Submitted:

27 December 2024

Posted:

27 December 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Scenario and Methodology

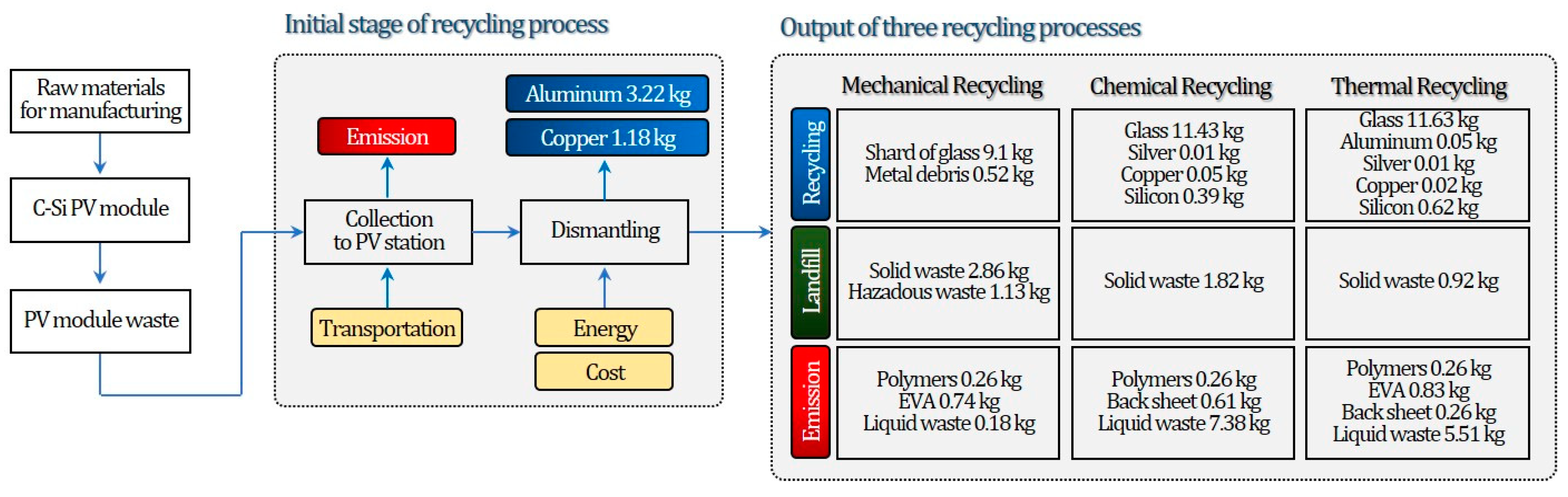

2.1. Description of Recycling Scenarios

2.2. Methodology

2.2.1. Environmental Sustainability and Indicator

2.2.2. Economic Sustainability and Indicator

3. Results and Discussion

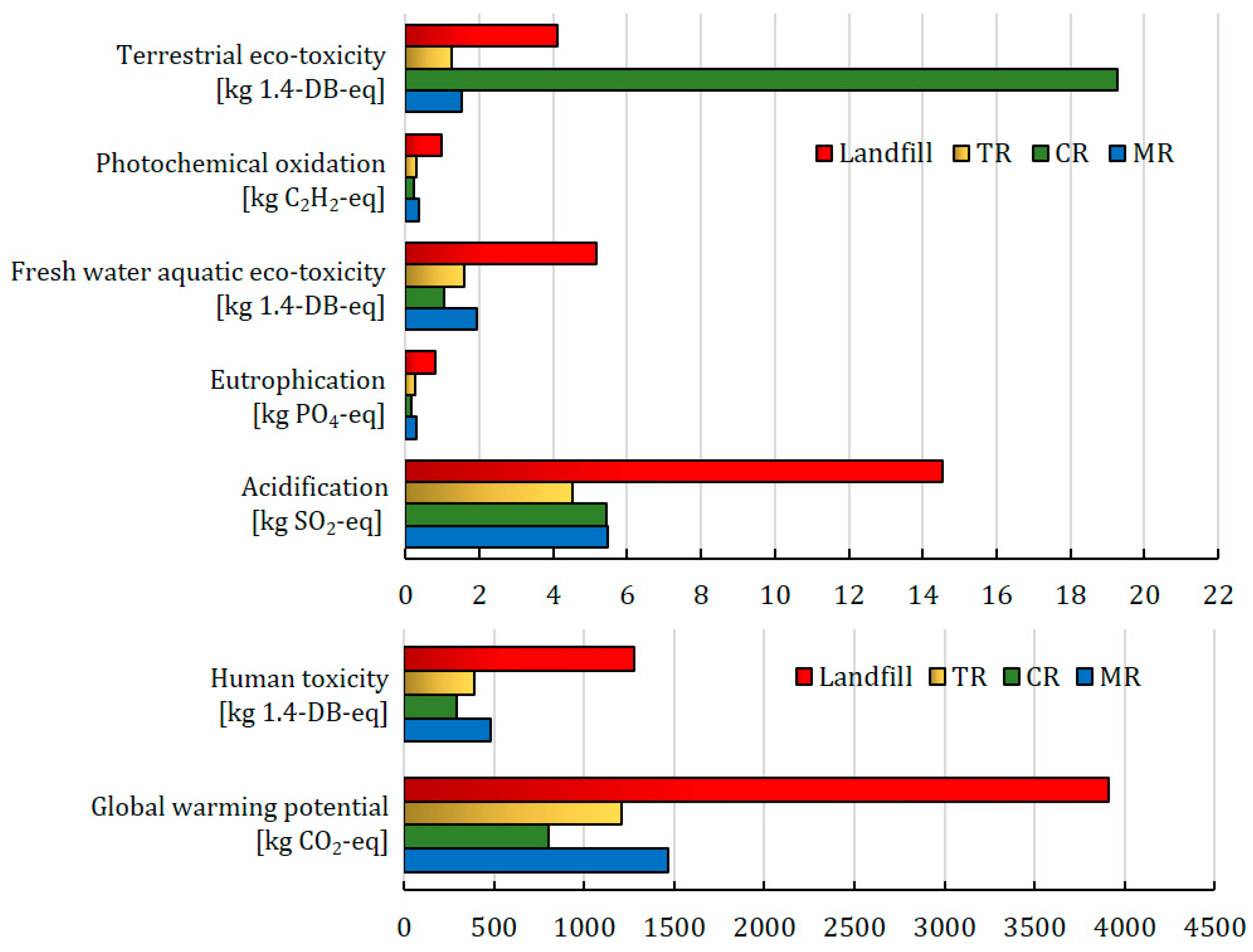

3.1. Environmental Impacts

3.2. Economic Impacts

3.3. Regulation Related to EoL Solar Panel in South Korea

4. Conclusions

- ▪

- In MR, after removing aluminum and copper from the waste panels, additional transportation and industrial processes are required during the cutting, grinding, and screening stages. The extensive use of fossil fuels and the resulting emissions during these processes lead to a higher GWP as well as higher acidification levels. In the CR scenario, the use of chemicals and subsequent landfilling significantly increase terrestrial ecotoxicity level, resulting in an environmental burden that is 4.7 times higher than that of landfilling. In the TR scenario, the use of thermal energy to melt the EVA layer results in an environmental burden owing to greenhouse gas emissions. However, the environmental burden of TR was generally lower than those of the two other recycling processes.

- ▪

- The government of South Korea introduced an Extended Producer Responsibility (EPR) system to promote the recycling of EoL solar panels, placing responsibility on producers for the collection and recycling of these PV materials. This system aims to reduce the environmental impacts of solar panels, encourage the development of recycling technologies, and establish an efficient waste management system in this regard. In addition to the EPR system, the use of eco-friendly materials in solar panel manufacturing and the mandatory use of recyclable materials should be enforced. The mandatory collection of EoL panels, the establishment of regional recycling centers, and the provision of incentives based on recycling performance will pave the way for an efficient future for solar panel recycling in South Korea.

Author Contributions

Funding

Conflicts of Interest

References

- International Energy Agency, Net zero by 2050: a roadmap for the global energy sector, Int. Energy Agency, https://www.iea.org/reports/net-zero-by-2050, 2021, 224.

- Weckend, Stephanie, Andreas Wade, and Garvin A. Heath. End of life management: solar photovoltaic panels. No. NREL/TP-6A20-73852. National Renewable Energy Lab.(NREL), Golden, CO (United States), 2016.

- Mahmoudi, Sajjad, Nazmul Huda, and Masud Behnia. "Critical assessment of renewable energy waste generation in OECD countries: decommissioned PV panels." Resources, Conservation and Recycling 164 (2021): 105145. [CrossRef]

- Qi, Xingnan, et al. "Bidirectional targeted therapy enables efficient, stable, and eco-friendly perovskite solar cells." Advanced Functional Materials 33.19 (2023): 2214714.

- Gao, Yueyue, et al. "Asymmetric Π-bridge engineering enables high-permittivity benzo [1, 2-B: 4, 5-B′] difuran-conjugated polymer for efficient organic solar cells." Advanced Materials 36.9 (2024): 2306373.

- Huang, Xiufang, et al. "Efficient and Stable Z907-Based Dye-Sensitized Solar Cells Enabled by Suppressed Charge Recombination and Photocatalytic Activity." ACS Sustainable Chemistry & Engineering 12.34 (2024): 13007-13016.

- Xu, Yan, et al. "Global status of recycling waste solar panels: A review." Waste Management 75 (2018): 450-458. [CrossRef]

- Mahmoudi, Sajjad, et al. "End-of-life photovoltaic modules: A systematic quantitative literature review." Resources, Conservation and Recycling 146 (2019): 1-16. [CrossRef]

- Aman, M. M., et al. "A review of Safety, Health and Environmental (SHE) issues of solar energy system." Renewable and Sustainable Energy Reviews 41 (2015): 1190-1204.

- Cho, et al. "Current Status and Utilization Technology of End-of-Life Photovoltaic Modules." 29.4 (2020): 15-30. [CrossRef]

- Sharma, Arvind, Suneel Pandey, and Mohan Kolhe. "Global review of policies & guidelines for recycling of solar PV modules." International Journal of Smart Grid and Clean Energy 8.5 (2019): 597-610. [CrossRef]

- Chowdhury, Md Shahariar, et al. "An overview of solar photovoltaic panels’ end-of-life material recycling." Energy Strategy Reviews 27 (2020): 100431. [CrossRef]

- Divya, A., et al. "Review on recycling of solar modules/panels." Solar Energy Materials and Solar Cells 253 (2023): 112151.

- Paiano, Annarita. "Photovoltaic waste assessment in Italy." Renewable and Sustainable Energy Reviews 41 (2015): 99-112.

- Li, Jing, et al. "Life cycle analysis of the economic costs and environmental benefits of photovoltaic module waste recycling in China." Resources, Conservation and Recycling 196 (2023): 107027. [CrossRef]

- Ali, Amjad, et al. "Policies and regulations for solar photovoltaic end-of-life waste management: Insights from China and the USA." Chemosphere 340 (2023): 139840. [CrossRef]

- Korea Energy Agency, "2020 New and Renewable Energy Supply Statistic" (2021) https://www.knrec.or.kr/biz/pds/statistic/view.do?no=120.

- Jo, J. H., S. Seo-won, and K. Yu-seon. "Management status and improvement plans of waste solar panels." Korea Environmental Research Institute (2018).

- Lee, Su-Hee, and Yong-Chul Jang. "Analysis for End-of-Life Solar Panel Generations by Renewable Energy Supply towards Carbon Neutrality in South Korea." Energies 16.24 (2023): 8039. [CrossRef]

- Strachala, David, et al. "Mechanical Recycling of Photovoltaic Modules." ECS Transactions 81.1 (2017): 199. [CrossRef]

- Del Pero, Francesco, et al. "Innovative device for mechanical treatment of End of Life photovoltaic panels: Technical and environmental analysis." Waste Management 95 (2019): 535-548.

- Camargo, Priscila Silva Silveira, et al. "c-Si PV module recycling: Analysis of the use of a mechanical pre-treatment to reduce the environmental impact of thermal treatment and enhance materials recovery." Waste Management & Research 41.11 (2023): 1661-1673. [CrossRef]

- Fiandra, Valeria, Lucio Sannino, and Concetta Andreozzi. "Photovoltaic waste as source of valuable materials: A new recovery mechanical approach." Journal of Cleaner Production 385 (2023): 135702. [CrossRef]

- Li, Jiayan, et al. "Recycling Si in waste crystalline silicon photovoltaic panels after mechanical crushing by electrostatic separation." Journal of Cleaner Production 415 (2023): 137908. [CrossRef]

- Azeumo, Maurianne Flore, et al. "Photovoltaic module recycling, a physical and a chemical recovery process." Solar Energy Materials and Solar Cells 193 (2019): 314-319.

- Padoan, Flavia CSM, Pietro Altimari, and Francesca Pagnanelli. "Recycling of end of life photovoltaic panels: A chemical prospective on process development." Solar Energy 177 (2019): 746-761. [CrossRef]

- Deng, Rong, et al. "A sustainable chemical process to recycle end-of-life silicon solar cells." Green Chemistry 23.24 (2021): 10157-10167. [CrossRef]

- Shin, Jeongeun, Jongsung Park, and Nochang Park. "A method to recycle silicon wafer from end-of-life photovoltaic module and solar panels by using recycled silicon wafers." Solar Energy Materials and Solar Cells 162 (2017): 1-6. [CrossRef]

- Maani, Thomas, et al. "Environmental impacts of recycling crystalline silicon (c-SI) and cadmium telluride (CDTE) solar panels." Science of The Total Environment 735 (2020): 138827. [CrossRef]

- Hua, Matthew, and Ramy Imam. "Concept for Solar Panel Recycling based on High-Temperature Density Separation." Journal of Student Research 11.4 (2022). [CrossRef]

- Finkbeiner, Matthias, et al. "The new international standards for life cycle assessment: ISO 14040 and ISO 14044." The international journal of life cycle assessment 11 (2006): 80-85. [CrossRef]

- Latunussa, Cynthia EL, et al. "Life Cycle Assessment of an innovative recycling process for crystalline silicon photovoltaic panels." Solar energy materials and solar cells 156 (2016): 101-111. [CrossRef]

- Lisperguer, Rubén Contreras, et al. "Environmental Impact Assessment of crystalline solar photovoltaic panels’ End-of-Life phase: Open and Closed-Loop Material Flow scenarios." Sustainable Production and Consumption 23 (2020): 157-173. [CrossRef]

- Maani, Thomas, et al. "Environmental impacts of recycling crystalline silicon (c-SI) and cadmium telluride (CDTE) solar panels." Science of The Total Environment 735 (2020): 138827. [CrossRef]

- Ansanelli, G., et al. "A Life Cycle Assessment of a recovery process from End-of-Life Photovoltaic Panels." Applied Energy 290 (2021): 116727. [CrossRef]

- Deng, Rong, et al. "A techno-economic review of silicon photovoltaic module recycling." Renewable and Sustainable Energy Reviews 109 (2019): 532-550. [CrossRef]

- Aryan, Venkat, Mercè Font-Brucart, and Daniel Maga. "A comparative life cycle assessment of end-of-life treatment pathways for photovoltaic backsheets." Progress in Photovoltaics: Research and Applications 26.7 (2018): 443-459.Finkbeiner, Matthias, et al. "The new international standards for life cycle assessment: ISO 14040 and ISO 14044." The international journal of life cycle assessment 11.2 (2006): 80-85. [CrossRef]

- Kim, Samyeon, and Seung Ki Moon. "Sustainable platform identification for product family design." Journal of cleaner production 143 (2017): 567-581. [CrossRef]

- Chung, Wu-Hsun, Gül E. Okudan Kremer, and Richard A. Wysk. "Life cycle implications of product modular architectures in closed-loop supply chains." The International Journal of Advanced Manufacturing Technology 70 (2014): 2013-2028. [CrossRef]

- Wernet, Gregor and Bauer, Christian and Steubing, Bernhard, et al. “The ecoinvent database version 3 (Part I): Overview and methodology.” The International Journal of Life Cycle Assessment 21 (2016): 1-13. [CrossRef]

- Ali, Amjad, et al. "Recycling and Material Extraction from End-of-Life Photovoltaic Modules Waste: Exploring Physical Recovery Techniques." 2024 IEEE 1st Karachi Section Humanitarian Technology Conference (KHI-HTC). IEEE, 2024.

- Niekurzak, Mariusz, et al. "Conceptual design of a semi-automatic process line for recycling photovoltaic panels as a way to ecological sustainable production." Sustainability 15.3 (2023): 2822. [CrossRef]

- Šleiniūtė, Agnė, et al. "Feasibilities for silicon recovery from solar cells waste by treatment with nitric acid." Chemija 31.3 (2020). [CrossRef]

- Wongnaree, Natcha, et al. "Recovery of silver from solar panel waste: an experimental study." Materials Science Forum. Vol. 1009. Trans Tech Publications Ltd., 2020. [CrossRef]

- Click, Natalie, et al. "Innovative recycling of high purity silver from silicon solar cells by acid leaching and ultrasonication." Solar Energy Materials and Solar Cells 270 (2024): 112834. [CrossRef]

- Kavousi, Maryam, and Eskandar Keshavarz Alamdari. "Comprehensive and Sustainable Recycling Process for Blended Different Types of End-of-Life Solar Panels: Leaching and Recovery of Valuable Base and Precious Metals." (2023).

- Prasad, D. S., et al. "A unique sustainable chemical method for the recovery of pure silicon from waste crystalline silicon solar panels." Sustainable Materials and Technologies 37 (2023): e00671. [CrossRef]

- Klugmann-Radziemska, Ewa, et al. "Experimental validation of crystalline silicon solar cells recycling by thermal and chemical methods." Solar energy materials and solar cells 94.12 (2010): 2275-2282. [CrossRef]

- Ferrão, Paulo, et al. "Environmental, economic and social costs and benefits of a packaging waste management system: A Portuguese case study." Resources, Conservation and Recycling 85 (2014): 67-78. [CrossRef]

- An, Miaorui, and Xinlu Sun. "Carbon footprints of solar panels in China provinces based on different production and waste treatment scenarios." Journal of Cleaner Production 435 (2024): 140453. [CrossRef]

| Impact category | Mechanical Recycling (MR) | Chemical Recycling (CR) | Thermal Recycling (TR) |

|---|---|---|---|

| Terrestrial eco-toxicity | -2.56131 | 15.1943 | -2.83348 |

| Photochemical oxidation | -0.59974 | -0.72082 | -0.66353 |

| Fresh water aquatic eco-toxicity | -3.2206 | -4.12505 | -3.56289 |

| Eutrophication | -0.49645 | -0.65664 | -0.54938 |

| Acidification potential | -34142.8 | -58912.65674 | -37772.2 |

| Human toxicity | -798.36438 | -981.34784 | -883.2034 |

| Global warming potential (GWP) | -2442.57795 | -3107.68639 | -2702.17943 |

| Ozone layer depletion (ODP) | -0.00022 | -0.00024 | -0.00024 |

| Marine aquatic eco-toxicity | -2689640 | -2953250 | -2975450 |

| Recycling process | Operational cost [US$] |

| Mechanical Recycling (MR) | 11,140 |

| Chemical Recycling (CR) | 7,080 |

| Thermal Recycling (TR) | 6,190 |

| Landfill | 5,880 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).