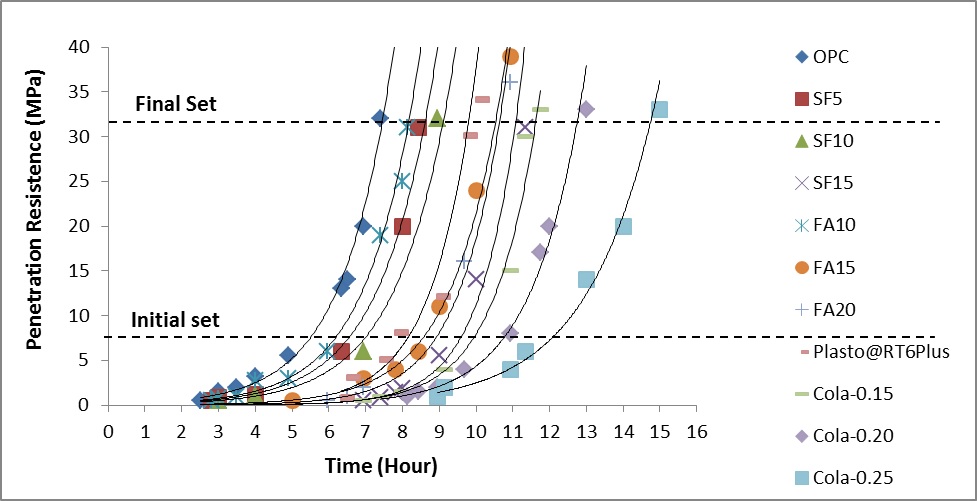

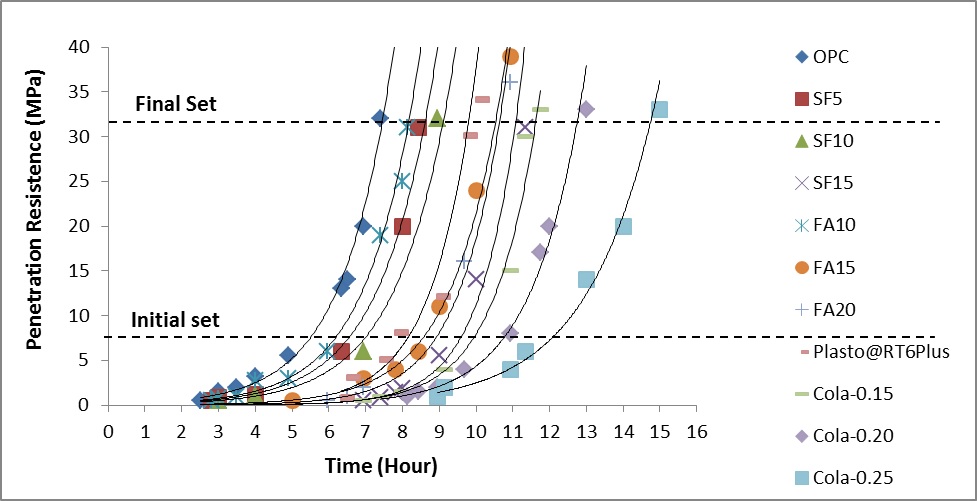

During the casting in a warmer tropical temperature, a setting time delay is required to maintain the workability of the concrete, commonly achieved by the addition of admixtures i.e. silica fume (SF), fly ash (FA), and Plastrocrete®. However, high sugar content Coca-Cola in niche conditions is proposed as an ingredient for delaying concrete setting time in combination with conventional admixtures. This research aims to compare the setting time of admixtures from Coca-Cola and Plastocrete® RT6 plus in concrete mixing with control data of concrete mixed with SF or FA. The second aim is to measure the compression strengths between combinations of Coca-Cola and Plastocrete® RT6 plus. Concretes were produced with admixtures of SF, FA, Plastocrete® RT6plus, or Coca-Cola. The concrete used to control was f'c20 and f'c 25, while other concrete mixes were produced with the addition of Coca-Cola at 0.15% from the weight of cement at variation of moisture treatments. The first method to produce concrete (f'c20+Plas0.23%+Cola0.15% and f'c25+Plas0.23%+Cola0.15%) did not employ water reduction. The second concrete productions (f'c25+Plas0.46%+Cola0.15% and f'c25+Plas0.46%+Cola0.15%) reduced the addition of water at 8.8% (v/w). The first concrete production method had a setting time 44% longer than control. The reduced water concrete in the second productions had a setting time 34% longer than control. Meanwhile, the Plastocrete® RT6 Plus admixture with the reduced water delayed the concrete setting time by 26% longer than control. The delayed setting time of Plastocrete® RT6 Plus admixture with reduction of water was shorter than in the treatment with Coca-Cola. The combination of the addition of Coca-Cola with Plastocrete® RT6 plus by reducing the amount of adding Coca-Cola to 0.10% with Plastocrete® RT6 plus can delay concrete setting time by 51% longer than normal concrete and increase concrete compressive strength by 13% higher than normal concrete. Mixing Coca-Cola with Plastocrete® RT6 plus not only provided an optimal delay effect on setting time but also significantly increase the compressive strength that was desired during the casting in warm tropical weather applied in building construction of Mulawarman University, Samarinda, Indonesia.