You are currently viewing a beta version of our website. If you spot anything unusual, kindly let us know.

Preprint

Article

Production of Hydroxyl Radical and Removal of Formaldehyde by Calcined Green Tuff Powder and Tile

Altmetrics

Downloads

281

Views

273

Comments

0

A peer-reviewed article of this preprint also exists.

This version is not peer-reviewed

Abstract

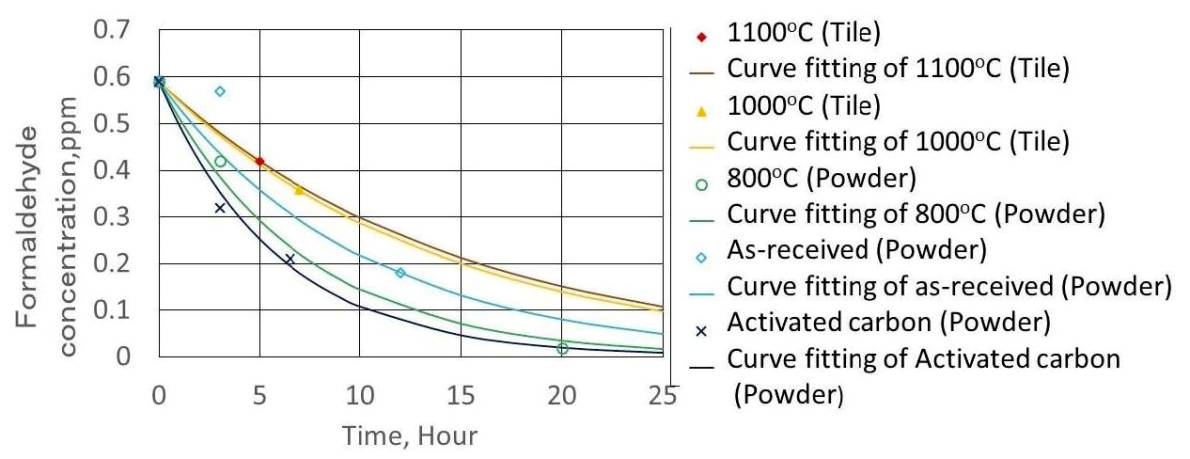

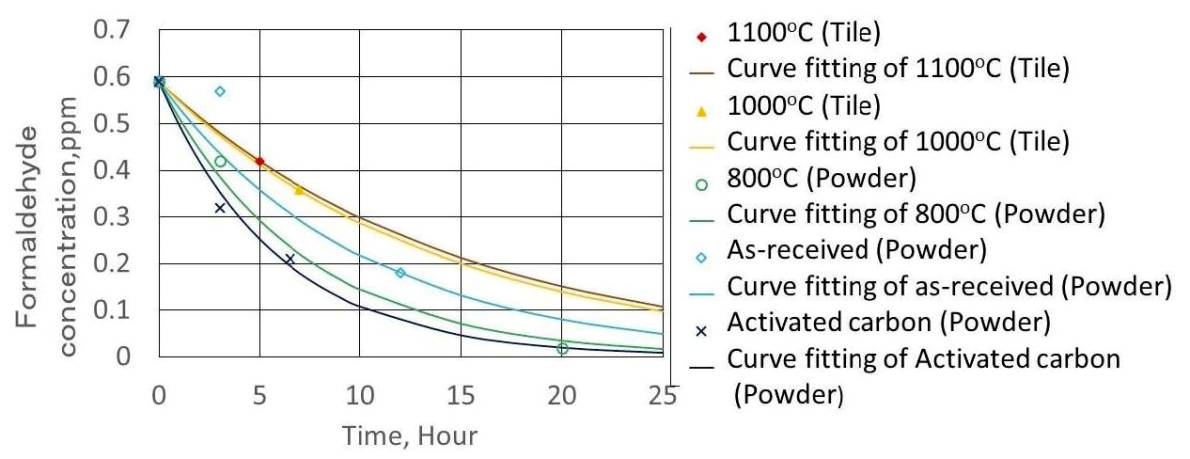

Wasted Green tuff powder produced by cutting Towada stone is recycled as environmental cleaning material. The optimum temperature for green tuff powder calcination to reduce the hydroxyl radical produced in hydrogen peroxide decomposition with ultraviolet light (UV) and no light. The green tuff calcined at 800 °C shows the large decomposition rate of hydrogen peroxide with no UV light when measured by using ESR. With UV light, the optimum temperature for calcinating the green tuff powder in order to reduce hydroxyl radical is also 800 °C. Next, the powder calcined at 800 °C is used to produce the tile by compression and heating, and then the formaldehyde adsorption rate was measured. The green tuff powder calcined at 800 °C showed a high adsorption rate, similar to that of the activated carbon. The tiles formed at 40 MPa and heated st 1100 °C were the strongest and also adsorbed formaldehyde. The adsorbed formaldehyde on the green tuff tile and powder might have a possibility to decompose by photocatalytic.

Keywords:

Subject: Engineering - Chemical Engineering

Copyright: This open access article is published under a Creative Commons CC BY 4.0 license, which permit the free download, distribution, and reuse, provided that the author and preprint are cited in any reuse.

Submitted:

10 May 2019

Posted:

13 May 2019

You are already at the latest version

Alerts

A peer-reviewed article of this preprint also exists.

This version is not peer-reviewed

Submitted:

10 May 2019

Posted:

13 May 2019

You are already at the latest version

Alerts

Abstract

Wasted Green tuff powder produced by cutting Towada stone is recycled as environmental cleaning material. The optimum temperature for green tuff powder calcination to reduce the hydroxyl radical produced in hydrogen peroxide decomposition with ultraviolet light (UV) and no light. The green tuff calcined at 800 °C shows the large decomposition rate of hydrogen peroxide with no UV light when measured by using ESR. With UV light, the optimum temperature for calcinating the green tuff powder in order to reduce hydroxyl radical is also 800 °C. Next, the powder calcined at 800 °C is used to produce the tile by compression and heating, and then the formaldehyde adsorption rate was measured. The green tuff powder calcined at 800 °C showed a high adsorption rate, similar to that of the activated carbon. The tiles formed at 40 MPa and heated st 1100 °C were the strongest and also adsorbed formaldehyde. The adsorbed formaldehyde on the green tuff tile and powder might have a possibility to decompose by photocatalytic.

Keywords:

Subject: Engineering - Chemical Engineering

Copyright: This open access article is published under a Creative Commons CC BY 4.0 license, which permit the free download, distribution, and reuse, provided that the author and preprint are cited in any reuse.

Solubility and Activation of Hydrogen in the Non-Catalytic Upgrading of Venezuela Orinoco, China Liaohe, and China Fengcheng Atmospheric Residues

Shunfeng Ji

et al.

Processes,

2021

Effect of Absorption Time for the Preparation of Activated Carbon from Wasted Tree Leaves of Quercus alba and Investigating Life Cycle Assessment

Muhammad Amin

et al.

C,

2022

Study on Reduction of Partially Oxidized Cauliflower-like Copper Powder by Hydrogen

Juan An

et al.

Metals,

2022

MDPI Initiatives

Important Links

© 2024 MDPI (Basel, Switzerland) unless otherwise stated