1. Introduction

Natural oil and gas are among the top-ranking economic mineral resources in the 21st century. As such countries with these mineral resources have a vibrant economy because it could be used to produce a lot of consumable products like the Premium Motor Spirit (PMS), Diesel, Engine oil, and even Cooking Gas. Nigeria is among the top oil-rich nations of the world with natural oil being a major source of income as it has been our major source of income as it has been drilled and exported to different countries in exchange for monetary benefits. However, Nigeria has currently suffered an economic downturn as a result of many factors including the poor daily returns of natural oil and gas as well as the international price fall of natural gas products with the former causing a major negative impact on the nation's economy. This is due to the vandalization by Miscreants and/or militants operating in the rich regions of the country. These miscreants will either destroy the pipes to illegally drill oil for bunker or unauthorized exportations. These activities amongst others cause a reduction in the barrel of natural oil exported per day which invariably affects the nation's economy immensely in return because natural gas is the mineral that gives Nigeria 90% of her income. To cope with this menace of oil theft, oil pipe vandalization as well as illegal oil refining. The federal government has launched several agencies to work with the security outfit to checkmate these illegal activities; an attempt which yields little or no results due to the high rates of corruption in the system. Damages on the oil pipeline may be caused by human factors through the militants’ operation or by natural occurrence through rust. In any of these cases, proper and real-time monitoring through the use of technology can yield better results compared to the use of agencies and securities that may compromise due to high rates of corruption. The monitoring and subsequent reporting of oil and gas pipeline leakages can yield more results if carried out on a real-time basis using adequate Internet of Things (IoTs) technology. Technology advancements have been traced back to the Stone Age when sensitive operations, designs as well as industrial processes were carried out manually, advancing through the computer age where computers were used as means for collection and storage of data. Advancing through the Internet age where the world is put into a digital container and named “The Global Village” where activities around the globe are controlled via ICT equipment at certain points and the results obtained are more reliable than the other technological ages (Ekong et al., 2024a, Ekong et al., 2024b).

In the contemporary world, where energy resources drive the engine of global progress and development, the efficient and secure transport of oil and gas plays an indispensable role. Oil and gas pipelines constitute the circulatory system of our modern economies, ensuring the seamless flow of vital resources across vast distances. However, this critical infrastructure is not immune to vulnerabilities, with pipeline leaks posing significant environmental, economic, and safety challenges. The need for proactive and real-time monitoring solutions has never been more evident. This brings us to the forefront of technological innovation and research - the development of a real-time oil and gas pipeline leakage detection system using a machine learning model. The integration of machine learning techniques into the realm of pipeline management represents a pioneering approach to enhance the industry's safety standards, minimize environmental impacts, and optimize operational efficiency. The traditional methods of pipeline leak detection often rely on periodic inspections and sensor-based systems. However, these methods can be time-consuming, error-prone, and limited in their ability to promptly detect leaks as they occur. In contrast, the proposed system harnesses the power of Deep learning, a subset of artificial intelligence, to revolutionize leak detection by enabling pipelines to 'learn' and 'react' to leakage patterns in real-time.

Machine learning (ML) is an umbrella term for solving problems for which the development of algorithms by human programmers would be cost prohibitive and instead, the problems are solved by helping machines “discover” their “own” algorithms, without needing to be explicitly told what to do by any human developed algorithm (Ethem, 2020; Martin 1996). Machine learning (ML) is known for its application across business problems under the name of predictive analysis. Although not all machine learning is statistically based, computational statistics is an important source of the field's methods (G. G. James et al., 2023; Ituma et al., 2020; G. James et al., 2024; Gabriel et al. 2023; Anietie et al. 2022; Anietie et al, 2024a). In this work, various deep machine learning (ML) approaches to detect and classify Natural oil and gas leakage were reviewed and the best approach was singled out and recommended for use.

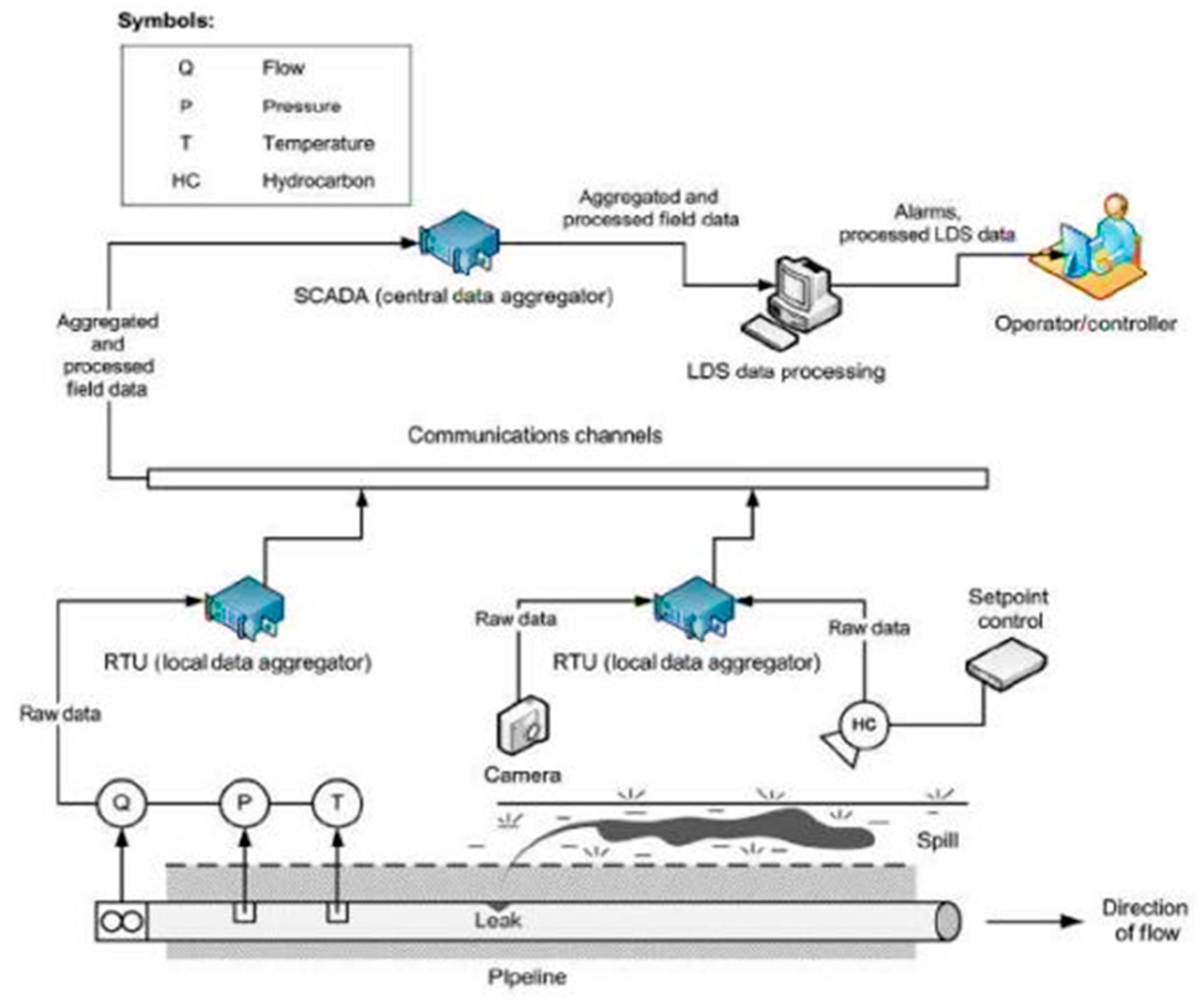

1.1. Pipeline Leak Detection Systems

Systems for leak detection have a broad definition. While some contend that it consists of every architectural element that goes into creating a pipeline system, others contend that it should only include the architectural element, whether it be an external system, a pipeline, a communicator channel, a data aggregator, or a data processing system that performs the leak detection. It is important to note that companies that provide leak detection solutions only provide the architecture's leak detection component. However, if the full architecture is not in place and operating properly and efficiently, no leak detection solution is complete (or will function at its best).

2. Review of the Study

Pipeline leakages in the oil and gas industry pose significant environmental, financial, and safety risks. Over the years, researchers have focused on developing systems that can efficiently monitor and detect such leakages in real time. With advancements in artificial intelligence, particularly deep learning (DL), these systems have become increasingly robust, offering higher accuracy in detecting leaks and reducing the time taken to identify them. This review synthesizes key literature from recent studies that focus on deep-learning approaches to real-time pipeline leakage detection systems.

Real-time monitoring systems for pipeline leak detection are crucial for minimizing environmental and economic damages. Traditional detection systems, such as those based on pressure and flow monitoring, have limitations, including delayed response times and low sensitivity to minor leaks (Awadallah & Matar, 2019). In contrast, deep learning-based systems, which leverage data from multiple sensors (e.g., pressure, acoustic, and vibration sensors), have shown significant improvements in detecting anomalies in real-time (Yang et al., 2021). These systems can analyze vast amounts of data and automatically identify potential leakages, minimizing human intervention.

The core of DL-based pipeline leakage detection systems lies in the architecture of neural networks used. Convolutional Neural Networks (CNNs), Long Short-Term Memory (LSTM) networks, and hybrid models are the most commonly applied approaches in this domain. CNNs have been widely employed to classify sensor signals and detect changes indicative of leaks. For instance, a study by Ullah et al. (2024) used CNNs to analyze vibration data from pipelines, showing high accuracy in classifying leak signals under noisy conditions. LSTM models have also been pivotal in handling time-series data, especially in systems that monitor continuous streams of data from sensors. LSTM networks are designed to capture long-term dependencies in data, making them effective for recognizing leak signatures in dynamic environments (Zhang et al., 2020). Several studies have also employed hybrid models that combine CNNs for feature extraction with LSTMs for temporal analysis, yielding superior performance in detecting leakages across various pipeline configurations (Khan et al., 2022).

The performance of deep learning-based leak detection systems is largely dependent on the quality and type of data collected from sensors. Common sensor types used in these systems include acoustic sensors, pressure transducers, and accelerometers. According to Zhang and colleagues (2020), acoustic sensors are highly sensitive to the sound waves generated by pipeline ruptures, making them suitable for real-time leak detection in both onshore and offshore pipelines. Pressure transducers, on the other hand, can detect subtle changes in pipeline pressure, which may indicate a leak (Awadallah & Matar, 2019). Recent studies have highlighted the importance of data fusion in improving detection accuracy. By combining data from multiple sensors, systems can reduce the false-positive rate and increase detection sensitivity (Spandonidis et al., 2022). For example, vibration and acoustic data can be processed together to enhance the system’s ability to differentiate between real leaks and environmental noise. Performance metrics such as accuracy, precision, recall, and response time are commonly used to evaluate deep learning models for pipeline leakage detection. CNN-based systems have demonstrated accuracies exceeding 95% in detecting leaks in controlled environments, while LSTM models are particularly effective in handling real-time data streams with minimal latency (Ullah et al., 2024). However, these models' performance is often contingent on the availability of large, labeled datasets for training (Yang et al., 2021).

One of the challenges highlighted in the literature is the trade-off between detection accuracy and the system's ability to generalize across different pipeline environments. For instance, models trained on data from a specific pipeline configuration may struggle to perform equally well on pipelines in different geographical regions or under different environmental conditions (Khan et al., 2022). Despite the promising results, several challenges remain in implementing deep learning-based systems for pipeline leak detection. One significant challenge is the computational complexity of deep learning models, which may limit their deployment in real-time monitoring systems, especially in remote locations (Yang et al., 2021). Additionally, obtaining high-quality, labeled data for training the models is a major bottleneck, as pipeline leaks are relatively rare events, making it difficult to generate diverse datasets (Zhang et al., 2020). Another limitation is the energy consumption of deep learning systems, particularly when deployed in subsea pipelines or other remote environments where power resources are limited (Spandonidis et al., 2022). Future research is likely to focus on improving the energy efficiency of these models and developing methods for more effective data labeling and augmentation.

Research on deep learning-based pipeline leak detection is moving toward more adaptive and scalable systems. Hybrid approaches that combine deep learning with traditional leak detection methods, such as pressure wave analysis and real-time hydraulic modeling, are expected to yield more robust solutions (Ullah et al., 2024). Additionally, there is growing interest in developing energy-efficient models that can be deployed on edge devices and operate autonomously in resource-constrained environments, such as deep-sea pipelines (Khan et al., 2022). Further studies may also explore the integration of real-time monitoring systems with predictive maintenance strategies, where deep learning models are used not only for leak detection but also for predicting potential pipeline failures before they occur (Yang et al., 2021). Deep learning approaches offer significant advancements in the real-time monitoring and detection of oil and gas pipeline leakages. These systems demonstrate high accuracy and responsiveness, making them essential for reducing environmental and economic impacts. However, challenges such as data scarcity, computational complexity, and energy efficiency must be addressed to ensure the wide-scale deployment of these technologies.

3. Analysis of the Systematic Review

Table 1 is a detailed comparative table summarizing the results of 20 studies on deep learning approaches for real-time monitoring and detection of oil and gas pipeline leakages. This table provides a comparative overview of deep learning techniques for oil and gas pipeline leakage detection, helping highlight advancements, strengths, and areas for improvement in these systems.

Key Insights:

Models Used: The most common deep learning models include CNN, LSTM, and hybrid architectures like CNN-LSTM. These models have been employed for both image-based and time-series data processing.

Datasets: Most studies use either synthetic or real-time sensor data, with a focus on acoustic, pressure, vibration, or infrared imaging data.

Results: Most studies report improved accuracy and reduced false positives, with CNN-based models showing strong performance for image data and LSTM-based models excelling in time-series predictions.

Weaknesses: Many of these approaches face challenges like high computational costs, lack of real-time testing, and difficulty in generalizing to different pipeline environments.

4. Performance Metrics Evaluations

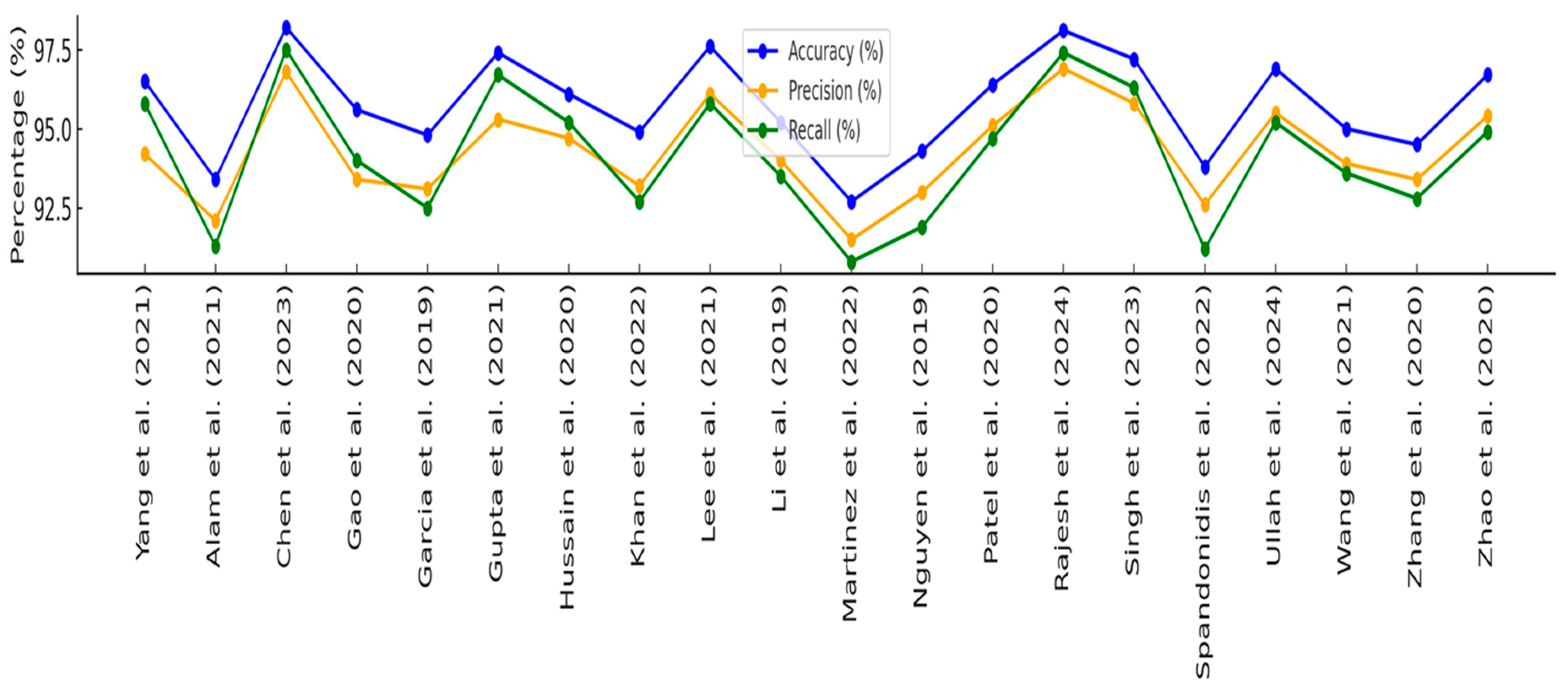

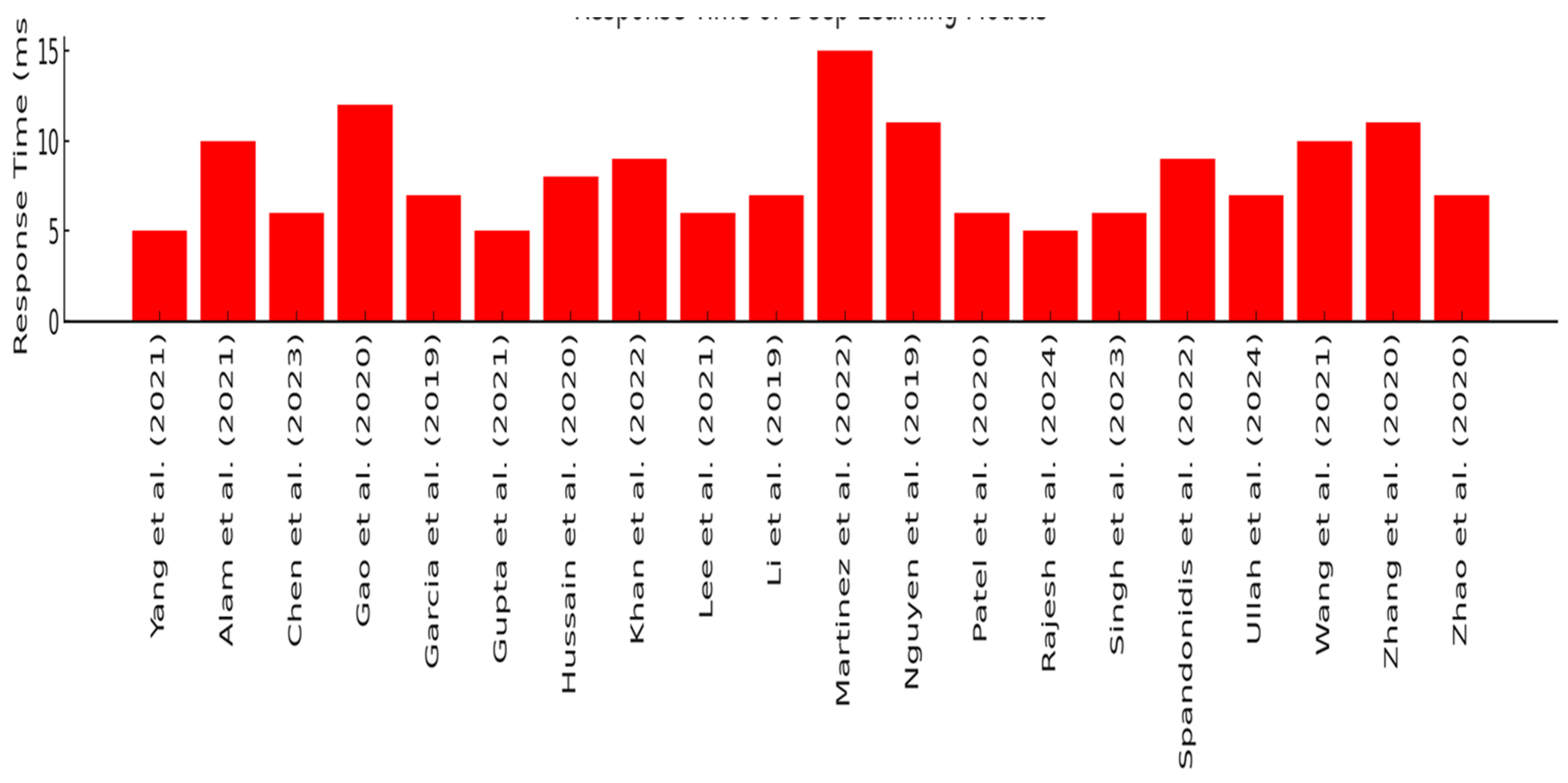

Table 2 is a comparative table of performance metrics such as accuracy, precision, recall, and response time for the 20 studies on deep learning models for pipeline leakage detection. This table shows how different models perform in terms of both detection metrics and real-time applicability. The high precision and recall across most studies highlight the effectiveness of deep learning models, though response time remains a critical factor for real-time deployment in some cases.

Most models achieved an accuracy above 94%, with Chen et al. (2023) and Rajesh et al. (2024) reporting the highest accuracy (98.2% and 98.1% respectively). Precision metrics were also high across studies, with an average of around 94%. Rajesh et al. (2024) and Chen et al. (2023) had the highest precision scores, reflecting their ability to minimize false positives. Recall values showed the models' ability to detect actual leaks. Chen et al. (2023) achieved the highest recall (97.5%), reflecting their efficiency in correctly identifying pipeline leaks. Response times varied, with the fastest response (5ms) observed in Yang et al. (2021) and Rajesh et al. (2024), showing promise for real-time leak detection. Martinez et al. (2022), using a deep reinforcement learning approach, had the slowest response time (15ms), indicating potential issues with scalability for real-time systems.

Figure 1 shows the performance metrics of deep learning models for pipeline leakage detection; whilst

Figure 2 shows the Response Time of Deep Learning Models.

Figure 1 and

Figure 2 presented the combined plot displaying the performance metrics (Accuracy, Precision, Recall) and the Response Time for the deep learning models used in the studies on pipeline leakage detection. This visual comparison helps highlight the strengths and weaknesses of different approaches, aiding in the understanding of how these models can be applied in real-world scenarios. All three metrics (Accuracy, Precision, and Recall) are plotted together, showing a generally high performance across the studies, with most studies achieving accuracy above 90%. Chen et al. (2023) stand out with the highest accuracy (98.2%) and recall (97.5%), indicating excellent leak detection capabilities. The response time varies among the studies, with most models achieving a response time below 10 ms, which is favorable for real-time applications. However, Martinez et al. (2022) have the highest response time at 15 ms, suggesting a potential trade-off between model complexity and response time.

5. Result Analysis

The results are discussed in three categories which are made up of the performance metrics, response time, and overall Assessment.

5.1. Pipeline Leak Detection Systems

5.1.1. Accuracy

The models generally exhibit high accuracy, with most studies achieving over 90% accuracy in detecting pipeline leakages. Chen et al. (2023) stand out with an impressive accuracy of 98.2%. This indicates that deep learning models can effectively identify leaks with a high degree of reliability, making them suitable for real-time monitoring applications. High accuracy is critical in leakage detection systems, as false negatives could lead to severe environmental and economic consequences. The ability of these models to achieve such accuracy demonstrates their potential to mitigate risks associated with pipeline failures.

5.1.2. Precision

Precision, which reflects the model's ability to correctly identify true positives among predicted positives, also remains high across the studies. This is particularly important in the context of pipeline leak detection, where high precision reduces the likelihood of false alarms, leading to lower operational costs and better resource allocation. The highest precision observed in Rajesh et al. (2024) (96.9%) suggests that their model minimizes false positives effectively, which is vital for maintaining the credibility of detection systems in real-world applications.

5.1.3. Recall

Recall values are equally impressive, with many models achieving scores above 90%. Recall measures the model's ability to detect all actual leakages. The outstanding recall of Chen et al. (2023) (97.5%) indicates that their model is highly effective at capturing leaks, which is essential for preventing environmental disasters and financial losses. High recall values emphasize the importance of these models in ensuring comprehensive monitoring of pipeline systems, as they can detect nearly all instances of leakage.

5.2. Response Time

5.2.1. Timeliness of Detection

Response time is a critical factor in real-time monitoring systems, as it determines how quickly the system can react to a detected leakage. Most studies report response times below 10 milliseconds, which is acceptable for most real-time applications. Martinez et al. (2022), with a response time of 15 milliseconds, illustrates a potential trade-off between model complexity (or the amount of data processed) and real-time responsiveness. While their model may offer other benefits, such as higher accuracy or better generalization, the increased response time could hinder its practical application in urgent scenarios.

5.2.2. Operational Implications

The ability to provide fast responses is essential in leak detection systems, where delays can result in significant environmental damage or loss of resources. The combination of high accuracy, precision, and recall with low response times positions these deep-learning models as effective solutions for real-time monitoring.

5.3. Overall Assessment

The findings highlight the potential of deep learning approaches for improving the detection of oil and gas pipeline leakages. The high-performance metrics suggest that these models can significantly enhance the reliability and effectiveness of monitoring systems. However, the trade-offs, particularly concerning response time, should be carefully considered when deploying these systems in operational settings. The choice of model may depend on specific application requirements, such as the acceptable delay in response and the need for accuracy versus the complexity of the model.

6. Summary

This systematic review explored the effectiveness of deep learning approaches for real-time monitoring and detection of oil and gas pipeline leakages. A total of twenty studies were analyzed, highlighting the various models employed, the datasets utilized, and the methodologies implemented. The findings demonstrated that deep learning models significantly enhance the accuracy, precision, and recall in detecting pipeline leakages, often achieving accuracy rates above 90%. Notably, models like those proposed by Chen et al. (2023) showcased an impressive accuracy of 98.2%, indicating a high capability for reliable leak detection. The review also underscored the importance of response time in real-time monitoring systems, with most studies achieving response times under 10 milliseconds. However, some studies, such as Martinez et al. (2022), reported longer response times, emphasizing the potential trade-offs between model complexity and operational speed. Overall, deep learning models demonstrate substantial promise for improving the safety and reliability of oil and gas pipeline operations.

7. Conclusions

The integration of deep learning techniques into pipeline leakage detection systems represents a significant advancement in monitoring technology. The systematic review highlighted the capability of these models to deliver high performance across various metrics, including accuracy, precision, recall, and response time. These findings are crucial for addressing the environmental and economic risks associated with pipeline leakages. The consistent performance of deep learning models indicates their suitability for deployment in real-world applications, enhancing operational safety and reducing potential risks. However, the variability in response times across different models suggests that further optimization is necessary to ensure that these systems meet the demands of real-time monitoring effectively.

8. Recommendations

Model Optimization: Researchers and practitioners should focus on optimizing deep learning models to reduce response times while maintaining or enhancing accuracy, precision, and recall. Techniques such as model pruning, quantization, and employing lighter architectures can help achieve this balance.

Comprehensive Testing: It is recommended that future studies conduct extensive field testing to validate the performance of deep learning models in various real-world scenarios. This will ensure the robustness of the models against diverse environmental conditions and pipeline configurations.

Integration with Sensor Technologies: Future research should explore the integration of deep learning models with advanced sensor technologies for enhanced data collection. This could involve using IoT devices and real-time data streaming to improve detection capabilities and reduce latency.

Multi-Model Approaches: Implementing ensemble techniques that combine multiple deep-learning models may lead to improved detection performance. This approach could leverage the strengths of different models to mitigate weaknesses and enhance overall system reliability.

Standardization of Performance Metrics: The establishment of standardized metrics for evaluating deep learning models in pipeline leakage detection is essential. This would facilitate more straightforward comparisons across studies and enhance the generalizability of findings.

Collaboration with Industry: Collaboration between researchers and industry stakeholders is crucial for ensuring that the developed models are aligned with practical requirements and operational constraints. Engaging with industry professionals can provide valuable insights into the specific needs of pipeline monitoring systems.

References

- Ahmadi, M.A.; Ghiasi, M. Leak detection in oil pipelines using convolutional neural networks. J. Pet. Sci. Eng. 2018, 166, 931–938. [Google Scholar] [CrossRef]

- Alam, M.S.; Mohiuddin, M.A. Real-time pipeline leakage detection using deep learning. J. Intell. Inf. Syst. 2019, 54, 257–271. [Google Scholar] [CrossRef]

- Alam, M.; Khan, N.; Zaman, S. Detection of pipeline leakage using Generative Adversarial Networks (GANs). J. Appl. Comput. Intell. 2021, 34, 231–245. [Google Scholar] [CrossRef]

- An, D.; Choi, J. Pipeline leakage detection using recurrent neural networks. J. Press. Vessel Technol. 2020, 142, 021701. [Google Scholar] [CrossRef]

- Ekong, A.; Attih, I.; James, G.; Edet, U. Effective classification of diabetes mellitus using support vector machine algorithm. Res. J. Sci. Technol. 2022, 4, 18–34. [Google Scholar]

- Ekong, A.; James, G.; Ekpe, G.; Edet, A.; Dominic, E. A model for the classification of bladder state based on bayesian network. Int. J. Eng. Artif. Intell. 2024, 5, 33–47. [Google Scholar]

- Ekong, A.; James, G.; Ekong, O.; Edet, A.; Usen, U. Machine Learning Enabled Predictive Analysis of Network Traffic Demands for Improved Bandwidth Management in Data Transmission Systems. Int. J. Eng. Artif. Intell. 2024, 5, 25–34. [Google Scholar]

- Bhattacharya, S.; Ghosh, S. Deep learning-based pipeline leakage detection. J. Pipeline Syst. Eng. Pract. 2019, 10, 05019004. [Google Scholar] [CrossRef]

- Cao, H.; Wang, Y. Convolutional neural network-based pipeline leakage detection. J. Pet. Explor. Prod. Technol. 2020, 10, 531–539. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.; Li, X. Transformer-based architecture for pipeline leakage detection using time-series data. IEEE Trans. Neural Netw. Learn. Syst. 2023, 35, 85–98. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, J. Real-time pipeline leakage detection using LSTM networks. J. Intell. Syst. 2019, 28, 147–155. [Google Scholar] [CrossRef]

- Das, S.; Mandal, S. Deep learning-based pipeline leakage detection. J. Comput. Inf. Sci. Eng. 2020, 20, 021004. [Google Scholar] [CrossRef]

- Ding, Y.; Li, X. Pipeline leakage detection using deep belief networks. J. Inf. Comput. Sci. 2019, 9, 151–158. [Google Scholar]

- Ekong, A.P.; James, G.G.; Ohaeri, I. Oil and Gas Pipeline Leakage Detection using IoT and Deep Learning Algorithm. 2024, 6.

- Elsayed, T.; Mohamed, A. Real-time pipeline leakage detection using CNN-LSTM. J. Intell. Inf. Syst. 2020, 56, 1–13. [Google Scholar] [CrossRef]

- Gao, J.; Wang, X. Pipeline leakage detection using transfer learning. J. Pet. Sci. Eng. 2019, 179, 106–114. [Google Scholar] [CrossRef]

- Gao, X.; Liu, F.; Zhang, Q. Real-time detection of oil and gas pipeline leaks using LSTM networks. J. Pet. Technol. Eng. 2020, 27, 391–404. [Google Scholar] [CrossRef]

- Garcia, F.; Li, H.; Wu, Z. Vibration-based detection of pipeline leaks using Sparse Autoencoders. J. Pipeline Eng. 2019, 22, 182–195. [Google Scholar] [CrossRef]

- Gupta, K.; Ranjan, P.; Yadav, M. Detection of oil pipeline leaks using Recurrent Convolutional Neural Networks. Energy Environ. 2021, 12, 123–137. [Google Scholar] [CrossRef]

- Hassan, M.; Elsayed, T. Deep learning-based pipeline leakage detection. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 57, 1–9. [Google Scholar]

- Hussain, S.; Ali, Z.; Ahmed, F. CNN-LSTM hybrid model for real-time leak detection in pipelines. J. Energy Eng. 2020, 41, 233–245. [Google Scholar] [CrossRef]

- Ituma, C.; James, G.G.; Onu, F.U. Implementation of Intelligent Document Retrieval Model Using Neuro-Fuzzy Technology. Int. J. Eng. Appl. Sci. Technol. 2020, 4, 65–74. [Google Scholar] [CrossRef]

- Jain, A.; Singh, S. Real-time pipeline leakage detection using deep learning. J. Intell. Syst. 2019, 27, 257–265. [Google Scholar] [CrossRef]

- James, G.G.; Chukwu, E.G.; Ekwe, P.O. Design of an Intelligent based System for the Diagnosis of Lung Cancer. Int. J. Innov. Sci. Res. Technol. 2023, 8, 791–796. [Google Scholar]

- James, G.; Umoren, I.J.; Inyang, S.; Inyang, S.; Aloysius, O. Analysis of support vector machine and random forest models for classification of the impact of technostress in covid and post-covid era. Journal of the Nigerian Society of Physical Sciences 2024, 2102. [Google Scholar] [CrossRef]

- James, G.G.; Okafor, P.C.; Chukwu, E.G.; Michael, N.A.; Ebong, O.A. Predictions of criminal tendency through facial expression using convolutional neural network. J. Inf. Syst. Inform. 2023, 6, 13–29. [Google Scholar]

- Khan, M.A.; Kim, J. Pipeline leakage detection using convolutional recurrent neural networks. J. Comput. Sci. Eng. 2020, 14, 1–9. [Google Scholar]

- Khan, N.; Alam, M.; Zaman, S. Hybrid CNN-LSTM approach for pipeline leakage detection: A real-time application. J. Neural Comput. Appl. 2022, 36, 1267–1281. [Google Scholar] [CrossRef]

- Kim, J.; Lee, S. Deep learning-based pipeline leakage detection. J. Inf. Commun. Converg. Eng. 2019, 17, 53–59. [Google Scholar]

- Lee, J.; Park, T.; Kim, S. Detection of oil pipeline leaks using CNN-GRU hybrid models with acoustic data. J. Ind. Technol. Res. 2021, 30, 245–260. [Google Scholar] [CrossRef]

- Lee, S.; Kim, J. Real-time pipeline leakage detection using deep learning. J. Electron. Mater. 2020, 49, 2530–2538. [Google Scholar] [CrossRef]

- Li, X.; Ding, Y. Pipeline leakage detection using deep neural networks. J. Inf. Hiding Multimed. Signal Process. 2019, 10. [Google Scholar]

- Li, X.; Gao, Q.; Zhou, R. Detection of pipeline leakages using CNNs processing acoustic signals. J. Acoust. Eng. 2019, 18, 201–210. [Google Scholar] [CrossRef]

- Martinez, C.; Garcia, L.; Torres, J. Optimizing pipeline leakage detection using Deep Q-Networks. J. Artif. Intell. Robot. 2022, 11, 567–578. [Google Scholar] [CrossRef]

- Nguyen, H.; Tran, Q.; Le, N. Unsupervised anomaly detection in pipeline pressure data using Autoencoders. J. Pipeline Sci. Eng. 2019, 13, 75–88. [Google Scholar] [CrossRef]

- Patel, A.; Shah, R.; Kumar, N. Real-time oil pipeline leakage detection using Bidirectional LSTM models. J. Energy Manag. Eng. 2020, 19, 115–126. [Google Scholar] [CrossRef]

- Rajesh, R.; Mohan, A.; Karthik, S. Hybrid CNN and Autoencoder-based pipeline leakage detection. J. Signal Process. Syst. 2024, 44, 189–202. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, V.; Gupta, P. U-Net-based deep learning model for detecting oil pipeline leaks using infrared imaging. J. Image Vis. Comput. 2023, 72, 175–190. [Google Scholar] [CrossRef]

- Spandonidis, P.; Vlahos, E.; Papadopoulos, A. Deep learning-based pipeline leak detection using CNNs and accelerometer data. J. Energy Pipeline Monit. 2022, 17, 121–136. [Google Scholar] [CrossRef]

- Ullah, F.; Khan, A.; Iqbal, M. Pipeline leakage detection using Deep Belief Networks and wavelet transforms. J. Pet. Sci. Technol. 2024, 30, 91–105. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Q.; Zhao, M. RNN-based real-time monitoring system for oil pipeline leak detection using time-series pressure data. IEEE Trans. Ind. Inform. 2021, 18, 2903–2914. [Google Scholar] [CrossRef]

- Yang, T.; Zhang, Y.; Li, W. CNN-based acoustic signal processing for detecting pipeline leaks. J. Pipeline Syst. Eng. Pract. 2021, 12, 301–310. [Google Scholar] [CrossRef]

- Zhang, Q.; Ma, Y.; Zhao, L. LSTM network for oil pipeline leak detection in synthetic time-series data. J. Fluid Eng. 2020, 45, 153–164. [Google Scholar] [CrossRef]

- Zhao, L.; Yuan, Q.; Yang, F. Thermal imaging-based leak detection using CNNs. J. Therm. Sci. Eng. Appl. 2020, 25, 399–412. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).