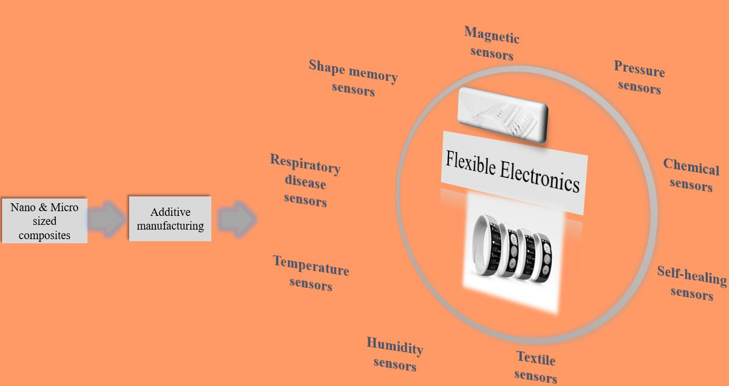

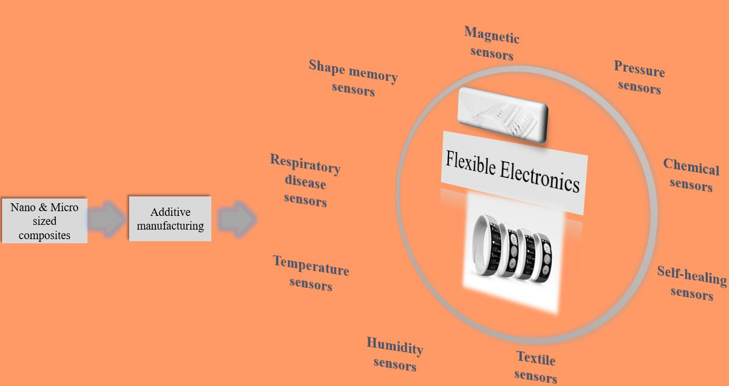

The use of flexible sensors has tripled over the last decade due to the increased demand in various fields including health monitoring, food packaging, electronic skins and soft robotics. Flexible sensors have the ability to be bent and stretched during use and can still maintain their electrical and mechanical properties. This gives them an advantage over rigid sensors that lose their sensitivity when subject to bending. Advancements in 3D printing have enabled the development of tailored flexible sensors. Various additive manufacturing methods are being used to develop these sensors including inkjet printing, aerosol jet printing, fused deposition modelling, direct ink writing, selective laser melting and others. Hydrogels have gained much attention in the literature due to their self-healing and shape transforming. Self-healing enables the sensor to recover from damages such as cracks and cuts incurred during use and this enables the sensor to have a longer operating life and stability. Various polymers are used as substrates on which the sensing conductive material is placed. Polymers including polydimethylsiloxane (PDMS), polyvinyl acetate (PVA), and Kapton are extensively used in flexible sensors. The most widely used nanomaterials in flexible sensors are carbon and silver, however, other nanomaterials such as iron, copper, manganese dioxide and gold are also used to provide controlled levels of conductivity or other functional properties.