1. Introduction

The success of the agriculture sector is one of the primary economic pillars of Ethiopia’s economy, and it has a significant impact on the country’s total economic growth [

1]. It is the primary activity in Ethiopia, where approximately 84 percent of the population is engaged in various agricultural activities and generates income for household consumption to sustain livelihood [

2]. Horticulture crops are one type of agricultural activities in Ethiopia uses to increase income and the nutritional status of the nation [

3]. It is season dependant and need proper management and harvest at appropriate time and techniques otherwise results in postharvest losses both in quantity and qualities. From harvest to consumption quantifiable quantitative loss of products was at any point in the postharvest chain [

4]. Food losses and huge economic losses result from this post- harvest loss [

5]. Post- harvest losses of fruits can range in size from 5% to 35% in industrialized nations and 20 to 50% in poor nations [

6]. The post-harvest phase has a significant impact on the environment, human health, and food security [

7]. Ethiopia is one of the sub-Saharan African countries on the margin of severe food insecurity and poverty [

8].

Fruit crops have a high humidity level and a high nutritional value, making them highly perishable. Fruit losses can result from a variety of factors, including farm operations and consumer purchased. These fruit post-harvest losses are primarily the result of incorrect handling, wrong harvesting, substandard storage facilities, inadequate post-harvest management strategies, and inadequate post-harvest infrastructure, and there are considerable output losses during these stages [

9].

Tropical fruit from the Lauraceae family, the avocado (Perseaamericana Mill.) is indigenous to tropical America [

10]. It is one of the most widely farmed fruits in the world to its outstanding nutritional value. Reducing postharvest losses of avocado fruits can both enhance the marketable surplus and income as well as the amount of avocado fruits that may be consumed. As a result, it might be a sustainable strategy to increase farmer income and strengthen food security standards. The production of avocado fruits in the study area for marketing purpose as well as for home consumption. From 2011E.c up to 2013 E.c the average area covered and the total output produced by are 3,038.98 hectors, and 430,783.18 quintals and 4,692.076 hectors and 690,093.29 quintals respectively for avocado produced KT and Wolaita zones respectively (ZBoARDOffice). Avocados are a source of key nutrients, including healthy fats and fiber. They also contain anti-inflammatory and antioxidant compounds and may help reduce heart disease risk. Nutritious, versatile, and delicious, avocados have become a kitchen staple in many homes around the world. It also used as well as processing industry is more prone to such losses due to high moisture content, physical injury, and attack of insect past and perishable nature. Reduction in the post harvest losses can increase the marketable surplus and hence the consumable quantity of the produce. It could be an efficient solution to increase the availability of food, reduce exploitation of natural resources, overcome hunger and improve farmers’ livelihoods. Besides increasing productivity, it is desirable to have an efficient processing and marketing conditions in order to reduce the extent of the losses and hence the study pertains to the estimation of losses in avocado at producer’s levels of farm. Post-harvest handling procedures need to for lowering the rate of avocado losses. The post-harvest management practice on avocado fruit at the producer’s level does not receive enough attention. Additionally, it was shown that the respondents differed in their understanding of the right methods for care for avocado fruit. Most study done on postharvest loss was fruits combine with vegetables or two or more fruits in general manner not at specific at particular fruits [

6,

9,

12,

14]. This study focuses on Postharvest loss of avocado alone; it is not incorporated with by fruits and vegetables. This is important to identify for specific commodity in postharvest practice and management as well as policy making for specified fruits. Also A few of research works have been done on avocado fruit value chain in the study area and no research was done on examine the amount of post-harvesting loss, and factors that determinates post harvest loss of avocado in the study areas. Also limited research has been conducted to asses post harvest losses of fruits with descriptive analysis and simple random with small sample respondents. Hence the study focused on the following specific objective: - (1) to compute the amount of post-harvest losses in the avocado at producers level (2) to identify factors affecting post harvesting losses of avocado fruit at the producer level.

2. Methodology

2.1. The Research Area’s Description

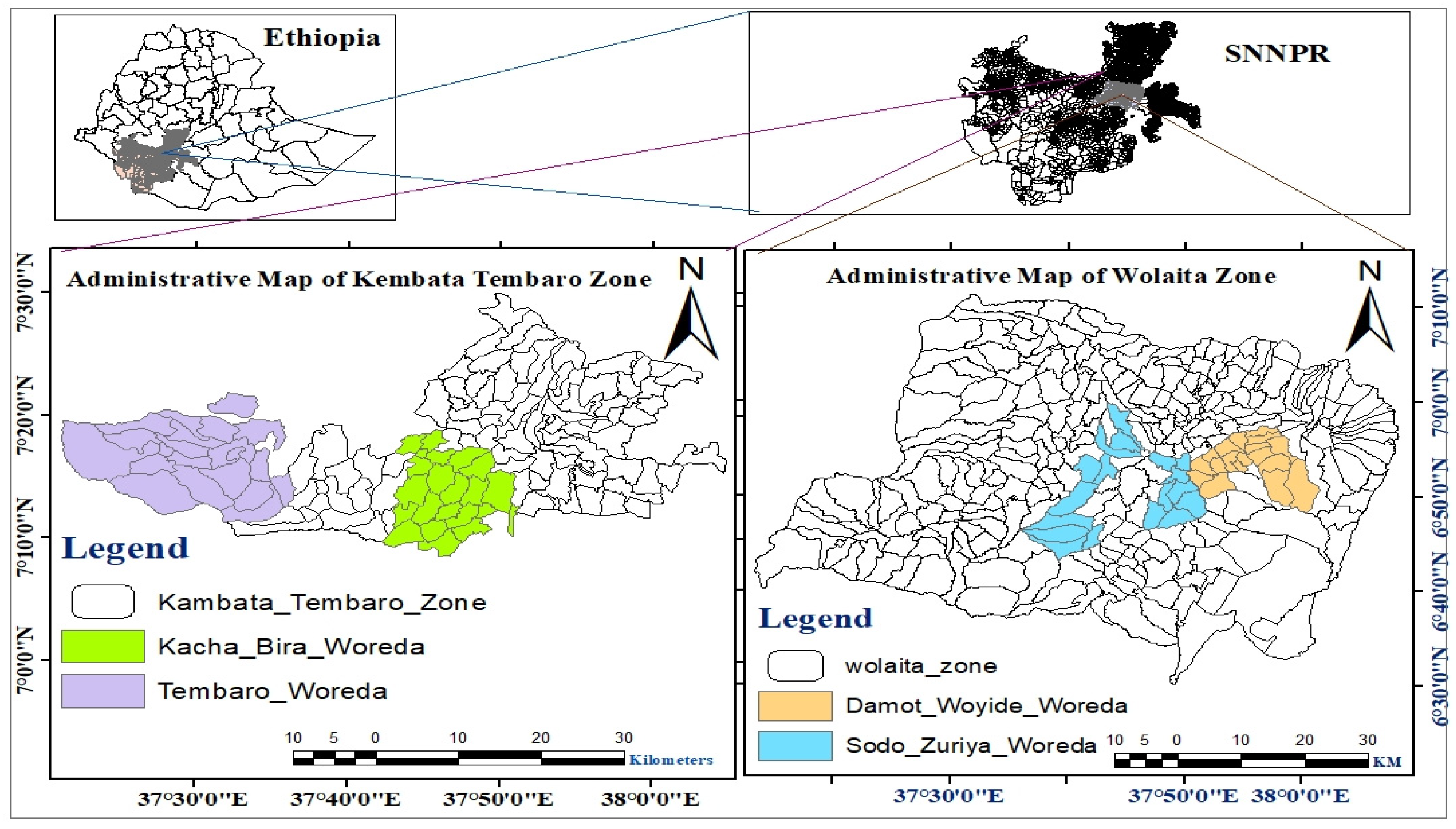

The research was done in SNNPR in two zones, namely Wolaita and Kembata Tembaro Zones. Wolaita and KembataTembaro Zones are among 13 zones of Southern Nations Nationalities and Peoples Regional (SNNPR), two of them are neighboring. An administrative center for the Wolaita Zone is Wolaita Sodo; Durame is the administrative center of KembataTembaro Zone. The Wolaita Zone has a total area of 4512 km2, administratively divided into 16 woredas and 6 registered towns. According to the Central Statistical Agency’s 2007 Census, this Zone has a total population of 2,473,190 people and a 4,208.64 square kilometer area. Whereas Kembata Tembaro Zone was subdivided into eight districts and five registered town. According to the CSA’s 2007 Census, the Kembata Tembaro zone has a total population of 1,080,837, of which 536,676 are males and 544,161 are women. The zone has a land area of 1,355.89 square kilometers. This study was conducted in of the major avocado fruits producing area from Wolaita zone; DamotWeyde and Sodo Zuriya distrcts,and from KambataTambero; KachaBira and Tembaro districts of SNNPR see figure below.

Figure 1.

Location of the research area (2022).

Figure 1.

Location of the research area (2022).

2.2. Source of the Data and Sampling Method

For this investigation, secondary data as well as primary data were employed. Reviewing secondary sources included looking at Central Statistical Authority, district agricultural and rural development office published and unpublished materials. In addition, websites and journals were visited to gather applicable secondary data concentrating on the study’s aims. Primary data were gathered from randomly chosen growers of avocado fruits in eight rural kebeles in the study area. Structured and semi-structured questionnaires, as well as computer-assisted personal interviews conducted by professional enumerators, were used to collect primary data. The producers of avocado fruits were chosen using multi-stage sampling techniques. In the first stage, four districts, namely Damot Weyde and Sodo Zuriya districts from Wolaita Zones, and Kacha Bira and Tembaro districts from Kembata Tembaro zones were chosen at random from the avocado fruits producing districts of the two zones. Using a simple random sample procedure, eight avocado fruit-producing kebeles or districts were chosen from each of the four districts in the second step. 385 farm households were chosen at simple random in the third stage using a probability proportional to their combined population size.

The study used Kothari’s sample size determination algorithm to determine a representative sample size for a cross-sectional household survey

where n is the sample size, Z is the inverse of the standard cumulative distribution that to the level of confidence, e is the desired level of precision, p is the estimated proportion of an attribute that is present in the population and q = 1-p. The value of Z is found from statistical table which contains the area under the normal curve of 95% confidence level.

2.3. Methods of Analyzing Data

The study employed both econometric and descriptive statistical methods, to examine the amount and determination of post-harvest loss of avocado in the study area. The sum of all these losses at various activities, such as harvesting techniques, storage, packaging materials and methods, transportation, insects, loading, and at the marketing level, is estimated to be the total post-harvest losses. Multiple linear regressions (LMLR) analysis was employed to determine what factors lead to post-harvest loss of avocado fruits at producer’s level. Quantity of avocado fruits post-harvest losses at percentage would be the dependent variable.

Quantitative Loss Assessment on Producer’s Level

The quantity of post harvest loss would be calculated using the equation given below.

where, Wrdv = Weight of rejected and damaged avocado fruits sorted out in Kg

Wtv = Total weight of avocado fruits before sorting in Kg

Wrdv=Total rejected and damaged at farm level the sum of (Collection, or Harvesting, Transportation, processing, storage, insects or disease attack, and exchange before sales and consumption)

Multiple linear regression models were used to examine the relationship between postharvest loss of avocado and explanatory variables at producers level. The general form of multiple linear regressions is:

Yi represents post-harvest loss and X1, X2, X3, X4…Xk represents explanatory variables that determinates of post harvest loss of avocado and εi is the stochastic disturbance term or error terms.

It is possible to write the function as:-

where α

o = intercept term.

3. Result and Discussion

3.1. Socio-Demographic and Institutional Characteristics of Respondent

A total of 385 respondents made up the sample. The sample ages varied from 32 to 61 years old, and their mean age was 45.95 years. The mean family size of sample respondents was 6.25, which was higher than the mean family size in the country, which is 4.6 people per home [

11]. Additionally, the sampled respondents traveled 2.8 kilometers to get to the major road and 3.07 kilometers to the nearest market center on foot (Table1). In light of this, the average length of formal education completed by sample respondents was 6.27 years. Tropical Livestock unit (TLU) per family was calculated to evaluate each household’s livestock holding. A sample respondent in the study area possessed a mean of 3.08 TLU of cattle. The sample study area’s average landholding size was 1.011 hectares, which is less than the 1.17 ha per household national average [

11]. The typical number of times extension service was offered to sampled respondent was 2.67 day/month. The average number of years that respondents to the sample had been actively involved in farming avocado fruits producers ‘production was 16.48years.Moreover, the mean annual yield quantities of avocado fruits production of the sampled household was 866.90kg with a minimum of 400.00kg and a maximum of 1800.00 kg. The average unit price per kilogram 16.25birr/kg.

Table 1.

Characteristics of sampled respondent (Continuous variable).

Table 1.

Characteristics of sampled respondent (Continuous variable).

| Variables |

Mini |

Maxi |

Mean |

Std. Err |

| Age of the respondent (Years) |

32 |

61 |

45.95 |

6.735 |

| Household size (Adults equivalence) |

3.70 |

7.95 |

6.2466 |

1.05500 |

| Education level of respondent (Grade level) |

2 |

12 |

6.27 |

3.266 |

| Total livestock holding(TLU) |

.60 |

7.32 |

3.0843 |

1.33417 |

| Land size (hect) |

0.1 |

3.5 |

1.011 |

1.021 |

| Number of productive avocado tree owned(Numbers) |

4 |

7 |

5.89 |

.776 |

| Distance from household residence to main road(KM) |

.25 |

10.00 |

2.8100 |

1.77842 |

| Distance from household to nearest market(Km) |

.50 |

10.00 |

3.0706 |

1.34163 |

| Extension agents contacts per months(Days) |

1 |

4 |

2.67 |

0.874 |

| Farming experiences for avocado fruits(Years) |

8 |

40 |

16.48 |

5.898 |

| Quantities of avocado fruits did you produce(Kg) |

400.00 |

1800.00 |

866.8831 |

275.49794 |

| Average unit price of avocado fruits(Birr/kg) |

10.00 |

30.00 |

16.2494 |

4.77899 |

Out of all survey respondents, 316 (82.1%) were headed by men, and 69 (17.9%) were headed by women among the respondent that produced avocados (

Table 2). The results showed that only 9 (2.3%) of the had access to irrigation, while 376 (90.7%) did not. About8.3% of respondents had obtained services for their own credit agricultural production. Moreover, 62.3% of the sampled respondents have accessed market information for avocado fruits marketing from different sources. Additionally, 172(44.6%) of the sampled respondents were also participated in off farm activities. Consequently, the findings in the research domain showed that 69.6% of the respondents have got training access. Training in the use of marketing for avocado fruits, the adoption of post-harvest loss techniques, and post-harvest losses will improve avocado output productivity and, as a result, expand the market for avocado fruit products. Moreover 69.9 % of the sampled respondents were also access to transportation.

3.2. Post Harvest Losses in Avocado Fruits at Farm Level

Based on the survey results, each farmer owns an average of 7.99 avocados. The number of productive avocado trees that are productive (avocado trees that bear fruit) of the sampled respondents is therefore more important for the objectives of this study than the number of avocado trees that have been planted. The average number of avocado trees with fruit held by each producer was 5.89, and the average amount of avocado produced annually was 866.9kg. Additionally, households sold 509.5584 kg of avocados, and on an annual basis, they made an average of 5577.5455 ETB from selling avocados (

Table 3). Consequently, 208.169 kg of avocado fruits were damaged or lost on average in the studied area from the total production at various processing phases.

3.3. Stage for Harvesting Avocado Fruits

Avocados’ harvesting stages are essential for extending their shelf life. The results in (

Table 4) below show that 66.2% of respondents in the sampled group in the study area say to harvest avocados when they are just ripe, 6% of them when they are still green, and 27.8% when they are fully grown. These findings imply that while fully matured avocado fruits are easier to spoil, immature avocado are more difficult to pick and are less likely to be harmed during transit. These findings support the finding by [

12] that unripe fruits are more difficult to pick than ripe ones.

3.4. Avocado Fruits Harvesting Methods

Avocado fruits harvested without mechanical damage to increase the qualities of avocado. It was damaged during the harvesting process, which may have a negative impact on the avocado fruit’s attractive appearance and serve as a point of entrance for post-harvest viruses that quickly cause decay during storage and transit. Below the (

Table 5) shows that 70.4% of the sampled respondent used cutter with attached bag to harvest avocado fruits. The rest 29.6% of the respondent used hand twisting, ladder and other mechanisms to harvest avocado fruits in the study area.

3.5. Avocado Fruits Packing Materials

The avocado fruit must be relocated to the shade as soon as it is harvested in order to prevent weight loss from moisture loss, which would happen quickly when they are exposed to the sun. A variety of conventional packaging materials are utilized in Ethiopia to retain agricultural products, however there is a dearth of standardized fruit packaging materials [

13]. In the study area, dried banana or enset leaf, carton, and plastic polyethylene were employed as avocado fruit packing materials. For packaging the avocado fruit, 68.6% of the farmers from the sampled household use dried banana or enset leaf, followed by 19% carton and 12.5% plastic boxes. Although the use of packaging materials increases the final price of avocado fruits, it usually enhances the fruit’s look and quality preservation. By preventing avocado fruits from mechanical damage and unfavorable physiological changes throughout storage, transit, and marketing, avocado fruit packaging is crucial for lowering postharvest losses. Avocado fruit transportation without adequate packing exposes the fruit to mechanical damage during loading and unloading as well as while traveling on rough roads, which increases the risk of fruit deterioration.

Table 6.

Packaging materials for storage.

Table 6.

Packaging materials for storage.

|

Frequency |

Percent |

Valid Percent |

Cumulative Percent |

|

Dried Banana leaf |

264 |

68.6 |

68.6 |

68.6 |

| Carton paper |

73 |

19.0 |

19.0 |

87.5 |

| Plastic bag Polyethylene |

48 |

12.5 |

12.5 |

100.0 |

| Total |

385 |

100.0 |

100.0 |

|

3.6. Producers Perceptions about Sources of Avocado Post-Harvest Loss

Avocado fruit losses happen during post-harvest handling procedures such as harvesting, picking, field storage, packaging, loading and unloading, transportation, insects, and farmer-level sales. According to the findings of the current study, postharvest loss that occurred during various operations or handling procedures, as indicated in (

Table 7 and

Table 8) below was responsible for around 24.014% of the total. The present study’s findings generally concur with those of other studies, who found that losses of fruits occurred in various value chains and ranged from 23 to 40% [

14]. As a result, a substantial portion of avocado fruit losses occur during the stages of harvest, storage, transportation, packaging, market or selling, insects, and loading. The post-harvest loss avocado fruits at the field level were estimated to be 24.01348315 % from total production of avocado fruits. This loss occurred on the farm as a result of injuries sustained when picking avocados by hand utilizing ladders and picking poles, poor packing techniques, disorganized storage facilities, unorganized transportation methods, and other factors during avocado fruit processing activities.

3.6.1. Causes of Producer-Level Post-Harvest Losses

Harvesting

Harvesting is the first step in the avocado supply chain and plays a crucial role in decisions on how to reduce waste and improve quality. The period of harvest and the methods are two crucial factors that affect losses during harvesting of avocado fruits in the research area. The findings indicate that the most important issue is the perception of losses during the harvesting phases. According to

Table 7 and

Table 8, 49.62 kg, or 5.7%, of the total post-harvest loss, happened at the harvesting procedures. These are related to a study by [

15] that found that severe PHL and quality deterioration of horticulture products occur in Ethiopia after harvest, and are then followed by marketing, shipping, and storage times.

Storage

Avocado fruits are collected after undergoing specialized treatments such cleaning, sorting, and packing of post-harvest fruits. 42.75 kg, or 21%, of the research area’s average avocado fruit value (

Table 7 and

Table 8) were lost at the farm level due to a lack of proper storage.

Insect Pests and Diseases

Small, dark patches that grow to uneven, dark-brown to-black blotches as the fruit ripens are signs of the condition. Postharvest loss in the research area comprises postharvest diseases and insect pests (worm, fly, and thrimps). According to

Table 7 and

Table 8, the average weight of avocado fruits lost on farms in the research area as a result of insects and dieses was 18.87 kg. At the time of the focal group discussion, insect and disease infestation, a lack of a quick market, and inadequate storage facilities were the main causes of avocado fruit losses.

Transportation

The avocado supply chain involves a lot of transportation since the fruits of the avocado have to be moved from one stage to another. 3.07 km was the typical distance traveled by the ripped, harvested avocado for the closest market. Therefore, they are using various modes of transportation, as seen in the above table where 14.5%, 62.5%, and 22.9 % of respondents said that avocado fruits are typically delivered from far places on the backs of women, animals, and men. Fruits are vulnerable to mechanical damage and heat buildup during all modes of transportation. The focus group participants said that there were lacks of access to suitable transportation, forcing farmers to harvest at a later stage of ripening and sell to local consumers even though most avocado producers in the research area use carts and human labor for transportation. Avocado fruits vibrate when traveling on bad roads, which cause losses. Out of these, 4.094382022 kg/qtl, or 17% of the total post-harvest losses, were attributable to the mode of transportation. Due to mechanical damage and product overheating are caused large amount of avocado losses.

Packing Materials

The shelf life of avocado fruits is increased and losses are decreased significantly by packaging. Therefore, incorrect packaging and the use of inappropriate packaging materials are two of the main reasons why avocado fruits are lost at post-harvest stages. Avocado fresh produce can be damaged by poor quality packaging materials, which can also hasten the deterioration of avocado fresh produce. Fruit goods, especially perishable ones, are less likely to be damaged by a well-designed packaging strategy [

16]. There are a variety of conventional packaging materials used to contain avocado fruits in the study area, including banana leaves, cartons, plastic bags, and others, but there aren’t many that are specified for avocado fruit packing. According to

Table 7 and

Table 8, among the average weights of avocado fruits in the study region, improper packing materials resulted in losses of 23.20 kg, or 11% of all post-harvest losses, on farms. This may be because conventional sack increased inside temperature; higher fruits injured inner fruits by compressing and piling them on top of one another during transportation; these actions intensified fruits softening and rotting.

Marketing or Selling

For market participants like farmers, wholesalers, and retailers to increase their incomes and prevent post-harvest losses of avocado fruits, a well-organized market system is necessary. However, in the study area, avocado fruits are typically sold and bought at open spaces/roadsides, plastic shelters, and houses, respectively. According to

Table 7 and

Table 8, among the average avocado fruit values in the study area, unsatisfactory marketing conditions resulted in losses of 20.92 kg, or 10%, of the total post-harvest losses.

4.3. Econometric Analyses

4.3.1. Determinants of Avocado Postharvest Loss

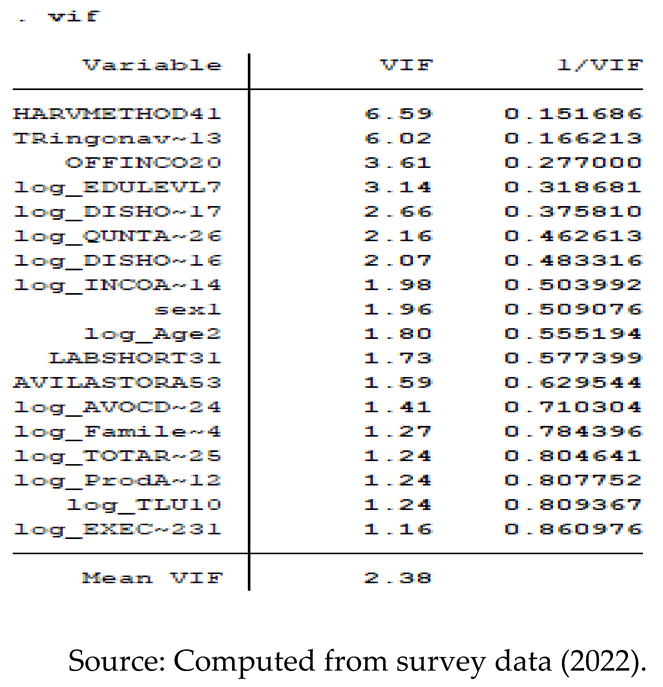

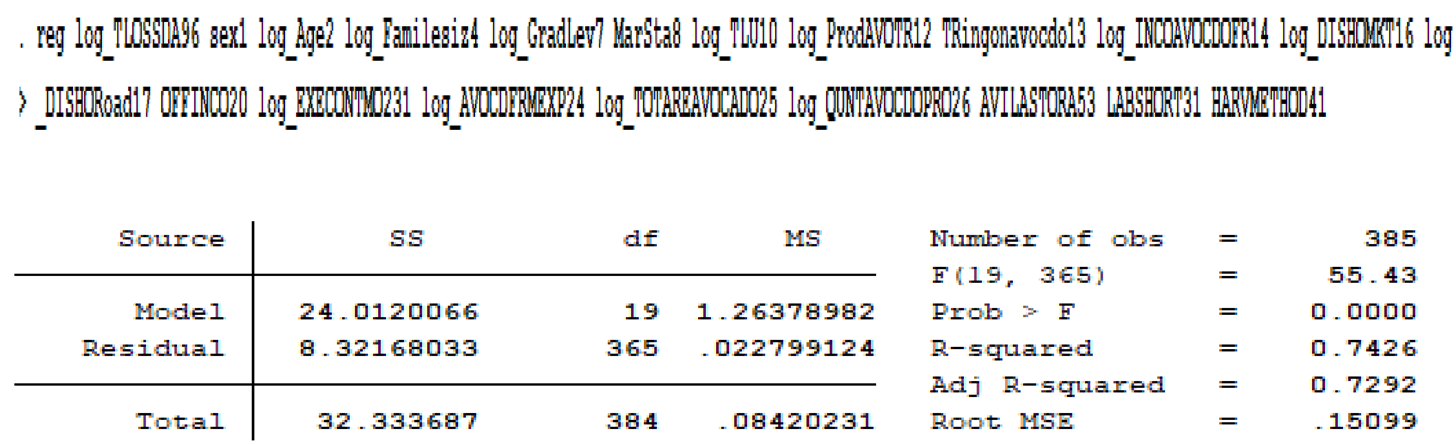

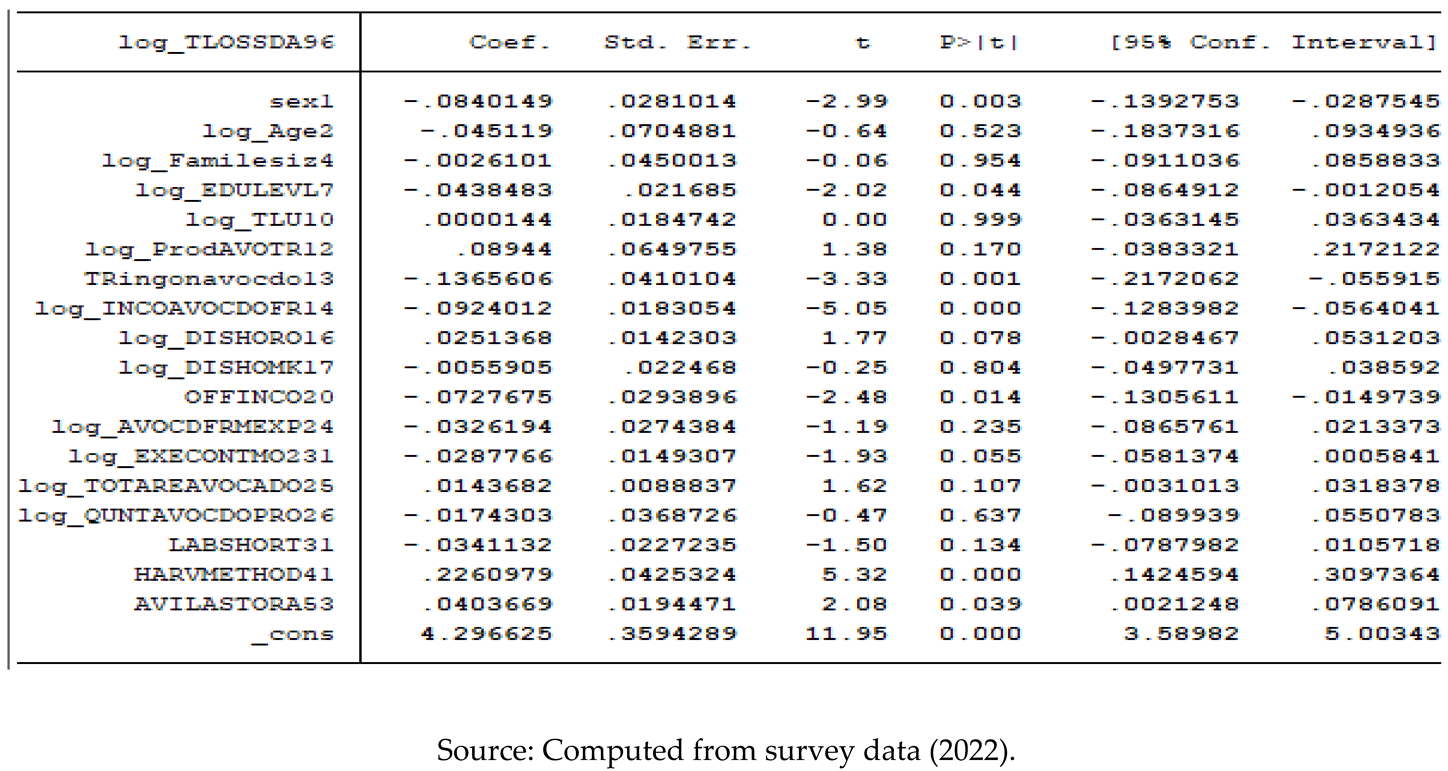

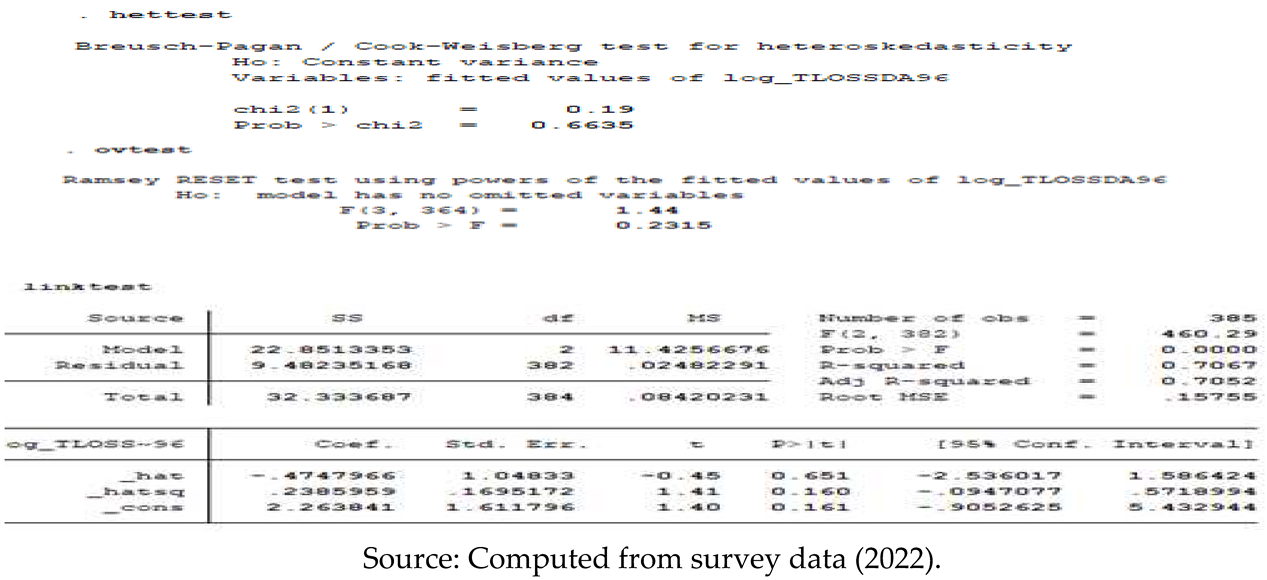

The factors that determine avocado post-harvest losses at the producer level in the area of study were examined using multiple linear regression models. The Breusch-Pagan test, the Ramsey RESET test; the result showed that there was no serious heteroscedasticity and multicollinearity problem gives a summary of the results obtained from the multiple regression analysis. The value was logged and expressed the dependent variables as in the model, LnTLOSSA. The model fit results for factors affecting post-harvest losses along avocado fruits are as shown in (

Table 9) given below.

Nine explanatory variables were discovered to explain the postharvest loss of avocado in the research area out of the 18 hypothesized variables. The regression variables sex of the respondent showed a negative relationship with postharvest loss at less than 1 % significance level. This suggests that households with female heads are more likely to experience post-harvest losses for these crops than families with male heads. The coefficients of the variable show that avocado producer being a male should decrease avocado postharvest loss by 0.09 quintal. The results of [

17], which came to the conclusion that there was little to no gender inequality in the growing of tomato fruits and, thus, no effect of sex on postharvest losses, are in conflict with this. The respondent’s educational level had a detrimental effect on avocado post-harvest loss and was significant at a probability level of 5% or less, supporting the hypothesis. The fact that there was a decline in amount lost as education level increased suggested that quantity lost was negatively correlated with education level. According to the variable’s coefficient, a one-year increase in schooling led to a 0.043848quintal decrease in the amount of avocado lost. According to the variable’s coefficient, an increase in avocado postharvest loss of 0.025 quintal occurred for every 1 km that the major road’s length was increased. The coefficient of the variable revealed that an increase in a day in extension agent engagement was responsible for the reduction in avocado postharvest loss by 0.28 quintal at less than 10% significant level while other factors remained unchanged. The increase of farmer training facilities and extension assistance could hasten the effort to change post-harvest loss handling procedures and its methods. Total off farm income was statistically significant at < 5% significance level and had negatively effect on quantity of avocado postharvest loss. The result is implied that; if the amount off- farm income obtained by avocado producers increase by one Birr, then the amount of avocado fruits post-harvest loss decreases by 0.72quntals,other things are constant. Income generating from by household from sales of avocado in the production year was found to have negative influence therefore leading to a decrease in post-harvest losses among farmers at 1% significance level. It is the amount of total income (measured in Birr) generated from avocado fruits increased by one birr, the post harvesting loss decreased by 0.092 Quintals. It is obvious that income earned from avocado fruits improves the post harvest loss of by purchasing or use modernized materials for reducing post harvest losses.The coefficient of the variable demonstrated that an increase in training access was responsible for the 0.13 quintal decrease in avocado postharvest loss at 1% significant level. Another major cause of avocado post-harvest a loss to farmers was the harvesting techniques; this is statistically significant affect avocado fruits post-harvest loss at 1% significance levels of avocado producers. The result shows that if producers used losses attributed to harvesting methods were least at farm level at about 22 percent per season. This shows that producers generally harvested their avocado fruits on the sampled respondent are not an appropriated methods of harvesting; this leads to high amount of loss at storage, harvesting methods, as well as transportation. In the same layer, availability of storage system adopted by the farmers was found to have a direct relationship with PHLs of avocado fruits in the study area. Avocado post-harvest losses among farmers are increased at a 5% significance level by the absence of storage facilities to regulate temperature on matured avocado fruits. In a review of post-harvest losses in tomatoes in Sub-Saharan Africa (SSA), Ref. [

19] came to the conclusion that post-harvest losses, particularly among smallholder farmers, were made worse by a lack of knowledge about essential quality standards.

4. Conclusion and Recommendation

The objective of this research work was to identify the factor that led to PHL in avocado fruit at the producer’s level in the Wolaita and Kembata Tembaro Zone of Ethiopia’s SNNPR. To improve the welfare of farm households, smallholder farmers must decrease post-harvest losses. The average number of avocado fruits lost after harvesting at the farm household head was 0.24. This suggested that the average loss from the production of all avocado fruits was equal to 24% of the total amount produced. This demonstrated that a substantial percentage of the yield of avocado fruits were lost.

The results of econometrics analysis found that sex, training on avocado management system and income generating from avocado fruits were significantly and negatively related with avocado PHLs for small -scale farmers (P< 0.01). But avocado harvesting methods significantly and positively affects post-harvest loss from small avocado fruits producers (P< 0.01).Beside the education level and off farm income level of the household head were variables which significantly and negatively related with avocado fruits PHLs for small scale farmers (P< 0.05), were as availability of the storage at household level have significantly and positively affected avocado fruits PHLs for small scale producers (P< 0.05. Also distance to nearest road significantly and positively affects PHLs for small avocado fruits producers (P< 0.1) and number of days extension contact per months significantly and negatively affects PHLs for small avocado fruits producers (P< 0.1).This study comes to the conclusion that more than one-fourth of the overall production of avocado fruits was lost throughout the post-harvest and consumption phases. Avocado fruits quantity loss is determined by physical and natural, institutional and demographic factors.

The following suggestions for policy changes are developed based on the study’s findings to decrease avocado fruit postharvest losses.

Since avocado fruit growers rarely use the usual post-harvest handling techniques, such as washing, grading, packaging, and shipping, the state of avocado fruit post-harvest management in the research area turned out to be poor. In order to minimize losses, the Ministry of Food and Agriculture, through its extension agent, be supposed to step up the training it offers to growers of avocado fruits, particularly women.

To reduce mechanical damages, roads connecting farms with markets need to be repaired. The Municipal and District Assemblies and private sector investors in the study area should improve the road infrastructure linking farms to market centers to reduce transport losses.

Post-harvest losses contribute significantly to food losses and give a serious hazard to the society’s and the nation’s main source of income. The reduction of post-harvest losses is not given enough focus by academics, the government, and researchers. The administration arrangement being practiced and the existing policy are also not helpfully for to overcome the problem. Highly government interference and coordination activities are, important for successful and sustainable controlling of the post harvesting losses of fruits.

Author Contributions

Abera: conceptualized, investigated, wrote the original draft, did the review and editing, software for analysis and interpreted the data; Wrote the paper. Berhanu and Lemma: supervised and validated along with methodological work. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

The authors acknowledge the Arake Agricultural Research Center and Wolaita and Kembata Tembaro zone agricultural office to give information and data for post harvest loss of fruit used in this study. The authors thank Ministry of education of Ethiopia (MOE) and Wolaita Sodo University Research and Community Service for funding the research work.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Data Availability Statement

All the necessary data are included in the manuscript. If additional data are required, the corresponding author can be contacted.

References

- FAO. (2014). Food and Agriculture Organization Ethiopia country programming framework. Office of the FAOR representative in Ethiopia to AU and ECA Addis Ababa, 2016.

- Central Statistical Agency 2019/20 Agricultural Sample survey: Crop and Livestock Product utilization survey. Addis Ababa, Ethiopia.

- EHPEA (Ethiopia Horticulture Producers and Exporters Association).(2013). Ethiopian Investment Commission database of licensed projects; Embassy of Ethiopia in China; All Africa.

- Kikulwe E.M., Okurut S., Ajambo S., Nowakunda K., Stoian D., Naziri D. Postharvest losses and their determinants: A challenge to creating a sustainable cooking banana value chain in Uganda. Sustainability 2018, 10, 2381. [CrossRef]

- Gross R., Schoeneberger H., Pfeifer H., Preuss H.J. 2000. Four dimensions of food and nutrition security: Definitions and concepts. SCN News 20: 20–25.

- Hailu G., Derbew B. Extent, causes and reduc-tion strategies of postharvest losses offresh fruits and vegetables–A review. Journal of Biology, Agriculture and Healthcare 2015, 5, 49–64.

- Lipinski B., Hanson C., Lomax J., Kitinoja L., Waite R., Searchinger T. 2013. Reducing food loss and waste. Working Paper, Installment 2 of Creating asus-tainable food future. World Resources Institute.

- FAO 2019. Reducing food losses through improved postharvest management in Ethiopia. Final eval-uation of phase 1. Food and Agriculture Organi-zation of the United Nations, Rome, Italy.

- Kasso, M., & Bekele, A. 2018.Post-harvest loss and quality deterioration of horticultural crops in Dire Dawa Region Ethiopia.

- Griesbach, J., (2005). Mango Growing in Kenya, World Agroforestry Centre, Nairobi World Agroforestry Centre (ICRAF), Nairobi, Kenya. Kul Graphics; Nairobi, Kenya, Internet http://\vww.worldagroforestrycentre.org.

- CSA, 2014, Agricultural Sample Survey 2013 / 2014; Volume I, Report on Area and Production of Major Crops, Statistical Bulletin 532; Addis Ababa, Ethiopia.

- Kadzere, I., Watkins, C.B., Merwin, I.A., Akinnifesi, F.K., Saka, J.D.K. and Mhango, J. (2006). Harvesting and post-harvest handling practices and characteristics of Uapaca kirkiana (Muell. Arg.) fruits.

- Bereda, S. 2016. Effect of harvesting, handling and storage techniques on quality and shelf life of avocado fruits in Sidama Ethiopia. MSc thesis, School of Plant and Horticultural Sciences, College of Agriculture, Hawassa University, Ethiopia, 72p.

- Aujla, K.M., M. Abbas, K. Mahmood and S. Saadullah. Marketing system of fruits, margins and export potential in Pakistan. Pakistan Journal of Life and Social Sciences 2007, 5, 34–39.

- Ban_jaw, T. iMed Pub Journals Review of Post-Harvest Loss of Horticultural Crops in Ethiopia, its Causes and Mitigation Strategies of Post-harvest Loss Horticultural Crops in Ethiopia in. Journal of Plant Scienceand Agricultural Research 2017, 2, 1–4. [Google Scholar]

- FellowsP. 2011. Packaging of agricultural products. Agromis a Foundation and CTA, Wageningen, the Nether lands. Agrodok 50; 70p.

- Babalola, D.A., Makinde, Y. O., Omonona, B.T. and Oyekanmi, M.O. (2010). Determinants of Post-harvest Losses in Tomato Production: a case study of Imeko – Afon local government area of Ogun state, Nigeria.

- Temesgen Deressa, Rashid M. Hassan, and Claudia Ringler. 2008. International Food Policy Research Institute: Measuring Ethiopian Farmers‟ Vulnerability to Climate Change Across Regional States.

- Sibomana, M. S., Workneh, T. S. and Audain, K. A review of post-harvest handling and losses in the fresh tomato supply chain: a focus on Sub-Saharan Africa. Food Science 2016, 8, 389–404.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).