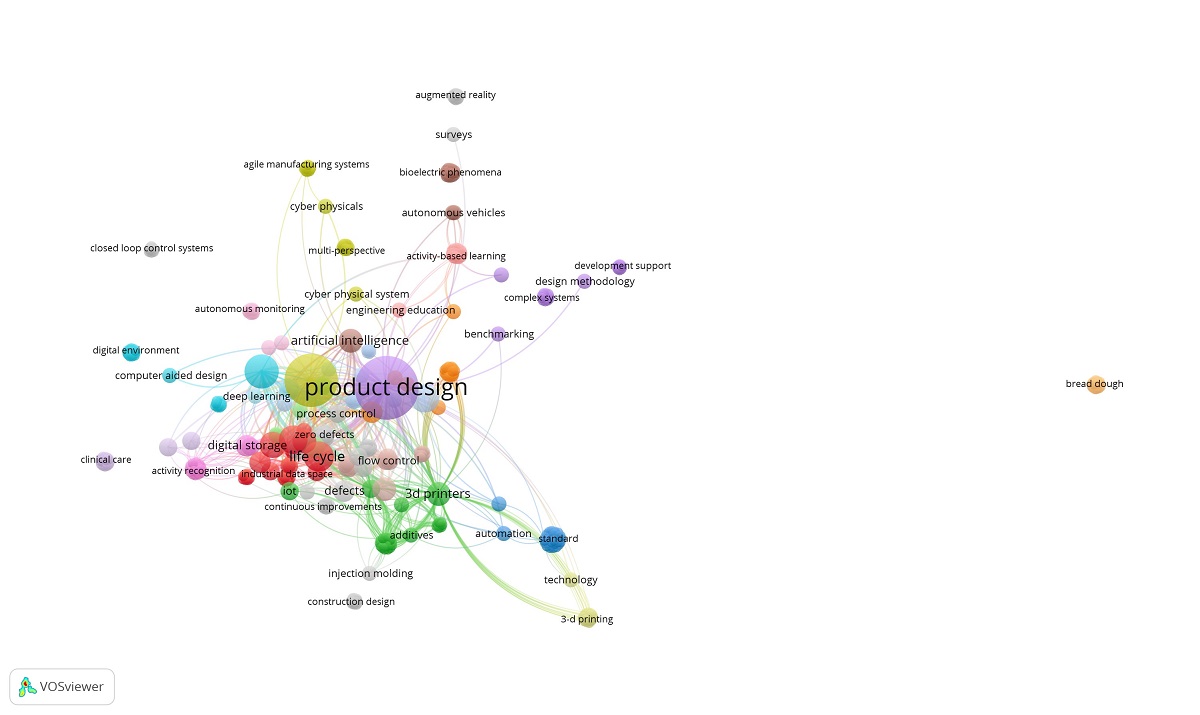

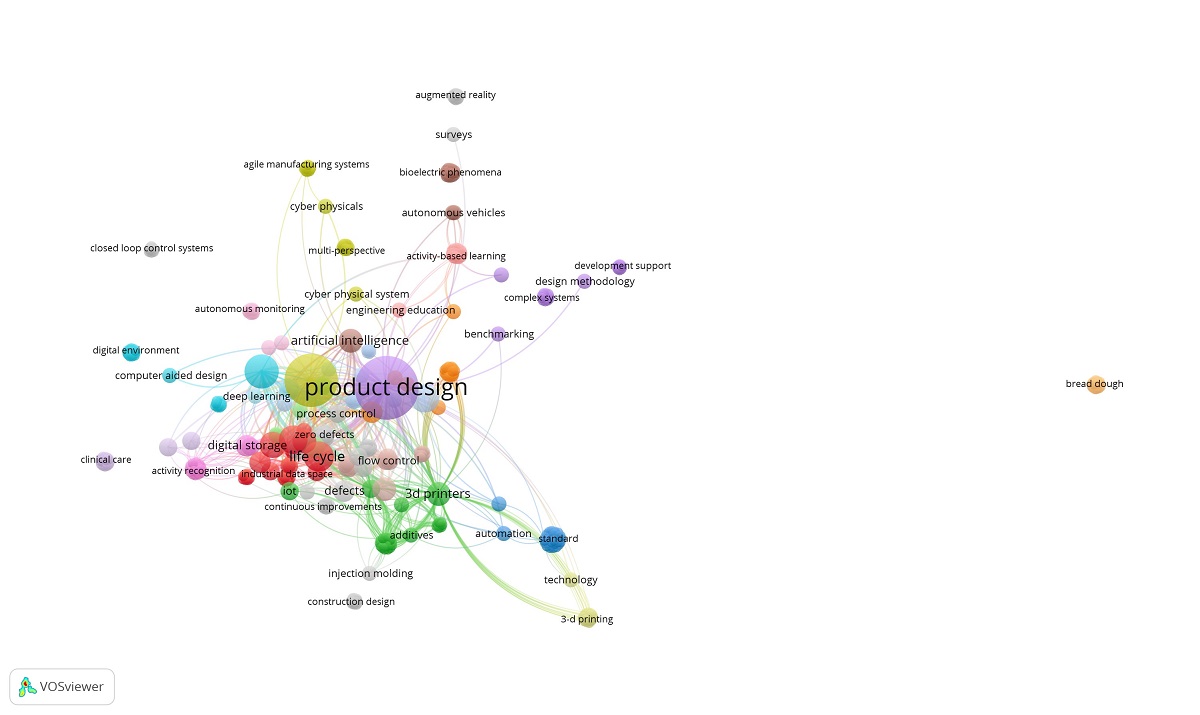

The fourth industrial revolution, also known as Industry 4.0, has led to an increased transition towards automation and reliance on data-driven innovations and strategies. Companies in the manufacturing sector are heavily integrating Industry 4.0 technologies, including cloud compu-ting, cyber-physical systems (CPS), big data analytics, horizontal and vertical system integration, the internet of things (IoT), and additive manufacturing (3d printing). The interconnected systems and processes have significantly increased operational efficiency, enhanced organizational capacity to monitor and control functions, reduced costs, and improved product quality. One significant way that companies have achieved these benefits is by integrating diverse sensor technologies within these innovations, allowing critical data collection on products, equipment performance, and maintenance. The sensors connect systems and machines, allowing them to communicate and track operations for enhanced operations. While numerous research has been conducted to show the role of sensors in industry 4.0, limited studies show how these innovations can leverage product design to maximize benefits and opportunities. Given the rapidly changing market conditions, Industry 4.0 requires new products and business models to ensure companies adjust to the current and future changes. These requirements call for the evolutions in product design processes to accommodate design features and principles applicable in the current dynamic business environment. This research paper employs a systematic bibliometric literature review (LRSB) methodology to explore and synthesize data on how Industry 4.0 and sensors can leverage product design. The results show that various product design features create opportunities to be leveraged to guarantee the success of Industry 4.0 and sensor technologies. However, the research also identifies numerous challenges that undermine the ongoing transition towards intelligent factories and products.