Submitted:

17 October 2024

Posted:

20 November 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

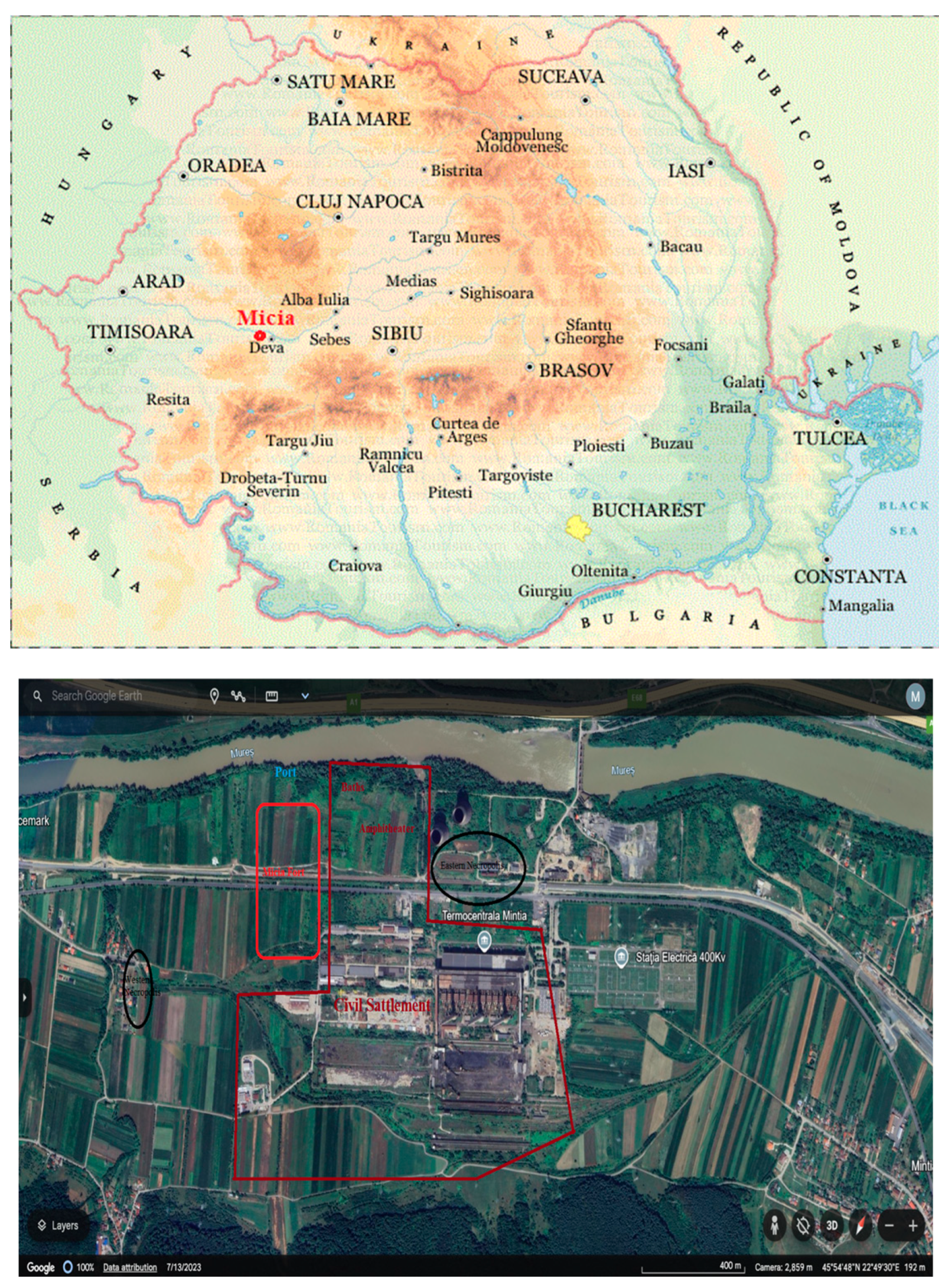

2. Description of the Archaeological Site

2.1. The Fort and the Ancient Settlement of Micia

3. Materials and Methods

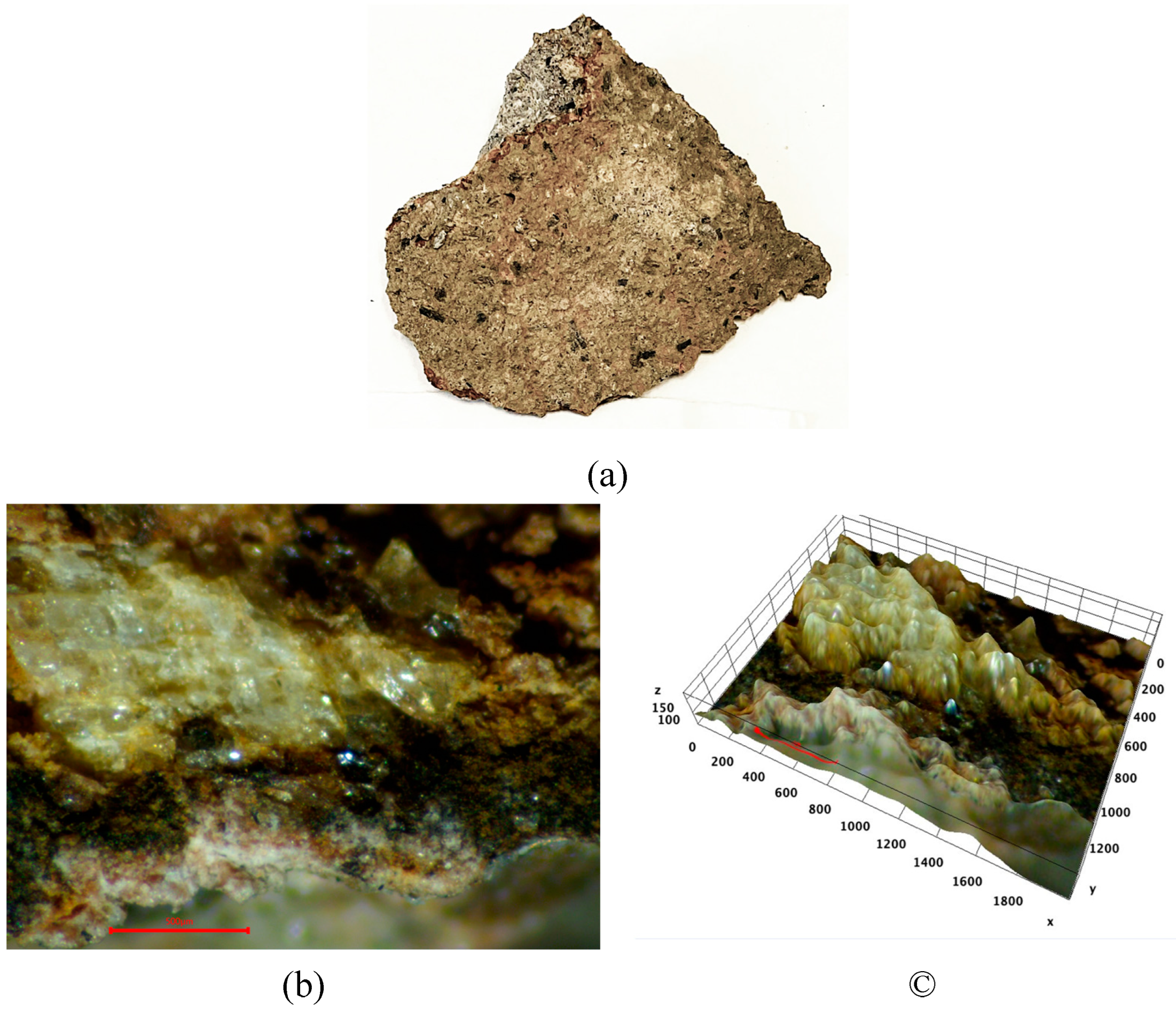

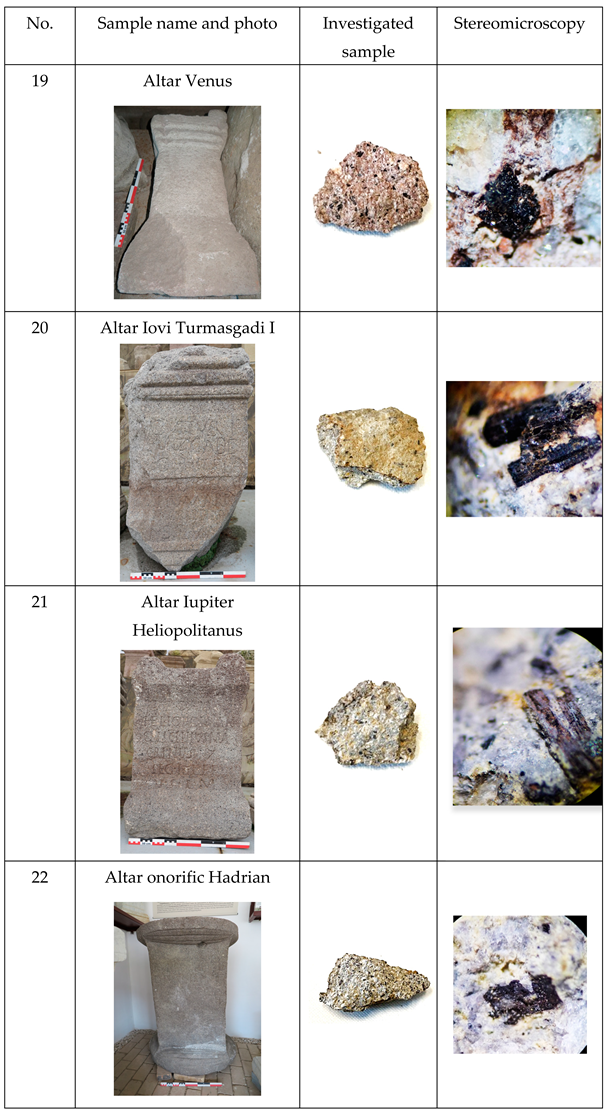

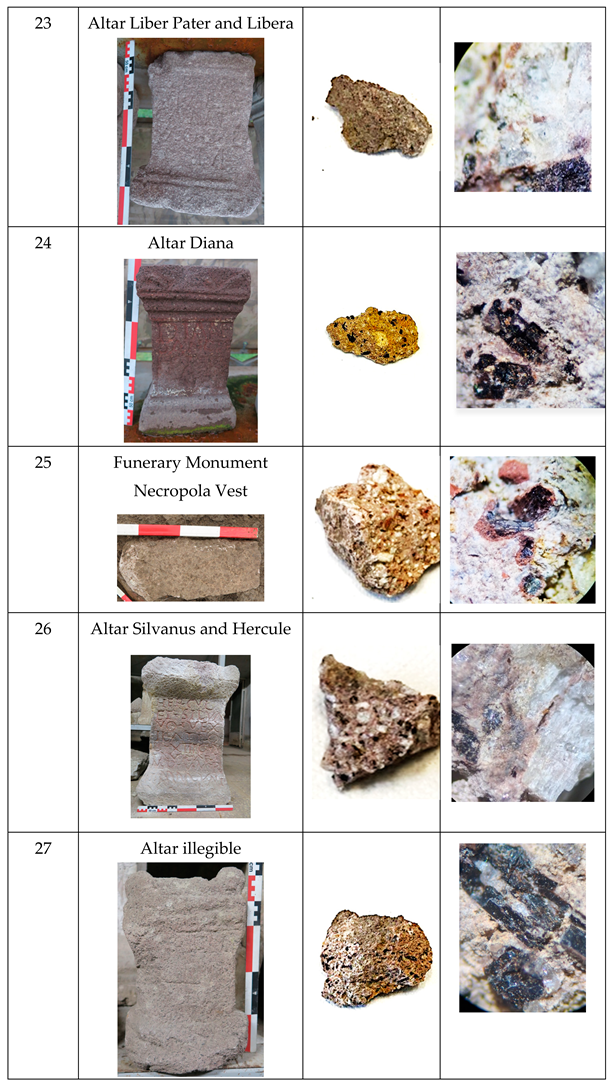

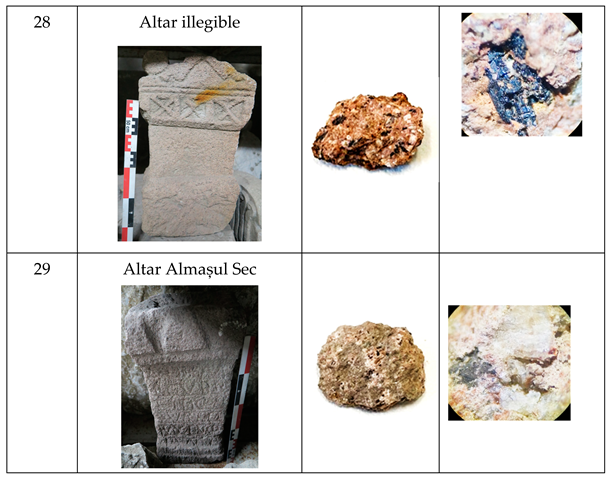

3.1. Materials

3.2. Analytical Techniques

4. Results

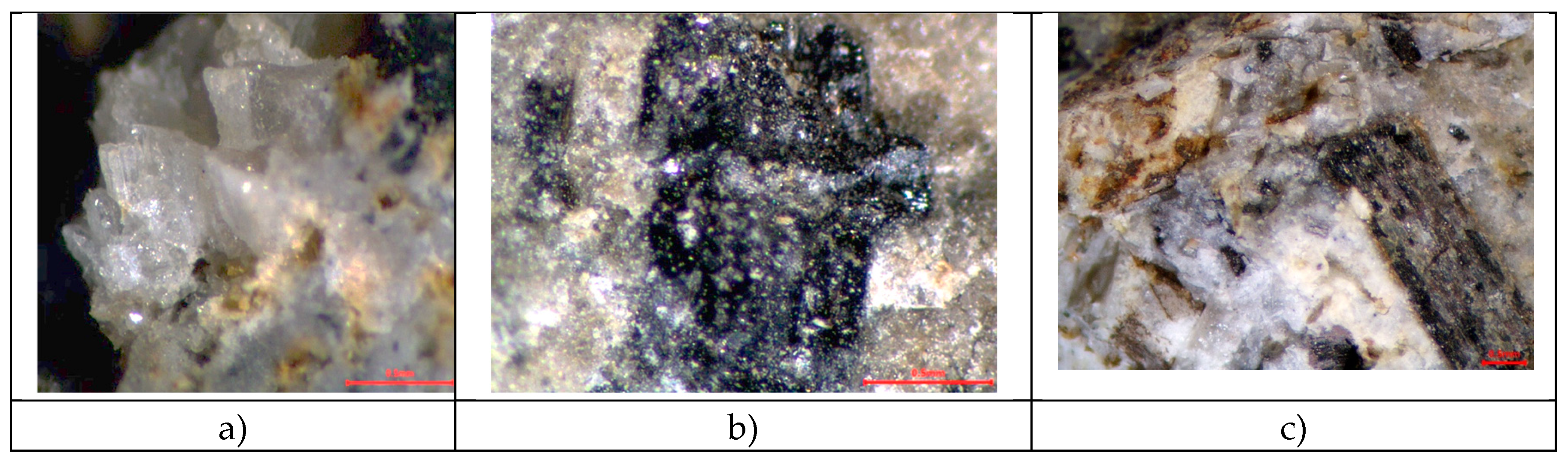

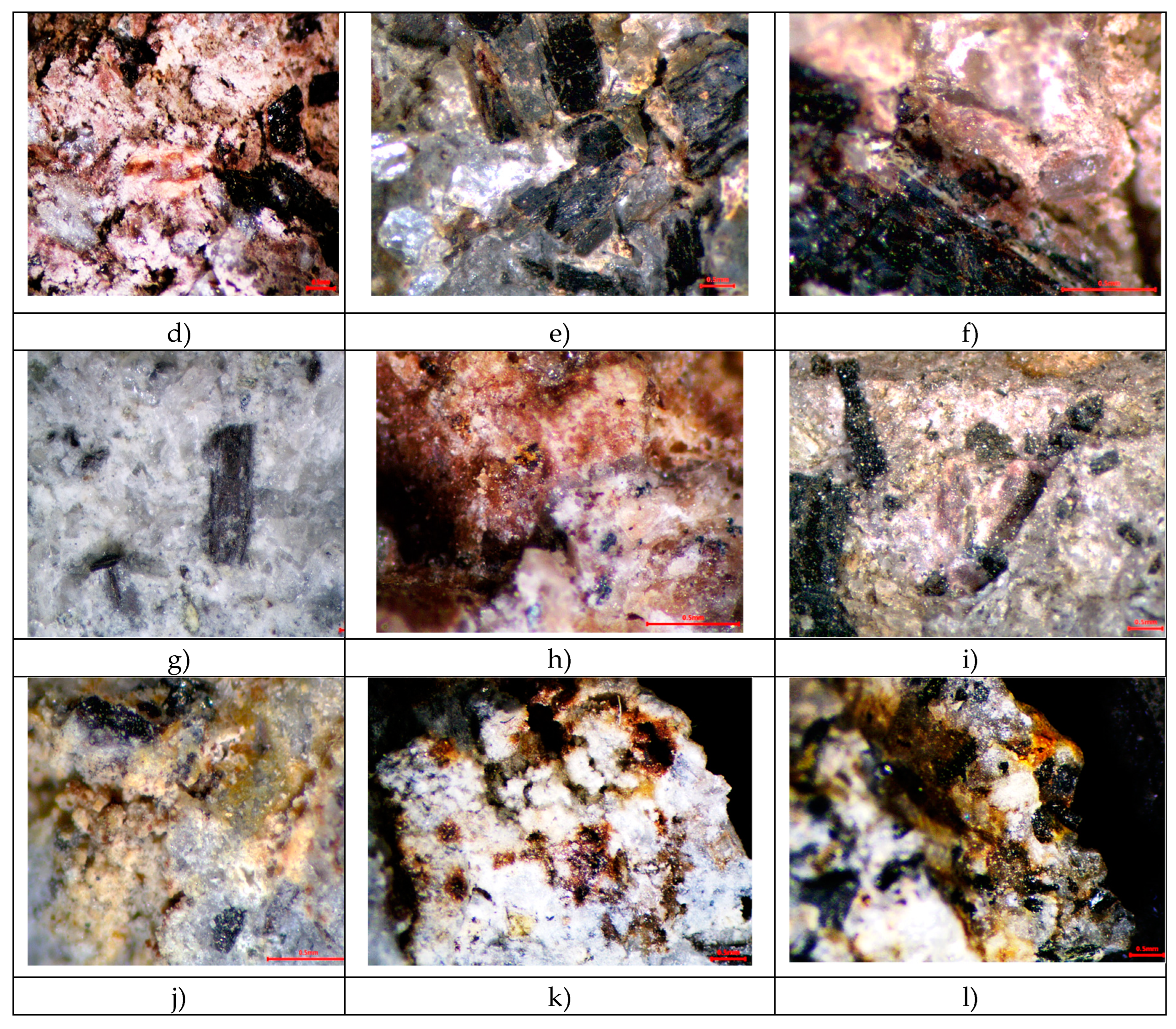

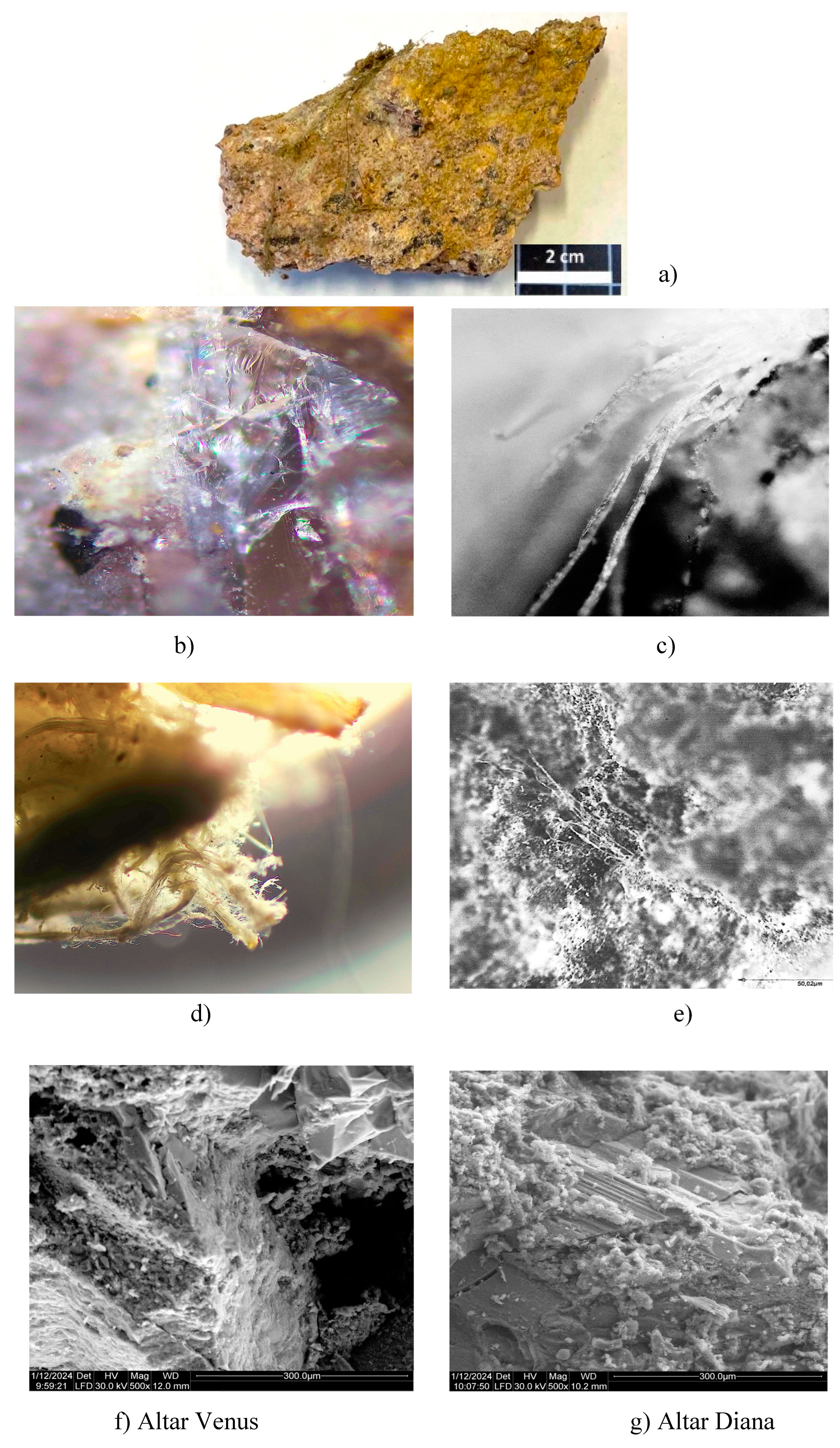

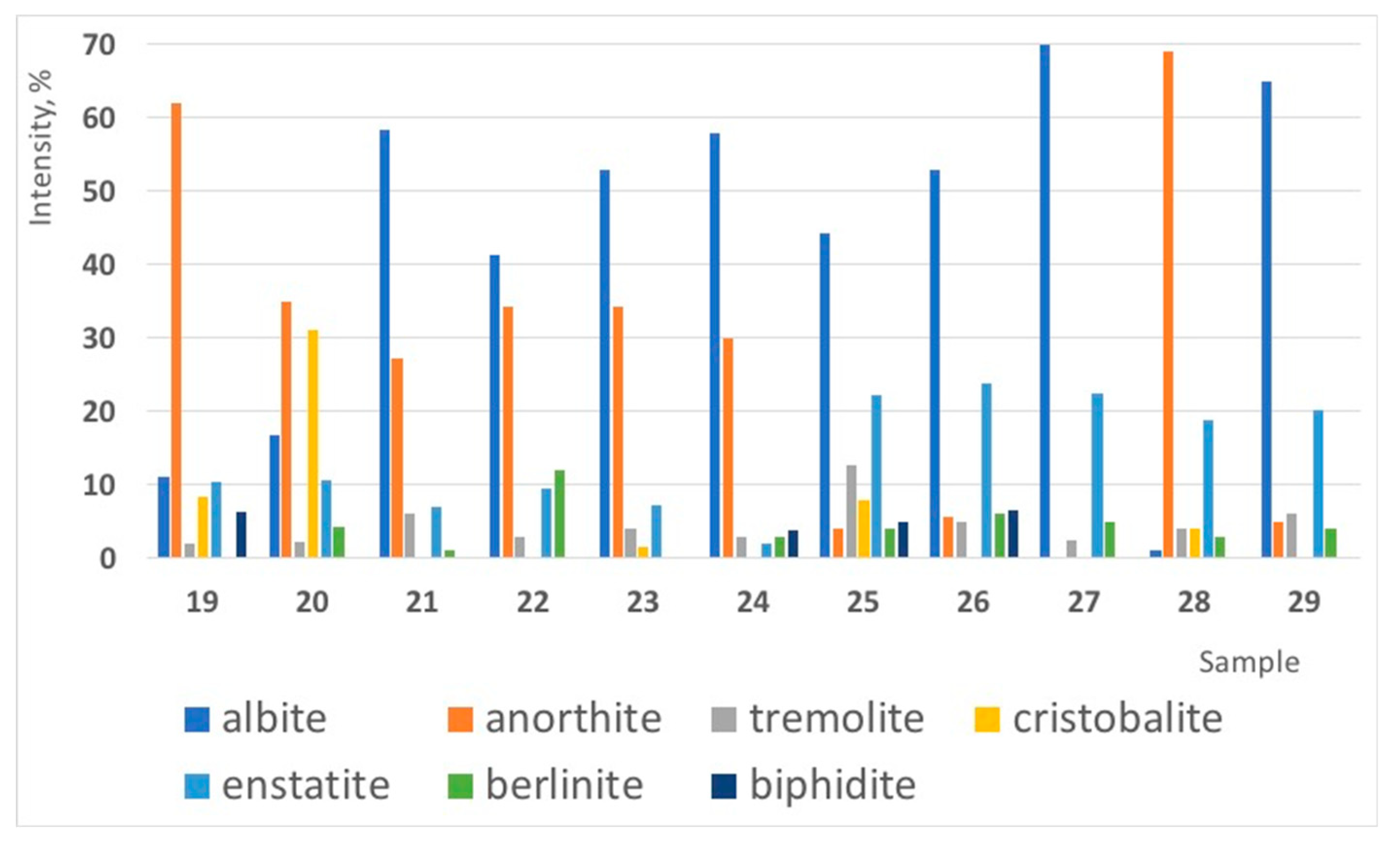

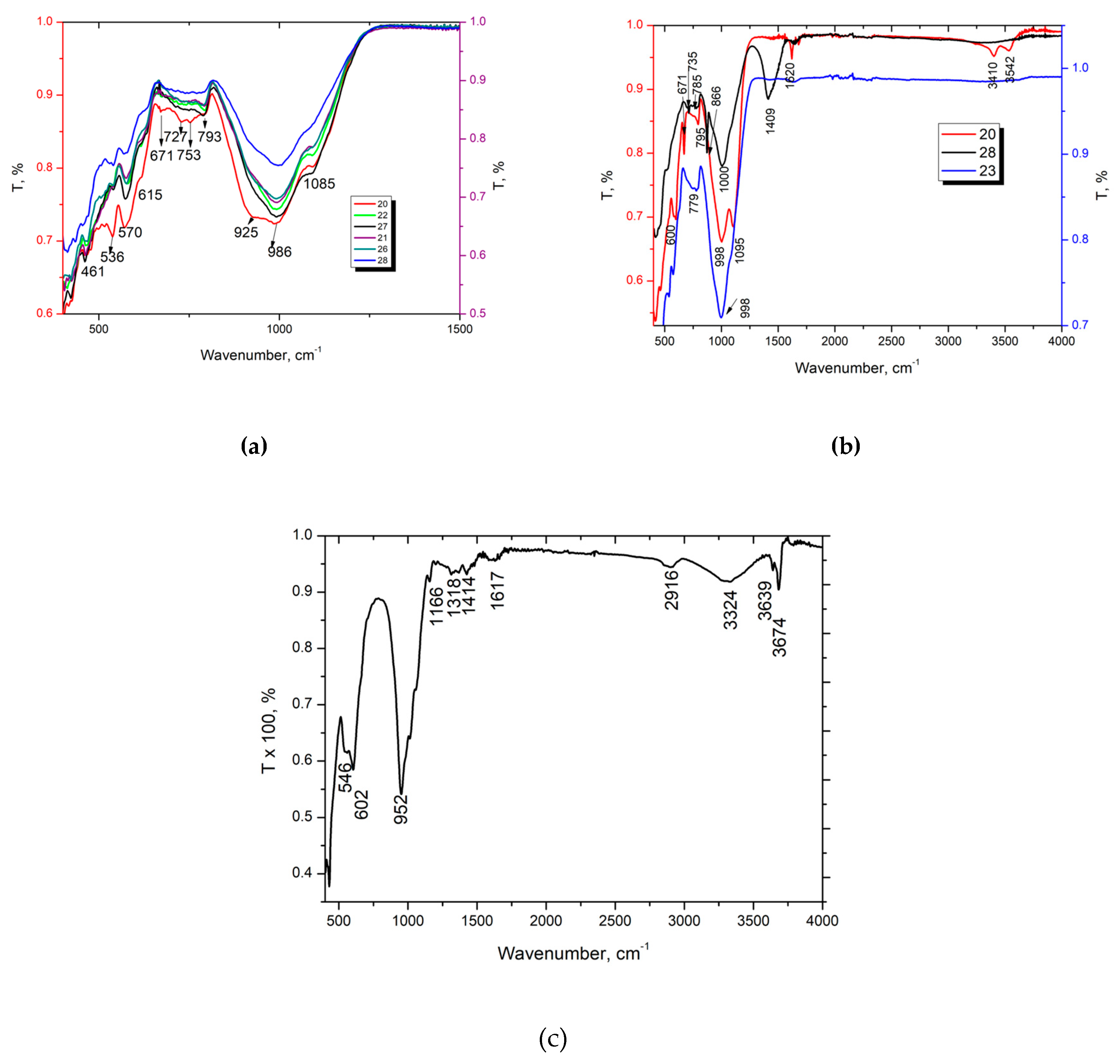

4.1. Microscopic, Mineralogical and Compositional Analysis

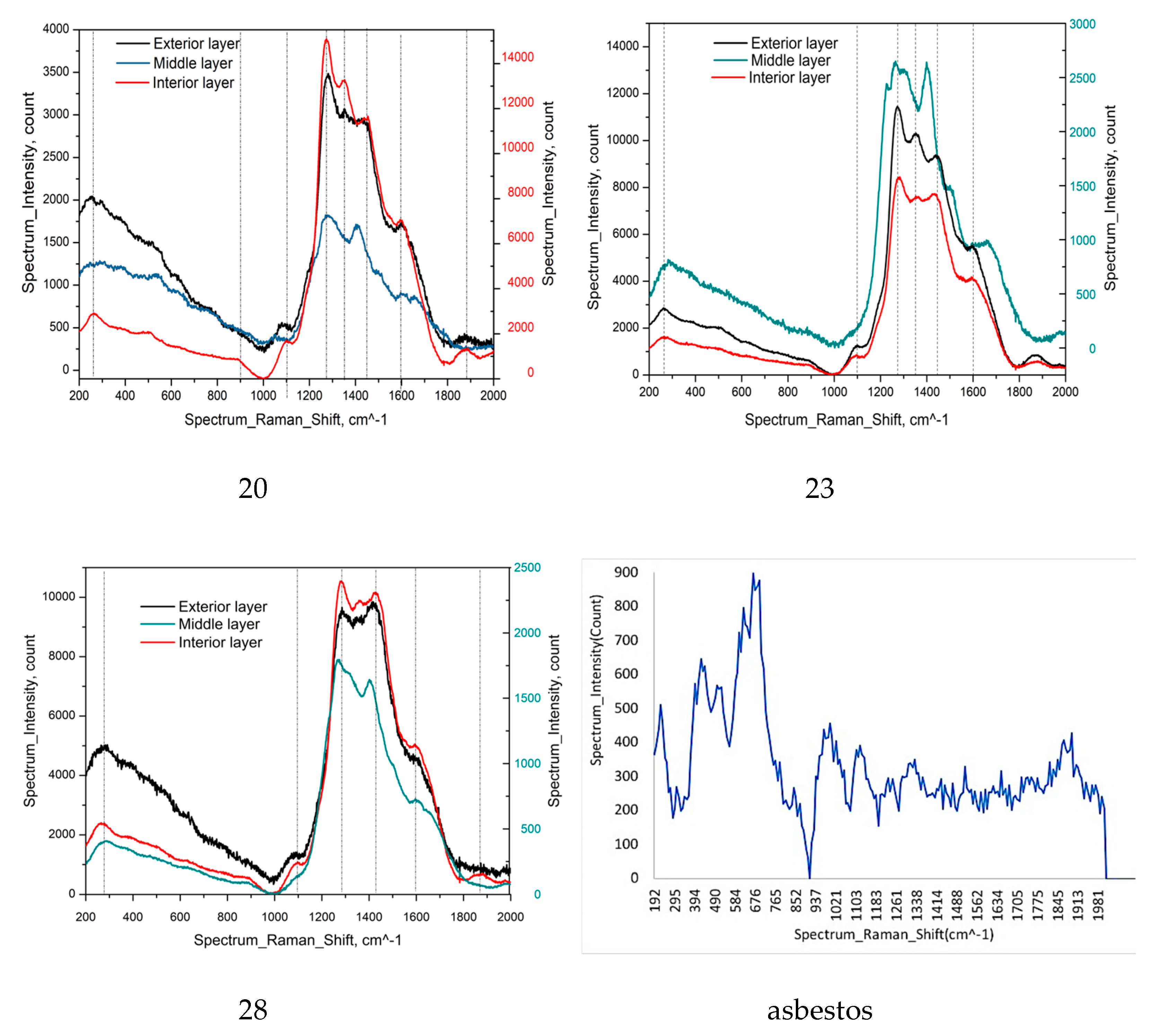

4.2. Microscopy Evidence of Tremolite-Asbestos Fibers

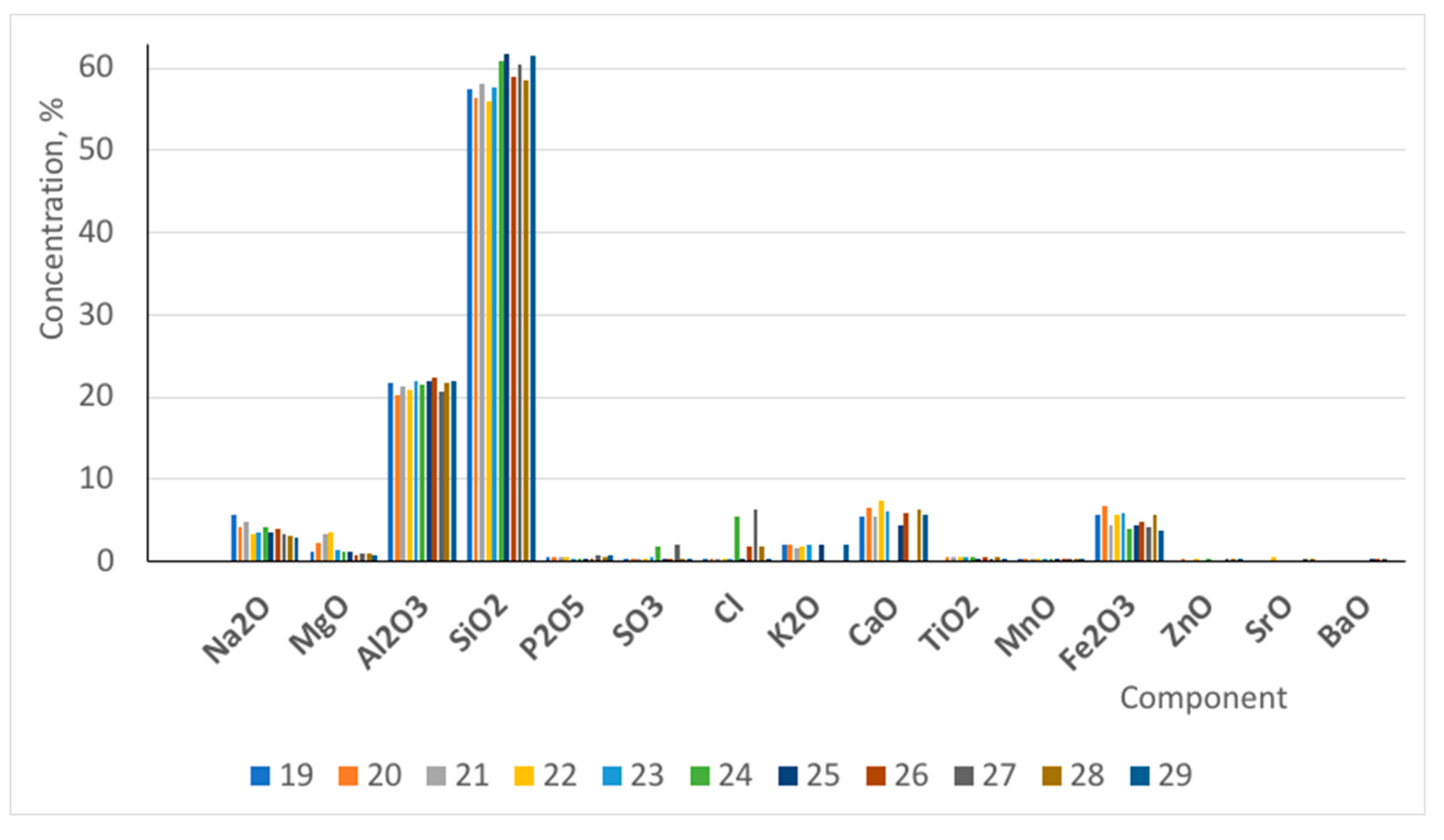

4.4. Chemical Analysis

5. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Adam, J. Roman building: materials and techniques; Taylor & Francis Group: London, 1994. [Google Scholar]

- Ion, R.-M.; Barbu, M.G.; Gonciar, A.; Vasilievici, G.; Gheboianu, A.I.; Slamnoiu-Teodorescu, S.; David, M.E.; Iancu, L.; Grigorescu, R.M. A Multi-Analytical Investigation of Roman Frescoes from Rapoltu Mare (Romania). Coatings 2022, 12, 530. [Google Scholar] [CrossRef]

- Ion, R.M.; Bakirov, B.A.; Kichanov, S.E.; Kozlenko, D.P.; Belushkin, A.V.; Radulescu, C.; Dulama, I.D.; Bucurica, I.A.; Gheboianu, A.I.; Stirbescu, R.M. Non-Destructive and micro-invasive techniques for characterizing the ancient Roman Mosaic fragments. Appl. Sci. 2020, 10, 3781. [Google Scholar] [CrossRef]

- Borsoi, G.; Silva, A.S.; Menezes, P.; Candeias, A.; Mirão, J. Analytical characterization of ancient mortars from the archaeological roman site of Pisões (Beja, Portugal). Constr. Build. Mater. 2019, 204, 597–608. [Google Scholar] [CrossRef]

- Bakolas, A.; Biscontin, G.; Contardi, V.; Franceschi, E.; Moropoulou, A.; Palazzi, D.; Zendri, E. Thermoanalytical research on traditional mortars in Venice. Thermochim. Acta 1995, 269, 817–828. [Google Scholar] [CrossRef]

- Belfiore, C.M.; Fichera, G.V.; La Russa, M.F.; Pezzino, A.; Ruffolo, S.; Galli, G.; Barca, D. A Multidisciplinary Approach for the Archaeometric Study of Pozzolanic Aggregate in R oman Mortars: The Case of V illa dei Q uintili (R ome, I taly). Archaeometry 2015, 57, 269–296. [Google Scholar] [CrossRef]

- Belfiore, C.M.; Fichera, G.V.; Ortolano, G.; Pezzino, A.; Visalli, R.; Zappalà, L. Image processing of the pozzolanic reactions in Roman mortars via X-Ray Map Analyser. Microchem. J. 2016, 125, 242–253. [Google Scholar] [CrossRef]

- Böke, H.; Çizer, Ö.; İpekoğlu, B.; Uğurlu, E.; Şerifaki, K.; Toprak, G. Characteristics of lime produced from limestone containing diatoms. Constr. Build. Mater. 2008, 22, 866–874. [Google Scholar] [CrossRef]

- Bruno, P.; Calabrese, D.; Di Pierro, M.; Genga, A.; Laganara, C.; Manigrassi, D.; Traini, A.; Ubbrıaco, P. Chemical–physical and mineralogical investigation on ancient mortars from the archaeological site of Monte Sannace (Bari—Southern Italy). Thermochim. Acta 2004, 418, 131–141. [Google Scholar] [CrossRef]

- DeLaine, J. Theory and practice of Roman architecture: studies offered to Pierre Gros. 2006.

- DeLaine, J. Production, transport and on-site organisation of Roman mortars and plasters. Archaeol. Anthropol. Sci. 2021, 13, 1–17. [Google Scholar] [CrossRef]

- Alicu, D. Turnuri de porti la castrele romane din Dacia. Acta Musei Napoc. 1973, 107–122. [Google Scholar]

- Alicu, D. Micia: Studii monografice. 1. Monumentele de spectacol şi de cult. 2004.

- Petculescu, L. Sapaturile arheologice din castrul Micia. Cercet. Arheol. 1984, VII, 117–119. [Google Scholar]

- Andritoiu, I. Istoricul cercetarilor privitoare la asezarea si fortificatia romana de la Micia. Sargetia 2003, XXXI, 181–202. [Google Scholar]

- Andrițoiu, I. Necropolele Miciei; Excelsior Art: Timisoara, 2006. [Google Scholar]

- Barbu, M.G. Consideratii privind planimetria castrului Micia. In Proceedings of the Simpozionul Stiintific National "Micia Rediviva", Deva, 2018., October 24-26.

- Czajlik, Z.; Berencki, S.; Rupnik, L. Aerial geoarchaeological survey in the valleys of the Mureş and Arieş rivers (2009-2013). Diss. Archaeol. 2014, 459–483. [Google Scholar] [CrossRef]

- Daicoviciu, C. Micia, I. Cercetări asupra castrului. Analele Comisiei Monumentelor Istorice; 1931; pp. 1–43.

- Floca, O.; Marghitan, L. Noi consideratii privitoare la castrul roman de la Micia. Sargetia 1970, VII, 43–57. [Google Scholar]

- Barbu, M.G.; Barbat, I.A. New Archaeological Information Regarding the Exploitation of Andesite in Măgura Uroiului (Hunedoara County). Sargetia 2017, VIII, 71–121. [Google Scholar]

- Barbu, M.G.; Barbat, I.A.; Tutuianu, C.-D. New Data about the Exploitation of Andesite in Prehistory and Antiquity in the Proximity of Deva City. Terra Sebus 2021, 13, 57–91. [Google Scholar]

- Petculescu, L. Cercetari arheologice in castrul roman de la Micia. Cercet. Arheol. 1979, III, 111–114. [Google Scholar]

- Neigebaur, J.D.F. Dacien: aus den Ueberresten des klassischen Alterthums, mit besonderer Rücksicht auf Siebenbürgen; Gött: 1851.

- Negula, D.I.; Moise, C.; Lazăr, A.M.; Rișcuța, N.C.; Cristescu, C.; Dedulescu, A.L.; Mihalache, C.E.; Badea, A. Satellite remote sensing for the analysis of the Micia and Germisara archaeological sites. Remote Sens. 2020, 12, 2003. [Google Scholar] [CrossRef]

- Bostock, J.; Riley, H.T. The Natural History. Pliny the Elder.. 1885. [Google Scholar]

- King, D.; History of Asbestos. Asbestos.com. Available online: https://www.asbestos.com/asbestos/history/. (accessed on October 1).

- Bianchi, C.; Bianchi, T. Asbestos between science and myth. A 6,000-year story. La Med. Del Lav. 2015, 106, 83–90. [Google Scholar]

- Oltean, I.; Hanson, W. Military vici in Roman Dacia: an aerial perspective. Acta Musei Napoc. 2001, 38, 123–134. [Google Scholar]

- Oltean, I.A.; Hanson, W.S. Defining the Roman limes in Romania: the contribution of aerial and satellite remote sensing. In Proceedings of the Limes XXII: Proceedings of the 22nd International Congress of Roman Frontier Studies, Ruse, Bulgaria, 2012; pp. 889–900.

- Marinescu, L.; Sion, A.; Petculescu, L.; Andritoiu, I.; Ionescu, E.; Braileanu, M. Santierul arheologic Micia (Vetel, jud. Hunedoara). Cercet. Arheol 1979, 3, 105–126. [Google Scholar]

- Petculescu, L.; Nemoianu, A.T.; Anastasiu, R. Raport preliminar asupra săpăturilor arheologice din 1978– 1979 în castrul Micia, co-muna Vetel, jud. Hunedoara. Cercet. Arheol. 1981, IV, 70–75. [Google Scholar]

- Petculescu, L. Castrul de la Micia (Vețel, jud. Hunedoara) în cadrul sistemului de apărare al Daciei romane. MUZEUL NAȚIONAL 1981, 109–114. [Google Scholar]

- Petculescu, L. Raport asupra sapaturilor arheologice din castrul Micia. Cercet. Arheol. 1983, VI, 45–50. [Google Scholar]

- Petculescu, L.; Filipescu, B.; Craciun, C. Raport asupra sapaturilor arheologice din castrul Micia (cpm. Vetel, Jud. Hunedoara), in campania 1983. Cercet. Arheol. 1986, VIII, 59–62. [Google Scholar]

- Allaby, M. A dictionary of earth sciences 3th Edition. 2008.

- D-16, A. Standard practice for calculation of color tolerances and color differences from instrumentally measured color coordinates. 2016.

- 15886, U.-E. Conservation of Cultural Property—Test Methods—Colour Measurement of Surfaces. 2011.

- Gheorghiu, C.; Mares, I. Erupţiunile neogene din Valea Mureşului (regiunea Deva-Zam) şi particularităţile petrografice ale rocilor; 1961.

- Leake, B.E.; Woolley, A.R.; Arps, C.E.; Birch, W.D.; Gilbert, M.C.; Grice, J.D.; Hawthorne, F.C.; Kato, A.; Kisch, H.J.; Krivovichev, V.G. Nomenclature of amphiboles; report of the Subcommittee on Amphiboles of the International Mineralogical Association Commission on new minerals and mineral names. Mineral. Mag. 1997, 61, 295–310. [Google Scholar] [CrossRef]

- Hawthorne, F.C.; Oberti, R.; Harlow, G.E.; Maresch, W.V.; Martin, R.F.; Schumacher, J.C.; Welch, M.D. Nomenclature of the amphibole supergroup. Am. Mineral. 2012, 97, 2031–2048. [Google Scholar] [CrossRef]

- Ballirano, P.; Bloise, A.; Gualtieri, A.F.; Lezzerini, M.; Pacella, A.; Perchiazzi, N.; Dogan, M.; Dogan, A.U. The crystal structure of mineral fibres. In Mineral Fibres: Crystal Chemistry, Chemical-Physical Properties, Biological Interaction and Toxicity, Gualtieri, A.F., Ed.; European Mineralogical Union: 2017; Volume 18, p. 0.

- Altaner, S.P.; Grim, R.E. Mineralogy, chemistry, and diagenesis of tuffs in the Sucker Creek Formation (Miocene), eastern Oregon. Clays Clay Miner. 1990, 38, 561–572. [Google Scholar] [CrossRef]

- Andreozzi, G.B.; Ballirano, P.; Gianfagna, A.; Mazziotti-Tagliani, S.; Pacella, A. Structural and spectroscopic characterization of a suite of fibrous amphiboles with high environmental and health relevance from Biancavilla (Sicily, Italy). Am. Mineral. 2009, 94, 1333–1340. [Google Scholar] [CrossRef]

- Bozhilov, K.N.; Jenkins, D.M. Analytical electron microscopy of tremolite. Mod. Res. Educ. Top. Microsc. 2007, 2, 616–625. [Google Scholar]

- Elsen, J. Microscopy of historic mortars—a review. Cem. Concr. Res. 2006, 36, 1416–1424. [Google Scholar] [CrossRef]

- Yang, H.; Evans, B.W. X-ray structure refinements of tremolite at 140 and 295 K; crystal chemistry and petrologic implications. Am. Mineral. 1996, 81, 1117–1125. [Google Scholar] [CrossRef]

- Zussman, J. Minerals and the electron microscope. Mineral. Mag. 1987, 51, 129–138. [Google Scholar] [CrossRef]

- Hawthorne, F.C.; Ventura, G.D.; Robert, J.-L.; Welch, M.D.; Raudsepp, M.; Jenkins, D.M. A Rietveld and infrared study of synthetic amphiboles along the potassium-richterite–tremolite join. Am. Mineral. 1997, 82, 708–716. [Google Scholar] [CrossRef]

- Petry, R.; Mastalerz, R.; Zahn, S.; Mayerhöfer, T.G.; Völksch, G.; Viereck-Götte, L.; Kreher-Hartmann, B.; Holz, L.; Lankers, M.; Popp, J. Asbestos Mineral Analysis by UV Raman and Energy-Dispersive X-ray Spectroscopy. Chemphyschem: A Eur. J. Chem. Phys. Phys. Chem. 2006, 7, 414–420. [Google Scholar] [CrossRef]

- Della Ventura, G.; Vigliaturo, R.; Gieré, R.; Pollastri, S.; Gualtieri, A.F.; Iezzi, G. Infra Red spectroscopy of the regulated asbestos amphiboles. Minerals 2018, 8, 413. [Google Scholar] [CrossRef]

- Millette, J.R.; Bandli, B.R. Asbestos identification using available standard methods. MICROSCOPE-LONDON THEN CHICAGO- 2005, 53, 179. [Google Scholar]

- Campopiano, A.; Olori, A.; Cannizzaro, A.; Iannò, A.; Capone, P.P. Quantification of tremolite in friable material coming from Calabrian ophiolitic deposits by infrared spectroscopy. J. Spectrosc. 2015, 2015, 974902. [Google Scholar] [CrossRef]

- Speil, S.; Leineweber, J. Asbestos Minerals in. Environ. Res. 1969, 2. [Google Scholar] [CrossRef]

- Apopei, A.I.; Buzgar, N. The Raman study of amphiboles. Analele Stiintifice De Univ. AI Cuza Din Iasi. Sect. 2 Geol. 2010, 56, 57. [Google Scholar]

- Rinaudo, C.; Belluso, E.; Gastaldi, D. Assessment of the use of Raman spectroscopy for the determination of amphibole asbestos. Mineral. Mag. 2004, 68, 455–465. [Google Scholar] [CrossRef]

- Bersani, D.; Andò, S.; Scrocco, L.; Gentile, P.; Salvioli-Mariani, E.; Fornasini, L.; Lottici, P.P. Composition of amphiboles in the tremolite–ferro–actinolite series by Raman Spectroscopy. Minerals 2019, 9, 491. [Google Scholar] [CrossRef]

- Leissner, L. Crystal chemistry of amphiboles studied by Raman spectroscopy. Mineral. -Petrogr. Inst. -Univ. Hambg. Hambg. Ger. 2014. [Google Scholar]

- Leissner, L.; Schlüter, J.; Horn, I.; Mihailova, B. Exploring the potential of Raman spectroscopy for crystallochemical analyses of complex hydrous silicates: I. Amphiboles. Am. Mineral. 2015, 100, 2682–2694. [Google Scholar] [CrossRef]

- Hawthorne, F.C.; Oberti, R. Amphiboles: crystal chemistry. Rev. Mineral. Geochem. 2007, 67, 1. [Google Scholar] [CrossRef]

- Rispoli, C.; De Bonis, A.; Esposito, R.; Graziano, S.F.; Langella, A.; Mercurio, M.; Morra, V.; Cappelletti, P. Unveiling the secrets of Roman craftsmanship: mortars from Piscina mirabilis (Campi Flegrei, Italy). Archaeol. Anthropol. Sci. 2020, 12, 1–18. [Google Scholar] [CrossRef]

- Kramar, S.; Zalar, V.; Urosevic, M.; Körner, W.; Mauko, A.; Mirtič, B.; Lux, J.; Mladenović, A. Mineralogical and microstructural studies of mortars from the bath complex of the Roman villa rustica near Mošnje (Slovenia). Mater. Charact. 2011, 62, 1042–1057. [Google Scholar] [CrossRef]

- Ergenç, D.; Fort, R.; Varas− Muriel, M.J.; Alvarez de Buergo, M. Mortars and plasters—How to characterize aerial mortars and plasters. Archaeol. Anthropol. Sci. 2021, 13, 197. [Google Scholar] [CrossRef]

- Kostova, B.; Dumanov, B.; Stoyanov, V.; Shivachev, B. Thermal and phase analysis of Roman and Late Antiquity mortars from Bulgarian archaeological sites. J. Therm. Anal. Calorim. 2023, 148, 1543–1555. [Google Scholar] [CrossRef]

- Bloise, A.; Catalano, M.; Barrese, E.; Gualtieri, A.F.; Bursi Gandolfi, N.; Capella, S.; Belluso, E. TG/DSC study of the thermal behaviour of hazardous mineral fibres. J. Therm. Anal. Calorim. 2016, 123, 2225–2239. [Google Scholar] [CrossRef]

- Viti, C. Serpentine minerals discrimination by thermal analysis. Am. Mineral. 2010, 95, 631–638. [Google Scholar] [CrossRef]

- Izzo, F.; Grifa, C.; Germinario, C.; Mercurio, M.; De Bonis, A.; Tomay, L.; Langella, A. Production technology of mortar-based building materials from the Arch of Trajan and the Roman Theatre in Benevento, Italy. Eur. Phys. J. Plus 2018, 133, 1–12. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Anagnostopoulou, S. Composite materials in ancient structures. Cem. Concr. Compos. 2005, 27, 295–300. [Google Scholar] [CrossRef]

- Gambino, F.; Glarey, A.; Cossio, R.; Appolonia, L.; d’Atri, A.; Borghi, A. SEM-EDS characterization of historic mortar as a tool in archaeometric study: an updated analytical protocol tested on the Roman theatre of Aosta (NW Italy). Archaeol. Anthropol. Sci. 2022, 14, 179. [Google Scholar] [CrossRef]

- De Luca, R.; Cau Ontiveros, M.A.; Miriello, D.; Pecci, A.; Le Pera, E.; Bloise, A.; Crisci, G.M. Archaeometric study of mortars and plasters from the Roman City of Pollentia (Mallorca-Balearic Islands). Period. Di Mineral. 2013, 82, 353–379. [Google Scholar]

- Santos, A.R.; do Rosário Veiga, M.; Silva, A.S.; de Brito, J.; Álvarez, J.I. Evolution of the microstructure of lime based mortars and influence on the mechanical behaviour: The role of the aggregates. Constr. Build. Mater. 2018, 187, 907–922. [Google Scholar] [CrossRef]

- Alvarez, J.I.; Martı́n, A.; Casado, P.G.a.; Navarro, I.; Zornoza, A. Methodology and validation of a hot hydrochloric acid attack for the characterization of ancient mortars. Cem. Concr. Res. 1999, 29, 1061–1065. [Google Scholar] [CrossRef]

- Stade, H. On the reaction of CSH (di, poly) with alkali hydroxides. Cem. Concr. Res. 1989, 19, 802–810. [Google Scholar] [CrossRef]

- Pagano, S.; Germinario, C.; Alberghina, M.F.; Covolan, M.; Mercurio, M.; Musmeci, D.; Piovesan, R.; Santoriello, A.; Schiavone, S.; Grifa, C. Multilayer technology of decorated plasters from the domus of Marcus Vipsanus Primigenius at Abellinum (Campania Region, Southern Italy): an analytical approach. Minerals 2022, 12, 1487. [Google Scholar] [CrossRef]

- Ward-Perkins, J.B. Roman imperial architecture; Yale University Press: 1994.

- Özkaya, Ö.A.; Böke, H. Properties of Roman bricks and mortars used in Serapis temple in the city of Pergamon. Mater. Charact. 2009, 60, 995–1000. [Google Scholar] [CrossRef]

- Fort, R.; Varas-Muriel, M.; Zoghlami, K.; Ergenç, D.; Zaddem, A. Analytical characterisation of 1st-and 2nd-century Roman mortars at the Utica archaeological site (Tunisia): Construction phases and provenance of the raw materials. J. Archaeol. Sci. : Rep. 2024, 54, 104404. [Google Scholar] [CrossRef]

- Marra, F.; Danti, A.; Gaeta, M. The volcanic aggregate of ancient Roman mortars from the Capitoline Hill: Petrographic criteria for identification of Rome's “pozzolans” and historical implications. J. Volcanol. Geotherm. Res. 2015, 308, 113–126. [Google Scholar] [CrossRef]

- Farci, A.; Floris, D.; Meloni, P. Water permeability vs. porosity in samples of Roman mortars. J. Cult. Herit. 2005, 6, 55–59. [Google Scholar] [CrossRef]

- Jackson, M.D.; Logan, J.M.; Scheetz, B.E.; Deocampo, D.M.; Cawood, C.G.; Marra, F.; Vitti, M.; Ungaro, L. Assessment of material characteristics of ancient concretes, Grande Aula, Markets of Trajan, Rome. J. Archaeol. Sci. 2009, 36, 2481–2492. [Google Scholar] [CrossRef]

- Pleuger, E.; Goiran, J.-P.; Mazzini, I.; Delile, H.; Abichou, A.; Gadhoum, A.; Djerbi, H.; Piotrowska, N.; Wilson, A.; Fentress, E. Palaeogeographical and palaeoenvironmental reconstruction of the Medjerda delta (Tunisia) during the Holocene. Quat. Sci. Rev. 2019, 220, 263–278. [Google Scholar] [CrossRef]

- Kawabata, Y.; Yamada, K.; Igarashi, G.; Sagawa, Y. Effects of Soak Solution Type on Alkali Release from Volcanic Aggre-gates− Is Alkali Release Really Responsible for Accelerating ASR Expansion?−. J. Adv. Concr. Technol. 2018, 16, 61–74. [Google Scholar] [CrossRef]

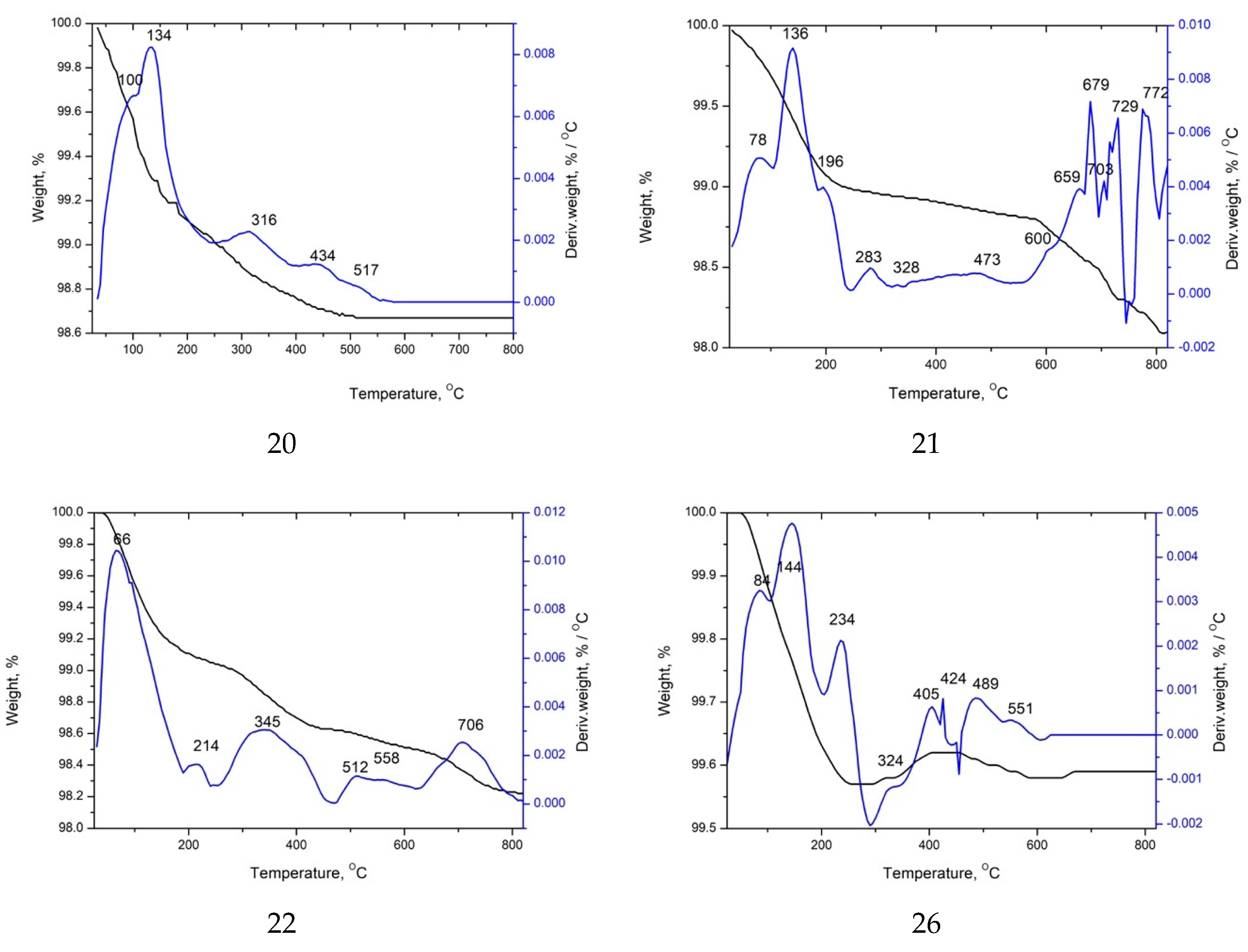

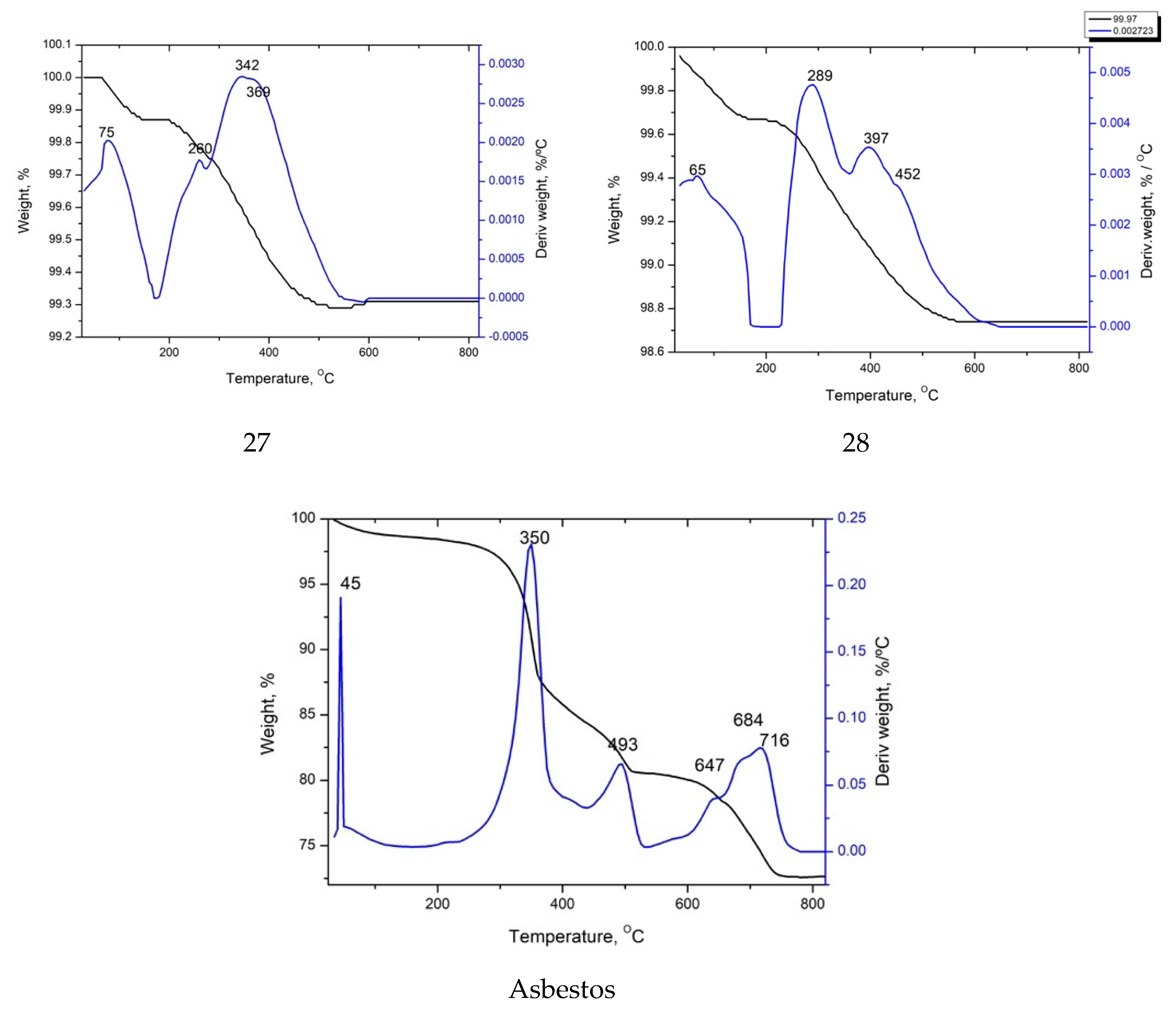

|

| Samples | <120 | 120–200 | 200–600 | >600 | CO2/H2O |

| 20 | 0.61 | 0.28 | 0.44 | 0 | 0 |

| 21 | 0.44 | 0.49 | 0.32 | 0.65 | 2.03 |

| 22 | 0.61 | 0.28 | 0.6 | 0.29 | 0.48 |

| 26 | 0.17 | 0.2 | 0.05 | 0.01 | 0.2 |

| 27 | 0.1 | 0.03 | 0.56 | 0 | 0 |

| 28 | 0.26 | 0.07 | 0.87 | 0 | 0 |

| asbestos | 3.59 | 1.2 | 4.23 | 10.15 | 2.4 |

| Sample | Surface Area (m2/g) | Pore Volume (cc/g) | Pore Diameter (nm) | K2O (%) |

Na2O (%) |

| 20 | 1.215 | 0.001 | 3.083 | 1.97 | 4.23 |

| 21 | 1.751 | 0.002 | 2.945 | 1.61 | 4.82 |

| 22 | 1.531 | 0.002 | 4.786 | 1.79 | 3.22 |

| 26 | 0.893 | 0.001 | 4.807 | 1.87 | 4.01 |

| 27 | 0.112 | 0.000 | 4.759 | 2.08 | 3.29 |

| 28 | 0.522 | 0.001 | 3.668 | 1.81 | 3.08 |

| Asbestos | 0.375 | 0.001 | 2.949 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).