2. Materials and Methods

How to effectively combine these resources into a system? The answer must be sought by analyzing other complex systems. The most important principle of systems theory is the principle of isomorphism of regularities of systems [

5]. According to this principle, a PLM system, as a complex system, must have such regularities of complex systems as emergence, “requisite variety”, hierarchy, historicity, non-linearity, self-organization, two-phase evolution, adaptation, feedbacks (negative and positive or “damping” and “amplification”), self-similarity, openness, memory, and also have a structure similar to them [

4]. Unfortunately, when developing PLM systems, this important principle is not often paid attention to [

3,

4]. Partially, these regularities are used in systems engineering [

6] and systems analysis [

7] techniques. In particular, the regularities of emergence, historicity, “requisite variety” and spontaneous order are noticeable in the systems analysis method “gradual formalization of the decision-making model” [

7]. The authors of the method note that most of projects of complex systems need to be described by a class of self-organizing systems, models of which must be constantly adjusted and developed. The product life cycle should be isomorphic to the life cycle of other complex systems. The work [

4] shows its correspondence to the activity cycle. Methodologists point out the importance of studying the phenomenon of activity: “activity is the only thing that exists from the very beginning, and nature is a certain construction of activity itself” [

8]. The

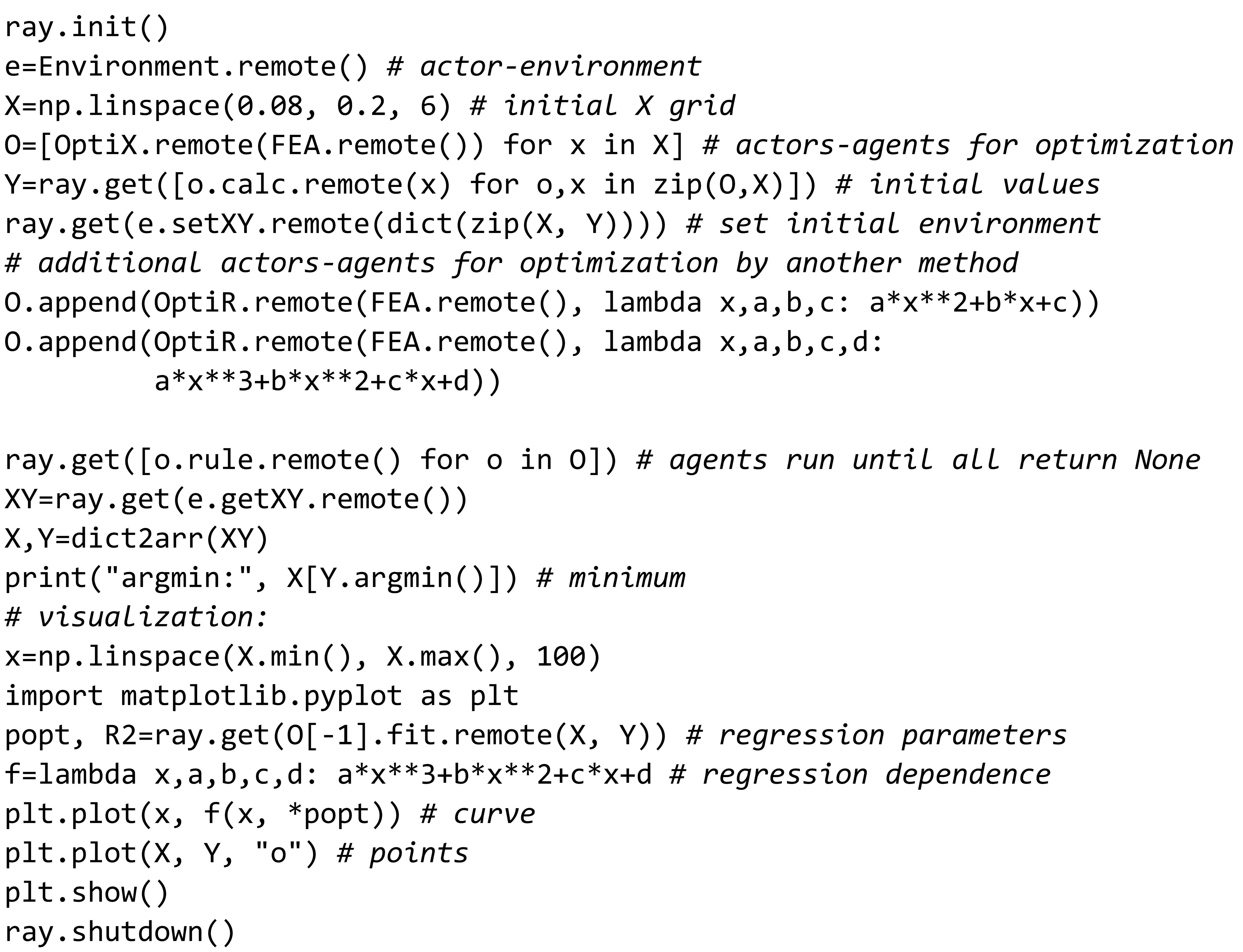

Figure 1 shows the main stages of activities related to PLM [

4].

At the Requirement-Idea stage, the requirements for the product and the idea of quality improvement are formulated, the resources of conceptual design, conceptual modeling (CAID - Computer Aided Industrial Design), heuristic methods, methods of activating the intuition of specialists (MAIS) [

4,

7] are used. The Motive-Analysis stage analyzes these requirements and ideas, typically using methods of formalized representation of systems (MFRS) [

4,

7], and indicates how these requirements and ideas can be implemented. At the Control-Decision stage, final decisions are made and the product is produced. At the Implementation-Evaluation stage, the product is operated with an assessment of its quality relative to its preliminary version. As a result of these assessments, new requirements and ideas for improving the product may arise. That is, several consecutive cycles actually form a helix, where all the turns are similar in structure, but correspond to different levels of product quality - with each turn of the helix, the quality improves and new requirements and ideas are implemented [

4]. According to the regularities of hierarchy and fractality [

5], each stage can be similar in structure to one turn and consist of sub-stages similar to the listed stages, which are also isomorphic to the life cycle, etc. For example, a technological preparation stage could have Requirement-Idea, Motive-Analysis, Control-Decision, Implementation-Evaluation sub-steps, but related to the technological process [

9].

Complex systems such as biological, social or economic systems have life cycles that are driven by evolution and consist of a large number of heterogeneous, decentralized, autonomous and relatively simple elements. A multi-agent approach [

10,

11,

12,

13,

14] can provide such a structure of an information system and create the prerequisites for the emergence of system-wide patterns in it.

Recent PLM solutions such as Siemens PLM Software (UGS), Dassault system software, Oracle/AgileSoft, PTC/ Windchill, SAP/mySAP PLM integrate functions such as Project/Portfolio, CAD/CAM, Product Data Management, Manufacturing Process Management, various types if collaboration, etc. [

3]. Many implementations of multi-agent PLM, among which the ontology-based approach is often used, testify to their effectiveness. In particular, a new approach, based on the ontology, the Semantic Web and the concept of agent, was proposed in [

15]. In [

16] the multi-agent system integrates the problem-solving method 8D, Process Failure Mode and Effect Analysis, Case-Based Reasoning, and PLM. The architecture of the system is based on SEASALT [

17] (Shared Experience using an Agent-based System Architecture LayouT), which is a multi-case base domain-independent reasoning architecture for extracting, analyzing, sharing, and providing experiences. In [

18,

19] the agent technology is used in the solution to support decision-making in the design of recycling-oriented products. In [

20] a knowledge engineering multi-agent module integrated in a PLM-system which is based on a multi-domain scheme (project, product, process and use) taking into consideration several viewpoints (structural, functional, dynamic, etc.). In [

21] a generic multi-agent framework using IoT-based protocol, as the communication medium, for PLM of the products having high collateral damage values and where monitoring and control of systems in real-time are vital, was developed. In [

22] a multi-agent software architecture that allows the capitalization of distributed and heterogeneous knowledge was designed. The research [

23] targets the development of a knowledge engineering multi-agent system integrated into a PLM–environment linked with virtual reality tools. In [

24] a PLM-framework supported by a proactive approach based on intelligent agents was proposed. The work [

25] describes the process and various details of developing the Semantic Object Model into an ontology using OWL-DL. The purpose of the study [

26] is to create, analyze and reuse an ontology-based approach during implementation of a multi-agent system capable of integrating different elements of a distributed control system. In [

27] a multi-agent software system for PLM and logistic support analysis related tasks solving and automation was presented.

Despite the fact that threaded connections seem to be simple products, there is a lot of scientific work related to the problems that appear at different stages of their life cycle, in particular during the design, manufacture and operation [

28,

29,

30,

31,

32]. Specifically for threaded connections of oil and gas equipment, such areas of research as analytical modeling [

33,

34,

35], investigation of manufacturing errors [

36,

37,

38] and corrosion fatigue [

39,

40,

41] are important. Due to the prevalence of such products, we chose an educational PLM-system for threaded connection for research. In [

42], using a systematic approach and the Python language, a PLM-system for threaded connections was developed. However, only design components have been developed and methods for their asynchronous operation have not been proposed.

The purpose of this work is to show, using a simple example, the principles of development, operation and use of a PLM-system with asynchronous agents to maintain the life cycle of a special threaded connection.

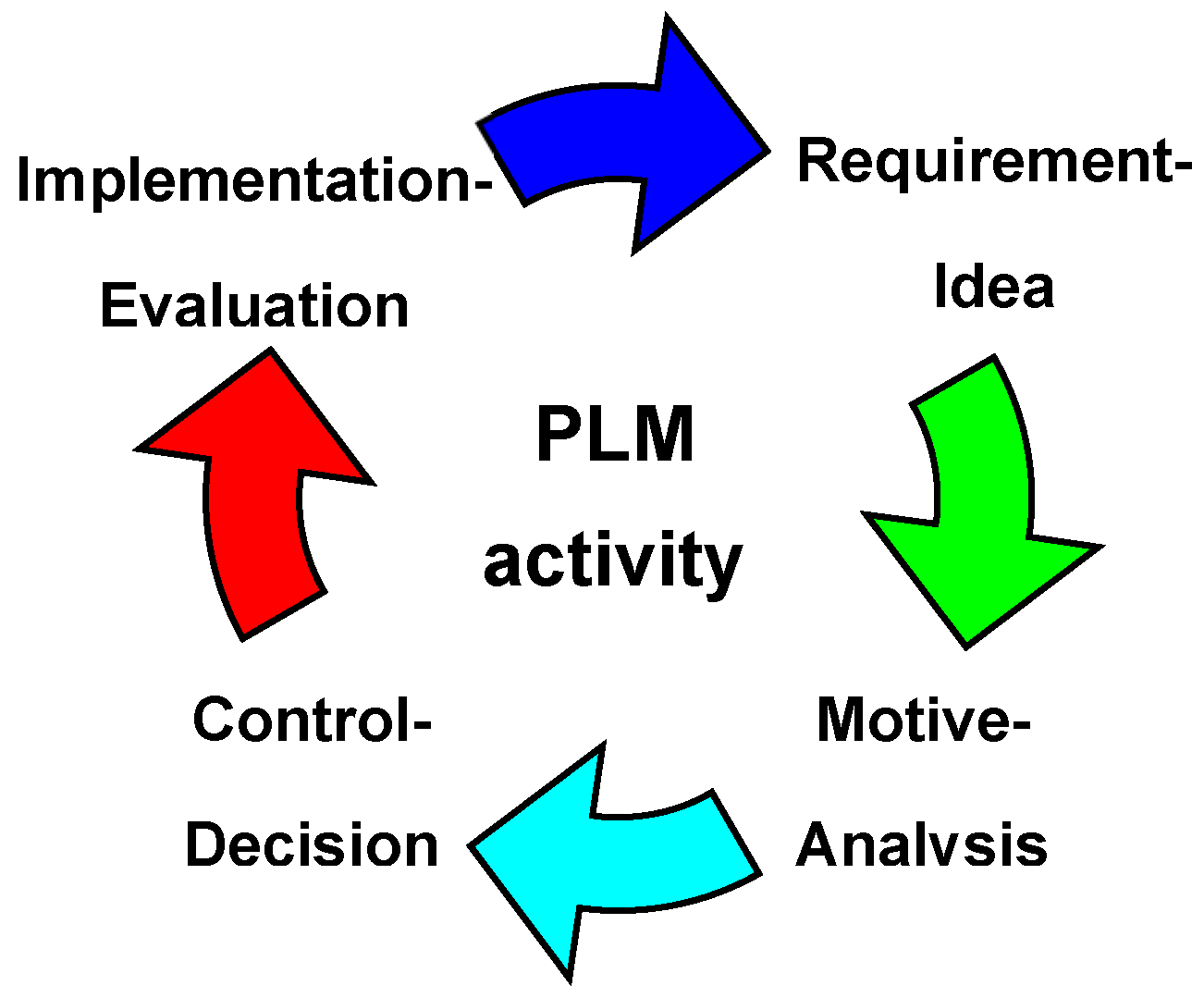

A simple example of a multi-agent PLM system is shown in

Figure 2.

Agents can implement knowledge base facts (facts, product requirements, hypotheses for its improvement), inference rules, inference engine, CAD, FEA, CAM, SCADA components, etc. Hypotheses and rules can be passed to the inference engine for analysis or to obtain new hypotheses, then passed to the “CAD + FEA1” agent for verification by finite element analysis (FEA) of the performability of the product model. If the analysis results confirm the hypothesis, the data is transferred to the “CAM1” agent to prepare the technological process for manufacturing the product. Otherwise, the hypothesis is not confirmed and the relevant facts are updated. Agent “ICS1” (Industrial Control System) manages the manufacturing process. The finished product is subjected to testing or operation, during which the “SCADA1” (Supervisory Control and Data Acquisition) agent monitors the technical condition of the product. Based on the results of monitoring, new requirements and hypotheses may appear, initiating a new turn of the spiral. At any stage of the life cycle, it should be possible to interrupt the cycle and return to the previous stages.

To develop a PLM system, the authors recommend first of all using free software, which is associated with the following advantages: open source, potentially unlimited developer community, intensive development, collaborative development opportunities, user independence from manufacturers, high degree of interoperability and scalability [

43]. In particular, you can use the CalculiX [

44] finite element analysis system, the Gmsh [

45] finite element mesh generator, the OpenModelica [

46] dynamic systems simulation environment, the Python [

47] general-purpose programming language, and the GRBL [

48] CNC machine control software. However, to expand the capabilities of the system, it should also be possible to use commercial programs available via the API. It can be: SOLIDWORKS – 3D CAD/CAE/CAM-system, Abaqus/CAE - finite element analysis system with Python API, fe-safe - fatigue life analysis system, and other software. Ideally, the system architecture should allow agents to be programmed in any language and not depend on the platform, for example, as service-oriented software architecture allows. You should also pay attention to such indicators of software quality as usability, maintainability and performance. Due to the fact that the components should be heterogeneous, decentralized, autonomous and relatively simple, their development should adhere to the well-known concept in a Unix philosophy “Do One Thing And Do It Well”. This concept is related with the regularity of specialization of elements and their “requisite variety”. To develop the components of the PLM educational system and their system integration, the authors used the popular Python language, for which many different packages have been developed. For the PLM system, Python packages can be used: pythonocc [

49] - Python wrapper for the Open CASCADE Technology [

50] geometry kernel, FreeCAD [

51] - 3D CAD, NumPy [

52] - package for N-dimensional arrays, SciPy [

53] - basic library for scientific computing, Matploltlib [

54] - creating 2D diagrams, Sympy [

55] - symbolic mathematics, scikit-learn [

56] - machine learning, Pycalculix [

57] - FEA based on CalculiX and Gmsh, Jupyter [

58] - interactive computing.

The following software versions were used in the work: Python 3.8.9x64, NumPy 1.22.4+mkl, SciPy 1.7.3, Matplotlib 3.5.0, Ray 1.8.0, Pycalculix 1.1.4, Pyserial 3.5, Jupyter Notebook 6.4.6, SymPy 1.10.1, Gmsh-4.8.4-Windows64, CalculiX 2.16.

An important performance problem of the PLM system is to ensure the parallel operation of agents. Ordinary synchronous functions are executed sequentially - before calling the function again, you should wait for the result of the previous call (

Table 1). An asynchronous function can be called without such a wait.

To implement parallelism and asynchronous calls, the actor model and the Ray Python package were used. Ray is an open source package that makes it easy to scale any computationally intensive Python program [

59]. The Ray Core package provides simple primitives for creating parallel and distributed Python programs with minimal code changes - you can easily convert synchronous code to asynchronous by adding the

@ray.remote decorator [

59]. With Ray, the code will run on a single machine and can be easily scaled up to a large cluster [

59]. For the FEA example, the simulation can be lengthy and block the operation of a synchronous system [

42]. But Ray allows you to create an FEA actor class, an instance of an actor, and run it asynchronously with other actors:

This class for finite element simulation uses the mypycalculix module described below.

3. Results

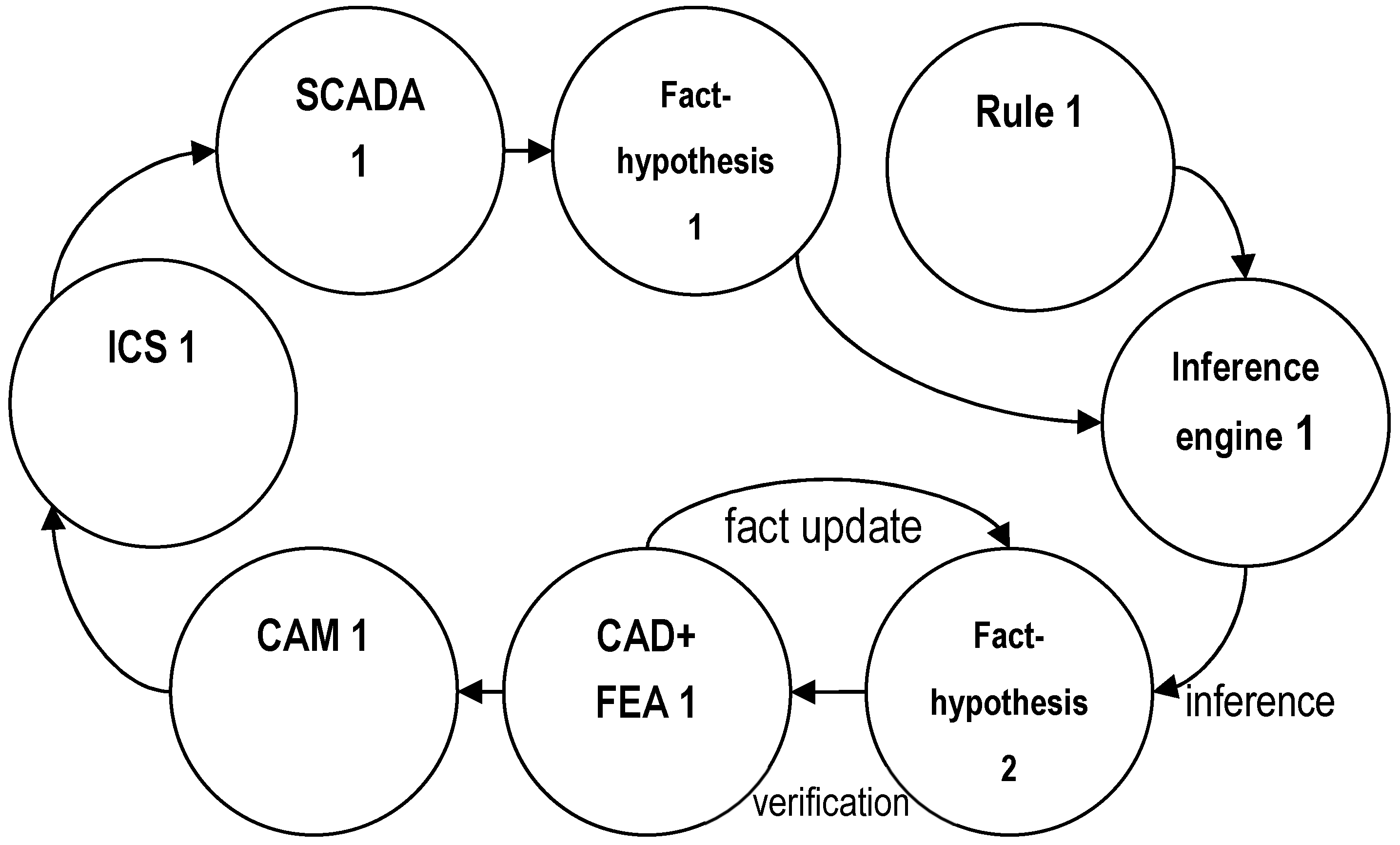

Let's consider an example of an educational PLM-system for threaded connection of plastic parts with special threads (

Figure 3). This product is used for educational purposes only and was chosen due to the ability of the design to optimize parameters and the ability to cut threads with a conventional disc milling cutter on a CNC 3018 Pro 3-axis training milling machine.

The source code of the developed PLM system is available on GitHub [

60]. Each agent of the system is a Ray-actor and has a

rule() function that describes its behavior. This function can take arguments and return results.

The inference engine allows you to derive new facts from existing ones using inference rules, as is done in the CLIPS production rule system [

61]. Facts are represented as triplets (subject, predicate, object) and stored in agents of the

Fact class, whose

rule() function returns a triple. For example, fact “An equivalent stress of 14 MPa occurs in a structure with a dimension

h=0.1 mm” can be represented as a triple

("Seqv=14", "match", "h=0.1"). The inference rules “if

A, then

B” can be written as follows:

A →

B, where

A ,

B are facts. For example, the inference rule (

X,

Y,

Z) → (

Z,

Y,

X) should be read as “If there is a fact (

X,

Y,

Z), then infer a new fact (

Z,

Y,

X)”, and the rule (

X,

Y,

Z) & (

Z,

Y,

W) → (

X,

Y,

W) - “If there is a fact (

X,

Y,

Z) and a fact (

Z,

Y,

W), then infer a new fact (

X,

Y,

W)”. Inference rule agents are created using actor classes (

Rule1,

Rule2), whose

rule() functions search for facts corresponding to facts

A of the rule and return the set of inferred facts

B. The

Reasoner actor class describes the concept of an inference engine. Its rule function runs in parallel (and once) the rules of the inference rule agents, which are passed triplets with facts, and returns a set of triplets with new facts.

The

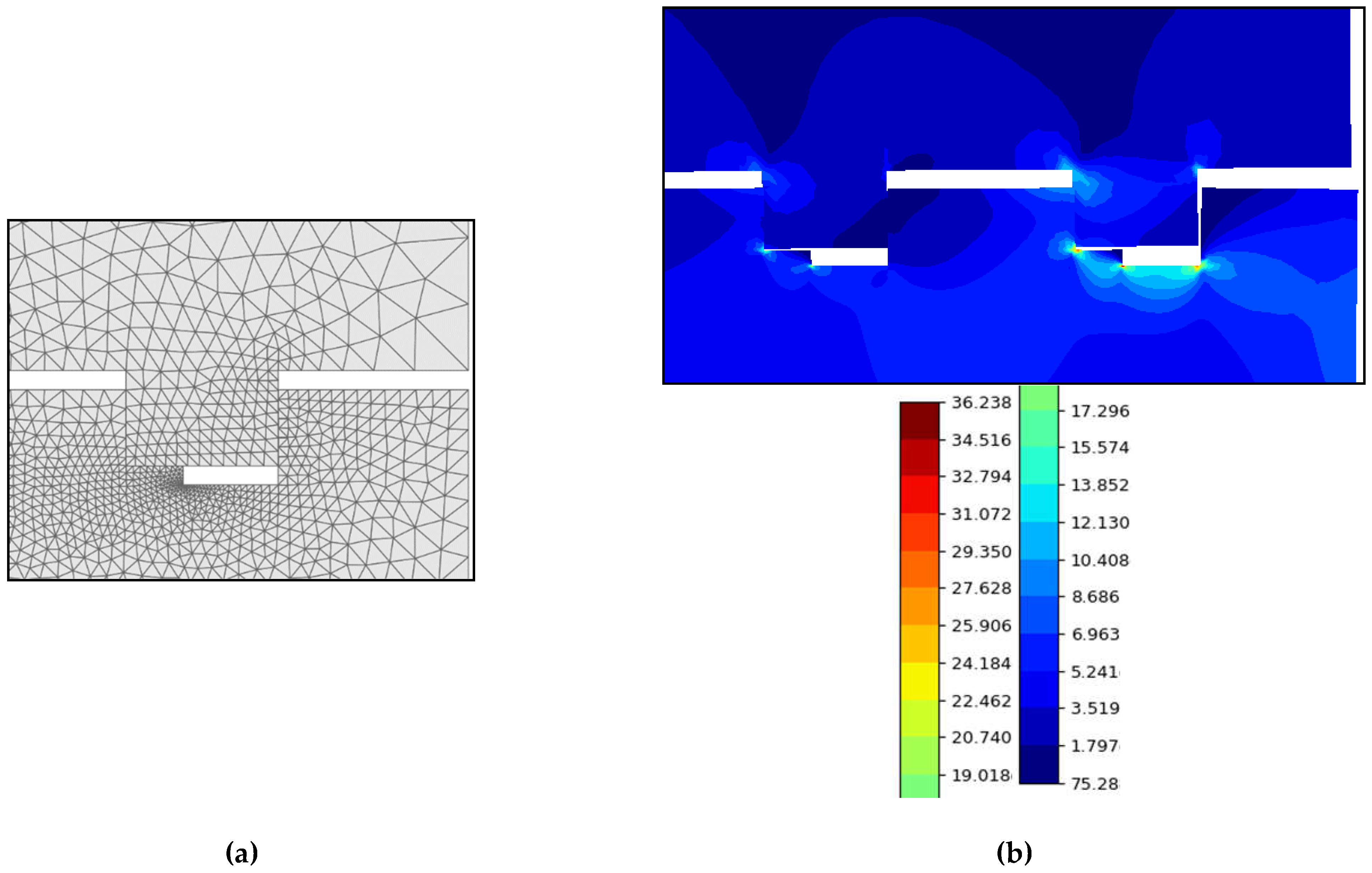

FEA actor class agent simulates the stress-strain state of the connection using an axisymmetric finite element model. The

rule() function takes the value of the connection parameter and returns the maximum stress. It uses the mypycalculix.py [

60] automated FEA module of a threaded connection, which is developed by the authors and in turn uses Pycalculix [

57]. A feature of the Pycalculix package is the ability to easily create parametric models with the ability to automate all stages of model building and create FEA programs for fully automatic parametric studies and design optimization. Before using Pycalculix, you must specify the path to the CalculiX solver (ccx.exe) and Gmsh generator (gmsh.exe) executable files in the file system. The package has the ability to visualize geometry, mesh and results using Matplotlib. The disadvantage of the package is the ability to create only two-dimensional models (planar or axisymmetric).

The mypycalculix.py module builds a geometric model of a threaded connection with given parameters, meshes with Gmsh, generates an input solver file, runs a simulation with the CalculiX solver, and gets the results. The description of a parametric model contains all model parameters with their values. The parametric model is created using Python code in an object-oriented way. In particular, the objects of the geometric model of the part (lines and arcs) are created using Pycalculix functions, which are passed the values of the model parameters:

where

r0,

l,

t1 are model parameters.

It is also possible to import a complex geometric model in DXF format. To facilitate the creation of parametric models, the

findLine() function developed by the authors can be used, which searches for the edges of a geometric model by their various attributes: midpoint coordinates, extreme point coordinates, length, etc. In general, the description of the model is similar to the description of models in other FEA packages: geometry creation, description of the mechanical characteristics of materials, description of surface contact, description of the finite element mesh (

Figure 4(a)), boundary conditions and loads. Instructions for building models, calculating and getting results are located in the run function, and model parameters are global variables. In the case of a parametric study (investigation of the influence of a parameter on stress or strain), the

run() function should be called for various values of the model parameter, saving the results in a list. For example:

Using the

FEA actor, you can perform these tasks in

parallel, which, in the case of a multiprocessor system, will reduce the

computation time:

After receiving the results (stresses or strains), the program can read their values at any node of the mesh or get the maximum values. The results (

Figure 4(b)) correspond to the expected ones - in joints of this type, the greatest stresses occur in the zone of the first turns. Thus, according to the results of the analysis, some elements should be provided in the design that would reduce these stresses.

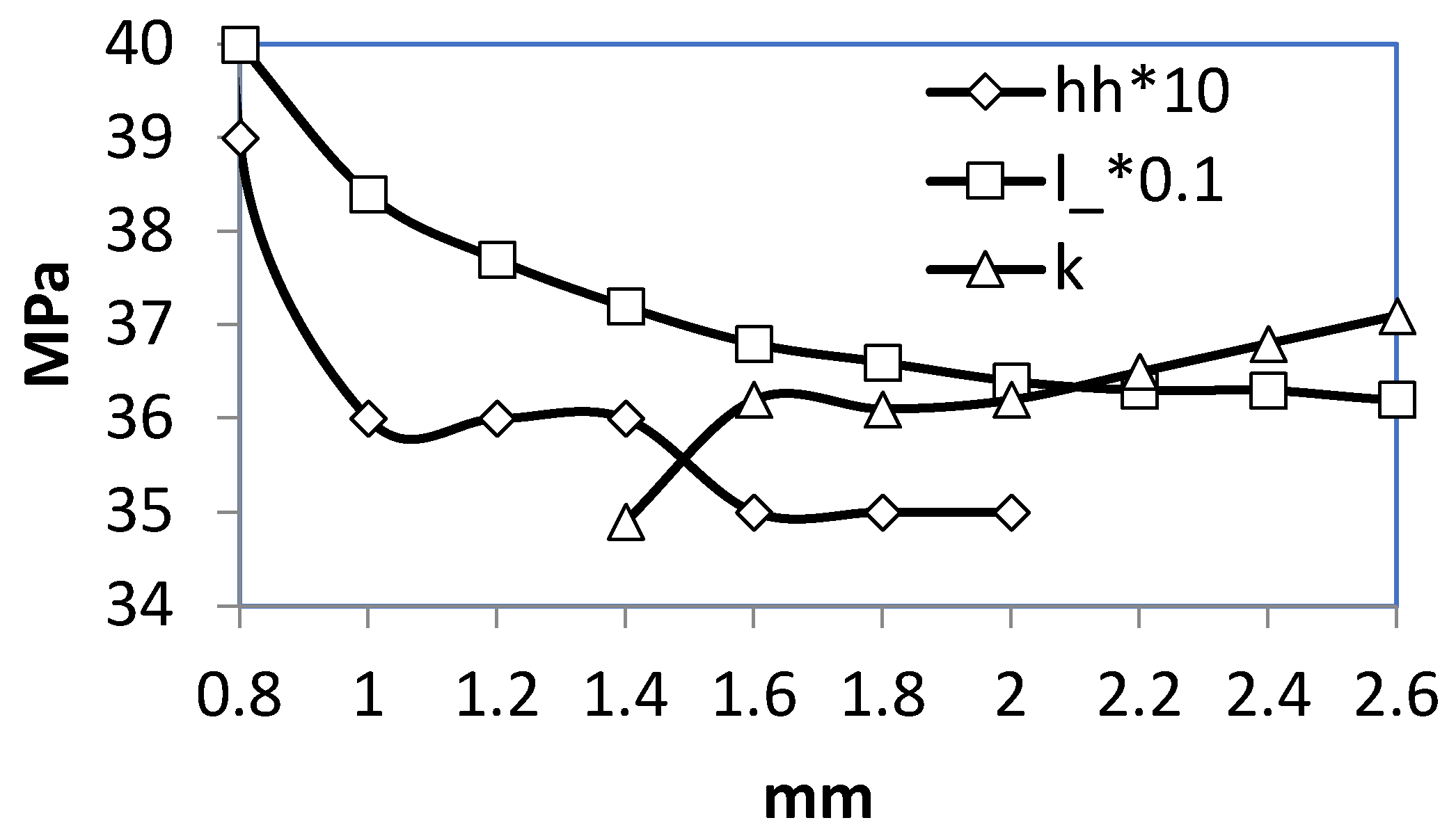

To demonstrate the operation of the module, the dependences of the maximum equivalent stresses in a threaded connection on such parameters as thread length, pitch, and clearance were obtained (

Figure 5). However, the maximum stress in a joint is not always a criterion for its durability, so it is necessary to find the stress value in the most dangerous zones where fatigue cracks may appear, for example, in the zone of the first thread root. In many cases, such dependencies can be easily formalized, including automatically [

42], and get knowledge base facts. For example, from the dependence σ

max(

l_) (

Figure 5) one can get the fact: “an increase in the length of the thread leads to a decrease in the maximum stresses”.

The

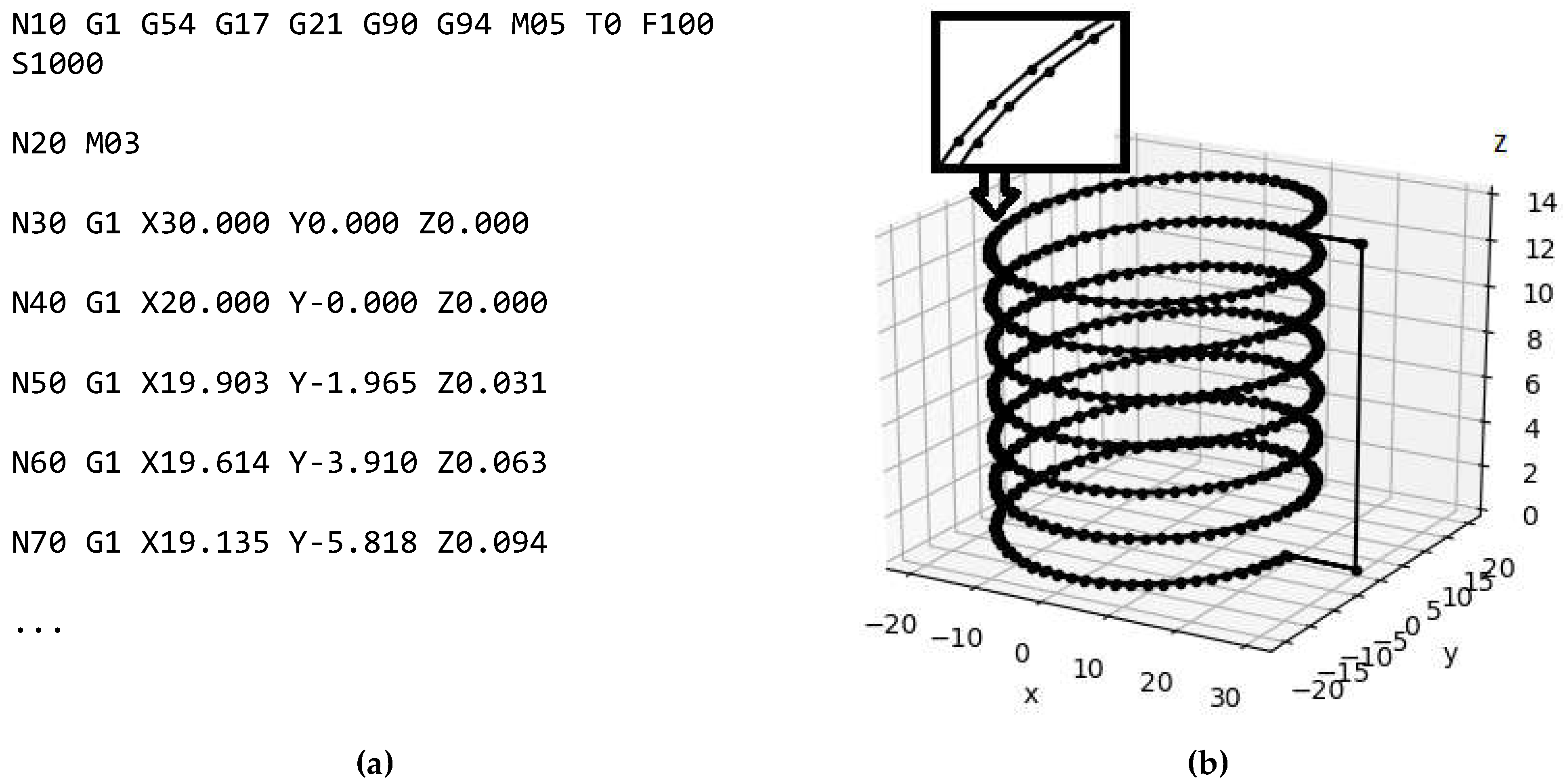

CAM [

60] actor class agent uses the CNC_thread_mill.py [

60] module developed by the authors to generate the G-code for thread milling on a three-axis CNC milling machine (

Figure 6(a)). The

rule() function takes the value of the connection parameter and returns the corresponding list of G-code points (

Figure 6(b)). Milling of taper external and internal threads with multiple passes and an arbitrary thread profile specified by point coordinates in the X-Z plane is supported.

The

helixPoints() function returns a list of helix points [

60]. Its parameters are:

r - minimum radius,

h - height,

p - pitch,

fi - taper angle,

n - number of points on one turn,

z0 - axial displacement. The coordinates of the points are determined by the parametric helix equation.

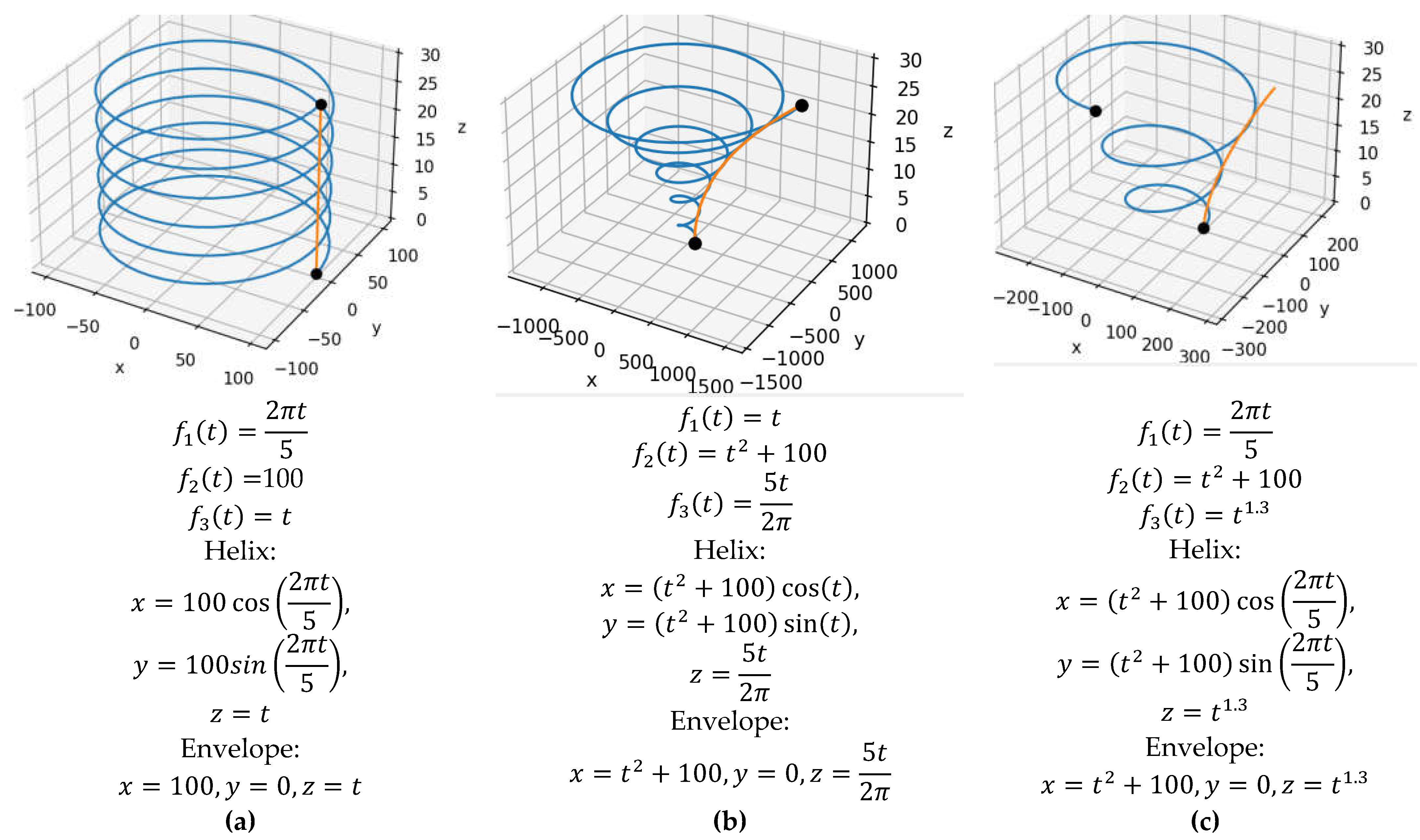

The

helixPoints2() function has also been developed, which also returns helix points, but allows you to build more complex and varied helixes. The function uses the SymPy symbolic mathematics package to construct a parametric helix equation by sequential transformations of a point object in the space [

62].

For example, a point object is described by a position vector

and there is a rotation path transformation around the z-axis

where

– arbitrary function. Then the position vector

describes a circle in the

xy plane. The

x and

y scaling transformation looks like this

and the

z translation transformation like this

Here

and

– arbitrary functions. If the

P vector describes not a point, but a curve, then by such transformations one can also obtain the equation of helical surfaces [

62].

The developed

helixPoints2() function uses the following transformations

However, the user can easily modify its code to apply additional transformations. If the user defines different functions

,

and

, this allows different helixes to be obtained. Some of these helixes are shown in the

Figure 7. Along with helixes, their planar envelope curves obtained using SymPy are shown.

Figure 7(a) shows a cylindrical helix with a radius of 100 and a pitch of 5, in the

Figure 7(b) the helix has a parabolic envelope, an initial radius of 100 and a pitch of 5, in the

Figure 7(c) the helix is different in that it has a variable pitch.

The parameters of the

helixPoints2() function are the strings

f1,

f2,

f3, which define the functions

,

, , the helix height

h

and the number of points on the helix

num.

By solving the equation

z(

t)=

h, the algorithm determines

the maximum value of the

t parameter and generates a list of points. An

example of using this function:

Functions

can even be piecewise-defined, which greatly increases the set of different types of curves that can be built. For example the function

allows you to create a helix with different pitches - the second part of the curve will have twice the pitch of the first. Then the

f3 parameter in the Python code should be like this

"Piecewise((t, t <= 10), (2*t-10, t > 10))".

The function can be used at the design stage of a threaded connection to create different types of thread helixes. The user can build a morphological matrix in which there are various combinations of , , , and then select the most promising options or transfer all elements of the matrix to CAD / FEA agents to identify the best options according to stress and strain criteria. Thus, the developed function complies with the principle of «requisite variety» in the threaded connection design subsystem.

The TreadMulti() function uses helixPoints() and returns a list of points for thread milling in multiple passes. Its parameters are: h – thread length (should be a multiple of pitch p), p – pitch, fi – taper angle, n – number of points on one turn, R, Z – lists with radii (x-coordinate) and z-coordinate of the first points helical lines. In other words, R and Z contain the x- and z-coordinates of the profile points. For one pass R=[r], Z=[0], where r is the minimum thread radius.

The

Gcode() function returns a G-code from a list of points. The

plotCNC() function plots points using Matplotlib. An example of code generation for thread milling in two passes (

Figure 6):

The module supports threading on CNC systems that do not have tool radius compensation and circular interpolation. Using Python Streaming Scripts [

63], the G-code is transmitted via a serial port to the GRBL program that controls the machine. There is the possibility of organizing a flexible manufacturing system that combines a CNC-machine with an industrial robot designed to install and remove a workpiece [

64]. A CNC 3018 Pro educational machine equipped with a control board supporting GRBL software was used. An Arduino Uno can be used as such a board. The workpiece 1 (

Figure 8) is installed on the table 3 on the cylindrical pin 4 and fixed with a bolt 2, a washer 5 and a nut 6. The thread is cut with a disc milling cutter 7 in several passes. You can use the free application Candle [

65] to set up the machine.

A

SCADA actor class agent is also proposed for monitoring the technical condition of a threaded connection at the testing or operation stage. Its rule function receives the value of the connection parameter and returns the dependence of the deformations on the running time. The agent uses a schema based on example from Proteus CAD «Arduino HX711 SparkFun Breakout Board with 200kg Load Cell» [

66]. Strain monitoring is done using an Arduino UNO board, an HX711 chip (24-bit ADC with strain gauge amplifier) and a strain gauge glued to the threaded connection. The Arduino sketch sends the results via a serial port using

pyserial package (

Table 2) to the HX711proteus_client.py module, which developed by the authors and associated with the agent. The results can be analyzed, compared with the previous ones and new facts can be obtained.

To demonstrate an example of using the PLM system, the authors developed an interactive document Jupyter Notebook [

60]. The document contains cells with Python code, cells with formatted text generated by the Markdown markup language, and execution results in the form of text and charts. Ray is initialized first. In this example, the resources of one computer are used for calculations, but a cluster can also be used. Next, the actor classes described above (

Fact,

Rule1,

Rule2,

Reasoner,

FEA,

CAM,

SCADA) and their actor objects (agents) that can work asynchronously are created.

In this case, the facts f1, f2, f3 are represented, containing the correspondence between the values of the input and output parameters of the threaded connection model: the geometric parameter h (mm), the maximum equivalent stress in the thread Seqv (MPa) and the maximum total displacement utot (mm). These facts can be obtained as a result of modeling, experiments, industrial data at the preliminary stages of the life cycle. The inference rules r1 and r2 are for the “match” property, which is symmetric, i.e. (1, match, 3) -> (3, match, 1), and transitive, i.e. (1, match, 3) & (3, match, 4) -> (1, match, 4).

Each agent works autonomously, receives input and returns results. The agent may return

None, which means no new results. The automatic operation of the system can be organized using a simple algorithm: while there are changes in the system, call the

rule() function of each agent. If all agents return

None, then automatic operation of the PLM system is terminated. For example, logical inference is implemented using a naive forward chaining algorithm: call the Reasoner agent's

rule() function while new facts are inferred.

As a result, the set of knowledge base facts is supplemented by the following:

Further in the document, a threaded connection variant is simulated using the

FEA agent. Using the

fea1 agent, a threaded connection with the

h=0.1 mm parameter (gap in the thread) is simulated. We wait results.

But all agents have the ability to run the simulation asynchronously, i.e. ro=fea1.rule.remote(0.1), and get the result in the cells below, i.e. y1=ray.get(ro).

The calculated maximum values of equivalent stresses and the distribution of strains and stresses in the thread are displayed (

Figure 4). G-code generation for milling an external thread variant (

h=0.1) is done using the CAM agent.

The coordinates of the first points of the generated trajectory and the plot of the trajectory are displayed using Matplotlib (

Figure 6(b)). With the help of a SCADA agent, the technical condition of a threaded connection variant (

h=0.1) is monitored during operation.

The following commands should be run when

scada1.rule() has completed. A graph of the dependence of deformations on the operating time is displayed.

At any stage of the life cycle, you can access the desired cells, edit the code and get the results. The user can enter new data, change the model or parameter value, create new agents, and restart the system. Thus, at each iteration step, new knowledge appears and the system evolves, like the product itself. Thus, the multi-agent system works interactively with user interaction.

However, agents for optimization calculations have also been developed that can work autonomously. The

Opti base class of agents for optimization has an

f attribute which is the object of optimization and must be a function or

ray.actor.ActorHandle. The attribute-function

calc() calculates the value of

f(x) using the

FEA agent. The class also contains the attribute-function

find(), which receives an

XY dictionary of arguments and values of the function, and by analyzing these values using a special algorithm, returns the hypothesis of the argument

x of the minimum. The attribute-function

rule() describes the rule of the agent's behavior in the environment of X and Y values. For all optimization agents, this function has the same implementation with the following general algorithm:

The loop continuation condition is a condition for the continuation of optimization calculations. It may be different. For example like this:

where SD is the standard deviation,

i is the index of the minimum value in the

Y array. In Python, this condition can be written as

Y[i-2:i+3].std()>0.01. But the restriction on the length of

XY (

len(XY)<20) is better to apply in case of a certain time limit for optimization calculations.

The

OptiX class inherits from

Opti and is designed to find the minimum using the grid-stochastic method. It differs from

Opti only in the

find() function. In this case, its algorithm is as follows:

This method is a combined global optimization method requiring an initial grid of x values with a desirably uniform step. At each step, finds x that is the same distance from the optimal value (found at the previous iteration) and neighbors to the right or left (random choice). In order not to get stuck in a local minimum, the algorithm provides for a random choice of x according to a given distribution law, the parameters of which can be changed.

The

OptiR class inherits from

Opti and is designed to find the minimum by building a regression model of the

XY data. The

F attribute is a function of the model, such as a second or third degree polynomial. The

fit() function uses the method of least squares to find the best

XY data model and returns the value of its coefficients and the coefficient of determination

R2. The

find() function finds the minimum of this model using a grid method with a sufficiently fine grid. This algorithm is deterministic, without stochastic elements, so it is the opposite of the

find() algorithm of the

OptiX class. The simultaneous use of these methods can provide a synergy effect and reduce the duration of calculations. In addition, not only agents of opposite optimization classes should be used, but also a set of agents of the same class with different parameters. As required by the “requisite variety” regularity. Advanced optimization algorithms, like basin-hopping [

67] or differential evolution [

68], often combine opposing methods.

The Environment class describes the environment of optimization agents and contains an XY dictionary in which the keys are the function arguments and the values are the function values. The getXY() and setXY() functions are for reading and writing the XY attribute. The setxy() function writes an (x, y) pair to an XY dictionary. If the place is already reserved, then the function only returns False.

The dict2arr() function is designed to convert an XY dictionary into NumPy arrays X and Y with values sorted by X. To test classes, you can use the f(x) test function to simulate long calculations using time.sleep. To do this, we need to modify the rule() function in the FEA class so that the s variable is assigned the value of f(x).

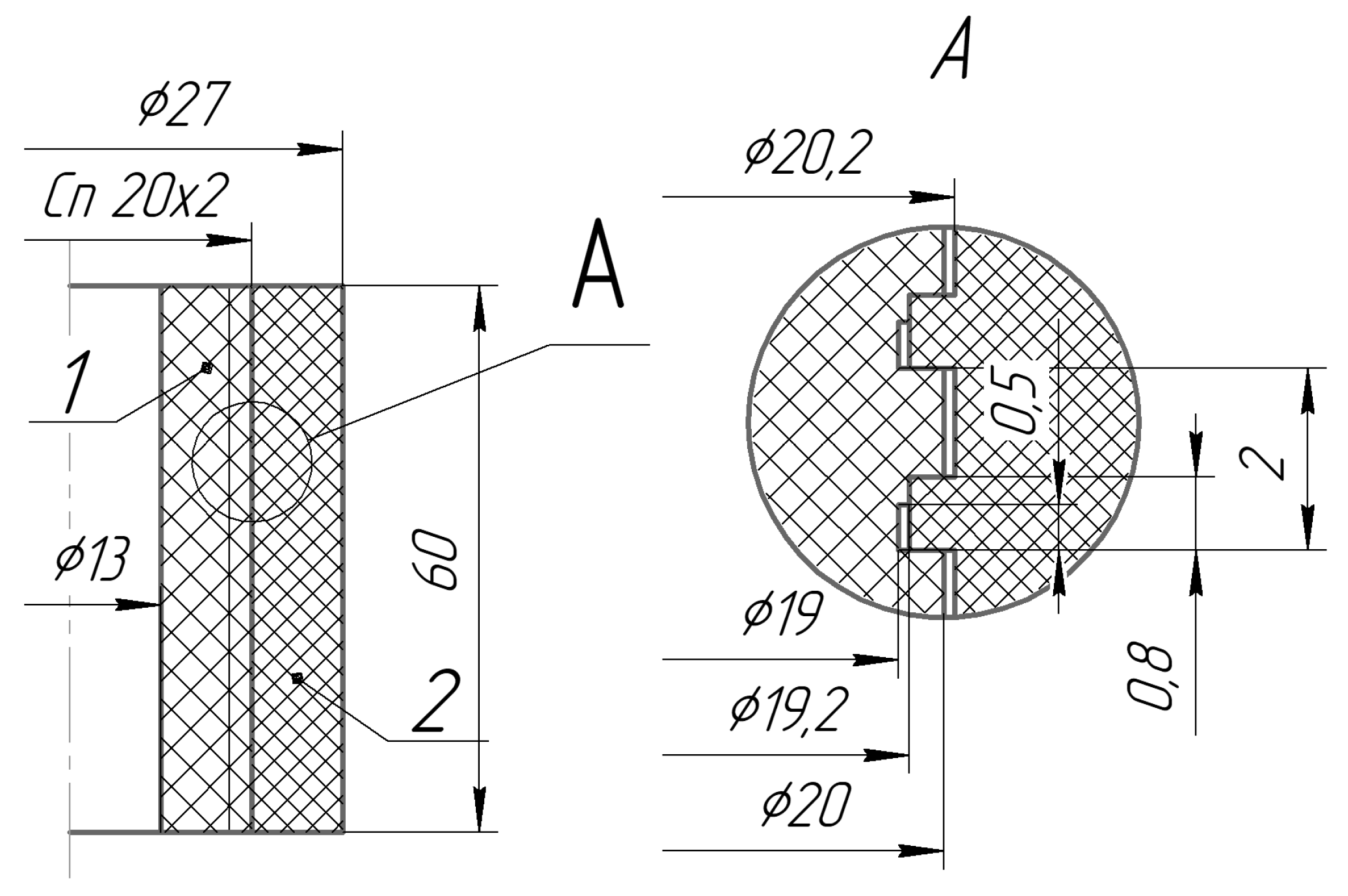

Let's consider an example of using these agents to optimize the parameter

hh according to the criterion of minimum equivalent stresses in the joint.

Ray is initialized first. Next, the agent environment

e is created. Then a uniform grid (array

X) with 6 values of

x in the interval [0.08, 0.2] is created. After that, agent-actors of the

OptiX class are created for optimization. Each receives an

FEA class agent and one value from the

X array. By executing the agents'

calc() function in parallel, the

y value is calculated. After that, the

XY data is written to the

e environment. Two additional actors of the

OptiR class are created that implement another optimization method. Since they use a deterministic algorithm, they must differ in

F functions. The first uses a second degree polynomial, the second uses a third degree polynomial. Next, the

rule() function of each agent is executed until they all return

None. After the completion of the calculations, we read the

XY attribute of the environment and find the minimum (

hh=0.2). You can also visualize the

XY points and the regression curve (

Figure 9). Calculating the minimum of the function σ(

hh) in this way on a computer with an Intel Xeon CPU E5-2630L v3 (eight cores) took 17 minutes, which is 5.6 times faster than sequential execution of tasks for 23 values of

x. The maximum CPU load is 64%, RAM is 20 GB. In most cases, this optimization method allows you to immediately obtain the regression equation

f(

hh)

which, in the case of a high value of

R2, can be formalized and placed in the knowledge base. Instead of

R2, you can use other indicators of the model quality, for example, obtained using cross-validation.

where r0, l, t1 are model parameters.

where r0, l, t1 are model parameters.