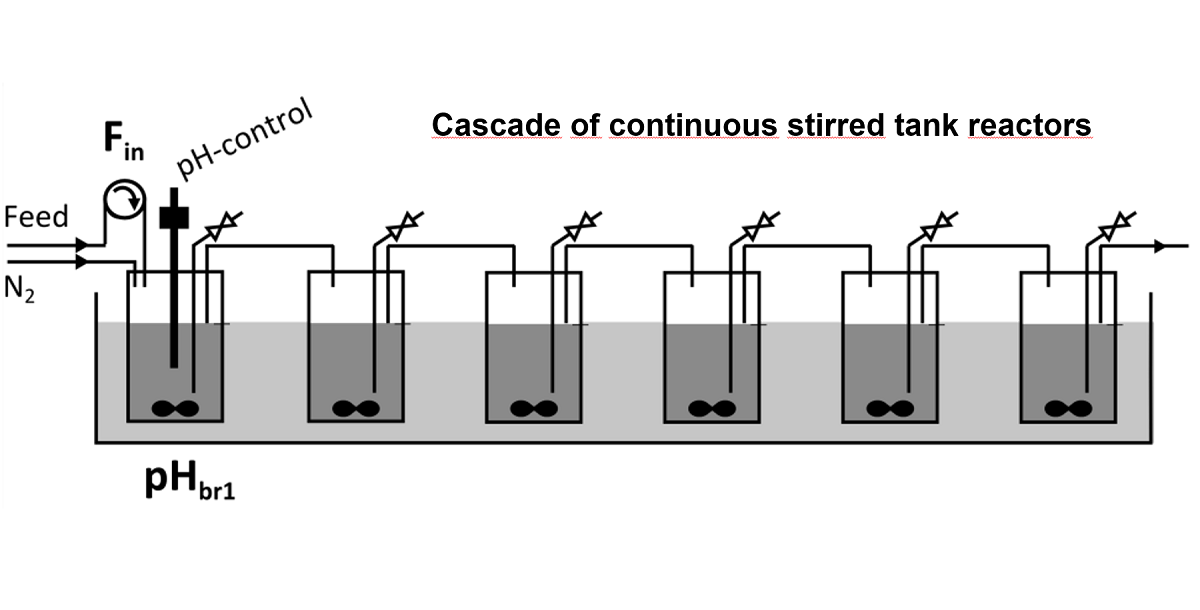

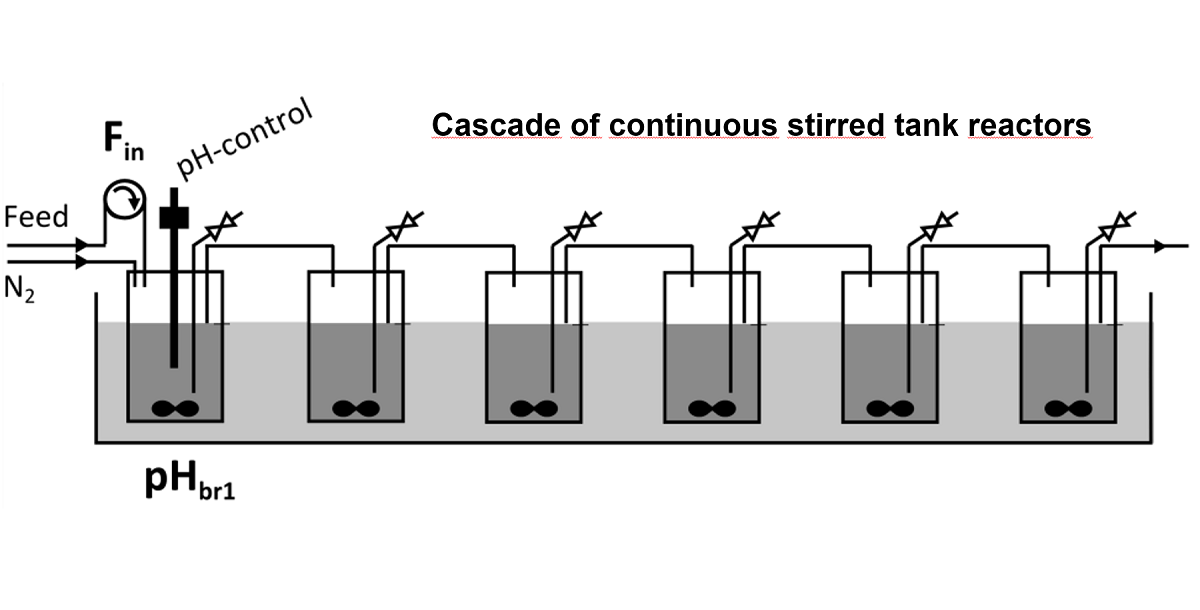

The production of butanol, acetone and ethanol by Clostridium acetobutylicum is a biphasic fer-mentation process. In the first phase the carbohydrate substrate is metabolized to acetic and bu-tyric acid, in the following second phase the product spectrum is shifted towards the economi-cally interesting solvents. Here we present a cascade of six continuous stirred tank reactors (CCSTR), which allows performing the time dependent metabolic phases of an ace-tone-butanol-ethanol (ABE) batch fermentation in a spatial domain. Experimental data of steady states under four operating conditions - with variations of the pH in the first bioreactor between 4.3 and 5.6 as well as the total dilution rate between 0.042 1/h and 0.092 1/h - were used to optimize and validate a corresponding mathematical model. Beyond a residence time distribution representation and substrate, biomass and product kinetics this model also includes the differen-tiation of cells between the metabolic states. Model simulations predict a final butanol product concentration of 8.2 g/L and a butanol productivity of 0.75 g/(L h) in the CCSTR operated at a pH in bioreactor 1 of 4.3 and D = 0.092 1/h, while 31 % of the cells are differentiated to the solventogenic state. Aiming at an enrichment of solvent-producing cells, a feedback loop was introduced into the cascade - sending cells from a later state of the process (bioreactor 4) back to an early stage of the process (bioreactor 2). In agreement with the experimental observations, the model accurately predicted an increase of butanol formation rate in bioreactor stages 2 and 3, resulting in an overall butanol productivity of 0.76 g/(L h) for the feedback loop cascade. The here presented CCSTR and the validated model will serve to investigate further ABE fermentation strategies for a controlled metabolic switch.