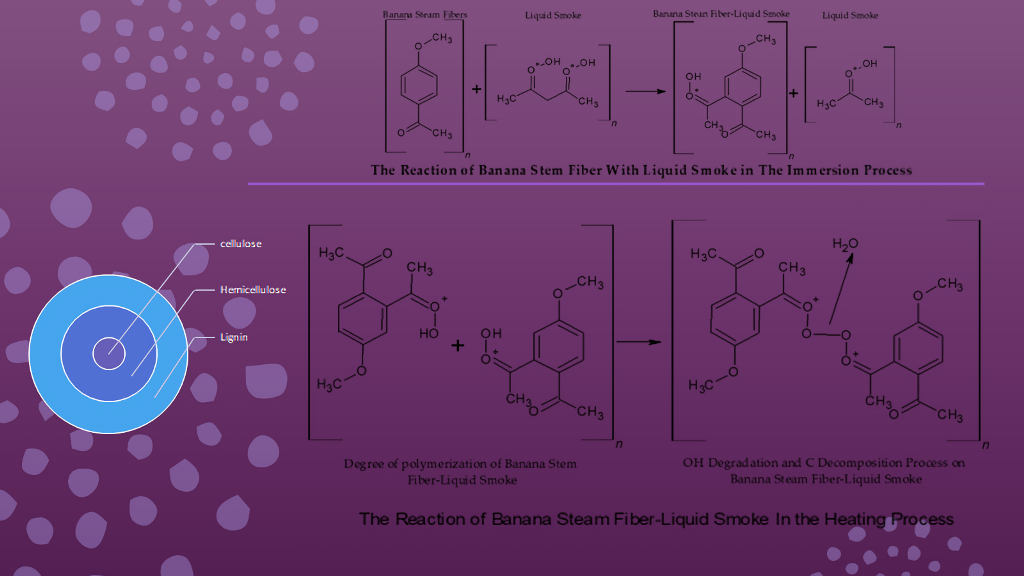

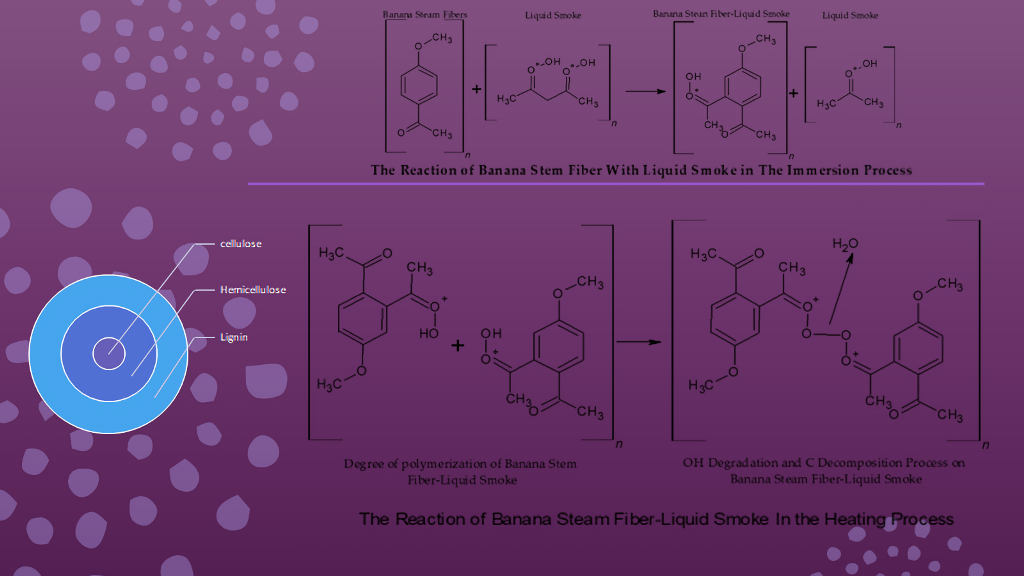

This study aims to investigate the effect of banana stem fibers (BSFs) treatment with liquid smoke on changes in the micro-mechanics properties of BSFs, the tensile strength of single fibers, mor-phology, crystalline properties, and functional groups. The research used four model specimen variations, namely fiber without treatment and immersion in liquid smoke for 1, 2, and 3 hours. The BSFs with treatment was dried in an oven with a temperature of 40ºC for 30 minutes. Several tests were conducted, including a tensile test of single fiber capacity of 50N standard ASTM 3379-02, SEM observation, XRD, and FTIR test. The results showed that the highest increase in fiber strength was P2J, which was 264.21 MPa, and the lowest was TP fiber at 148.54 MPa. Fibers treatment with liquid smoke can form strong C-C elemental bonds caused by the H2O degradation process in BSFs, hence carbon atoms (C) are dense, and in conditions of excessive H2O degradation, the fiber strength will become brittle and the liquid smoke can increase the tensile strength of the fiber. The morphology of the fiber changed where the untreated fiber was covered with lignin, while the treated fiber had an elongated rectangular line pattern, porous, and the lignin was eroded. Crystalline properties in the X-ray diffractogram pattern differ between untreated and treated fibers. At an angle of 2ϴ, the lowest diffraction peak is around 160 in untreated wool, and the highest is 230 in treated fiber. The functional group of the fiber has changed where there is a difference in the wave crest between untreated and treatment fiber. The longer immersion time, the element of Carbon (C) will increase. In conclusion, treating BSFs with liquid smoke can change the physical, mechanical, and chemical properties, hence becoming a choice of composite reinforcement material in the future which is lightweight and environmentally friendly.