1. Introduction

The plantain and plantain sectors in Colombia are experiencing significant growth, underscoring their role as cornerstones of the national economy and exemplifying the country’s agricultural potential. Plantains (Musa paradisiaca, AAB) and plantains (Musa paradisiaca, AAA) are vital agricultural products, providing essential food sources and employment opportunities for many developing countries, including Colombia. This cultivation is crucial for the income of producers, as well as for the economic stability of other stakeholders and, in particular, suppliers and marketers.

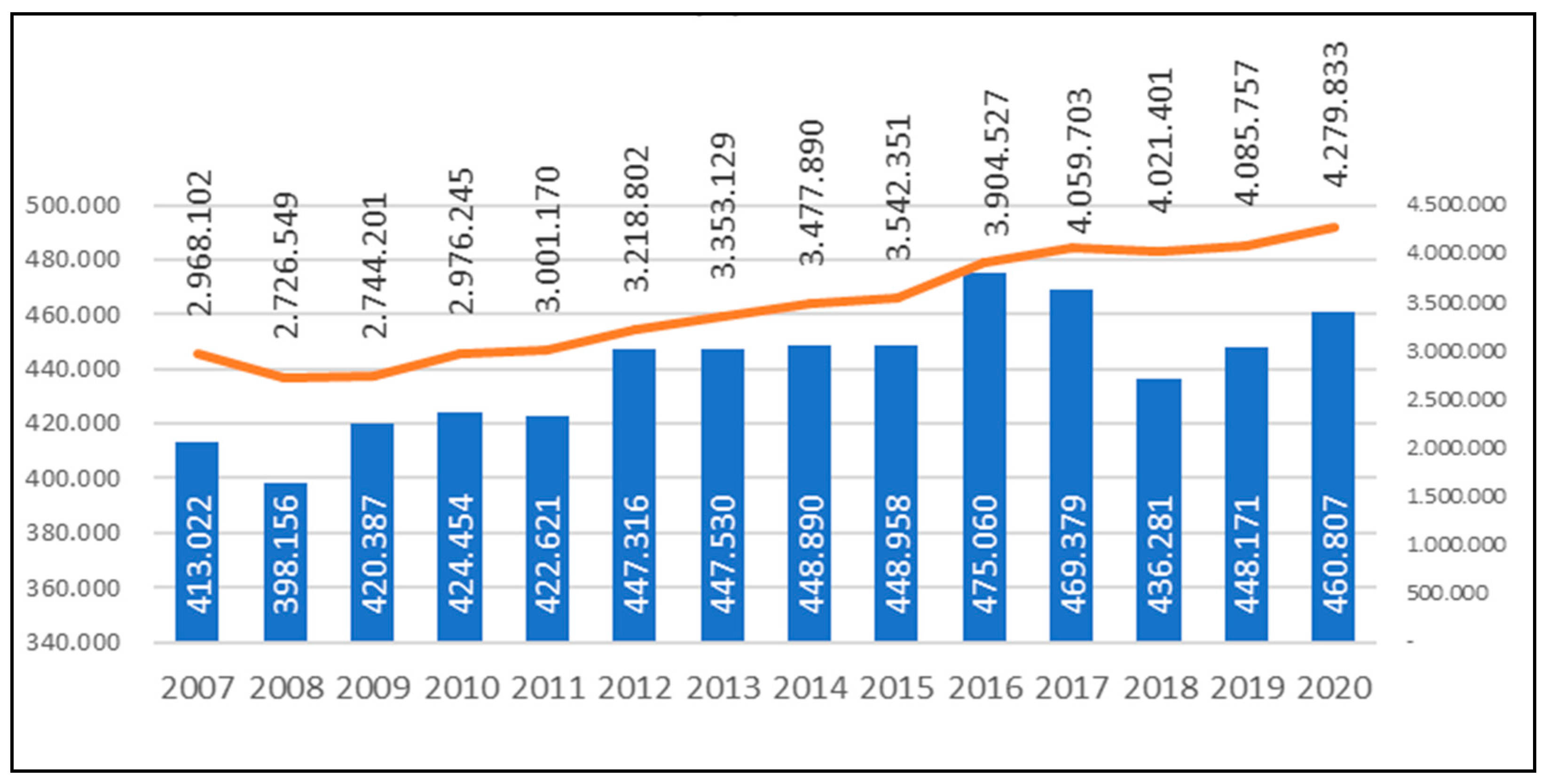

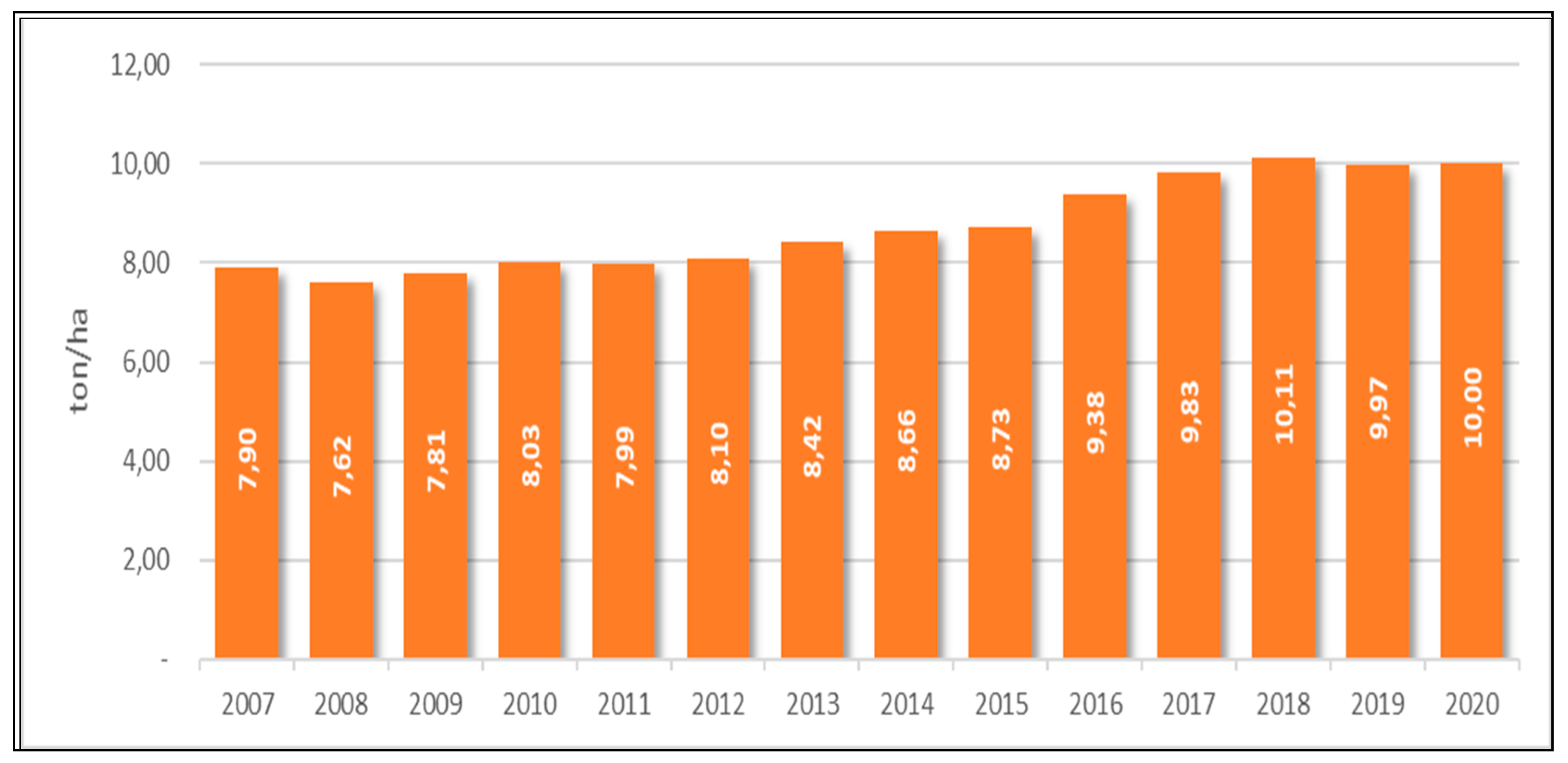

The importance of this agro-industrial chain is highlighted by its production and marketing statistics. According to data from the Greenland Group, Banacol—part of this conglomerate—exported 14.1 million boxes of bananas and 770,000 boxes of plantains in 2023. Notably, banana production increased by 2% in 2020, with a corresponding rise in planted area by 1%, resulting in a total output of 4,279,833 tons across 460,807 hectares. By 2021, production figures approached 4.4 million tons over approximately 465,000 hectares, as reported by UPRA. The national average yield per hectare has also shown improvement, rising from 7.9 tons per hectare in 2007 to 10 tons per hectare in 2020, significantly exceeding the global average yield of 7 tons per hectare in 2018.

Figure 1.

Indicators of Production Area and Yield per Hectare Planted (left vertical axis) and Number of Tons (right vertical axis). Note: The blue line represents the total area planted in hectares, while the orange line represents total production in tons. Source: [3].

Figure 1.

Indicators of Production Area and Yield per Hectare Planted (left vertical axis) and Number of Tons (right vertical axis). Note: The blue line represents the total area planted in hectares, while the orange line represents total production in tons. Source: [3].

Figure 2.

Yield in Tons per Hectare. Source: [3].

Figure 2.

Yield in Tons per Hectare. Source: [3].

In Colombia, four primary regions are recognized as major producers of plantains: Urabá, Northeast Antioquia, the central region, and the Eastern Plains. Antioquia leads in production, accounting for 14% of the total area cultivated—approximately 61,000 hectares. The plantain crop is the most widely cultivated fruit in Colombia, constituting an integral part of the national food basket and serving as a cornerstone for food security. The dominant varieties include Dominico Hartón, Hartón, Dominico, and Cachaco. Current estimates for 2024 may vary based on the latest data from governmental and agricultural institutions; however, Colombia consistently ranks among the world’s top plantain producers, particularly in regions like Urabá, Magdalena, and Valle del Cauca. Recent analyses by the Colombian Horticultural Association indicate a notable 16% increase in plantain exports in January 2024, totaling 9,756 tons, production above January 2023.

Amid these developments, there is a growing interest in applying concepts, methodologies, techniques, and tools related to innovation management within organizations. Innovation Management Models (IMMs) have gained prominence, both in theoretical discourse and practical applications within businesses. This trend reflects an urgent need to align innovation strategies with organizational structures and management models, fostering a cohesive connection between research, development, and innovation processes with the functions inherent to innovative management. This dynamic is particularly salient for organizations within the agro-industrial chains in the Armenia-Quindío region, where effective integration of innovation is critical for success and sustainability. Consequently, the proposal of an IMM aimed at enhancing Science, Technology, and Innovation (CTEI) within the plantain sector emerges as a strategic initiative to bolster development and competitiveness in this field.

2. Theoretical Framework

2.1. The Context of the Plantain Agro-industrial Chain in Colombia

The concept of a productive chain encompasses diverse interpretations and definitions [

5,

6,

7,

8,

9]. It is crucial to clarify that a productive chain is distinct from a value chain or a supply chain. The term “productive chain” originated in Latin America during the 1990s, reflecting collaborative efforts among various production links, as well the development of State policies to support the actors in the chain In legal terms, it should be noted that Law 811 of 2023 established clear rules for the organization of agro-industrial chains in Colombia and defined that a chain corresponds to a series of interconnected economic and technical activities for the benefit of the different actors [10].

In Colombia, this agri-food chain is made up of various actors ranging from producers to research centers. Among the government actors, it is important to highlight two entities: the National Learning Service (SENA) and the Colombian Agricultural Institute (ICA). The latter entity has several agricultural development centers, distributed in different Colombian territories. In addition, the chain has the support of the International Center for Tropical Agriculture (CIAT), Asohofrucol, agricultural secretariats and regional autonomous corporations.

The National Competitiveness Agreement for the Chain, signed in 2010 and subsequently updated for the period 2011-2020, established a mission and vision predicated on productivity indicators. In 2015, this production chain, thanks to research and genetic development, underwent significant changes, such as a greater increase in production per hectare (from 7.3 to 10.0 tons), a decrease in costs and greater productivity, which represented an increase of 4% to 10% in exports.

Projections for 2025 indicate that the plantain production chain in Colombia is poised to reach unprecedented levels of productivity and competitiveness, with anticipated yields of 12 tons per hectare, a 10% reduction in production costs, a stabilized cultivated area of 750,000 hectares, and an allocation of 12% of production for international markets. These advancements are expected to significantly enhance the living and working conditions of producers. The chain is expected to advise the government on issues of continuous improvement in the sector, while serving as a facilitator and coordinator among stakeholders to strengthen business operations and achieve the outlined objectives for 2015 and 2025.

Globally, and in terms of gross production value, plantain ranks fourth, with India as the largest producer (30.5 million tons per year). Ecuador is the main exporter and captures a substantial share of the global plantain trade. Colombia ranks fifth in global production, with the Dominican Republic achieving the highest yield worldwide at 21.7 tons per hectare. Africa accounts for approximately 60% of global plantain production, totaling around 24 million tons, followed by the Americas, which produce 27%, equating to 10.5 million tons.

In Colombia’s coffee-growing region of Quindío, there are around 30 plantain processing industries, which predominantly produce green and ripe plantain snacks, pre-cooked items, frozen products, and flours The plantain (Musa paradisiaca L.) is a cornerstone of Colombia’s agricultural economy, contributing approximately 0.4% to the nation’s Gross Domestic Product, ranking third after coffee and flowers According to the Colombian Banana Association -Augura-, cited by [13], the main variety cultivated is the “hartón”, followed by others that are linked to local and regional characteristics, such as “pelipita”, “dominico”, “cachaco”, “dominico hartón” and “popocho”.

2.2. Foresight

Foresight, as defined by [14], involves both preactive and proactive anticipation, which informs present actions by illuminating possible and desirable futures. This approach emphasizes the importance of preparing for anticipated changes, while still retaining the capacity to react in ways that can catalyze desired transformations. Furthermore, [15] suggests that technology foresight encompasses systematic efforts to not only identify emerging technologies, but also actions to address, in the near future, the volatilities and uncertainties of the sector.

One of the most widely utilized methods for conducting future studies is the Delphi Method. Named after the ancient Greek town of Delphi, known for its oracle through which predictions from the god Apollo were conveyed, the Delphi Method has become synonymous with forecasting [16,17]. This technique gathers relevant and direct information through consultations with experts, typically via questionnaires or interviews, to achieve a reliable consensus of opinions [18].

According to [19], the DM originated between the years 1940 and 1960, and its origins correspond to the work of the Corporation in Research and Development -RAND-, located in Santa Monica, United States. This method was, in its beginnings, applied to military exercises and, specifically, during the Cold War, in order to avoid possible war actions by the Soviet Union [21,22,23].

The original Delphi method (DM) was developed to address a specific problem for the US Air Force, focusing on forecasting military potential by consulting experts Since its inception, the DM has been applied across various sectors, regions, countries, and organizations worldwide, particularly in the domains of technology and innovation [24,25]. Over time, the method has evolved, with recent applications often aligning more closely with a “modified Delphi” approach. This version is characterized by guaranteeing anonymity, presenting options and carrying out a smaller number of rounds for analysis The DM collects expert assessments on trending topics that are related to different themes. Finally, and in order to contrast the information, at least two rounds are carried out using questionnaires [27].

In its classical form, the DM facilitates efficient communication among experts who remain anonymous to one another, thus enabling the resolution of complex problems Furthermore, [29] identifies four foundational principles of the method: 1. Anonymity of participants; 2. Iterative rounds of questioning; 3. Controlled feedback, allowing participants to critique each other’s judgments; and 4. Statistical aggregation of group responses, providing descriptive statistics of quantitative judgments after each round. This anonymity empowers each expert to contribute their judgments freely, involving two rounds of inquiry accompanied by corresponding comments. Experts receive statistical results from the first round, which inform their responses in the second round, gradually moving towards consensus [30,31].

For [32], the DM “poses a question and invites a highly qualified group of experts to offer their opinions or solutions, with the process carried out anonymously” (p. 32). McKinnon et al. (2001), cited in [17], pointed out that this method is interactive, since it appeals to a panel of experts, and constitutes a flexible element to reach consensus and seek solutions to the problems or sectors where it is applied [33].

DM, according to Leon and Montero (2006), cited in [26] and [34], is a data collection method that allows geographically dispersed experts to converge on a topic of interest and involves the application of questionnaires for decision making on complex issues. Fitch et al., 2001 and Hunter, 1995, cited in [35], emphasize that this is a method that facilitates a greater understanding of the issues addressed in research. DM identifies four key characteristics: interaction, anonymity, statistics and feedbackand [22] and [25].

Different authors mention a series of stages in the DM, which correspond to delimitation, document review, proposal of variables, sending and receiving responses for, in particular, the two rounds with their respective questionnaires, followed by statistical analysis and writing the final report The original DM overcomes discussions that do not lead to any result and structures the debate around the processes and procedures, among which the two rounds stand out and the results are always the product of consensus [37].

Modifications to the DM can be specific to the project or adapted to specific circumstances, given that it seeks to achieve results that are the product of consensus and not imposition (Turolf, 1975, cited in [38]). A notable distinction of the MDM is its typically reduced number of rounds; while the original DM often involves three or more rounds, the modified version usually conducts only two. This adjustment addresses several practical considerations: the Delphi process can be lengthy and costly for both researchers and experts, each phase demands significant time investment, and maintaining an acceptable response rate becomes increasingly challenging. By limiting the process to two rounds, the MDM helps sustain panelists’ interest, focusing on reaction to a topic rather than its initial generation and aiming for agreement rather than topic construction [26].

3. Materials and Methods

For this study it was necessary to apply different information gathering techniques, such as surveys, consultation with interest groups and comparison of results, based on secondary sources from specialized databases (Google Scholar and Scopus), as well as consultation of tertiary sources (reports, statistical documents, among others).

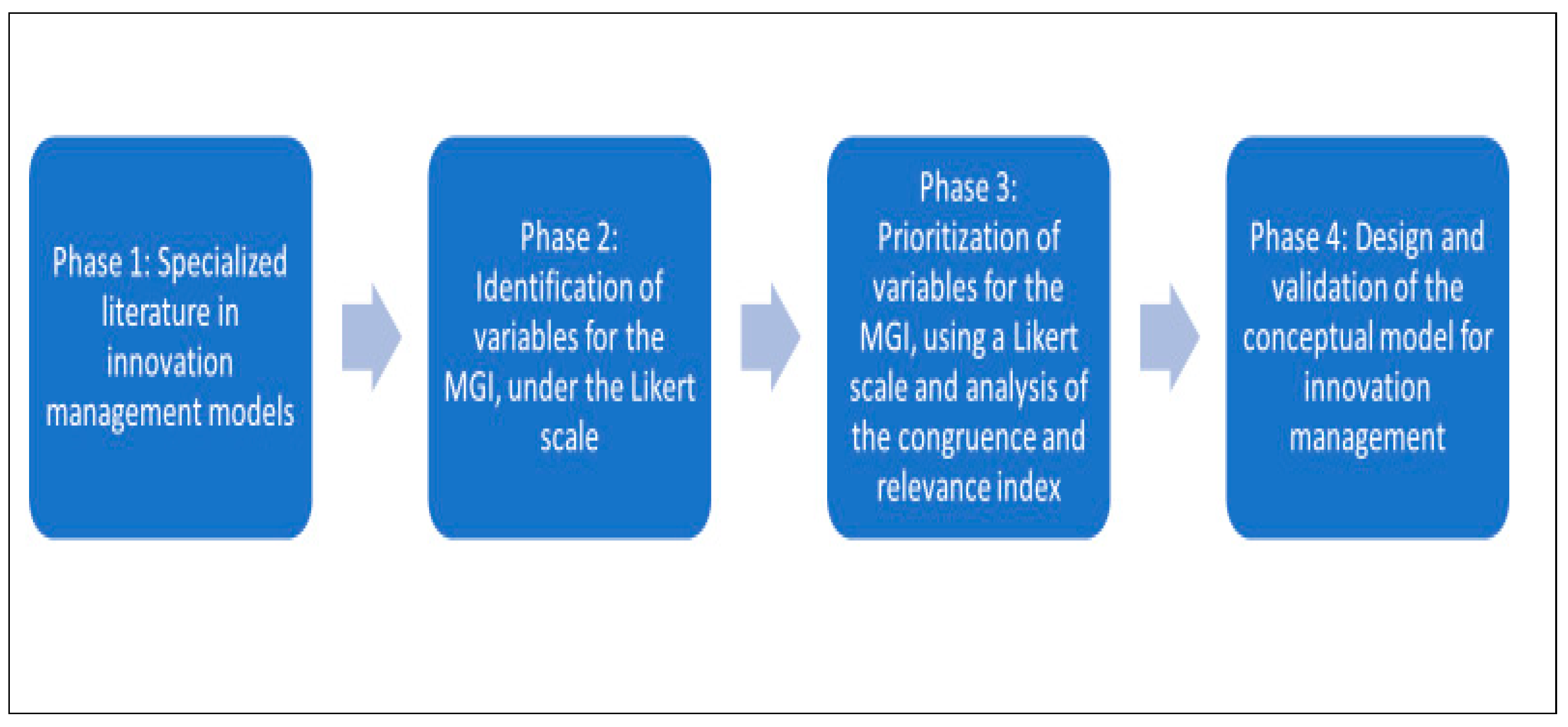

The methodological framework unfolds across four fundamental phases, which are meticulously detailed in the accompanying figure (see

Figure 3).

3.1. Phase 1: Specialized Literature

At this stage, a comprehensive review of management and innovation models was carried out with emphasis on the chain studied. The inquiry utilizes various academic databases, including Scopus and Google Scholar.

The search concentrated on innovation management models applicable to the plantain industry. For the review, the PRISMA protocol was used (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) This involved applying standardized steps that included defining research questions, establishing inclusion criteria, identifying information sources, outlining search strategies, executing selection processes, and evaluating the quality of the data obtained [40,41].

For this study, the following phases were proposed: the identification of Critical Monitoring Factors (CMFs), which encompass the proposed research questions, relevant descriptors or keywords, and the specific conditions of the study (see

Table 1).

Table 2 (Search equation applied in Scopus for the banana sector) presents the equations formulated from the review of specialized literature, which covers a range of articles related to innovation management models and broader innovation frameworks.This collection of information allows us to establish relevant variables essential for the formulation of innovation management models that are classified into three components: input, transformation and output.

Using the same keywords, additional searches were conducted on Google Scholar, which resulted in the following related articles (see

Table 3).

The search for articles pertaining to innovation management models and innovation frameworks yielded a total of 40 publications, of which 10 were found to be directly relevant to the study (see

Table 4).

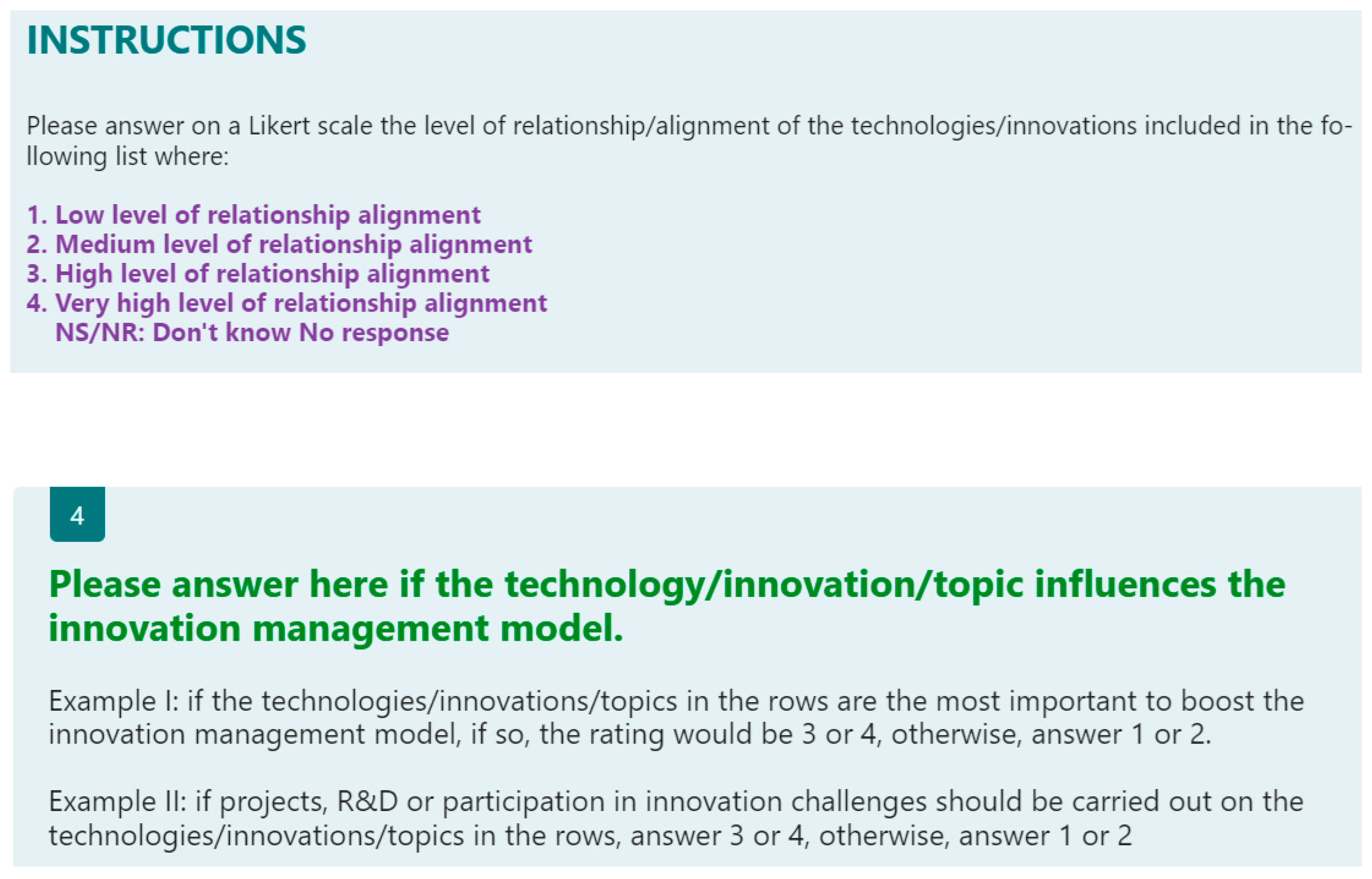

3.2. Phase 2: Identification of variables with Likert Scale

In this phase, the objective was to prioritize the variables identified for the innovation management model specific to the plantain sector through the application of a Likert scale. These variables were categorized into three groups: input, transformation, and output. This systematic approach enabled the identification of key variables deemed most significant by participants, thereby highlighting critical areas of focus within innovation management.

3.3. Phase 3: Prioritization of Variables for the IMM Using the Likert Scale and Analysis of Congruence and Relevance Indexes

The goal of this phase was to assess the relevance and coherence of questions pertaining to key variables in the innovation management model for the plantain sector, employing specific indexes for evaluation. Additionally, three conceptual graphic models were developed to visually represent the relationships and outcomes associated with these variables across different performance levels: excellent, good, average, and poor.

3.4. Phase 4: Development of the Proposal for the IMM Design

This final phase focused on selecting the most suitable IMM for the plantain sector, guided by the prioritization of variables identified in the previous phases. Efforts were made to align these prioritized variables within the chosen innovation management model to ensure effective and coherent implementation.

3.5. Selection of articles

Equation 1, which employed specific terms such as “innovation,” “model,” “plantain,” and “Musa,” retrieved 6 articles, all of which were highly relevant but focused on a more limited area of research. In contrast, Equation 2, with a broader focus on “innovation” and “management” in relation to plantains, yielded 60 articles, of which only 20 were relevant, indicating lower precision. Finally, Equation 3, utilizing more general terms and the operator “OR,” generated 29 articles, but only 6 were relevant, suggesting an even less precise search.

Additionally, the search conducted in Google Scholar using the keywords “innovation management models” and “innovation models” for the plantain sector produced a total of 40 articles, of which only 10 were directly related to the topic of interest.

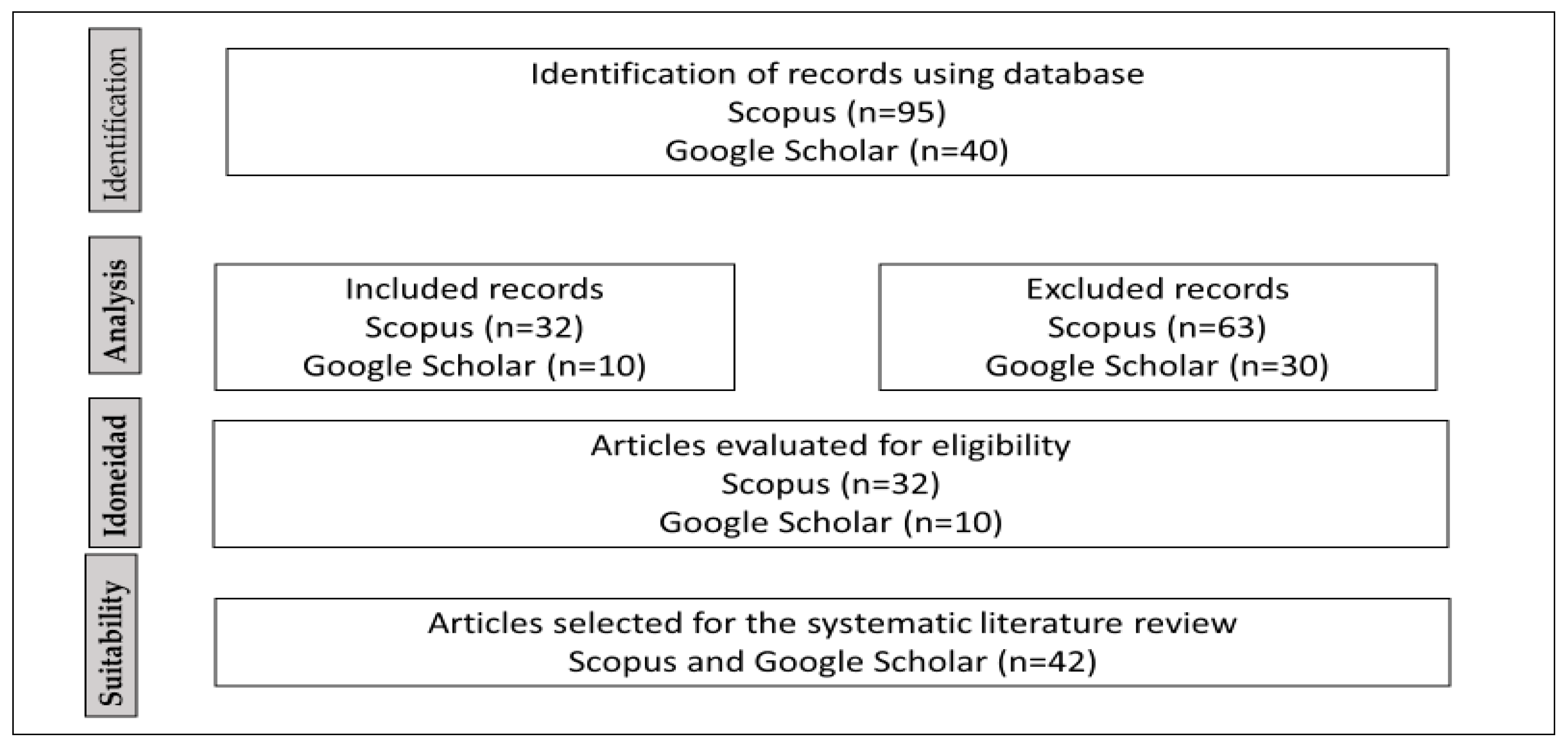

Below,

Figure 4 presents the PRISMA 2020 process flow to select the final documents.

4. Results

4.1. Phase 1

After selecting relevant articles, a review was conducted to define variables that could influence the development of the model. The analysis of the specialized literature yielded 32 Scopus articles, which provided useful variables for the banana sector. Among the key aspects identified were the authors, titles, variables or characteristics of the model, as well as the publications [42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63].

The interconnected complexity of the agricultural sector and the multiple facets influencing its development and sustainability were emphasized. Fundamental aspects such as entrepreneurial skills and sustainable models for agricultural capacity development emerged as essential foundations for enhancing efficiency and competitiveness. Both agricultural and technological innovations were identified as common threads.

The inclusion of social and gender variables highlighted the importance of ethical and equitable considerations in agricultural innovation. Variables related to research and development, along with market strategies, indicated the importance of a solid knowledge base and effective connections between farmers, institutions, and markets. The creation of prototypes and virtual experimentation illustrated the necessity for innovative and technological approaches to enhance farming practices. Additionally, business development initiatives and international collaborations, along with a focus on sustainable practices, consolidated a comprehensive vision for equitable, sustainable, and innovative agricultural development.

Conversely, the analysis of specialized literature in Google Scholar yielded 10 articles, recognizing similar aspects identified in Scopus [63,64]. The variables identified for the plantain sector within this database encompassed crucial dimensions for sustainable development, value chain efficiency, and innovative management. Government export policies, value addition, and quality were highlighted as key factors for international competitiveness. Comprehensive resource management emphasized the need for sustainable agricultural practices, while product diversification and social innovation sought new business opportunities through participatory approaches.

In the technological domain, the adoption of advances was deemed essential for enhancing agro-industrial efficiency. The human dimension—encompassing talent management and corporate social responsibility—was identified as crucial for the success of innovation and sustainable development. In agricultural innovation, practices related to crop management, new cultivars, and crop management systems were considered vital for addressing climate challenges. A variety of innovation approaches, including incremental, radical, and technological innovations, alongside creativity techniques, were noted as drivers of progress in the sector. Economic variables underscored the importance of the plantain agro-industry as a key engine for growth and employment. Social dimensions, such as social and environmental responsibility, social capital, and technology transfer, emphasized the need for ethical and community considerations in agricultural innovation. Collectively, these variables provide a comprehensive framework to guide strategies and policies toward effective development and innovation in plantain cultivation.

4.2. Phase 2

This section presents the analysis of results obtained from the initial survey, which included responses from six experts. The results were tabulated, and the following values were calculated: Winning-priority variables (mode 4 or 5 with consensus above the thematic group average), non-winning variables (mode 0, 1, or 2 with consensus above the thematic group), and variables under discussion (the remaining variables).

With respect to the variables collected during the input phase for the plantain sector, the data were organized (see

Table 5), where the results obtained from the surveys carried out on the experts are presented, with a total of 27 variables evaluated.

For the results obtained in the transformation phase, the data is presented in

Table 6, which displays the outcomes achieved through the surveys conducted with the experts.

Following the analysis of the experts’ responses, a significant consensus emerged regarding the key variables for the innovation management model. Specifically, the production process, value-added transformation, value chain, and market validation achieved a consensus level of 50%. Additionally, there was notable interest in methodologies such as Design Thinking, Lean processes, and Agility, which garnered support from 40% of participants. These findings provide a robust foundation for defining and prioritizing variables within the innovation management model.

The data related to the variables identified in the output phase is presented in

Table 7. In total, 19 variables were evaluated based on the technical expertise of the participating experts.

The analysis indicates a strong consensus among experts regarding several critical variables for the innovation management model, each receiving a support level of 50%. These key variables include competitive advantages, know-how, value creation, environmental impact and sustainability, quality, and performance. This agreement underscores the equal significance attributed to these dimensions in the context of innovation management.

The next step involved formulating specific questions for each prioritized variable, followed by the administration of a survey to assess the relevance and coherence of these variables. The final phase included the construction of three conceptual models, which were presented for approval during the second workshop focused on co-developing the management model design proposal. This comprehensive methodological approach facilitated a thorough and participatory evaluation, ensuring the selection of the most suitable model for innovation in the plantain sector.

4.3. Phase 3

After determining the relevant variables, a second tool was developed, referred to as “definitive variables for the model,” drawing on various authors [64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82]. In this stage, each input, transformation and output variable was evaluated and questions were asked to clarify the priorities relevant to the companies or institutions in which the experts operate.

4.4. Phase 4

4.4.1. Proposed First Innovation Management Model: Linear

The proposed analytical model adopts a linear approach, structured sequentially to clearly illustrate the roles of the variables in the input, transformation, and output processes of innovation management within the plantain sector.

In the context of the first Innovation Management Model (IGM 1), the input variables constitute the foundation of the innovation management process, encompassing essential aspects necessary for initiating transformation. The input variables include: idea management and creativity, leadership, financial and human resources, facilities, types of innovation, competitiveness, engagement, capacity building, innovation management systems, Agriculture 4.0 and/or 5.0, agroecology, technological change, innovation management models, compliance with government policies and regulations, technological development and key technologies, management functions and strategic direction, customer and consumer demand, benchmarking, product quality, organizational innovation, innovation culture and climate, product innovation, technological and competitive intelligence, compliance with Sustainable Development Goals, food security, information and communication technologies, and the circular economy.

The input variables undergo transformation and evolution throughout the innovation process, facilitating technological development and manufacturing while also contributing to the commercialization of services. At this stage, key factors such as the production process, value-added transformation, design thinking, lean processes, agility, value chain management, and market validation become integral to the model.

The output variables include competitive advantages, acquired knowledge (know-how), value creation, technological capability and intellectual property, environmental impact and sustainability, as well as quality and performance metrics. Additionally, the outputs encompass economic and commercial impacts, strategic and organizational advancements, innovations in quality and sustainability, improvements in operational efficiency, customer satisfaction, brand image, organizational resilience, and access to new markets.

Furthermore, they reflect enhancements in the supply chain, the development of new capabilities, adaptation to environmental changes, compliance with regulations, participation in innovation networks, and various financial and business outcomes.

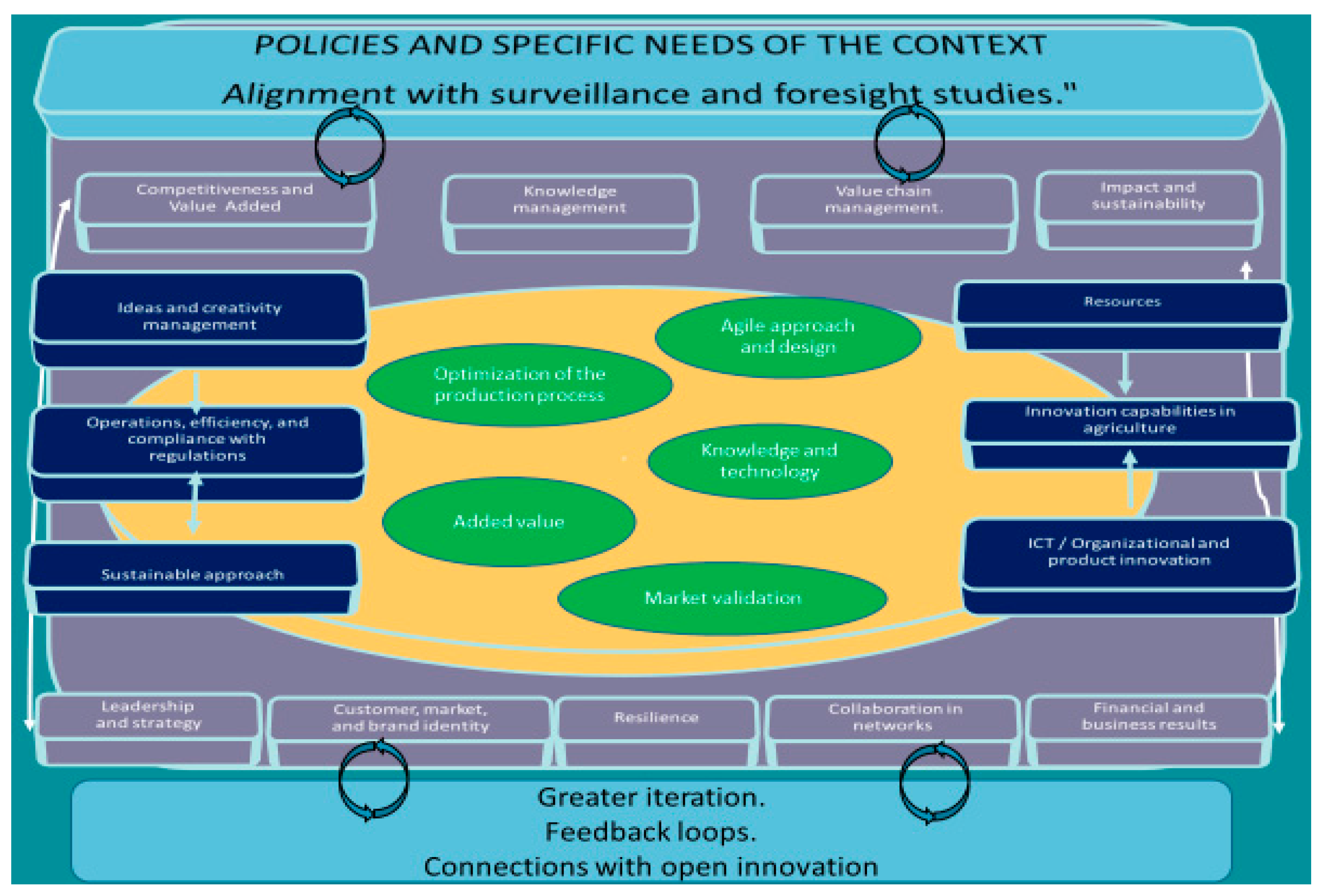

4.4.2. Proposed Second Innovation Management Model: Generic-Interactive

The review and adaptation of the second generic-interactive model for organizations in the plantain sector enabled a more precise and contextually relevant structuring of the variables. The first relationship connects the variables with policies and contextual needs. And the second highlights the interaction between input and transformation variables, while the third relationship underlines the integration of policies and contextual needs with variables that receive significant feedback.

In the contributions of the second Innovation Management Model (IGM 2), the input variables encompass essential factors, resources, and initial conditions necessary to initiate the innovation management process. This phase emphasizes elements such as idea management, leadership, as well as the principles of Agriculture 4.0 and/or 5.0. These foundational components set the stage for innovation within the plantain sector.

The transformation phase involves elements that undergo modifications or developments throughout the innovation management process. Key aspects in this phase include the production process, value-added transformation, design thinking, and market validation, highlighting the evolution and adaptation of critical variables. Finally, the output variables represent the results, impacts, and achievements derived from the implementation of innovative initiatives. These outputs range from competitive advantages and acquired knowledge to enhancements in operational efficiency, organizational resilience, and participation in innovation networks, collectively demonstrating the comprehensive impact of innovation management in the plantain sector.

4.4.3. Proposed Third Innovation Management Model: Strategic Alignment and Innovation

The third proposal (see

Figure 5) introduces a model of strategic alignment and innovation, advocating for a more effective integration of the various phases of the innovation process. This model considers specific policies and contextual needs, aligning with studies on monitoring and foresight.

The model’s foundation rests on the interlocking of variables within each process associated with innovation management, illustrating a deep understanding of the necessary interconnections among key elements.The inherent flexibility of each process allows for the sequential development of variables, adapting to the unique characteristics and objectives of the specific organization in which it is implemented. This adaptable approach offers a strategic advantage by aligning with the distinct policies and needs of each organizational context.

In the context of the third Innovation Management Model (IGM 3), it is posited that the identified input variables constitute a comprehensive array of factors, resources, and initial conditions critical for initiating the innovation management process. In contrast, the transformation variables not only serve as foundational inputs but also adapt and evolve as the organization advances its innovation strategy. The output variables, therefore, effectively encapsulate the tangible and intangible results, impacts, and achievements that stem from the innovation process.

The incorporation of clear definitions concerning the classification of variables based on their roles within the innovation process significantly bolsters the analytical rigor of this proposal. This conceptual clarity not only enhances comprehension of the proposed model but also lays a solid groundwork for its practical implementation and subsequent evaluation. IGM 3 presents an adaptive framework that regards these variables as interconnected elements within a dynamic process, thereby offering the potential to refine innovation management practices and yield outcomes.

Moreover, by underscoring the interdependence of input, transformation, and output variables, the model advocates for a holistic approach to innovation management. Such a perspective cultivates a culture of continuous improvement and fosters responsiveness to emerging challenges and opportunities within the plantain sector. By aligning innovation strategies with organizational objectives, IGM 3 aspires to enhance both operational efficiency and competitive advantage, ultimately contributing to the sustainable growth of the industry.

5. Discussion

This section is structured around two primary axes of discussion. Axis 1 pertains to the proposal of the Innovation Management Model (IGM) within the plantain sector, contextualized through a comparison with foresight and open innovation frameworks. Axis 2 examines the alignment of key themes and technologies emerging from a prospective study of the plantain agro-industrial chain up to 2035. This latter axis underscores the significance of sustainability variables and their interplay with the chosen IGM as perceived by stakeholders within the chain.

5.1. Axis 1

Given the critical role of industrial agro-chains in socio-economic contexts, numerous prospective studies have emerged within agro-industry to monitor and forecast trends and scenarios specific to various production chains Notably, the prospective analyses conducted by Grass Ramírez et al. on coconuts [87] and by Hincapié et al. related to the fishing agro-industry [91] serve as vital frameworks for organizations and policymakers to discern trends, guide decision-making, mitigate sector-specific uncertainties, and align strategies with available capacities and resources.

The literature review indicates a paucity of significant references in the scholarly discourse regarding IGM specifically tailored for the plantain agro-industrial chain. For instance, a preliminary search in the Scopus database under the themes of foresight and the plantain agro-industrial chain revealed only one document, which, while relevant, did not align with the focus of this study. This document [86] addressed the recycling of low-value residual materials and explored the prospective applications of agro-industrial by-products in unconventional construction materials aimed at reducing housing costs.

A second search criterion within the same database focusing on foresight and agro-industrial chains yielded four relevant documents. The first, authored by [87], involved a foresight study on coconuts (Cocos nucifera), aimed at identifying pertinent technologies. This study utilized the Delphi method across two rounds to prioritize these innovations, supplemented by technological monitoring through literature reviews and commercial surveillance.

Other study, conducted by [88], examined fertilizers as essential inputs within agro-industrial chains. The authors suggested that strategic alliances could mitigate risks associated with price volatility and supply chain stability. A third article is a prospective analysis of the impact of the pandemic on the food industry in Italy, arguing that this unprecedented crisis might catalyze efforts toward greater sustainability in food systems, as framed by the European Green Deal Lastly, a fourth article by [90] performed a forecasting exercise for the Ministry of Agriculture of the Russian Federation, identifying key trends impacting supply and demand within the agriculture and food industry, thus providing actionable insights for policymakers.

In relation to the IGM for plantains and open innovation models, existing studies and application cases suggest valuable contributions, particularly regarding best practices for stakeholder engagement. However, the literature addressing IGMs within the plantain sector remains limited. An intentional review of databases revealed that investigations into IGMs and their integration with open innovation models are often confined to specific themes, rather than encompassing the broader agro-industrial chain. For instance, research by [92] explored local open innovation frameworks as mechanisms for enhancing collaboration among small and medium enterprises (SMEs). The authors concluded that diverse open innovation models should be employed to foster regional development across various contexts. Similarly, [93] examined the multifaceted nature of open innovation, contrasting it with internal or closed innovation models, each presenting unique benefits and challenges.

The open innovation paradigm promotes collaboration among a diverse array of stakeholders, enabling the flow of knowledge both within and beyond organizational boundaries. This approach is particularly advantageous in agro-industrial sectors, such as plantains, which rely heavily on the integration of local, scientific, and technological knowledge. Open innovation, therefore, facilitates the adoption of sustainable technologies and practices by fostering active participation from farmers, research institutions, and private enterprises. Its primary strength lies in its inherent flexibility and adaptability to the specific challenges faced by the agro-industrial chain, including genetic enhancement, pest management, and environmental sustainability.

In contrast, linear innovation models, such as those proposed by [94], present a more rigid perspective on the innovation process, characterized by a unidirectional flow from basic research to commercial application. While this approach has significantly advanced technological innovations across various sectors, its applicability in the agro-industrial context may be constrained. Given the plantain sector’s dependence on climatic and social variables, a more flexible, iterative approach is essential for facilitating rapid responses to both local and global challenges. In conclusion, although linear models offer foundational insights for innovation, the complexity and dynamism inherent in the plantain agro-industrial chain necessitate the adoption of more flexible frameworks. These models not only enhance adaptability to localized conditions but also promote collaboration among various actors, ultimately leading to improved sustainability and long-term success.

The discussions highlighted in the aforementioned studies reveal that, while the themes explored are pertinent, they do not directly correlate with the findings of this study, particularly as they have not been specifically applied to the plantain agro-industrial chain, which is central to the proposed IGM methodology involving stakeholders connected to the chain.

5.2. Axis 2

Within the framework established by the Colombian Ministry of Science and the General Royalty System, the development of the Innovation Management Model (IGM) utilized the Delphi method as a prospective tool to 2035, informed by consultations with industry experts and stakeholders [95,96,97]. This approach involved soliciting feedback from actors within the agro-industrial chain to identify and prioritize themes and technologies that could serve as focal points for forthcoming projects, open innovation challenges, funding initiatives, and public policies relevant to the plantain sector. The Delphi study, conducted in two rounds and involving 27 experts, culminated in the identification of 64 themes and priority technologies, which were categorized into several domains: plantain varieties, plantain agro-industry, waste recycling, cultivation, research capacities, emerging opportunities, nutritional aspects, and genetics. Subsequently, a survey was administered to the same 24 actors who participated in the initial project, yielding four valid responses that aligned these 64 priority themes and technologies with the proposed innovation management model (See

Figure 6).

The results from the Delphi 2035 study identified 23 themes and technologies with a notable degree of alignment to the Innovation Management Model (IGM). Key areas of focus concerning environmental impact and sustainability included biodegradable packaging, climate change adaptation, and food security. In relation to Information and Communication Technologies (ICT), the pertinent variable identified was “ICT for commercial activities associated with the Hartón plantain” Furthermore, the variables aligned within the innovation management process included: characterization of banana-based flours, use of native, resistant and modified starches derived from banana, application of banana cellulose and functional foods.

When compared to previous studies, such as that conducted by [98], which delineated 11 priority themes/technologies up to 2032 without reference to an innovation management model, the results of this research offer a novel opportunity for stakeholders in the agro-industrial chain. Our findings provide direct inputs to models of innovation processes and management that have been previously underrepresented in the literature.

A similar lack of alignment with innovation management models is evident in earlier studies of agro-industrial chains [87,97,98,99,100,101,102,103], which, while identifying priority themes and technologies for future horizons, failed to serve as inputs for innovation management frameworks within agro-industrial enterprises.

6. Conclusions

The application of DM and the information gathering techniques used allow us to propose a tailored Innovation Management Model (IM) for the banana sector, called IM 3. This process involved identifying pertinent variables through a comprehensive bibliographic analysis, leading to the selection of 53 input variables, 36 transformation variables, and 31 output variables. This structured methodology serves as a guide to enhance innovation and technology within organizations in the sector, promoting the generation of novel ideas and strategies.

The alignment of the 23 identified themes and technologies with the IGM will empower stakeholders in the supply chain to initiate new projects, innovate products and processes, and create opportunities for open innovation. This approach enables solvers from diverse regions and countries to contribute solutions that integrate innovative practices for the benefit of the sector. These themes and technologies are intricately related to the three core variables of the model: optimization of the production process, knowledge and technology acquisition, agile methodologies, market design/validation, and value addition. They also correlate with other variables within the innovation management model, including a sustainable focus, impact and sustainability metrics, ICT integration, idea management and creativity, operational efficiency, and regulatory compliance.

The identification of priority variables reveals potential gaps in leadership capacity, strategic resource allocation, agricultural innovation, market competitiveness, ICT integration, regulatory compliance, and resilience within collaborative networks. These gaps may adversely affect creativity, innovation, and sustainability within the plantain sector.

In this context, Proposal 3 introduces an IGM that effectively integrates various phases of the innovation process, considering specific policies and contextual needs while aligning with surveillance and foresight studies. This model emphasizes open innovation throughout its formulation and implementation, facilitating dynamic feedback among input, transformation, and output variables. Input variables such as creativity management and strategic leadership form the foundation for fostering innovation in the plantain sector, while transformation variables, including production process optimization, drive continuous improvement and competitive advantage. Output variables, such as enhanced competitiveness and the adoption of innovative technologies, reflect the positive outcomes achieved, demonstrating a substantial impact on the sector’s sustainable development.

The relevance of the selected IGM for the Colombian plantain agro-industrial sector lies in its potential to transform a traditionally unsustainable industry into a more sustainable and competitive one. It is crucial for both public and private stakeholders to collaborate in overcoming existing barriers and nurturing an innovation culture focused on sustainability. The variables identified in this study are directly linked to the central variable of the business model: sustainable development, and should align with other relevant variables related to R&D.

Developing an innovation management model for plantain cultivation in Colombia is fraught with challenges due to the complexity of the agricultural sector, the specific characteristics of the crop, and the prevailing socioeconomic conditions. Challenges include limited access to cutting-edge technology and knowledge, sustainability and environmental management issues related to the intensive use of agrochemicals and deforestation practices, fragmentation and lack of coordination within the production chain, difficulties in accessing financing, climate change and variability, a deficit of an innovation culture, and inadequate regulatory frameworks.

A comprehensive approach combining government support, collaboration between value chain actors and the development of sustainable technologies is needed to stimulate innovation in the Colombian plantain sector.

7. Recommendations

Application within Sector Companies: Focus on enhancing competitiveness and value addition, essential for achieving financial and commercial success.

Adaptation to Sector Characteristics: Tailor the IM to the specific attributes of the plantain industry, fostering collaboration among value chain actors while promoting environmental and economic sustainability.

Encouragement of Advanced Technology Adoption: Facilitate the integration of advanced technologies and develop the requisite capacities for their effective implementation.

Monitoring and Evaluation Mechanisms: Establish systems to evaluate the proposed model and make any required adjustments.

Indicators for Measuring Impact: Identify and incorporate indicators that measure benefits and impacts, including comprehensive risk and financial analyses.

Open Innovation Approach: Embrace a collaborative model that engages various sources of innovation and integrates them into business processes.

Technological Surveillance and Foresight Studies: Conduct ongoing surveillance and foresight analyses to anticipate opportunities and threats, thereby enhancing strategic planning, promoting innovation, and improving competitiveness.

For effective implementation of the proposed IM in the plantain sector, organizations should also consider:

Alignment with Business Strategy: Ensure that the IM is aligned with the organization’s long-term objectives to maximize its relevance and impact.

Resource Allocation: Allocate appropriate financial and human resources to support both the implementation and ongoing operation of the IM.

Progress Monitoring Systems: Develop effective systems for monitoring and evaluating the results achieved through the model, allowing for timely adjustments.

Cultivation of an Innovative Culture: Promote a culture that values innovation and continuous learning, empowering employees to actively engage in the transformation process.

Effective Communication Mechanisms: Establish strong communication and collaboration frameworks, both internally and with external partners, including universities and government entities, to fully leverage opportunities for synergy.

Holistic Approach: Adopt a comprehensive strategy that encompasses training, strategic alignment, innovation culture, and effective collaboration with stakeholders.

Author Contributions

Conceptualization, Luis Horacio Botero Montoya, Julio González Candia and Jhon Wilder Zartha Sossa; methodology, data curation: Nolberto Gutiérrez Posada and Adriana Maria Zuluaga Monsalve; software, investigation, writing—review, Julio González Candia, Gina Lia Orozco Mendoza; validation, Luis Fernando Gutiérrez Cano and José Orlando Gómez Salazar; formal analysis, Jhon Wilder Zartha Sossa; investigation, Luis Fernando Gutiérrez Cano, writing—original draft preparation, Jhon Wilder Zartha Sossa y Luis Horacio Botero Montoya.; writing—review and editing, Jhon Wilder Zartha Sossa. All authors have read and agreed to the published version of the manuscript.”.

Conflicts of Interest

“The authors declare no conflicts of interest.”

References

- Medina, M. “Durante 2023 exportamos 14,1 millones de cajas de banano y 770.000 de plátano”. 2024, 6 de febrero. La República. Recuperado de el 28 de agosto de 2024 de. Available online: https://www.larepublica.co/empresas/entrevista-con-victor-manuel-enriquez-principal-gestor-del-grupo-greenland-hablo-de-las-proyecciones-de-la-compania-3795117#:~:text=La%20industria%20agroindustrial%2C%20adem%C3%A1s%20de,770.000%20de%20pl%C3%A1tano%20durante%202023.

- Unidad de Producción Rural Agropecuaria -UPRA- Informe del sector agropecuario colombiano. 2021. Recuperado el 28 de agosto de 2024 de. Available online: https://upra.gov.co/es-co/Paginas/quienes-somos.

- Ministerio de Agricultura. Cadena del Plátano. Dirección de Cadenas Agrícolas y Forestales. 2021. Recuperado el 28 de agosto de 2024 de. Available online: https://sioc.minagricultura.gov.co/Platano/Documentos/2021-06-30%20Cifras%20Sectoriales.

- Asohofrucol, Informe sobre exportaciones de plátano. 2024. Recuperado el 28 de agosto de 2024 de. Available online: https://asohofrucol.com.

- Rojas, J. J. B. , Cano, J. A., & Giraldo, M. D. Apertura económica y política comercial: estudio del sector lácteo y sus dificultades en Colombia. Revista Venezolana de Gerencia: RVG 2020, 25, 846–868. [Google Scholar]

- [6]. de Morais, J. P. G., Campana, M., Del Valle, T. A., Moreira, T. G., da Silva, E. D. R., do Prado, R. F., & de Oliveira, R. E. Inclusion of babassu bran produced in milk production in Amazonia. Tropical Animal Health and Production 2021, 53, 527. [Google Scholar] [CrossRef]

- Dernat, S. , Etienne, R., Hostiou, N., Pailleux, J.Y., Rigolot, C. Consecuencias ex post de los procesos de prospectiva participativa en la agricultura. ¿Cómo ayudar a los productores de leche a afrontar los resultados de la planificación de decisiones colectivas? 2022. [CrossRef]

- Martinelli, R. R. , Damasceno, J. C., de Brito, M. M., da Costa, V. D. V., Lima, P. G. L., & Bánkuti, F. I. Horizontal collaborations and the competitiveness of dairy farmers in Brazil. Journal of Co-operative Organization and Management 2022, 10. [Google Scholar] [CrossRef]

- Bianchi, A. E. , Reichen, C., Borges, L. I., Santos, J. G. R., Rudek, L.. dos S., Fernandes, S. R., Morais, O. R. de, & Monteiro, A. L. G. Análise estratégica da cadeia produtiva de leite ovino no Brasil: uma abordagem pela metodologia SWOT. Semina: Ciências Agrárias 2023, 44, 971–988. [Google Scholar] [CrossRef]

- Congreso de la República de Colombia (Ley 811 (junio de 2003). Cadenas productivas. Bogotá D.C. 2003. Recuperado el 30 de mayo de 2024 de https://www.minambiente.gov.co/wp-content/uploads/2021/06/ley-811-2003.

- Londoño, A. , Rey, R., y Pérez, M. Risaralda Territorio Agroindustrial, 1a Ed., 2016. Pereira, Risaralda, Colombia.

- Mahecha-Vásquez, G. , Sierra, S., & Posada, R. Índices de diversidad utilizando hongos micorrízicos arbusculares para evaluar el estado del suelo en cultivos de banano en Colombia. Applied Soil Ecology 2017, 109, 32–39. [Google Scholar] [CrossRef]

- Giraldo-Gómez, G. I. , Rodríguez-Barona, S., & Sanabria-González, N. R. Preparation of instant green plantain flour powders by an extrusion process. Powder Technology 2019, 353, 437–443. [Google Scholar] [CrossRef]

- Godet, M. , & Durance, P. Prospectiva Estratégica: problemas y métodos. Cuadernos de LIPSOR 2007, 104, 169–187. [Google Scholar]

- Martin, B. R. Foresight in science and technology. Technology analysis & strategic management 1995, 7, 139–168. [Google Scholar] [CrossRef]

- Landeta, J. Current validity of the Delphi method in social sciences. Technological forecasting and social change 2006, 73, 467–482. [Google Scholar] [CrossRef]

- Wakefield, R. , & Watson, T. A reappraisal of Delphi 2.0 for public relations research. Public Relations Review 2014, 40, 577–584. [Google Scholar] [CrossRef]

- Tello, M. , & Miklos, T. Planeacion prospectiva” Una estrategia para el diseño del futuro. 2007, México Limusa.

- Nielsen, C. , & Thangadurai, M. Janus and the Delphi oracle: Entering the new world of international business research. Journal of International Management 2007, 13, 147–163. [Google Scholar] [CrossRef]

- Dalkey, N. , & Helmer, O. An experimental application of the Delphi method to the use of experts. Management science 1963, 9, 458–467. [Google Scholar] [CrossRef]

- Fletcher, A. J. , & Marchildon, G. P. Using the Delphi method for qualitative, participatory action research in health leadership. International Journal of Qualitative Methods 2014, 13, 1–18. [Google Scholar] [CrossRef]

- Rowe, G. , & Wright, G. The Delphi technique as a forecasting tool: issues and analysis. International journal of forecasting 1999, 15, 353–375. [Google Scholar] [CrossRef]

- Linstone, HA y Turoff, M. (Eds.). El método Delphi, A: 1975. Reading, MA, 1975.

- Duin, P. A. Qualitative futures research for innovation. 2006. Eburon Uitgeverij BV.

- Castelló, M. and Callejo, J. “La prospectiva tecnológica y sus métodos, Observatorio de prospectiva científica y tecnológica de Argentina – SeTCIP”. 2000.

- [26] Cabero, J. “Formación del profesorado universitario en tic. Aplicación del método Delphi para la selección de los contenidos formativos”. 2013, 17, 21. [Google Scholar] [CrossRef]

- Auvinen, H. , Tuominen, A., & Ahlqvist, TTowards long-term foresight for transport: envisioning the Finnish transport system in 2100. Foresight 2012, 14, 191–206. [Google Scholar] [CrossRef]

- Nazarko, J. , Radziszewski, P., Dębkowska, K., Ejdys, J., Gudanowska, A., Halicka, K, …& Vilutienė, T. Foresight study of road pavement technologies. Procedia Engineering 2015, 122, 129–136. [Google Scholar] [CrossRef]

- Santos, C. , Araújo, M., & Correia, N. A methodology for the identification of strategic technological competences: An application in the sheet metal equipment industry. Futures 2017, 90, 31–45. [Google Scholar] [CrossRef]

- Huang, W. C. , & Lee, Y. Y. Strategic planning for land use under extreme climate changes: A case study in Taiwan. Sustainability 2016, 8, 53. [Google Scholar] [CrossRef]

- Chen, M. , & Lv, J. H. Research on Advanced Manufacturing Technology Foresight of Chinese Furniture Industry. In Informatics and Management Science I. 2013, pp. 243–249. Springer London.

- Abend, J. Innovation Engines, International Publication Patent Number:WO02/19597 A2. 2002.

- Helmer, O. , & Rescher, N. Sobre la epistemología de las ciencias inexactas. Management science 1959, 6, 25–52. [Google Scholar]

- Fitch, K. , Bernstein, S. J., Aguilar, M. D., Burnand, B., LaCalle, J. R., Lazaro, P.,... & Kahan, J. P. (RAND/UCLA appropriateness method user’s manual. 2000, Santa Monica, CA: RAND corporation.

- Debin, M. , Souty, C., Turbelin, C., Blanchon, T., Boëlle, P. Y., Hanslik, T.,... & Falchi, A. Determination of French influenza outbreaks periods between 1985 and 2011 through a web-based Delphi method. BMC Medical Informatics and Decision Making 2013, 13, 1–8. [Google Scholar] [CrossRef]

- Cancelo, M.J. , Neyro, J.L. and Baquero, J.L “Probiotics as adjuvant therapy for vaginitis”, Agreement Based on the Delphi Method. Progresos de Obstetricia Y Ginecologia. . [CrossRef]

- Gordon, T. and Helmer, O. Report on a Long – Range Forecasting Study, The RAND Corporation. 1964, pp. 1–71. [CrossRef]

- Zeedick, D. M. The modified delphi method to analyze the application of instructional design theory to online graduate education. The George Washington University. 2012.

- Zartha Sossa, J. W. , Orozco Mendoza, G. L., Álvarez Ríos, V. T., Palacio Piedrahíta, J. C., Muñoz Castaño, Y., & Cano Díaz, V. E. Modelos de gestión de la innovación en agronegocios. 2019. Recuperado el 26 de julio de 2024 de. Available online: https://repository.upb.edu.co/bitstream/handle/20.500.11912/4556/Modelos%20de%20gestion%20de%20la%20innovaci%c3%b3n%20en%20agronegocios.pdf?

- Moher, D. , Liberati, A., Tetzlaff, J., Altman, DG y Prisma, G. Ítems de referencia para publicar sistemáticamente y metaanálisis: la Declaración PRISMA. Revista Española de Nutrición Humana y Dietética 2014, 18, 172–181. [Google Scholar] [CrossRef]

- Page, MJ, McKenzie, JE, Bossuyt, PM, Boutron, I. , Hoffmann, TC, Mulrow, CD,... & Alonso-Fernández, S. Declaración PRISMA 2020: una guía actualizada para la publicación de revisiones sistemáticas. Revista española de cardiología 2021, 74, 790–799. [Google Scholar]

- Mudyazvivi, E. , & Maunze, S. Developing Viable Business with Smallholders through Local Service Providers-the Case of Plantain (Musa spp.) Value Chain Development in Zimbabwe. In IV International Symposium on Plantain: International Conference on Plantain and Plantain in Africa: Harnessing International 2008, 879 (pp. 773-779). https://www.actahort.org/books/879/879_84.

- [43]. Ogunlade, I., & Coulibaly, O. A proposal for the use of the partnership-extension model to facilitate adoption of the International Institute of Tropical Agriculture’s plantain and plantain (Musa spp.) technologies in Nigeria. In IV International Symposium on Plantain: International Conference on Plantain and Plantain in Africa: Harnessing International. 2008, 879, pp. 791–796) https://wwwactahortorg/books/879/879_86htm.

- Blazy, JM, Tixier, P. , Thomas, A., Ozier-Lafontaine, H., Salmon, F. y Wery, J. BANAD: Un modelo agrícola para la evaluación ex ante de innovaciones agroecológicas y su aplicación a las explotaciones bananeras en Guadalupe. Sistemas Agrícolas 2010, 103, 221–232. [Google Scholar] [CrossRef]

- Blazy, J. M. , Dorel, M., Salmon, F., Ozier-Lafontaine, H., Wery, J., & Tixier, P. Model-based assessment of technological innovation in plantain cropping systems contextualized by farm types in Guadeloupe. European Journal of Agronomy 2009, 31, 10–19. [Google Scholar] [CrossRef]

- Tixier, P. , Malézieux, E., Dorel, M. y Wery, J. SIMBA, un modelo para el diseño de sistemas de cultivo sustentables a base de banano. Sistemas Agrícolas 2008, 97, 139–150. [Google Scholar]

- Faturoti, B. O. , Emah, G. N., Isife, B. I., Tenkouano, A., & Lemchi, J. Prospects and determinants of adoption of IITA plantain and plantain-based technologies in three Niger Delta States of Nigeria. African Journal of Biotechnology, 4310. [Google Scholar]

- Staver, C. , Mora, G. , Coria, J. J., Guzmá n, E., Flores, O. E., Acevedo, G.,... & Arias, M. Ma $ Banano: an app to leverage data from smallholder organic export plantain for continual improvement. In XXXI International Horticultural Congress (IHC2022): XII International Symposium on Plantain: Celebrating Plantain Organic 2022, 1367, 299–306. [Google Scholar] [CrossRef]

- Bezard, M. , Barlagne, C., Diman, J. L., Angeon, V., Morin, R., Ozier-Lafontaine, H., & Andrieu, N. Co-designing innovative plantain cropping systems to support the diversity of agroecological pathways in Guadeloupe. Agronomy for Sustainable Development 2023, 43, 28. [Google Scholar]

- Coral, C. , & Mithöfer, D. The backbone of agrifood value chain resilience: Innovation in the Ecuadorian plantain value chain from a historical perspective. World Development Perspectives 2023, 29, 100476. [Google Scholar] [CrossRef]

- Burgos, J. B. , Orellana, A. R., Sasi, L. B., & Vásquez, J. C. Ciclo de vida de empresas bananeras familiares y no familiares en Ecuador: modelo de ecuaciones estructurales. Revista de ciencias sociales 2023, 29, 332–354. [Google Scholar]

- Abdoussalami, A. , Hu, Z., Islam, A. R. M. T., & Wu, Z. Climate change and its impacts on plantain production: a systematic analysis. Environment, Development and Sustainability, /: https, 1007. [Google Scholar]

- Vázquez-Euán, R. , Chi-Manzanero, B., Hernández-Velázquez, I., Tzec-Simá, M., Islas-Flores, I., Martínez-Bolaños, L.,... & Canto-Canché, B. Identification of new hosts of pseudocercospora fijiensis suggests innovative pest management programs for black sigatoka disease in plantain plantations. Agronomy 2019, 9, 666. [Google Scholar]

- Iradukunda, F. , Bullock, R., Rietveld, A., & van Schagen, B. Understanding gender roles and practices in the household and on the farm: Implications for plantain disease management innovation processes in Burundi. Outlook on Agriculture 2019, 48, 37–47. [Google Scholar]

- Tinzaara, W. , Ocimati, W. , Kubiriba, J., & Karamura, E. Ecologically sustainable technologies for management of highland plantain pests in East and Central Africa. In X International Symposium on Plantain: ISHS-ProMusa Symposium on Agroecological Approaches to Promote Innovative Plantain 2016, 1196, pp. 105–112 https://wwwactahortorg/books/1196/1196_12htm. [Google Scholar]

- Pattison, A. B. , East, D. , Ferro, K., & Dickinson, G. Agronomic consequences of vegetative groundcovers and reduced nitrogen applications for plantain production systems. In X International Symposium on Plantain: ISHS-ProMusa Symposium on Agroecological Approaches to Promote Innovative Plantain 2016, 1196, pp. 155–162 https://wwwactahortorg/books/1196/1196_18htm. [Google Scholar]

- Tinzaara, W. , Karamura, E. B., Kubiriba, J., Ochola, D., Ocimati, W., Blomme, G., & Ssekiwoko, F. The plantain Xanthomonas wilt epidemic in east and central Africa: current research and development efforts. In XXIX International Horticultural Congress on Horticulture: Sustaining Lives, Livelihoods and Landscapes (IHC2014): IX 1114, 2014, pp. 267–274. [Google Scholar] [CrossRef]

- Egyir, Irene & Owusu-Bennoah, Emmanuel & Anno-Nyako, F.O. & Banful, Ben. An analysis of the agricultural science, technology and innovation system for plantain (Musa spp.) in Ghana. Acta Horticulturae, 1766. [CrossRef]

- Lescot, T. , & Ganry, J. Plantain (Musa spp.) cultivation in Africa: a brief summary of developments over the previous two decades. In IV International Symposium on Plantain: International Conference on Plantain and Plantain in Africa: Harnessing International 2008, 879, 445–455. [Google Scholar] [CrossRef]

- Tetang, J. T. , Kwa, M. , Temple, L., Bikoï, A., Njukwe, E., Staver, C., & Ottou, JF. Meeting the challenge of the plantain (Musa spp.) subsector economic restructuring in cameroon. In IV International Symposium on Plantain: International Conference on Plantain and Plantain in Africa: Harnessing International 2008, 879, 829–835. [Google Scholar]

- Nowakunda, K. , Ngambeki, D. , & Tushemereirwe, W. INCREASING SMALL-SCALE FARMERS’COMPETITIVENESS IN PLANTAIN (MUSA SPP.) PRODUCTION AND MARKETING. In IV International Symposium on Plantain: International Conference on Plantain and Plantain in Africa: Harnessing International 2008, 879, 759–766 https://wwwactahortorg/books/879/879_82htm. [Google Scholar]

- Blazy, J. M. , Ozier-Lafontaine, H., Doré, T., Thomas, A., & Wery, J. A methodological framework that accounts for farm diversity in the prototyping of crop management systems. Application to plantain-based systems in Guadeloupe. Agricultural systems 2009, 101, 30–41. [Google Scholar] [CrossRef]

- Staver, C. Increasing the pro-poor impact of plantain crop protection strategies: knowing our clients, involving new players and linking more effectively. In III International Symposium on Plantain: ISHS-ProMusa Symposium on Recent Advances in Plantain Crop Protection for Sustainable 2008, 828, pp. 361–374 Available online: https://wwwactahortorg/books/828/828_37htm. [Google Scholar]

- Jiménez Herrera, A. M. Descripción del comportamiento y de los factores que influyen en las exportaciones de dos sectores tradicionales café y banano y de un sector no tradicional materiales de la construcción 2000–2015. 2017. Available online: https://dspace.tdea.edu.

- Aaron Cabas, W. D. Diseño de un modelo de innovación social como estrategia para la economía circular del sector bananero en el marco de los objetivos de desarrollo sostenible-ODS. 2023. Available online: https://repository.ucc.edu. 4609. [Google Scholar]

- Arkeman, Y. Welcome Message from The General Chairs of ICAIA 2015. Available online: https://ieeexplore.ieee.org/stamp/stamp.jsp? 7506. [Google Scholar]

- Dewi, H. , Maarif, M. S., & Sunarti, T. C. Innovation strategy to improve the competitiveness of Micro, Small, and Medium Enterprises of Bandar Lampung Plantain chips. Indonesian Journal of Business and Entrepreneurship (IJBE) 2017, 3, 64. [Google Scholar]

- Ashqui Sigcha, J. G. , & Sevilla Solís, V. D. La cultura organizacional en la innovación del sector agrícola bananero de la provincia de Los Ríos (Bachelor’s thesis, Universidad Técnica de Ambato. Facultad de Ciencias Administrativas. Carrera de Organización de Empresas).

- Reinhardt, D. H. , dos Santos-Serejo, J. A., & da S. Souza, J. Panorama of the plantain industry in latin America and the caribbean Islands, with a special focus on Brazil. In VII International Symposium on Plantain: ISHS-ProMusa Symposium on Plantains and Plantains: Towards Sustainable Global Production 2011, 986, pp. 27–37. [Google Scholar]

- Gómez, E. A. C. Propuesta para el incremento de las utilidades y reutilización de insumos mediante innovación tecnológica para la empresa agropecuaria la leyenda SAS. 2023. Available online: https://repository.ucatolica.edu. 3771. [Google Scholar]

- Añez Salas, A. , Guerra, A. S., & Sánchez Castaño, J. Situación actual del sector bananero frente a la economía circular en el Departamento del Magdalena. 2023.

- Cárdenas, J. L. The effect of social capital and stakeholder behavior on technology transfer networks: the case of plantain agribusiness in Ecuador. Gent University, Faculty of Bioscience Engineering, Department of Agricultural Economics, Bélgica. V DOCTORAL CONSORTIUM.

- Prieto, A. V. , Díaz, E. A., & Sánchez, A. C. A. Estado del arte de los métodos de evaluación de la sostenibilidad. CLIO América 2022, 16, 1–2. [Google Scholar]

- Zartha Sossa, J. W. El método Delphi modificado como dinamizador de la estrategia de innovación en el marco de un modelo de gestión de la innovación en organizaciones del sector productivo. 2017. (Doctoral dissertation, Tesis de Doctorado).

- Oslo Manual: Guidelines for collecting and Interpreting Innovation Data, 3rd Edition, ISBN 9264013083, © OECD/European Communities, 2005.

- Española, U. N. Gestión de la I+ D+ i: Sistema de vigilancia e inteligencia (UNE 166006). 2018.

- FAO. FAO Strategy for Private Sector Engagement, 2021-2025. Rome. 2021. [CrossRef]

- Boxwell, D. A. In Formation: Male Homosocial Desire in Willa Cather’s One of Ours. Genders 1994, (19), 285. [Google Scholar]

- Naciones Unidas. Objetivos de Desarrollo Sostenibles. 2015. https://www.un.

- Díaz, R. A. , & Hartwich, F. Cadenas de valor: un paso innovador para la agricultura Centroamericana. Alternativas para el Desarrollo.

- Cartaya, J. C. C. , & Suárez, J. R. C. La inteligencia empresarial y el Sistema de Gestión de Calidad ISO 9001: 2000. Ciencias de la Información 2008, 39, 31–44. [Google Scholar]

- Rivera, R. A. VModelos de Resiliencia Organizacional en las Pymes y su Impacto en la Cadena de Abastecimiento. Revista ingeniería, matemáticas y ciencias de la información.

- Villegas Hincapié, A. C. Modelo de gestión del conocimiento para el desarrollo de capacidades dinámicas en una empresa de tecnología de Información en Colombia: caso Sophos Solutions. 2020. (Doctoral dissertation, Universidad Eafit).

- Nonaka, I. , & Takeuchi, H. La organización creadora de conocimiento Cómo las compañías japonesas crean la dinámica de la innovación. In Oxford University Press. 1995.

- Rabi, JA, Santos, SF, Tonoli, GHD y Saavedra, A. Materiales de construcción: propiedades, rendimiento y aplicaciones. 2009, págs.

- Grass Ramírez JF, Muñoz RC and Zartha Sossa JW. Innovations and trends in the coconut agroindustry supply chain: A technological surveillance and foresight analysis. Front. Sustain. Food Syst 2023, 7, 1048450. [Google Scholar] [CrossRef]

- Farias, P. I. V. , Freire, E., Cunha, A. L. C. D., Grumbach, R. J. D. S., & Antunes, A. M. D. S. The fertilizer industry in Brazil and the assurance of inputs for biofuels production: prospective scenarios after COVID-19. Sustainability 2020, 12, 8889. [Google Scholar] [CrossRef]

- Barcaccia, G. , D’Agostino, V., Zotti, A., & Cozzi, B. Impact of the SARS-CoV-2 on the Italian agri-food sector: An analysis of the quarter of pandemic lockdown and clues for a socio-economic and territorial restart. Sustainability 2020, 12, 5651. [Google Scholar] [CrossRef]

- Gokhberg, L. , Kuzminov, I.,Chulok, A., De La Cruz, T. The future of Russian agriculture and food industry between global opportunities and technological limitations. Revista internacional de sostenibilidad agrícola 2017, 15, 457–466. [Google Scholar]

- Hincapié, J. M. M. , Martínez, E. E. V., Concha, J. L. H., Piedrahita, J. C. P., Rincón, J. F. A., Fernández, G. L. R., & Sossa, J. W. Z. Priority technologies and innovations in the fishing agribusiness by the year 2032. Foresight study through the Delphi method. Revista Lasallista de Investigacion 2017, 14, 105–120. [Google Scholar] [CrossRef]

- Leckel, A. , Veilleux, S., & Dana, L. P. Local Open Innovation: A means for public policy to increase collaboration for innovation in SMEs. Technological Forecasting and Social Change 2020, 153, 119891. [Google Scholar] [CrossRef]

- Diener, K. , Luettgens, D., & Piller, F. T. Intermediation for open innovation: Comparing direct versus delegated search strategies of innovation intermediaries. 2020; 24. [Google Scholar] [CrossRef]

- Rosenberg, N. Uncertainty and technological change. In The economic impact of knowledge. 2009, pp. 17–34. Routledge.

- Pereira, G. I. , da Silva, P. P., & Soule, D. Policy-adaptation for a smarter and more sustainable EU electricity distribution industry: a foresight analysis. Environment, Development and Sustainability.

- Zartha Sossa, J. W. , Halal, W., & Hernández Zarta, R. Delphi method: analysis of rounds, stakeholder and statistical indicators. Foresight 2019, 21, 525–544. [Google Scholar]

- Zartha Sossa, J. W. , Palacio Piedrahita, J. C., Orozco Mendoza, G. L., Hincapié Llanos, C. A., Ríos Mesa, A. F., & Álvarez López, C. Prospective of Agroindustrial Engineering in Ibero-America to 2035: Application of the scenario methodology and the Delphi method. Ciencia y Tecnología Agropecuaria.

- Suárez, L. M. , Agudelo, D. A., Zartha, J. W., & Orozco, G. L. La cadena productiva de mora en el Departamento Risaralda en el marco de un estudio de prospectiva a 2032: Blackberry productive value chain in Risaralda within the framework of a prospective study to 2032. Scientia et Technica 2021, 26, 183–190. [Google Scholar]

- Zartha, J. , Manrique, J., Montes, J., Palacio, J., Orozco, G. Delphi Method in Emerging Technologies. International Journal of Innovation, Creativity and Change. www.ijicc.net.

- Meza, D. , ‘Quintero, J., Zartha, J., Hernández, Z. Estudio de prospectiva del sector cacao al año 2032 como base de programas de capacitación universitaria en el sector agroindustrial. Aplicación del método Delphi Información Tecnológica 2020, 31, 219–230. [Google Scholar] [CrossRef]

- Montoya, L. H. B. , Sossa, J. W. Z., Piedrahíta, J. C. P., Mendoza, G. L. O., Montoya, A. F. R., & Pérez, W. A. P. Innovation management model for functional food ingredients and additives. Alignment with hype cycle, Python S-curves, and open innovation variables. Journal of Open Innovation: Technology, Market, and Complexity 2024, 10. [Google Scholar] [CrossRef]

- Sossa, J. W. Z. , Posada, N. G., Montoya, L. H. B., Monsalve, A. M. Z., Piedrahíta, J. C. P., Mendoza, G. L. O.,... & Cano, L. F. G. Foresight study using scenarios and the Delphi method in the leather agroindustrial chain to 2035-Alignment of results with open innovation. Journal of Open Innovation: Technology, Market, and Complexity 2024, 10. [Google Scholar] [CrossRef]

- Botero Montoya, L.H.; Gutiérrez, N.; Zuluaga, A.; Gutiérrez, L.F.; Gómez, J.O.; Orozco, G.L.; Zartha, J.W. Proposal for Sustainability-Oriented Innovation Management Model (MGI) for Agro-Industrial Leather Chain. Sustainability 2024, 16, https:// doiorg/103390/su16208981. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).