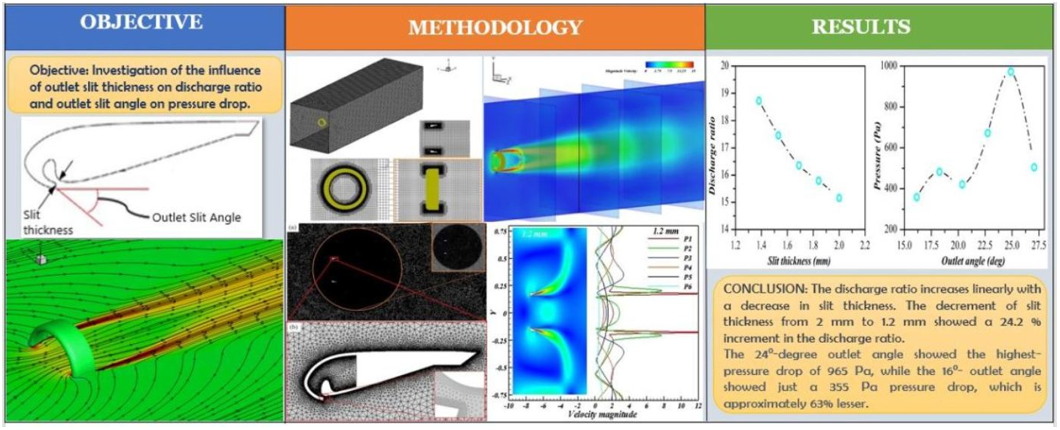

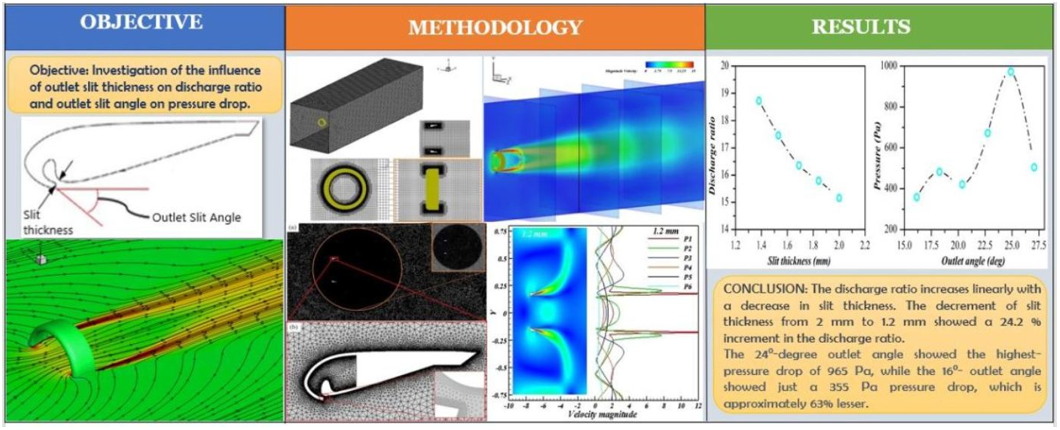

Toshiba devised the bladeless fan (or Air Multiplier) concept in 1981. Researchers like James Dyson and Jafari et al. further developed it. Bladeless fans are more energy-efficient, safer due to the hidden blades, easier to clean, and more adjustable than conventional fans. From a performance point of view, bladeless fans are better because they multiply mass flow rate, eliminate buffeting, consume less power, and are quieter. This paper investigates the influence of the airfoil’s outlet slit thickness on the discharge ratio by varying the outlet slit thickness of an Eppler 473 airfoil from 1.2 mm to 2 mm in intervals of 0.2 mm. Results indicated that smaller slits showed higher discharge ratios. The airfoil with a 1.2 mm slit thickness showed a discharge ratio of 18.78, a 24% increase from the discharge ratio of the 2 mm slit. The effect of outlet angle on the pressure drop across the airfoil was also studied. Outlet angles were varied from 16∘ to 26∘ by an interval of 2∘. The airfoil profile with a 24∘ outlet angle showed a maximum pressure difference of 965 Pa between the slit and leading edge. In contrast, the 16∘ outlet angle showed the least pressure difference of 355 Pa. Parameters such as average velocity, turbulent kinetic energy, the standard deviation of velocity and outlet velocity magnitude was used to assess the performance of airfoil profiles used in bladeless fan.