Submitted:

24 March 2025

Posted:

25 March 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

- − the organoleptic method, used in industrial practice and trade, as an auxiliary instrument for assessing straw and flax fibre. This method can use standards that are used as a visual aid during the assessment,

- − the instrumental-laboratory method, which is an element of control and assessment in relation to certain features of straw and fibre, for determining fibre content, strength, divisibility or level of impurities,

- − the organo-technical method, which consists in trial combing of the scutched fibre and determining the average number (average grade of scutched and combed fibre), the efficiency of the combed fibre and the total combing losses,

- − the technological method, which consists in trial spinning of long combed and short flax fibre [28].

2. Materials and Methods

2.1. Characteristics of Varieties

2.2. Research Conditions

2.2.1. Geographical Location

2.2.2. Agrotechnics Conditions

- − Avoiding growing flax in succession (due to diseases and soil depletion).

- − Succession of plants with different nutritional requirements and impact on soil structure.

- − Maintaining an appropriate balance of nutrients in the soil.

2.2.3. Natural Conditions

2.2.4. Soil Conditions

2.2.5. Meteorological Conditions

2.3. Straw Harvest

2.4. Retting of Flax Straw

2.5. Flax Fibre Production

2.5.1. Dew Retting of Flax Straw

2.5.2. Assessment of Retting Degree

2.5.3. Flax Fibre Yield

2.6. Laboratory Evaluation of Fiber

2.7. Statistical Calculations

3. Results

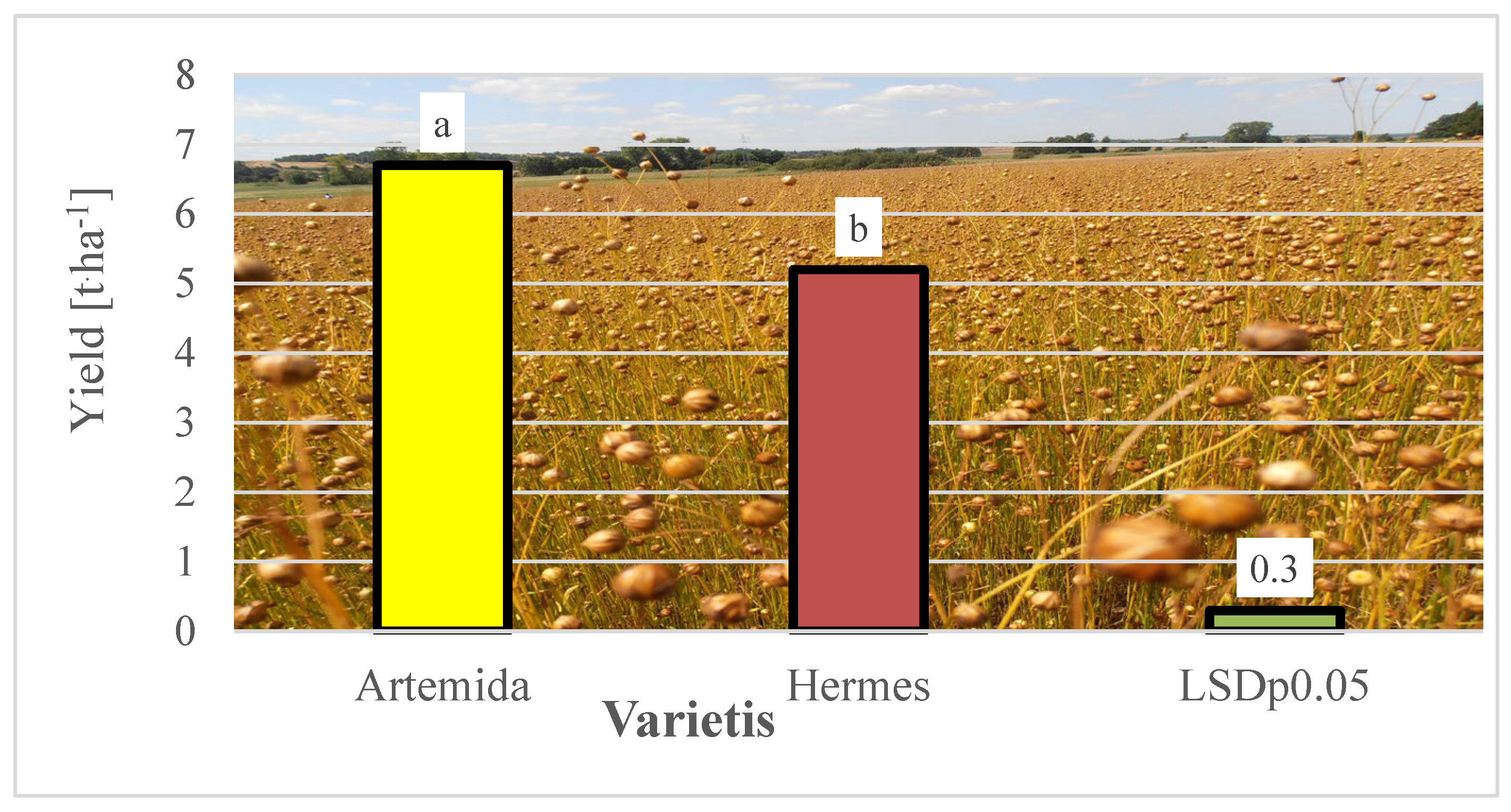

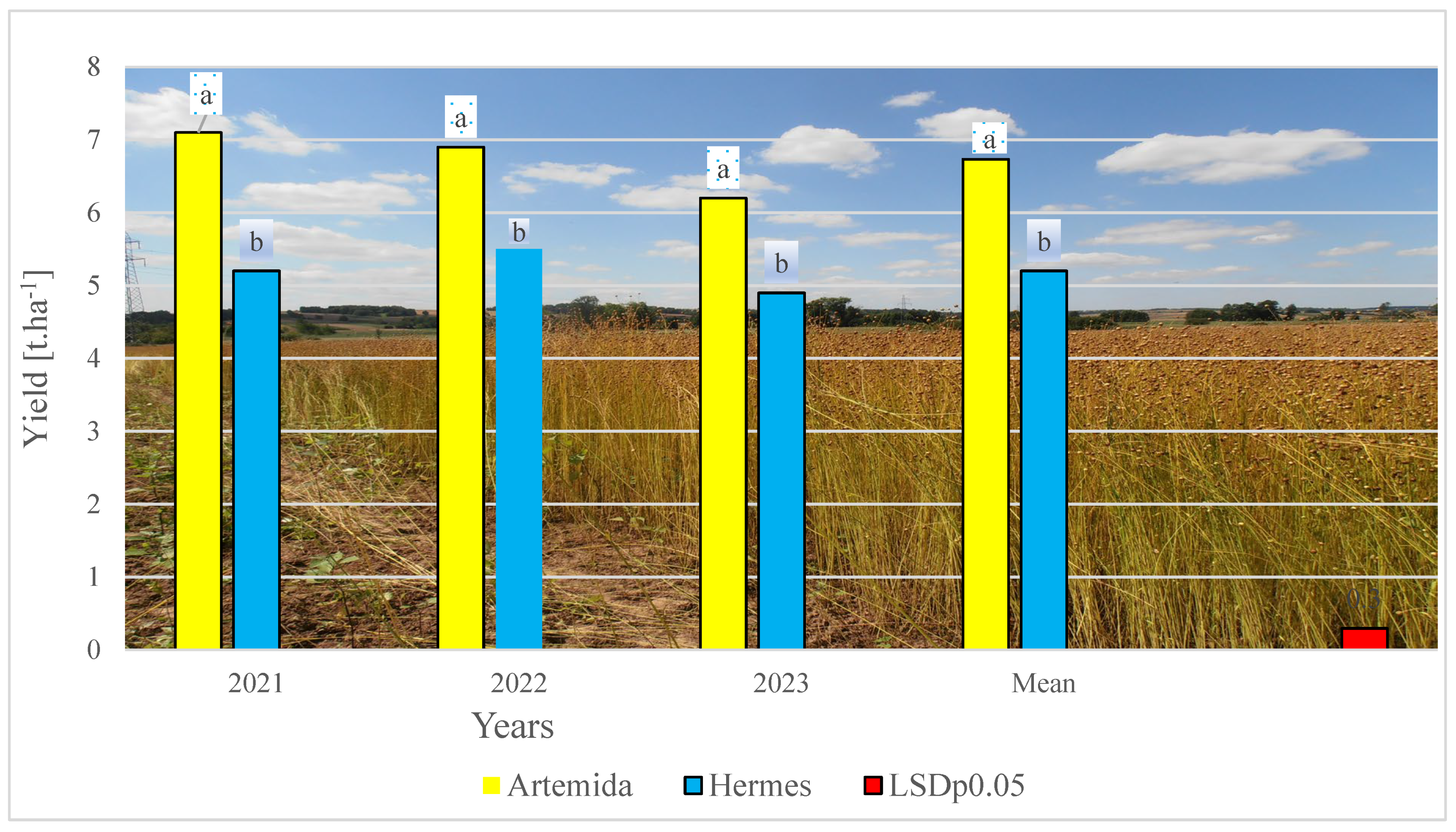

3.1. Yield of Straw

3.2. Total and Technical Length of Straw

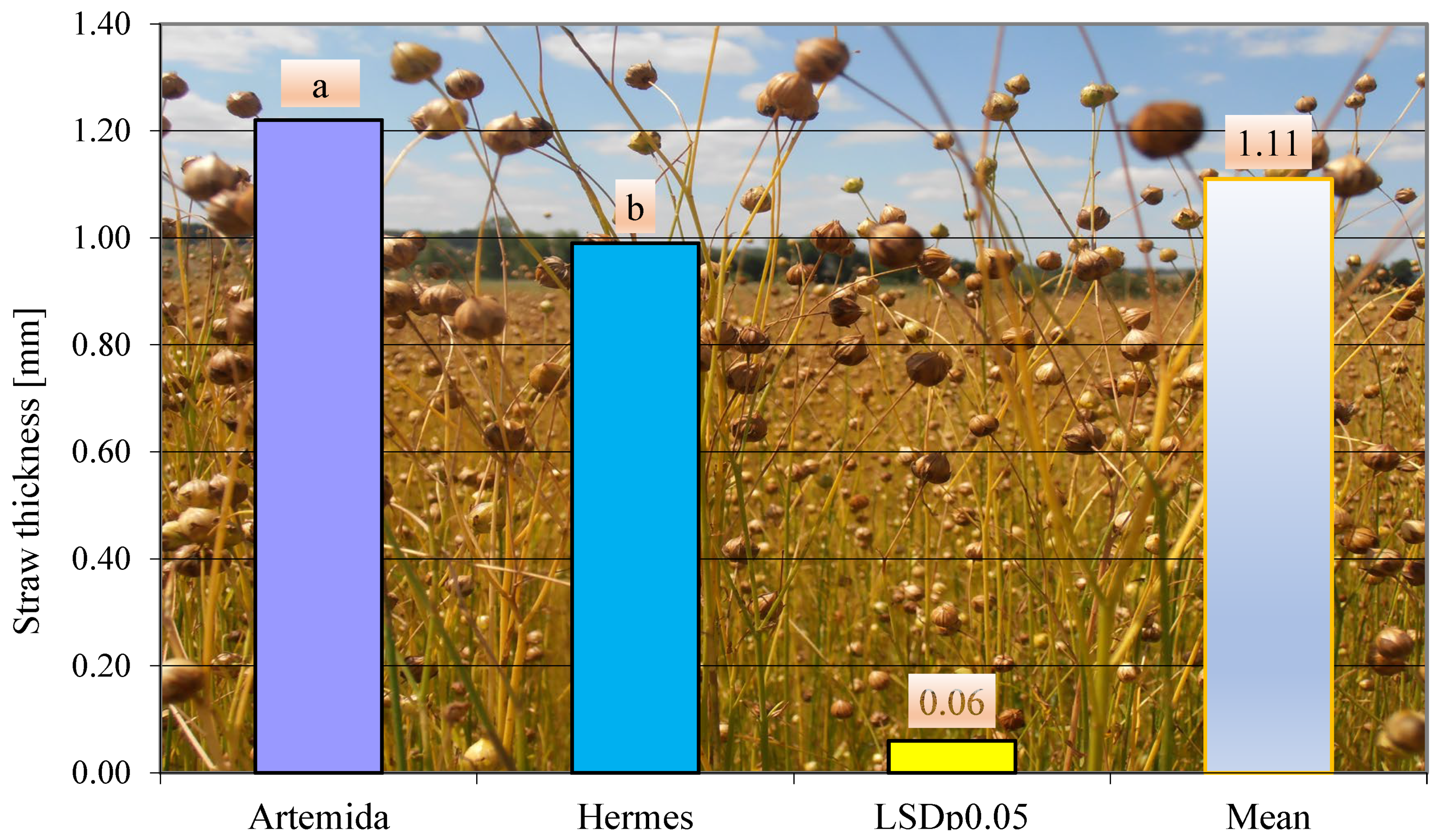

3.3. Straw Thickness

3.4. Straw Color

3.5. Straw Contamination

3.6. Straw Retting

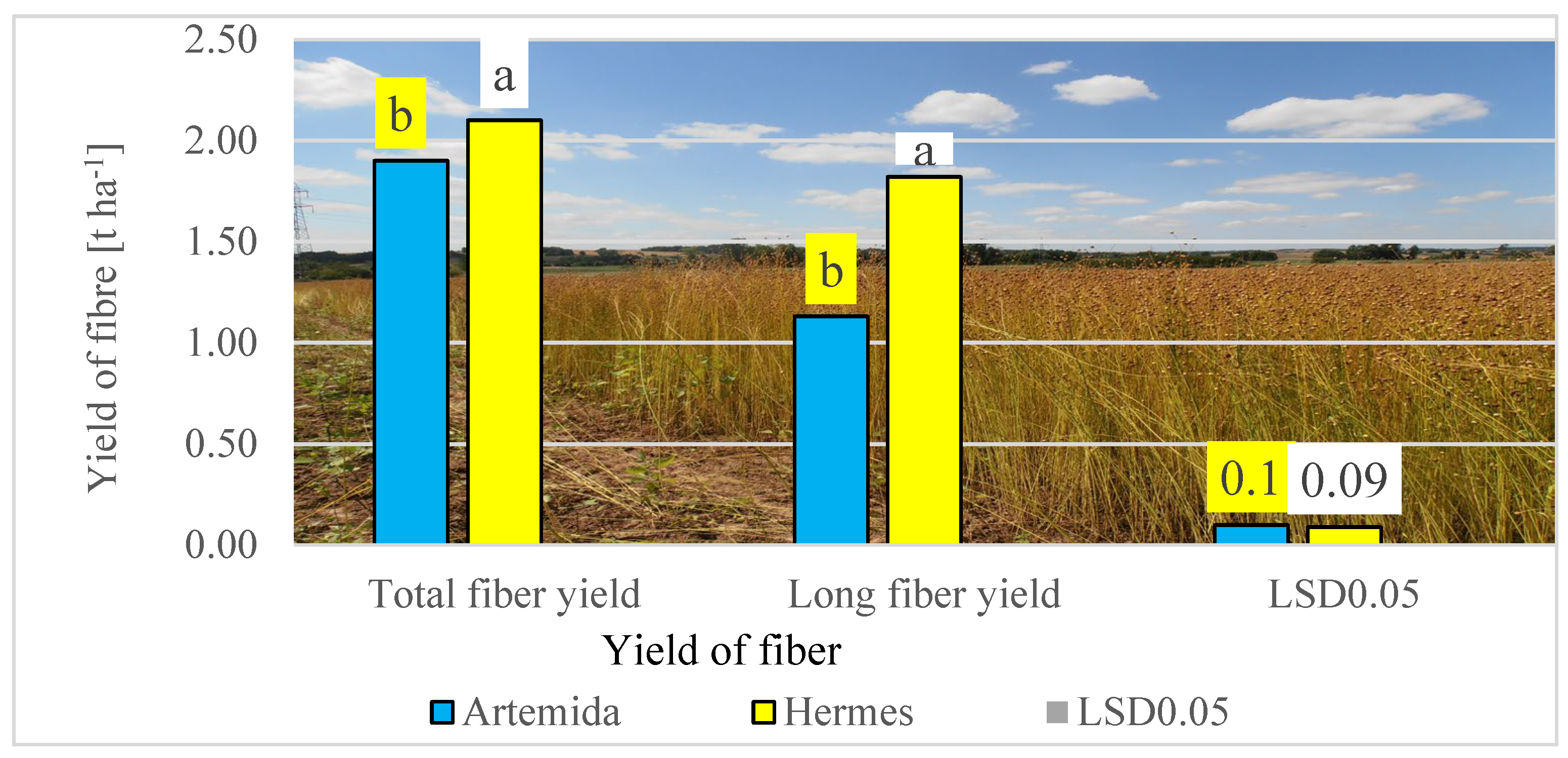

3.7. Fiber Yield

3.8. Fiber Efficiency

3.9. Fibre Quality Assessment

3.10. Descriptive Statistics

3.11. Interaction of Straw and Fiber Characteristics

4. Discussion

4.1. Flax Production

- − Tow – a raw material for carded yarns,

- − Shive – used in the production of boards,

- − Retting waste – for the paper industry,

4.2. Influence of Variety and Environmental Factors on Flax Straw Yield

4.3. Fibre Deglutination

4.4. Flax Straw Commodity Evaluation

4.5. Straw Quality

4.6. Yield and Quality of Flax Fibre

4.7. The Influence of Abiotic Factors on the Quality of Flax Fiber

4.8. Correlation Relationships

4.9. Indications for Agricultural Practice and Processing

5. New Trends and Challenges

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Biradar, S. A., Ajithkumar, K., Rajanna, B., Savitha, A. S., Shubha, G. V., Shankergoud, I., Chittapur, B. M., Singh, P. K. 2016. Prospects and challenges in linseed (Linum usitatissimum L.) production: A review. Journal of Oilseeds Research, 33(1): 1-13. [CrossRef]

- Célino, A., Fréour, S., Jacquemin, F., Casari, P. 2014. The hygroscopic behavior of plant fibres: a review. Frontiers in Chemistry, 2014, 1, 43: 1-12. [CrossRef]

- Gacek (ed.). Descriptive list of varieties. Publishing house: COBORU, Słupia Wielka, 50-54, 2012. (in Polish).

- Diedrichson, A., Richardson, K., 2003. Cultivated Flax and the Genus Linum L. taxonomy and germplasm conservation. In: Muir, A.D., Westcott, N.D. (Eds.), The genus Linum. Taylor & Francis, New York, pp. 22-54.

- Popis, E., Ratusz K., Przybysz M., Krygiel K., Sakowska A., Konarska M. World and Polish production of linseed and linseed oil. notebook Problem School of the Warsaw University of Life Sciences in Warsaw. World Agriculture Problems, 2015, 15: 106-116. (in Polish).

- Silska, G. 2017. Description of twelve ancient varieties of flax grown in Poland. Agricultural Advisory Issues, 89(3): 111-122. (in Polish).

- Preisner M, Wojtasik W., Wojtasik, Kulma A., Żuk M., Szopa J. Flax Fiber. [In book:] Kirk-Othmer Encyclopedia of Chemical Technology, Publisher: John Wiley & Sons, Inc., 2014. [CrossRef]

- Preisner, M., Wojtasik, W., Szopa, J., Kulma, A. The development, differentiation, and composition of flax fiber cells. Postępy Biochemii, 2015, 61(4): 416-429.

- Silska G, Bocianowski J. 2018. Characterisation and evaluation of morphological trials, biological features, and seed field of twenty-three flax accessions (Linum usitatissimum L.) of different geographical origins. Herba Polonica 65(4):1-13. [CrossRef]

- Heller, K., Sheng, Q.C., Guan, F., Alexopoulou, E., Hua, L.S., Wu, G.W., Jankauskienė, Z., Fu, WY. A comparative study between Europe and China in crop management of two types of flax: linseed and fibre flax. Industrial Crops and Products, 2015, 68: 24-31. [CrossRef]

- Pinsard L, Revol N, Pomikal H, De Luycker E, Ouagne P. Production of Long Hemp Fibers Using the Flax Value Chain. Fibers, 2023, 11(5): 38. [CrossRef]

- Silska, G. Valorisation of morphological and agricultural traits of twenty-one varieties of flax Linum usitatissimum L. Herba Polonica, 2022, 68(2): 24-35.

- Arminger, B., Jaxel, J., Bacher, M., Gindl-Altmutter, W., Hansmann, C. On the drying behaviour of natural oils used for solid wood finishing. Progress in Organic Coatings, 2020, 148, 105831. [CrossRef]

- Chaudhary, B., Tripathi, M. K., Pandey, S. K., Bhandari, H. R., Meena, D. R., Prajapati, S.P. Uses of flax (Linum usitatisimum) after harvest. International Journal of Tropical Agriculture, 2016, 34(4): 159-164.

- İşeri-Çağlar, D., Baştürk, E., Oktay, B., Kahraman, M.V. Preparation and evaluation of linseed oil, based alkyd paints. Progress in Organic Coatings, 2014, 77(1): 81-86. [CrossRef]

- Ullah, F., Bano, A., Ali, S. Optimization of protocol for biodiesel production of linseed (Linum usitatissimum L.) oil. Polish Journal of Chemical Technology, 2013, 15(1): 74-77.

- Bullon, J., González Arrieta, M.A., Hernández Encinas, A., Queiruga Dios, M.A. Manufacturing processes in the textile industry. Expert Systems for fabrics production. Advances in Distributed Computing and Artical Intelligence Journal, 2017, 6(1): 41-50. [CrossRef]

- Karunaratne, P. V. M., Withanage, D. Consumer demand for linen apparel fashion in Sri Lanka. World Scientific News, 2020, 147: 104-123.

- Kashyap, R. Sustainable fibres and fabrics used in home textiles. International Journal for Scientific Research and Development, 2015, 3(9): 901-903.

- Kumar, R., Ul Haq, M. I., Raina, A., Anand, A. Industrial applications of natural fibre-reinforced polymer composites–challenges and opportunities. International Journal of Sustainable Engineering, 2019, 12(3): 212-220. [CrossRef]

- Hussain, S., Anjum, F.M., Alamri, M.S., Mohamed, A.A., Nadeem, M. Functional flaxseed in baking. Quality Assurance and Safety of Crops & Foods, 2013, 5(4): 375-385. [CrossRef]

- Tiwari, A., Mishra, S. Nutritive evaluation of wheat bran biscuits incorporated with flaxseed. International Journal of Science and Research, 2019, 8(9): 1249-1251.

- Zhang, S., Chen, Y., McClements, D. J., Hou, T., Geng, F., Chen, P., Xie, B., Sun, Z., Tang, H., Pei, Y., Quan, S., Yu, X., Deng, Q. Composition, processing, and quality control of whole flaxseed products used to fortify foods. Comprehensive Reviews in Food Science and Food Safety, 2023, 22(1): 587-614. [CrossRef]

- Kaniewski, R., Jankowiak, J., Zajączek, J. New possibilities of using cold-pressed linseed oil. Postępy Fitoterapii, 2019, 3: 204-207. (in Polish).

- Tang, Z. X., Ying, R. F., Lv, B. F., Yang, L. H., Xu, Z., Yan, L. Q., Bu, J. Z., Wei, Y. S. Flaxseed oil: extraction, health benefits and products. Quality Assurance and Safety of Crops & Foods, 2021, 13(1): 1-19. (in Polish).

- Bartkowski, L. Flax seeds - a natural source of health and beauty. Chemik, 2013,67(3): 186-191. (in Polish).

- Pandey, R., Dayal, R., Srivastava, R.L. Flax Fibre – Processing Technology. Chandra Shekhar AZAD, University of Agriculture & Technology, Kanpur, 36 pp, 2014.

- Sharma, H.S.S., Faughey, G.J. Comparison of subjective and objective methods to assess flax straw cultivars and fibre quality after dew-retting. Ann. Appl. Biol. 1999. 135: 495–501. [CrossRef]

- Heller, K. Methodology of Integrated Pest Management for Cultivation of Flax Fiber. ed. Institute of Natural Fibers and Medicinal Plants, Poznań, 2012, https://www.agrofagi.com.pl/plik,577,len-wloknisty-wersja-dla-doradcy.pdf (accessed 05.07.2023).

- Fijałkowski J. Report on geological reconnaissance research behind the block building stone in the Zemos Voivodship in the town of Gródki (currently Gródki). Centrum Archeologii i Geologii – Państwowy Instytut Geologiczny, Warszawa, 1984. (in Polish).

- Kłysewicz K., Michalski T., Mielnik T., Kubrak Z., Skibiński B. Roztocze. 2024, Wydawnictwo Libra pl, Wydanie: 2: ss. 424, ISBN: 9788368153040 (in Polish).

- Bujanowicz-Harnaś B. Environmental determinants of the competitiveness of agriculture in the Lublin region. Stowarzyszenie Ekonomistów Rolnictwa i Agrobiznesu. Rocz. Nauk. 2008, 10 (1): 39-43. (in Polish).

- Zalecenia Ochrony Roślin 2020/2021 Instytut Ochrony Roślin – Państwowy Instytut Badawczy Poznań 2020, (in Polish).

- Abdel-Wahab, M. K., El-Sharabasy, M. M. A., El-Didamony, MI. Development and performance evaluation of a pulling flax machine. Journal of Agricultural Engineering, 2012, 29(3), 973-992.

- Twardowski, J., Hurej, M., Ścibior, R., Kotecki, A. The effect of different seeding densities of linseed (Linum usitatissimum L.) on flax flea beetles (Coleoptera: Chrysomelidae). Journal of Plant Protection Research, 2017, 57(2), 158-166. [CrossRef]

- Kanapina A, Rozhmina T, Bankin M, Surkova S, Duk M, Osyagina E, Samsonova M. Genetic Determinants of Fiber-Associated Traits in Flax Identified by Omics Data Integration. International Journal of Molecular Sciences. 2022, 23(23): 14536. [CrossRef]

- Coroller G., Lefeuvre A., Le Duigou A., Bourmaud A., Ausias G., Gaudry T., Baley Ch. Effect of flax fibers individualization on tensile failure of flax/epoxy unidirectional composite. Composites Part A. Applied Science and Manufacturing 2013, 51: 62-70.

- PN-R-04023:1996. Chemical and agricultural soil analysis. Determination of the content of available phosphorus in mineral soils. Polish Committee for Standardization: Warsaw, Poland. 1996 (in Polish).

- PN-R-04022:1996+Az1:2002. Chemical and agricultural soil analysis - determination of bioavailable potassium content. Polish Committee for Standardization: Warsaw, Poland, 2002. (in Polish).

- PN-R-04020:1994+Az1:2004. Chemical and agricultural soil analysis - determination of bioavailable manganese content. Polish Committee for Standardization: Warsaw, Poland, 2004. (in Polish).

- PN-P-04680-10:1980. (PN-80/P-04680.10). Methods of testing textile raw materials. Retted linen straw - determining the degree of retting. ed. Polish Committee for Standardization, Warsaw, Poland (in Polish).

- PN-P-04680-05: 1987. Test methods for textile raw materials - Retted flax straw - Determination of long fiber yield. ed. Polish Committee for Standardization, Warsaw, Poland. (in Polish).

- Kaniewski R. Methods of evaluation and control of quality parameters of straw and flax and hemp fibre. Wyd. IWN, Poznań, 2007. (in Polish).

- PN-P-80103:1996. Flax straw. ed. Polish Committee for Standardization, Warsaw, Poland. (in Polish).

- PN-P-04680-05: 1979. Test methods for textile raw materials - Retted flax straw - Determination of long fiber yield. ed. Polish Committee for Standardization, Warsaw, Poland. (in Polish).

- PN-P-80104:1997. Textile raw materials. Long brushed and combed biological flax fiber Requirements Wyd. Polish Committee for Standardization, Warsaw, Poland. (in Polish).

- PN-P-80105: 1998. Textile raw materials. Short linen yarn. ed. Polish Committee for Standardization, Warsaw, Poland. (in Polish).

- SAS Institute Inc. 2008. SAS/STAT®®9.2 User’s Guide. Cary, NC: SAS Institute Inc.

- IBM SPSS Statistics 28 User’s Guide - IBM Core System. chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://www.ibm.com/docs/en/SSLVMB_28.0.0/pdf/en/IBM_SPSS_Statistics_Core_System_User_Guide.pdf (accessed 02.07.2023).

- Koronacki, J. Statistics, for Students of Technical and Natural Sciences; Scientific and Technical Publishing House: Warsaw, Poland, 2009; p. 491. (In Polish).

- Strażyński, P., Mrówczyński, M. Test methods for textile raw materials - Retted flax straw - Determination of long fiber yield. ed. Polish Committee for Standardization, Warsaw, Poland. ISBN 978-83-64655-34-0, 2017. (in Polish).

- Dai F., Song X F., Guo W. J., Zhao W.Y., Zhang F. W, Zhang S.L. Simulation and test on separating cleaning process of flax threshing material based on gas-solid coupling theory. Int J Agric & Biol. Eng, 2020, 13(1): 73–81.

- Mańkowski, J., Maksymiuk, W., Spychalski, G., Kołodziej, J., Kubacki, A., Kupka, D., Pudełko, K. Research on new technology of fiber flax harvesting. Journal of Natural Fibers, 2018, 15(1): 53-61. [CrossRef]

- Bozorova, S. T., Jumanova, M., Inoyatova, X. Technology of making pectin from flaxseed. Indonesian Journal of Innovation Studies, 2019, 5: 1-12.

- Raveendran Nair, G., Singh, A., Zimniewska, M., Raghavan, V. Comparative evaluation of physical and structural properties of water retted and non-retted flax fibers. Fibers, 2013, 1(3): 59-69. [CrossRef]

- Koncewicz, W., Zimniewska, M., Valera, M.A. The selection of a retting method for the extraction of bast fibers as response to challenges in composite reinforcement. Textile Research Journal, 2018, 88(18): 2104-2119.

- Mańkowski J. Influence of retting methods on the quantity and quality of monomorphic flax fiber. Fragmenta Agronomica, 2014, 31(2): 46–55. (in Polish).

- Lyu, P., Zhang, Y., Wang, X., Hurren, C. Degumming methods for bast fibers -A mini review. Industrial Crops and Products, 2021, 174: 114158. [CrossRef]

- Dey, P., Mahapatra, B. S., Pramanick, B., Kumar, A., Negi, M. S., Paul, J., Shukla, D. K., Singh, S. P. 2021. Quality optimization of flax fibre through durational management of water retting technology under subtropical climate. Industrial Crops and Products, 162, 113277. [CrossRef]

- Camano, S., Behary, N., Vroman, P., Campagne, C. Comparison of bio and eco-technologies with chemical methods for pre-treatment of flax fibers: impact on fiber properties. Journal of Engineered Fibers and Fabrics, 2014, 9(4): 56-68. [CrossRef]

- De Prez, J., Van Vuure, A. W., Ivens, J., Aerts, G., Van de Voorde, I. Effect of enzymatic treatment of flax on chemical composition and the extent of fiber separation. BioResources, 2019, 14(2): 3012-3030.

- De Prez, J., Van Vuure, A. W., Ivens, J., Aerts, G., Van de Voorde, I. 2020. Flax treatment with strategic enzyme combinations: effect on fibre fineness and mechanical properties of composites. Journal of Reinforced Plastics and Composites, 39(5-6): 231-245.

- Chares Subash, M., Muthiah, P. Eco-friendly degumming of natural fibres for textile applications: A comprehensive review. Cleaner Engineering and Technology, 2021, 5, 100304. [CrossRef]

- Konczewicz, W., Kryszak, N., Nowaczkiewicz, E., Kozlowski, R., Wojtysiak, J., Podsiedlik, W. Osmosis phenomena, based degumming of bast fibrous plants as a promising method in primary processing. Molecular Crystals and Liquid Crystals, 2013, 571(1): 116-131.

- Konczewicz W., Kozłowski R., Kaniewski R., Wojtysiak J., Podsiedlik W. Extraction of bast plant fiber by osmotic debonding. Flax and Hemp Newsletter /Biuletyn Len i Konopie 2011, 16: 34–44. (in Polish).

- Kozłowski R., Mańkowski J., Kubacki A. Efficient technology for the production of decorticated hemp and flax fibres and linseed as a raw material for different industries. J. Nat. Fibres, 2004, 1(2): 107–108. [CrossRef]

- Romanowska B., Bogacz E., Kicińska-Jakubowska A., Zimniewska M. Characteristics of bast fibers. Bulletin. Information Polish Linen, 2012, 19: 37-44. (in Polish).

- PN-P-04961: 1984 (PN-84/P-04961). Methods of testing textile raw materials - Straw and flax and hemp fiber - Organoleptic tests. ed. Polish Committee for Standardization, Warsaw, Poland. (in Polish).

- Alcock, M., Ahmed, S., DuCharme, S., Ulven, CA. Influence of stem diameter on fibre diameter and the mechanical properties of technical flax fibers from linseed flax Fibers, 2018, 6(1), 10. [CrossRef]

- Vinogradova T. A., Kudryashova T. A., Koziyakova N. N. Evaluation of fibre flax varieties by quality uniformity of long fiber when processing flax straw. fubsy, Agronomia, 2022. [in Russian]. [CrossRef]

- Bronia J., Paczocha J. Synthesis of the results of registration experiments. Oily and fibrous, 2011, 125: 3-10. (in Polish).

- Broniarz J., Paczocha J. Synthesis of the results of registration experiments. Oily and fibrous, 2014, 125:77-82. (in Polish).

- Arslanoglu, ŞF., Sert, S., Şahin, HA., Aytaç, S., El Sabagh, A. Yield and yield criteria of flax fiber (Linum usititassimum L.) as influenced by different plant densities. Sustainability, 2022, 14(8), 4710. [CrossRef]

- El-Gedwy, E.S.M. Effect of nitrogen fertilizer rates and plant density on straw, fiber yield and anatomical manifestations of some flax cultivars. Annals of Agricultural Science, Moshtohor, 2020, 58(4): 855-700.

- Emam, S.M. Effectiveness of Sowing Dates and N Rates on Productivity of Two Flax (Linum usitatissimum L.) Cultivars. Egyptian Journal of Agronomy, 2019, 41(3): 261-274.

- Mańkowski, J., Pudełko, K. Evaluation of the effect of the tillage system and weed control on the yield of flax fibre and its quality. Fibres & Textiles in Eastern Europe, 2015, 3 (111): 33-37. [CrossRef]

- Akin, D. E., Henriksson, G., Evans, J. D., Adamsen, A. P. S., Foulk, J. A., Dodd, R. B. Progress in enzyme-retting of flax. Journal of Natural Fibers, 2004 1(1): 21-47.

- Chabert, B., Padovani, J., Djamel, C., Osmond, J., Lemaitre, A., Yoshinaga, A., Hawkins, S., Greco, S., Beaugrand, J., Kurek, B. Multimodal assessment of flax dew retting and its functional impact on fibres and natural fibre composites. Industrial Crops and Products, 2020, 148, 112255.

- Heller K. Methodology of integrated plant protection for flax cultivation. ed. Institute of Natural Fibers and Medicinal Plants – Poznań, 2012. (in Polish).

- Jiao, Y., Grant, CA., Bailey, LD. Growth and nutrient response of flax and durum wheat to phosphorus and zinc fertilizers. Can. J. Plant Sci., 2013, 87(3): 461-470. [CrossRef]

- Kissable AK, Czernenok, VG, Normani, YT, Persikova, TF, Hanako, BZ, Kuzdanova, RS, Sericea, ZK, Sensible management of soil fertility and flax productivity. Arab. J. Geosmin. 2020, 13, 787.

| No. Field | 2021 | 2022 | 2023 |

|---|---|---|---|

| 1 | Flax | Weta | Raps |

| 2 | Flax | Barley | Onion |

| 3 | Flax | Sugar beet | Wheat |

| 4 | Flax | Barley | Parsley |

| 5 | Wheat | Rape | Barley |

| 6 | Sugar beet | Barley | Wheat |

| Years | Soil agronomic category | Soil acidity | The content of absorbable forms [mg·100 g-1 air dry wright of the soil] | ||||||

| pHKCl | Soil reaction | P2O5 | K2O | Mg | |||||

| 2021 | pglp | 5.04 | Sour | 6.3 | short | 22.0 | high | 4.5 | Short |

| 2022 | pgl | 5.64 | Slightly sour | 11.1 | mean | 15.5 | mean | 5.4 | Mean |

| 2023 | pgl | 6.37 | Slightly sour | 18.9 | high | 16.0 | mean | 10.8 | very high |

| Mean | pgl | 5.6 | sour | 11.8 | mean | 8.13 | mean | 6.8 | Mean |

| Years | Months | |||||

| Rainfall (mm) | ||||||

|

2021 2022 2023 |

April | May | June | Juni | August | September |

| 27.1 | 58 | 19.2 | 20.7 | 239.7 | 8.1 | |

| 13.4 | 79.8 | 62.8 | 49.0 | 26.6 | 86.2 | |

| 43.0 | 83.0 | 42.0 | 94.0 | 72.0 | 61.0 | |

| Air temperature (°C) | ||||||

| 2021 | 9.2 | 13.9 | 17.7 | 22.5 | 17.7 | 15.5 |

| 2022 | 9.2 | 15.8 | 19.1 | 19.3 | 19.2 | 13.1 |

| 2023 | 9.4 | 13.5 | 18.2 | 18.8 | 18.6 | 12.5 |

| Sielianinov’s hydrothermal coefficient* | ||||||

| 2021 | 1.0 | 1.3 | 0.4 | 0.3 | 4.4 | 0.2 |

| 2022 | 0.5 | 1.6 | 1.1 | 0.8 | 0.4 | 2.2 |

| 2023 | 1.5 | 2.0 | 0.8 | 1.6 | 1.2 | 1.6 |

| Variety | Total length of straw | Technical length of straw | ||||||

| Years | Mean | Years | Mean | |||||

| 2021 | 2022 | 2023 | 2021 | 2022 | 2023 | |||

| Artemida | 55.4b* | 71.0a | 56.6b | 63.5a | 46.2b | 60.8a | 47.2b | 51.4b |

| Hermes | 60.0a | 66.4a | 64.5a | 63.4a | 53.7a | 51.7a | 58,2a | 54.5a |

| LSDp0.05 | 9.5 | 3.2 | 7.9 | 2.6 | ||||

| Mean | 60.0b | 68.7a | 60.6b | 63.1 | 50.0b | 56.3a | 52.7ab | 53.0 |

| LSDp0.05 | 4.7 | 4.0 | ||||||

| Variety | Years | Mean | ||

| 2021 | 2022 | 2023 | ||

| Artemida | 1.19a* | 1.31a | 1.15a | 1.22a |

| Hermes | 0.98a | 1.02a | 0.98a | 0.99b |

| LSDp0.05 | 0.17 | 0.06 | ||

| Mean | 1.09b | 1.17a | 1.07b | 1.11 |

| LSDp0.05; | 0.08 | |||

| Variety | Straw color [%] | |

|---|---|---|

| Steel gray | Light gray | |

| ‘Artemida’ | 90.0b* | 10.0a |

| ‘Hermes’ | 100.0a | 0.0b |

| LSDp0,05 | 4.8 | 0.2 |

| Mean | 95.0 | 5.0 |

| Year | Straw color [%] | |

| Steel gray | Light gray | |

| 2021 | 94.0a* | 6.0a |

| 2022 | 96.0a | 4.0c |

| 2023 | 95.0a | 5.0b |

| LSDp0.05 | 7.2 | 0.3 |

| Average | 95.0 | 5,0 |

| Variety | Years | Mean | ||

| 2021 | 2022 | 2023 | ||

| Artemida | 0.50a* | 0.50a | 0.60a | 0.53b |

| Hermes | 1.50b | 1.20c | 2.00a | 1.57a |

| LSDp0.05 | 0.20 | 0.10 | ||

| Mean | 1.00b | 0.85c | 1.30a | 1.05 |

| LSDp0.05 | 0.10 | |||

| Varieties | Degree of straw growth | ||

|---|---|---|---|

| Properly | Undergrown | Overgrown | |

| ‘Artemida’ | 85.0b* | 0.0b | 15.0a |

| ‘Hermes’ | 92.7a | 7.3a | 0.0b |

| LSDp0,05 | 5.0 | 0.2 | 0.4 |

| Mean | 0 88.8 | 3.7 | 7.5 |

| Year | Variety | Flax Straw | ||

| Properly Grown (%) | Underdeveloped (%) | Overgrown (%) | ||

| 2021 | Artemida | 90.0a* | 0.0c | 10.0c |

| 2021 | Hermes | 93.0a | 7.0b | 0.0d |

| 2022 | Artemida | 84.0b | 0.0c | 16.0b |

| 2022 | Hermes | 92.0a | 8.0a | 0.0d |

| 2023 | Artemida | 81.0b | 0.0c | 19.0a |

| 2023 | Hermes | 93.0a | 7.0b | 0.0d |

| LSD (p=0.05) | – | 13.0 | 0.6 | 1.2 |

| Mean | 88.8 | 3.7 | 7.5 | |

| Variety | Total yield of fiber | Long fiber yield | ||||||

| Years | Mean | Years | Mean | |||||

| 2021 | 2022 | 2023 | 2021 | 2022 | 2023 | |||

| Artemida | 1.88a* | 2.11a | 1.71b | 1.90b | 1.07b | 1.39a | 0.92bc | 1.13b |

| Hermes | 2.19a | 2.11a | 1.99a | 2.10a | 1.92a | 1.79a | 1.76b | 1.82a |

| LSDp0.05 | 0.30 | 0.10 | 0.20 | 0.10 | ||||

| Mean | 2.04a | 2.11a | 1.85b | 2.00 | 1.50a | 1.59a | 1.34b | 1.48 |

| LSDp0.05 | 0.10 | 0.10 | ||||||

| Variety | Long fiber | Short fiber | ||||||

| Years | Mean | Years | Mean | |||||

| 2021 | 2022 | 2023 | 2021 | 2022 | 2023 | |||

| Artemida | 15.00b* | 20.20a | 14.80b | 16.67b | 11.50a | 10.40b | 12.70a | 11.53a |

| Hermes | 37.00a | 32.50b | 35.90a | 35.13a | 5.10a | 5.60a | 4.70a | 5.13b |

| LSDp0.05 | 3.90 | 1.30 | 1.30 | 0.40 | ||||

| Mean | 26.00a | 26.35a | 25.35a | 25.90 | 8.30a | 8.00b | 8.70a | 8.33 |

| LSDp0.05 | 1.90 | 0.60 | ||||||

| Variety | Years | Mean | ||

| 2021 | 2022 | 2023 | ||

| Artemida | 26,50a* | 30,60a | 27,50a | 28,20b |

| Hermes | 42,10a | 38,40a | 40,60a | 40,37a |

| LSDp0.05 | 5,10 | 1,70 | ||

| Mean | 34,30a | 34,50a | 34,05a | 34,28 |

| LSDp0.05 | 2,60 | |||

| Variety | Linen fiber efficiency [%] | ||

| Long fiber | Short fiber | Total fiber | |

| ‘Artemida’ | 16.7b* | 11.5a | 28.2b |

| ‘Hermes’ | 35.2a | 5.2b | 40.4a |

| LSD p0.05 | 1.3 | 0.4 | 1.7 |

| Average | 26.0 | 8.4 | 34.3 |

| Year | Linen fiber efficiency [%] | ||

| Long fiber | Short fiber | Total fiber | |

| 2021 | 25.5a* | 8.1b | 33.6a |

| 2022 | 26.2a | 8.5a | 34.7a |

| 2023 | 26.3a | 8.6a | 34.9a |

| LSDp0.05 | 1.9 | 0.5 | 2.6 |

| Average | 26.0 | 8.4 | 34.3 |

| A sample | Destructive force [N] | SD [%] | Elongation [%] | Destructive force [N] | SD [%] | Elongation [%] | Destructive force [N] | SD [%] | Elongation [%] | Destructive force [N] | SD [%] | Elongation [%] |

| A25 | 7.42 | 1,52 | 4.26 | 0,97 | 6.68 | 1,78 | 7,84 | 1.35 | 8.91 | 2.91 | 8.76 | 1.07 |

| A35 | 7.62 | 0,96 | 5.00 | 0,82 | 6.15 | 2.47 | 8.54 | 1,96 | 7,78 | 1,63 | 7,87 | 0,62 |

| A45 | 6.47 | 2.30 | 5.19 | 2.12 | 4.48 | 0,89 | 8.63 | 2.83 | 7,86 | 1.04 | 7,69 | 0,85 |

| M25 | 6.57 | 1.12 | 6.40 | 1,96 | 6.05 | 3.01 | 10.40 | 5,68 | 8.21 | 2.29 | 9.06 | 0,45 |

| M35 | 6.57 | 0,50 | 5,89 | 0,68 | 6.03 | 1,82 | 7.37 | 1,52 | 5.53 | 1,86 | 10.35 | 2.73 |

| M45 | 6.36 | 0,62 | 5.71 | 0,85 | 6.36 | 1.30 | 7,96 | 1.43 | 5.28 | 0,45 | 7,89 | 0,67 |

| S25 | 10.15 | 1,69 | 6.30 | 1.01 | 10.28 | 2.39 | 9,89 | 1,77 | 8.04 | 0,82 | 9.66 | 1,63 |

| S35 | 6.53 | 1.14 | 4.35 | 1,63 | 7.03 | 2.12 | 9,96 | 4.43 | 7.15 | 1,78 | 8.15 | 0,61 |

| S45 | 6.11 | 1.11 | 4.48 | 0,97 | 5.91 | 1,57 | 10.56 | 4.07 | 6.52 | 1.48 | 7.05 | 0,85 |

| Cultivars |

Fiber quality evaluation | ||

| Fiber | Description | ||

| ‘Artemida’ | Long |

Ns 68(25) |

Medium-thick, medium-delicate fibre, medium self-breaking resistance, tearing sound quite clear |

| Short | Ns 333(4) |

fiber less divisible, not very delicate, medium strength, medium breaking resistance | |

| Mean | Ns 250(6) |

Fiber less divisible, less delicate, medium strength, medium breaking resistance | |

| ‘Hermes’ | Long |

Ns333(4) | Ribbon of fibre, compact structure, clearly unframed, technical fibre, medium-thick, medium-fine, buttery, medium-heavy |

| Short | Ns56(30) | medium divisible fiber, medium fine, medium breaking resistance, quite clear breaking sound | |

| Mean | Ns250(6) | Medium divisible fiber, medium delicate, medium breaking resistance, quite clear sound | |

| Specification | straw yield | straw technical length | total straw length | straw thickness | Steel gray color of straw | light gray straw color | fiber contamination | The fiber is properly sprouted | immature fiber | overgrown fiber | long fiber | short fiber | total fiber yield |

| Mean | 6,0 | 53,0 | 62,3 | 1,1 | 95,0 | 5,0 | 1,1 | 88,8 | 3,7 | 7,5 | 25,9 | 8,3 | 34,3 |

| Median | 5,9 | 52,7 | 62,3 | 1,1 | 95,0 | 5,0 | 0,9 | 90,0 | 2,5 | 5,0 | 26,4 | 8,0 | 34,5 |

| Standard deviations | 0,9 | 5,5 | 5,7 | 0,1 | 5,1 | 5,1 | 0,6 | 5,2 | 4,1 | 8,3 | 9,8 | 3,4 | 6,5 |

| Kurtosis | -1,7 | -1,5 | -1,3 | -1,2 | -2,3 | -2,3 | -1,3 | -0,8 | -1,5 | -1,6 | -2,0 | -2,0 | -2,0 |

| Skewness | 0,2 | 0,1 | 0,2 | 0,5 | 0,0 | 0,0 | 0,5 | -0,6 | 0,4 | 0,4 | 0,0 | 0,1 | 0,0 |

| Range | 2,2 | 14,6 | 15,6 | 0,3 | 10,0 | 10,0 | 1,5 | 15,0 | 10,0 | 20,0 | 22,2 | 8,0 | 15,6 |

| Minimum | 4,9 | 46,2 | 55,4 | 1,0 | 90,0 | 0,0 | 0,5 | 80,0 | 0,0 | 0,0 | 14,8 | 4,7 | 26,5 |

| Maximum | 7,1 | 60,8 | 71,0 | 1,3 | 100,0 | 10,0 | 2,0 | 95,0 | 10,0 | 20,0 | 37,0 | 12,7 | 42,1 |

| V (%) | 14,3 | 10,4 | 9,1 | 11,4 | 5,4 | 102,9 | 55,7 | 5,8 | 110,7 | 110,3 | 37,7 | 40,5 | 18,9 |

| Specification | y1 | x1 | x2 | x3 | x4 | x5 | x6 | x7 | x8 | x9 | y2 | y3 | y4 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| y1 | 1.00 | ||||||||||||

| x1 | -0.27 | 1.00 | |||||||||||

| x2 | -0.13 | 0.86 | 1.00 | ||||||||||

| x3 | 0.93 | 0.03 | 0.15 | 1.00 | |||||||||

| x4 | -0.92 | 0.29 | 0.24 | -0.91 | 1.00 | ||||||||

| x5 | 0.92 | -0.29 | -0.24 | 0.91 | -1.00 | 1.00 | |||||||

| x6 | -0.94 | 0.39 | 0.17 | -0.88 | 0.91 | -0.91 | 1.00 | ||||||

| x7 | -0.77 | 0.74 | 0.73 | -0.53 | 0.76 | -0.76 | 0.76 | 1.00 | |||||

| x8 | -0.83 | 0.20 | 0.12 | -0.85 | 0.93 | -0.93 | 0.77 | 0.60 | 1.00 | ||||

| x9 | 0.88 | -0.56 | -0.52 | 0.75 | -0.93 | 0.93 | -0.85 | -0.92 | -0.87 | 1.00 | |||

| x10 | -0.90 | 0.48 | 0.36 | -0.83 | 0.97 | -0.97 | 0.91 | 0.82 | 0.92 | -0.96 | 1.00 | ||

| x11 | 0.87 | -0.46 | -0.37 | 0.82 | -0.98 | 0.98 | -0.91 | -0.81 | -0.90 | 0.95 | -0.99 | 1.00 | |

| x12 | -0.91 | 0.48 | 0.35 | -0.83 | 0.97 | -0.97 | 0.91 | 0.82 | 0.93 | -0.97 | 1.00 | -0.98 | 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).