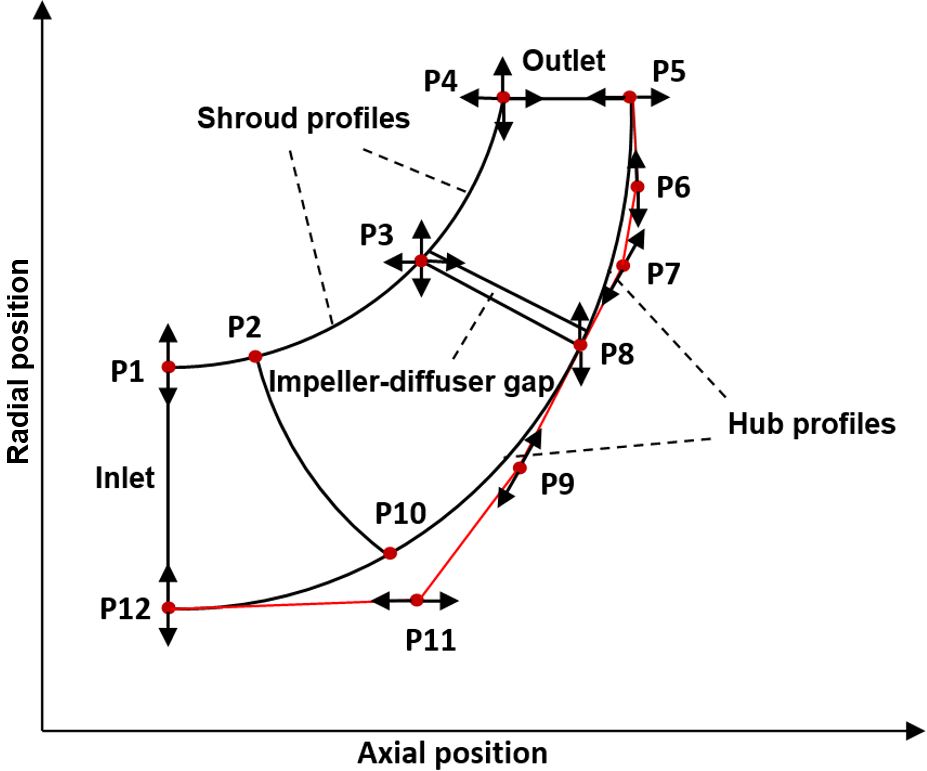

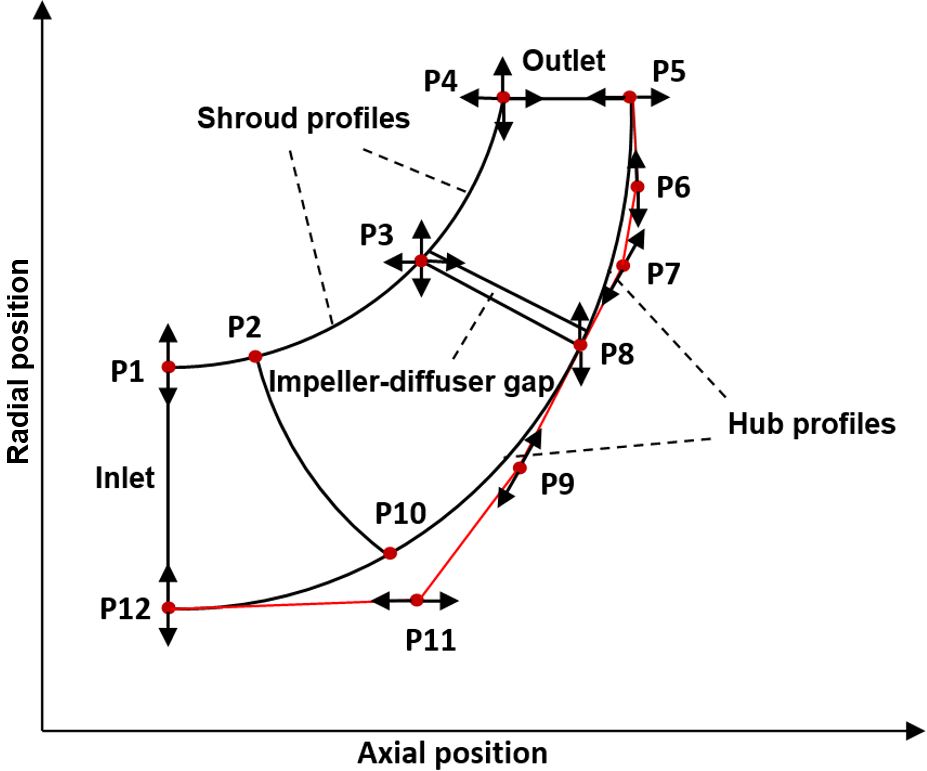

This paper studies the optimization method of pump hydraulic performance based on the response surface method. A parametric model of impeller and diffuser is established. Three-dimensional optimization is carried out on the basis of the initial model obtained by one-dimensional design method. We select the pump hydraulic efficiency and the head as objective function and constraint function. Response surface models are constructed to analyze the relationship between the objectives and the design variables, and the global optimization of hydraulic performance is realized. According to the internal flow characteristics of pump, this paper proposes the strategy of two steps optimization, which aims at meridional plane and blade shape, respectively, to solve the problem of large numbers of design parameters and computational cost. The optimization results show that the hydraulic efficiency of pump increased by 3.7%, and the head is nearly the same.