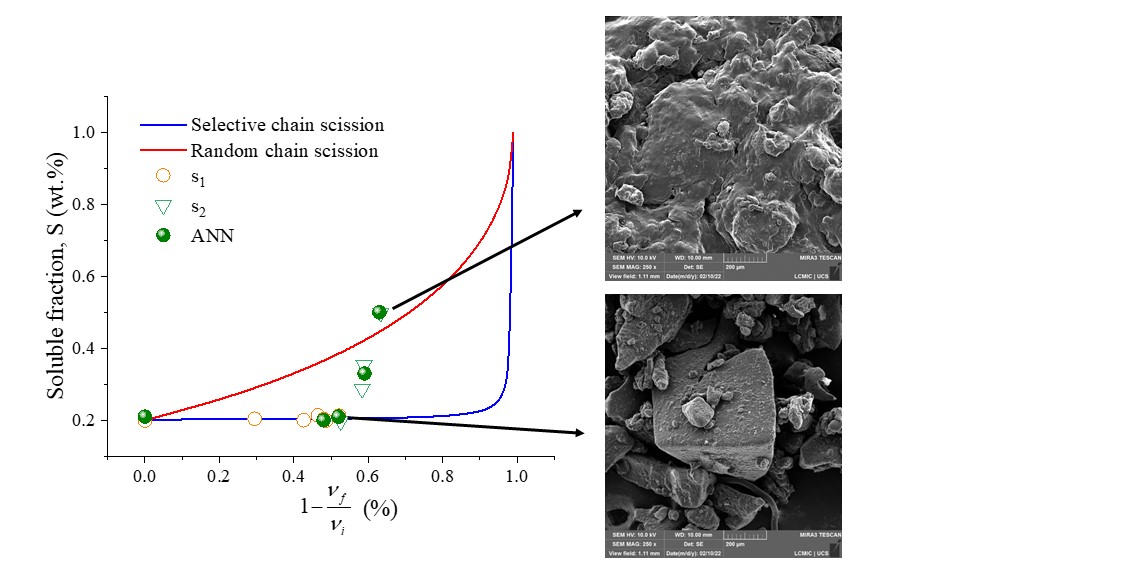

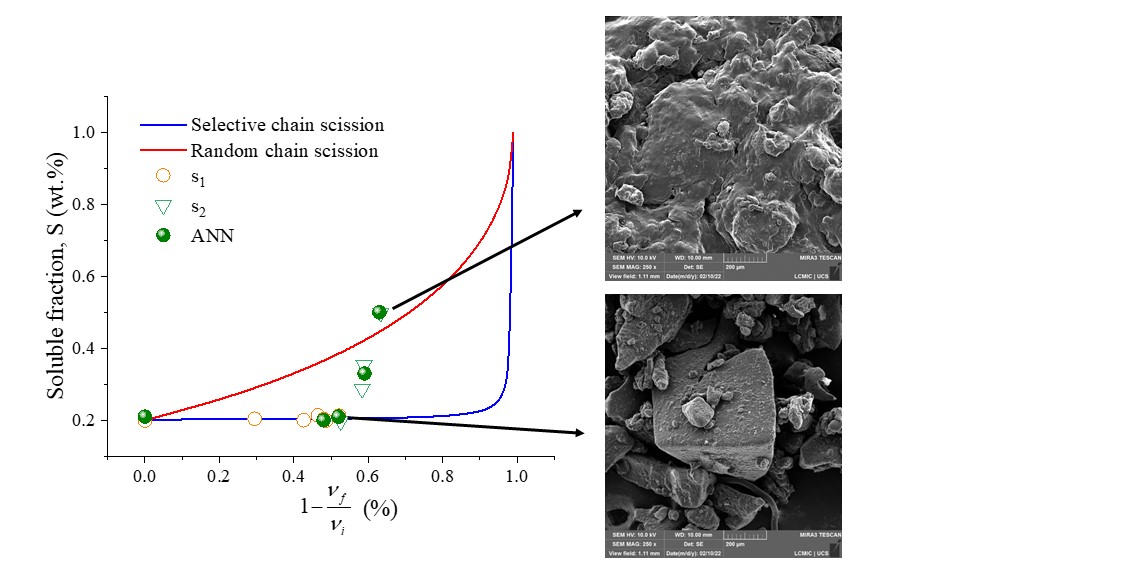

This publication highlights the effect of mechanochemical treatment in a high-speed thermoki-netic mixer as an alternative for recycling ground tire rubber (GTR). The GTR initially has an 80% gelled fraction and presented up to 50% gel fraction in the most intensive condition (5145 rpm, s2). Processing at the lowest speed (2564 rpm, s1) resulted in greater selectivity concerning the mechanochemical treatment (K~1). In the most intense processing condition (10 min. at s2), more significant degradation was observed via random scission with a reduction of the glass transition temperature, Tg (11ºC), an increase of the soluble polymer fraction, and a more signif-icant reduction in crosslink density. The artificial neural network could describe and correlate the thermal degradation profile and processing conditions with the physicochemical characteris-tics of the GTR. The approach presented here represents an alternative for mechanochemical treatment since it can reduce the crosslink density with selectivity and in short times (1-3 min.).