1. Introduction

The convergence of virtual reality (VR) and engineering education is redefining paradigms in technical training within the context of Industry 4.0. VR, which has transcended its origins in entertainment, is now positioned as a transformative technology in the field of education and advanced professional training. This technology enables the creation of high-fidelity simulated environments that emulate complex industrial scenarios, facilitating experiential learning without the risks associated with handling expensive equipment or working in high-risk situations [

1].

This study focuses on the development and implementation of a next-generation educational VR application, designed to enable the virtual disassembly and assembly of 3D models of complex industrial systems. Using the Meta Quest 3 platform in conjunction with the ShapesXR development environment, this application offers users an immersive and highly interactive experience, allowing detailed manipulation of virtual components. This approach has significant implications in the field of industrial education, where a deep understanding of the structure and functioning of sophisticated machinery is crucial. The main objectives of this study are:

Demonstrate the effectiveness of virtual reality (VR) as an advanced pedagogical tool in technical education, allowing detailed manipulation of virtual models of complex industrial systems in a safe and efficient manner.

Evaluate the impact of VR on the acquisition of advanced technical skills, comparing its effectiveness with traditional teaching methods based on physical component manipulation.

Propose a VR implementation model in technical education that exemplifies the principles of Industry 4.0, prioritizing experiential learning, safety, and scalability in professional training.

Analyze the implications of using immersive technologies in advanced technical training, considering changes in required competencies and job roles in the modern industry.

The relevance of this study lies in the growing imperative to develop advanced technical skills in the workforce of the future. The ability to provide practical and detailed training through virtual means represents a significant advancement in preparing professionals for the challenges of modern industry, allowing students and professionals to gain experience with complex systems in a safe, efficient, and highly scalable way [

2].

The rest of the article is structured as follows: Section II provides a review of the state-of-the-art in the application of immersive technologies and their use in the context of Industry 4.0. Section III details the materials and methods used in the development and implementation of the educational VR application focused on the disassembly and assembly of industrial 3D models. Section IV presents the results obtained, including improvements in learning, technical understanding, and safety in handling industrial systems. Finally, Section V discusses the implications of our findings and offers conclusions on the future of technical education in the context of Industry 4.0, highlighting the opportunities and limitations of using VR in advanced professional training.

2. State of the Art

The integration of VR in technical education has shown significant benefits in areas that require advanced spatial skills. Research shows that VR enables more effective learning compared to traditional methods, especially where 3D visualization is crucial [

1]. Immersion in VR facilitates direct interaction with digital representations, overcoming the physical limitations of traditional laboratories. In industrial training, VR is positioned as an innovative tool for training in the assembly and disassembly of machinery, a process that is high-cost and risky [

3]. The virtual nature of the training allows experimentation without material consequences, fostering practical learning based on trial and error. VR not only enhances information retention but also intrinsic motivation. A study showed that students who used VR to learn complex anatomy retained information better and had a positive attitude toward learning [

4].

VR devices such as the Meta Quest 3 have advanced in both capability and accessibility. This system eliminates dependence on a computer, providing ideal freedom of movement for education [

5]. The Quest 3 includes the Snapdragon XR2 Gen 2, a processor designed for XR applications, enabling it to handle complex graphics and run AI algorithms in real-time. Additionally, its Touch Plus controllers offer advanced haptic feedback, enhancing interaction with complex 3D models. Platforms like Unity and ShapesXR have been widely adopted to develop VR environments. ShapesXR, optimized for the Quest 3, allows the import and manipulation of 3D models for high-performance educational applications [

6]. The integration of VR into education has shown promising results across several disciplines. It has been demonstrated to improve understanding of abstract concepts in mathematics and science by enabling the visualization and manipulation of three-dimensional models [

7].

Optimizing 3D models for VR requires advanced techniques that balance visual quality and performance. Blender is key in creating models for VR, facilitating polygon reduction and the application of optimized textures, which are essential to maintain high visual quality without compromising performance [

8]. Optimization on standalone devices like the Quest 3 is critical to avoid latency and maintain a stable frame rate. Blender allows efficient management of meshes and textures, exporting models in formats compatible with platforms like ShapesXR. Optimizing 3D models for VR is not limited to polygon reduction; it also includes dynamic level of detail (LOD) techniques. In this regard, adaptive approaches adjust model complexity based on the user’s distance and attention, improving performance without sacrificing visual quality [

9].

3. Methodology

The development of this educational VR application followed a structured methodological approach in four main phases: conceptualization, design, development of 3D models, and construction of the VR environment. Each phase was executed with a focus on optimization for high-performance VR environments and adherence to advanced pedagogical principles. An iterative approach was used to ensure the quality and effectiveness of the application, with regular usability testing and adjustments based on user feedback.

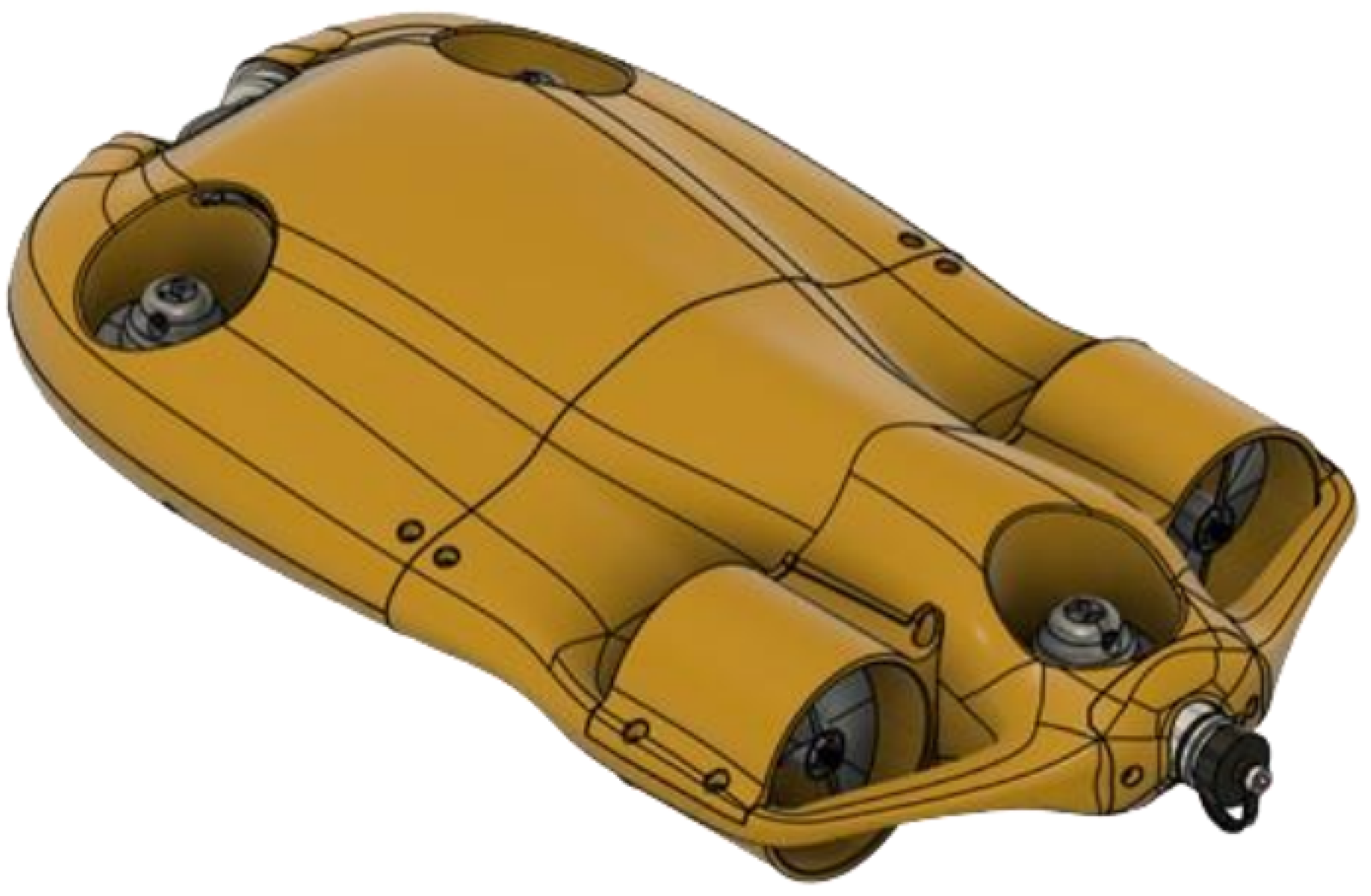

The initial conceptualization phase focused on defining the precise objectives and scope of the project, emphasizing the creation of an educational VR application for the disassembly and assembly of complex industrial 3D models. The CPS Drone was selected as the base model for the study, due to its structural complexity and relevance in the context of Industry 4.0. During this phase, a systematic literature review was conducted to identify best practices in the development of educational VR applications. Seminal studies on the effectiveness of VR in technical education, such as the work by [

10], which demonstrated the effectiveness of VR in advanced surgical training, were analyzed.

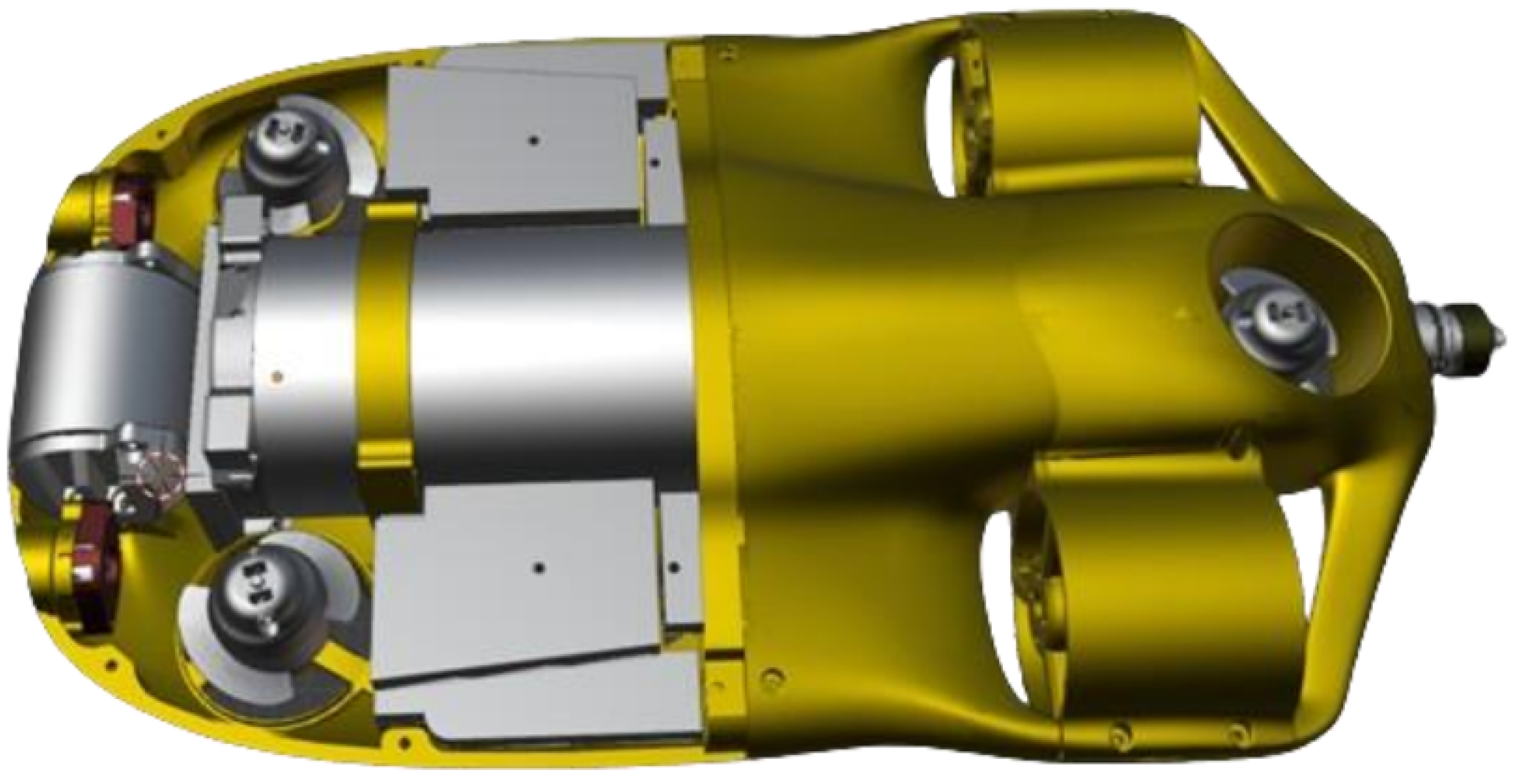

The design phase began with the creation of detailed parametric models of the CPS Drone using Autodesk Fusion 360 (

Figure 1), followed by optimization in Blender for VR environments. Advanced polygon reduction techniques were implemented, and optimized textures were applied to improve performance and visual fidelity in the VR environment [

8]. Various export formats were evaluated, ultimately selecting the .fbx and .obj formats. In this phase, user-centered design (UCD) principles were implemented to ensure that the application interface was intuitive and ergonomic in the VR context. Initial prototypes were developed, and usability tests were conducted with a group of expert users to refine the interface before final implementation, based on the methodology proposed by [

11].

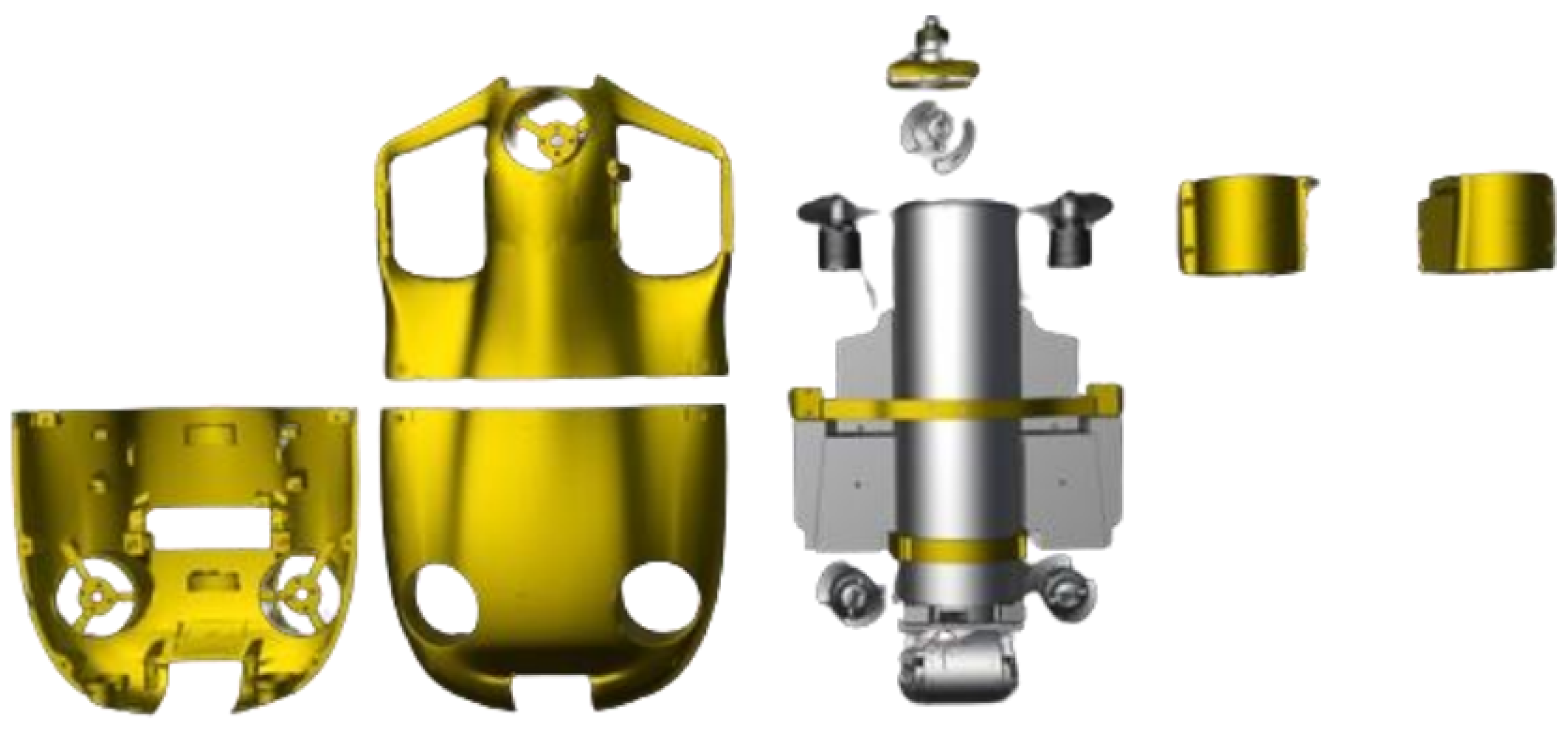

The 3D model development phase involved segmenting the CPS Drone model into its individual components (

Figure 2), allowing independent manipulation of each part in the ShapesXR environment. In Blender, each component was subjected to an optimization and individual texturing process, followed by optimized export for integration into the VR environment [

6]. Procedural animations were implemented to facilitate the disassembly and assembly sequences, as well as advanced performance optimization techniques, including an adaptive Level of Detail (LOD) system [

12]. The construction of the interactive VR environment was carried out using ShapesXR, implementing ergonomic user interface elements adapted to the VR environment. The integration of Meta Quest 3’s Touch Plus controllers was optimized, and advanced VR interaction techniques were implemented based on the research of [

13]. A step-by-step guide system was developed following the multimedia learning principles of [

14], and a real-time feedback and user performance evaluation system was implemented using machine learning algorithms and natural language processing, inspired by the approach of [

15] for intelligent tutoring systems in virtual environments.

4. Results

The development of the interactive virtual reality (VR) application successfully achieved the stated objectives, establishing an advanced educational tool that allows users to perform disassembly and assembly tasks of 3D models of complex industrial systems. Using the Meta Quest 3 platform and the ShapesXR development environment, an immersive and interactive environment has been implemented, replicating high-fidelity industrial scenarios, thus facilitating experiential learning in a controlled and safe environment.

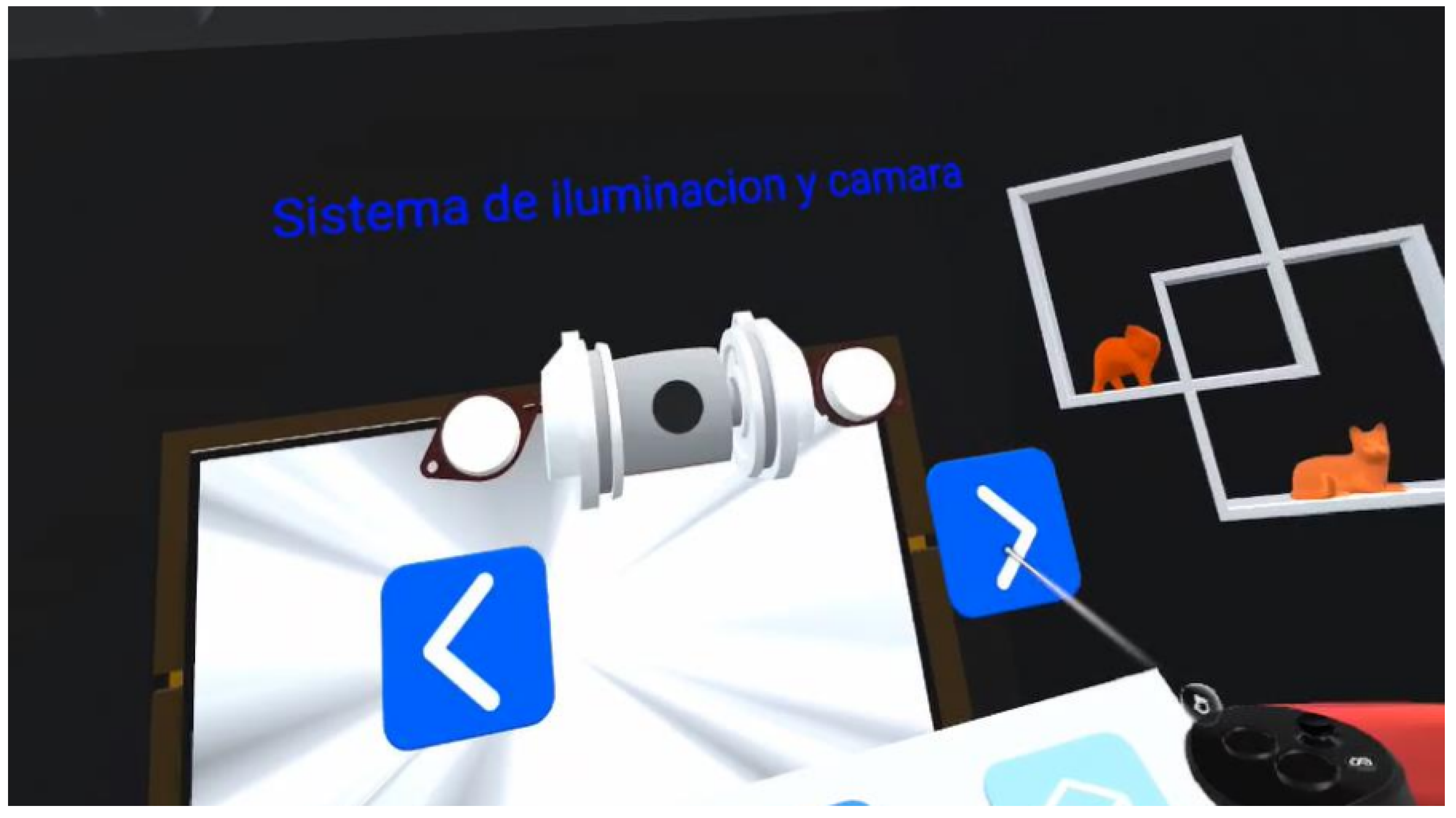

Figure 4.

Interaction with components in the VR environment.

Figure 4.

Interaction with components in the VR environment.

Figure 5.

Interactive VR environment in ShapesXR.

Figure 5.

Interactive VR environment in ShapesXR.

One of the most notable results is the users’ ability to manipulate virtual components in a detailed and precise manner. The 3D models developed and optimized for VR allow for smooth interaction, maintaining a balance between the complexity of the systems represented and the ease of manipulation by users. This approach has enabled both students and professionals to acquire advanced technical skills without facing the risks of a real industrial environment. Additionally, the application provides an immersive experience that significantly enhances technical understanding of the systems represented, compared to traditional teaching methods based on 2D simulations or theoretical exercises.

The performance of the application has been generally positive. Despite the limitations imposed by the use of educational versions of software like Fusion 360 and Blender, which restrict storage and processing capacity of the 3D models, the implementation has managed to handle high-resolution models without significantly compromising the fluidity of the environment. The integrity of textures and essential component details were maintained, ensuring that users can visualize and understand the assembly of industrial systems with clarity.

However, some areas for improvement were identified. For example, the virtual environment in which the interaction takes place, while functional, lacks an aesthetic level that could enhance the immersive experience. The inclusion of more detailed textures and improvements in lighting and environment rendering could provide a more engaging and visually appealing experience. Additionally, it was observed that some additional functionalities, such as dynamic simulations of system operation, would further improve the interactivity and pedagogical value of the application.

Users who participated in initial testing of the application highlighted the ease of use of the graphical interface, which allows intuitive navigation between the different assembly and disassembly options for the models. The interaction tools with the components, such as rotation, zoom, and part separation controls, were effective in allowing practical learning, and the learning curve for the tool was relatively short, even for those with no prior VR experience.

In terms of educational impact, the results demonstrate that virtual reality provides a significantly more effective environment for advanced technical teaching compared to traditional tools. The ability of users to directly interact with the 3D models and disassemble or assemble components at their own pace fosters a deeper understanding of technical concepts and improves knowledge retention. Furthermore, the use of simulated environments allows users to become familiar with complex industrial systems without the physical or economic risks associated with real equipment.

5. Conclusions

The implementation of this educational virtual reality application has proven to be highly effective in the context of advanced technical training, offering an innovative solution within the framework of Industry 4.0. The project has successfully integrated virtual reality into technical education, allowing users to perform complex disassembly and assembly tasks of industrial models without the need to access expensive equipment or face the inherent risks of an industrial environment.

The use of immersive technologies like VR not only enhances the learning experience by providing a deeper understanding of technical systems, but also represents a viable and efficient alternative to traditional teaching methods based on physical component manipulation. The ability of users to experiment with these models in a controlled virtual environment fosters experimentation and reduces costs related to wear or damage to real equipment, a key factor in the adoption of this technology in technical education.

However, it should be noted that the development of the application was limited by the constraints inherent in the use of educational software versions, which affected the ability to handle more complex or highly detailed models. While the project was successful in its implementation, the storage and processing limitations highlighted the need for more robust tools for future developments. With access to unrestricted software and greater processing capacity, the potential of the project could be much greater, allowing for an even richer experience in terms of visuals and interaction.

Another relevant aspect is the possibility of expanding the functionality of the application by including dynamic simulations that allow users not only to interact with the components but also to observe their operation within a complete system. Such features could enhance the user’s understanding of how industrial systems operate together, offering an even more valuable learning experience.

In conclusion, the project has demonstrated the potential of virtual reality as an advanced pedagogical tool, not only for its ability to improve the understanding of complex systems but also for its safety, efficiency, and scalability in technical training. The areas of improvement identified in terms of performance and functionality open the door to future optimizations, which will undoubtedly further elevate the quality and effectiveness of this type of solution in the educational field.

Future developments should aim to improve the aesthetics of the virtual environment by optimizing textures and incorporating more advanced lighting effects. Additionally, further functionalities, such as dynamic simulations of the represented systems and greater real-time interaction with components, could be explored.

References

- L. Green and M., Zhao. Evaluating the effectiveness of vr in engineering education: A meta-analysis. Educational Technology Research and Development 2020, 68, 1903–1925. [Google Scholar]

- M. Wang, V. Callaghan, J. Bernhardt, K. White, and A. Pe˜na-Rios, Augmented reality and virtual reality: Empowering human, place and business. Springer, 2018.

- G. Burdea and P., Coiffet. The impact of virtual reality-based training on health care: a survey among medical colleges in china. International Journal of Medical Informatics 2019, 126, 118–125. [Google Scholar]

- G. Makransky and G. B. Petersen, “Motivational and cognitive benefits of training in immersive virtual reality based on multiple assessments,” Journal of Computer Assisted Learning, vol. 35, no. 6, pp. 691–707, 2019.

- R. Thompson and E., Andrews. Advances in standalone vr devices: Analysis of meta quest 3 performance and applications. IEEE Transactions on Visualization and Computer Graphics 2023, 28, 987–995. [Google Scholar]

- J. Brown and D. Smith, “Development and evaluation of an immersive virtual reality training system for mechanical assembly tasks,” Virtual Reality, vol. 26, pp. 441–455, 2022.

- M. Roussou, “Immersive interactive virtual reality in the museum,” Proceedings of TiLE (Trends in Leisure Entertainment), 2006.

- S. White and R. Johnson, “Optimization techniques for 3d models in virtual reality applications,” Computer Graphics Forum, vol. 40, no. 1, pp. 283–302, 2021.

- J. Cao, Z. Huang, and W. B. Tay, “Adaptive level-ofdetail and dynamic streaming of 3d models for virtual reality applications,” IEEE Transactions on Visualization and Computer Graphics, vol. 25, no. 5, pp. 2049– 2062, 2019.

- N. E. Seymour, A. G. Gallagher, S. A. Roman, M. K. O’Brien, V. K. Bansal, D. K. Andersen, and R. M. Satava, “Virtual reality training improves operating room performance: results of a randomized, double-blinded study,” Annals of surgery, vol. 236, no. 4, p. 458, 2002.

- J. L. Gabbard, D. Hix, and J. E. Swan. Usability engineering for virtual environments: A structured method for comparing task support mechanisms. Presence: Teleoperators & Virtual Environments 2003, 12, 588–612. [Google Scholar]

- D. Luebke, M. Reddy, J. D. Cohen, A. Varshney, B. Watson, and R. Huebner, Level of detail for 3D graphics. Morgan Kaufmann, 2003.

- D. A. Bowman, E. Kruijff, J. J. LaViola Jr. An introduction to 3-d user interface design. Presence: Teleoperators & Virtual Environments 2001, 10, 96–108. [Google Scholar]

- R. E. Mayer, “Multimedia learning,” Psychology of learning and motivation, vol. 41, pp. 85–139, 2002.

- W. L. Johnson and J. C. Lester, “Intelligent tutoring systems: An overview,” Handbook of Artificial Intelligence in Education, pp. 1–16, 2017.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).