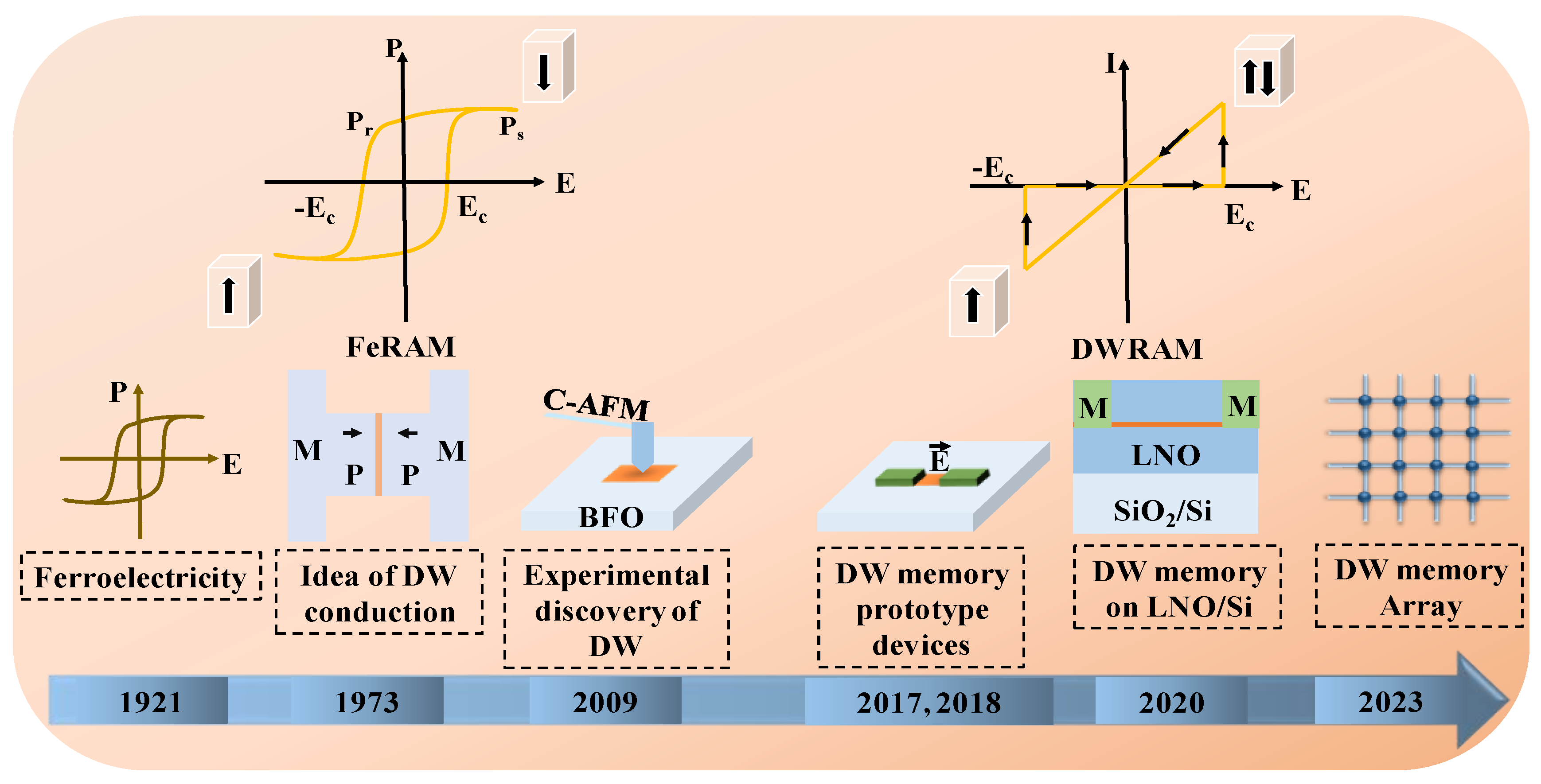

1. Introduction

Free-standing ferroelectric films have emerged as a transformative technology in the realm of flexible electronics, driven by their unique properties such as high mechanical flexibility, super-elasticity, and robust ferroelectric characteristics [

1,

2]. These films are not constrained by rigid substrates, allowing them to exhibit enhanced functionalities critical for next-generation electronic devices. The ability to manipulate spontaneous polarization in these materials opens up new possibilities for applications in sensors, actuators, and energy harvesting systems [

3].

The significance of ferroelectric materials lies in their ability to retain a permanent electric polarization that can be reversed by an external electric field. This property is particularly valuable in applications such as non-volatile memory, where data retention without power is essential [

4]. The recent advancements in the fabrication of free-standing ferroelectric films have significantly improved their quality and performance. Techniques such as laser lift-off and wet etching have been developed to create high-quality ferroelectric membranes that maintain their functional properties even at reduced thicknesses [

5]. The ability to produce ultrathin films that can achieve room-temperature ferroelectricity is crucial for practical applications in flexible devices [

6]

Moreover, the exploration of super-elastic properties in these films has gained considerable attention within the scientific community. Recent studies utilizing phase-field simulations have provided insights into the dynamic behavior of domain structures within freestanding ferroelectric thin films, revealing the strong coupling between strain and polarization [

5]. Understanding this relationship is pivotal for designing novel mechanical structures that can leverage the unique properties of these materials in various applications. For instance, innovative designs such as 2D wrinkles and helical structures have been proposed to enhance mechanical performance while maintaining electrical functionality.

The integration of ferroelectric materials with two-dimensional semiconductors represents another promising avenue for enhancing device performance. This combination can lead to innovative device architectures that capitalize on the strengths of both material types [

6]. Such hybrid systems not only improve electrical characteristics but also introduce multifunctional capabilities that expand the range of potential applications in flexible electronics. Moreover, flexible inorganic materials, including freestanding two-dimensional (2D) atomic-layer crystals and thin films on flexible layered substrates, display exceptional physical behaviors and diverse properties, offering a distinctive foundation for advanced flexible electronics [

7,

8,

9,

10].

Furthermore, recent research has highlighted the potential of free-standing ferroelectric films in energy harvesting applications [

11,

12,

13,

14]. The piezoelectric effect inherent in these materials allows them to convert mechanical energy into electrical energy efficiently, making them suitable for use in wearable devices and self-powered sensors [

15]. The ability to create energy-harvesting devices that are both flexible and transparent represents a significant advancement in sustainable technology.

In summary, free-standing ferroelectric films represent a significant advancement in the field of flexible electronics. Their unique properties, combined with ongoing innovations in fabrication techniques and material integration strategies, position them as key materials for future technological developments [

16]. Continued research is essential to fully harness their capabilities and explore new applications across various domains in electronics, paving the way for more efficient, multifunctional devices that can meet the demands of modern technology [

15].

2. Fabrication Techniques

2.1. Traditional Methods

The fabrication of ferroelectric thin films has evolved significantly, with various methods employed to achieve the desired structural and functional properties. Traditional techniques for growing ferroelectric thin films typically fall into two categories: chemical methods and physical methods. Each approach has its strengths and limitations, influencing the performance of the resulting films.

2.1.1. Chemical Methods

Chemical methods, such as Chemical Solution Deposition (CSD) [

17,

18], Chemical Vapor Deposition (CVD) [

19], and sol-gel processes [

20,

21], are widely used for synthesizing ferroelectric thin films. These techniques offer significant advantages in terms of composition regulation, allowing for the preparation of films with complex chemical compositions. The ability to control the chemical composition is critical for tuning properties such as remnant polarization, leakage current, and piezoelectric response. However, chemical methods often yield polycrystalline films, which may exhibit inferior electrical properties compared to epitaxial thin films due to grain boundaries that can trap charge carriers [

5]

2.1.2. Physical Methods

Physical methods like Pulsed Laser Deposition (PLD) [

22,

23], Molecular Beam Epitaxy (MBE) [

24,

25], and Sputtering [

26] are preferred for producing high-quality epitaxial thin films. These techniques allow for precise control over film thickness and layering at the atomic level, enabling the creation of heterostructures and superlattices with tailored properties [

15]. For example, PLD has been extensively used to synthesize complex oxide thin films, including many ferroelectric systems, by focusing a laser beam on a target material to vaporize it and deposit it onto a substrate [

6]. This method is particularly effective for achieving high-quality interfaces essential for maintaining ferroelectric properties.

2.1.3. Strain Engineering

An important aspect of ferroelectric film fabrication involves strain engineering, which can be induced by a lattice mismatch between the film and substrate [

27,

28,

29].

Recent studies have demonstrated that ferroic oxide membranes can endure extremely large tensile strains, far surpassing those achievable in bulk materials and epitaxial films. For instance, Han et al. reported an impressive uniaxial strain of approximately 6.4% in ferroelectric PTO freestanding films, a remarkable value for ferroelectric perovskite oxides [

30]. Additionally, Zang et al. achieved significant modulation of the interfacial thermal resistance of Al/BFO membranes by an order of magnitude through uniaxial strain, offering a novel approach to enhancing thermal transport performance in next-generation nano-devices, power electronics, and thermal logic systems [

31].

Biaxial strain can significantly influence the ferroelectric properties of thin films; for instance, vertical tensile strain can induce tetragonal distortion in non-ferroelectric materials, thereby inducing ferroelectricity. The realization of effective strain engineering depends on both the deposition method and the thermal treatment process applied during film growth [

32,

33,

34,

35,

36].

2.1.4. Buffer Layers

To mitigate issues arising from thermal expansion mismatches between ferroelectric films and their substrates, buffer layers are often employed. For example, LaNiO

3 has been used as a conductive buffer layer to enhance the ferroelectricity of Pb(Zr, Ti)O

3 films grown on metal substrates [

5]. These buffer layers help accommodate thermal stresses and improve overall film quality.

In summary, traditional methods for fabricating ferroelectric thin films encompass a range of chemical and physical techniques that influence the structural integrity and functional performance of the resulting materials. Understanding these methods is crucial for advancing the development of free-standing ferroelectric films that can be integrated into flexible electronic applications.

2.2. Advanced Techniques

The development of advanced fabrication techniques for free-standing ferroelectric films has significantly enhanced their performance and applicability in flexible electronics. Unlike traditional methods, which often impose constraints due to substrate rigidity, these advanced techniques enable the production of high-quality films that maintain their ferroelectric properties while being flexible and transparent. This section discusses several key methods, including laser lift-off, Vander Waals epitaxy, wet etching, and the use of sacrificial layers.

2.2.1. Laser Lift-Off (LLO)

Laser lift-off is a prominent technique initially developed for transferring epitaxial films from rigid substrates [

37,

38]. In this process, a laser beam is directed at the back of a substrate, selectively ablating the interface between the ferroelectric film and the substrate material [

5]. This method allows for the creation of freestanding films while minimizing mechanical damage to the ferroelectric material. However, LLO can result in thermal damage at the interface, necessitating further treatment to recover the film's surface structure [

39].

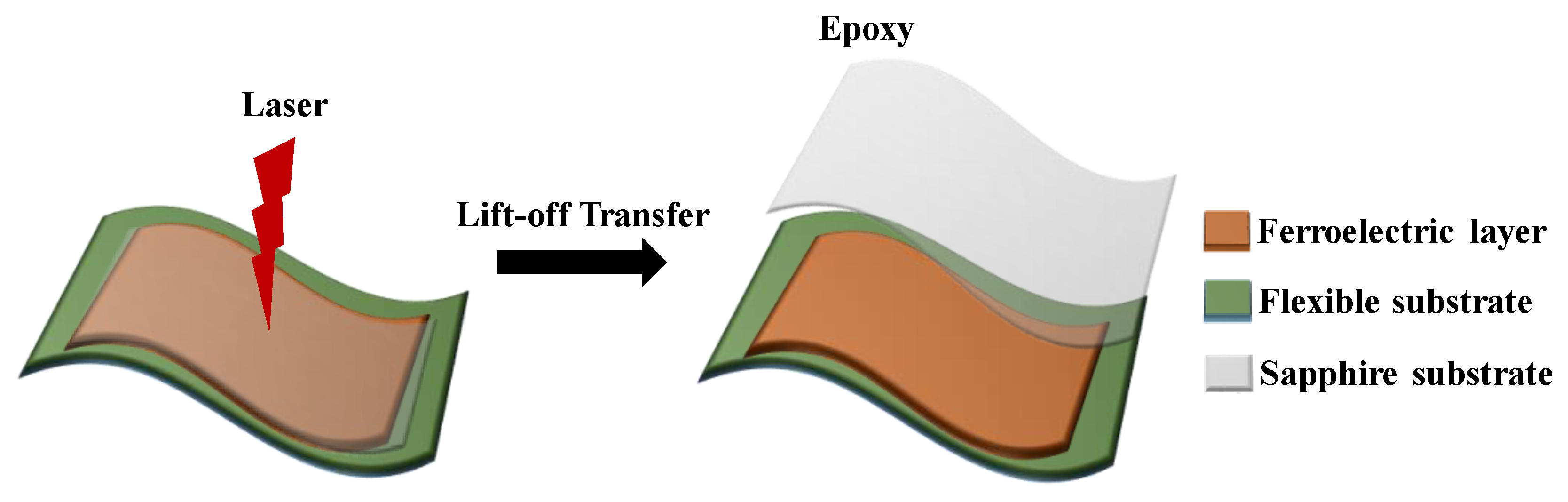

Figure 1 shows the laser lift-off process where an excimer laser is used to detach the ferroelectric film from the substrate.

2.2.2. Wet Etching

Wet etching has emerged as a cost-effective and efficient alternative for fabricating free-standing ferroelectric films. This method involves selectively removing layers from the substrate or sacrificial layers using chemical solutions. Wet etching can be categorized into three types: substrate etching, interface layer etching, and sacrificial layer etching [

5]. The latter is particularly advantageous as it allows for the retention of high-quality single-crystal ferroelectric thin films while achieving significant cost savings compared to other methods.

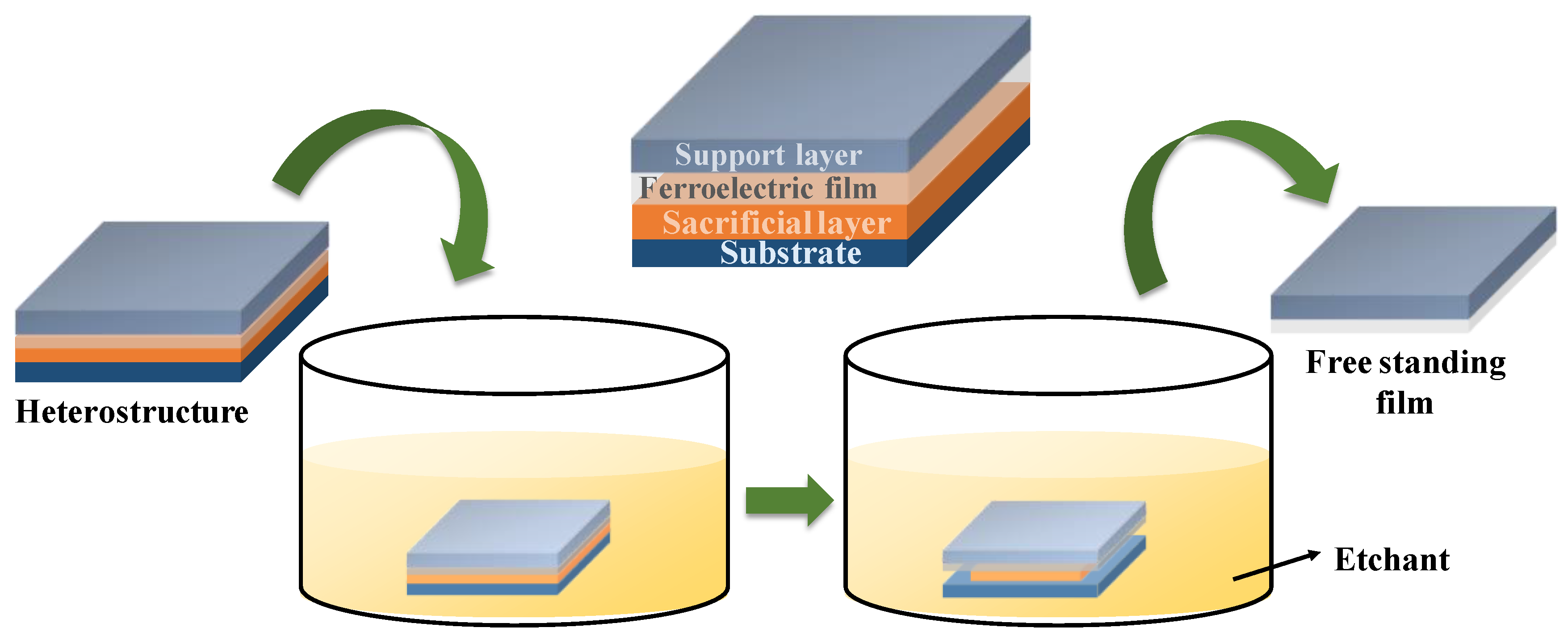

Figure 2 illustrates a schematic of wet etching of a sacrificial layer.

For instance, a study illustrated the process of integrating complex perovskite oxide films onto a flexible substrate. Using the pulsed laser deposition (PLD) technique, a (001) SrRuO

3/Pb(Zr

0.2Ti

0.8)O

3/SrRuO

3 sandwich capacitor was grown on a thin La

0.7Sr

0.3MnO

3-coated SrTiO

3 substrate. The La

0.7Sr

0.3MnO

3 layer was selectively removed through wet etching with a diluted KI + HCl solution, freeing the SrRuO

3/Pb(Zr

0.2Ti

0.8)O

3/SrRuO

3 capacitor, which was coated with polymethyl methacrylate (PMMA) as a transfer stamp. The capacitor was then transferred onto a PET substrate coated with a 10-nm platinum layer. The adhesion between SrRuO

3 and the flexible substrate proved strong enough to ensure the stability of the SrRuO3/Pb(Zr0.2Ti0.8)O3/SrRuO3 stack on the flexible substrate [

40,

41,

42]. This innovative approach not only preserves the structural integrity of the ferroelectric films but also enhances their mechanical flexibility and super-elasticity.

2.2.3. Vander Waals Epitaxy

Ferroelectric materials can also be deposited on flexible substrates by Vander Waals epitaxy. This method uses substrates made from materials without dangling bonds on their surface. As a result, the interaction between the film and substrate is limited to weak van der Waals forces. Thus epitaxy enables the production of almost strain-free films with lower defects [

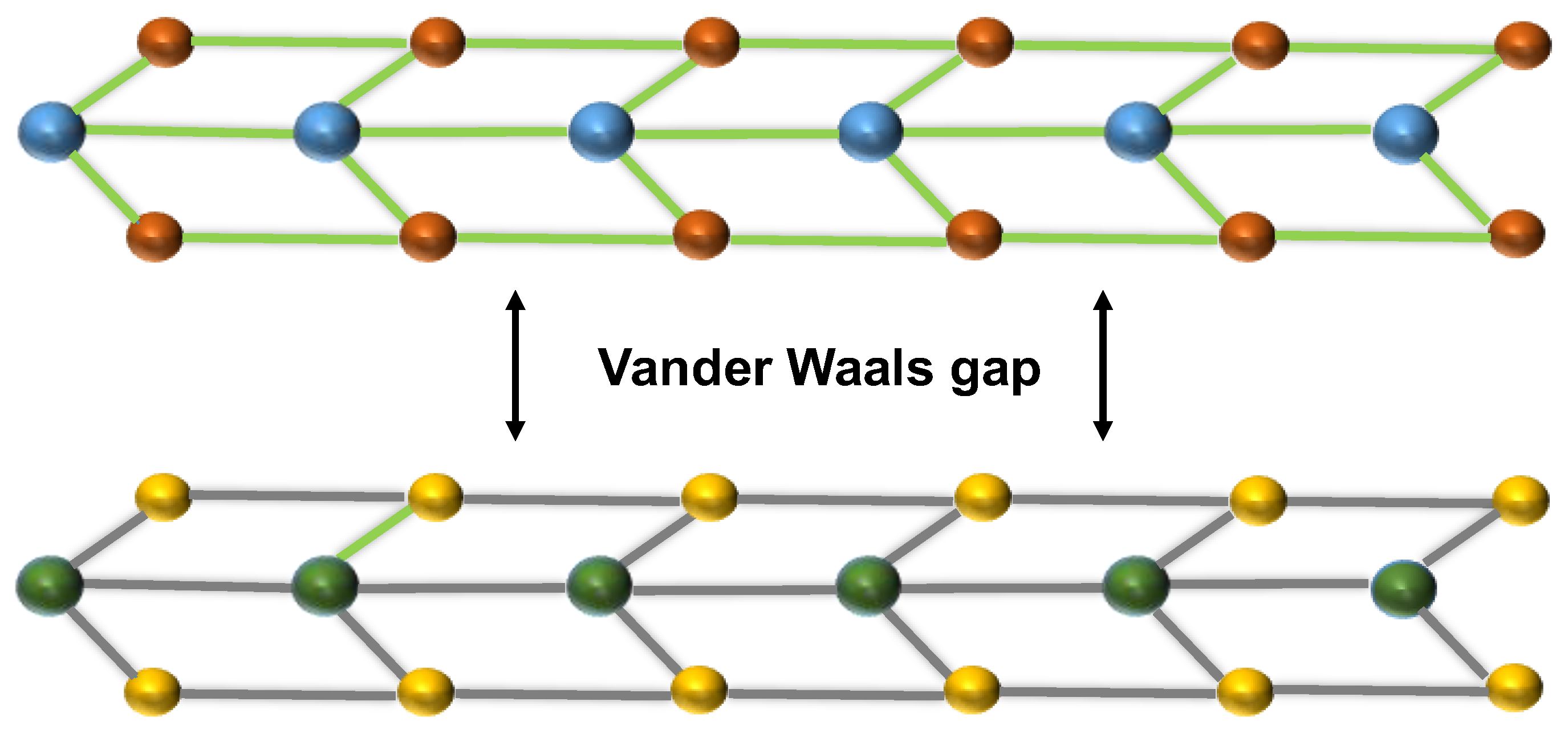

43]. Typically, one layered material is deposited onto the fractured surface of another layered material without any dangling bonds, as shown in

Figure 3. The substrate that is often used for Vander Waal’s epitaxy is Mica due to its transparency, high thermal stability, and good flexibility. For example, Jiang et. al reported the successful fabrication of a ferroelectric thin film on a mica substrate [

44]. Also, a remarkable study was done by Yang et al. that demonstrated a cost-effective, flexible, and translucent resistive memory device SRO/BaTi0.95Co0.05O3/Au (SRO/BTCO/Au) on a mica substrate. This device maintained its functionality even when bent to a radius of 1.44mm. Additionally, it reliably writes, erases, and stores information across a temperature range of 25 °C to 180 °C, and remains operational after annealing at 500 °C [

45]. This flexible memory device with excellent thermal stability and high transparency makes it highly promising for applications in flexible and wearable electronics.

2.2.4. Sacrificial Layers

The use of sacrificial layers is crucial in many advanced fabrication techniques for free-standing ferroelectric films [

40,

46]. These layers are deposited beneath the ferroelectric material and later removed to release the film from its substrate. Sacrificial layers can be made from materials such as Sr3Al2O6 or La0.7Sr0.3MnO3, which can be selectively etched away without damaging the overlying ferroelectric film [

15]. This method allows for the production of high-quality membranes that are free from substrate constraints, enabling novel applications in flexible electronics.

2.2.4. Phase-Field Simulations

In addition to these physical fabrication techniques, phase-field simulations have become an essential tool for understanding and optimizing the properties of free-standing ferroelectric films [

47,

48]. These simulations provide insights into domain-switching behavior and phase transitions at a mesoscopic scale, facilitating the design of films with tailored mechanical and electrical properties [

5]. By elucidating the strong coupling between strain and polarization in these materials, researchers can develop new design strategies that enhance performance in practical applications.

In conclusion, advanced fabrication techniques such as laser lift-off, wet etching, and sacrificial layer methods have revolutionized the production of free-standing ferroelectric films.

Table 1 presents various fabrication techniques, highlighting their advantages, disadvantages, and applications. These innovations not only improve the quality and functionality of the films but also expand their potential applications in flexible electronics and other emerging technologies. Continued exploration of these methods will be vital for unlocking further advancements in this field.

2.3. Challenges in Fabrication

The fabrication of free-standing ferroelectric films presents several challenges that can significantly impact their performance and applicability in flexible electronics. Understanding these challenges is crucial for optimizing the fabrication processes and ensuring the reliability of the resulting films. This section highlights key issues related to intrinsic residual stresses, thermal stresses, and defect management during the deposition process.

2.3.1. Intrinsic Residual Stresses

Intrinsic residual stresses are internal stresses that develop during the deposition of thin films and are not solely attributed to external factors such as temperature changes. These stresses arise from various mechanisms, including lattice mismatches between the substrate and the deposited film, grain growth, and the incorporation of impurities or defects during film formation [

15]. For example, when a ferroelectric film is deposited onto a substrate with a different lattice constant, the resulting strain can induce compressive or tensile residual stresses within the film. These stresses can adversely affect the electrical properties of ferroelectric materials, leading to reduced polarization stability and increased leakage currents [

53,

54].

2.3.2. Thermal Stresses

Thermal stresses occur due to differences in thermal expansion coefficients between the thin film and its substrate. As the temperature changes during deposition or subsequent processing, these differences can lead to significant mechanical stress, potentially causing delamination or cracking. For instance, if a ferroelectric film expands more than its rigid substrate upon heating, tensile stresses may develop that exceed the film's fracture toughness. Conversely, cooling can induce compressive stresses that may also lead to failure modes such as buckling or delamination [

55].

2.3.3. Defect Management

The presence of defects in thin films is another critical challenge that affects their performance [

1]. Defects can arise from various sources during the deposition process, including voids, dislocations, and atomic-level point defects [

15]. These imperfections can act as scattering centers for charge carriers, leading to increased resistivity and reduced ferroelectric performance. Furthermore, defects can exacerbate intrinsic residual stresses by providing sites for stress concentration during mechanical loading [

56]. To mitigate these challenges, researchers are exploring various strategies such as optimizing deposition parameters (e.g., temperature and pressure), employing advanced techniques like atomic layer deposition (ALD) for better control over film microstructure, and utilizing post-deposition treatments to relieve residual stresses [

15,

57]. By addressing these fabrication challenges, it is possible to enhance the quality and functionality of free-standing ferroelectric films for flexible electronic applications.

In conclusion, while significant advancements have been made in the fabrication of free-standing ferroelectric films, overcoming challenges related to intrinsic residual stresses, thermal stresses, and defect management remains essential for realizing their full potential in flexible electronics. Continued research in this area will be vital for developing reliable fabrication methods that yield high-performance ferroelectric materials suitable for next-generation applications.

3. Properties of Free-Standing Ferroelectric Films

3.1. Ferroelectric Properties

Ferroelectric materials are characterized by their ability to exhibit spontaneous polarization, which can be reversed by the application of an external electric field [

58]. This property is crucial for various applications, including non-volatile memory devices, sensors, and actuators [

59]. The ferroelectric properties of free-standing films can differ significantly from those of bulk materials or films constrained to rigid substrates due to the unique mechanical and electrical environments they experience.

Table 2 displays the various properties of ferroelectric films.

3.1.1. Polarization Stability

One of the primary challenges in utilizing free-standing ferroelectric films is ensuring polarization stability [

60]. In traditional configurations, ferroelectric materials often suffer from reduced stability due to mechanical stress and external influences. However, recent studies have shown that optimizing the structure of free-standing films can enhance their polarization stability. For instance, a study on PZT films with Au doped demonstrated a remarkable increase in remnant polarization (Pr) to approximately 80 μC/cm² which is about 50% higher compared to pure PZT films [

61]. Additionally, certain materials exhibit greater remnant polarization in their freestanding state compared to their substrate-bound counterparts [

62,

63,

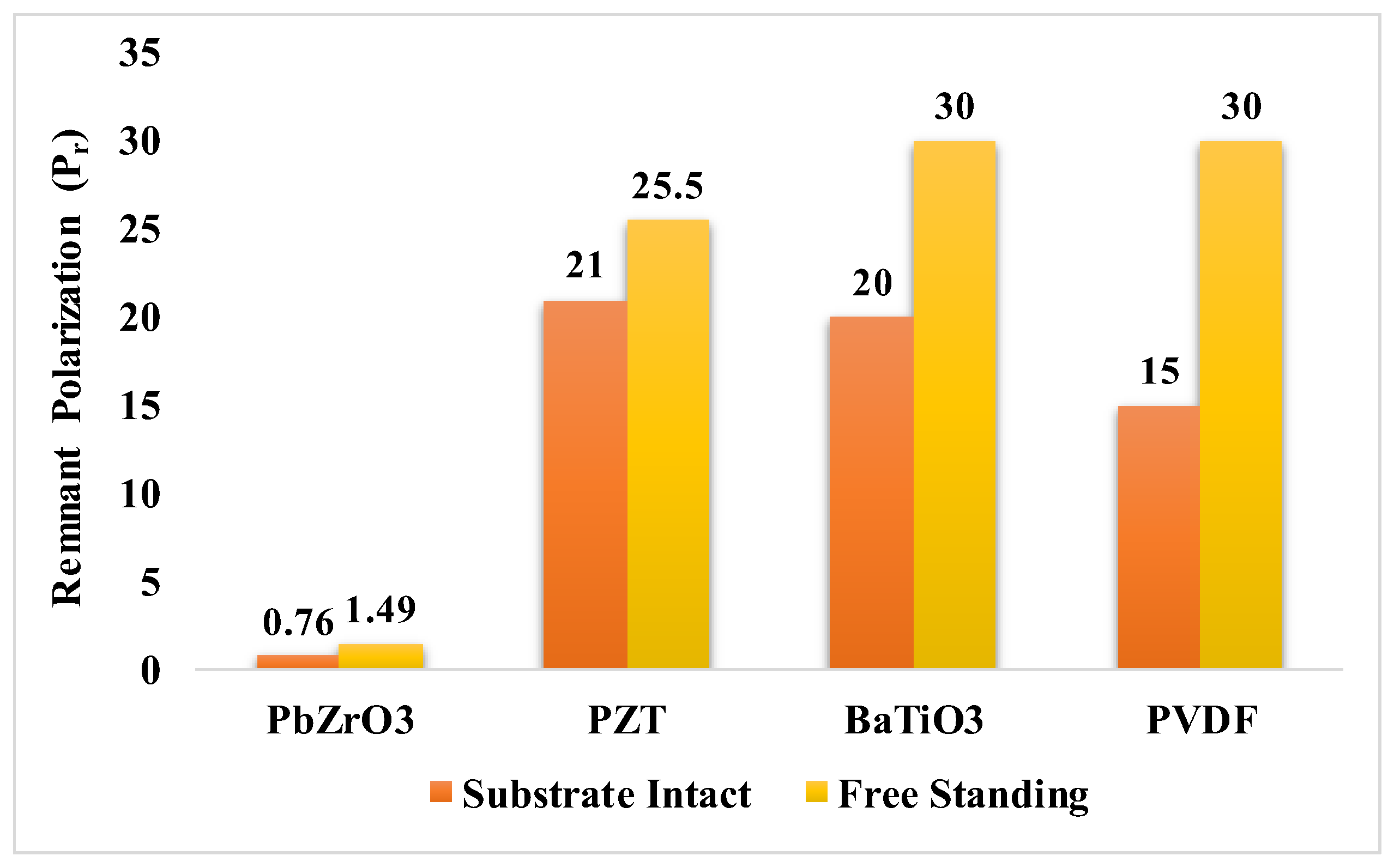

64]. A bar chart illustrating the comparison of remnant polarization values for various materials in their freestanding form and when attached to a substrate is shown in

Figure 4.

Table 2.

Properties of Various Ferroelectric Materials.

Table 2.

Properties of Various Ferroelectric Materials.

| Material |

Curie Temperature (°C) |

Remnant Polarization (µC/cm²) |

Dielectric constant (εr) |

Piezoelectric coefficient

(pC/N) |

Flexibility/Compatibility |

Applications |

| Barium Titanate (BTO) |

~120 |

~20–25 |

~1000 |

~190 |

High permittivity; brittle, but flexible as thin films |

Capacitors and nanogenerators [65,66,67] |

| Lead Zirconate Titanate (PZT) |

~300 |

~30–50 |

~500–1000 |

~250–600 |

Brittle; improved flexibility when integrated on polymer substrates |

Memory devices, Nanogenerators, and Sensors [51,68] |

| HfO₂-based oxides |

~450–500 |

~10–30 |

~20–30 |

~10–15 |

CMOS-compatible; suitable for ultra-thin layers |

Non-volatile memory and energy storage [69,70] |

Poly(vinylidene fluoride- trifluoroethylene)

|

~100 |

~6–12 |

~10–12 |

~20–30 |

Excellent flexibility |

Flexible sensors and generators [71,72,73] |

| ZnO-based materials |

- |

Low (<1) |

~9 |

~10 |

Highly flexible |

Sensors and actuators [69,74,75]

|

3.1.2. Thickness Dependence

The thickness of ferroelectric films plays a critical role in determining their ferroelectric properties [

57,

76,

77]. As films become thinner, they often exhibit a phenomenon known as the "size effect," where the ferroelectric properties can diminish or even vanish below a critical thickness. For example, recent research has successfully synthesized BTO nanosheets with a thickness of just 1.8 nm while maintaining stable ferroelectric responses, indicating that careful control over film thickness can yield functional materials even at the nanoscale [

78].

3.1.3. Domain Structure and Switching Behavior

The domain structure within ferroelectric films significantly influences their switching behavior and overall performance [

79,

80]. The dynamic behavior of domain structures is essential for understanding how these materials respond to external electric fields [

81,

82]. Phase-field simulations have emerged as a powerful tool for exploring domain-switching behavior and phase transitions at the mesoscopic scale [

5]. These simulations confirm the strong coupling between strain and polarization in super-elastic ferroelectric nanostructures, leading to new design strategies that enhance switching speeds and efficiency.

Figure 5 shows a roadmap of domain wall motion in freestanding films.

3.1.4. Electromechanical Coupling

Electromechanical coupling is another critical aspect of ferroelectric properties that affects device performance. The piezoelectric effect in ferroelectric materials allows them to convert mechanical stress into electrical energy and vice versa. This property is particularly valuable for applications in sensors and actuators where precise control over movement or deformation is required [

15,

83,

84,

85]. The integration of free-standing ferroelectric films with flexible substrates can enhance this electromechanical coupling, enabling the development of highly responsive devices.

In summary, the ferroelectric properties of free-standing films are influenced by factors such as polarization stability, thickness dependence, domain structure dynamics, and electromechanical coupling. Ongoing research into optimizing these properties through advanced fabrication techniques and structural modifications will be essential for realizing the full potential of free-standing ferroelectric films in flexible electronic applications.

3.2. Mechanical Properties

The mechanical properties of free-standing ferroelectric films are critical for their performance in flexible electronic applications. Unlike traditional ferroelectric materials, which are often constrained by rigid substrates, free-standing films can exhibit unique mechanical behaviors such as super-elasticity and flexibility. This section explores the key mechanical properties of these films, focusing on their elasticity, tensile strength, and the implications of these properties for practical applications.

3.2.1. Super-Elasticity

Super-elasticity refers to the ability of a material to undergo large strains and return to its original shape upon unloading. This property is particularly valuable for applications in flexible electronics, where materials must endure repeated mechanical deformation without permanent damage. Freestanding oxide membranes demonstrate exceptional flexibility. Recent studies have demonstrated that high-quality freestanding single-crystal ferroelectric thin films, such as those made from BaTiO

3 (BTO) and BiFeO

3 (BFO), exhibit remarkable super-elastic behavior [

5,

86,

87]. For instance, BTO films fabricated using pulsed-laser deposition (PLD) were shown to withstand bending to angles of up to 180° without cracking, demonstrating their exceptional flexibility and resilience [

86]. Notably, reversible folding and unfolding cycles driven by an external electric field result in remarkable super-elastic piezoelectricity in BTO membranes [

88]. This ability to recover from significant deformation is essential for the development of durable flexible devices.

3.2.2. Tensile Strength and Ductility

The tensile strength of ferroelectric films is another critical factor influencing their mechanical performance. While conventional ferroelectric materials are typically brittle, recent advancements in fabrication techniques have led to the production of freestanding membranes that exhibit enhanced ductility. For example, studies have shown that freestanding BTO membranes can endure mechanical bending strains of up to 10% without fracture [

15]. This increased ductility is attributed to the absence of substrate constraints, which allows for more uniform stress distribution across the film during deformation.

3.2.3. Strain Engineering

Strain engineering plays a vital role in enhancing the mechanical properties of free-standing ferroelectric films. By carefully controlling the deposition conditions and post-processing treatments, researchers can manipulate the internal stress states within the films to optimize their mechanical performance [

15]. Phase-field simulations have provided insights into how strain affects domain configurations and switching behaviors in these materials, leading to new design strategies for improving both electrical and mechanical properties [

5,

89].

Thus, the mechanical properties of free-standing ferroelectric films are crucial for their application in flexible electronics. The combination of super-elasticity, enhanced tensile strength, and strain engineering provides opportunities for creating durable and efficient devices. Ongoing research into optimizing these properties will further expand the potential applications of free-standing ferroelectric films in next-generation electronic systems.

3.3. Thermal and Electrical Stability

The thermal and electrical stability of free-standing ferroelectric films is critical for their performance in flexible electronic applications. These properties determine how well the films can maintain their functionality under varying environmental conditions, including temperature fluctuations and electrical stress. This section discusses the factors influencing thermal stability, electrical stability, and the implications for device applications.

3.3.1. Thermal Stability

Thermal stability refers to the ability of ferroelectric materials to retain their ferroelectric properties at elevated temperatures. As ferroelectric films are subjected to thermal cycling or high-temperature environments, they may undergo phase transitions that can degrade their ferroelectric characteristics [

90]. For instance, hafnia-based ultrathin films have been shown to exhibit room-temperature ferroelectricity even at thicknesses as low as 1 nm, but their structural phases can be susceptible to temperature changes [

6]. The transition from a metastable rhombohedral phase to an orthorhombic phase can occur without significant loss of ferroelectricity; however, external factors such as interfacial defects and electrode materials can influence this stability [

6].To enhance thermal stability, researchers are exploring multilayer structures that incorporate dielectric layers within the ferroelectric film. This approach has been shown to stabilize polarization in free-standing films, allowing them to maintain robust ferroelectricity at higher temperatures [

26,

91,

92,

93]. By optimizing the composition and thickness of these dielectric layers, it is possible to achieve a balance between mechanical flexibility and thermal stability.

3.3.2. Electrical Stability

Electrical stability is another crucial aspect of free-standing ferroelectric films. The ability of these materials to withstand electric fields without experiencing significant degradation in performance is essential for applications in memory devices and sensors. One common issue is the occurrence of leakage currents, which can arise from defects within the film or at the interfaces with electrodes [

78]. These leakage currents can lead to increased power consumption and reduced efficiency in devices.

Recent studies have demonstrated that optimizing the microstructure of free-standing films can mitigate leakage currents. For example, defect-free BaTiO3 nanosheets synthesized at low temperatures have exhibited stable ferroelectric responses with minimal leakage [

78]. The careful control of synthesis parameters allows for the production of films with fewer defects, thereby enhancing both electrical performance and stability [

94,

95,

96].

In summary, the thermal and electrical stability of free-standing ferroelectric films is crucial for their practical applications in flexible electronics. Ongoing research aimed at optimizing these properties through advanced fabrication techniques and material engineering will be essential for developing reliable and efficient devices capable of operating under diverse conditions.

4. Applications in Flexible Electronics

4.1. Energy Harvesting Devices

Energy harvesting devices are increasingly gaining attention for their ability to convert ambient energy sources into usable electrical energy, making them essential components in the development of sustainable and self-powered electronic systems [

97,

98,

99,

100]. Free-standing ferroelectric films, with their unique properties, offer significant advantages in this field. This section explores the mechanisms of energy harvesting using free-standing ferroelectric films, their performance characteristics, and recent advancements that enhance their applicability in flexible electronic devices [

101,

102,

103,

104].

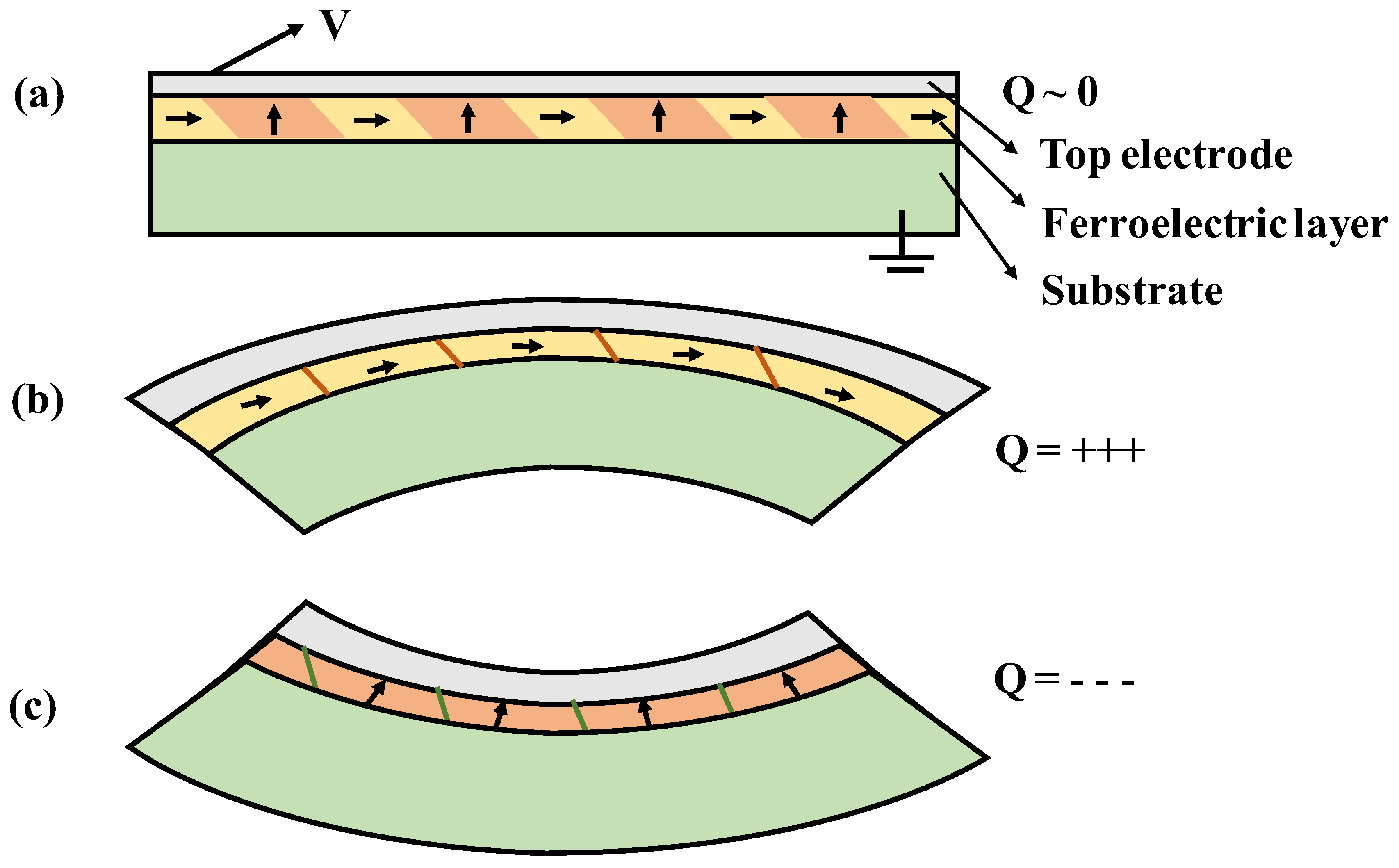

4.1.1. Mechanisms of Energy Harvesting

The primary mechanism by which free-standing ferroelectric films harvest energy is through the piezoelectric effect. When mechanical stress is applied to a piezoelectric material, it generates an electrical charge due to the displacement of dipoles within the material [

15].

Figure 6 (a-c) shows a concept of energy harvesting in these materials where bending the substrate induces mechanical strain on the ferroelectric film, leading to the switching of polarization domains [

80]. In the context of free-standing ferroelectric films, this effect is particularly pronounced due to their high flexibility and super-elasticity, allowing them to undergo significant deformation without structural failure [

5]. Recent studies have demonstrated that free-standing ferroelectric films can effectively convert mechanical vibrations from various sources—such as human motion or environmental vibrations—into electrical energy. For example, BaTiO

3 (BTO) films have been shown to generate substantial electrical output when subjected to mechanical stress, making them suitable for applications in wearable electronics and sensors [

86].

4.1.2. Performance Characteristics

The performance of energy harvesting devices utilizing free-standing ferroelectric films is influenced by several factors, including film thickness, mechanical properties, and the nature of the applied stress. Thinner films generally exhibit higher piezoelectric coefficients due to reduced clamping effects and enhanced domain switching capabilities [

78,

105,

106,

107]. Additionally, the mechanical flexibility of these films allows for effective energy harvesting in dynamic environments where traditional rigid materials would fail. For instance, recent advancements have led to the fabrication of ultra-thin hafnia membranes that maintain ferroelectric properties even at thicknesses as low as 1 nm [

6]. These membranes can be integrated into flexible energy-harvesting devices that can operate efficiently under various mechanical stresses.

4.1.3. Recent Advancements

Innovative approaches in the design and fabrication of free-standing ferroelectric films have further enhanced their potential for energy harvesting applications. The incorporation of multilayer structures has been shown to improve polarization stability and piezoelectric performance significantly [

108,

109,

110]. Furthermore, phase-field simulations have provided valuable insights into optimizing domain structures within these materials. Understanding how strain affects domain-switching behavior allows for better design strategies that maximize energy harvesting capabilities [

5].

4.1.4. Applications in Flexible Electronics

The integration of free-standing ferroelectric films into flexible electronic devices opens up new possibilities for self-powered systems. Applications range from wearable sensors that harvest energy from body movements to environmental sensors capable of converting vibrations from machinery or traffic into electrical power [

101,

102,

104]. These devices not only reduce reliance on external power sources but also contribute to the development of sustainable technologies.

In conclusion, free-standing ferroelectric films represent a promising platform for energy-harvesting applications in flexible electronics. Their unique piezoelectric properties, combined with ongoing advancements in material design and fabrication techniques, position them as key components in the development of efficient self-powered devices capable of operating in diverse environments. Continued research and innovation will be essential for unlocking their full potential in this rapidly evolving field.

4.2. Sensors and Actuators

Free-standing ferroelectric films are increasingly being recognized for their potential in sensor and actuator applications due to their unique electromechanical properties, flexibility, and ability to operate under various environmental conditions [

111]. This section explores the mechanisms by which these films function as sensors and actuators, highlights recent advancements in their design and fabrication, and discusses their implications for next-generation electronic devices [

112].

4.2.1. Mechanisms of Sensing and Actuation

The operation of ferroelectric materials in sensors and actuators is primarily based on the piezoelectric effect, where mechanical stress induces an electrical charge within the material. Conversely, applying an electric field can induce mechanical deformation. This bidirectional coupling makes ferroelectric films particularly suitable for applications requiring precise control over movement or sensing capabilities [

15,

113]. For instance, when a mechanical force is applied to a free-standing ferroelectric film, it generates a measurable voltage output, allowing it to function as a sensor for pressure or vibration [

114]. These properties enable the development of sensitive sensors capable of detecting minute mechanical changes in their environment, such as vibrations from machinery or pressure variations in wearable applications [

115,

116].

4.2.2. Integration with Flexible Substrates

The ability to integrate free-standing ferroelectric films with flexible substrates significantly enhances their applicability in various sensor and actuator designs [

117,

118]. The use of van der Waals stripping methods allows for the easy transfer of these films onto flexible surfaces without compromising their structural integrity [

78]. This integration facilitates the creation of lightweight and conformable devices that can be used in a wide range of applications, including biomedical sensors that monitor physiological parameters or environmental sensors that detect changes in air quality.

4.2.3. Recent Advances in Design and Fabrication

Innovative fabrication techniques have further enhanced the performance of free-standing ferroelectric films for sensing and actuation applications [

43,

119].

Additionally, phase-field simulations have provided insights into optimizing domain structures within free-standing ferroelectric films. By understanding how strain affects domain-switching behavior, researchers can develop new design strategies that maximize sensor sensitivity and actuator performance [

5].

4.2.4. Applications in Flexible Electronics

The versatility of free-standing ferroelectric films extends to a variety of applications in flexible electronics. In wearable technology, these films can be used to create sensors that monitor physical activity or vital signs by detecting changes in pressure or motion [

78]. In industrial settings, they can serve as actuators that control machinery or robotic systems with high precision. Moreover, the integration of free-standing ferroelectric films with other functional materials opens up possibilities for multifunctional devices capable of performing multiple tasks simultaneously. For instance, combining piezoelectric sensors with energy harvesting capabilities can lead to self-powered systems that reduce dependence on external power sources [

15].

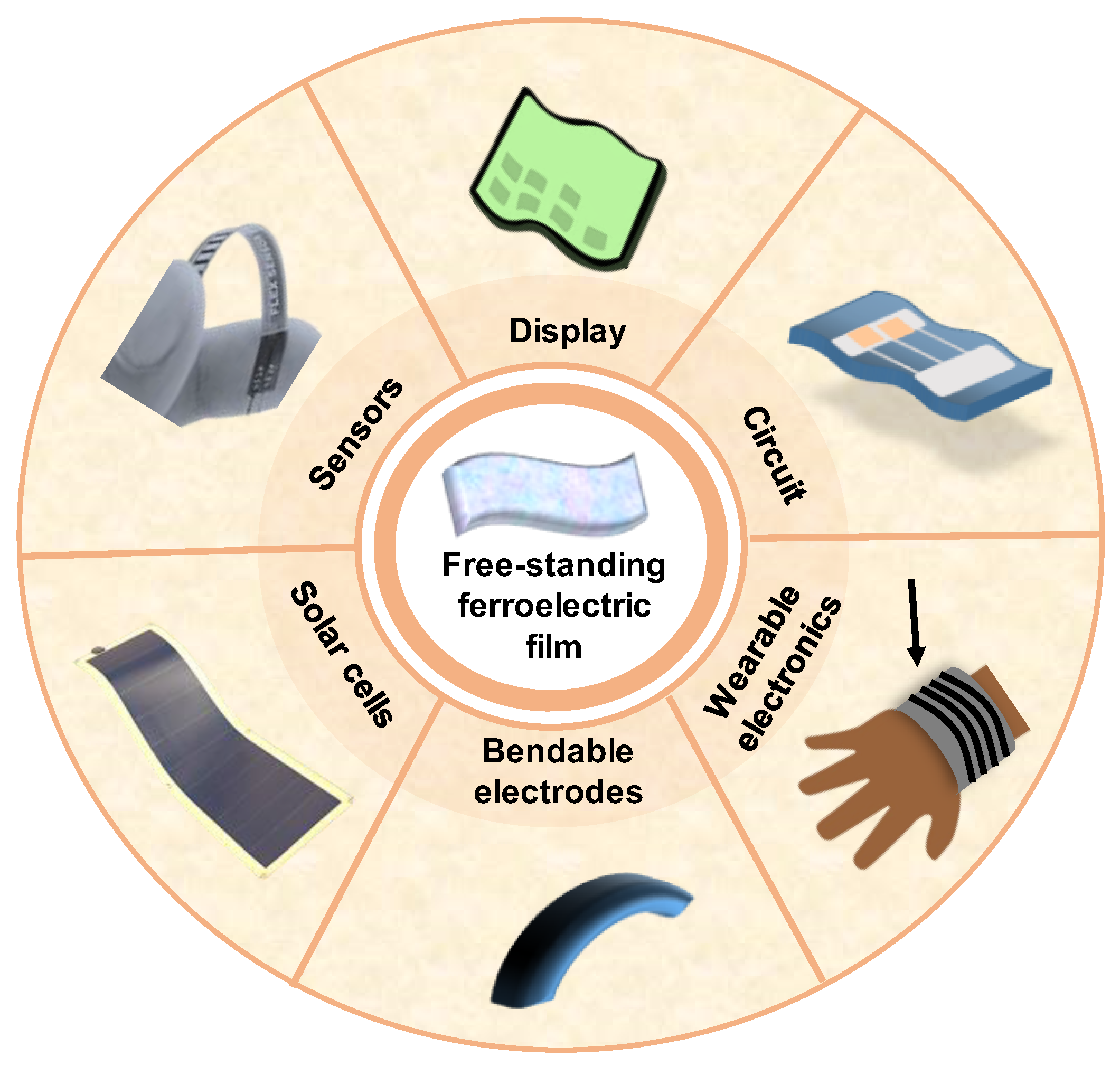

In summary, free-standing ferroelectric films hold great promise for advancing sensor and actuator technologies due to their unique electromechanical properties and flexibility. An illustrative figure with various applications of freestanding films has been shown in

Figure 7. Ongoing research into optimizing their design and fabrication will be essential for realizing their full potential in next-generation flexible electronic devices across various applications.

4.3. Next-Generation Devices

The integration of free-standing ferroelectric films into next-generation devices represents a significant advancement in flexible electronics, enabling the development of multifunctional systems that can perform a variety of tasks simultaneously. These films, characterized by their unique electromechanical properties, mechanical flexibility, and ease of integration with other materials, are paving the way for innovative applications across various domains.

4.3.1. Flexible Memory Devices

One of the most promising applications for free-standing ferroelectric films is in flexible non-volatile memory devices. Ferroelectric materials are well-suited for memory applications due to their ability to retain polarization states without a continuous power supply. Recent studies have demonstrated that free-standing ferroelectric thin films can achieve high remnant polarization values and robust switching characteristics, making them ideal candidates for next-generation memory technologies [

120,

121]. The ability to fabricate these films on flexible substrates allows for the development of bendable memory devices that can be integrated into wearable electronics and flexible displays. For instance, HfO

2 films can be transferred onto flexible substrates while maintaining strong ferroelectric properties and are also used in memristors [

122,

123,

124].

4.3.2. Energy Harvesting Systems

Free-standing ferroelectric films also hold great promise for energy harvesting applications. Their piezoelectric properties enable them to convert mechanical energy from vibrations or movements into electrical energy efficiently. Recent advancements in fabrication techniques have led to the development of lead-free piezoceramic films with high piezoelectric coefficients, such as Ba

0.85Ca

0.15Zr

0.1Ti

0.9O

3 (BCZT), which can be utilized in microenergy harvesting systems [

15]. Ferroelectric films based on HfO

2/ZrO

2 are also widely utilized in energy storage applications [

125,

126,

127,

128]. These energy harvesters can power small electronic devices or sensors, contributing to the development of self-sustaining systems that reduce reliance on external power sources.

4.3.3. Sensors and Actuators

The unique electromechanical properties of free-standing ferroelectric films make them highly suitable for sensor and actuator applications [

129]. By leveraging their piezoelectric effect, these films can be designed to detect minute changes in pressure, temperature, or mechanical stress [

78]. Recent innovations have led to the creation of flexible sensors that can monitor physiological signals or environmental conditions in real time. Additionally, the integration of these films into actuators enables precise control over movement in robotic systems or adaptive structures.

4.3.4. Integration with Other Functional Materials

The ability to integrate free-standing ferroelectric films with other functional materials opens up new possibilities for creating multifunctional devices. For instance, combining ferroelectric films with magnetic materials could lead to devices that exploit both ferroelectricity and magnetism, enabling novel functionalities such as magnetoelectric coupling [

6]. This integration can enhance device performance and expand the range of applications, including advanced data storage solutions and smart sensors.

4.3.5. Environmental Sensors and Biosensors

Free-standing ferroelectric films are also being explored for use in environmental sensors and biosensors due to their sensitivity and flexibility [

130,

131]. For example, piezoelectric sensors made from these films can detect changes in environmental conditions such as humidity or chemical concentrations [

15]. Furthermore, their biocompatibility makes them suitable for biomedical applications where they can monitor physiological parameters or detect biomolecules associated with diseases [

130,

132,

133].

In conclusion, free-standing ferroelectric films are poised to play a pivotal role in the development of next-generation electronic devices. Their unique properties enable a wide range of applications across various fields, including flexible memory technologies, energy harvesting systems, sensors, actuators, and multifunctional devices. As research continues to advance in this area, the integration of these innovative materials into practical applications will likely lead to significant breakthroughs in flexible electronics and beyond.

5. Recent Advances and Innovations

The field of free-standing ferroelectric films has witnessed significant advancements and innovations that enhance their properties and broaden their applications in flexible electronics. This section highlights key recent developments, focusing on strategies for performance optimization, novel material systems, and emerging applications that capitalize on the unique characteristics of these materials.

5.1. Performance Optimization Techniques

Recent studies have introduced various strategies to optimize the performance of free-standing ferroelectric films. One such example is the experimental optimization of thickness scaling in Hf

1–xZr

xO

2 thin films to achieve stable low-voltage operation with enhanced reliability done by Park

et al [

134]. Another effort involves refining process conditions to improve ferroelectric capacitor performance, which studies the structural and electrical modifications in metal-ferroelectric-metal capacitor systems [

135]. Overall, extensive efforts have been dedicated to optimizing ferroelectric films at multiple levels to enhance their performance [

136,

137].

5.2. Emerging Material Systems

The exploration of new material systems is another area of active research. Lead-free piezoceramics, such as Ba

0.85Ca

0.15Zr

0.1Ti

0.9O

3 (BCZT), have gained attention due to their excellent piezoelectric properties and environmental safety [

138]. The development of a van der Waals stripping method for fabricating large-area freestanding BCZT films demonstrates the potential for creating flexible piezoceramic materials suitable for energy harvesting and sensing applications. These lead-free films (including hafnium and zirconium oxide films) exhibit a high piezoelectric coefficient (

d33 = 209 pm/V) and outstanding flexibility, making them ideal candidates for integration into next-generation electronic devices [

139,

140].

5.3. Innovative Fabrication Techniques

Innovative fabrication techniques have also contributed to the advancement of free-standing ferroelectric films. The use of phase-field simulations has provided valuable insights into the design of super-elastic ferroelectric thin films by exploring domain-switching behavior and phase transitions at the mesoscopic scale [

5]. These simulations have led to the development of novel mechanical structures, such as two-dimensional wrinkles and three-dimensional nanosprings, which leverage the unique strain-polarization coupling in these materials to enhance their mechanical performance [

141,

142,

143].

5.4. Applications in Multifunctional Devices

The advancements in free-standing ferroelectric films have opened new avenues for multifunctional devices that combine various functionalities into a single platform. For example, integrating piezoelectric sensors with energy harvesting capabilities can lead to self-powered systems that are capable of monitoring environmental conditions while generating energy from mechanical vibrations [

15]. Additionally, the combination of ferroelectric materials with magnetic components could enable magnetoelectric devices that exploit both ferroelectricity and magnetism for advanced data storage solutions [

144].

6. Future Perspectives

The field of free-standing ferroelectric films is poised for significant advancements as researchers continue to explore new materials, fabrication techniques, and applications. While considerable progress has been made, several challenges remain to be addressed to fully realize the potential of these materials in flexible electronics and other emerging technologies. A few areas for future exploration include improving thermal stability [

145,

146,

147], reducing leakage currents [

148,

149], and enhancing cycling stability to meet commercialization requirements [

138,

150]. This section outlines key areas for future research and development, focusing on enhancing performance, expanding applications, and addressing commercialization challenges.

6.1. Enhancing Performance

One of the primary goals for future research is to improve the performance characteristics of free-standing ferroelectric films. Current limitations such as large leakage currents, low nanoscale polarization values, and poor cycling stability hinder the commercialization of ferroelectric devices [

138]. Strategies to overcome these challenges include optimizing the composition of ferroelectric materials, utilizing advanced fabrication techniques like phase-field simulations to tailor domain structures, and exploring novel multilayer configurations that enhance polarization stability [

56,

70,

151].

Additionally, research into lead-free piezoceramics, such as Ba

0.85Ca

0.15Zr

0.1Ti

0.9O

3 (BCZT), shows promise for developing environmentally friendly alternatives with high piezoelectric coefficients and flexibility [

138,

152]. Continued exploration of these materials could lead to breakthroughs in energy harvesting and sensing applications.

6.2. Expanding Applications

The versatility of free-standing ferroelectric films allows for a wide range of applications beyond traditional uses in memory devices and sensors. Future research should focus on integrating these films into multifunctional devices that combine energy harvesting, sensing, and actuation capabilities in a single platform [

15]. For instance, self-powered wearable devices that monitor health metrics while harvesting energy from body movements represent a promising application area.

Furthermore, the development of hybrid systems that integrate ferroelectric materials with other functional components—such as magnetic or optical materials—could lead to innovative device architectures with enhanced functionalities [

6]. This integration can facilitate advancements in areas such as data storage solutions and smart sensors capable of responding dynamically to environmental changes.

6.3. Addressing Commercialization Challenges

Despite the promising advancements in free-standing ferroelectric films, several barriers must be overcome to achieve successful commercialization [

2,

153,

154]. The high cost of production and scalability issues associated with current fabrication techniques pose significant challenges [

138]. Future research should focus on developing cost-effective manufacturing processes that maintain high quality while being scalable for industrial applications.

Moreover, regulatory considerations surrounding the use of certain materials—particularly lead-based compounds—will necessitate the development of alternative formulations that comply with environmental standards [

155,

156,

157]. As sustainability becomes increasingly important in electronics manufacturing, the shift towards green fabrication methods will be essential.

In summary, the future of free-standing ferroelectric films is bright but requires concerted efforts across multiple fronts.

Table 3 highlights the challenges encountered in film fabrication and their potential solutions. By enhancing performance characteristics, expanding application areas, and addressing commercialization challenges through innovative research and development strategies, free-standing ferroelectric films can play a pivotal role in shaping the next generation of flexible electronics. Continued interdisciplinary collaboration will be crucial in unlocking their full potential and driving forward advancements in this dynamic field.

7. Conclusion

Free-standing ferroelectric films represent a significant advancement in the field of flexible electronics, offering unique properties that enable a wide range of applications. The ability to manipulate spontaneous polarization and achieve robust electromechanical coupling makes these materials particularly suitable for use in sensors, actuators, and energy-harvesting devices. Recent research has highlighted innovative fabrication techniques, such as multilayer structures and van der Waals epitaxy, which enhance the performance and stability of these films while maintaining their flexibility.

The ongoing exploration of new material systems, particularly lead-free piezoceramics like Ba

0.85Ca

0.15Zr

0.1Ti

0.9O

3 (BCZT), demonstrates the potential for developing environmentally friendly alternatives with high piezoelectric coefficients and mechanical resilience [

138]. These advancements not only contribute to the sustainability of electronic devices but also expand the application landscape for ferroelectric materials in emerging technologies.

Despite the promising developments, challenges remain in the commercialization of free-standing ferroelectric films. Issues such as large leakage currents, low nanoscale polarization values, and poor cycling stability must be addressed to meet industry standards [

15]. Future research should focus on optimizing fabrication processes, enhancing material properties, and exploring multifunctional applications that leverage the unique characteristics of these films.

As flexible electronics continue to evolve, free-standing ferroelectric films are poised to play a pivotal role in the development of next-generation devices that are not only efficient but also adaptable to diverse environments and applications. Continued interdisciplinary collaboration among materials scientists, engineers, and industry stakeholders will be essential for unlocking the full potential of these innovative materials in practical applications.

Acknowledgments

The authors acknowledge support through Ramanujan Fellowship grant (RJF/2022/000116) from the Science and Engineering Research Board (SERB), Department of Science and Technology (DST), Government of India.

References

- Ji, J.; Park, S.; Do, H.; Kum, H.S. A Review on Recent Advances in Fabricating Freestanding Single-Crystalline Complex-Oxide Membranes and Its Applications. Phys. Scr. 2023, 98, 052002. [CrossRef]

- Lee, D. Flexoelectricity in Thin Films and Membranes of Complex Oxides. APL Mater. 2020, 8, 090901. [CrossRef]

- Dai, L.; Yao, D.; An, F.; Cheng, M.; Zhong, X.; Tang, Z.H.; Zhong, G. Freestanding Ferroelectric Thin Film with Robust Ferroelectricity Via Inserted Dielectric Layers 2024.

- Jia, X.; Guo, R.; Tay, B.K.; Yan, X. Flexible Ferroelectric Devices: Status and Applications. Adv. Funct. Mater. 2022, 32, 2205933. [CrossRef]

- Guo, C.; Huang, H. Design of Super-Elastic Freestanding Ferroelectric Thin Films Guided by Phase-Field Simulations. Microstructures 2022, 2, 21. [CrossRef]

- Shen, Y.; Ooe, K.; Yuan, X.; Yamada, T.; Kobayashi, S.; Haruta, M.; Kan, D.; Shimakawa, Y. Ferroelectric Freestanding Hafnia Membranes with Metastable Rhombohedral Structure down to 1-Nm-Thick. Nat. Commun. 2024, 15, 4789. [CrossRef]

- Novoselov, K.S.; Mishchenko, A.; Carvalho, A.; Castro Neto, A.H. 2D Materials and van Der Waals Heterostructures. Science 2016, 353, aac9439. [CrossRef]

- Zheng, L.; Wang, X.; Jiang, H.; Xu, M.; Huang, W.; Liu, Z. Recent Progress of Flexible Electronics by 2D Transition Metal Dichalcogenides. Nano Res. 2022, 15, 2413–2432. [CrossRef]

- Gao, W.; Zhu, Y.; Wang, Y.; Yuan, G.; Liu, J.-M. A Review of Flexible Perovskite Oxide Ferroelectric Films and Their Application. J. Materiomics 2020, 6, 1–16. [CrossRef]

- Zhang, T.; Yao, G.; Pan, T.; Lu, Q.; Lin, Y. Flexible Inorganic Oxide Thin-Film Electronics Enabled by Advanced Strategies. J. Semicond. 2020, 41, 041602. [CrossRef]

- Jayakrishnan, A.R.; Kumar, A.; Druvakumar, S.; John, R.; Sudeesh, M.; Puli, V.S.; Silva, J.P.B.; Gomes, M.J.M.; Sekhar, K.C. Inorganic Ferroelectric Thin Films and Their Composites for Flexible Electronic and Energy Device Applications: Current Progress and Perspectives. J. Mater. Chem. C 2023, 11, 827–858. [CrossRef]

- Tripathy, A.; Saravanakumar, B.; Mohanty, S.; Nayak, S.K.; Ramadoss, A. Comprehensive Review on Flexoelectric Energy Harvesting Technology: Mechanisms, Device Configurations, and Potential Applications. ACS Appl. Electron. Mater. 2021, 3, 2898–2924. [CrossRef]

- Peng, R.; Zhang, B.; Dong, G.; Wang, Y.; Yang, G.; Zhang, J.; Peng, B.; Zhao, Y.; Liu, M. Enhanced Piezoelectric Energy Harvester by Employing Freestanding Single-Crystal BaTiO 3 Films in PVDF-TrFE Based Composites. Adv. Funct. Mater. 2024, 34, 2316519. [CrossRef]

- Khatua, D.K.; Kim, S.-J. Perspective on the Development of High Performance Flexible Piezoelectric Energy Harvesters. J. Mater. Chem. C 2022, 10, 2905–2924. [CrossRef]

- Li, S.; Wang, Y.; Yang, M.; Miao, J.; Lin, K.; Li, Q.; Chen, X.; Deng, J.; Xing, X. Ferroelectric Thin Films: Performance Modulation and Application. Mater. Adv. 2022, 3, 5735–5752. [CrossRef]

- Dai, L.; An, F.; Zou, J.; Zhong, X.; Zhong, G. Freestanding Inorganic Oxide Films for Flexible Electronics. J. Appl. Phys. 2022, 132, 070904. [CrossRef]

- Badillo, M.; Taleb, S.; Mokabber, T.; Rieck, J.; Castanedo, R.; Torres, G.; Noheda, B.; Acuautla, M. Low-Toxicity Chemical Solution Deposition of Ferroelectric Ca:HfO 2. J. Mater. Chem. C 2023, 11, 1119–1133. [CrossRef]

- Sun, Y.; Ning, J.; Xi, J.; Duan, J.; Zhou, D. Enhancement of Ferroelectricity in Chemical-Solution-Deposited ZrO2 Thin Films through Fine Phase Transition Control. Ceram. Int. 2024, 50, 27371–27379. [CrossRef]

- Wang, L.; Sun, G.; Yuan, S. Chemical Vapor Deposition Growth of 2D Ferroelectric Materials for Device Applications. Adv. Mater. Technol. 2024, 9, 2301973. [CrossRef]

- Dalba, D.A.; Zhang, X.; Xu, W.; Bhattarai, B.; Gamachchi, D.M.; Karunarathne, I.M.; Meng, W.J.; Meng, A.C. Effect of ZnO Interfacial Seed Layer in Sol–Gel Grown ZnMgO Ferroelectric. ACS Appl. Electron. Mater. 2024, acsaelm.4c00281. [CrossRef]

- Yi, J.; Liu, L.; Shu, L.; Huang, Y.; Li, J.-F. Outstanding Ferroelectricity in Sol–Gel-Derived Polycrystalline BiFeO 3 Films within a Wide Thickness Range. ACS Appl. Mater. Interfaces 2022, 14, 21696–21704. [CrossRef]

- Luo, Y.; Tang, Z.; Yin, X.; Chen, C.; Fan, Z.; Qin, M.; Zeng, M.; Zhou, G.; Gao, X.; Lu, X.; et al. Ferroelectricity in Dopant-Free HfO2 Thin Films Prepared by Pulsed Laser Deposition. J. Materiomics 2022, 8, 311–318. [CrossRef]

- Song, T.; Solanas, R.; Qian, M.; Fina, I.; Sánchez, F. Large Enhancement of Ferroelectric Polarization in Hf 0.5 Zr 0.5 O 2 Films by Low Plasma Energy Pulsed Laser Deposition. J. Mater. Chem. C 2022, 10, 1084–1089. [CrossRef]

- Savant, C.; Gund, V.; Nomoto, K.; Maeda, T.; Jadhav, S.; Lee, J.; Ramesh, M.; Kim, E.; Nguyen, T.-S.; Chen, Y.-H.; et al. Ferroelectric AlBN Films by Molecular Beam Epitaxy. Appl. Phys. Lett. 2024, 125, 072902. [CrossRef]

- Wang, D.; Wang, P.; Wang, B.; Mi, Z. Fully Epitaxial Ferroelectric ScGaN Grown on GaN by Molecular Beam Epitaxy. Appl. Phys. Lett. 2021, 119, 111902. [CrossRef]

- Mimura, T.; Shimizu, T.; Uchida, H.; Funakubo, H. Room-Temperature Deposition of Ferroelectric HfO2-Based Films by the Sputtering Method. Appl. Phys. Lett. 2020, 116, 062901. [CrossRef]

- Dhole, S.; Chen, A.; Nie, W.; Park, B.; Jia, Q. Strain Engineering: A Pathway for Tunable Functionalities of Perovskite Metal Oxide Films. Nanomaterials 2022, 12, 835. [CrossRef]

- Pesquera, D.; Parsonnet, E.; Qualls, A.; Xu, R.; Gubser, A.J.; Kim, J.; Jiang, Y.; Velarde, G.; Huang, Y.; Hwang, H.Y.; et al. Beyond Substrates: Strain Engineering of Ferroelectric Membranes. Adv. Mater. 2020, 32, 2003780. [CrossRef]

- Xu, S.; Shi, X.; Pan, H.; Gao, R.; Wang, J.; Lin, Y.; Huang, H. Strain Engineering of Energy Storage Performance in Relaxor Ferroelectric Thin Film Capacitors. Adv. Theory Simul. 2022, 5, 2100324. [CrossRef]

- Han, L.; Fang, Y.; Zhao, Y.; Zang, Y.; Gu, Z.; Nie, Y.; Pan, X. Giant Uniaxial Strain Ferroelectric Domain Tuning in Freestanding PbTiO 3 Films. Adv. Mater. Interfaces 2020, 7, 1901604. [CrossRef]

- Zang, Y.; Di, C.; Geng, Z.; Yan, X.; Ji, D.; Zheng, N.; Jiang, X.; Fu, H.; Wang, J.; Guo, W.; et al. Giant Thermal Transport Tuning at a Metal/Ferroelectric Interface. Adv. Mater. 2022, 34, 2105778. [CrossRef]

- Fernandez, A.; Acharya, M.; Lee, H.; Schimpf, J.; Jiang, Y.; Lou, D.; Tian, Z.; Martin, L.W. Thin-Film Ferroelectrics. Adv. Mater. 2022, 34, 2108841. [CrossRef]

- Lyu, J.; Fina, I.; Solanas, R.; Fontcuberta, J.; Sánchez, F. Tailoring Lattice Strain and Ferroelectric Polarization of Epitaxial BaTiO3 Thin Films on Si(001). Sci. Rep. 2018, 8, 495. [CrossRef]

- Xu, R.; Huang, J.; Barnard, E.S.; Hong, S.S.; Singh, P.; Wong, E.K.; Jansen, T.; Harbola, V.; Xiao, J.; Wang, B.Y.; et al. Strain-Induced Room-Temperature Ferroelectricity in SrTiO3 Membranes. Nat. Commun. 2020, 11, 3141. [CrossRef]

- Bae, I.-T.; Lingley, Z.R.; Foran, B.J.; Adams, P.M.; Paik, H. Large Bi-Axial Tensile Strain Effect in Epitaxial BiFeO3 Film Grown on Single Crystal PrScO3. Sci. Rep. 2023, 13, 19018. [CrossRef]

- Adamo, C.; Ke, X.; Wang, H.Q.; Xin, H.L.; Heeg, T.; Hawley, M.E.; Zander, W.; Schubert, J.; Schiffer, P.; Muller, D.A.; et al. Effect of Biaxial Strain on the Electrical and Magnetic Properties of (001) La0.7Sr0.3MnO3 Thin Films. Appl. Phys. Lett. 2009, 95, 112504. [CrossRef]

- Jeong, C.K.; Park, K.-I.; Son, J.H.; Hwang, G.-T.; Lee, S.H.; Park, D.Y.; Lee, H.E.; Lee, H.K.; Byun, M.; Lee, K.J. Self-Powered Fully-Flexible Light-Emitting System Enabled by Flexible Energy Harvester. Energy Env. Sci 2014, 7, 4035–4043. [CrossRef]

- Lee, H.S.; Chung, J.; Hwang, G.; Jeong, C.K.; Jung, Y.; Kwak, J.; Kang, H.; Byun, M.; Kim, W.D.; Hur, S.; et al. Flexible Inorganic Piezoelectric Acoustic Nanosensors for Biomimetic Artificial Hair Cells. Adv. Funct. Mater. 2014, 24, 6914–6921. [CrossRef]

- Han, S.; Meng, Y.; Xu, Z.; Kim, J.S.; Li, Y.; Roh, I.-P.; Ahn, H.; Kim, D.-H.; Bae, S.-H. Freestanding Membranes for Unique Functionality in Electronics. ACS Appl. Electron. Mater. 2023, 5, 690–704. [CrossRef]

- Bakaul, S.R.; Serrao, C.R.; Lee, M.; Yeung, C.W.; Sarker, A.; Hsu, S.-L.; Yadav, A.K.; Dedon, L.; You, L.; Khan, A.I.; et al. Single Crystal Functional Oxides on Silicon. Nat. Commun. 2016, 7, 10547. [CrossRef]

- Bakaul, S.R.; Serrao, C.R.; Lee, O.; Lu, Z.; Yadav, A.; Carraro, C.; Maboudian, R.; Ramesh, R.; Salahuddin, S. High Speed Epitaxial Perovskite Memory on Flexible Substrates. Adv. Mater. 2017, 29, 1605699. [CrossRef]

- Lu, D.; Baek, D.J.; Hong, S.S.; Kourkoutis, L.F.; Hikita, Y.; Hwang, H.Y. Synthesis of Freestanding Single-Crystal Perovskite Films and Heterostructures by Etching of Sacrificial Water-Soluble Layers. Nat. Mater. 2016, 15, 1255–1260. [CrossRef]

- Yao, M.; Cheng, Y.; Zhou, Z.; Liu, M. Recent Progress on the Fabrication and Applications of Flexible Ferroelectric Devices. J. Mater. Chem. C 2020, 8, 14–27. [CrossRef]

- Jiang, J.; Bitla, Y.; Huang, C.-W.; Do, T.H.; Liu, H.-J.; Hsieh, Y.-H.; Ma, C.-H.; Jang, C.-Y.; Lai, Y.-H.; Chiu, P.-W.; et al. Flexible Ferroelectric Element Based on van Der Waals Heteroepitaxy. Sci. Adv. 2017, 3, e1700121. [CrossRef]

- Yang, Y.; Yuan, G.; Yan, Z.; Wang, Y.; Lu, X.; Liu, J. Flexible, Semitransparent, and Inorganic Resistive Memory Based on BaTi 0.95 Co 0.05 O 3 Film. Adv. Mater. 2017, 29, 1700425. [CrossRef]

- Zhang, Y.; Shen, L.; Liu, M.; Li, X.; Lu, X.; Lu, L.; Ma, C.; You, C.; Chen, A.; Huang, C.; et al. Flexible Quasi-Two-Dimensional CoFe 2 O 4 Epitaxial Thin Films for Continuous Strain Tuning of Magnetic Properties. ACS Nano 2017, 11, 8002–8009. [CrossRef]

- Peng, R.-C.; Cheng, X.; Peng, B.; Zhou, Z.; Chen, L.-Q.; Liu, M. Domain Patterns and Super-Elasticity of Freestanding BiFeO3 Membranes via Phase-Field Simulations. Acta Mater. 2021, 208, 116689. [CrossRef]

- Zhang, K.; Ren, Y.; Cao, Y. Mechanically Tunable Elastic Modulus of Freestanding Ba1− x Sr x TiO3 Membranes via Phase-Field Simulation. Appl. Phys. Lett. 2022, 121, 152902. [CrossRef]

- Dinu, L.A.; Romanitan, C.; Aldrigo, M.; Parvulescu, C.; Nastase, F.; Vulpe, S.; Gavrila, R.; Varasteanu, P.; Serban, A.B.; Noumi, R.; et al. Investigation of Wet Etching Technique for Selective Patterning of Ferroelectric Zirconium-Doped Hafnium Oxide Thin Films for High-Frequency Electronic Applications. Mater. Des. 2023, 233, 112194. [CrossRef]

- Su, Y.; Liu, Y.; Fei, Y.; Wang, L.; Cai, J.; Chen, S.; Wu, Z. A Two-Step Wet Etching Process of PZT Thin Film with Ultra-Low Undercut for MEMS Applications. Sens. Actuators Phys. 2023, 349, 114014. [CrossRef]

- Yang, C.; Han, Y.; Qian, J.; Cheng, Z. Flexible, Temperature-Stable, and Fatigue-Endurable PbZr 0.52 Ti 0.48 O 3 Ferroelectric Film for Nonvolatile Memory. Adv. Electron. Mater. 2019, 5, 1900443. [CrossRef]

- Jeong, C.K.; Kim, I.; Park, K.-I.; Oh, M.H.; Paik, H.; Hwang, G.-T.; No, K.; Nam, Y.S.; Lee, K.J. Virus-Directed Design of a Flexible BaTiO 3 Nanogenerator. ACS Nano 2013, 7, 11016–11025. [CrossRef]

- Denis-Rotella, L.M.; Esteves, G.; Walker, J.; Zhou, H.; Jones, J.L.; Trolier-McKinstry, S. Residual Stress and Ferroelastic Domain Reorientation in Declamped {001} Pb(Zr 0.3 Ti 0.7 )O 3 Films. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 68, 259–272. [CrossRef]

- Huff, M. Review Paper: Residual Stresses in Deposited Thin-Film Material Layers for Micro- and Nano-Systems Manufacturing. Micromachines 2022, 13, 2084. [CrossRef]

- Pesquera, D.; Fernández, A.; Khestanova, E.; Martin, L.W. Freestanding Complex-Oxide Membranes. J. Phys. Condens. Matter 2022, 34, 383001. [CrossRef]

- Park, D.-S.; Pryds, N. The Fabrication of Freestanding Complex Oxide Membranes: Can We Avoid Using Water? J. Mater. Res. 2024, 39, 2907–2917. [CrossRef]

- Liu, Y.-C.; Chen, B.-C.; Wei, C.-C.; Ho, S.-Z.; Liou, Y.-D.; Kaur, P.; Rahul; Chen, Y.-C.; Yang, J.-C. Thickness-Dependent Ferroelectricity in Freestanding Hf 0.5 Zr 0.5 O 2 Membranes. ACS Appl. Electron. Mater. 2024, acsaelm.3c01856. [CrossRef]

- Setter, N.; Damjanovic, D.; Eng, L.; Fox, G.; Gevorgian, S.; Hong, S.; Kingon, A.; Kohlstedt, H.; Park, N.Y.; Stephenson, G.B.; et al. Ferroelectric Thin Films: Review of Materials, Properties, and Applications. J. Appl. Phys. 2006, 100, 051606. [CrossRef]

- Martin, L.W.; Rappe, A.M. Thin-Film Ferroelectric Materials and Their Applications. Nat. Rev. Mater. 2016, 2, 16087. [CrossRef]

- Shao, M.-H.; Zhao, R.-T.; Liu, H.; Xu, W.-J.; Guo, Y.-D.; Huang, D.-P.; Yang, Y.-Z.; Li, X.-R.; Shao, W.; Shen, P.-H.; et al. Challenges and Recent Advances in HfO2-Based Ferroelectric Films for Non-Volatile Memory Applications. Chip 2024, 3, 100101. [CrossRef]

- Bai, Y.; Wang, Z.J.; He, B.; Cui, J.Z.; Zhang, Z.D. Enhancement of Polarization in Ferroelectric Films via the Incorporation of Gold Nanoparticles. ACS Omega 2017, 2, 9067–9073. [CrossRef]

- Guo, Y.; Peng, B.; Lu, G.; Dong, G.; Yang, G.; Chen, B.; Qiu, R.; Liu, H.; Zhang, B.; Yao, Y.; et al. Remarkable Flexibility in Freestanding Single-Crystalline Antiferroelectric PbZrO3 Membranes. Nat. Commun. 2024, 15, 4414. [CrossRef]

- Tian, Z.; Kim, J.; Fernandez, A.; Huang, X.; Martin, L.W. Effect of Substrate Clamping on Evolution of Properties in Homovalent and Heterovalent Relaxor Thin Films. Phys. Rev. B 2022, 105, 094107. [CrossRef]

- Xu, Q.; Jia, M.; Zhou, P.; Zhang, Y.; Guo, W.; Zhao, S.; Zeng, H.; Zhang, J.; Yan, M.; Jiang, S.; et al. High-Performance Ultrasensitive Flexible Piezoelectric Thin Film Sensors via a Cost-Effective Transfer Strategy. Adv. Funct. Mater. 2024, 2414211. [CrossRef]

- Park, K.-I.; Lee, S.Y.; Kim, S.; Chang, J.; Kang, S.-J.L.; Lee, K.J. Bendable and Transparent Barium Titanate Capacitors on Plastic Substrates for High Performance Flexible Ferroelectric Devices. Electrochem. Solid-State Lett. 2010, 13, G57. [CrossRef]

- Sahu, M.; Hajra, S.; Lee, K.; Deepti, P.; Mistewicz, K.; Kim, H.J. Piezoelectric Nanogenerator Based on Lead-Free Flexible PVDF-Barium Titanate Composite Films for Driving Low Power Electronics. Crystals 2021, 11, 85. [CrossRef]

- Dudem, B.; Kim, D.H.; Bharat, L.K.; Yu, J.S. Highly-Flexible Piezoelectric Nanogenerators with Silver Nanowires and Barium Titanate Embedded Composite Films for Mechanical Energy Harvesting. Appl. Energy 2018, 230, 865–874. [CrossRef]

- Ma, S.W.; Fan, Y.J.; Li, H.Y.; Su, L.; Wang, Z.L.; Zhu, G. Flexible Porous Polydimethylsiloxane/Lead Zirconate Titanate-Based Nanogenerator Enabled by the Dual Effect of Ferroelectricity and Piezoelectricity. ACS Appl. Mater. Interfaces 2018, 10, 33105–33111. [CrossRef]

- Liu, X.; Wei, C.; Zhang, F.; Peng, Y.; Sun, T.; Peng, Y.; Tang, H.; Yang, J.; Ding, M.; Jiang, C.; et al. A Flexible Hf 0.5 Zr 0.5 O 2 Nonvolatile Memory with High Polarization Based on Mica Substrate. ACS Appl. Electron. Mater. 2024, acsaelm.4c01108. [CrossRef]

- Chen, Y.; Yang, Y.; Yuan, P.; Jiang, P.; Xu, Y.; Lv, S.; Ding, Y.; Dang, Z.; Gong, T.; Wang, Y.; et al. Flexible Hf x Zr 1-x O 2 Thin Films on Polyimide for Energy Storage With High Flexibility. IEEE Electron Device Lett. 2022, 43, 930–933. [CrossRef]

- Pereira, N.; Gonçalves, S.; Barbosa, J.C.; Gonçalves, R.; Tubio, C.R.; Vilas-Vilela, J.L.; Costa, C.M.; Lanceros-Mendez, S. High Dielectric Constant Poly(Vinylidene Fluoride-Trifluoroethylene-Chlorofluoroethylene) for Capacitive Pressure and Bending Sensors. Polymer 2021, 214, 123349. [CrossRef]

- Shepelin, N.A.; Lussini, V.C.; Fox, P.J.; Dicinoski, G.W.; Glushenkov, A.M.; Shapter, J.G.; Ellis, A.V. 3D Printing of Poly(Vinylidene Fluoride-Trifluoroethylene): A Poling-Free Technique to Manufacture Flexible and Transparent Piezoelectric Generators. MRS Commun. 2019, 9, 159–164. [CrossRef]

- Stadlober, B.; Zirkl, M.; Irimia-Vladu, M. Route towards Sustainable Smart Sensors: Ferroelectric Polyvinylidene Fluoride-Based Materials and Their Integration in Flexible Electronics. Chem. Soc. Rev. 2019, 48, 1787–1825. [CrossRef]

- Shin, S.-H.; Park, D.H.; Jung, J.-Y.; Lee, M.H.; Nah, J. Ferroelectric Zinc Oxide Nanowire Embedded Flexible Sensor for Motion and Temperature Sensing. ACS Appl. Mater. Interfaces 2017, 9, 9233–9238. [CrossRef]

- Dutta, S.; Chakraborty, T.; Sharma, S.; Mondal, D.; Saha, A.; Pradhan, A.K.; Chakraborty, C.; Das, S.; Sutradhar, S. Fabrication of Rare Earth-Doped ZnO-PVDF Flexible Nanocomposite Films for Ferroelectric Response and Their Application in Piezo-Responsive Bending Sensors. Dalton Trans. 2024, 53, 14347–14363. [CrossRef]

- Chen, Y.; Wang, L.; Liu, L.; Tang, L.; Yuan, X.; Chen, H.; Zhou, K.; Zhang, D. Thickness-Dependent Ferroelectric Properties of HfO2/ZrO2 Nanolaminates Using Atomic Layer Deposition. J. Mater. Sci. 2021, 56, 6064–6072. [CrossRef]

- Sawabe, Y.; Saraya, T.; Hiramoto, T.; Su, C.-J.; Hu, V.P.-H.; Kobayashi, M. On the Thickness Dependence of the Polarization Switching Kinetics in HfO2-Based Ferroelectric. Appl. Phys. Lett. 2022, 121, 082903. [CrossRef]

- Hagiwara, K.; Byun, K.N.; Morita, S.; Yamamoto, E.; Kobayashi, M.; Liu, X.; Osada, M. Molecularly Thin BaTiO 3 Nanosheets with Stable Ferroelectric Response. Adv. Electron. Mater. 2023, 9, 2201239. [CrossRef]

- Han, M.-G.; Marshall, M.S.J.; Wu, L.; Schofield, M.A.; Aoki, T.; Twesten, R.; Hoffman, J.; Walker, F.J.; Ahn, C.H.; Zhu, Y. Interface-Induced Nonswitchable Domains in Ferroelectric Thin Films. Nat. Commun. 2014, 5, 4693. [CrossRef]

- Balakrishna, A.R.; Huber, J.E. Nanoscale Domain Patterns and a Concept for an Energy Harvester. Smart Mater. Struct. 2016, 25, 104001. [CrossRef]

- Lu, H.; Schönweger, G.; Petraru, A.; Kohlstedt, H.; Fichtner, S.; Gruverman, A. Domain Dynamics and Resistive Switching in Ferroelectric Al 1–x Sc x N Thin Film Capacitors. Adv. Funct. Mater. 2024, 34, 2315169. [CrossRef]

- Buragohain, P.; Erickson, A.; Mimura, T.; Shimizu, T.; Funakubo, H.; Gruverman, A. Effect of Film Microstructure on Domain Nucleation and Intrinsic Switching in Ferroelectric Y:HfO 2 Thin Film Capacitors. Adv. Funct. Mater. 2022, 32, 2108876. [CrossRef]

- Lv, H.-P.; Liao, W.-Q.; You, Y.-M.; Xiong, R.-G. Inch-Size Molecular Ferroelectric Crystal with a Large Electromechanical Coupling Factor on Par with Barium Titanate. J. Am. Chem. Soc. 2022, 144, 22325–22331. [CrossRef]

- Zhang, M.; Ma, R.; Zhou, J.; Zhang, Y.; Wang, J.; Weng, S. Unveiling Frequency-Dependent Electromechanical Dynamics in Ferroelectric BaTiO3 Nanofilm with a Core-Shell Structure. Coatings 2024, 14, 1437. [CrossRef]

- Yang, S.; Li, J.; Liu, Y.; Wang, M.; Qiao, L.; Gao, X.; Chang, Y.; Du, H.; Xu, Z.; Zhang, S.; et al. Textured Ferroelectric Ceramics with High Electromechanical Coupling Factors over a Broad Temperature Range. Nat. Commun. 2021, 12, 1414. [CrossRef]

- Dong, G.; Li, S.; Yao, M.; Zhou, Z.; Zhang, Y.-Q.; Han, X.; Luo, Z.; Yao, J.; Peng, B.; Hu, Z.; et al. Super-Elastic Ferroelectric Single-Crystal Membrane with Continuous Electric Dipole Rotation. Science 2019, 366, 475–479. [CrossRef]

- Ji, D.; Cai, S.; Paudel, T.R.; Sun, H.; Zhang, C.; Han, L.; Wei, Y.; Zang, Y.; Gu, M.; Zhang, Y.; et al. Freestanding Crystalline Oxide Perovskites down to the Monolayer Limit. Nature 2019, 570, 87–90. [CrossRef]

- Elangovan, H.; Barzilay, M.; Seremi, S.; Cohen, N.; Jiang, Y.; Martin, L.W.; Ivry, Y. Giant Superelastic Piezoelectricity in Flexible Ferroelectric BaTiO 3 Membranes. ACS Nano 2020, 14, 5053–5060. [CrossRef]

- Guo, C.; Yang, H.; Dong, S.; Tang, S.; Wang, J.; Wang, X.; Huang, H. Advancing Energy-Storage Performance in Freestanding Ferroelectric Thin Films: Insights from Phase-Field Simulations. Adv. Electron. Mater. 2024, 10, 2400001. [CrossRef]

- Meng, N.; Ren, X.; Wu, J.; Bilotti, E.; Reece, M.J.; Yan, H. Low-Cost Free-Standing Ferroelectric Polymer Films with High Polarization Produced via Pressing-and-Folding. J. Materiomics 2022, 8, 640–648. [CrossRef]

- Guido, R.; Lomenzo, P.D.; Islam, M.R.; Wolff, N.; Gremmel, M.; Schönweger, G.; Kohlstedt, H.; Kienle, L.; Mikolajick, T.; Fichtner, S.; et al. Thermal Stability of the Ferroelectric Properties in 100 Nm-Thick Al 0.72 Sc 0.28 N. ACS Appl. Mater. Interfaces 2023, 15, 7030–7043. [CrossRef]

- Islam, Md.R.; Wolff, N.; Yassine, M.; Schönweger, G.; Christian, B.; Kohlstedt, H.; Ambacher, O.; Lofink, F.; Kienle, L.; Fichtner, S. On the Exceptional Temperature Stability of Ferroelectric Al1-xScxN Thin Films. Appl. Phys. Lett. 2021, 118, 232905. [CrossRef]

- Kim, H.-B.; Jung, M.; Oh, Y.; Lee, S.W.; Suh, D.; Ahn, J.-H. Superior and Stable Ferroelectric Properties of Hafnium-Zirconium-Oxide Thin Films Deposited via Atomic Layer Deposition Using Cyclopentadienyl-Based Precursors without Annealing. Nanoscale 2021, 13, 8524–8530. [CrossRef]

- Zhu, B.; Kong, Z.; Cheng, H.; Han, K.; Chen, P.; Wang, K.; Zhang, H.; Wang, J.; Huang, Z.; Wu, W.; et al. Interfacial Strain-Insensitive Thermal and Electrical Stability of (K,Na)NbO 3 -Based Lead-Free Ferroelectric Films. J. Phys. Chem. C 2024, 128, 17886–17893. [CrossRef]

- Kang, S.; Jang, W.-S.; Morozovska, A.N.; Kwon, O.; Jin, Y.; Kim, Y.-H.; Bae, H.; Wang, C.; Yang, S.-H.; Belianinov, A.; et al. Highly Enhanced Ferroelectricity in HfO 2 -Based Ferroelectric Thin Film by Light Ion Bombardment. Science 2022, 376, 731–738. [CrossRef]

- Kale, S.; Petraru, A.; Kohlstedt, H.; Soni, R. Electrically Controlled Reversible Polarization Fatigue–Recovery in Ferroelectric Thin Film Capacitors. ACS Appl. Electron. Mater. 2022, 4, 1692–1702. [CrossRef]

- Chen, C.; Sharafi, A.; Sun, J.-Q. A High Density Piezoelectric Energy Harvesting Device from Highway Traffic – Design Analysis and Laboratory Validation. Appl. Energy 2020, 269, 115073. [CrossRef]

- Nechibvute, A.; Chawanda, A.; Luhanga, P. Piezoelectric Energy Harvesting Devices: An Alternative Energy Source for Wireless Sensors. Smart Mater. Res. 2012, 2012, 1–13. [CrossRef]

- Li, T.; Lee, P.S. Piezoelectric Energy Harvesting Technology: From Materials, Structures, to Applications. Small Struct. 2022, 3, 2100128. [CrossRef]

- Covaci, C.; Gontean, A. Piezoelectric Energy Harvesting Solutions: A Review. Sensors 2020, 20, 3512. [CrossRef]

- Gupta, R.; Sahoo, S.; Deswal, S.; Kothavade, P.; Dixit, P.; Zaręba, J.K.; Shanmuganathan, K.; Boomishankar, R. A Flexible Energy Harvester from an Organic Ferroelectric Ammonium Salt. Chem. – Asian J. 2021, 16, 4122–4129. [CrossRef]

- Jangra, M.; Thakur, A.; Dam, S.; Chatterjee, S.; Hussain, S. Enhanced Dielectric Properties of MoS2/ PVDF Free-Standing, Flexible Films for Energy Harvesting Applications. Mater. Today Commun. 2023, 34, 105109. [CrossRef]

- Veeralingam, S.; Badhulika, S. Lead-Free Transparent Flexible Piezoelectric Nanogenerator for Self-Powered Wearable Electronic Sensors and Energy Harvesting through Rainwater. ACS Appl. Energy Mater. 2022, 5, 12884–12896. [CrossRef]

- Panda, S.; Shin, H.; Hajra, S.; Oh, Y.; Oh, W.; Lee, J.; Rajaitha, P.M.; Panigrahi, B.K.; Shukla, J.; Sahu, A.K.; et al. Ferroelectric Composite-Based Piezoelectric Energy Harvester for Self-Powered Detection of Obstructive Sleep. J. Materiomics 2023, 9, 609–617. [CrossRef]

- Mahapatra, S.D.; Mohapatra, P.C.; Aria, A.I.; Christie, G.; Mishra, Y.K.; Hofmann, S.; Thakur, V.K. Piezoelectric Materials for Energy Harvesting and Sensing Applications: Roadmap for Future Smart Materials. Adv. Sci. 2021, 8, 2100864. [CrossRef]

- Aabid, A.; Raheman, M.A.; Ibrahim, Y.E.; Anjum, A.; Hrairi, M.; Parveez, B.; Parveen, N.; Mohammed Zayan, J. A Systematic Review of Piezoelectric Materials and Energy Harvesters for Industrial Applications. Sensors 2021, 21, 4145. [CrossRef]

- Zhao, X.; Song, K.; Huang, H.; Han, W.; Yang, Y. Ferroelectric Materials for Solar Energy Scavenging and Photodetectors. Adv. Opt. Mater. 2022, 10, 2101741. [CrossRef]

- Yan, M.; Xiao, Z.; Ye, J.; Yuan, X.; Li, Z.; Bowen, C.; Zhang, Y.; Zhang, D. Porous Ferroelectric Materials for Energy Technologies: Current Status and Future Perspectives. Energy Environ. Sci. 2021, 14, 6158–6190. [CrossRef]

- Li, H.; Bowen, C.R.; Yang, Y. Scavenging Energy Sources Using Ferroelectric Materials. Adv. Funct. Mater. 2021, 31, 2100905. [CrossRef]

- Wei, X.; Domingo, N.; Sun, Y.; Balke, N.; Dunin-Borkowski, R.E.; Mayer, J. Progress on Emerging Ferroelectric Materials for Energy Harvesting, Storage and Conversion (Adv. Energy Mater. 24/2022). Adv. Energy Mater. 2022, 12, 2270102. [CrossRef]

- Jia, X.; Guo, R.; Chen, J.; Yan, X. Flexoelectric Effect in Thin Films: Theory and Applications. Adv. Funct. Mater. 2024, 2412887. [CrossRef]

- Deng, C.; Zhang, Y.; Yang, D.; Zhang, H.; Zhu, M. Recent Progress on Barium Titanate-Based Ferroelectrics for Sensor Applications. Adv. Sens. Res. 2024, 3, 2300168. [CrossRef]

- Li, W.; Li, C.; Zhang, G.; Li, L.; Huang, K.; Gong, X.; Zhang, C.; Zheng, A.; Tang, Y.; Wang, Z.; et al. Molecular Ferroelectric-Based Flexible Sensors Exhibiting Supersensitivity and Multimodal Capability for Detection. Adv. Mater. 2021, 33, 2104107. [CrossRef]

- Ji, Y.; Yin, S.; Liu, Y.; Bowen, C.R.; Yang, Y. Dual-Mode Temperature Sensor Based on Ferroelectric Bi0.5Na0.5TiO3 Materials for Robotic Tactile Perception. Nano Energy 2024, 128, 109982. [CrossRef]

- Liu, W.; Lin, D.; Zeng, W.; Wang, Q.; Yang, J.; Peng, Z.; Zhang, Q.; Zhu, G. A Multifunctional Flexible Ferroelectric Transistor Sensor for Electronic Skin. Adv. Mater. Interfaces 2021, 8, 2101166. [CrossRef]