPa, Epplk - modulus of elasticity of the laboratorian specimen, taking into account the approximate modulus of elasticity and Poisson's ratios of each of the constituent materials of the composite, GPa,

Epl – modulus of elasticity of punched steel tape, GPa, Epp - modulus of elasticity of polypropylene tape, GPa, Ψ - volume fraction of the punched steel tape in the cross-section of the laboratory specimen, ϑpp – Poisson's ratio for polypropylene, ϑpl – Poisson's ratio for punched steel tape.

The value of the volume fraction of punched steel tape in the cross-section of the laboratory specimen was equal to 0.046. The Poisson's polypropylene and punched steel tape ratios were taken as 0.41 and 0.60, respectively. The approximate value of the modulus of elasticity of the laboratory specimen was equal to 7.50 GPa. The modulus of elasticity of the laboratory specimen, considering the approximate modulus of elasticity and Poisson's ratios of each constituent material of the composite, was equal to 1.57 GPa. The coefficient of stress concentration was determined as the relation of the maximum normal stresses to the nominal value of the normal stresses, equal to the relation of the axial force acting on the member to the effective area of the member's cross-section, determined by considering the perforation.

3. Results and Discussions

The experiment found that in the polypropylene layer before the PPLK collapse, microcracks are formed, which replicate the contour lines of the perforation slits in the tape. However, the material does not collapse and continues to deform. This resulted in a simultaneous loss of structural capacity, where the LPM-4 and polypropylene components lost their load-carrying capacity at the same moment the LPM-4 tapes collapsed. It should be noted that this failure mode was typical and observed for all PPLK laboratory specimens. For example,

Figure 6b) shows the failure mode for PPLK-6.

In some places, the adhesion between the metallic and polymeric components was not sufficiently good, resulting in delamination between the components. The delamination occurred due to poor adhesion, which was also anticipated. The interlocking of the structure was ensured by the penetration of the polypropylene into the perforation slots and mutual adhesion. Adding chemically active agents could probably solve the problem of adhesion improvement. On the other hand, the perforation slots were filled with a polymer tightly bound to each other.

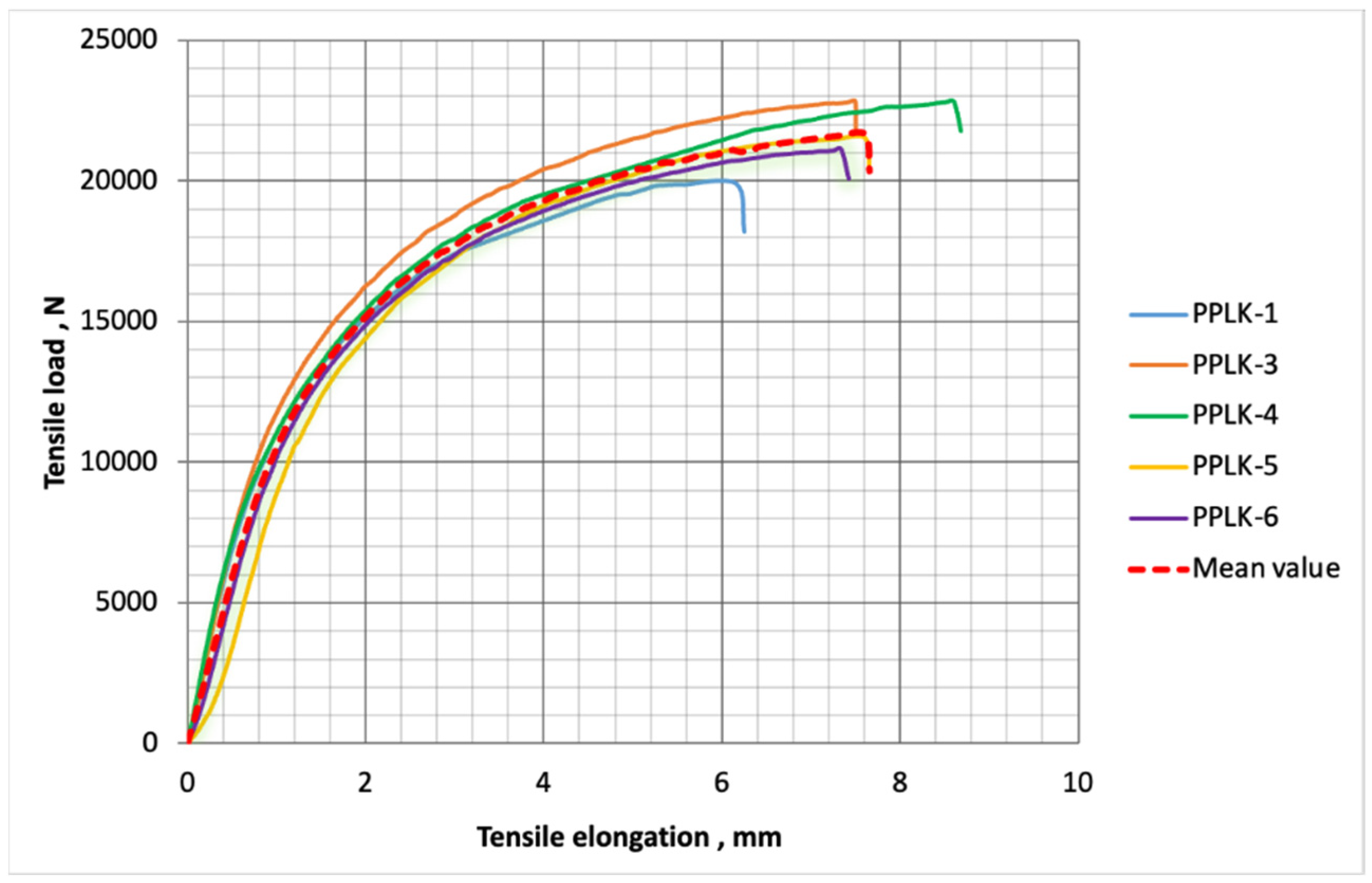

The load-carrying capacities of the specimens changed within the limits from 19.93 to 22.82 kN. The tensile elongation of the specimens changed within the limits from 3.43 to 4.78%. The mean values of the load-carrying capacity and strain were equal to 21.64 kN and 4.14%, respectively. The moduli of elasticity of the PPLK specimens changed within the limits from 2.79 to 3.74 GPa. The mean value of the modulus of elasticity was equal to 3.38 GPa. The dependences of the tensile elongation of the PPLK specimens on the axial tensile load are shown in

Figure 7.

The maximum difference between the results obtained by the analytical approach and the experiment was observed for the modulus of elasticity of the PPLK specimens, and was equal to 53.55%. The increase of the experimental value of the modulus of elasticity of the composite specimen, in comparison with the value obtained by the analytical calculations, was due to the redistribution of stresses between the punched steel tape and polypropylene, which also increased the load-carrying capacity of the composite specimen. Comparison of analytical calculations and experimental results indicates that the experimentally determined values are higher than those calculated analytically. This suggests that the polypropylene and punched steel tape in the composite specimens mutually improve each other's properties. The dependence of the axial tension force on the elongation of the composite PPLK specimens is given in

Figure 8.

The elastic modulus of the PPLK composite specimens decreased relative to the modulus of elasticity of the punched steel tape LPM-4 component. Hence, the deformation of the composite specimen increased compared to the deformations of the punched steel tape.

The load-carrying capacity of the PPLK composite specimen (21.64 kN) is higher than the sum of the load-carrying capacities of its constituent components (19.18 kN). This means that the performance of the individual materials in the PPLK composite specimen increased the total load-carrying capacity of the composite specimen by 2.46 kN or 11.37%. The increased load capacity is due to the redistribution of stresses in the polypropylene and its local failure not only along the perforation contour but also inside it. This means that the behaviour of the PPLK composite specimen also involved the polypropylene material filling the perforation slots. The filling of the perforation slots also influenced the stress redistribution in the punched steel band and decreased the coefficient of stress concentration. The load-carrying capacity of the PPLK composite specimen depends on the mechanical properties of the matrix and, first of all, on its modulus of elasticity. Using matrices with an increased value of the modulus of elasticity can enable the reduction of stresses in the punched steel tape. It allows an increase in the structural efficiency of punched metal materials-based composites. This question is considered in Chapter 4 of the current study.

4. Finite Element Analysis of the Structural Efficiency of Composites Based on Punched Metal Materials (PMM)

4.1. Description of FE Model

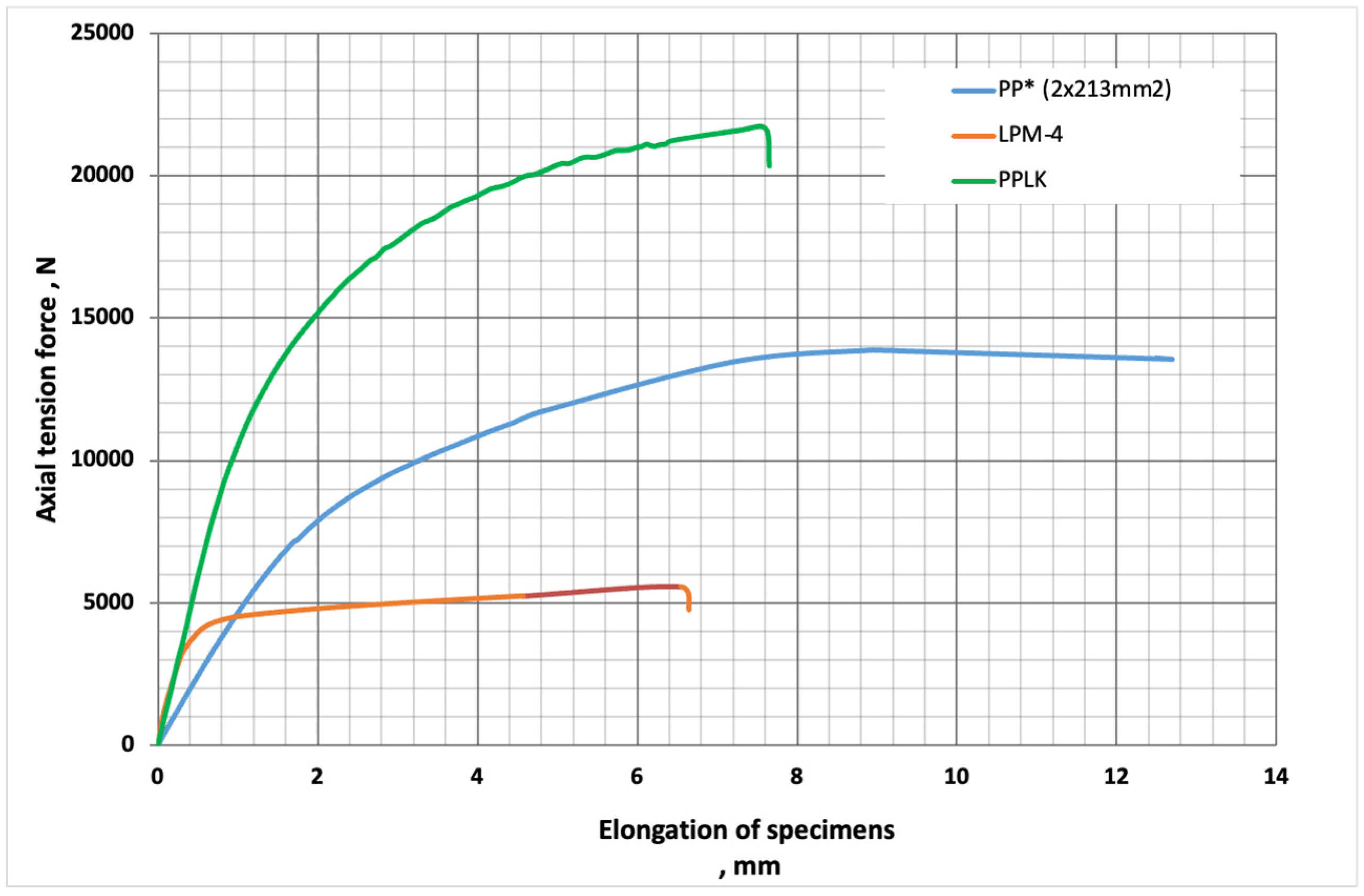

The stress distribution in the PPLK composite specimen was analysed analytically using the finite element method (FEM), realised by the software ANSYS 2023R2. The FE model was built in ANSYS Mechanical APDL software using SOLID185 finite elements. A parametric study on the friction coefficient between steel and polypropylene was done. The results obtained using 0.1, 0.3, and 0.7 friction coefficients were compared. No significant effect of the value of the friction coefficient on the behaviour of the composite sample model was found. The results of the PPLK behaviour analysis by the suggested FE model are shown in

Figure 9.

Numerically, the load-bearing capacity was the same for all friction coefficients. A model with merged steel and polypropylene nodes on the contact surfaces was calculated for comparison. As expected, it showed higher stiffness and strength of the composite sample. The finite element model was loaded by displacement, as it is in the experimental equipment. The force in the numerical specimen was calculated as the sum of the reaction forces. The developed FE model can be used to predict the behaviour of the PPLK composite specimens.

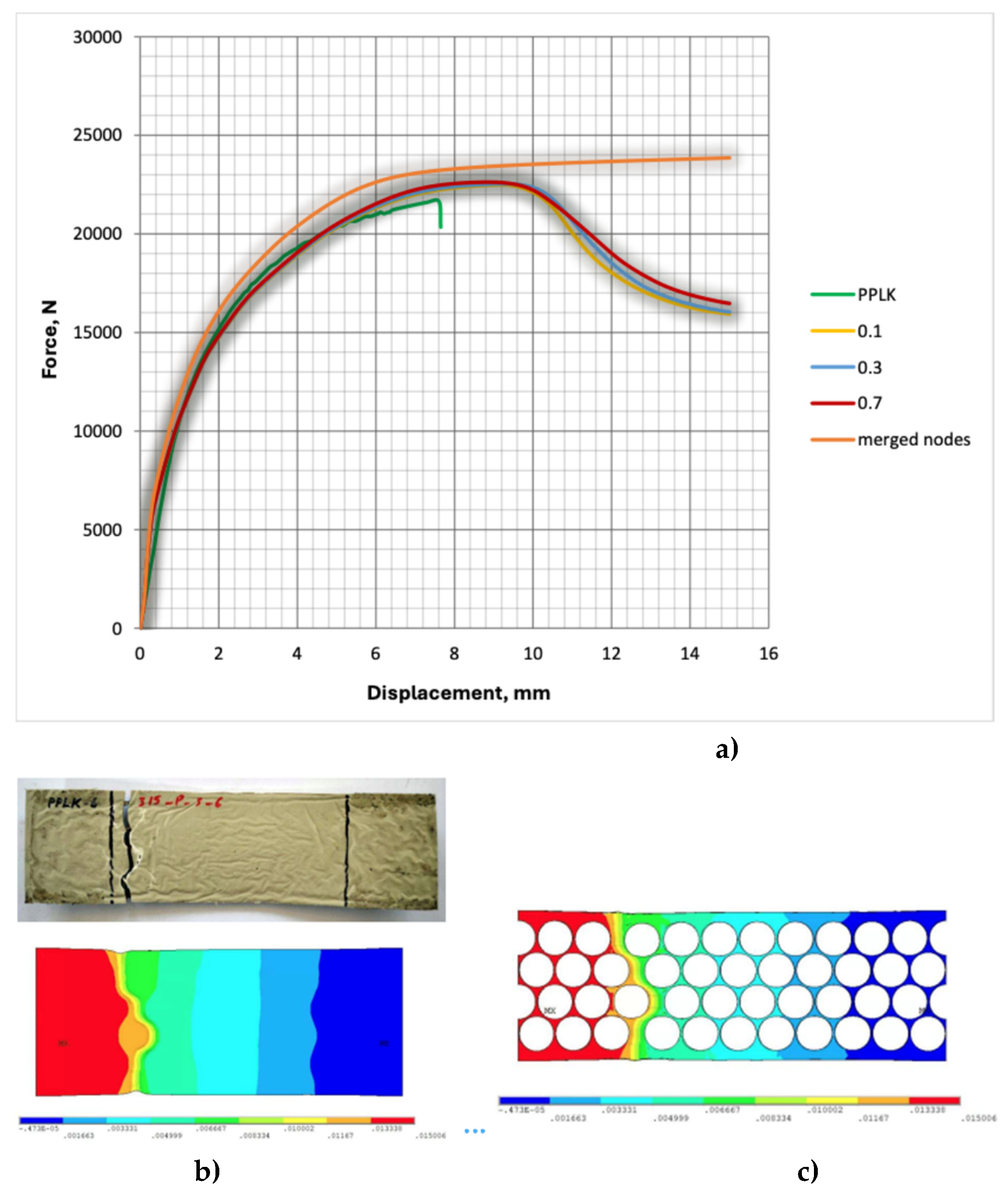

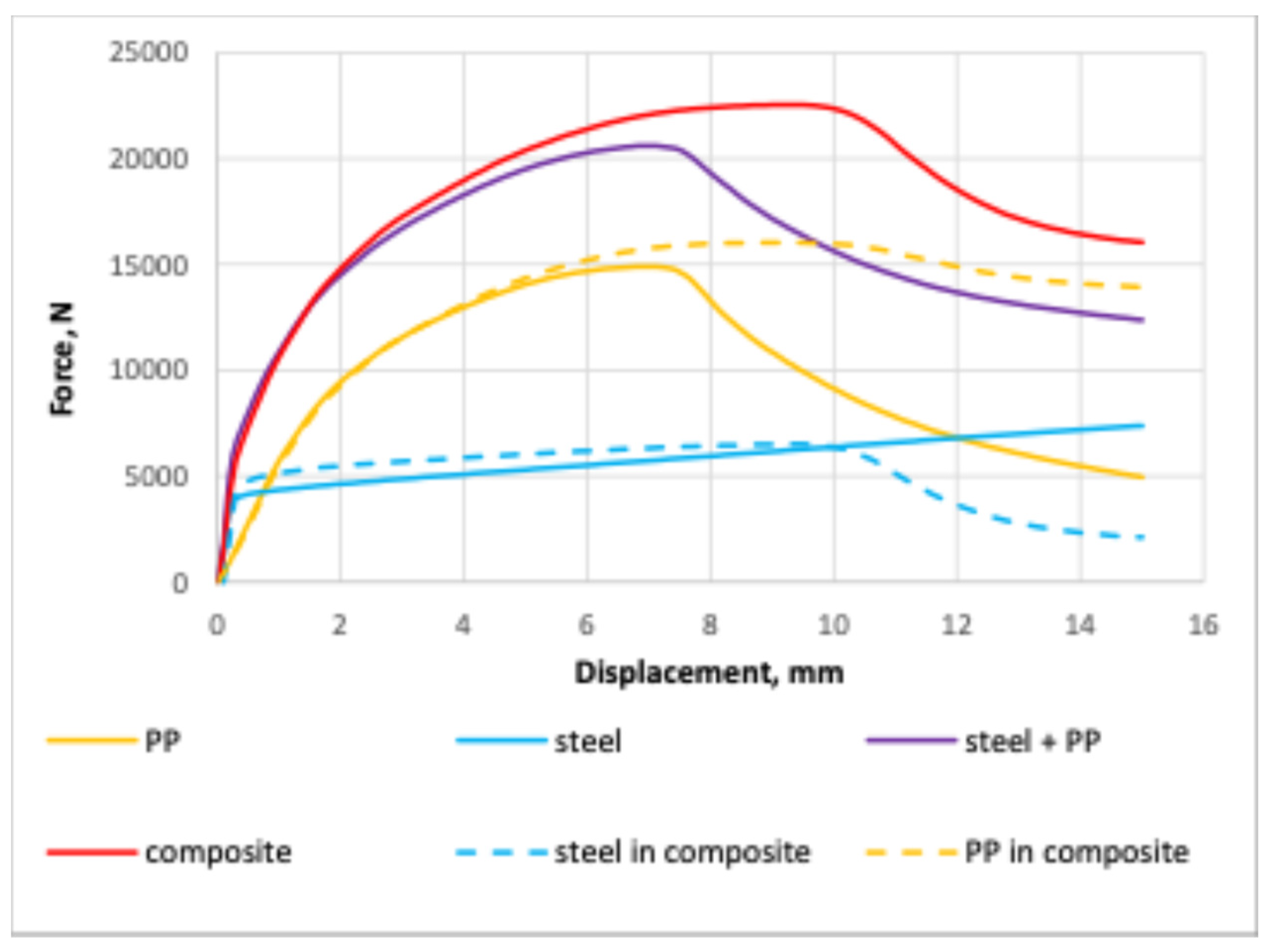

The dependence of the axial tension force and elongation (displacements) obtained by the FE models for the components of the PPLK composite specimen (steel and polypropylene), for the steel and polypropylene sum (of steel and polypropylene), and the PPLK composite specimen are shown in

Figure 10.

In

Figure 10, "PP" is a chart obtained for the separate polypropylene component, "Steel" is a chart obtained for the separate steel component, and "steel + PP" is a chart obtained by summing the charts obtained for polypropylene and steel. Three other charts, "composite", "steel in composite", and "polypropylene in composite", were obtained by the FE model analysis of the PPLK composite. The results obtained by the FE model confirm that the PPLK composite can withstand a higher axial tension force than the sum of the steel and polypropylene. This can be attributed to the decrease in the coefficient of stress concentration.

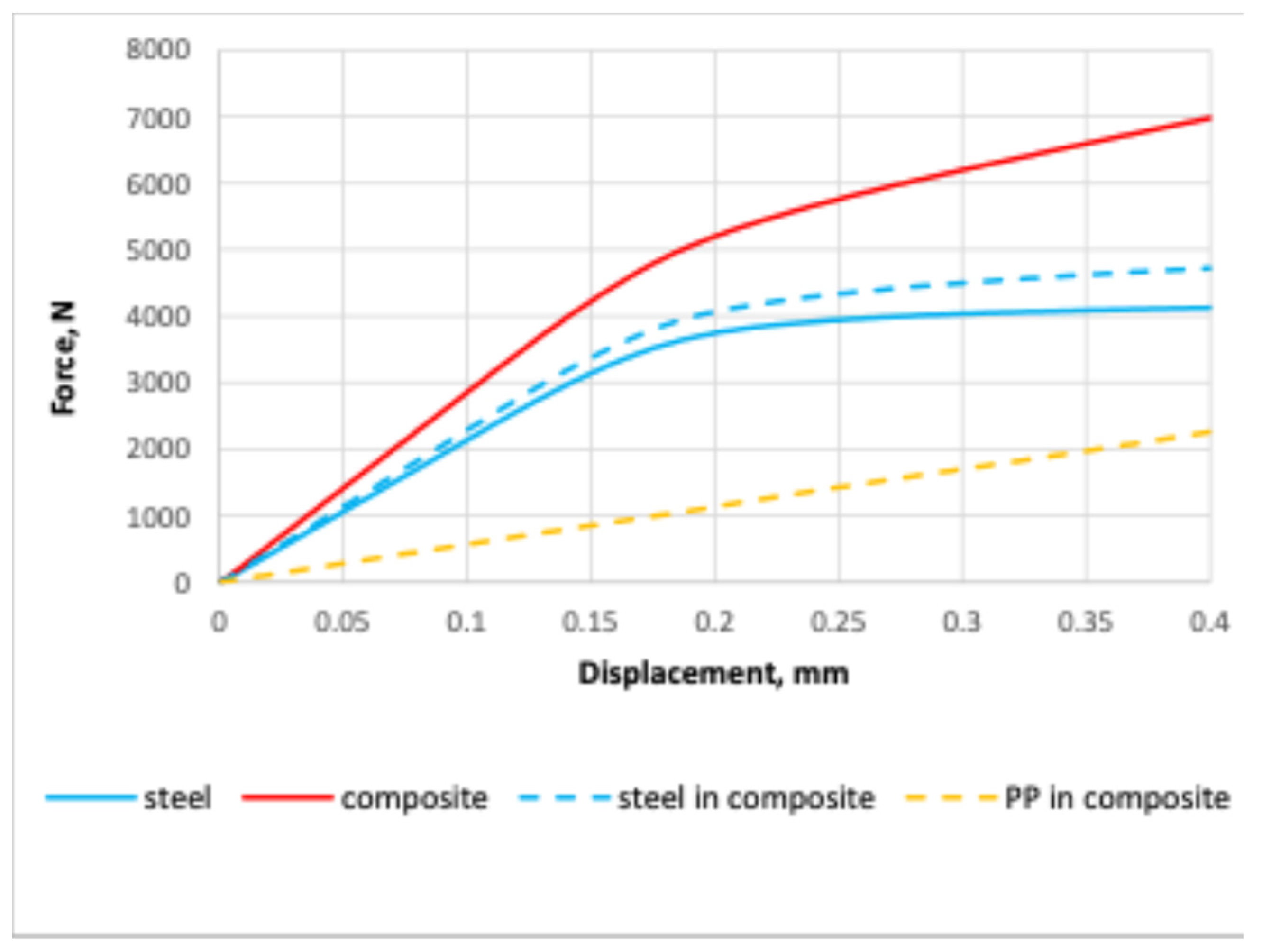

4.2. Decrease the Coefficient of Stress Concentration in the Steel Component of the PPLK Composite

Additional analyses of the composite specimen, the punched steel tape in the composite separately, and the polypropylene by the FE model were carried out to analyse the behaviour of the steel in the context of elastic work. The tension force was applied as the corresponding value of the displacements. The PPLK composite specimen and its components were subjected to absolute deformation (displacements) up to 0.4 mm, with a step of 0.002 mm. Initially, the FE models of the PPLK composite specimen and the punched steel tape were subjected to an absolute elongation of 15 mm applied with a step of 0.1 mm. The axial force N as a function of the displacements (mm) applied to the composite specimen, the punched steel tape in the composite and separately, and the polypropylene are shown in

Figure 11.

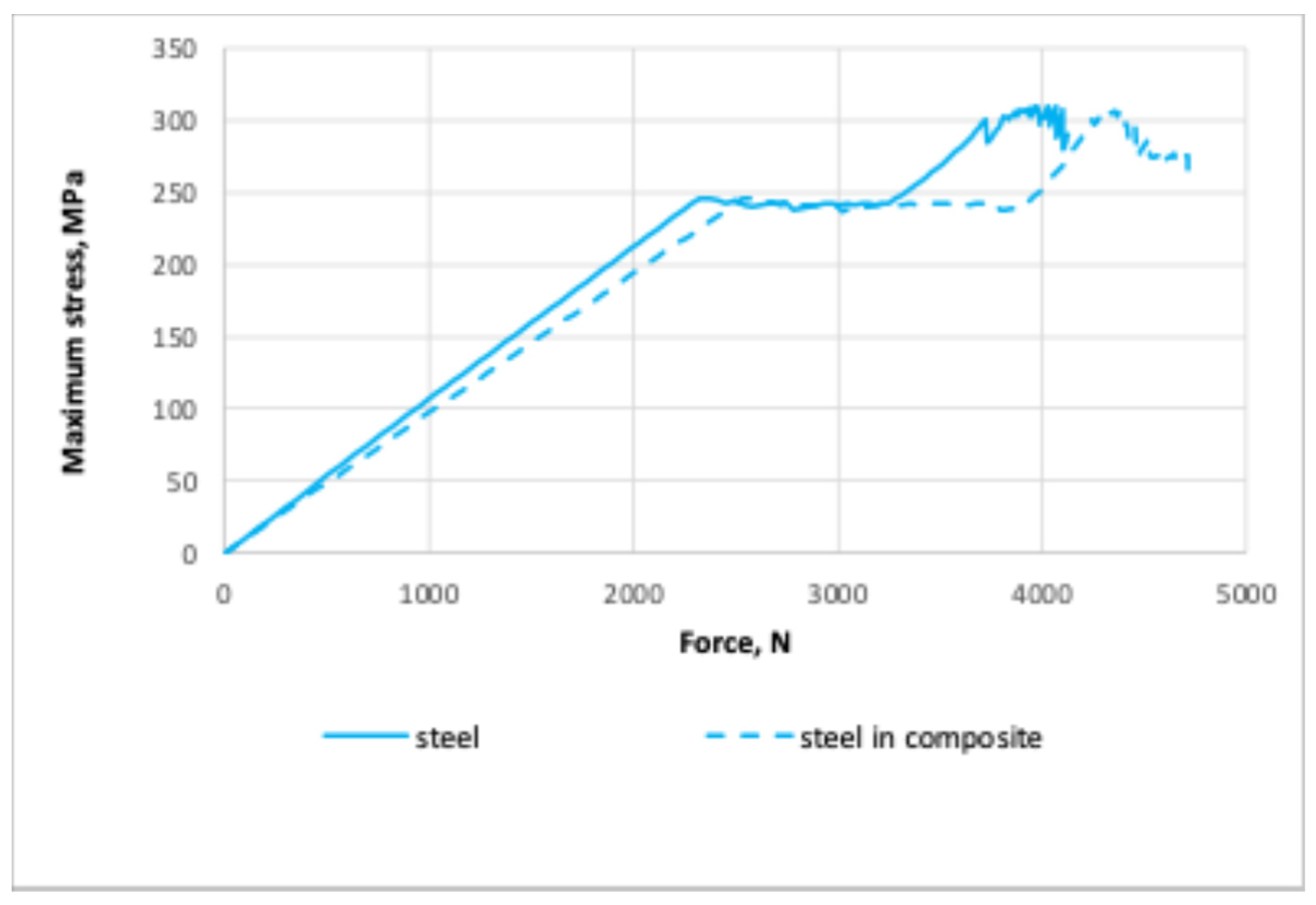

At the deformation of 0.4 mm, the stresses in the steel component (punched steel tape) of the PPLK composite specimen reach the yield point. A primary interest is comparing the behaviour of the punched steel tape separately and in the PPLK composite specimen. The maximum stresses in the punched steel tape as a function of the axial force are shown in

Figure 12.

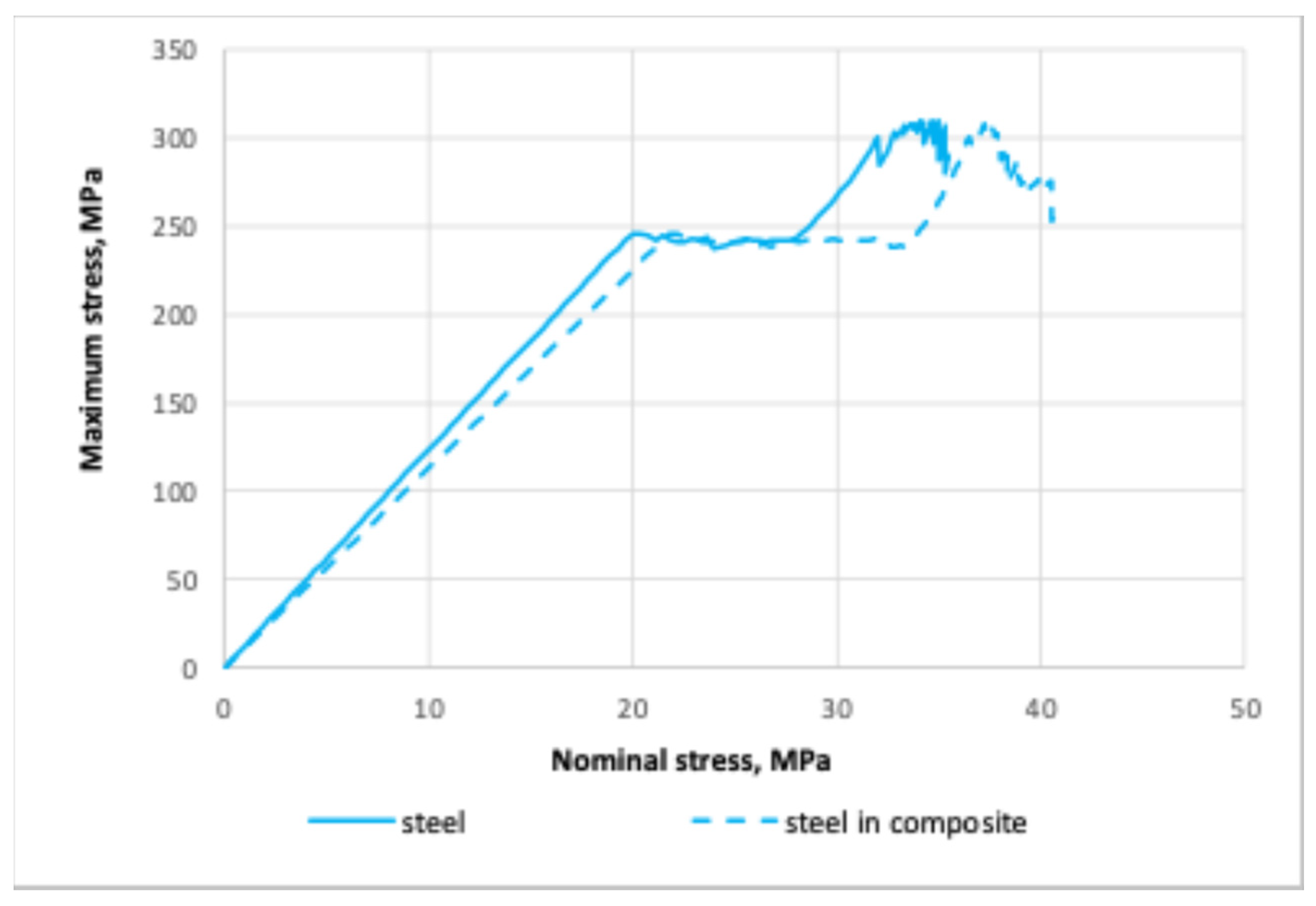

The point of yielding in the separate punched steel tape and the steel component of the PPLK composite specimen occurs at axial forces of 2312.5 N and 2562.5 N, respectively. So, the influence of the polypropylene matrix increases the load-carrying capacity of the punched steel tape component and the whole PPLK composite specimen. Then, taking into account the dimensions of the punched steel tape cross-section, 77.5 x 1.5 mm without perforations, the maximum stresses (MPa) as a function of the nominal stresses (MPa) in the separate punched steel tape and the steel component of the PPLK composite specimen can be obtained (

Figure 13).

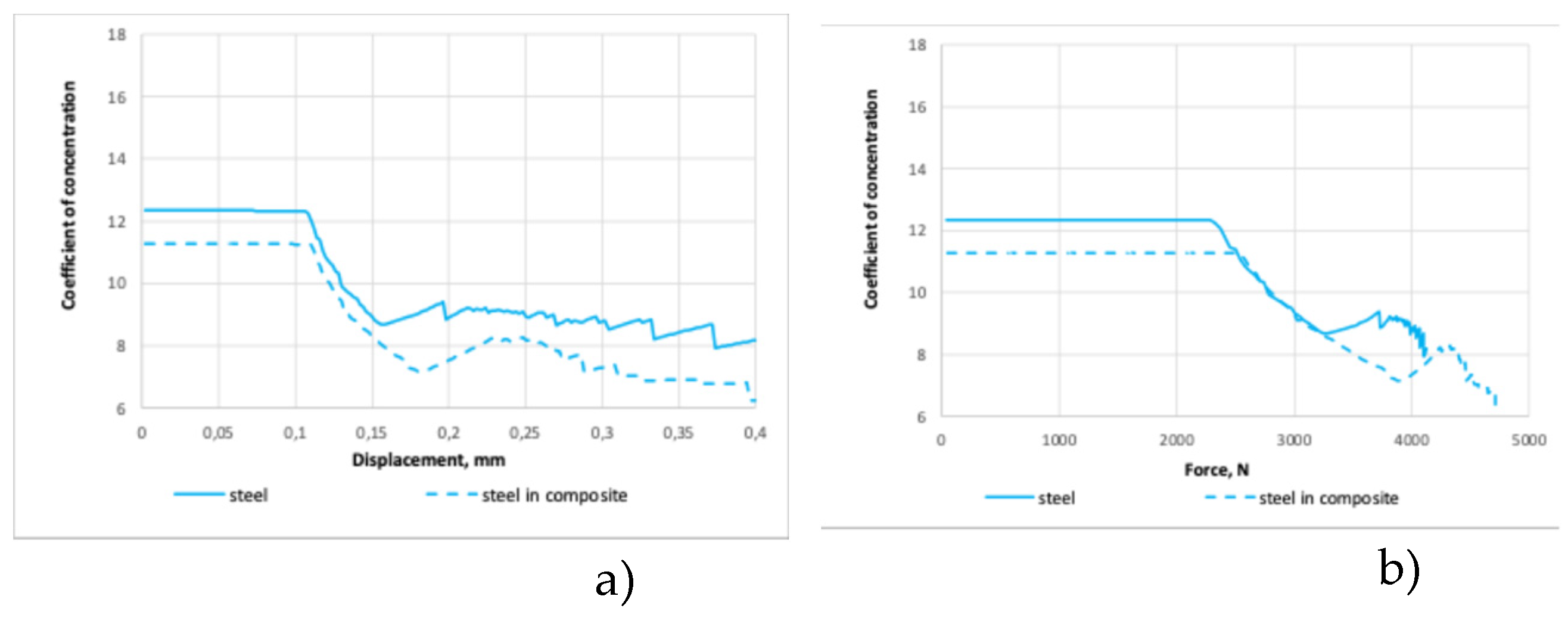

Suppose we consider the coefficient of stress concentration as the ratio of the maximum stress to the nominal stress. In that case, we can derive its value as a function of the displacement (we can go from displacements to deformations). The coefficient of stress concentration as a function of the displacements is shown in

Figure 14a. The coefficient of stress concentration as a function of the axial tension force is shown in

Figure 14b.

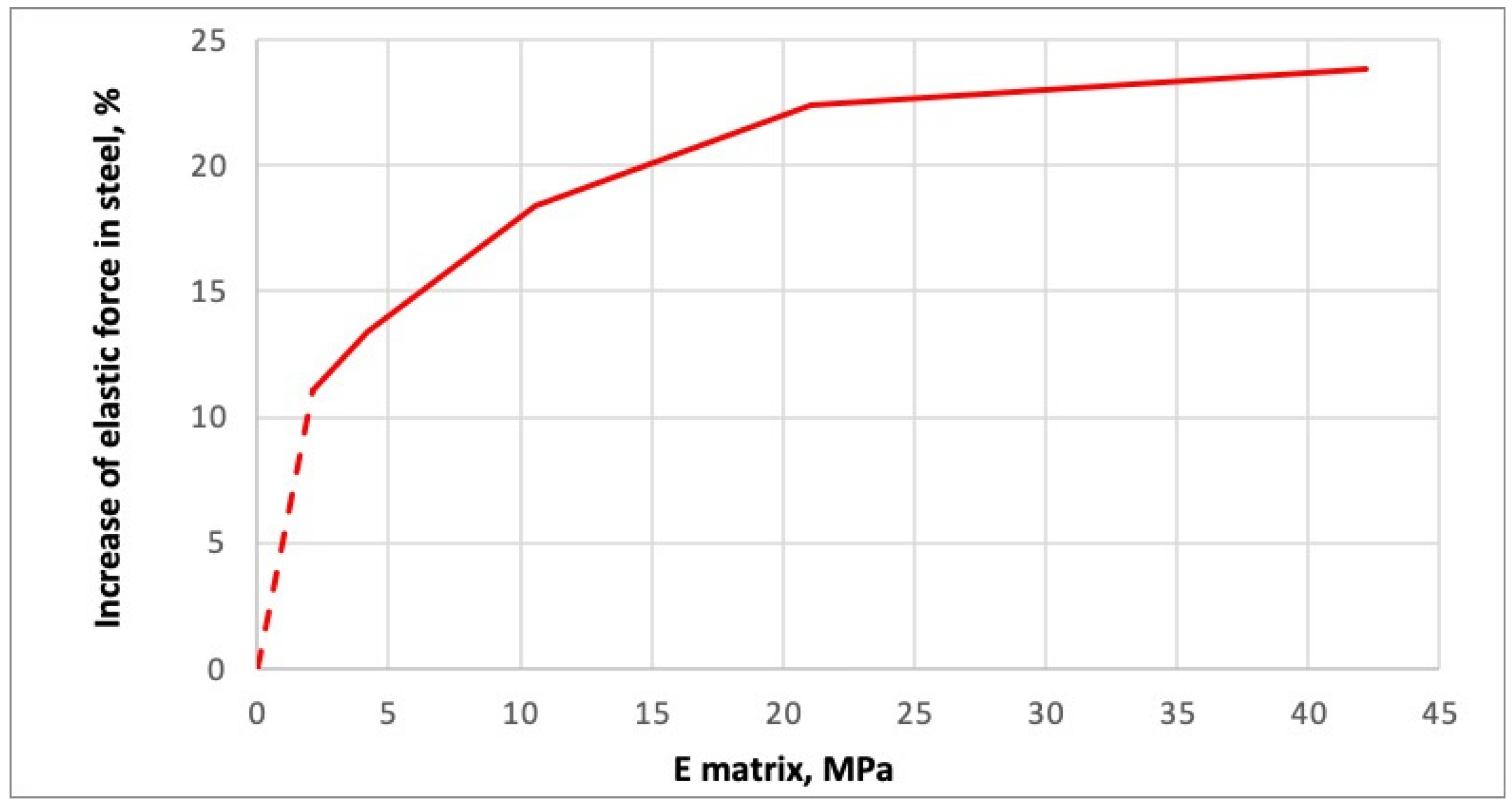

Additional analyses were performed with the matrix elastic modulus increased up to 42 MPa to evaluate the stress concentration coefficient. The dependence shown in

Figure 15 displays the increase in the 'elastic' force (axial force) in the punched steel tape as a function of the matrix modulus of elasticity. The maximum elastic force, in this case, is determined when the increase in force is no longer proportional to the increase in applied displacement (the increase in force with a uniform increase in applied displacement decreases to the initial rise in force by more than 1%). Thus, this graph shows the increase in axial force at which the behaviour of the punched steel tape becomes plastic. The appearance of individual plastic zones in places of stress concentration at the edges of the holes is not considered here.

It should be noted that the forces at which the first plastic zones appear are less than the analysed ones by only 2-3% (i.e., local zones fuse, and the whole section becomes plastic at a slight increase in the force). The dependence of the magnitude of these forces on the matrix elastic modulus is the same. Thus, this graph, shown in

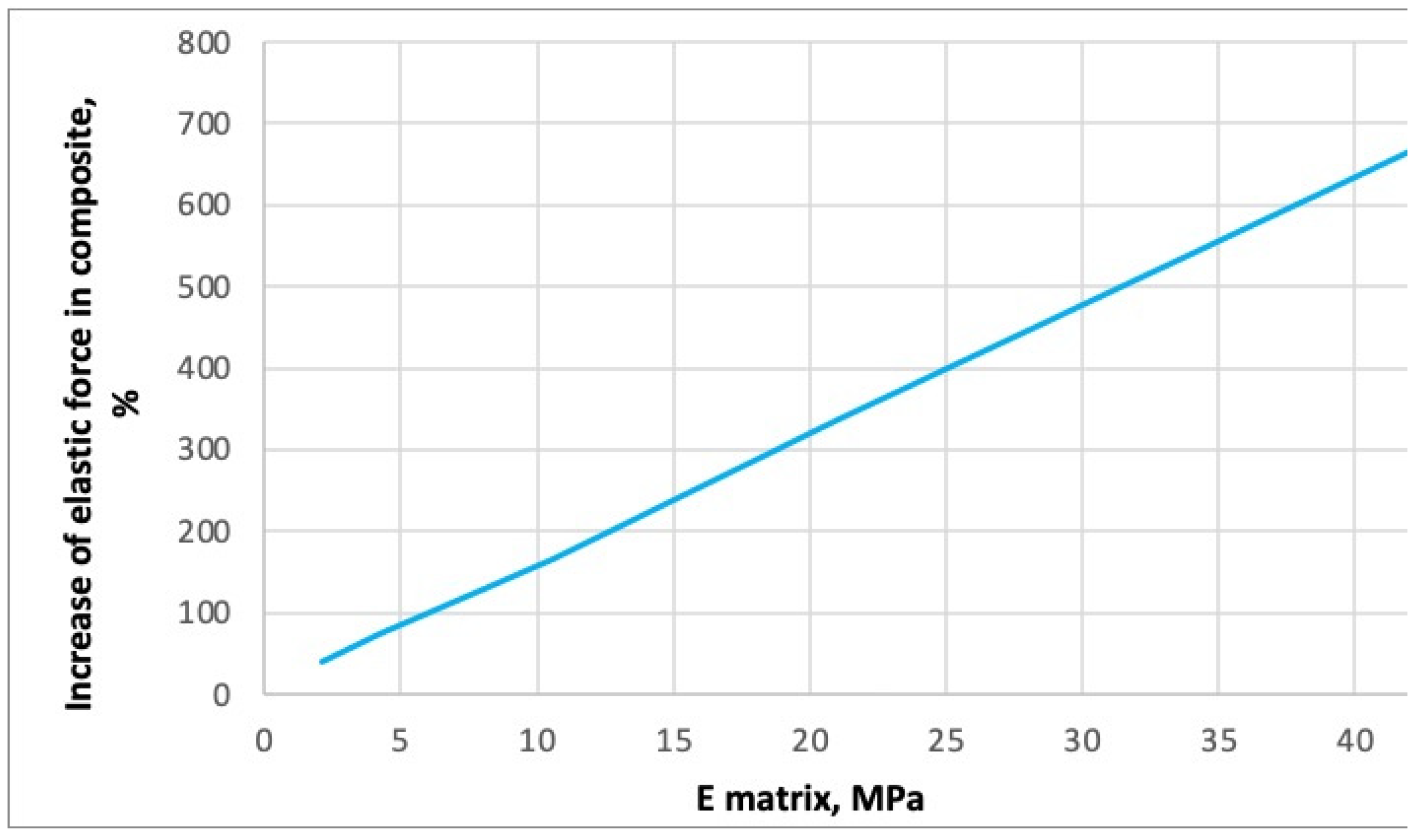

Figure 16, is valid for describing the change of forces in steel at which the first plastic zones appear in the places of stress concentration. So far, in the parametric study of the effect of matrix stiffness, we have not considered how the forces in the PPLK composite specimen change. It is assumed that the matrix works elastically. Then, the forces in the PPLK composite specimen at the moment the steel transitions to plastic behaviour change, as shown in

Figure 16.

It was demonstrated that an increase in the modulus of elasticity of the matrix up to 42 MPa results in a 24% enhancement in the elastic force in the steel component of the PPLK composite specimen compared to the separate punched steel tape. The elastic force in the composite increases by a factor of six. This demonstrates that the efficiency of the punched steel tape in composite materials is contingent upon the modulus of elasticity of the matrix, as it exerts an influence on the coefficient of stress concentration. The coefficient of stress concentration declines in proportion to the augmentation of the elastic force in the composite.

5. Conclusions

The study successfully demonstrates the feasibility of incorporating punched steel waste (specifically LPM-4-grade steel tape) into a composite material (PPLK) for structural applications. The resulting composite material, with specimens measuring 310 x 90 x 6.30 mm, shows promise for use in load-bearing elements subjected to tensile forces, potentially replacing traditional steel reinforcement in some applications.

The PPLK composite exhibits a significantly improved load-carrying capacity compared to the sum of its components (polypropylene and steel tape). The experimental average load-carrying capacity of 21.64 kN surpasses the theoretically calculated capacity (19.18 kN) by 2.46 kN (an 11.37% increase), highlighting a synergistic effect between the materials. This enhancement is attributed to stress redistribution within the composite structure, particularly the role of the polypropylene filling the perforations in the steel tape. The average modulus of elasticity (3.38 GPa) also indicates improved stiffness compared to the polypropylene matrix alone (1.3 GPa), representing a more than 2.5-fold increase.

Finite element analysis (FEA) confirms that including the polypropylene matrix effectively mitigates stress concentration in the steel component. By increasing the matrix's elastic modulus to 42 MPa (a significant increase from the initial 1.3 GPa), a 24% increase in the elastic force within the steel component was observed, further reducing the stress concentration coefficient. This is crucial for enhancing the composite material's overall structural efficiency and durability. The simultaneous failure of the steel and polymer components under tensile loading, observed in all five tested specimens (PPLK-1, PPLK-3-PPLK-6), suggests effective stress transfer and a well-integrated composite structure.

The study clearly shows that the mechanical properties and performance of the PPLK composite are highly sensitive to the characteristics of the polymer matrix. Utilising matrices with higher moduli of elasticity can further optimise the composite's performance and reduce stress concentration. Areas for further investigation include exploring different polymer matrices with even higher moduli of elasticity, potentially leading to further increases in load-carrying capacity and stiffness.

The successful integration of punched steel waste into a functional composite material offers a promising and sustainable solution for managing this significant industrial byproduct. The findings contribute to the Circular Economy principles by promoting resource efficiency and reducing waste in the construction sector. Further research and development could lead to broader adoption of this approach in construction, potentially reducing reliance on virgin materials and decreasing the environmental impact of steel production and waste disposal.

While the study demonstrates the effectiveness of the PPLK composite, delamination occurred in some areas due to insufficient adhesion between the steel and polypropylene, notably affecting the consistency in load-carrying capacity observed in the range of 19.93 to 22.82 kN. Future work should focus on improving the interfacial adhesion between the components (possibly via the addition of chemical bonding agents) to enhance overall composite performance and reliability, leading to a more consistent and predictable material response. Additional research into optimising the manufacturing process (e.g., adjusting the hot press parameters to improve adhesion) and exploring different geometries for the composite could also yield further improvements in strength and reduce the 53.55% discrepancy noted between analytical and experimental modulus of elasticity values.

Author Contributions

Conceptualisation, M.L., and D.S.; methodology, M.L., P.A., and D.S.; software, P.A., M.L.; investigation, M.L., V.M., and P.A.; data curation, M.L., P.A. and D.S.; writing—original draft preparation, D.S., V.M. and V.G.; writing—review and editing, V.L. and D.S.; visualisation, M.L and P.A..; project administration, D.S. All authors have read and agreed to the published version of the manuscript.

Data Availability Statement

The data that support the findings of this study are available from the first author [M.L.] upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Directive 2008/98/EC of the European Parliament and of the Council of on Waste and Repealing Certain Directives (Text with EEA Relevance); 2008; Vol. 312; 19 November.

- Council Regulation (EU) No 333/2011 of Establishing Criteria Determining When Certain Types of Scrap Metal Cease to Be Waste under Directive 2008/98/EC of the European Parliament and of the Council; 2011; Vol. 31 March.

- Al-Jabri, K.S.; Al-Saidy, A.H.; Taha, R. Effect of Copper Slag as a Fine Aggregate on the Properties of Cement Mortars and Concrete. Construction and Building Materials 2011, 25, 933–938. [Google Scholar] [CrossRef]

- Giorgi, S.; Lavagna, M.; Wang, K.; Osmani, M.; Liu, G.; Campioli, A. Drivers and Barriers towards Circular Economy in the Building Sector: Stakeholder Interviews and Analysis of Five European Countries Policies and Practices. Journal of Cleaner Production 2022, 336, 130395. [Google Scholar] [CrossRef]

- Awogbemi, O.; Kallon, D.V.V.; Bello, K.A. Resource Recycling with the Aim of Achieving Zero-Waste Manufacturing. Sustainability 2022, 14, 4503. [Google Scholar] [CrossRef]

- Branca, T.A.; Colla, V.; Algermissen, D.; Granbom, H.; Martini, U.; Morillon, A.; Pietruck, R.; Rosendahl, S. Reuse and Recycling of Byproducts in the Steel Sector: Recent Achievements Paving the Way to Circular Economy and Industrial Symbiosis in Europe. Metals 2020, 10, 345. [Google Scholar] [CrossRef]

- Li, P.; Li, X.; Li, F. A Novel Recycling and Reuse Method of Iron Scraps from Machining Process. Journal of Cleaner Production 2020, 266, 121732. [Google Scholar] [CrossRef]

- Abdullah, W.; Sasan, S.; Latif, S. Punched Metal Straps as Replacements for Main Steel Rebars in Normal Concrete Beams. Iran J Sci Technol Trans Civ Eng 2024, 48, 669–677. [Google Scholar] [CrossRef]

- Mironovs, V.; Kuzmina, J.; Serdjuks, D.; Usherenko, Y.; Lisicins, M. Sustainable Lifecycle of Perforated Metal Materials. Materials 2023, 16, 3012. [Google Scholar] [CrossRef] [PubMed]

- Elmessalami, N.; El Refai, A.; Abed, F. Fiber-Reinforced Polymers Bars for Compression Reinforcement: A Promising Alternative to Steel Bars. Construction and Building Materials 2019, 209, 725–737. [Google Scholar] [CrossRef]

- Shakir Abbood, I.; Odaa, S. aldeen; Hasan, K.F.; Jasim, M.A. Properties Evaluation of Fiber Reinforced Polymers and Their Constituent Materials Used in Structures – A Review. Materials Today: Proceedings 2021, 43, 1003–1008. [Google Scholar] [CrossRef]

- Yuhazri, M.Y.; Zulfikar, A.J.; Ginting, A. Fiber Reinforced Polymer Composite as a Strengthening of Concrete Structures: A Review. IOP Conf. Ser.: Mater. Sci. Eng. 2020, 1003, 012135. [Google Scholar] [CrossRef]

- Wang, Y.; Cai, G.; Li, Y.; Waldmann, D.; Si Larbi, A.; Tsavdaridis, K.D. Behavior of Circular Fiber-Reinforced Polymer–Steel-Confined Concrete Columns Subjected to Reversed Cyclic Loads: Experimental Studies and Finite-Element Analysis. Journal of Structural Engineering 2019, 145, 04019085. [Google Scholar] [CrossRef]

- Fang, H.; Bai, Y.; Liu, W.; Qi, Y.; Wang, J. Connections and Structural Applications of Fibre Reinforced Polymer Composites for Civil Infrastructure in Aggressive Environments. Composites Part B: Engineering 2019, 164, 129–143. [Google Scholar] [CrossRef]

- Dagdag, O.; Hsissou, R.; El Harfi, A.; Berisha, A.; Safi, Z.; Verma, C.; Ebenso, E.E.; Ebn Touhami, M.; El Gouri, M. Fabrication of Polymer Based Epoxy Resin as Effective Anti-Corrosive Coating for Steel: Computational Modeling Reinforced Experimental Studies. Surfaces and Interfaces 2020, 18, 100454. [Google Scholar] [CrossRef]

- Al-saadi, A.U.; Aravinthan, T.; Lokuge, W. Structural Applications of Fibre Reinforced Polymer (FRP) Composite Tubes: A Review of Columns Members. Composite Structures 2018, 204, 513–524. [Google Scholar] [CrossRef]

- Less, T.; Demir, A.; Sezen, H. Structural Performance and Corrosion Resistance of Fiber Reinforced Polymer Wrapped Steel Reinforcing Bars. Construction and Building Materials 2023, 366, 130176. [Google Scholar] [CrossRef]

- Soufeiani, L.; Foliente, G. ; Nguyen, Kate. T.Q.; San Nicolas, R. Corrosion Protection of Steel Elements in Façade Systems – A Review. Journal of Building Engineering 2020, 32, 101759. [Google Scholar] [CrossRef]

- Han, S.; Sung, M.; Jang, J.; Jeon, S.-Y.; Yu, W.-R. The Effects of Adhesion on the Tensile Strength of Steel-Polymer Sandwich Composites. Advanced Composite Materials 2021, 30, 443–461. [Google Scholar] [CrossRef]

- Yang, J.; Han, S.; Yu, W.-R. Detection of Delamination of Steel–Polymer Sandwich Composites Using Acoustic Emission and Development of a Forming Limit Diagram Considering Delamination. Heliyon 2023, 9. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Yu, W.-R. Effect of Interfacial Properties on the Damping Performance of Steel–Polymer Sandwich Cantilever Beam Composites. Journal of Vibration and Control 2023, 29, 400–410. [Google Scholar] [CrossRef]

- Skincs, A.; Serdjuks, D.; Buka-Vaivade, K.; Goremikins, V.; Mohamed, A.Y. Steel and Composite Tapes in Timber to Concrete Joint. In Sustainable Energy Systems: Innovative Perspectives; Sinitsyn, A., Ed.; Lecture Notes in Civil Engineering; Springer International Publishing: Cham, 2021; ISBN 978-3-030-67654-4. [Google Scholar] [CrossRef]

Figure 1.

Punched steel waste from the stamping process in mechanical engineering: a) - Steel tape orientation in the stamping machine; b) - Punched steel waste in coil form after stamping of drive chain components.

Figure 1.

Punched steel waste from the stamping process in mechanical engineering: a) - Steel tape orientation in the stamping machine; b) - Punched steel waste in coil form after stamping of drive chain components.

Figure 2.

Punched steel profiles made from the waste materials: a) – laboratorian specimens; b) – structural members of the walls framework [

19].

Figure 2.

Punched steel profiles made from the waste materials: a) – laboratorian specimens; b) – structural members of the walls framework [

19].

Figure 3.

The geometric parameters of the grade LPM-4 punched steel tape a) and total view of the composite load-carrying structural element b) [

18].

Figure 3.

The geometric parameters of the grade LPM-4 punched steel tape a) and total view of the composite load-carrying structural element b) [

18].

Figure 4.

Determination of mechanical properties of LPM-4 grade punched steel strip: a) - using the INSTRON 8802 tester; b) - zone of maximum normal stress concentration; c) - failure mode and zone of specimen collapse.

Figure 4.

Determination of mechanical properties of LPM-4 grade punched steel strip: a) - using the INSTRON 8802 tester; b) - zone of maximum normal stress concentration; c) - failure mode and zone of specimen collapse.

Figure 5.

The laboratory specimen PPLK-6 a) and the hot press b) were used for the specimen preparation.

Figure 5.

The laboratory specimen PPLK-6 a) and the hot press b) were used for the specimen preparation.

Figure 6.

Testing the laboratory composite specimen: a) - testing device INSTRON 8802; b) – laboratory composite specimen PPLK-6 after it collapses.

Figure 6.

Testing the laboratory composite specimen: a) - testing device INSTRON 8802; b) – laboratory composite specimen PPLK-6 after it collapses.

Figure 7.

The dependences of the tensile elongation of the PPLK specimens on the axial tensile load.

Figure 7.

The dependences of the tensile elongation of the PPLK specimens on the axial tensile load.

Figure 8.

The dependence of axial tension force on the elongation of the composite PPLK specimens.

Figure 8.

The dependence of axial tension force on the elongation of the composite PPLK specimens.

Figure 9.

PPLK composite specimens behaviour analysis with the FE model: a) – axial tension force as a function of the elongation in tension; b) - the experimental and numerical deformed shape of the specimen after failure; the) - the numerical deformed shape of steel after failure.

Figure 9.

PPLK composite specimens behaviour analysis with the FE model: a) – axial tension force as a function of the elongation in tension; b) - the experimental and numerical deformed shape of the specimen after failure; the) - the numerical deformed shape of steel after failure.

Figure 10.

Comparison of results obtained by the FE models for steel, polypropylene, a sum of steel and polypropylene, and PPLK composite.

Figure 10.

Comparison of results obtained by the FE models for steel, polypropylene, a sum of steel and polypropylene, and PPLK composite.

Figure 11.

Axial force as a function on the displacements applied to the composite specimen, punched steel tape in composite and separately and polypropylene.

Figure 11.

Axial force as a function on the displacements applied to the composite specimen, punched steel tape in composite and separately and polypropylene.

Figure 12.

The maximum stresses in the the punched steel tape as a function of the axial force separately and in the PPLK composite specimen.

Figure 12.

The maximum stresses in the the punched steel tape as a function of the axial force separately and in the PPLK composite specimen.

Figure 13.

The maximum stresses (in MPa) are a function of the nominal stresses (in MPa) in the separate punched steel tape and the steel component of the PPLK composite specimen.

Figure 13.

The maximum stresses (in MPa) are a function of the nominal stresses (in MPa) in the separate punched steel tape and the steel component of the PPLK composite specimen.

Figure 14.

The coefficient of stress concentration as a function of the displacements a) and the axial tension force b).

Figure 14.

The coefficient of stress concentration as a function of the displacements a) and the axial tension force b).

Figure 15.

The increase in the 'elastic' force (axial force) in the punched steel tape is a function of the matrix modulus of elasticity.

Figure 15.

The increase in the 'elastic' force (axial force) in the punched steel tape is a function of the matrix modulus of elasticity.

Figure 16.

The elastic force increases in the PPLK composite specimen at the moment of steel-to-plastic transition changes as a function of the modulus of elasticity of the matrix.

Figure 16.

The elastic force increases in the PPLK composite specimen at the moment of steel-to-plastic transition changes as a function of the modulus of elasticity of the matrix.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).