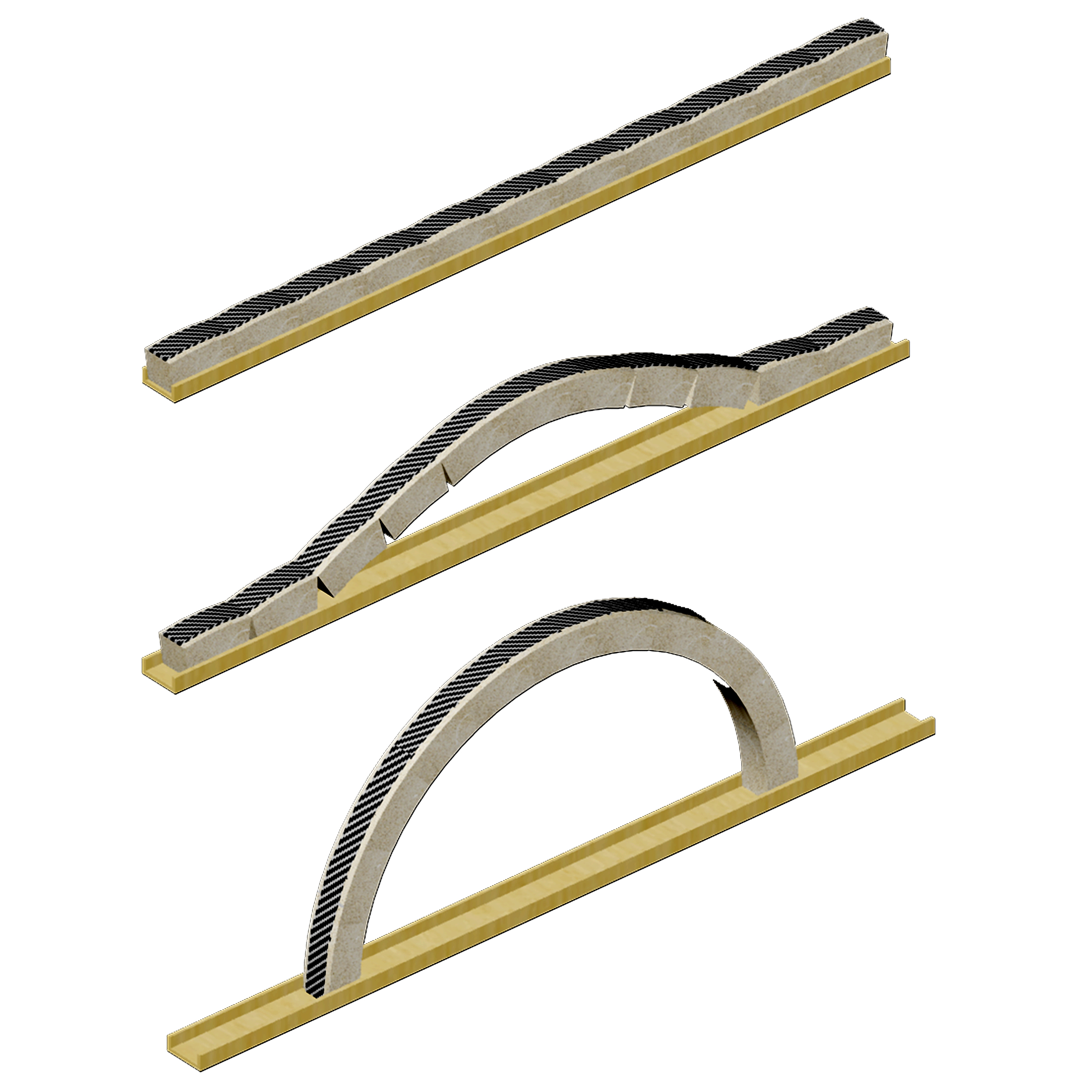

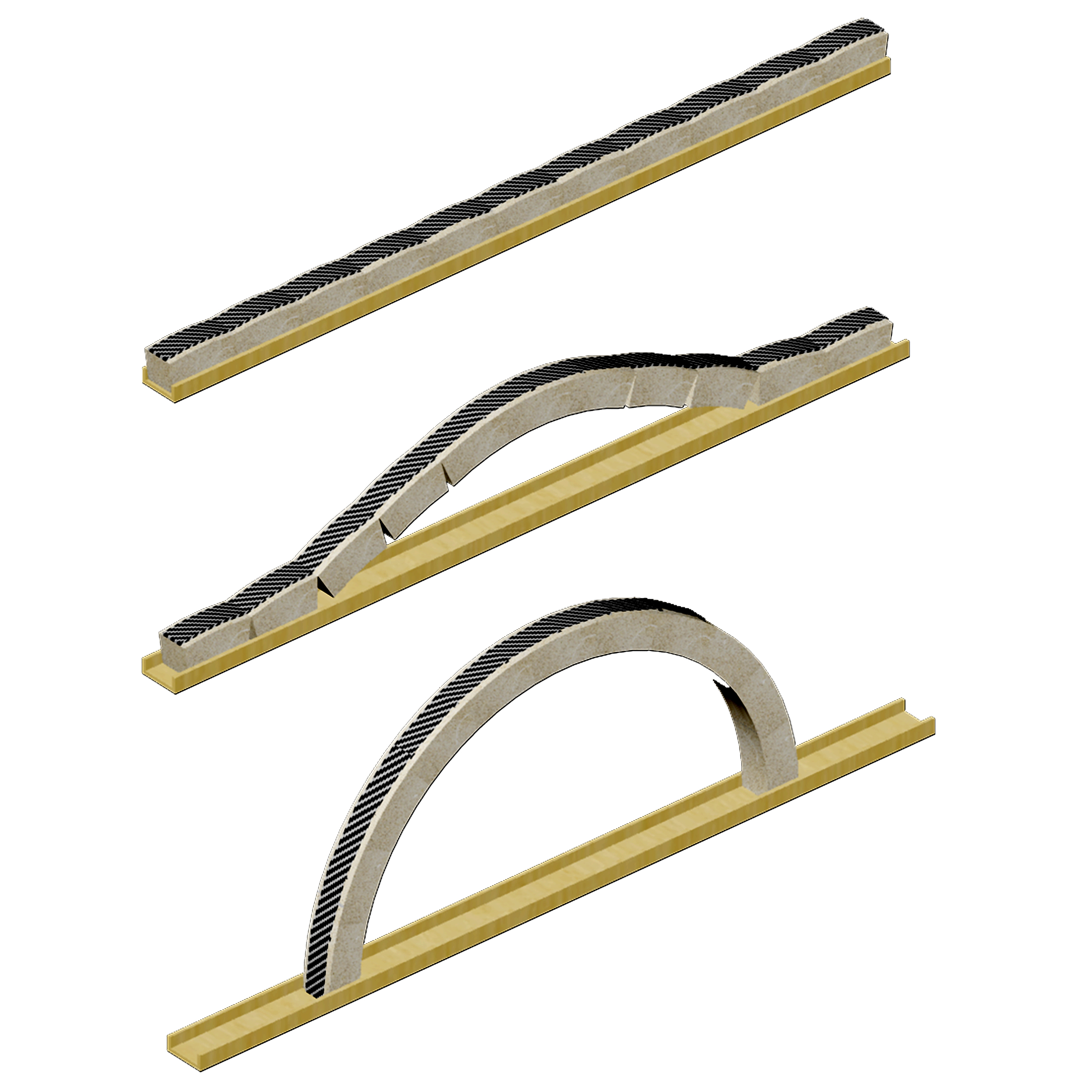

The masonry building Heritage is appreciated for its aesthetic and historical value all around the world. The widespread presence of curved elements, such as arch, vault and dome express the relevant constructive abilities in the different historical epochs. These curved elements are characterized by architectural beauty, structural strength (especially against the gravity loads), thermal comfort and fire resistance. On the other hand, curved structures required scaffolding in order to be erected. The design, the construction and the dismantling of the scaffolds is typically time-consuming and expensive. In addition, the on-site working risk is related to time-interferences (e.g. in manpower working, at the same time, over and under scaffold). This technology dates back to the Era of the Roman Empire and it is currently still used, despite its limitations and disadvantages. In the present paper, an innovative technique (recently patented), aiming for the construction of a curved structural member without scaffolds, is proposed and illustrated. It consists in a Hinged Lifting Arch (HLA), using FRP (Fiber Reinforced Polymer) bonded strips. In details, a series of blocks are cut following an arch geometry and then aligned on the ground-floor in order to bond a composite on their top surface. Moreover, the impregnation of the polymeric adhesive is not allowed at the extremities of each block. The fiber sheet is applied continuously along the entire extrados. In this sense, hinges are introduced, in fact, the FRP-connected blocks are able to easily rotate, in the opposite direction, around the contact ends (i.e. hinge). Finally, the middle block is lifted-up and the arch takes the desiderated shape. In the first experimental demonstration, the natural calcareous stone was used, even if the proposed technique is totally material-independent. Moreover, an analytical model is proposed and discussed for designing the proper aspect ratio of the blocks in order to ensure the full mutual contact when the HLA is totally lifted up. The advantages of the proposed technique are related to the absence of scaffolds and improved seismic strength against horizontal loads thanks to the presence of the FRP, which limits the occurrence of hinges at the extrados.