Submitted:

20 November 2024

Posted:

22 November 2024

You are already at the latest version

Abstract

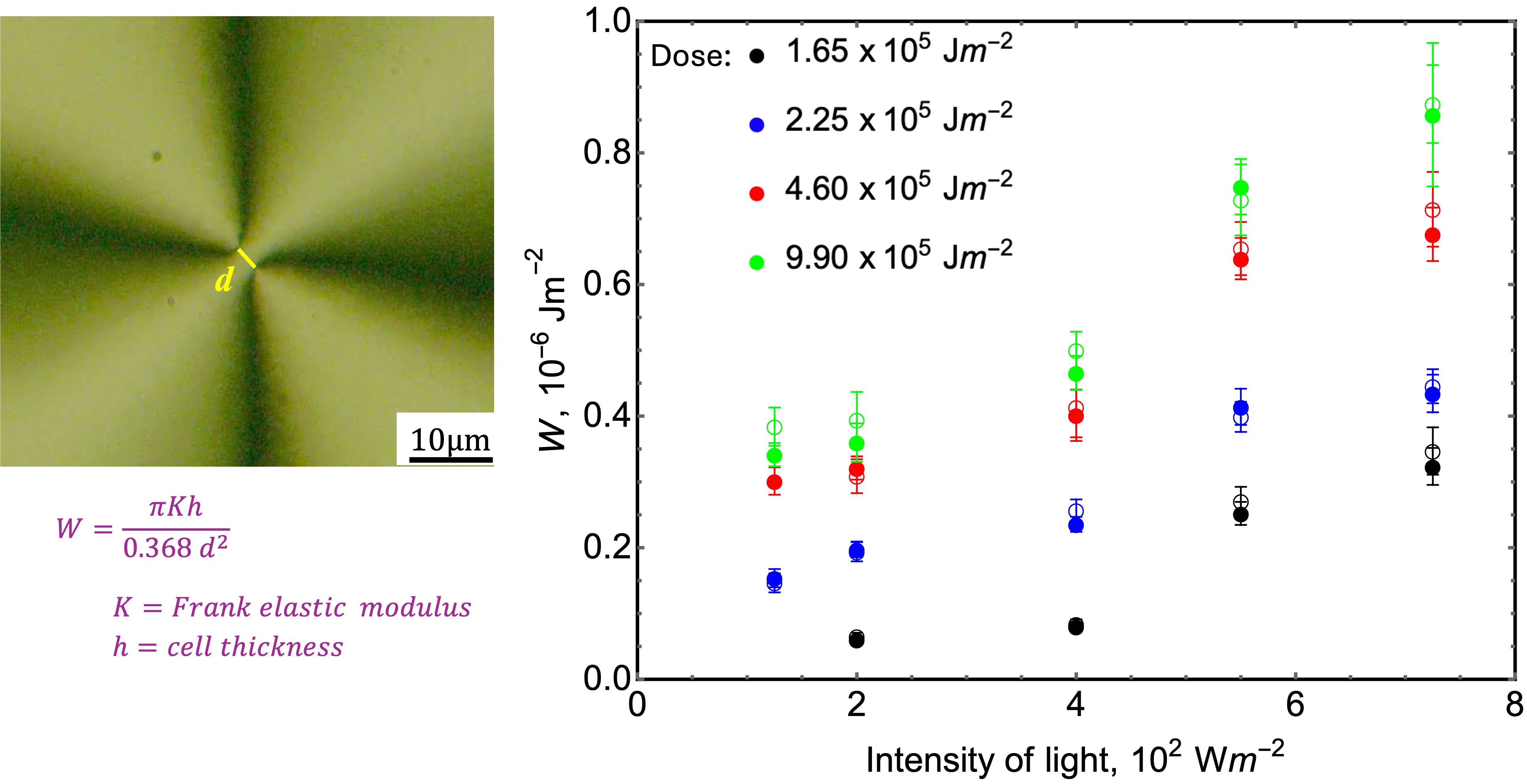

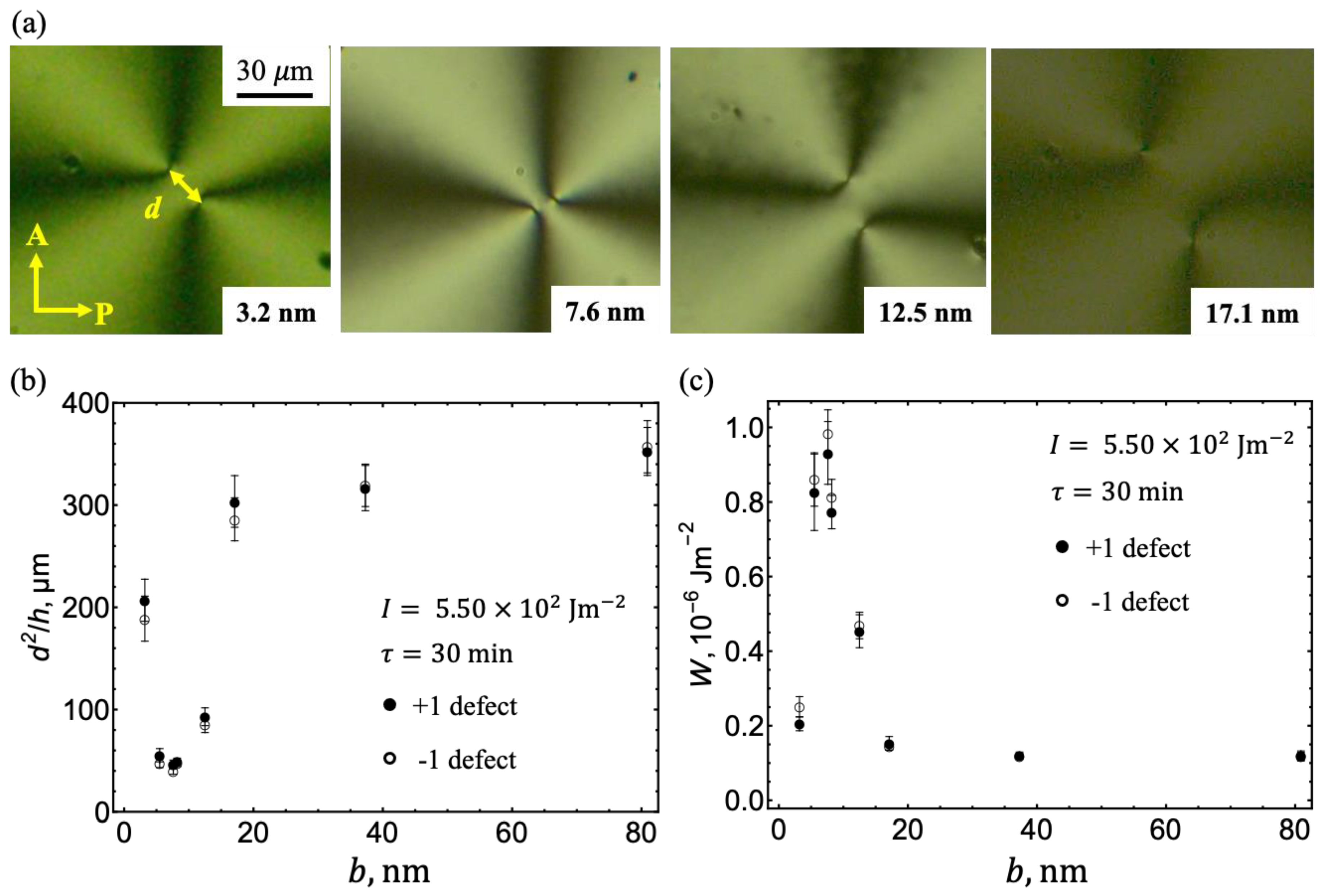

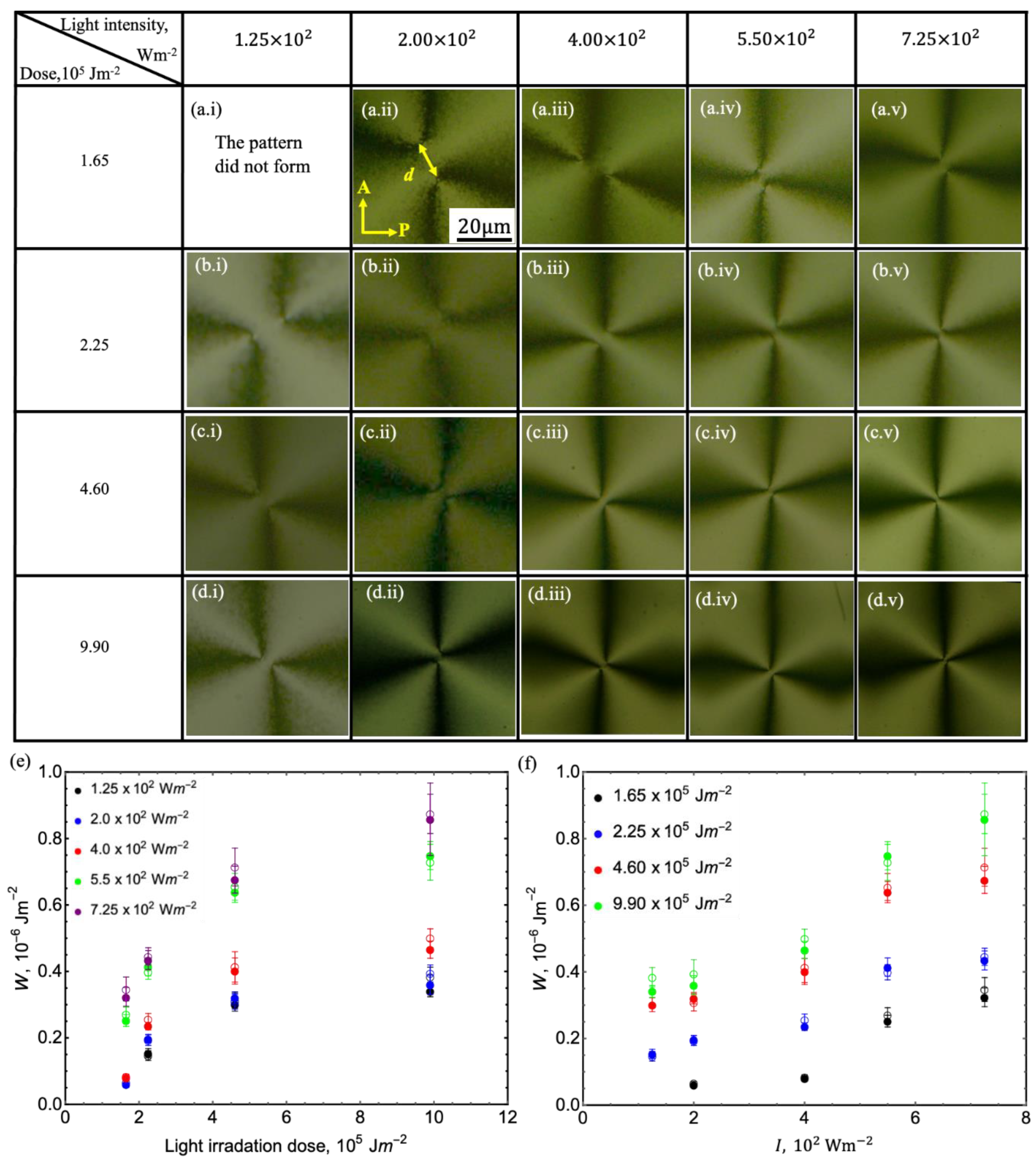

Spatially-varying alignment of liquid crystals is essential for research and applications. One widely used method is based on the photopatterning of thin layers of azo-dye molecules, such as Brilliant Yellow (BY), that serve as an aligning substrate for a liquid crystal. In this study, we examine how photopatterning conditions, such as BY layer thickness (b), light intensity (I), irradiation dose, and age affect the alignment quality and the strength of the azimuthal surface anchoring. The azimuthal surface anchoring coefficient, W, is determined by analyzing the splitting of integer disclinations into half-integer disclinations at prepatterned substrates. The strongest anchoring is achieved for b in the range of 5–8 nm. W increases with the dose, and within the same dose, W increases with I. Aging of a non-irradiated BY coating above 15 days reduces W. Sealed photopatterned cells filled with a conventional nematic preserve their alignment quality for up to four weeks, after which time W decreases. This work suggests the optimization pathways for photoalignment of nematic liquid crystals.

Keywords:

1. Introduction

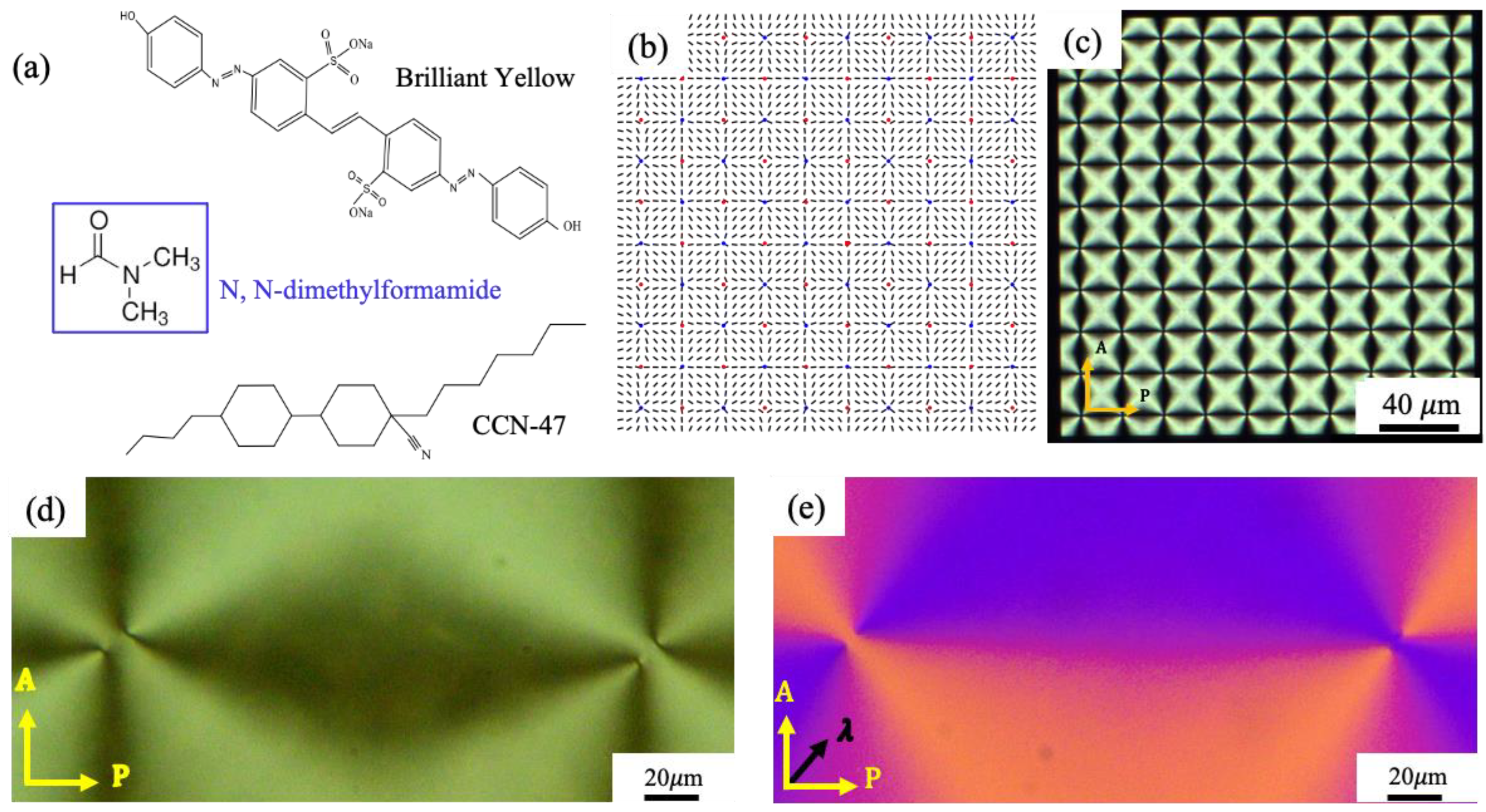

2. Materials and Methods

2.1. Cell Preparations

2.2. Photopatterning

2.3. Nematic Material

2.4. Optical Microscopy Characterization

2.5. Theoretical Background

3. Results

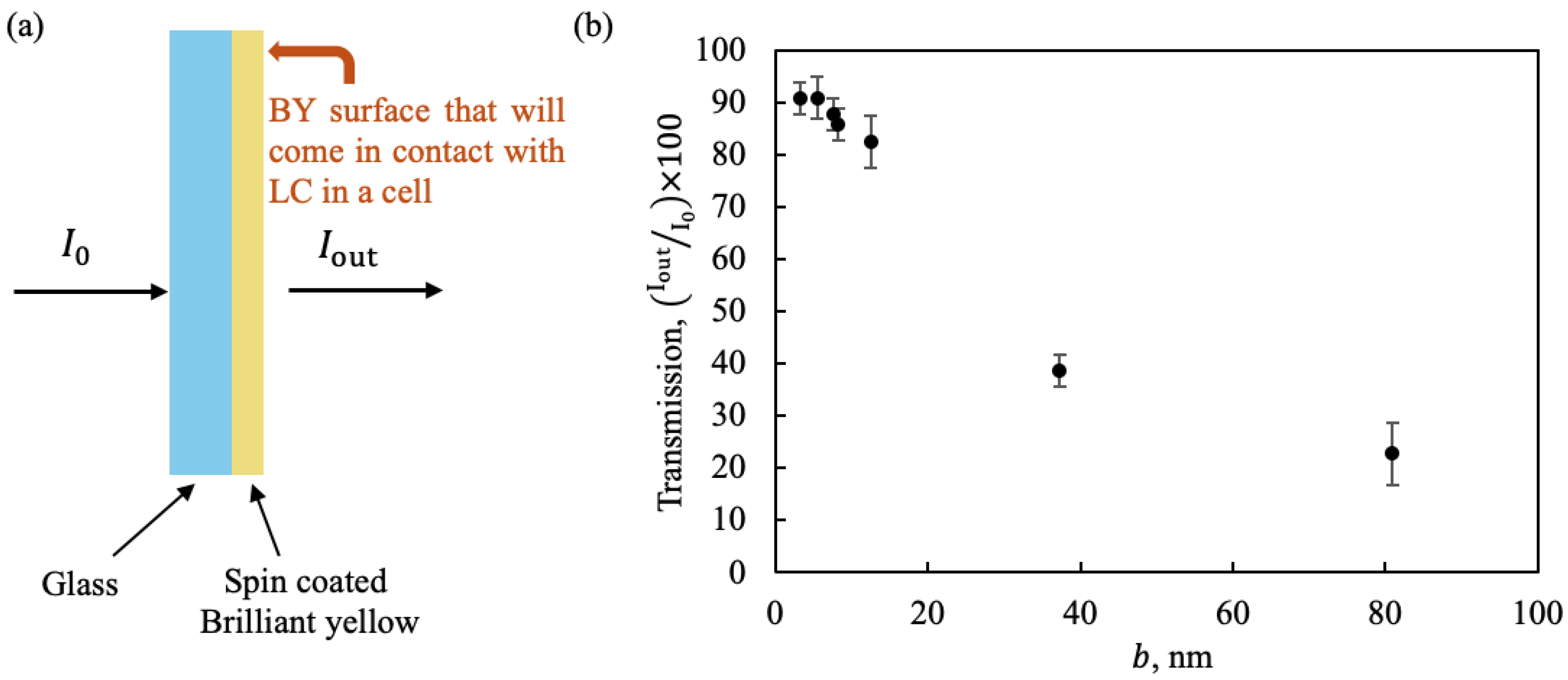

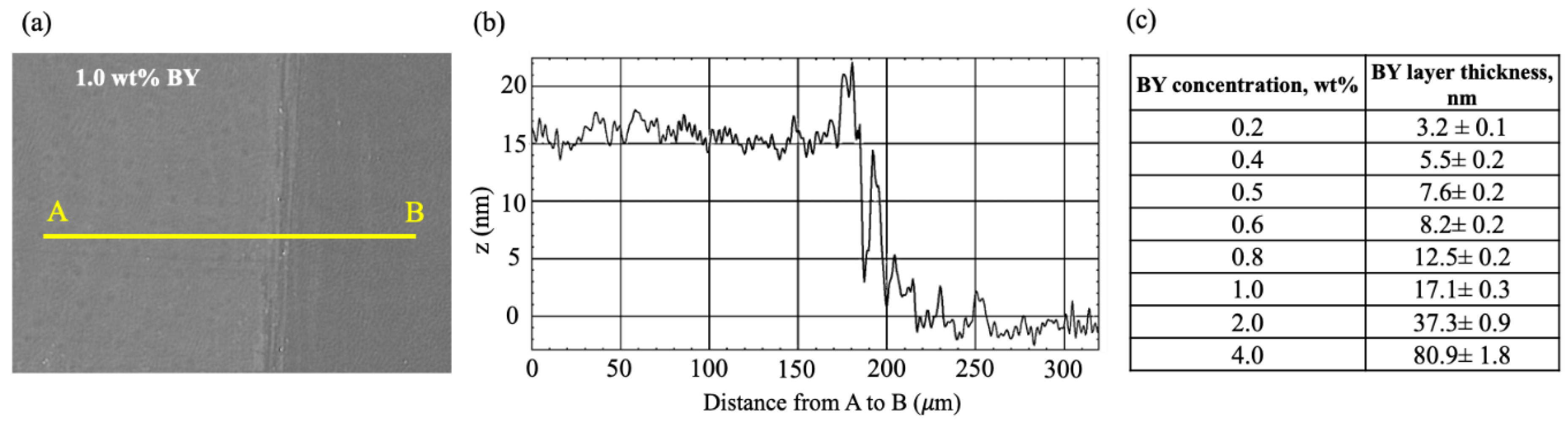

3.1. Effect of BY Layer Thickness on Photoalignment

3.1. Effect of Light Dose and Intensity on Photoalignment

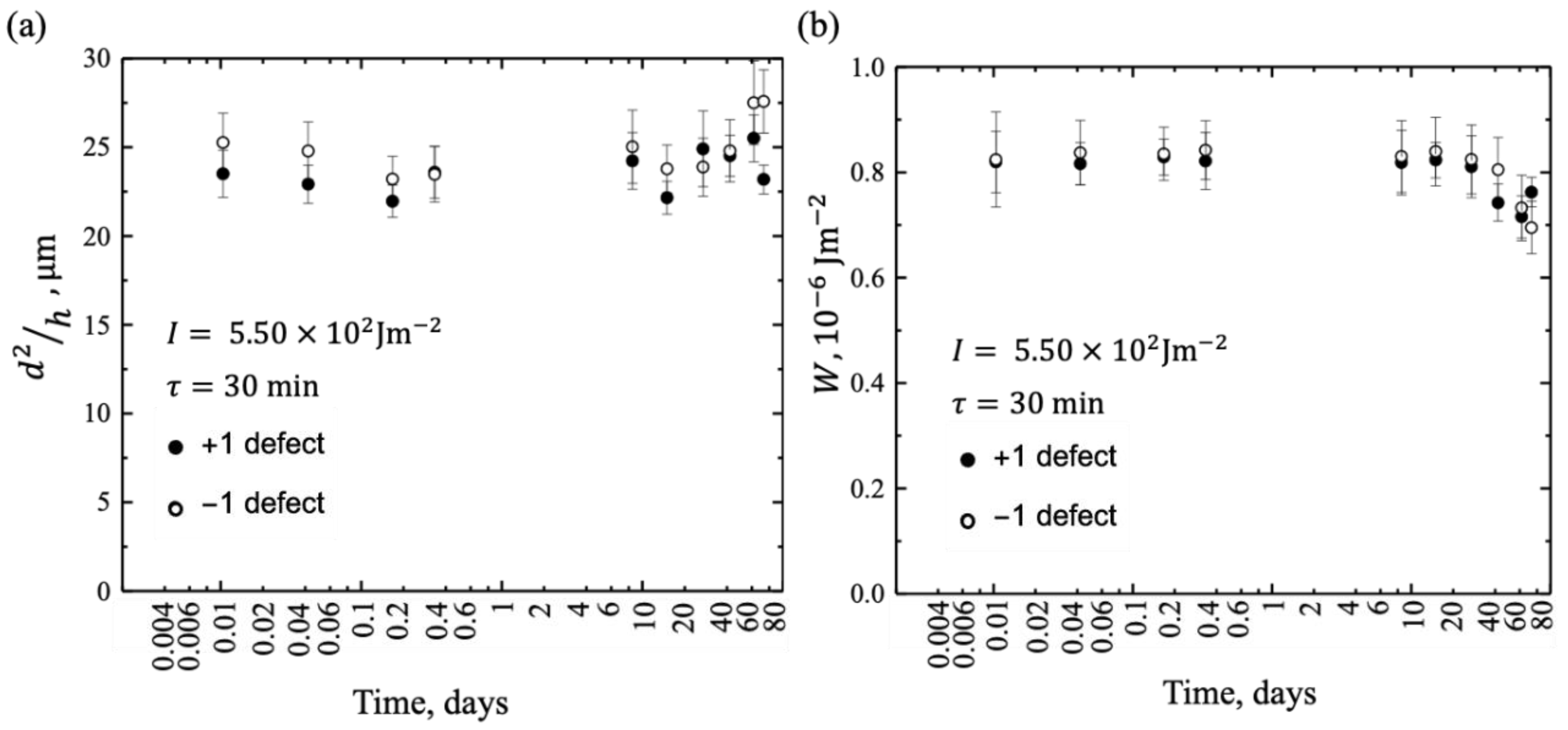

3.1. Effect of Aging of Non-Irradiated BY Coatings

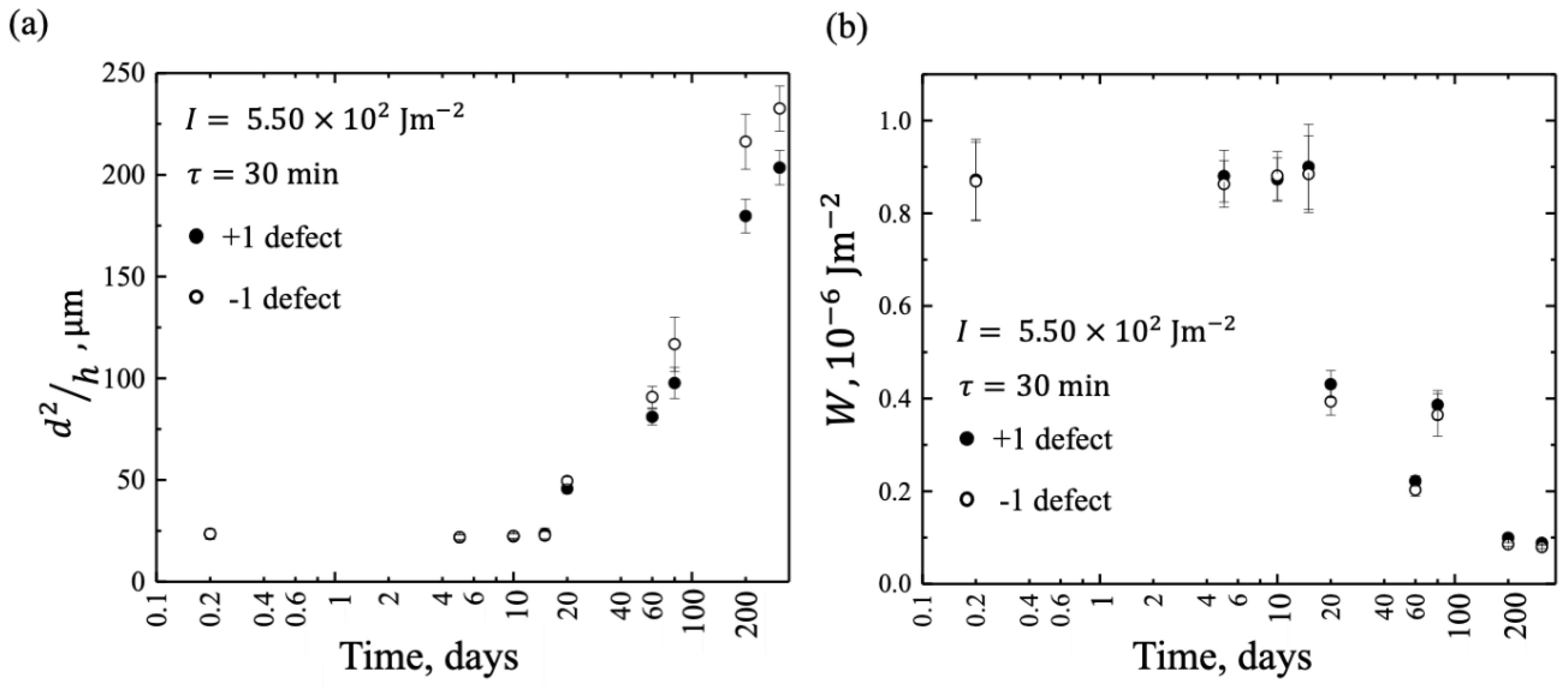

3.1. Surface Patterning Stability of Aged LC-Filled Cells

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cognard, J. Alignment of nematic liquid crystals and their mixtures. Mol. Cryst. Liq. Cryst. 1982, 78, 1. [Google Scholar]

- Babakhanova, G.; Lavrentovich, O.D. The techniques of surface alignment of liquid crystals. In Proceedings of the Modern Problems of the Physics of Liquid Systems: Selected Reviews from the 8th International Conference “Physics of Liquid Matter: Modern Problems”, Kyiv, Ukraine, May 18-22, 2018 8, 2019; pp. 165-197.

- Muravsky, A.; Murauski, A. Q&A of liquid crystal alignment: theory and practice. Frontiers in Soft Matter 2024, 4, 1382925. [Google Scholar]

- Huang, Y.H.; Ko, S.W.; Li, M.S.; Chu, S.C.; Fuh, A.Y.G. Modulation of shape and polarization of beam using a liquid crystal q-plate that is fabricated via photo-alignment. Optics Express 2013, 21, 10954–10961. [Google Scholar] [CrossRef] [PubMed]

- Jiang, M.; Guo, Y.; Yu, H.; Zhou, Z.; Turiv, T.; Lavrentovich, O.D.; Wei, Q.H. Low f-Number Diffraction-Limited Pancharatnam–Berry Microlenses Enabled by Plasmonic Photopatterning of Liquid Crystal Polymers. Advanced Materials 2019, 31, 1808028. [Google Scholar] [CrossRef]

- Tang, D.; Shao, Z.; Zhou, Y.; Lei, Y.; Chen, L.; Xie, J.; Zhang, X.; Xie, X.; Fan, F.; Liao, L. Simultaneous surface display and holography enabled by flat liquid crystal elements. Laser & Photonics Reviews 2022, 16, 2100491. [Google Scholar]

- Jiang, M.; Yu, H.; Feng, X.; Guo, Y.; Chaganava, I.; Turiv, T.; Lavrentovich, O.D.; Wei, Q.H. Liquid crystal Pancharatnam–Berry micro-optical elements for laser beam shaping. Advanced Optical Materials 2018, 6, 1800961. [Google Scholar] [CrossRef]

- Chen, P.; Wei, B.Y.; Hu, W.; Lu, Y.Q. Liquid-crystal-mediated geometric phase: from transmissive to broadband reflective planar optics. Advanced Materials 2020, 32, 1903665. [Google Scholar] [CrossRef]

- Ware, T.H.; McConney, M.E.; Wie, J.J.; Tondiglia, V.P.; White, T.J. Voxelated liquid crystal elastomers. Science 2015, 347, 982–984. [Google Scholar] [CrossRef]

- Mostajeran, C.; Warner, M.; Ware, T.H.; White, T.J. Encoding Gaussian curvature in glassy and elastomeric liquid crystal solids. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences 2016, 472, 20160112. [Google Scholar] [CrossRef]

- Babakhanova, G.; Turiv, T.; Guo, Y.; Hendrikx, M.; Wei, Q.H.; Schenning, A.P.; Broer, D.J.; Lavrentovich, O.D. Liquid crystal elastomer coatings with programmed response of surface profile. Nature communications 2018, 9, 456. [Google Scholar] [CrossRef]

- McConney, M.E.; Martinez, A.; Tondiglia, V.P.; Lee, K.M.; Langley, D.; Smalyukh, I.I.; White, T.J. Topography from topology: photoinduced surface features generated in liquid crystal polymer networks. Advanced Materials 2013, 25, 5880–5885. [Google Scholar] [CrossRef] [PubMed]

- Feng, W.; Liu, D.; Broer, D.J. Functional liquid crystal polymer surfaces with switchable topographies. Small Structures 2021, 2, 2000107. [Google Scholar] [CrossRef]

- Babakhanova, G.; Yu, H.; Chaganava, I.; Wei, Q.H.; Shiller, P.; Lavrentovich, O.D. Controlled placement of microparticles at the water–liquid crystal elastomer interface. ACS applied materials & interfaces 2019, 11, 15007–15013. [Google Scholar]

- Peng, C.; Turiv, T.; Guo, Y.; Wei, Q.H.; Lavrentovich, O.D. Command of active matter by topological defects and patterns. Science 2016, 354, 882–885. [Google Scholar] [CrossRef] [PubMed]

- Turiv, T.; Koizumi, R.; Thijssen, K.; Genkin, M.M.; Yu, H.; Peng, C.; Wei, Q.H.; Yeomans, J.M.; Aranson, I.S.; Doostmohammadi, A. Polar jets of swimming bacteria condensed by a patterned liquid crystal. Nature Physics 2020, 16, 481–487. [Google Scholar] [CrossRef]

- Koizumi, R.; Turiv, T.; Genkin, M.M.; Lastowski, R.J.; Yu, H.; Chaganava, I.; Wei, Q.H.; Aranson, I.S.; Lavrentovich, O.D. Control of microswimmers by spiral nematic vortices: Transition from individual to collective motion and contraction, expansion, and stable circulation of bacterial swirls. Physical Review Research 2020, 2, 033060. [Google Scholar] [CrossRef]

- Dhakal, N.P.; Jiang, J.; Guo, Y.; Peng, C. Self-assembly of aqueous soft matter patterned by liquid-crystal polymer networks for controlling the dynamics of bacteria. ACS applied materials & interfaces 2020, 12, 13680–13685. [Google Scholar]

- Turiv, T.; Krieger, J.; Babakhanova, G.; Yu, H.; Shiyanovskii, S.V.; Wei, Q.H.; Kim, M.-H.; Lavrentovich, O.D. Topology control of human fibroblast cells monolayer by liquid crystal elastomer. Science Advances 2020, 6, eaaz6485. [Google Scholar] [CrossRef]

- Dhakal, N.P.; Jiang, J.; Guo, Y.; Peng, C. Photopatterning DNA structures with topological defects and arbitrary patterns through multiple length scales. Physical Review Applied 2020, 13, 014026. [Google Scholar] [CrossRef]

- Jiang, J.; Dhakal, N.P.; Guo, Y.; Andre, C.; Thompson, L.; Skalli, O.; Peng, C. Controlled dynamics of neural tumor cells by templated liquid crystalline polymer networks. Advanced Healthcare Materials 2020, 9, 2000487. [Google Scholar] [CrossRef]

- Culbreath, C.; Glazar, N.; Yokoyama, H. Note: Automated maskless micro-multidomain photoalignment. Review of Scientific Instruments 2011, 82. [Google Scholar] [CrossRef] [PubMed]

- Shteyner, E.A.; Srivastava, A.K.; Chigrinov, V.G.; Kwok, H.-S.; Afanasyev, A.D. Submicron-scale liquid crystal photo-alignment. Soft Matter 2013, 9, 5160–5165. [Google Scholar] [CrossRef]

- Guo, Y.; Jiang, M.; Peng, C.; Sun, K.; Yaroshchuk, O.; Lavrentovich, O.D.; Wei, Q.H. Designs of plasmonic metamasks for photopatterning molecular orientations in liquid crystals. Crystals 2016, 7, 8. [Google Scholar] [CrossRef]

- Guo, Y.; Jiang, M.; Peng, C.; Sun, K.; Yaroshchuk, O.; Lavrentovich, O.; Wei, Q.H. High Resolution and High Throughput Plasmonic Photopatterning of Complex Molecular Orientations in Liquid Crystals. Advanced Materials 2016, 28, 2353–2358. [Google Scholar] [CrossRef] [PubMed]

- Yun, H.; Jiang, S.; Chen, H.; Zhu, Y.; Xu, X.; Li, B.; Xi, P.; Jiang, M.; Wei, Q.H. Ultra-high spatial resolutions in photopatterning molecular orientations. Optics Express 2024, 32, 31107–31119. [Google Scholar] [CrossRef]

- Padmini, H.N.; Rajabi, M.; Shiyanovskii, S.V.; Lavrentovich, O.D. Azimuthal anchoring strength in photopatterned alignment of a nematic. Crystals 2021, 11, 675. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, X.; Akomolafe, O.I.; Tang, W.; Asilehan, Z.; Ranabhat, K.; Zhang, R.; Peng, C. Collective transport and reconfigurable assembly of nematic colloids by light-driven cooperative molecular reorientations. Proceedings of the National Academy of Sciences 2023, 120, e2221718120. [Google Scholar] [CrossRef]

- Chigrinov, V.G.; Kozenkov, V.M.; Kwok, H.S. Photoalignment of liquid crystalline materials: physics and applications; John Wiley & Sons: 2008.

- Chigrinov, V.; Sun, J.; Wang, X. Photoaligning and photopatterning: New LC technology. Crystals 2020, 10, 323. [Google Scholar] [CrossRef]

- Yaroshchuk, O.; Gurumurthy, H.; Chigrinov, V.G.; Kwok, H.S.; Hasebe, H.; Takatsu, H. Photoalignment properties of brilliant yellow dye. In Proceedings of the Proc. IDW, 2007; pp. 1665-1668.

- Folwill, Y.; Zeitouny, Z.; Lall, J.; Zappe, H. A practical guide to versatile photoalignment of azobenzenes. Liquid Crystals 2021, 48, 862–872. [Google Scholar] [CrossRef]

- Lall, J.; Zappe, H. In situ, spatially variable photoalignment of liquid crystals inside a glass cell using brilliant yellow. In Proceedings of the Photosensitive Materials and their Applications II, 2022; pp. 91-97.

- Chigrinov, V.; Kudreyko, A.; Guo, Q. Patterned photoalignment in thin films: physics and applications. Crystals 2021, 11, 84. [Google Scholar] [CrossRef]

- Yin, K.; Xiong, J.; He, Z.; Wu, S.T. Patterning liquid-crystal alignment for ultrathin flat optics. ACS omega 2020, 5, 31485–31489. [Google Scholar] [CrossRef] [PubMed]

- Fang, G.; Shi, Y.; Maclennan, J.E.; Clark, N.A.; Farrow, M.J.; Walba, D.M. Photo-reversible liquid crystal alignment using azobenzene-based self-assembled monolayers: comparison of the bare monolayer and liquid crystal reorientation dynamics. Langmuir 2010, 26, 17482–17488. [Google Scholar] [CrossRef] [PubMed]

- Fang, G.; Maclennan, J.; Yi, Y.; Glaser, M.; Farrow, M.; Korblova, E.; Walba, D.; Furtak, T.; Clark, N. Athermal photofluidization of glasses. Nature communications 2013, 4, 1521. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; McGinty, C.; West, J.; Bryant, D.; Finnemeyer, V.; Reich, R.; Berry, S.; Clark, H.; Yaroshchuk, O.; Bos, P. Effects of humidity and surface on photoalignment of brilliant yellow. Liquid Crystals 2017, 44, 863–872. [Google Scholar] [CrossRef]

- Shi, Y.; Zhao, C.; Ho, J.Y.L.; Song, F.; Chigrinov, V.G.; Luo, D.; Kwok, H.S.; Sun, X.W. High photoinduced ordering and controllable photostability of hydrophilic azobenzene material based on relative humidity. Langmuir 2018, 34, 4465–4472. [Google Scholar] [CrossRef]

- Zawadzki, A.; Walton, H. Measurements of the splay and bend elastic constants of 4′-butyl-4-heptyl-bicyclohexyl-4-carbononitrile, CCN47. Molecular Crystals and Liquid Crystals 2012, 569, 10–14. [Google Scholar] [CrossRef]

- Kleman, M.; Laverntovich, O.D. Soft Matter Physics: An Introduction; Springer: 2003.

- Chiccoli, C.; Feruli, I.; Lavrentovich, O.; Pasini, P.; Shiyanovskii, S.V.; Zannoni, C. Topological defects in schlieren textures of biaxial and uniaxial nematics. Physical Review E 2002, 66, 030701. [Google Scholar] [CrossRef]

- Taylor, J. Introduction to error analysis, the study of uncertainties in physical measurements, 2nd ed.; University Science Books: 1997.

- Ramdane, O.O.; Auroy, P.; Forget, S.; Raspaud, E.; Martinot-Lagarde, P.; Dozov, I. Memory-free conic anchoring of liquid crystals on a solid substrate. Physical Review Letters 2000, 84, 3871. [Google Scholar] [CrossRef]

- Vilfan, M.; Olenik, I.D.; Mertelj, A.; Čopič, M. Aging of surface anchoring and surface viscosity of a nematic liquid crystal on photoaligning poly-(vinyl-cinnamate). Physical Review E 2001, 63, 061709. [Google Scholar] [CrossRef]

- Perny, S.; Barny, P.L.; Delaire, J.; Buffeteau, T.; Sourisseau, C.; Dozov, I.; Forget, S.; Martinot-Lagarde, P. Photoinduced orientation in poly (vinylcinnamate) and poly (7-methacryloyloxycoumarin) thin films and the consequences on liquid crystal alignment. Liquid crystals 2000, 27, 329–340. [Google Scholar] [CrossRef]

- Drzaic, P.S. Liquid Crystal Dispersions; World Scientific: 1995.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).