1. Introduction

Certification tests are one of the most important tests during the design and implementation of a new product for public transport. This is due to the requirements of the standards and the need to conduct them in strictly defined conditions by a recognized certification laboratory. This path also applies to gondolas to overhead cableways. In the case of fatigue testing of gondolas for cableways, the most important standards are: “Safety requirements for passenger cableways. After-driving. Part 3: Fatigue tests" - EN 13796-3:2017 [

1], "Safety requirements for cableway installations designed to carry persons - Carriers - Part 1: Grips, carrier trucks, on-boards brakes, cabins, chairs, carriages, maintenance carriers, tow-hangers” - EN 13796-1:2017 [

2] and “General requirements for the competence of testing and calibration laboratories” - EN ISO/IEC 17025 [

3]. The gondola design process itself is complex [

4]. The preconditions [

5] (number of people, method of support, materials) as well as working conditions and safety regulations must be taken into account. In the design process, it is also necessary to take into account the possibility of dynamic loads [

6], hence the need to extend the calculations and experimental tests with appropriate safety factors. The design of the gondola should also take into account the strength of the load-bearing ropes 6] and intermediate elements [

7]. Rope damage can cause an accident [

8]. About the testing of trolleys, it is important to select the appropriate methods of connecting elements (welding, riveting, etc.) and their fatigue life [

9,

10,

11,

12,

13]. Concerning the wagons and the vehicles themselves, risk management in the event of overloading is introduced [

4], which also translates into the level of safety factors. Due to the limited information contained in the normative documents [

1,

2,

3], it is necessary to make several decisions based on experience and interpretation of the regulations. The biggest problems in designing and carrying out fatigue tests of cableway gondolas are:

method of attachment;

the method of receiving the degrees of freedom;

method of load distribution on the ground;

a method of smoothly generating a sinusoidal load of a satisfactory frequency;

correct verification of deformation of structures with relatively large dimensions.

This work shows the details of the discussed problems and suggested ways to solve them, while maintaining all the requirements of the EN 13796-3 standard and other standards taken into account in material, fatigue and certification tests. The discussed solutions, taking into account additional suggestions and good practices, will be presented on the example of fatigue tests carried out on a gondola for cableways, by TRANSSYSTEM S.A. (Wola Dalsza 367, 37-100 Łańcut, Poland).

2. Standards Background

The most important provisions regarding the fatigue tests of cableway gondolas are contained in the following regulations and standards:

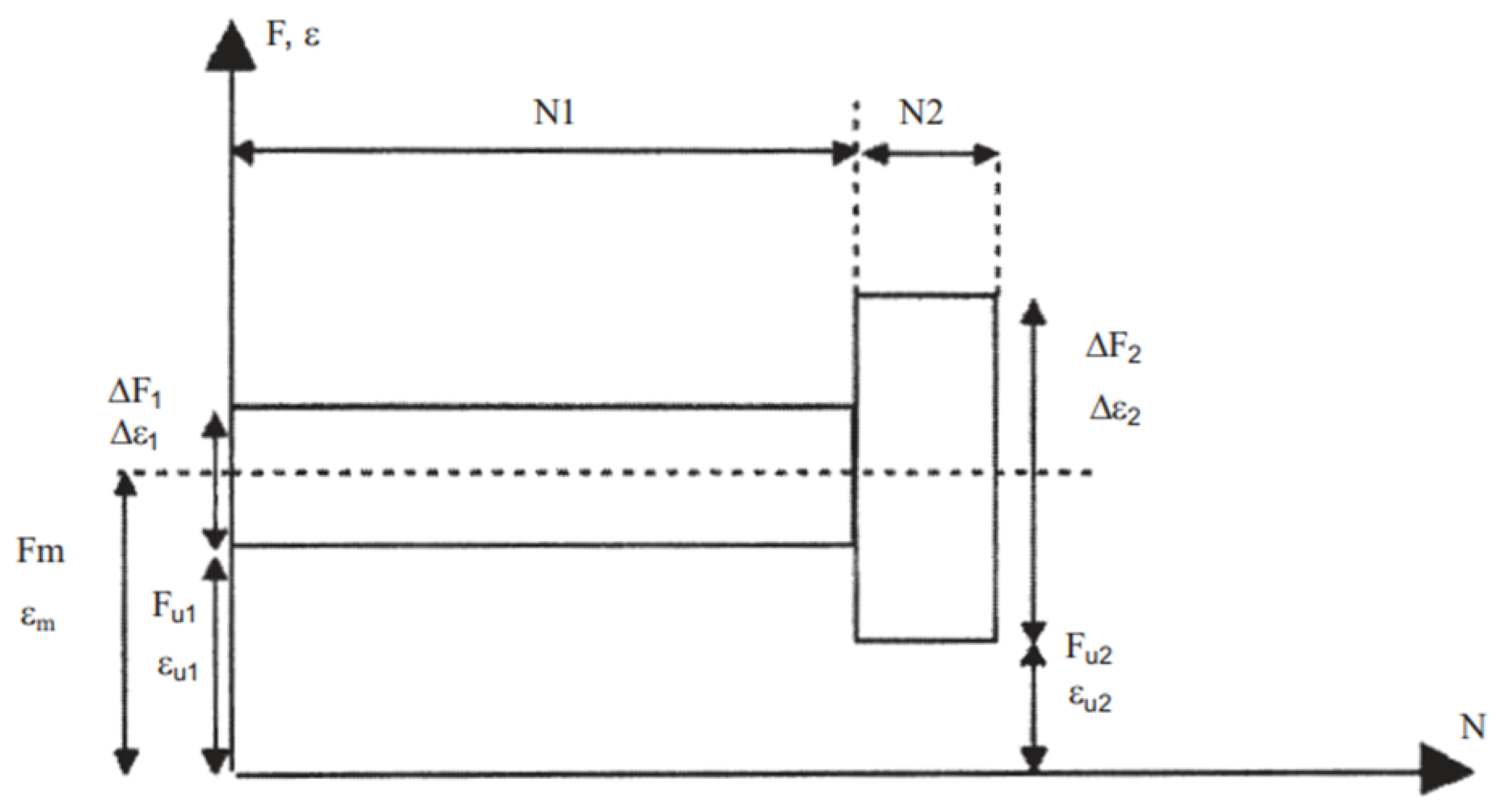

The basic quantities characterizing the cyclical fatigue loads are:

According to

Figure 2, due to the lack of a coupling, i.e. testing only the cabin, the load factor was reduced from

to

. The tests are carried out as a function of the intensity of the load (the standard allows for implementation as a function of the elongation that the given load will cause). The generated load should be sinusoidal. In addition, the EN 13796-3 standard assumes that the construction should be verified every

cycles. Additionally, standard EN 13796-1 [

2], point 6.3.3.2.2, indicates the method of load application. According to the mentioned point "the load equivalent to a standing or semi-seated passenger shall be distributed on the floor", which means that the load equivalent (by default in

Figure 1) should be distributed on the floor. The payload values defined by TRANSSYSTEM S.A. are

, i.e.

N (acceleration of gravity

). The specified dead weight of the vehicle was defined as

, i.e.

N.

Figure 1.

Test parameters for circular overhead railways with detachable headstocks [

1].

Figure 1.

Test parameters for circular overhead railways with detachable headstocks [

1].

Figure 2.

Test parameters for circular overhead railways with detachable headstocks [

1].

Figure 2.

Test parameters for circular overhead railways with detachable headstocks [

1].

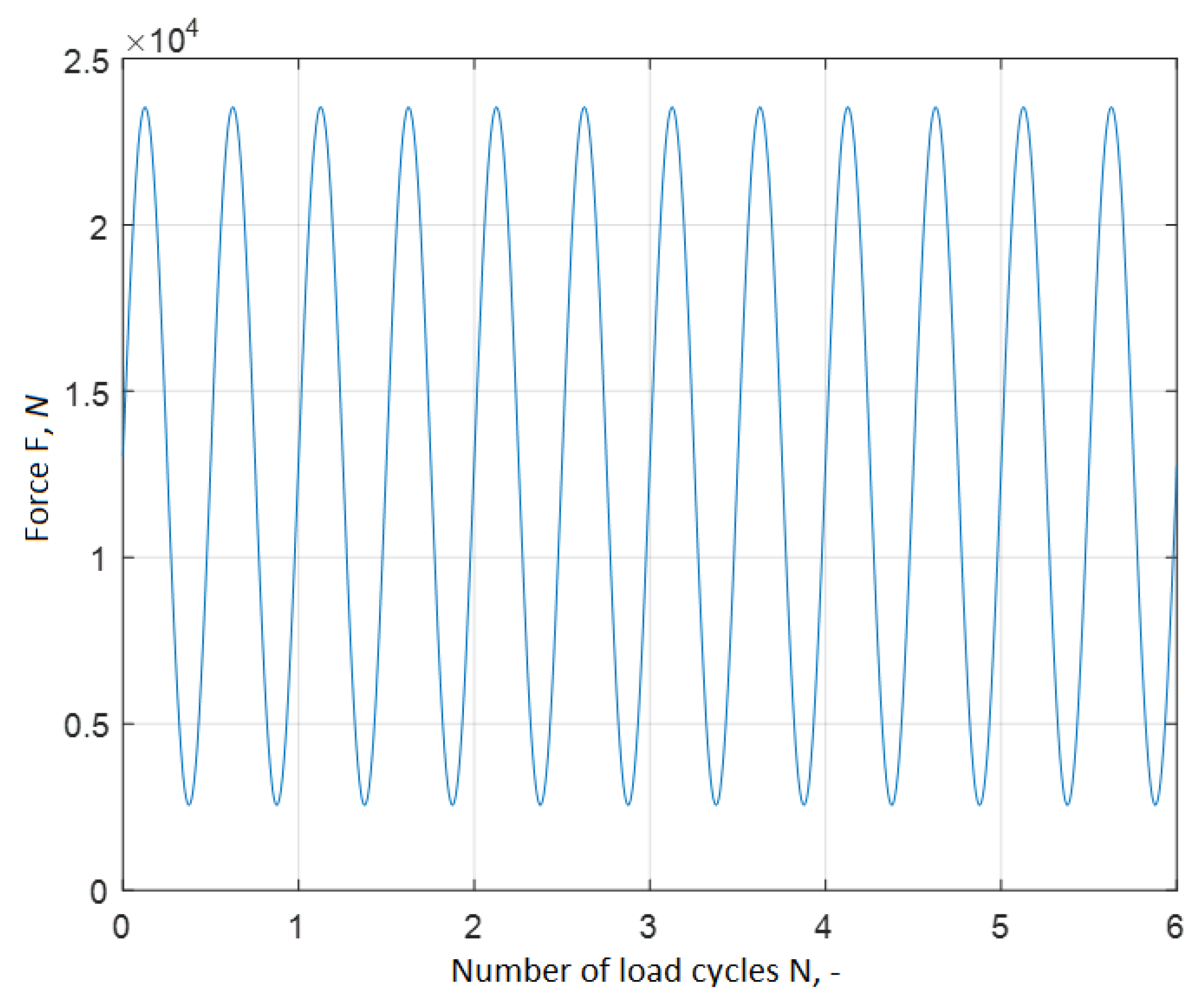

3. Research Object

The research facility is a gondola for circular overhead railways designed by TRANSSYSTEM S.A. -

Figure 3. The basic division of the structure divides it into 4 parts:

The upper frame is connected to the A and B rings (

Figure 4 by bolts at the top of the rings. In the upper frame, there are 4 mounting holes for the sling/clutch, which will be used for positioning and mounting the gondola in fatigue tests. The lower frame is connected to the rings in a similar manner to the upper frame in the lower part of the rings. The structure of the floor is based on two C-beams and a system of transverse and longitudinal beams forming the basis of the future floor. The gondola subjected to the tests has a width of 1999

, a length of 2391

and a height of 2600

.

The tested gondola is made of steel and aluminum alloys. As part of the fatigue tests, the entire structure is verified [

14], and all elements, regardless of the material of manufacture, are subjected to visual tests. The manufacturer was not obliged to provide detailed information about the materials of which the tested gondola is made. Before starting the tests, the certification body (in the case of Poland - Transportowy Dozor Techniczny, abbreviation TDT) should verify the consistency of the documentation with the tested object and verify potential damage.

4. Load Generation

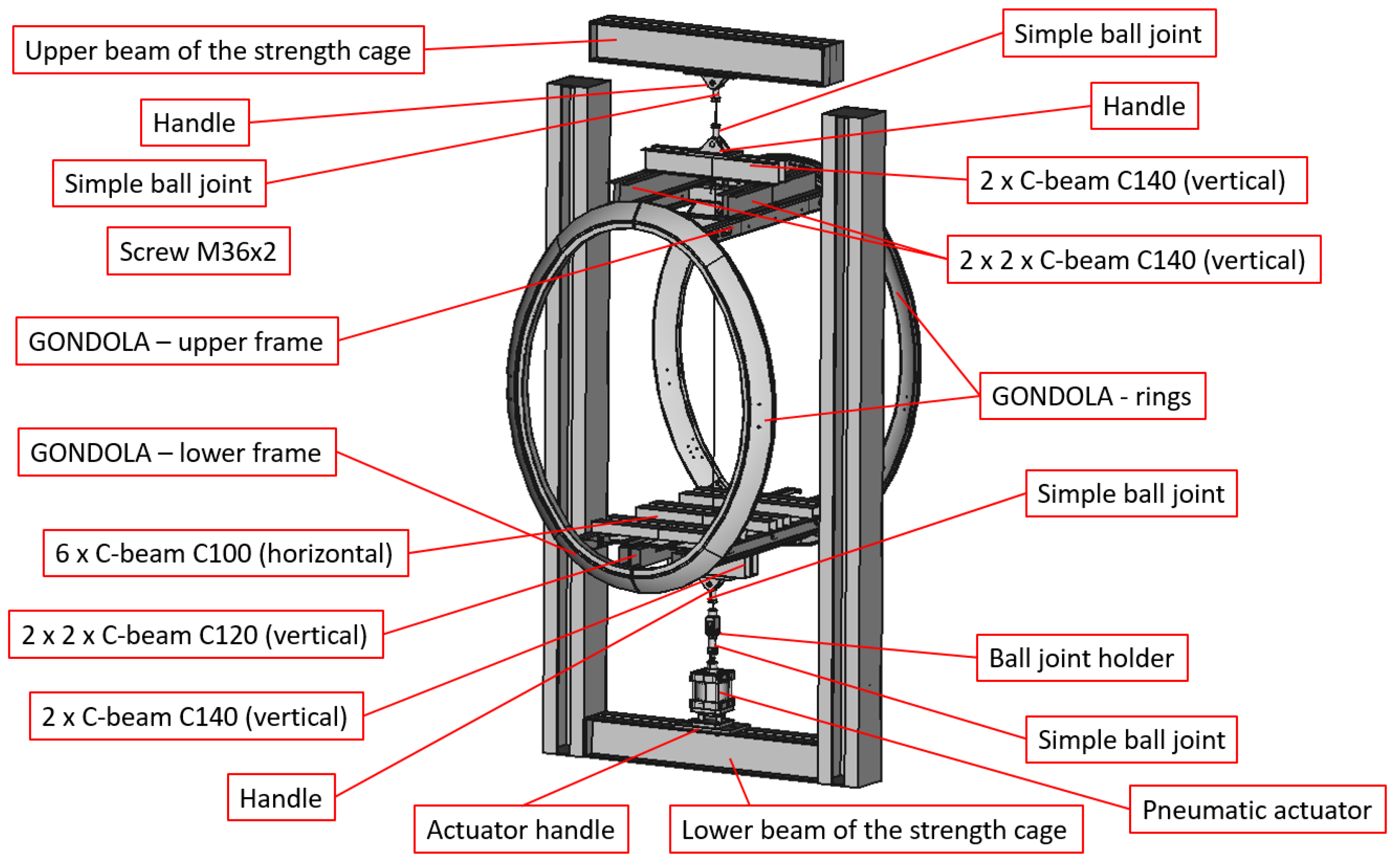

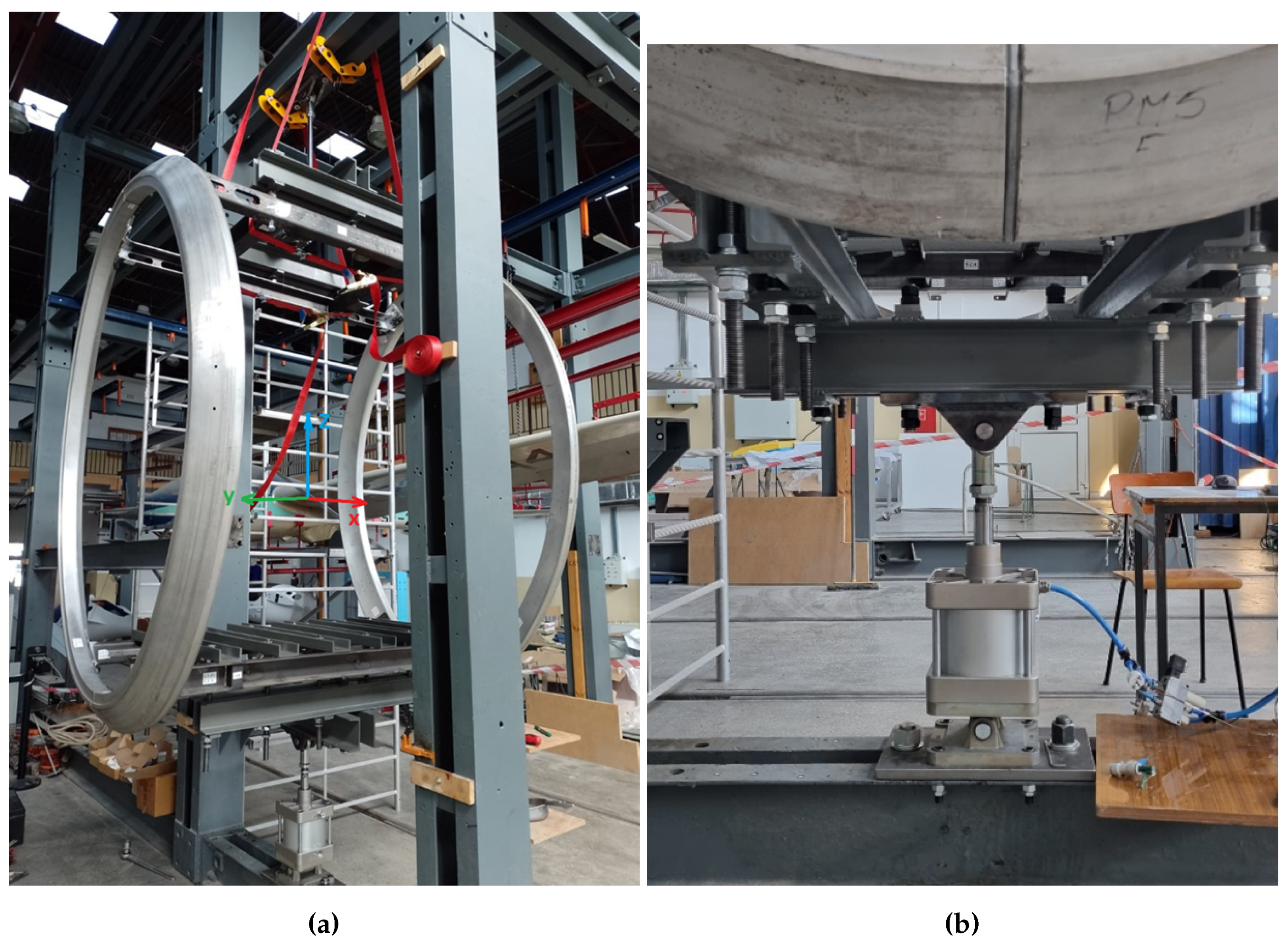

The gondola should be mounted in a strength cage using a system of C-beams and articulated joints ensuring the appropriate number of degrees of freedom. The gondola is suspended from the upper beam of the main endurance cage. The diagram of the gondola assembly system is shown in

Figure 5. The basis for the assembly of the upper gondola are sets of C140 beams in the configurations shown in

Figure 5. In the case of the gondola loading system, C100, C120 and C140 beams were used in the configurations presented in

Figure 5. All beams are made of S235 steel. Bolts in screw connections are made of 42CRMo4 +QT steel (data 40HM+QT), on which a fine thread M24x2 is made.

The designed assembly system leaves an appropriate number of degrees of freedom (all rotations are allowed in several points while blocking the displacement of the upper part of the gondola and allowing the displacement of the rest of the gondola as a result of the axial load).

This is done through the following movable connections (

- displacement in the direction of the

X axis,

- displacement in the direction of the

Y axis,

- displacement in the direction of the

Z axis,

- rotation around the

X axis,

- rotation around the

Y axis,

- rotation around the

Z axis (definition of the axis in

Figure 6a):

ball joint in the bolt connection between the upper beam and the M36x2 bolt - locked: , , ; free: , , ;

ball joint in the pin connection between the M36x2 bolt and the C-beam system - locked: , , ; free: , , ;

ball joint in the pin connection between the system of C-beams and the cylinder - locked: , , ; free: , , ;

simple bolt conection - locked: , , , , ; casual: .

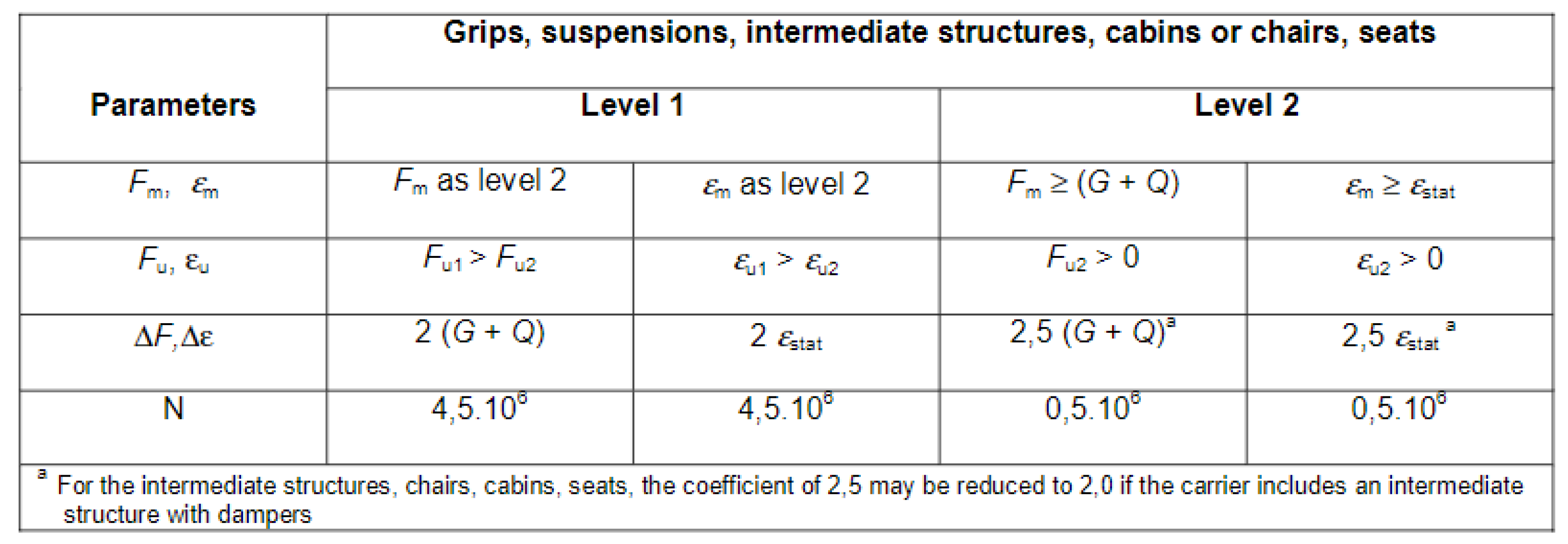

The methodology of loading cableway gondolas is based on the dynamic generation of tensile force. In the discussed case, where the tests will be performed in the hanging position of the gondola, this corresponds to a vertical change in the direction of the force. The transducer generating the force will be a double-acting pneumatic cylinder controlled by a valve and quick-release valves. The method is commonly used in force systems, due to the speed of reaction and independence of the generated force from the occurring deformation of the structure. In the case of stepper and mechanical actuators, it is necessary to establish the stroke, which can change with the potential permanent deformation of the structure. In the presented case, i.e. pressure control, the forcing force will be repeatable due to the direct relationship between the generated pressure in the actuator and the force (the force is the product of the piston rod area and the pressure in the pneumatic system), i.e. the force in this solution depends from the amount of pressure. The pressure value signal supplied to the system in the DasyLab environment is converted into the actual value of the force with the simultaneous recording of its value in a continuous mode on the disk of the controlling computer.

Figure 7.

Load diagram in gondola fatigue tests.

Figure 7.

Load diagram in gondola fatigue tests.

A pneumatic cylinder CQ 200x50

by Airworks (presented in

Figure 6), compliant with the ISO15552 standard, was selected to generate loads as part of the fatigue tests of the cableway gondola. According to the manufacturer’s data [

15], it can work at a working pressure of up to 10

, and at a pressure of 7

it achieves a force of 2199

. Due to the fact that the relationship between the force and working pressure is linear, it was determined that the assumed load of 2140

is obtained at a pressure of about

. The pneumatic system at the Department of Aeronautical and Space Engineering operates at a pressure of 8

. The pressure transducer used is the MPX5700DP Motorola, Freescale piezoresistive transducer - calibrated to the FLUKE718 1G pressure calibrator + 750P06 module. Based on the above control system and the assumed method of loading, a sinusoidal load cycle presented in

Figure 6 will be introduced into the gondola structure. There are plans to conduct tests with the frequency of the load from 1 to 4

, depending on the demand for air and the ability to properly control the real system. The EN 13796-3 and EN 13796-1 standard do not define the load frequency. Standards for fatigue testing of steel allow frequencies up to 10

.

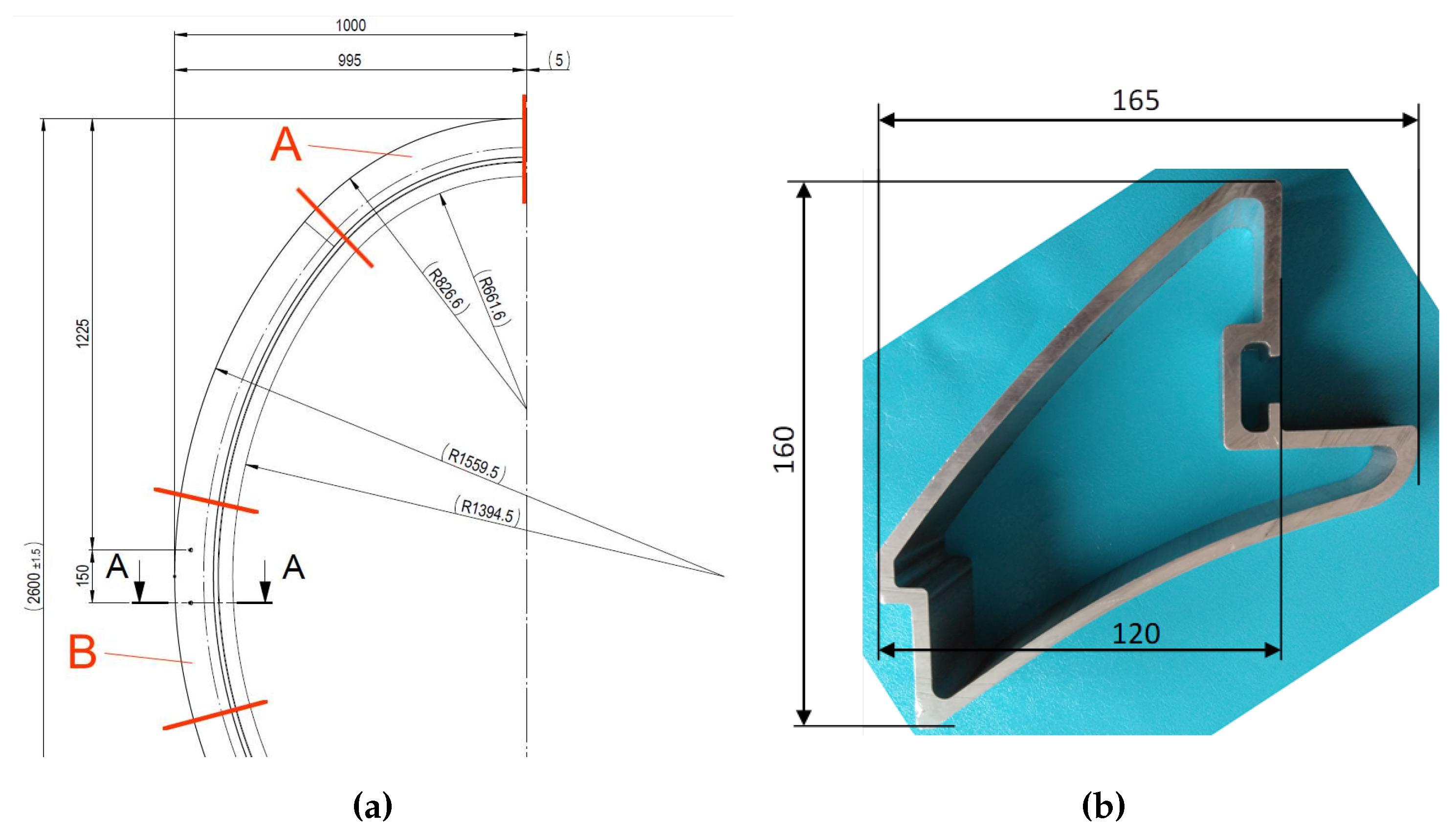

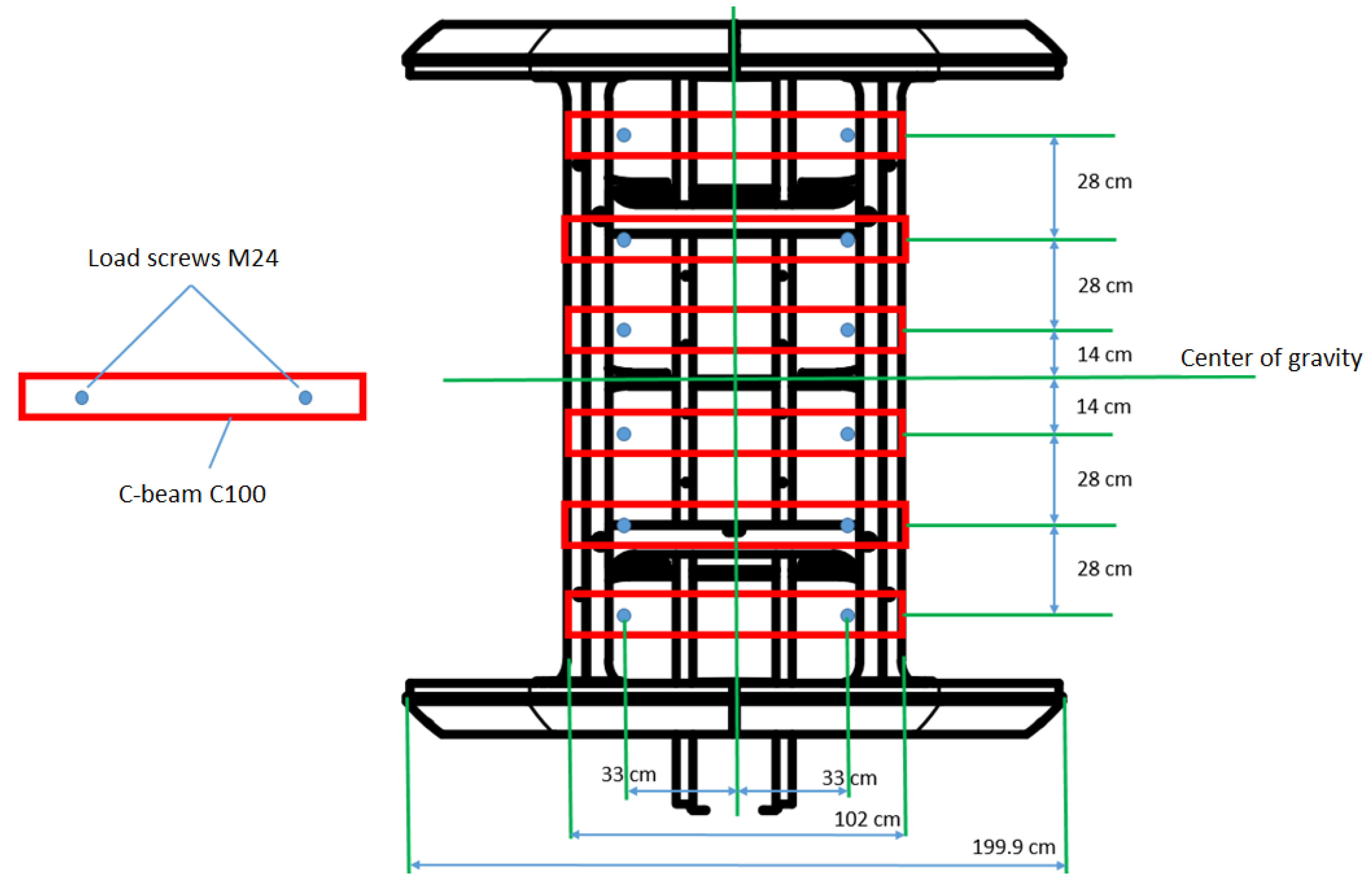

5. Force Distribution

According to the EN 13796-1 standard, the load should be evenly distributed on the floor. Due to the above, it was decided that the load would be carried by a series of 6 C100 beams lying horizontally. The number of beam sections was selected based on the assumed passenger capacity of the tested gondola - 6 people. Each beam bar rests on edge beam bars and angle bars from the lower gondola frame (

Figure 6a). The arrangement of C-beams and force application points is shown in

Figure 8. Due to the fact that the total load should be 21

, theoretically one bolt carried about

. A total of 12 bolts transferred the load between the beams (and the lower frame) and the lower load generating system connected to the pneumatic actuator. C-beams are spaced every 28

, of which the two middle ones are offset from the gondola axis (in the direction of the

Y axis) by 14

. At the same time, the loading bolts are distributed 33

from the central axis of the gondola (in the direction of the

X axis), i.e. the distance between the bolts is 66

. This distance corresponds to about 1/3 of the width of the entire gondola (

) and about 2/3 of the width of the lower frame of the gondola (102

). At the same time, the extreme points of force application are approximately

from the edge of the bottom frame/rings.

6. Construction Monitoring

In order to verify the deformation and permanent deformation of the cableway gondola structure, various structure monitoring systems can be used during the fatigue tests. In the presented studies, two independent monitoring systems were chosen. The first discussed method of controlling displacements of the structure were laser sensors HG-C1030-P from Panasonic (or similar). It is an optical laser sensor designed for precise measurements. Sensor response time up to 1.5 . The applicability range is 30 and the accuracy is 10 . Thanks to the use of a system of two such laser sensors, it was possible to measure the actual distance of the lower frame from the ground during the test and verify the uniformity of deformation of this structure. Due to the assumptions of the EN 13796-3 standard, the gondola had to be inspected every cycles. In addition to the visual inspection assumed by the standard, tests were conducted based on Digital Image Correlation (DIC) tools. On the gondola structure, a "cloud of reference points" should be marked, which have been verified geometrically using an optical 3D coordinate measuring device - TRITOP by GOM. Then, in each test break, the geometrical coordinates of these points were re-measured, thanks to which it was possible to assess their mutual displacement, angles of rotation and permanent deformation of the entire structure. The accuracy of the aforementioned measuring system, in the case of a structure with the dimensions of the tested gondola, is about 30 .

7. Conclusions

Tests of gondolas for cableways in accordance with the EN 13786-3 standard should be carried out using a strength cage. The loads, in the conducted tests, can be generated by a pneumatic cylinder mounted in the lower part of the strength cage. The transfer of the load from the actuator to the lower frame of the gondola is carried out by a system of C-beams, articulated and screw connections. In order to evenly distribute the load on the structure of the lower frame of the gondola, a set of C100 beams (located horizontally) should be prepared, which will transfer the loads to the beams suspended under the gondola through the M24 bolts. The actuator together with the system of beam sections fixing the gondola through the upper frame and the lower frame should be located in one axis. Such arrangement of the fastening and loading components ensures adequate rigidity of the structure while ensuring the axial character of the generated load. In the case of the discussed gondola (designed by TRANSSYSTEM S.A.), the values of loads N and N were determined. A load of about 21 ( N) applied along the Z axis causes stretching of the gondola. The character of the load cycle obtained in this way is compliant with the EN 13796-3 standard. The load is sinusoidal with the initial load , i.e. 2550 N. The value of the average load in the discussed tests was N. The load generated with a frequency of about 2 (in the range from to - depending on the elasticity of the system and the "return of the gondola"). The maximum value of the load observed in the gondola was 23544 N. Every load cycles, a technical break should be introduced during which visual inspections (organoleptic and endoscope inspections - to verify the screw connections used to build the gondola) should be made. It is a good practice to additionally conduct research using digital image correlation (DIC) in order to detect potential permanent deformation/relative displacement of individual gondola elements. By default, 11 visual inspections and DIC tests should be performed - pre-test, every load cycles. cycles and after fatigue tests. The inspections carried out, together with the appropriate photographic documentation, should be attached to the final report. After the fatigue tests are completed, before dismantling the gondola from the strength cage, an inspection should be carried out by the Certification Laboratory (in the case of the test facility in question - the TDT Laboratory with its registered office in Krakow).

Author Contributions

Conceptualization, A.B. and K.B.; methodology, A.B. and K.B.; software, R.K.; validation, A.B., P.K., Z.S. and R.K.; formal analysis, A.B.; investigation, A.B., P.K., Z.S. and R.K.; resources, K.B.; writing-original draft preparation, A.B.; writing-review and editing, A.B. and K.B.; visualization, A.B. and R.K..; funding acquisition, A.B. and K.B. All authors have read and agreed to the published version of the manuscript.

Funding

The research leading to these results has received funding under Priority Axis I Competitive and Innovative Economy of the Regional Operational Program of the Podkarpackie Voivodeship for 2014-2020: RPPK.01.02.00-18-0052/17 - Development of a technology for manufacturing an innovative gondola for railways performed by TRANSSYSTEM S.A.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data generated or analysed during this study are included in this published article.

Acknowledgments

Not applicable

Conflicts of Interest

The authors declare no conflict of interest.

References

- 13796-3:2007, E. Safety requirements for cableway installations designed to carry persons. Carriers. Part 3: Fatigue tests; 2017.

- 13796-1:2007, E. Safety requirements for cableway installations designed to carry persons - Carriers - Part 1: Grips, carrier trucks, on-board brakes, cabins, chairs, carriages, maintenance carriers, tow-hangers; 2017.

- 17025, I. General requirements for the competence of testing and calibration laboratories; 2017.

- Štollmann, V.; Ilčík. Assessment of the current theory for projecting cableway routes in terms of the risk level in overloading. RES. AGR. ENG. 2009, 55, 35–38. [Google Scholar] [CrossRef]

- Pamela, V.; Paúl, C.; Vinicio, M.; Víctor, L. Design of an Aerial Cable Transport Cabin. Innovation and Research; Botto-Tobar, M., Zambrano Vizuete, M., Díaz Cadena, A., Eds.; Springer International Publishing: Cham, 2021; pp. 491–504. [Google Scholar]

- Brownjohn, J.M. Dynamics of an aerial cableway system. Engineering Structures 1998, 20, 826–836. [Google Scholar] [CrossRef]

- Koller, R.E.; Piskoty, G.; Zgraggen, M. Scheme of the Failure Analysis Taking the Example of Profile Wire Breaks in the Support Cable of a Cable Car System. Practical Metallography 2016, 53, 798–810. [Google Scholar] [CrossRef]

- Mapelli, C.; Barella, S. Failure analysis of a cableway rope. Engineering Failure Analysis 2009, 16, 1666–1673. [Google Scholar] [CrossRef]

- Lieurade, H.; Huther, I.; Lefebvre, F. Effect of Weld Quality and Postweld Improvement Techniques on the Fatigue Resistance of Extra High Strength Steels. Weld World 2008, 52, 106–115. [Google Scholar] [CrossRef]

- Weibull, W. Fatigue Testing and Analysis of Results; Pergamon Press: Sweden, 1961. [Google Scholar]

- Sonsino, C. Fatigue testing under variable amplitude loading. International Journal of Fatigue 2007, 29, 1080–1089. [Google Scholar] [CrossRef]

- Combe, S.; Barjon, Y.; Bejic, I.; Merrien, P.; Lieurade, H.P.; Serror, M. Definition of the inspection periodicity of steel welded joints of posts of ski lifts from fatigue cracking tests. Revue de Métallurgie 2007, 104, 106–111. [Google Scholar] [CrossRef]

- Mei, J.; Dong, P.; Xing, S.; Vasu, A.; Ganamet, A.; Chung, J.; Mehta, Y. An overview and comparative assessment of approaches to multi-axial fatigue of welded components in codes and standards. International Journal of Fatigue 2021, 146, 106144. [Google Scholar] [CrossRef]

- Wang, A.; Xue, H.; Bayraktar, E.; Yang, Y.; Saud, S.; Chen, P. Analysis and Control of Twist Defects of Aluminum Profiles with Large Z-Section in Roll Bending Process. Metals 2020, 10. [Google Scholar] [CrossRef]

- Airworks. Pneumatic Actuator 200X50 MM CQ.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).