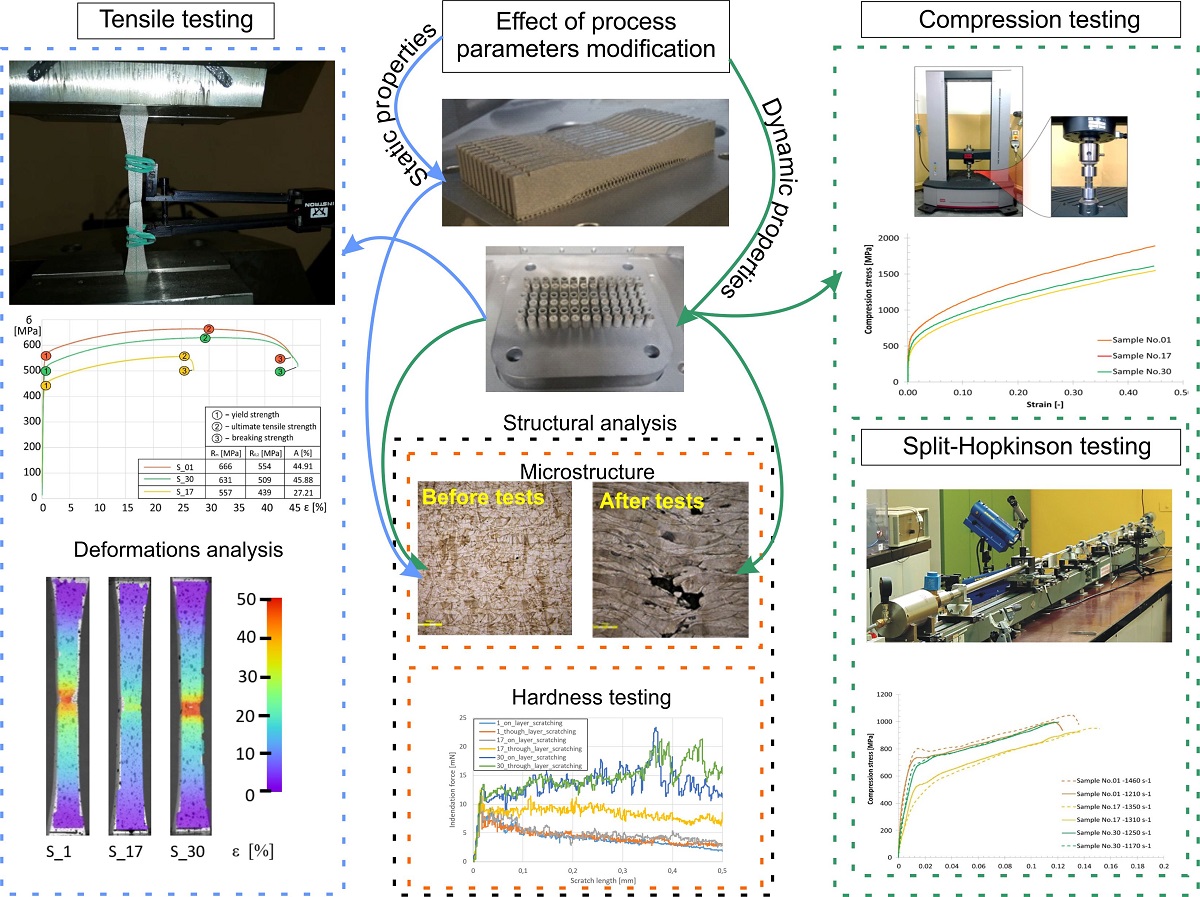

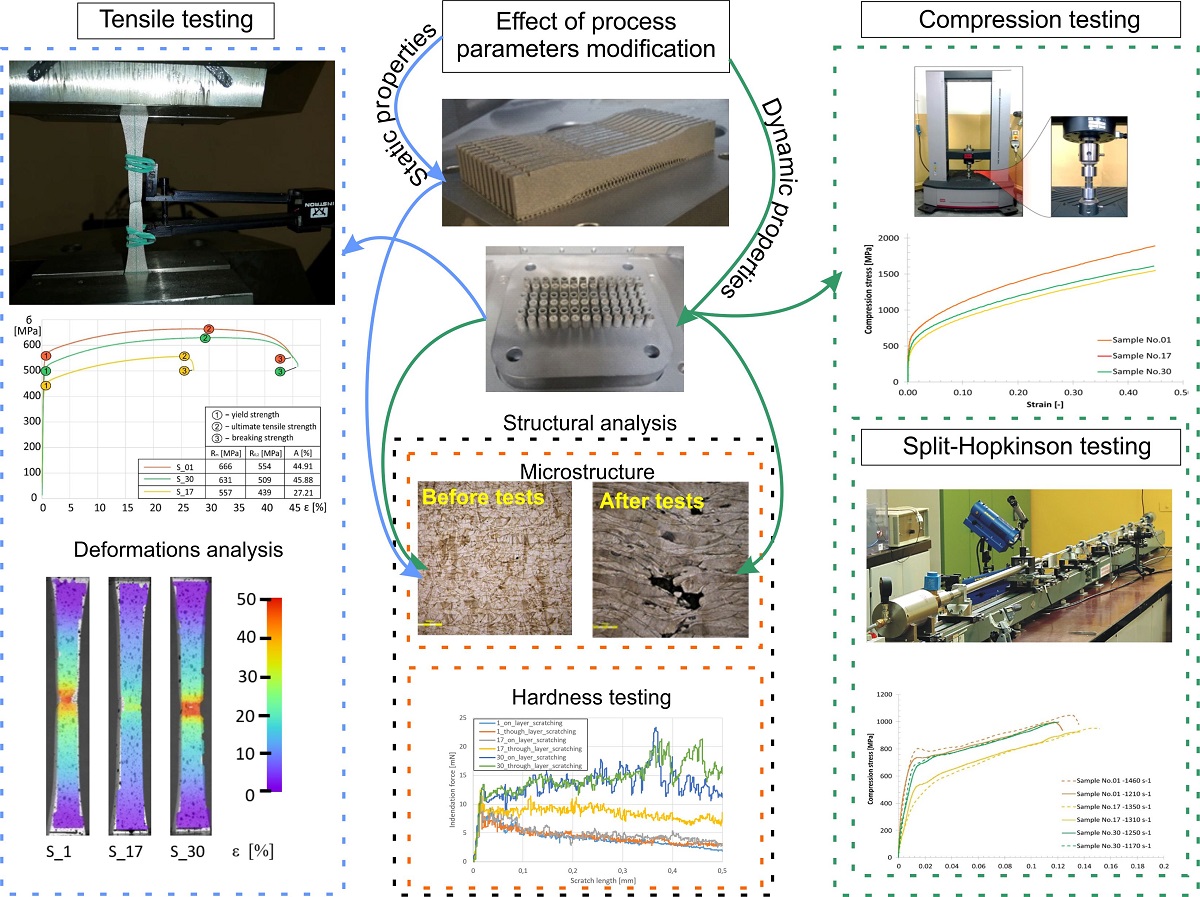

The main aim of this study is to investigate the optimization of the technological process for selective laser melting (SLM) additive manufacturing. The group of process parameters considered was selected from the first-stage parameters identified in preliminary research. Samples manufactured using three different sets of parameter values were subjected to static tensile and compression tests. The samples were also subjected to dynamic Split–Hopkinson tests. To verify the microstructural changes after the dynamic tests, microstructural analyses were conducted. Additionally, the element deformation during the tensile tests was analyzed using digital image correlation (DIC). To analyze the influence of the selected parameters and verify the layered structure of the manufactured elements, sclerometer scratch hardness tests were carried out on each sample. Basing on the research results it was possible to observe the porosity growth mechanism and its influence on the material strength (including static and dynamic tests). Parameters modifications that caused 20% lower energy density, elongation of the elements during tensile testing decreased twice, which was strictly connected with porosity growth. An increase of energy density by almost three times caused a significant reduction of force fluctuations differences between both tested surfaces (parallel and perpendicular to the building platform) during sclerometer hardness testing. That kind of phenomenon had been taken into account in the microstructure investigations before and after dynamic testing where it had been spotted a positive impact on material deformations based on fused material grains formation after SLM processing.