Submitted:

05 November 2024

Posted:

06 November 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Establishing the kinematic and stiffness models of the considered manipulator.

- Reducing the number of design variables to two geometrical parameters.

- Developing an original procedure for workspace analysis, combining the chord method with subsequent sampling, transformed into a point-in-polygon problem.

- Solving the multi-objective optimization problem with a hierarchical method.

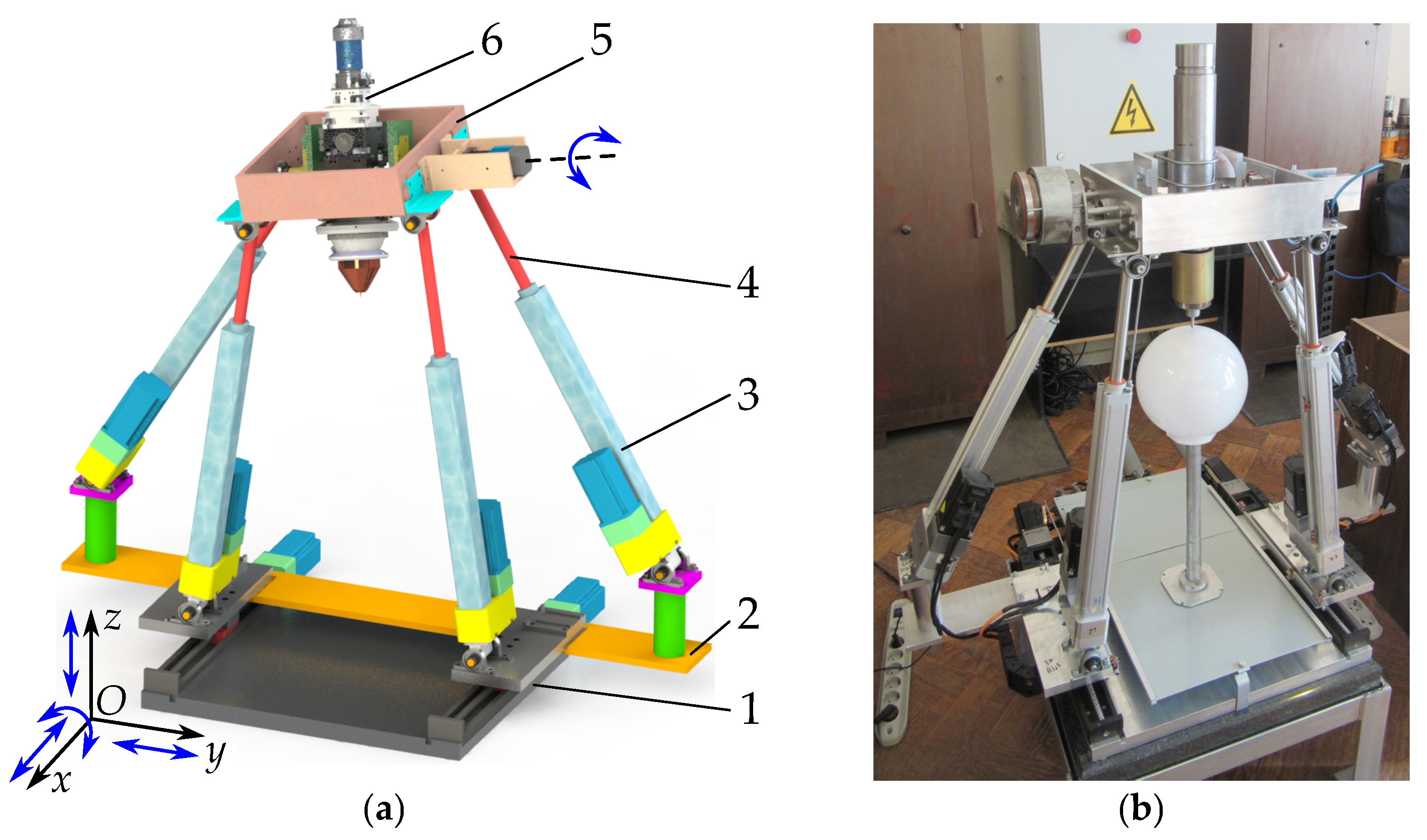

2. Manipulator Design and Problem Formulation

3. Dimensional Synthesis

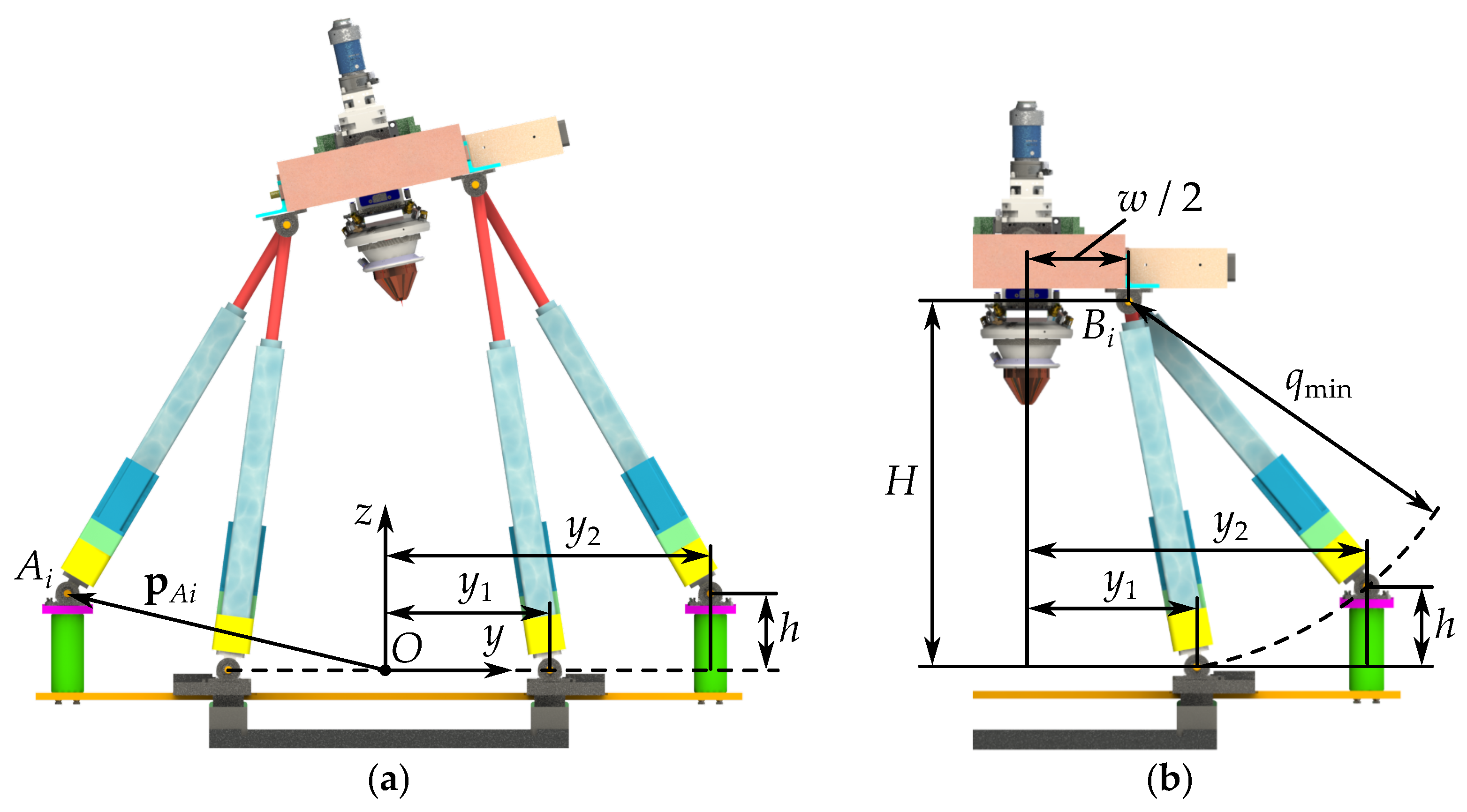

3.1. Geometrical Parameters

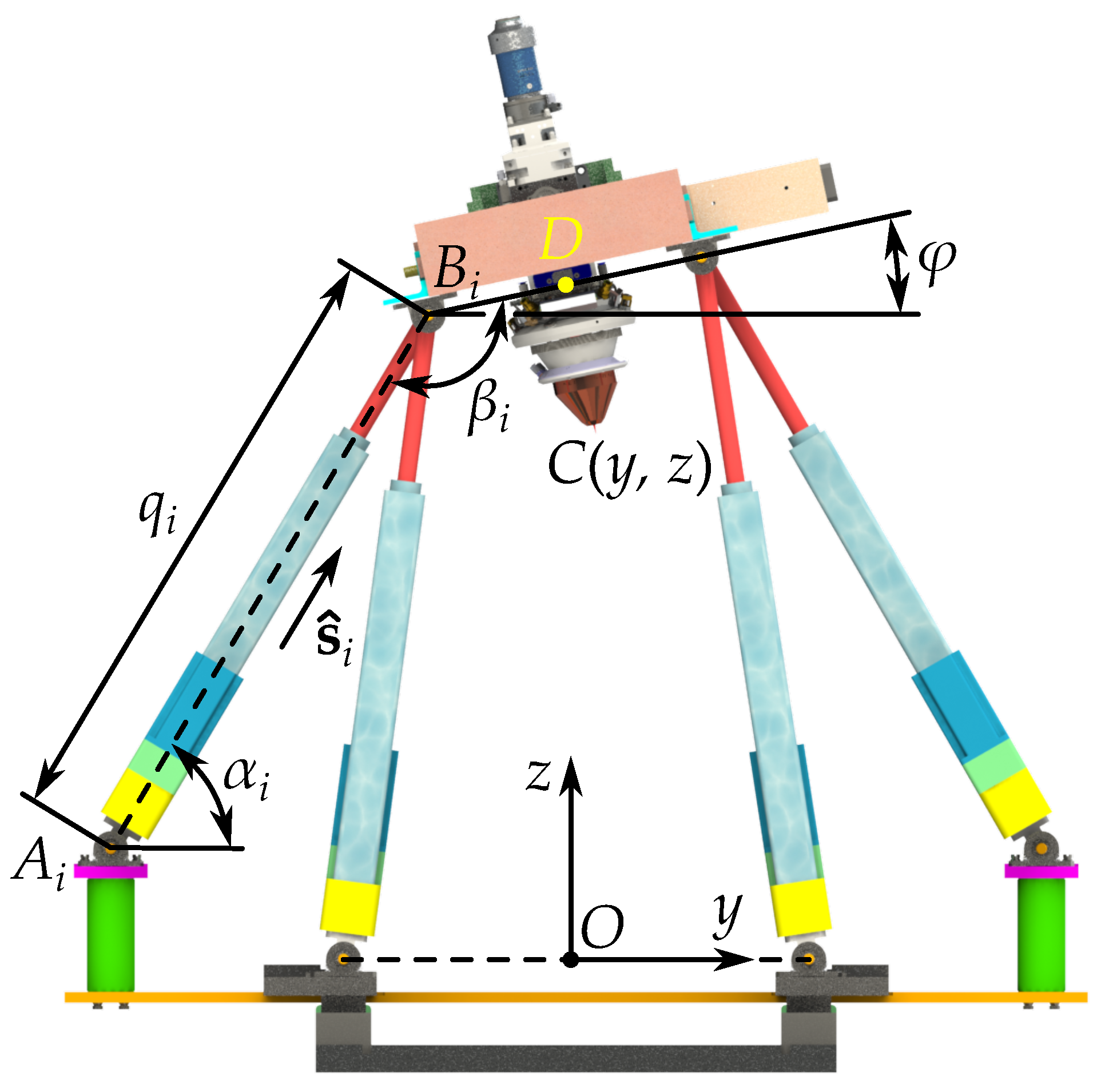

3.2. Kinematic Model

3.3. Stiffness Model

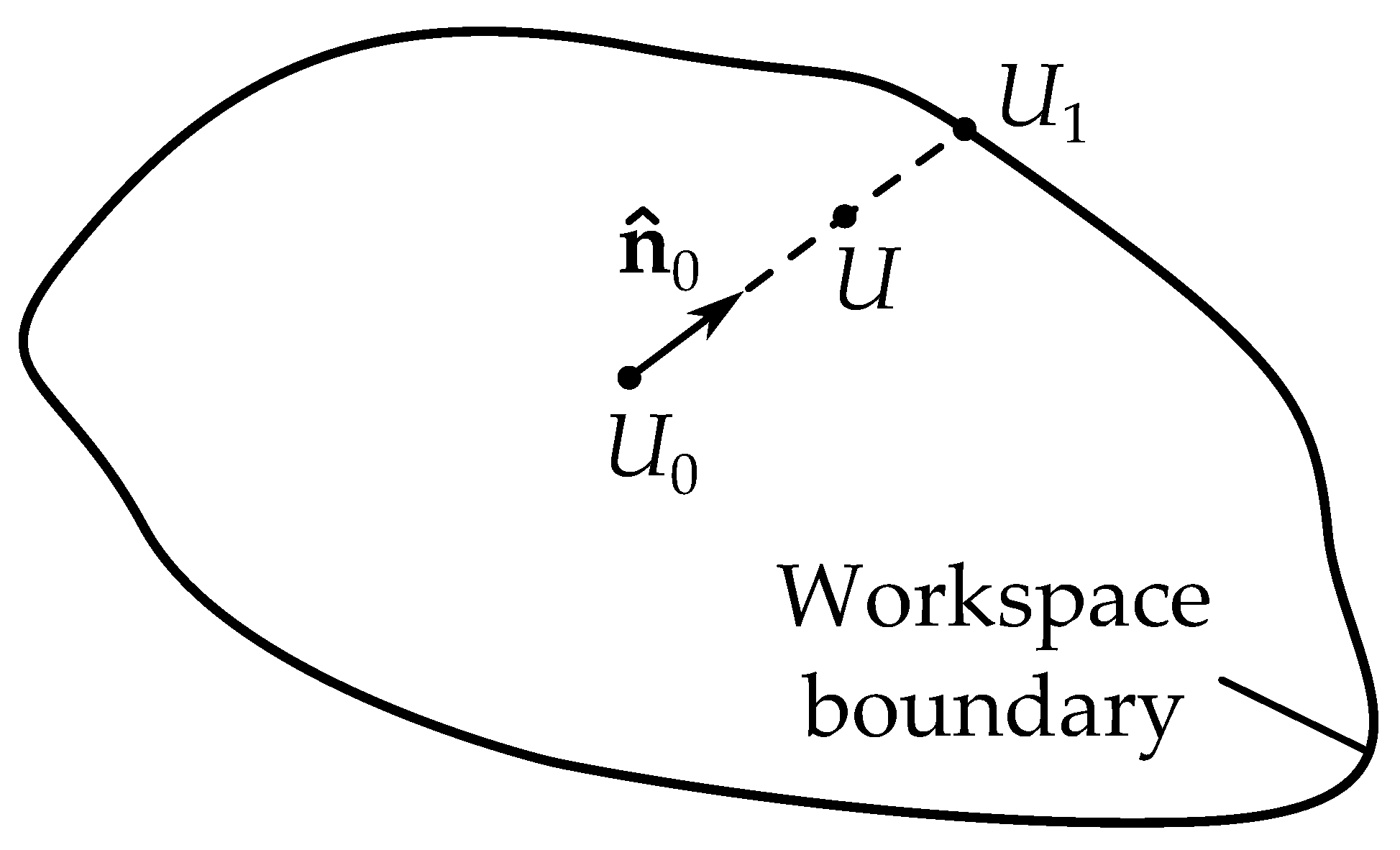

3.4. Workspace Analysis

3.4.1. Finding a Point on the Boundary

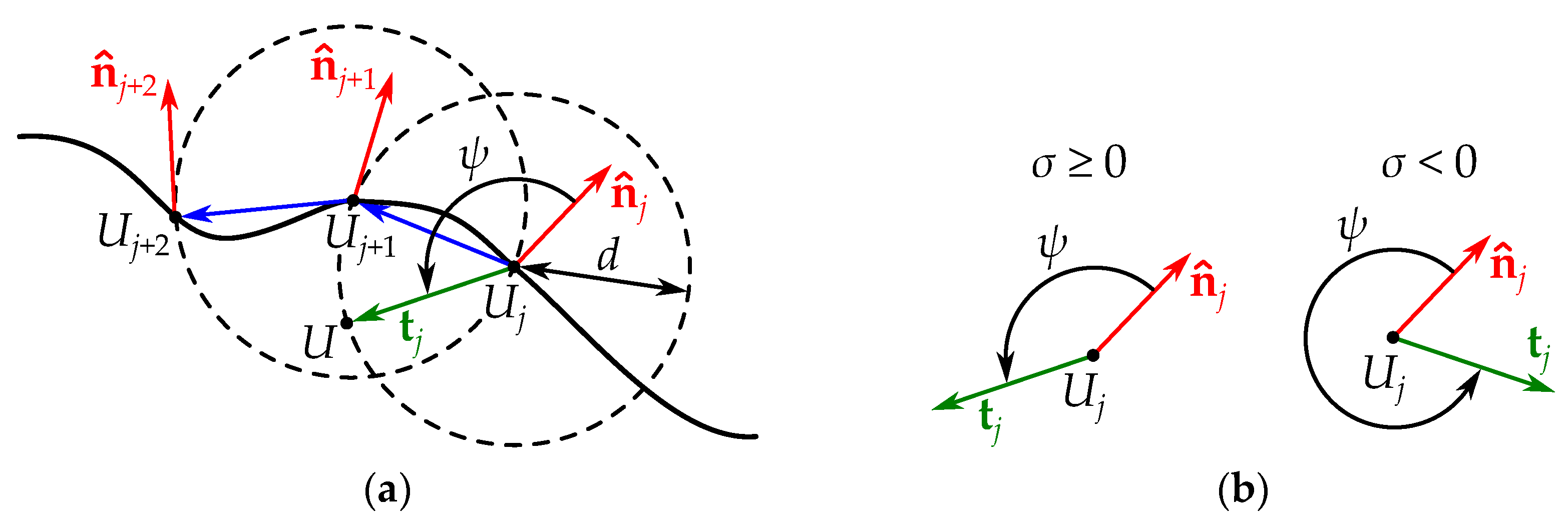

3.4.2. Tracing the Boundary

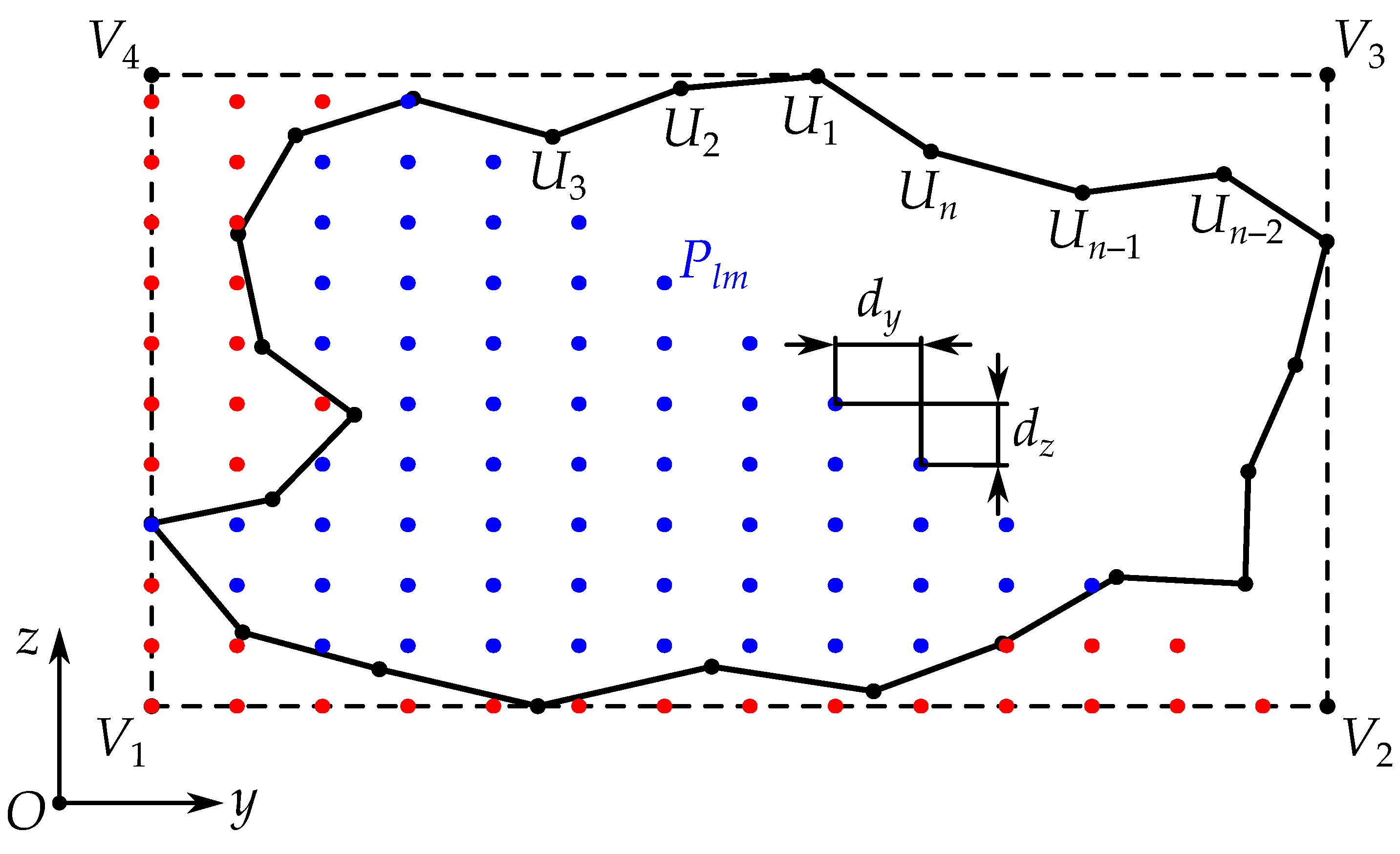

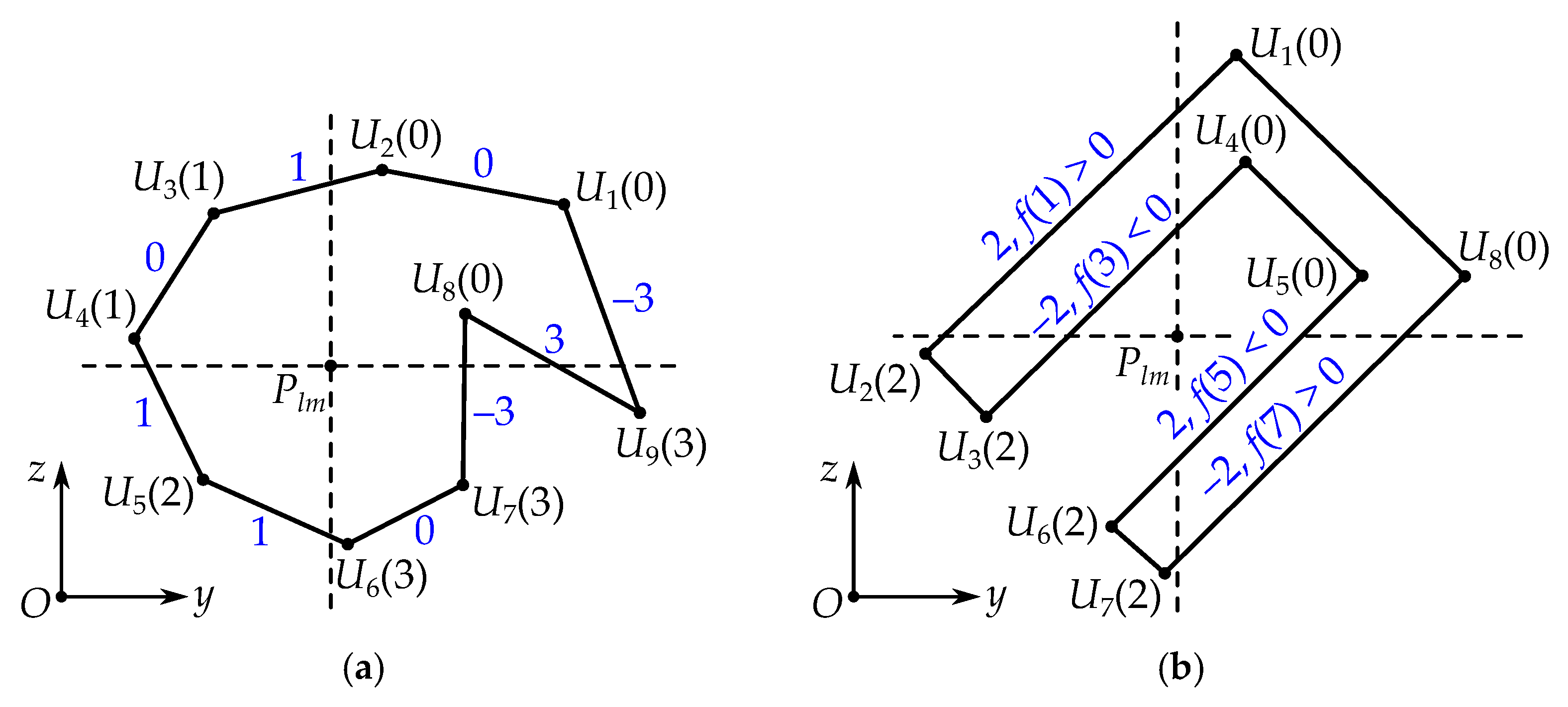

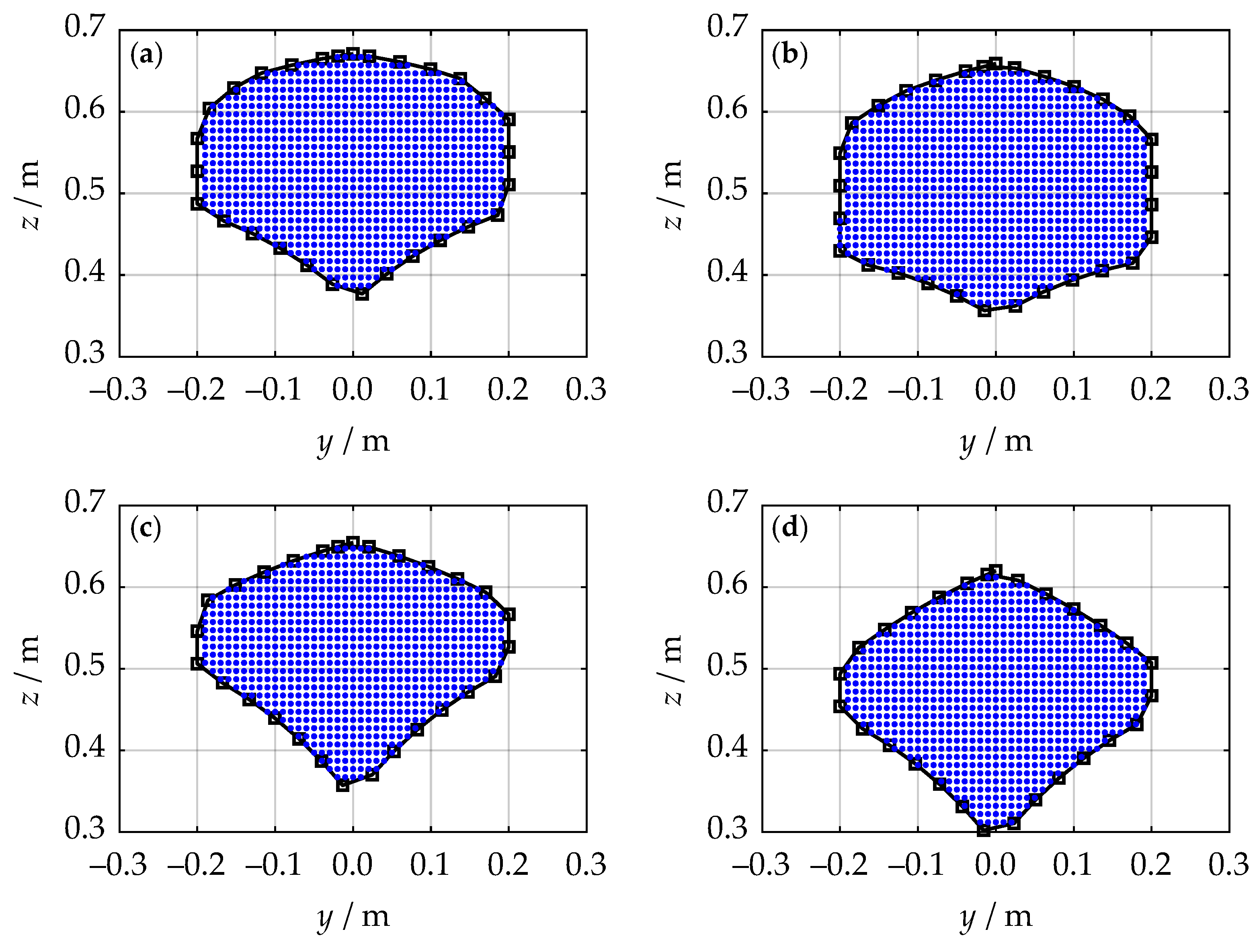

3.4.3. Sampling Inside the Boundary

3.5. Synthesis Algorithm

-

Find the maximum and minimum values of each objective function over set :Considering Equation (27), we can compute these values in a straightforward manner.

- Solve the following optimization problems sequentially for :where is the optimal value of the objective function after solving the r-th optimization problem, and we have ; is used to set a “distance” to optimum value . Similar to problems (29), we can solve each optimization problem by simple evaluation of the objective functions over set .

-

Define constant parameters:

- Geometrical parameters of the manipulator: w, .

- Joint constraints: , , , , , .

- Drive stiffness: c.

- Parameters of the chord method: , , , , , d.

- Parameters of the workspace sampling method: , .

- Parameters of the design space sampling : , , , , , .

- Parameters of the hierarchical optimization: , .

- Define orientation of the end-effector.

- Sample parameters and (with ) and determine number K of the samples.

-

For each sample :

- Find the first point on the workspace boundary by solving optimization problem (17).

- Determine the whole boundary by solving a sequence of optimization problems (19).

- Find sample points inside the rectangle using algorithm (25).

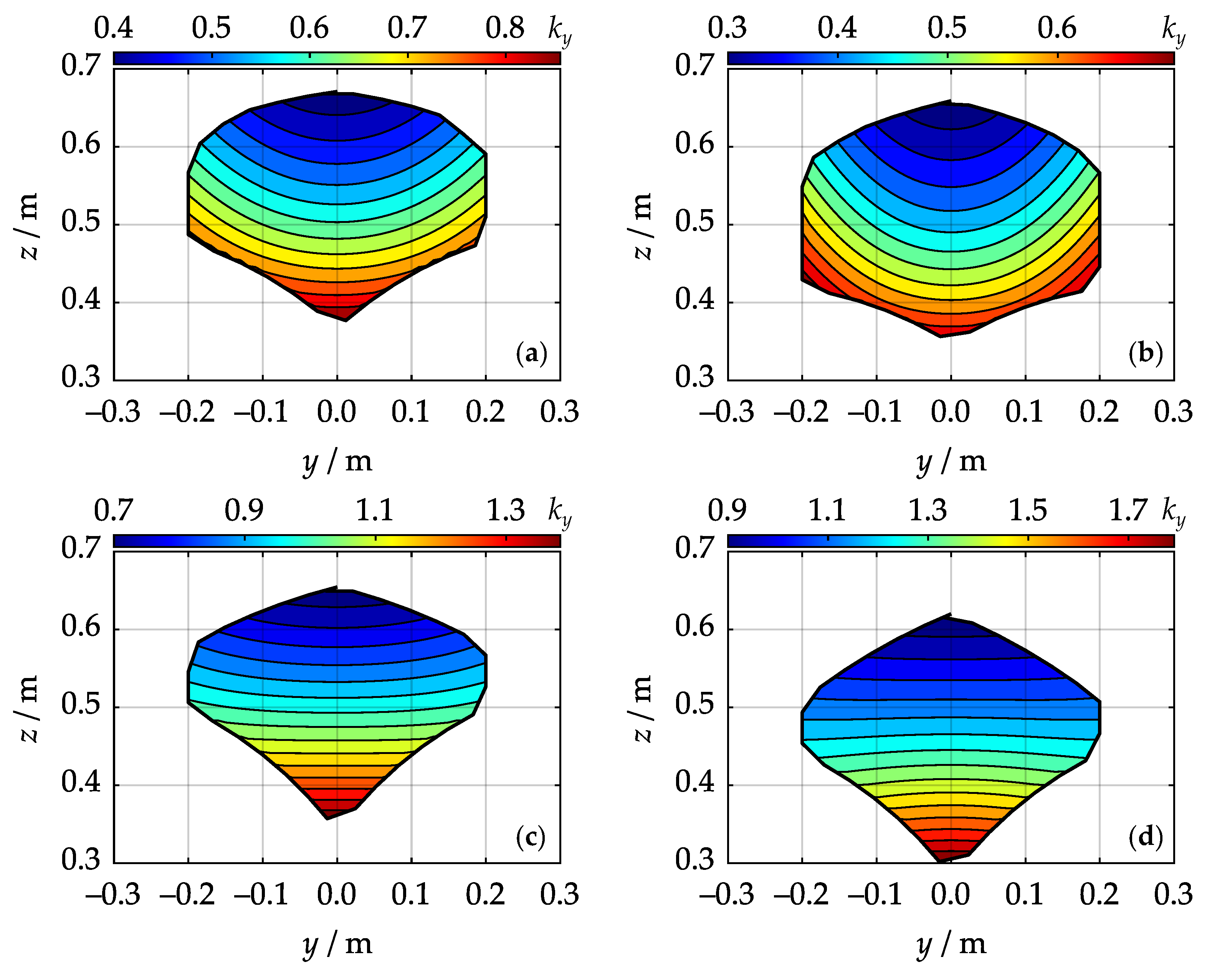

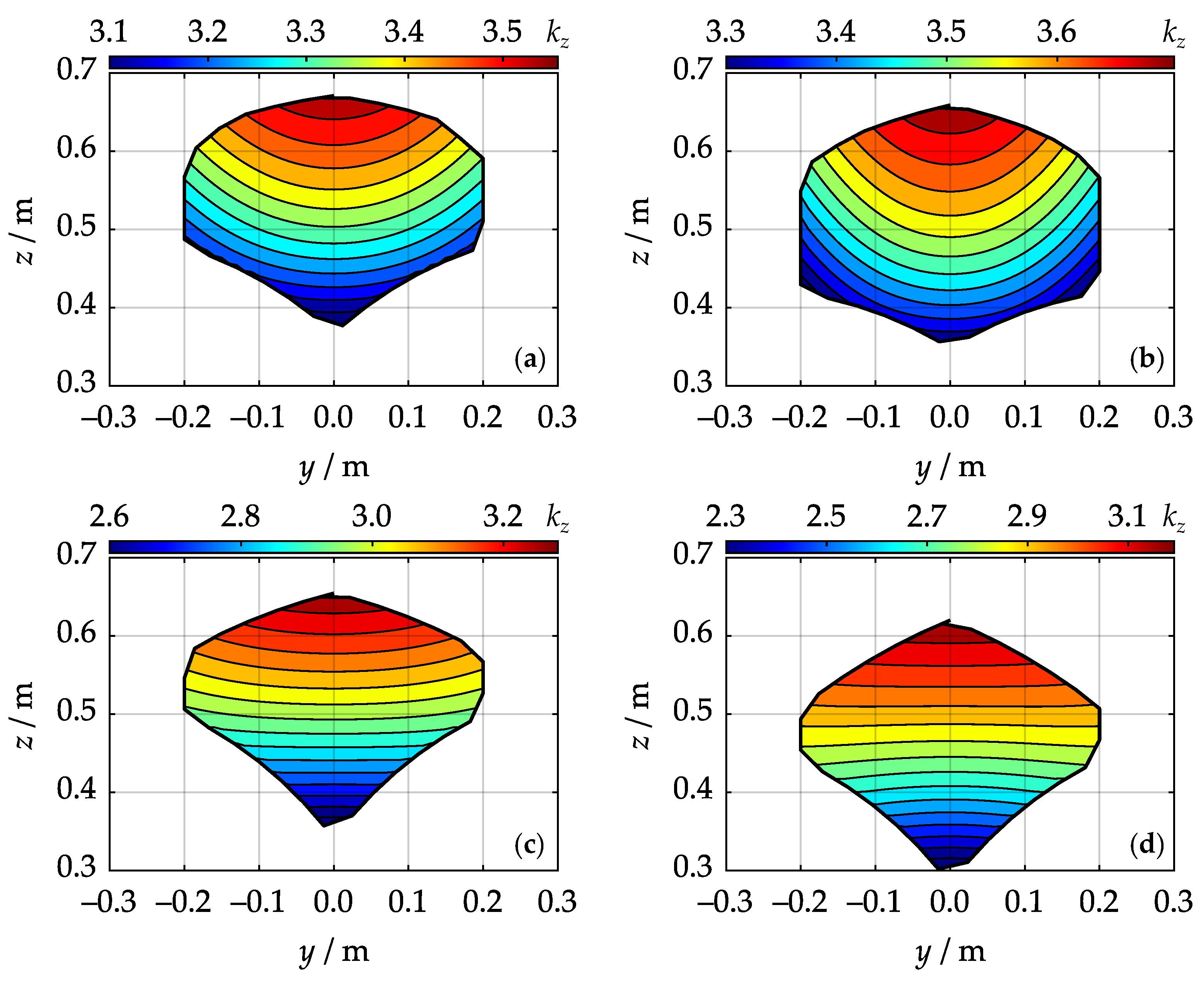

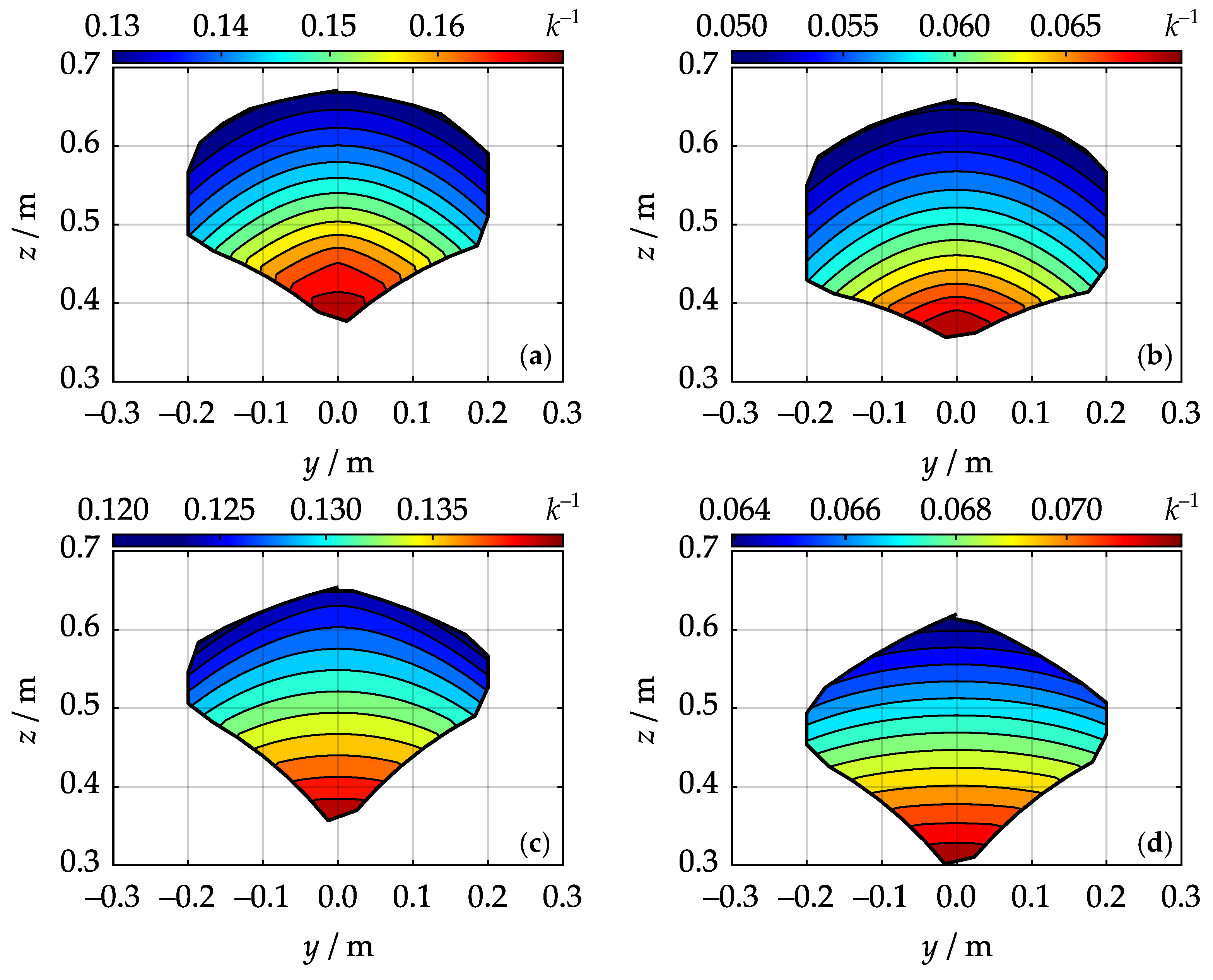

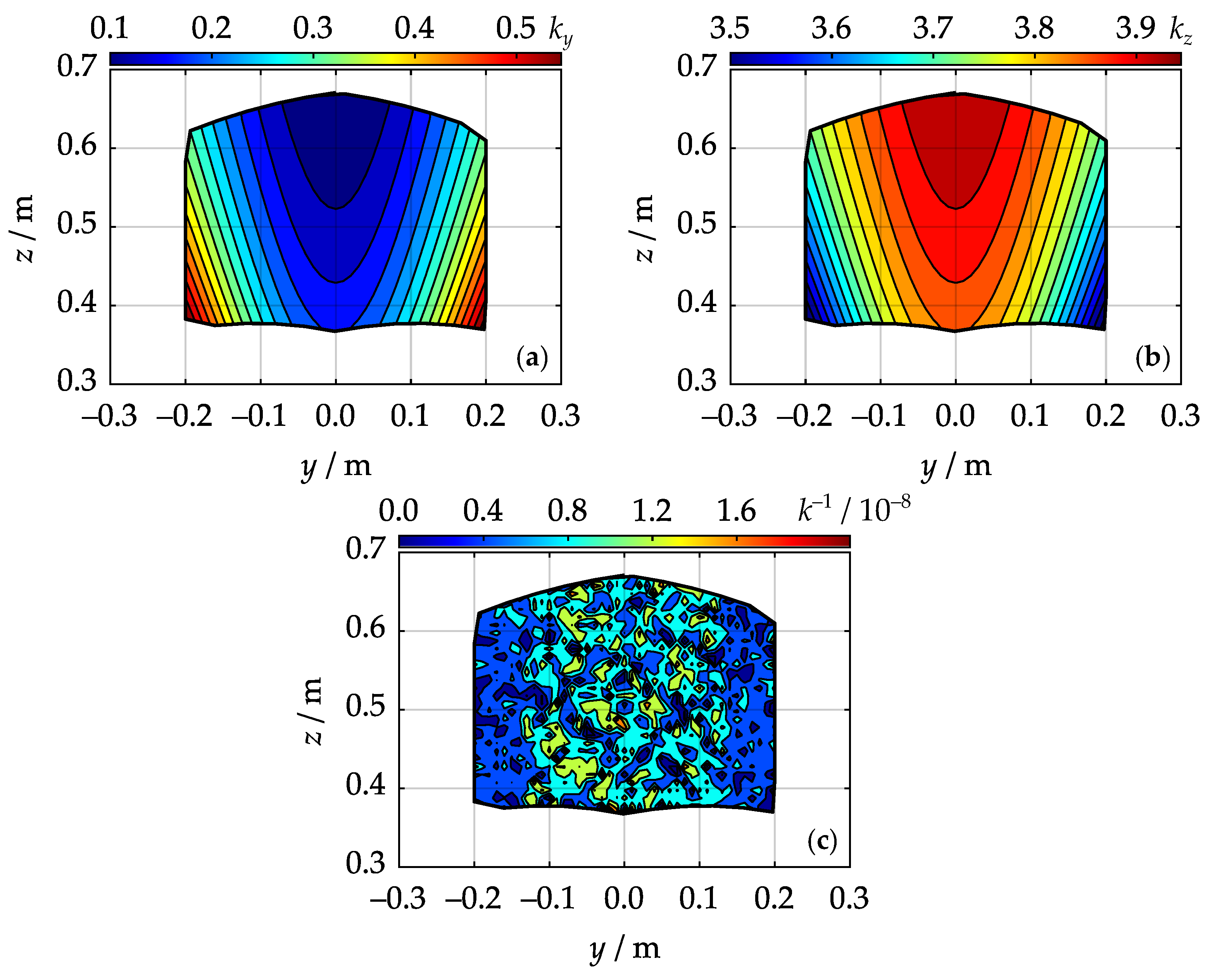

- Compute the average values of these stiffness indices using Equation (26).

- Compute the workspace area using Equation (28).

- Find the optimal values of design parameters and by solving a sequence of optimization problems (30).

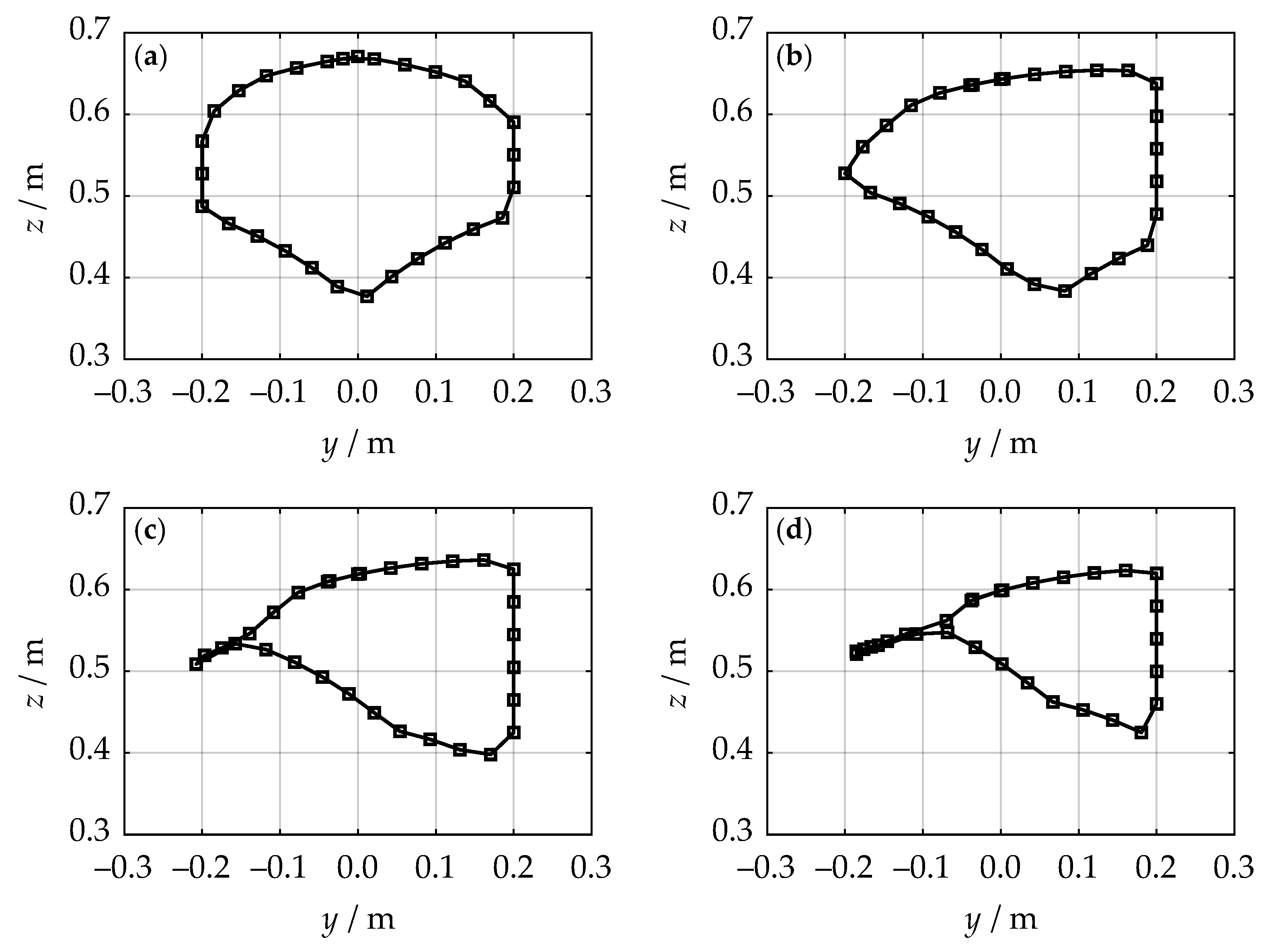

4. Simulations and Results

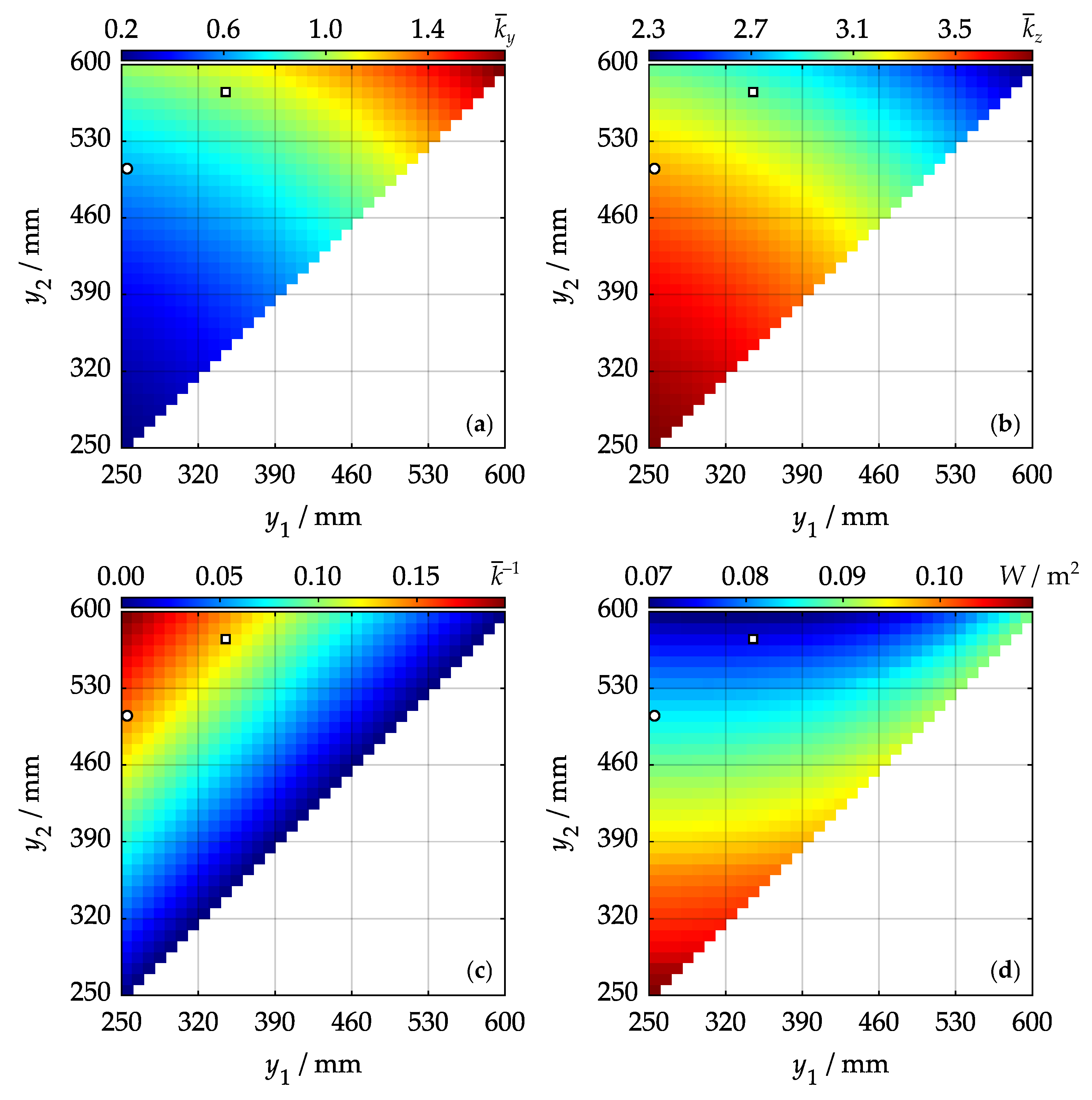

- Average lateral stiffness increases as sum increases.

- Average vertical stiffness increases as sum decreases.

- Average overall stiffness increases as difference increases.

- Workspace area W increases as sum decreases.

- Average lateral stiffness has increased by 54.1 %.

- Average vertical stiffness has decreased by 10.3 %.

- Average overall stiffness has decreased by 9.9 %.

- Workspace area W has decreased by 12.1 %.

5. Discussion

- Enhancing the stiffness model. In Section 3.3, we assumed the drives were the only source of mechanism compliance. We can get more accurate results if we consider the stiffness of the revolute joints, moving plate, cylinders, and pistons.

- Modifying the optimization algorithm. In Section 3.5, we solved the multi-objective optimization problem with the hierarchical approach and assigned a priority factor to each objective. Instead of setting these factors, it looks more attractive to a designer to explicitly specify the decrease rate of the low-priority objectives.

- Experimental validation. The theoretical results presented in Section 4 look reasonable, but they have not been verified in practice yet. To validate the results, we plan to estimate the end-effector displacements under the specified load using external measurement systems (e.g., a laser tracker or interferometer).

6. Conclusions

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Russo, M.; Zhang, D.; Liu, X.J.; Xie, Z. A review of parallel kinematic machine tools: design, modeling, and applications. Int. J. Mach. Tools Manuf. 2024, 196, 104118. doi:10.1016/j.ijmachtools.2024.104118. [CrossRef]

- Qin, X.; Li, Y.; Feng, G.; Bao, Z.; Li, S.; Liu, H.; Li, H. A novel surface topography prediction method for hybrid robot milling considering the dynamic displacement of end effector. Int. J. Adv. Manuf. Technol. 2024, 130, 3495–3508. doi:10.1007/s00170-023-12814-y. [CrossRef]

- Lin, C.; Guang, C.; Zheng, Y.; Ma, K.; Yang, Y. Preliminary evaluation of a novel vision-guided hybrid robot system for capsulotomy in cataract surgery. Displays 2022, 74, 102262. doi:10.1016/j.displa.2022.102262. [CrossRef]

- Tao, B.; Feng, Y.; Fan, X.; Lan, K.; Zhuang, M.; Wang, S.; Wang, F.; Chen, X.; Wu, Y. The accuracy of a novel image-guided hybrid robotic system for dental implant placement: an in vitro study. Int. J. Med. Robot. Comput. Assist. Surg. 2023, 19, e2452. doi:10.1002/rcs.2452. [CrossRef]

- Huang, T.; Li, Z.; Li, M.; Chetwynd, D.G.; Gosselin, C.M. Conceptual design and dimensional synthesis of a novel 2-DOF translational parallel robot for pick-and-place operations. J. Mech. Des. 2004, 126, 449–455. doi:10.1115/1.1711822. [CrossRef]

- Zou, Q.; Zhang, D.; Huang, G. Kinematic models and the performance level index of a picking-and-placing hybrid robot. Machines 2023, 11, 979. doi:10.3390/machines11100979. [CrossRef]

- Giri, G.S.; Maddahi, Y.; Zareinia, K. An application-based review of haptics technology. Robotics 2021, 10, 29. doi:10.3390/robotics10010029. [CrossRef]

- Tang, Z.; Payandeh, S. Experimental studies of a novel 6-DOF haptic device. 2013 IEEE International Conference on Systems, Man, and Cybernetics; , 2013; pp. 3372–3377. doi:10.1109/SMC.2013.575. [CrossRef]

- Kumar, S.; Wöhrle, H.; de Gea Fernández, J.; Müller, A.; Kirchner, F. A survey on modularity and distributivity in series-parallel hybrid robots. Mechatronics 2020, 68, 102367. doi:10.1016/j.mechatronics.2020.102367. [CrossRef]

- Feller, D.; Siemers, C. Mechanical design and analysis of a novel three-legged, compact, lightweight, omnidirectional, serial–parallel robot with compliant agile legs. Robotics 2022, 11, 39. doi:10.3390/robotics11020039. [CrossRef]

- Li, Q.; Yang, C.; Xu, L.; Ye, W. Performance Analysis and Optimization of Parallel Manipulators; Springer: Singapore, 2023. doi:10.1007/978-981-99-0542-3. [CrossRef]

- Xu, D.; Dong, J.; Wang, G.; Cai, J.; Wang, H.; Yin, L. Redundant composite polishing robot with triangular parallel mechanism-assisted polishing to improve surface accuracy of thin-wall parts. J. Manuf. Process. 2024, 124, 147–162. doi:10.1016/j.jmapro.2024.04.029. [CrossRef]

- Gao, J.S.; Li, M.X.; Li, Y.Y.; Wang, B.T. Singularity analysis and dimensional optimization on a novel serial-parallel leg mechanism. Procedia Eng. 2017, 174, 45–52. doi:10.1016/j.proeng.2017.01.140. [CrossRef]

- Liu, H.; Huang, T.; Mei, J.; Zhao, X.; Chetwynd, D.G.; Li, M.; Hu, S.J. Kinematic design of a 5-DOF hybrid robot with large workspace/limb–stroke ratio. J. Mech. Des. 2007, 129, 530–537. doi:10.1115/1.2712220. [CrossRef]

- Jin, Y.; Bi, Z.M.; Liu, H.T.; Higgins, C.; Price, M.; Chen, W.H.; Huang, T. Kinematic analysis and dimensional synthesis of Exechon parallel kinematic machine for large volume machining. J. Mech. Robot. 2015, 7, 041004. doi:10.1115/1.4029499. [CrossRef]

- Xu, Y.; Ni, S.; Wang, B.; Wang, Z.; Yao, J.; Zhao, Y. Design and calibration experiment of serial–parallel hybrid rotary platform with three degrees of freedom. Proc. Inst. Mech. Eng., Part C: J. Mech. Eng. Sci. 2019, 233, 1807–1817. doi:10.1177/0954406218774352. [CrossRef]

- Zhang, D.S.; Xu, Y.D.; Yao, J.T.; Zhao, Y.S. Analysis and optimization of a spatial parallel mechanism for a new 5-DOF hybrid serial-parallel manipulator. Chin. J. Mech. Eng. 2018, 31, 54. doi:10.1186/s10033-018-0251-4. [CrossRef]

- Xu, L.; Chai, X.; Ding, Y. Design of a 2RRU-RRS parallel kinematic mechanism for an inner-cavity machining hybrid robot. J. Mech. Robot. 2024, 16, 054501. doi:10.1115/1.4062649. [CrossRef]

- Yu, G.; Wu, J.; Wang, L.; Gao, Y. Optimal design of the three-degree-of-freedom parallel manipulator in a spray-painting equipment. Robotica 2020, 38, 1064–1081. doi:10.1017/S0263574719001255. [CrossRef]

- Dong, C.; Liu, H.; Xiao, J.; Huang, T. Dynamic modeling and design of a 5-DOF hybrid robot for machining. Mech. Mach. Theory 2021, 165, 104438. doi:10.1016/j.mechmachtheory.2021.104438. [CrossRef]

- Li, J.; Ye, F.; Shen, N.; Wang, Z.; Geng, L. Dimensional synthesis of a 5-DOF hybrid robot. Mech. Mach. Theory 2020, 150, 103865. doi:10.1016/j.mechmachtheory.2020.103865. [CrossRef]

- Xu, P.; Li, B.; Cheung, C.F.; Zhang, J.F. Stiffness modeling and optimization of a 3-DOF parallel robot in a serial-parallel polishing machine. Int. J. Precis. Eng. Manuf. 2017, 18, 497–507. doi:10.1007/s12541-017-0060-1. [CrossRef]

- Gao, Z.; Zhang, D. Performance analysis, mapping, and multiobjective optimization of a hybrid robotic machine tool. IEEE Trans. Ind. Electron. 2015, 62, 423–433. doi:10.1109/TIE.2014.2327008. [CrossRef]

- Deng, F.; Liu, X.; Zhang, N.; Zhang, F. Dimension synthesis of a 3T2R labelling robot with hybrid mechanism. J. Eur. Syst. Autom. 2019, 52, 509–514. doi:10.18280/jesa.520510. [CrossRef]

- Li, C.; Wu, H.; Eskelinen, H. Design and multi-objective optimization of a dexterous mobile parallel mechanism for fusion reactor vacuum vessel assembly. IEEE Access 2021, 9, 153796–153810. doi:10.1109/ACCESS.2021.3127947. [CrossRef]

- Antonov, A.V.; Chernetsov, R.A.; Ulyanov, E.E.; Ivanov, K.A. Use of the chord method for analyzing workspaces of a parallel structure mechanism. IOP Conf. Ser.: Mater. Sci. Eng. 2020, 747, 012079. doi:10.1088/1757-899X/747/1/012079. [CrossRef]

- Antonov, A. Stiffness evaluation and dimensional synthesis of a 5-DOF parallel-serial robot. In Mechanism Design for Robotics; Lovasz, E.C.; Ceccarelli, M.; Ciupe, V., Eds.; Springer: Cham, Switzerland, 2024; pp. 99–107. doi:10.1007/978-3-031-67383-2_10. [CrossRef]

- Lynch, K.M.; Park, F.C. Modern Robotics: Mechanics, Planning, and Control; Cambridge University Press: Cambridge, UK, 2017. doi:10.1017/9781316661239. [CrossRef]

- Dai, J.S.; Sun, J. Geometrical revelation of correlated characteristics of the ray and axis order of the Plücker coordinates in line geometry. Mech. Mach. Theory 2020, 153, 103983. doi:10.1016/j.mechmachtheory.2020.103983. [CrossRef]

- Rosyid, A.; El-Khasawneh, B.; Alazzam, A. Review article: performance measures of parallel kinematics manipulators. Mech. Sci. 2020, 11, 49–73. doi:10.5194/ms-11-49-2020. [CrossRef]

- Wu, J.; Wang, J.; Wang, L.; You, Z. Performance comparison of three planar 3-DOF parallel manipulators with 4-RRR, 3-RRR and 2-RRR structures. Mechatronics 2010, 20, 510–517. doi:10.1016/j.mechatronics.2010.04.012. [CrossRef]

- Gosselin, C. Stiffness mapping for parallel manipulators. IEEE Trans. Robot. Autom. 1990, 6, 377–382. doi:10.1109/70.56657. [CrossRef]

- Hay, A.M.; Snyman, J.A. The chord method for the determination of nonconvex workspaces of planar parallel manipulators. Comput. Math. Appl. 2002, 43, 1135–1151. doi:10.1016/S0898-1221(02)80018-9. [CrossRef]

- Hormann, K.; Agathos, A. The point in polygon problem for arbitrary polygons. Comput. Geom. Theory Appl. 2001, 20, 131–144. doi:10.1016/S0925-7721(01)00012-8. [CrossRef]

- Gunantara, N. A review of multi-objective optimization: methods and its applications. Cogent Eng. 2018, 5, 1502242. doi:10.1080/23311916.2018.1502242. [CrossRef]

- Pereira, J.L.J.; Oliver, G.A.; Francisco, M.B.; Cunha Jr, S.S.; Gomes, G.F. A review of multi-objective optimization: methods and algorithms in mechanical engineering problems. Arch. Comput. Methods Eng. 2022, 29, 2285–2308. doi:10.1007/s11831-021-09663-x. [CrossRef]

- Grodzevich, O.; Romanko, O. Normalization and other topics in multi-objective optimization. Fields-MITACS Industrial Problems Workshop; , 2006; pp. 89–101.

- Zhou, Y.; Niu, J.; Liu, Z.; Zhang, F. A novel numerical approach for workspace determination of parallel mechanisms. J. Mech. Sci. Technol. 2017, 31, 3005–3015. doi:10.1007/s12206-017-0544-z. [CrossRef]

- Hay, A.M.; Snyman, J.A. A multi-level optimization methodology for determining the dextrous workspaces of planar parallel manipulators. Struct. Multidiscip. Optim. 2005, 30, 422–427. doi:10.1007/s00158-005-0536-y. [CrossRef]

- Rashoyan, G.; Shalyukhin, K.; Antonov, A.; Aleshin, A.; Skvortsov, S. Analysis of the structure and workspace of the Isoglide-type robot for rehabilitation tasks. In Advances in Artificial Systems for Medicine and Education III; Hu, Z.; Petoukhov, S.; He, M., Eds.; Springer: Cham, Switzerland, 2020; pp. 186–194. doi:10.1007/978-3-030-39162-1_17. [CrossRef]

- Hay, A.M.; Snyman, J.A. The optimal synthesis of parallel manipulators for desired workspaces. In Advances in Robot Kinematics; Lenarčič, J.; Thomas, F., Eds.; Springer: Dordrecht, The Netherlands, 2002; pp. 337–346. doi:10.1007/978-94-017-0657-5_36. [CrossRef]

- Marler, R.T.; Arora, J.S. The weighted sum method for multi-objective optimization: new insights. Struct. Multidiscip. Optim. 2010, 41, 853–862. doi:10.1007/s00158-009-0460-7. [CrossRef]

| 1 | Normalization of Jacobian matrix does not affect parameters and , and the latter can be computed using either matrix or normalized matrix . |

| 2 | We have omitted angle , as we consider it to be predefined for this optimization problem. |

| 3 | For , we consider edge and compute . |

| Parameter | Value |

|---|---|

| Platform width, w | 298 mm |

| End-effector length, | 163 mm |

| Minimum actuator stroke, | 541 mm |

| Maximum actuator stroke, | 841 mm |

| Minimum angle in joint , | |

| Maximum angle in joint , | |

| Minimum angle in joint , | |

| Maximum angle in joint , |

| Parameter | Value |

|---|---|

| Chord length, d | 40 mm |

| Left limit of the workspace, | mm |

| Right limit of the workspace, | 200 mm |

| Direction for the ray search, | |

| Step for the initial guess in the ray search, | 10 mm |

| Step for the initial guess in the circular searches, | 10 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).