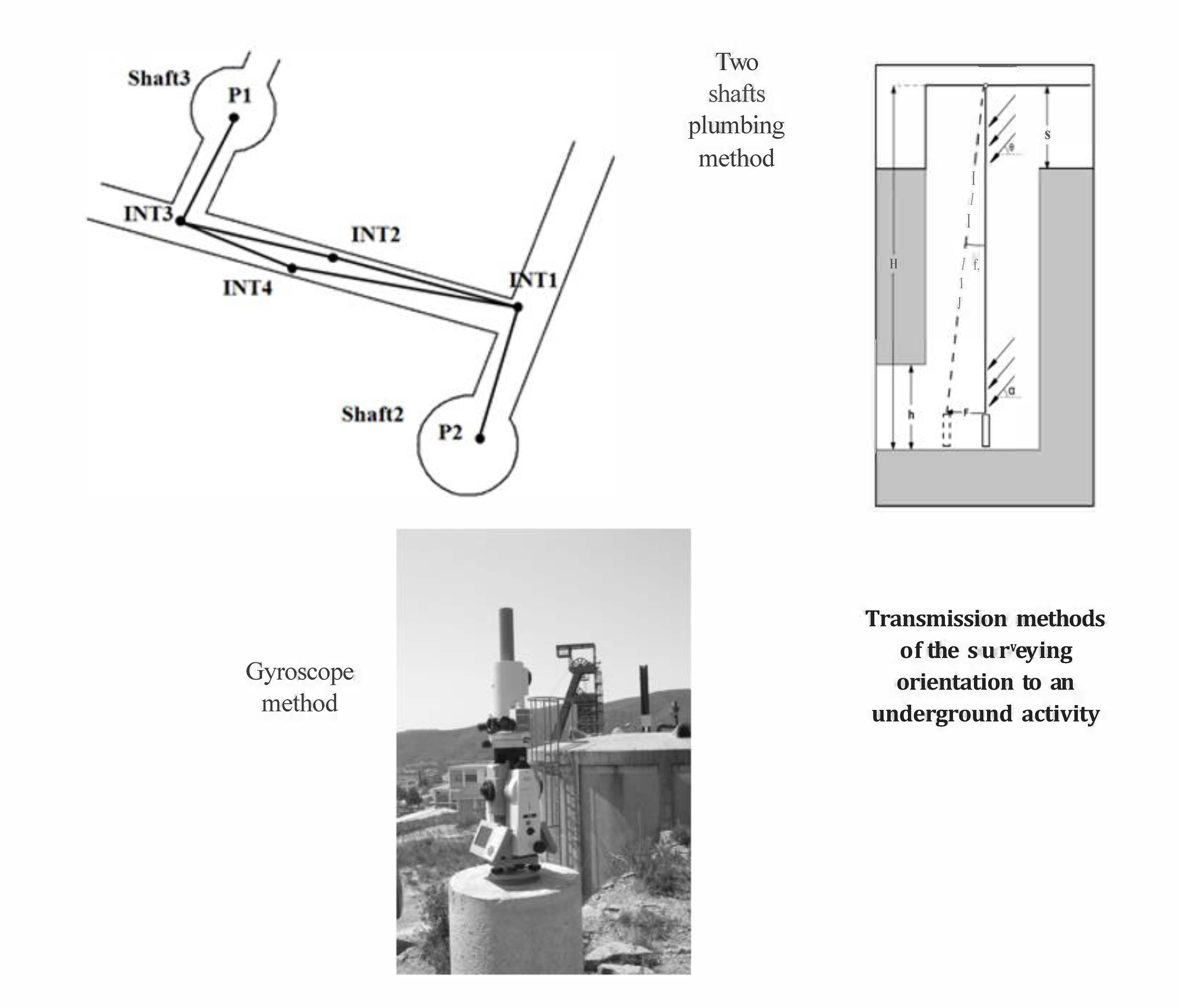

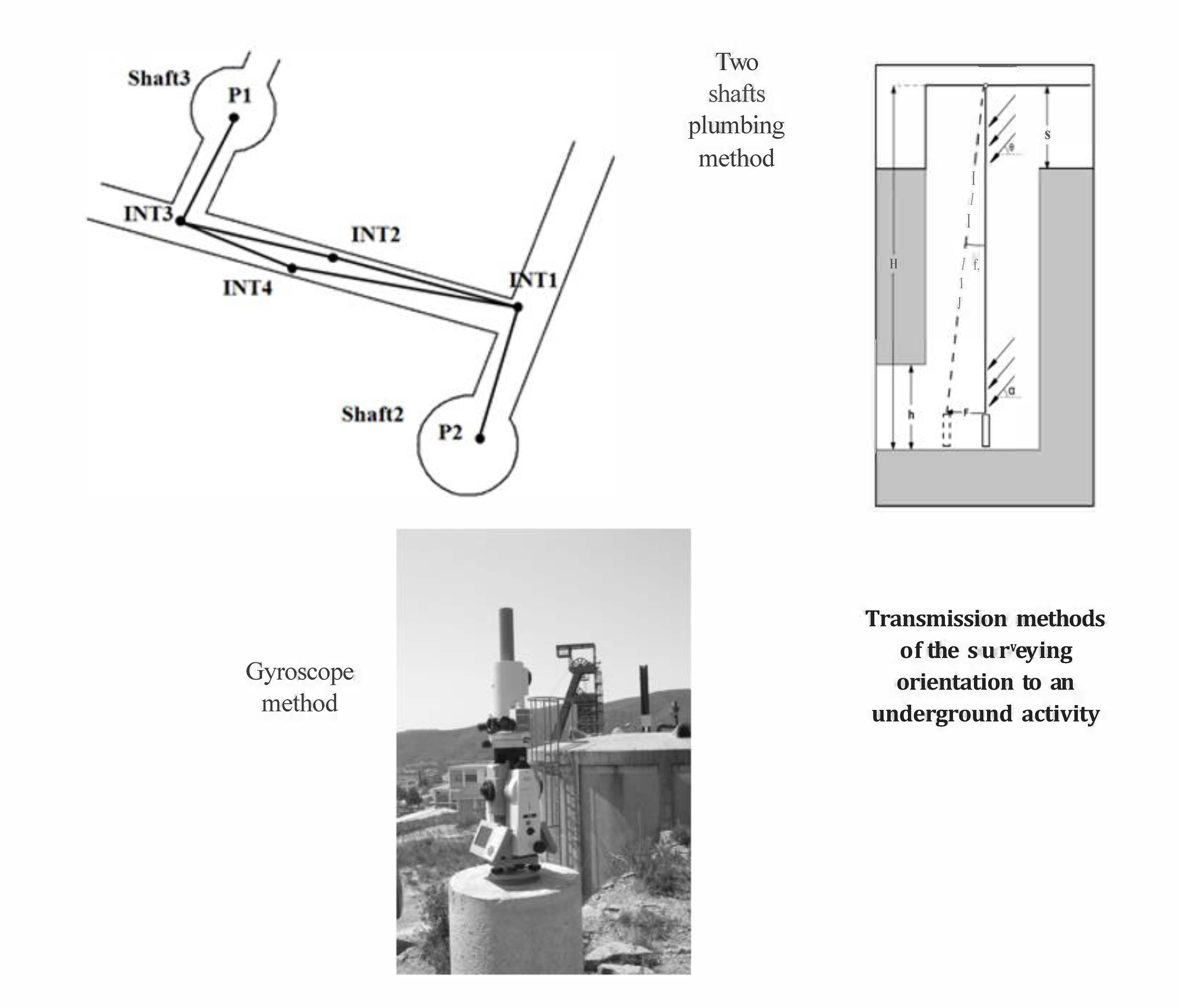

A proper transmission of the orientation between surface and underground workings, by means of vertical shafts, is an important challenge in the mining industry, especially when the mine exceeds 200 meters deep. In fact, this study is developed in a mine located to 700 meters deep. Likewise, this paper assesses the accuracy of this operation, in a case study, using the two shafts plumbing and gyroscope methods in order to compare and analyse the planimetric displacement of the base line due to different source of errors in each one. Upsides and downsides of both methods are analysed in the paper. Some disadvantages in each method have been reduced thanks to the technological progress, especially in the two shaft plumbing method. The different sources of error that affect the measures are thoroughly analysed in the study with the aim to compensate them and achieve the required precision for an underground infrastructure. Mine ventilation has been found as one of the most important sources of error in the plumbing method due to intake and return airflow. In this direction, the paper unfolds some measures to reduce the ventilation influence and details a compensation method to reduce ventilation errors.