Introduction

Loess is wind-blown sediment that occurs in arid and semi-dry areas where fine sand, silt, and clay accumulate. China has 640,000 km

2 of loess, 4.4% of it‘s total land area. Most loess comes from the 317,000 km

2 Loess Plateau in the upper and middle Yellow River. According to [

1], the Loess Plateau has around 300 million inhabitants. Loess is utilised in high-filled foundations, subgrade, and embankments because it is inexpensive and plentiful.

Loess as a construction material, on the other hand, is lower in tensile and compressive strength and may bend easily. Loess structures are brittle, easily damaged, and weatherproof [

2,

3]. Loess soils, recognised for their collapsibility, have several landsides and fast creep events. The deterioration of soils and slopes is often attributed to rapid creep. Loess collapses vary, increasing the danger of landslides and plate edge failures [

4]. Clay or bonding material shortages contributed to collapse. Thus, binding loess particles might limit collapsibility and damage. These calamities are still caused by loess interparticle brittleness. There are resistance-boosting methods to fix these concerns.

According to hardening and stabilising interparticle interactions [

5]. Stabilizing loess slopes in geotechnical engineering, especially in China, remains a challenge. Loess landslides have been studied to ensure engineering safety. This led to effective loess instability prevention and mitigation techniques [

6]. [

7] provided and confirmed equation constitutive for dynamic hydrological monitoring for landslide detection. Loess is stabilised to strengthen and endure these obstacles. Lime, cement, and fly ash are among the cementitious materials used worldwide to stabilise soil for better engineering performance.

Researchers found cement inclusion improves soil mechanical properties [

8]. Ordinary Portland Cement (OPC) is the industry standard binder for stabilisation and solidification because to its effectiveness, cheap cost, availability, and dependability [

9]. Cement’s hydration, pozzolanic reaction, and cation exchange may agglomerate small soil particles and form chemical bonds. This would improve a problematic soil’s geotechnical qualities including plasticity, strength, stiffness, and durability. Cement stabilisation is best for low to medium-sticky soil but less effective in excessively plastic soil [

10]. “Cement is the most common binder used in the deep mixing process. Common cement percentages in Japan and the United States are 20–30% and 10–50%” [

11].

Ordinary Portland cement (OPC) is the major stabilizing agent among all hydraulic binders used for stabilization. A reasonable proportion of cement, in addition to boosting saturated strength, improves water erosion resistance both immediately and long-term. [

12,

13] show that the cement concentration, packing density, Moisture content, curing conditions, mineralogy, and physical qualities of the sand all interact in complicated ways, making it difficult to characterise the unconfined compressive strength of the cemented soil. Recent studies show that fragile loess interparticle interactions cause landslides. According to the study in the introduction, cement is an excellent soil development method, the best material for stabilising loess, and produces amazing results. If cementing agents correct loess, binder concentration increases optimal water content.

This research examines loess-cement interactions. To do this, loess stabilised with different curing durations must be characterised physically and mechanically. SEM and XRF were used to study cement and loess particle interactions.

1. Materials and Methods

1.1. Raw materials

China’s Loess Plateau provided test soils. Four soil samples were assessed for specific gravity (Gs) using an Ultra Pyconometer, and the average was considered typical (

Table 1). The soil compaction curve showed that 12.00% moisture was optimal and 1.82 g/cm

3 was the maximum dry density (

Figure 1). The soil liquid limit (LL) was 31.33% and the plastic limit 18.33%. (

Table 1). Displaying particle size distribution (

Table 1). Clay, silt, and sand fraction sizes vary (

Table 1).

Table 1.

Physical properties of Loess.

Table 1.

Physical properties of Loess.

| Properties |

Values |

|

Gs |

2.71 |

| ρmax (g/cm3) |

1.82 |

| wopt (%) |

12.00 |

| Atteberg limits |

|

| Liquid Limit (%) |

31.33 |

| Plasticity Index (%) |

15.00 |

| Plastic Limit (%) |

18.33 |

Particle size

distribution

|

|

| Sand, 0.05–2.0 mm |

19.43% |

| Silt, 0.002–0.05 mm |

73.98% |

| Clay, < 0.002 mm |

7.59% |

The experiments used P.O. 42.5 regular Portland cement from Tongchuan Dongguan Cement Co., Ltd.

Table 4 and

Table 5 provide representative chemical compositions and essential features.

Table 2.

Chemical compositions of the studied loess.

Table 2.

Chemical compositions of the studied loess.

| Chemical name |

SiO2

|

A12O3

|

CaO |

Fe2O3

|

MgO |

K2O |

Na2O |

TiO2

|

| % |

59.47 |

14.72 |

11.82 |

5.07 |

3.21 |

2.79 |

1.59 |

0.72 |

| USDA classification |

Silt loam |

| Minerals present |

Kaolinite and illite |

Table 3.

Elemental composition of Loess.

Table 3.

Elemental composition of Loess.

| Elemental analysis |

Si |

Ca |

A1 |

Fe |

K |

Mg |

Ti |

| % |

52.84 |

16.38 |

13.21 |

8.09 |

4.87 |

3.26 |

1.04 |

Table 4.

Chemical compositions of ordinary Portland cement.

Table 4.

Chemical compositions of ordinary Portland cement.

| SiO2

|

Al2O3

|

Fe2O3

|

MnO2

|

SO3

|

CaO |

Ignition loss |

| 22.60 |

4.98 |

2.90 |

2.32 |

2.31 |

61.60 |

4.48 |

Table 5.

Basic properties of cement.

Table 5.

Basic properties of cement.

| Density/(g.cm-3) |

Specific surface area/(m2/kg) |

Setting time /min |

Flexural strength/MPa |

Compressivestrength/MPa |

| 3.16 |

363 |

Initial |

Final |

3 d |

28 d |

3 d |

28 d |

| |

|

170 |

210 |

6.3 |

9.2 |

26.8 |

49.7 |

1.2. Specimen preparation

The mix ratios were compared to the cement, loess, and water masses. Dry cement and loess were thoroughly mixed. Water to loess ratio was 0.4. The original combinations were all loess and ranged in cement content (3, 5, 7, 9%). After adding water, they mixed. We kept the mixture airtight in a plastic bag. We kept the mixture for 24 hours to balance moisture before compaction. The material was crushed in layers within a cylindrical steel mould with a 61.8 mm diameter and 125 mm height to create a homogeneous cement stabilised loess. GB/T50123 required four layers with 20 knocks each. The samples were 80mm long and 39.1mm wide. Compacted specimens were removed from the mould. They were labelled and sealed. Samples were made and cured for 3, 7, and 28 days.

1.3. Testing Methods

1.3.1. Flexural strength test

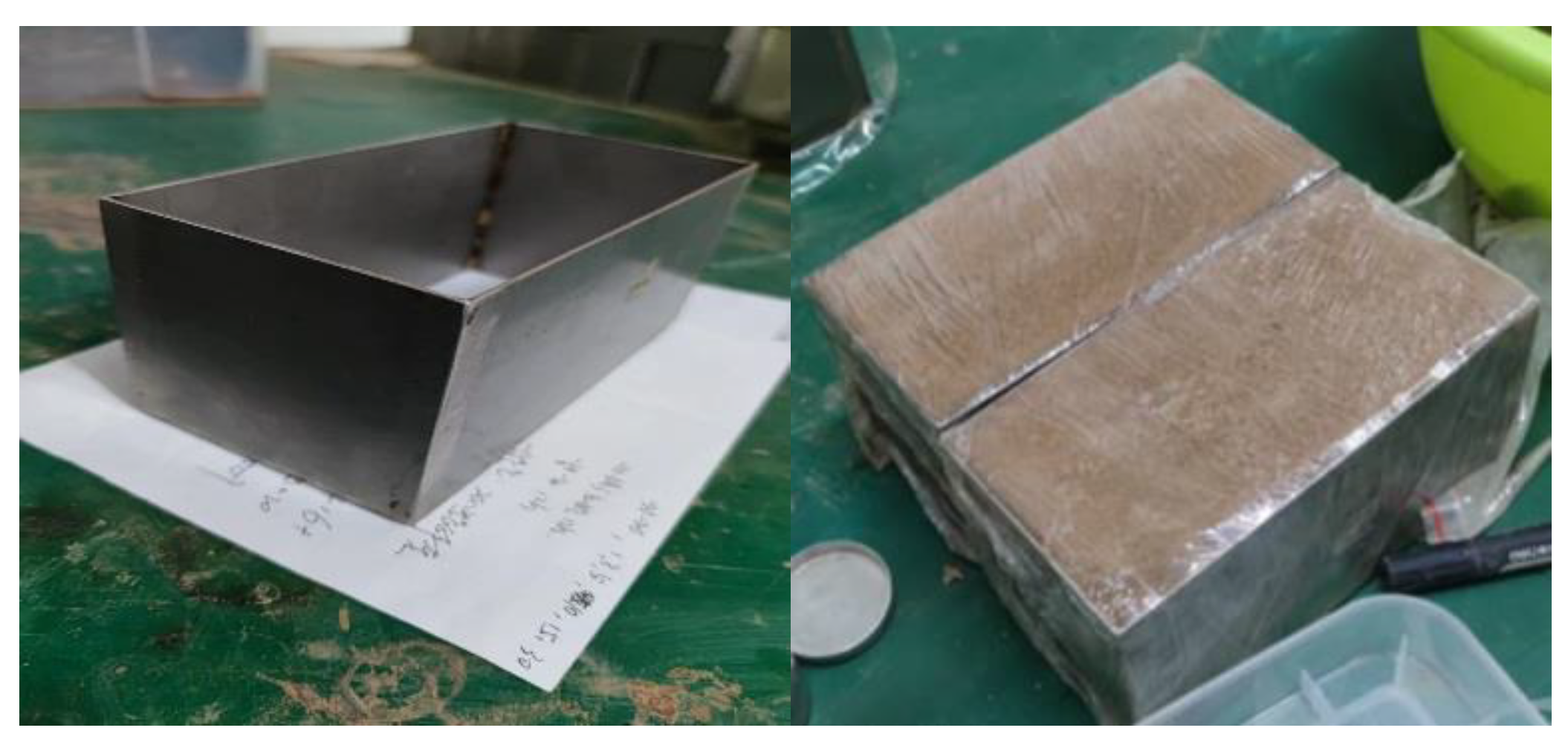

Steel moulds 105 x 99.5 x 213 mm formed beams for the study (

Figure 1a). Next, beam flexural tensile strengths are measured. Molded three homogenous cement-loess layers. After modification, the moulds were sealed in plastic (

Figure 1b) and left overnight. At this point, the samples could sustain their own weight. Demolded samples were aged for 28 days at 20°C, 1°C relative humidity and temperature.

We measured the flexural tensile strength of beams made from cement-stabilized loess in accordance with PN-EN 12390-5, the European standard for evaluating hardened concrete. Test specimens flexural strength [

14]. Four different samples of cement were used in the study. The examples were built around two 20 mm-diameter steel shafts with a 30 cm base. Each beam’s load shaft was placed in the center of its length.

The formula was used to compute the flexural tensile strength of each sample:

where: d

1= depht, d

2= width

Figure 1.

(a) steel mould, (b) sample wrapped with plastic.

Figure 1.

(a) steel mould, (b) sample wrapped with plastic.

1.3.2. Unconfined Compression Test

Mechanical properties of stabilized soils are often evaluated by measuring their unconfined compressive strength (UCS). To characterize the mechanical characteristics of the loess specimens, we estimated their unconfined compressive strength using the formula given in [

15]. There was direct compression applied to the samples, and the displacement rate was measured at 0.01mm/s (

Figure 2).

1.3.3. Compaction Test

Compaction tests indicate the appropriate moisture level per Chinese National Standard GB/T50123-2019. Three layers of varied water-content loess samples fill the squeezed cylinder. Each layer of loess is pounded 25 times. Before compressing samples, the cylinders are filled. Dividing the sample weight by the compressed cylinder capacity gives the wet density. Applying formula yields dry density:

The above approach correlates wet and dry densities for each category. The graphs show that the peak point’s ordinate has the largest water content and the abscissa the highest dry density.

1.3.4. Indirect Tensile Strength

The British Standards Institution’s indirect tension test method was used to determine the indirect tensile strength of cement stabilize loess specimens [

16]:

This Test Method Determines Hydraulically Bound Mixture Indirect Tensile Strength. Test individuals had a 2.05 slenderness ratio. Two plywood pieces 4x4x80mm, were used as bearing strips. Compressed samples were analysed at 0.002mm/s. Applying a vertical force to two parallel sides of a horizontal cylinder measured the material’s tensile strength. A vertical sample split followed. This mathematical equation indirectly calculates tensile strength [

17]. BSI [

16]. Indirect tension testing was utilised to evaluate stabilised loess specimen tensile strengths. "Test Method for Determining the Indirect Tensile Strength of Hydraulically Bound Mixtures."

Slenderness ratio is 2.05, low. Bearing strips were two 4x4x80mm wooden pieces. Samples were compressed at 0.002 mm/s. This test measured the tensile strength of a horizontal cylinder using a vertical force on two parallel sides. The sample was sliced vertically into equal parts. This formula may determine indirect tensile strength [

17].

where R is the indirect tensile strength,

F is the maximum applied force,

H is the length of the sample, and

D is the diameter of the sample (

Figure 3).

1.3.5. Direct shear test

The direct shear test follows the [

18] standard (1994). In this study, the shear ring in cement stabilised loess was 60 mm by 60 mm by 25 mm. The specimens were then removed from the shear box. At 50, 100, 200, and 300 kPa, shear strength was measured. 0.05 mm/min was the horizontal displacement rate. Each mixture combination included three specimens, and the test data average was determined. Based on addition proportions (3%, 5%, 7%, and 9%), the samples were divided into four groups to assess cohesiveness c and internal friction angle. Curing took seven days.

1.3.6. Water absorption test

Water absorption and softening coefficient were studied to assess cement stabilised loess water resistance. For the water adsorption test, the specimens’ dry weight after 28 days was determined, followed by their weight after 1 day in water. The following approaches yielded water adsorption:

where Mn is the dry mass and Mn is the water-immersed material. The compressive strength of specimens after 28 days and after one day in water were assessed to establish the softening coefficient. This equation calculated the softening coefficient:

where K is the softening coefficient, I

0 is the compressive strength at 28d, and I

1 is the corresponding compressive strength after immersion in water.

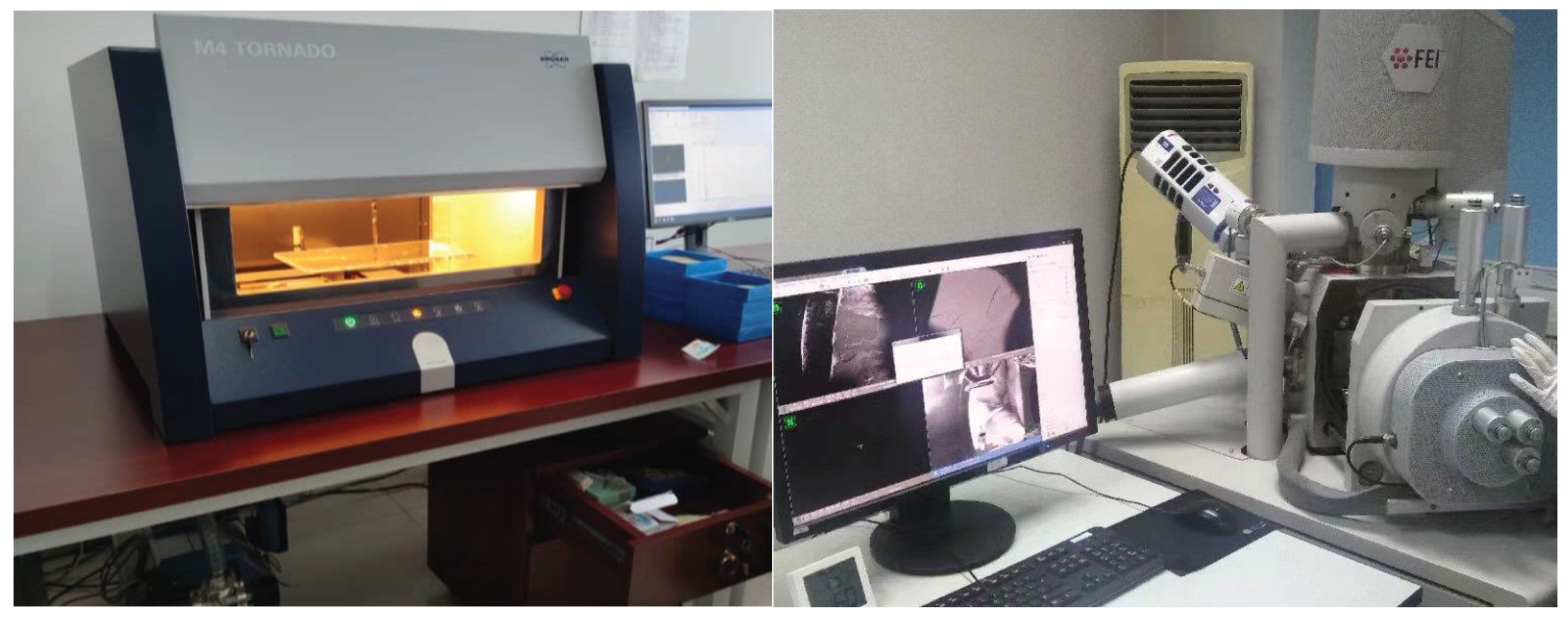

1.3.7. Microstructural analysis

Cementitious components alter compacted mixture microstructure in several studies. After 28 days of curing with cement percentages of 3%, 5%, 7%, and 9%, SEM was employed. X-ray power diffraction (XRF) showed loess’ usual quartz and clay composition.

An XRF spectrometer is used to perform non-destructive chemical tests on rocks, minerals, sediments, and fluids. The behaviour of atoms in X-rays allowed XRF analysis of primary and trace elements in geological rocks.

Figure 4.

(a) Micro-XRF spectrometers M4 Tornado, (b) Scanning Electron Microscope.

Figure 4.

(a) Micro-XRF spectrometers M4 Tornado, (b) Scanning Electron Microscope.

2. Results and Discussion

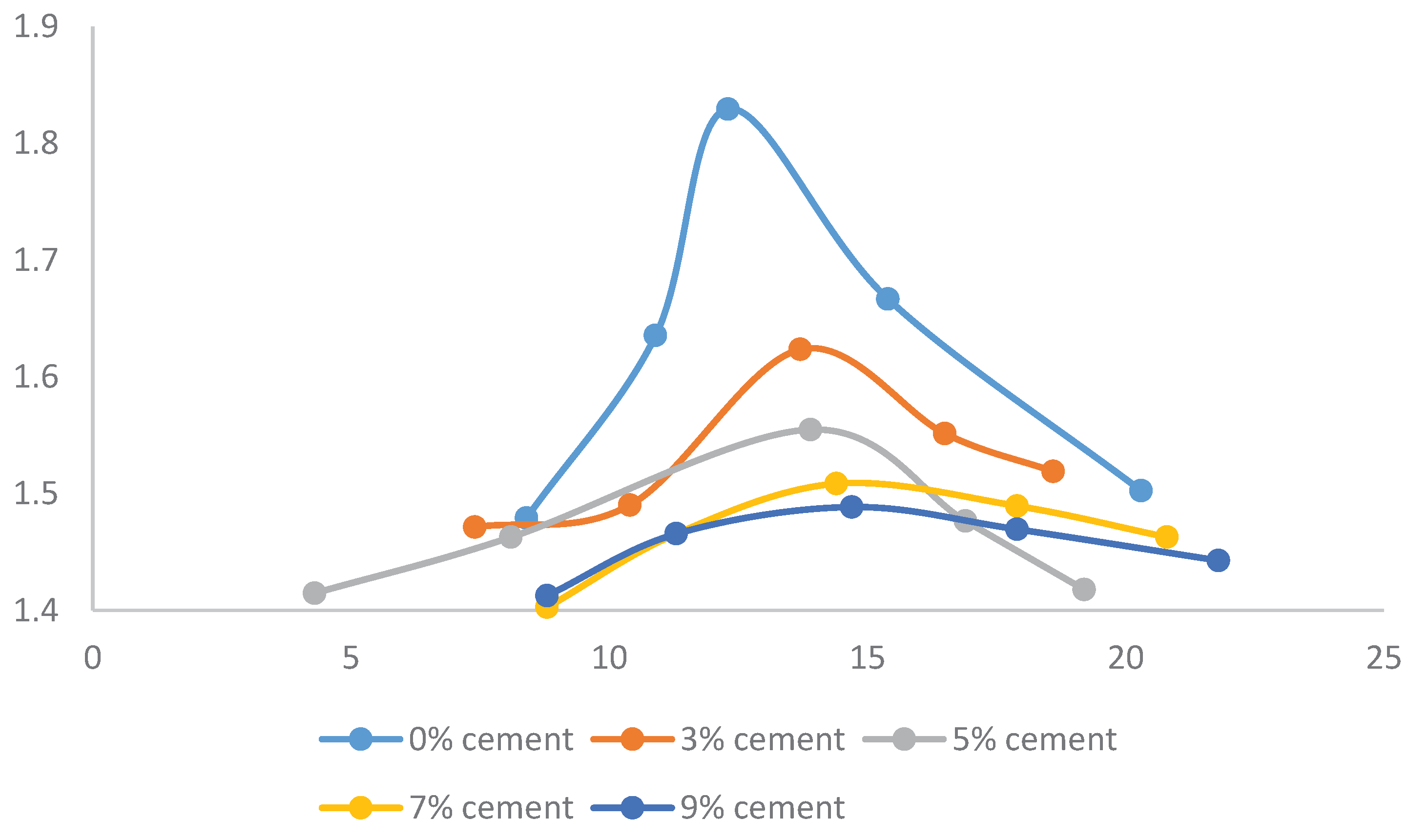

2.1. Compaction properties

The standard test approach for laboratory soil compaction characteristics was used to perform compaction tests with normal effort. Trace cement in loess soil affected its usual Proctor compaction curves. The maximum dry unit weight decreased from 1.82 g/cm3 to 1.48 g/cm3 when the cement concentration climbed from 0% to 9% and the appropriate moisture level increased from 0.12% to 0.14%. Dry unit weight decreased steadily with cement concentration.

Figure 5.

Moisture content-dry density relation curves of cement stabilized loess.

Figure 5.

Moisture content-dry density relation curves of cement stabilized loess.

It was shown that the ideal moisture content grew as a function of cement percentage because cement hydration necessitated an increasing amount of moisture [

19].

“These changes may be related to the pozzolanic reaction, as occurs with related clay materials” [

20]. The optimal water content rises together with the percentage of binder used to enhance loess [

21].

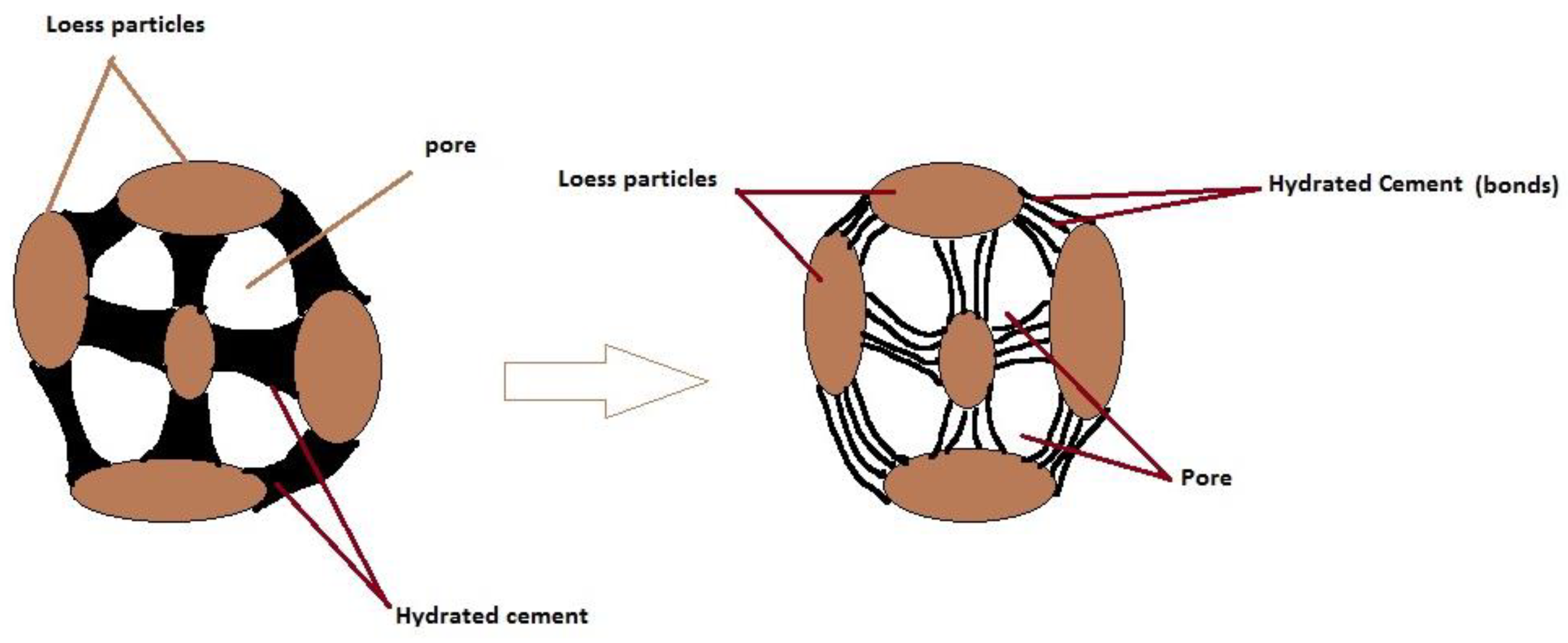

The addition of cement increases flexibility, which agrees with the idea that the Optimum Water Content should grow by around 10 %. The inclusion of cement, which has a higher density relative to loess and soil skeletal stiffness, may explain the increased maximum dry density in loess-cement mixtures . Cement-stabilized loess develops its final macrostructure as a result of primary cement linkages between aggregated loess and cement particles.

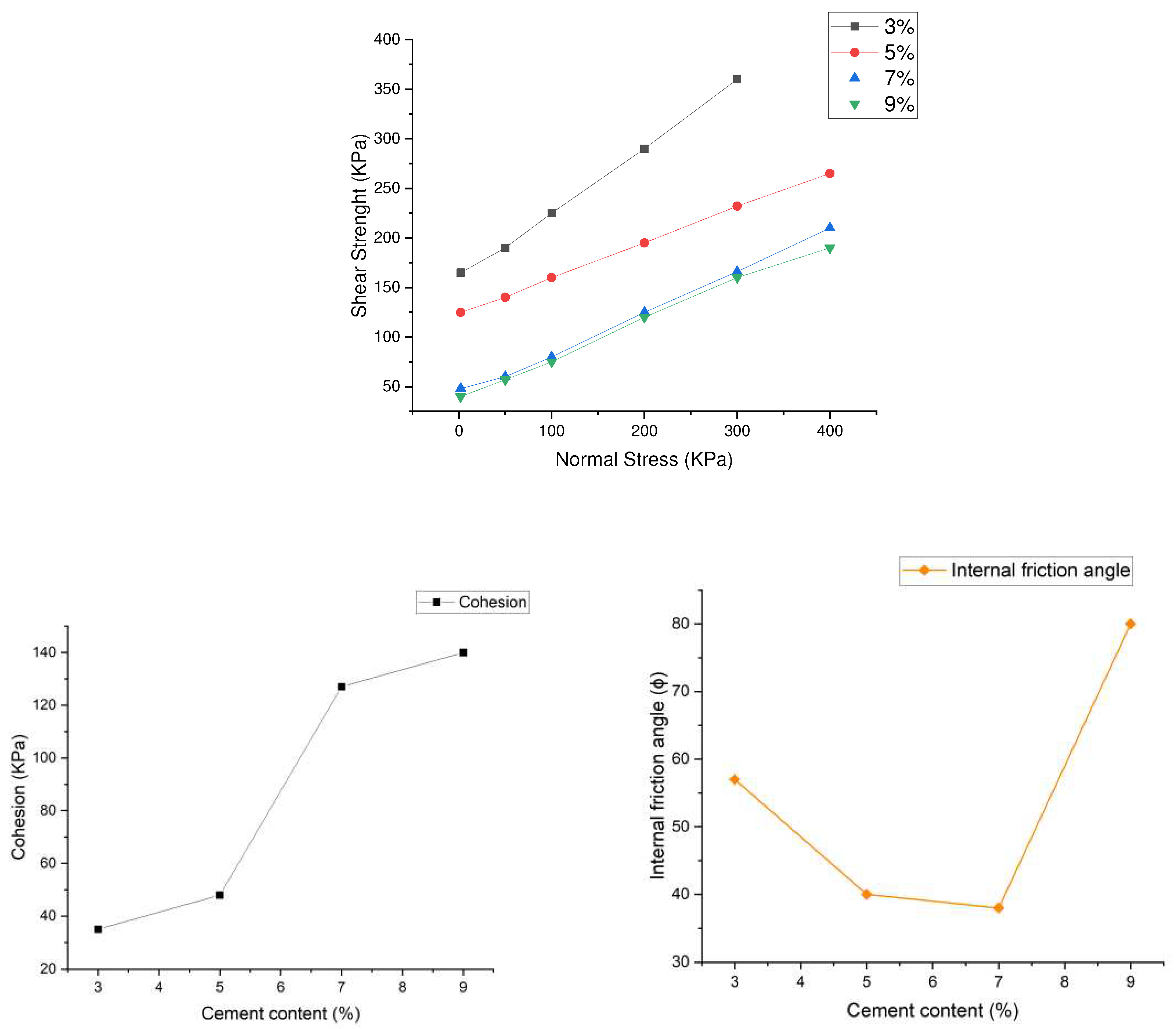

2.2. Shear Strenght

After seven days, cement-stabilized loess has a maximum shear strength (

Figure 6a). Shear strength increased steadily as cement content increased.

These findings show how cement boosts peak shear strength. As illustrated, cement-stabilized loess strength envelopes determined their friction angle and cohesiveness (

Figure 6b). The association between cement and friction angle dropped, demonstrating that soil structure had no effect at a certain cement concentration. The friction angle decreased from 30° to 11.3° as the cement percentage increased from 0% to 7%. The cement percentage increased with shear strength. The 7% cement composite was four times stiffer than the 3%. This data reveals that cohesion, which increases shear strength, is more structure-sensitive than friction angle. Remolded samples with cement percentages under 9% demonstrated minimal friction angles. Cementitious linkages between loess mineral components create a matrix that encloses unbonded particles and aggregates, resulting in more complex engineering behaviours [

22].

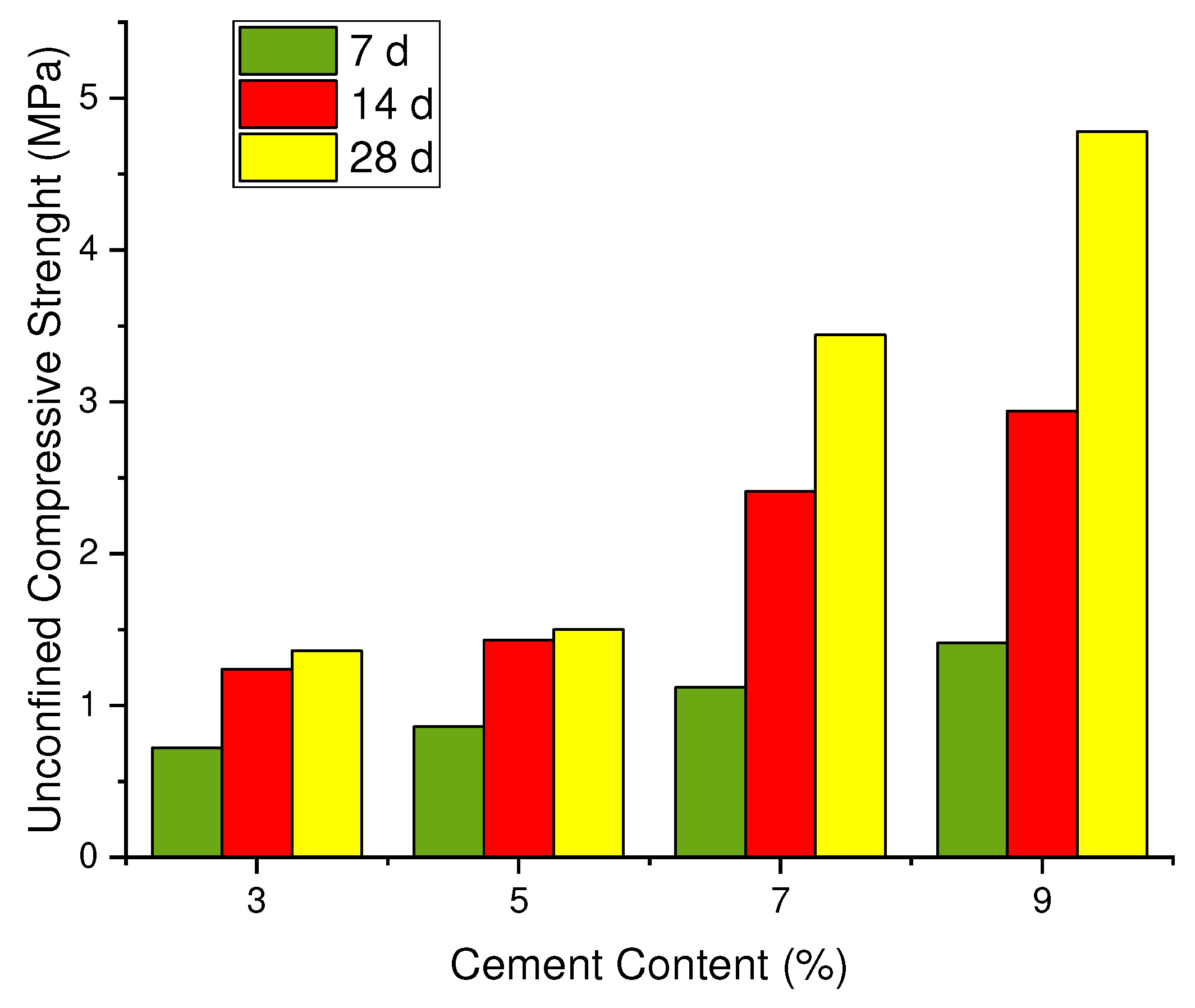

2.3. Unconfined compressive test

The unconfined compressive strength test is used in soil stabilisation applications to measure loess improvement after treatment. We examined portland cement’s effect on loess by adding different percentages of cement by weight. Each cylindrical UCS test item was 39.9 mm wide and 80 mm high. Placing soil-cement samples in a humid and temperature-controlled curing chamber. After seven days of curing, loam with 3% to 7% cement increased UCS. Cement ratios over 6% gain strength after 28 days. Specifically, 9% stabilisation increased UCS to 4.78 MPa. Curing day has a greater effect on UCS than cement concentration. Cement stabilised loess’ mechanical properties improve with enough curing days, according to testing. Cement, which forms C-S-H, strengthens the material. C-S-H gel may combine soil particles close together. C-S-H gel and unconfined compressive strength improve with cement.

Figure 7.

Variation of unconfined compressive strength with cement content.

Figure 7.

Variation of unconfined compressive strength with cement content.

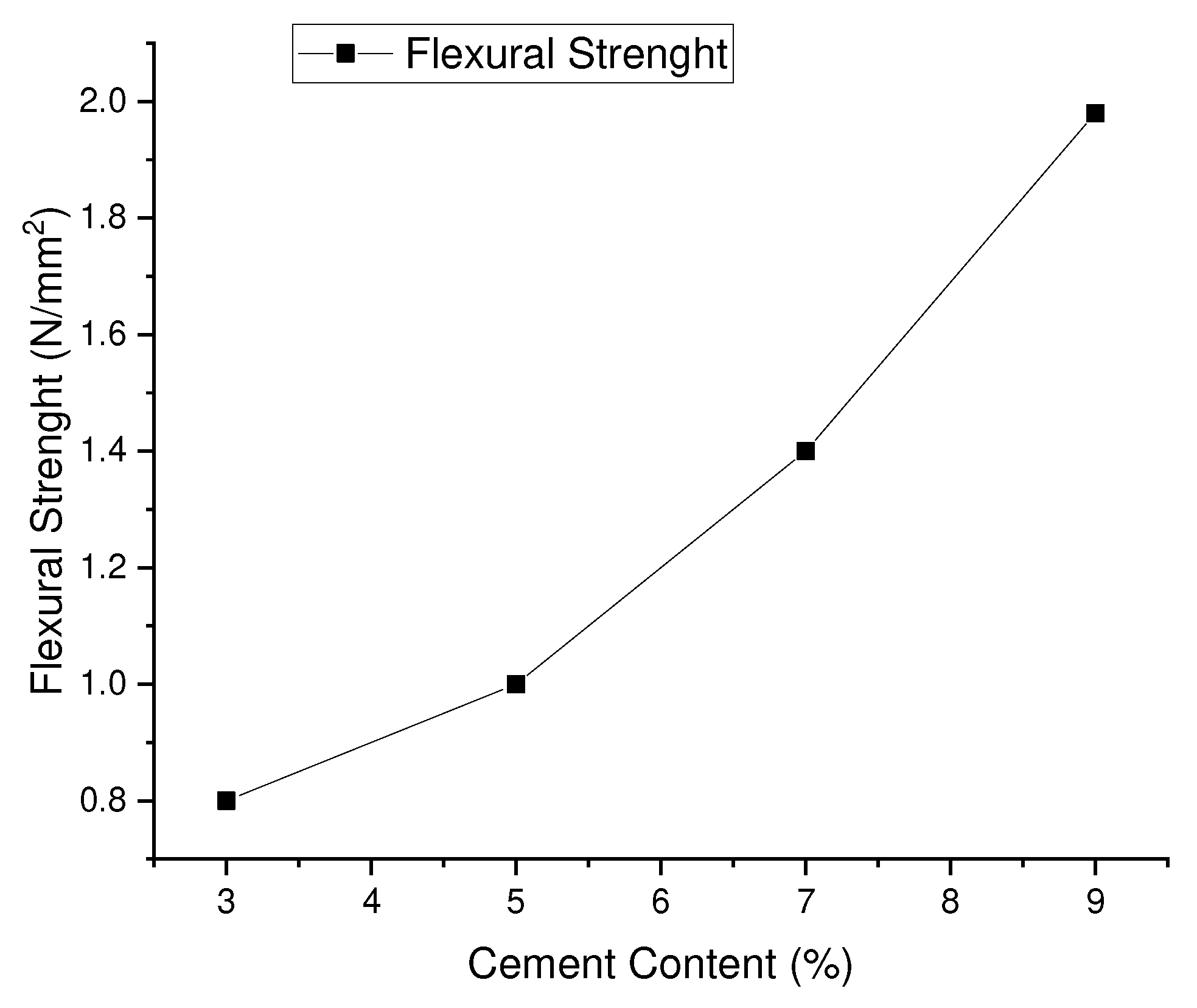

2.4. Flexural Strenght

Cement-stabilized loess samples were flexural tensile tested. Cement strengthens the structure, as planned. Cement improved strength by 0.8 N/mm2, 5.1 N/mm2, 1.4 N/mm2, and 1.98 N/mm2 for 3%, 5%, 7%, and 9%, respectively. Ettringite and C-S-H gel would provide strength, and humidity would optimise hydration. Cementing loess modifies failure mechanisms. Cement-stabilized loess samples maintained strength throughout the test. Post-peak strength did not decrease.

Figure 8.

The flexural strength of loess stabilize cement, cured time at 28 days.

Figure 8.

The flexural strength of loess stabilize cement, cured time at 28 days.

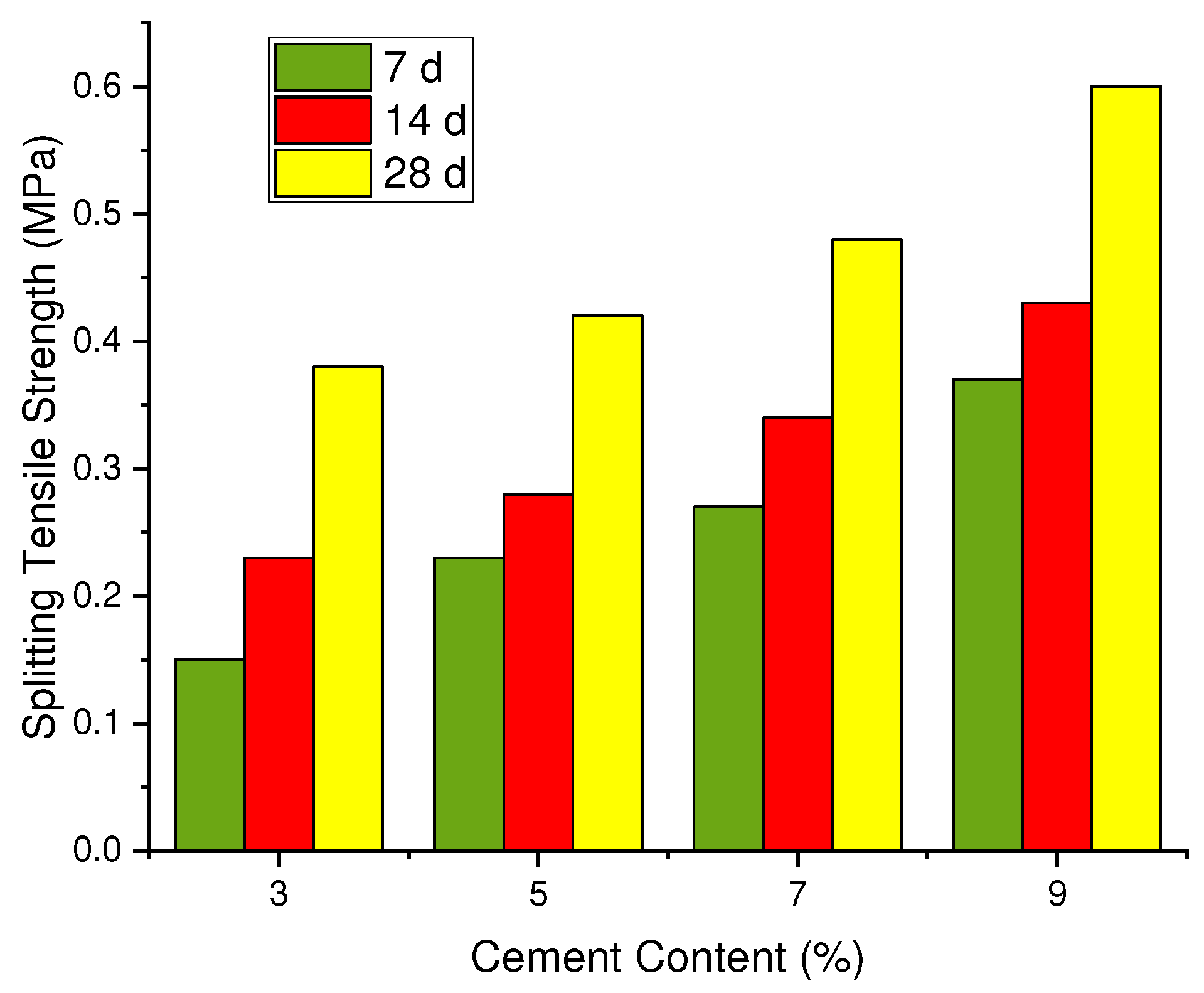

2.5. Splitting tensile strength test

Tensile strength is often lower than compressive strength, making measurement difficult. Geotechnical engineering uses tensile strength. Thus, academics have studied it using direct and indirect experimental methods. This research used cement-stabilized loess to measure indirect tensile strength. Cement amount and curing time increase peak tensile force. After 28 days of curing, 3%, 5%, and 7% raise cement stable load peak tensile strength to 0.38 MPa, 0.42 MPa, and 0.48 MPa. Portland cement increases loess splitting tensile strength. As cement concentration grows from 3% to 5% to 7% to 9%, splitting tensile strength increases from 0.23 MPa to 0.28 MPa to 0.34 MPa and 0.44 MPa in 14 days. After 7 days of cure, the cement-bound loess’s maximum tensile force is 0.15 MPa, 0.23 MPa, 0.27 MPa, and 0.37 MPa.

Figure 9.

Variation of tensile strenght of with cement content.

Figure 9.

Variation of tensile strenght of with cement content.

2.6. Flexural-compressive strenght relationship

Flexural and indirect tensile strength are as important as unconfined compressive strength for assessing material stabilisation (UCS). (

Figure 10) show flexural and unconfined compressive strengths at different cement concentrations (with an R value of 0.71). The material was homogeneous since the UCS and flexural strength samples were different. The findings can be compared and connected, but they are not reliable.

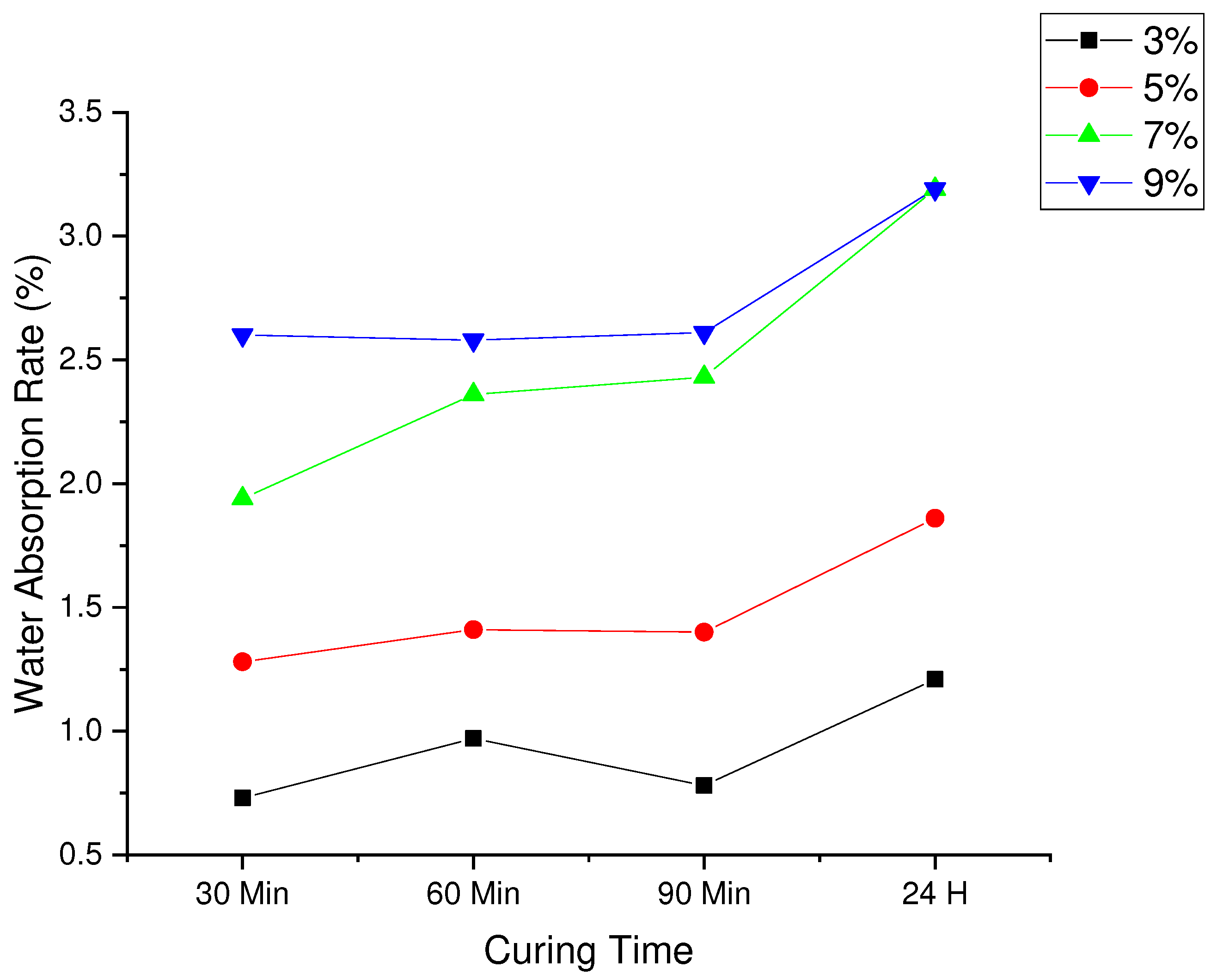

2.7. Water-resistance

Different cement and loess samples were used to determine how curing time impacts water absorption, R

n. (

Figure 11) indicates that soaking increased R

n from 30 minutes to 24 hours. Stabilized samples in water for the same duration at various temperatures decreased R

n. R

n grows by 3%, 5%, 7%, and 9% from 30 to 60 minutes in water, while between 60 and 90 minutes, it declines by 3% to 5%.

3%, 5%, 7%, and 9% cement percentages increased significantly between 90 minutes and 24 hours. Hydration solutions would fill interior spaces as cure time rose. Cement formed ettringite and CSH gel, preventing water erosion.

2.8. Microstructure analysis

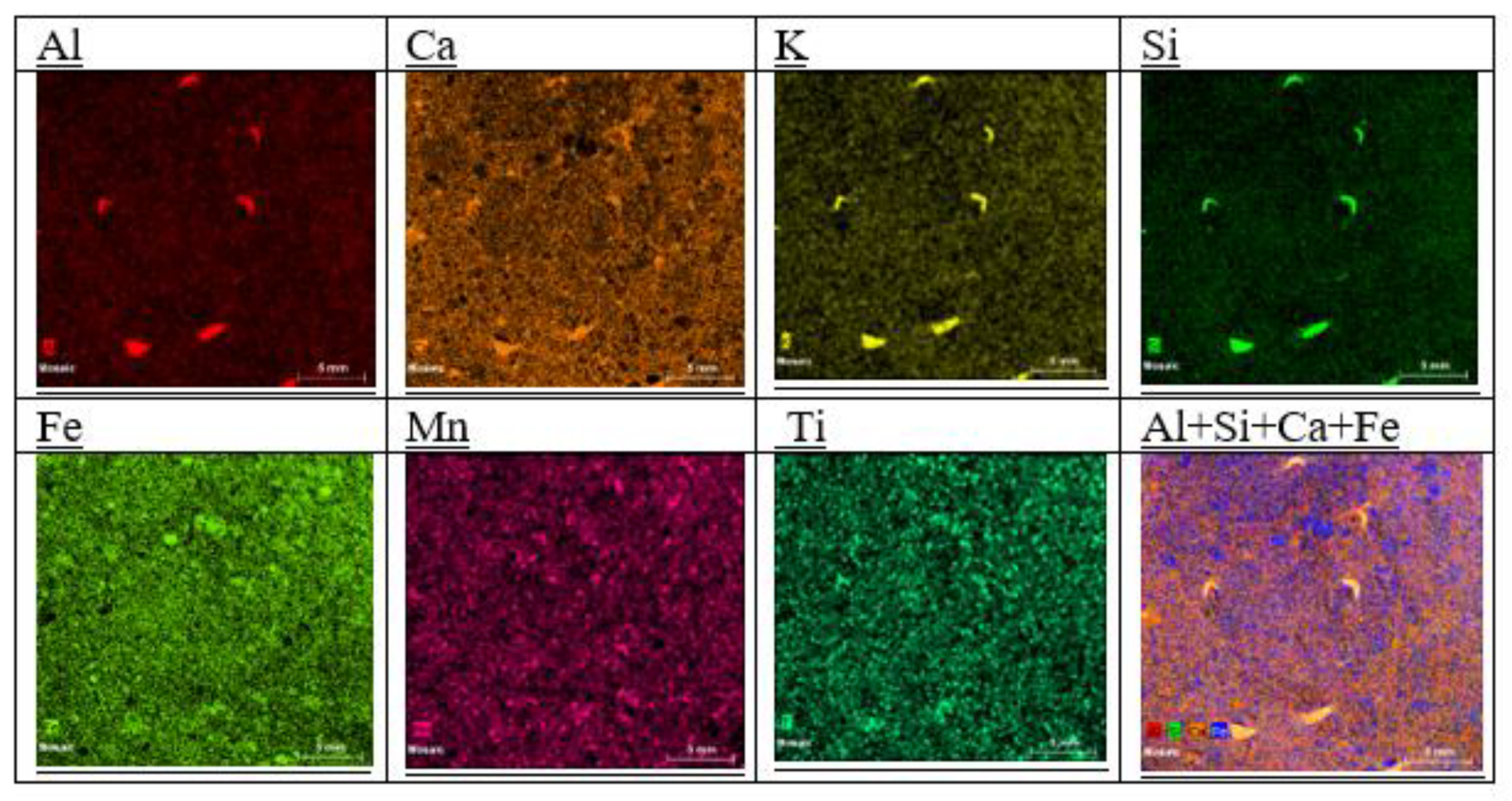

2.8.1. XRF analyses

Cement-stabilized loess was analysed by XRF. Micro-XRF (M4 Tornado, German) measured elemental composition (

Table 6,

Figure 12). 6.95%, 12.09%, 1.72%, 7.54%, 2.31%, 0.15%, and 0.61% were Si, Ca, Al, Fe, K, Mn, and Ti. SiO

2, Al

2O

3, CaO, Fe

2O

3, and K

2O comprised 14.86%, 3.25%, 16.92%, 10.79%, and 2.79% of the soil’s oxides by weight. Cement use affects loess chemical composition (

Table 6).

From (

Table 6) Cement alters loess minerals. Cementing loess decreases SiO

2, Al

2O

3, and Fe

2O

3 while increasing CaO, MgO, and TiO

2. The pozzolanic reaction, or chemical interaction between reactive silica or alumina in portlandite during cement hydration in water at ambient temperature, creates it. Cement is mostly CaO (16.92%), SiO

2 (14.86%), and Al

2O

3 (3.25%). SO

3 content does not completely affect cement quality.

Cement’s setting time will be prolonged if its content exceeds the prescribed limit. according to [

23] the maximum SO

3 concentration is 4%.

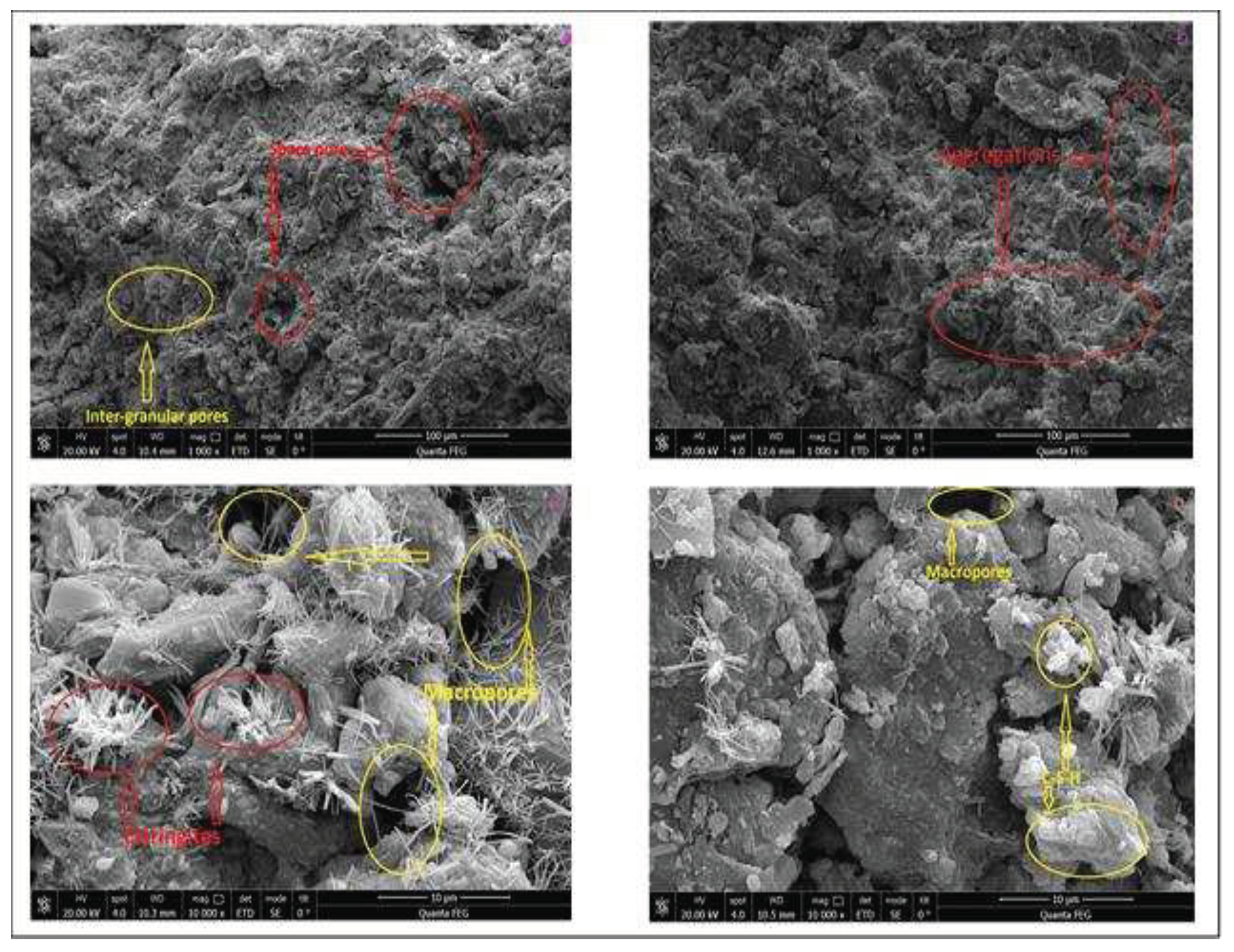

2.8.2. SEM Analyses

The stabilised loess soil was photographed using SEM. SEM micrographs of Portland cement-stabilized loess soil at 3%, 5%, 7%, and 9% show significant microstructural changes. The cure took 28 days.

Reaction products and hydration affect loess matrix changes (

Figure 13a). The fibrous growths may be seen in the sample because the loess matrix is porous and the composite mixture has a high water to cement ratio. At higher magnification, hydration product production was fast (

Figure 13c). As cement concentration increases, natural soil flocculations thicken. Cement produced flocculations may create a stronger, more controllable loess structure with denser particles. Thus, increasing cement dose improved flocculation and loess strength. This statement may be explained by recognising that the flocculations are the consequence of the cement hydrating throughout the curing time, and that additional cement would result in a greater hydration, cementing weak soil particles and enhancing soil strength. C-S-H gel hydration products form the reticular fibrous network after 28 days (Figur13d). Calcium-silicate-hydrate (C-S-H) is thought to boost Portland Cement’s strength when hydrated. C-S-H synthesis may strengthen soil stabilised by Ca(OH)

2 from cement hydration. Calcium and alumina may produce the C-A-H cementitious complex. Ettringite grew with C-S-H phases (3CaO.Al

2O

3.3CaSO

4.32H

2O or C6AS3H323CaO).

The cement-stabilized loess’s strength comes from additional cementation products created during curing. Cation exchange, pozzolanic reactions, and carbonation strengthen cement-stabilized loess. Cement stabilized loess aggregates during short-term cation exchange, increasing its strength. Slow pozzolanic reactions and carbonation create new cementitious materials, make loess particles less porous, and bond soil particles. This makes cement-stabilized loess considerably stronger.

Conclusions

Loess from China’s Loess Plateau was tested for geotechnical properties after being combined with different cements. Water resistance, density, and compressibility of cement-stabilized loess were measured. The direct shear, flexural, unconfined compressive, and tensile strengths were also measured to compare strength at various curing stages. Results:

(1) Cement minimises loess flexibility. Rising shear strength matched cohesiveness changes. This study shows that cohesiveness in cement-stabilized loess is more structure-sensitive than friction angle and that bonding is necessary for shear strength gain following remoulding.

(2) The compressive strength increases without limit as the cement amount and curing time increase. The unconfined compressive strength of a given cement content increases as curing time increases.

(3) With more cement added and the ideal moisture level decreased, the maximum dry density increases.

(4) Tensile and bending strength get better as the amount of cement and curing time increases.

(5) After 28 days, the specimen’s flexural strength increased most when the cement concentration was between 7% and 9%.

Declarations of Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

“This work was supported by the National Natural Science Foundation of China, grant number (42230712 and 41877225), the authors would like to thank the support of Chang‘an University.”, This is both practical and conducive to the publication of the article.

References

- Peng D, Xu Q, Qi X, Fan X, Dong X, Li S, Ju Y. Study on early recognition of loess landslides based on field investigation. International Journal Geohazards and environment 2016, 32–52. [Google Scholar]

- Shi, Y.C.; Lin, X.W.; Wang, L.M.; Wang, W.F.; Fu, C. Earthquake damage characteristics of raw soil buildings in loess areas and disaster prevention countermeasures. Journal of Natural Disasters 2003, 12, 87–92. [Google Scholar]

- Pei, X.; Zhang, F.; Wu, W.; Liang, S. Physico chemical and Index properties of loess stabilized with lime and fly ash piles. Applied Clay Science 2015, 114, 77–84. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Qu, Y.X. Cements of sand loess and their cementation in North Shaanxi and West Shaanxi. Engineering Geology 2005, 13, 18–28. [Google Scholar]

- Jefferson, I.; Rogers, C.; Evstatiev, D.; Karastanev, D. Treatment of metastable loess soils: Lessons from Eastern Europe. Elsevier Geo-Engineering Book Series 2005, 5, 723–762. [Google Scholar]

- Qiu, H.; Cui, P.; Hu, S.; Liu, Q.; Wang, Y.; Gao, Y.; Deng, M. Size-frequency distribution of landslides in different landforms on the Loess Plateau of Northern Shaanxi. Earth Science 2016, 41, 343–350. [Google Scholar]

- Crawford, M.M.; Bryson, L.S.; Woolery, E.W.; Wang, Z. Long-term landslide monitoring using soil water relationships and electrical data to estimate suction stress. Eng Geol 2019, 251, 146–157. [Google Scholar] [CrossRef]

- Jayasinghe, C.; Kamaladasa, N. Compressive strength characteristics of cement stabilized rammed earth walls. Constr. Build. Mater. 2007, 21, 1971–1976. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Cho, D.W.; Tsang, D.C.; Yang, J.; Hou, D.; Poon, C.S. Novel synergy of Si-rich minerals and reactive MgO for stabilisation/solidification of contaminated sediment. J. Hazard. Mater. 2019, 365, 695–706. [Google Scholar] [CrossRef]

- James, J.; Pandian, P.K. Industrial Wastes as Auxiliary Additives to Cement/Lime Stabilization of Soils. Hindawi publishing Corporation, 2016.

- Rashid, A.S.A.; Bunawan, A.R.; Said, K.N.M. The deep mixing method: bearing capacity studies. Geotechnical and Geological Engineering. s.l.: Geotechnical and Geological Engineering. Geotechnical and Geological Engineering 2017, 35, 1271–1298. [Google Scholar] [CrossRef]

- Kaniraj, S.R.; Havanagi, V.G. Compressive strength of cement stabilized fly ash-soil mixtures. Cem. Concr. Res. 1999, 29, 673–677. [Google Scholar] [CrossRef]

- Subramanian, S.; Khan, Q.; Ku, T. Effect of sand on the stiffness characteristics of cement-stabilized clay. Constr. Build. Mater. 2020, 264, 120192. [Google Scholar] [CrossRef]

- PN-EN12390-5. Testing hardened concrete. Flexural strength of test specimens.

- GB/T 50123. Standard for Soil Test Method; Planning Press: China, Beijing, 1999. [Google Scholar]

- EN13286-42. test method for the determination of the indirect tensile strength of hydraulically bound mixtures. Europe: European standards, 2003.

- EN13286-42. Test Method for the Determination of the Indirect Tensile Strength of Hydraulically Bound Mixtures,. Europe: European Standards, 2003.

- ASTM International. Standard Test Method for Direct Shear Test of Soils under Consolidated Drained Conditions. ASTM D3080-98, ASTM International: West Conshohocken, PA, USA, 1998.

- Kma, H.; Lachemi, M.; Easa, S. Stabilized soils for construction applications incorporating natural resources of Papua New Guinea. Resources. ELSEVIER Resources, Conservation and Recycling 2007, 51, 711–731. [Google Scholar]

- Seco, A.; Ramírez, F.; Miqueleiz, L.; et al. Stabilization of expansive soils for use in construction. Applied Clay Science 51. Applied Clay Science 2011, 51, 348–352. [Google Scholar]

- Kumar, A.; Walia, B.S.; Bajaj, A. Influence of fly ash lime and polyester fibers on compaction and strength properties of expansive soil. Journal of Materials in Civil Engineering 2007, 19, 242–248. [Google Scholar] [CrossRef]

- Kasama, K.; Zen, K.; Iwataki, K. Undrained Shear Strength of Cement-Treated Soils, Soils and Foundations. Soils and Fondations 2006, 46, 221–232. [Google Scholar] [CrossRef]

- SNI 7064:2014.2014 Semen Portland Komposit. Jakarta: Badan Standar Nasional, 2014.

- Zhang, D.; Wang, G.; Luo, C.; Chen, J.; Zhou, Y. Discussion on “A rapid loess flowslide triggered by irrigation in China”. Landslide 2009, 6, 55–60. [Google Scholar] [CrossRef]

- Petry, T.M.; Little, D.N. Review of stabilization of clays and expansive soils in pavements and lightly loaded structures—history, practice, and future. Journal of Materials in Civil Engineering 2002, 14, 447–460. [Google Scholar] [CrossRef]

- Fitzmaurice. Manual on stabilised soil constructions for housing. Technical Assistance Program. United Nations, New York : s.n., 1958.

- Wang, L.; Chen, L.; Tsang, D.C.; Li, J.S.; Yeung, T.L.; Ding, S.; Poon, C.S. Green remediation of contaminated sediment by stabilization/solidification with industrial by-products and CO2 utilization. Sci. Total Environ. 2018, 1321–1327. [Google Scholar] [CrossRef]

- Kumar, A.; Walia, B.S.; Bajaj, A. Influence of fly ash, lime, and polyester fibers on compaction and strength properties of expansive soil. Journal of Materials in Civil Engineering 2007, 19, 247–248. [Google Scholar] [CrossRef]

- Kumar, A.; Walia, B.S.; Bajaj, A. Influence of fly ash, lime, and polyester fibers on compaction and strength properties of expansive soil. Journal of Materials in Civil Engineering 2007, 19, 242–248. [Google Scholar] [CrossRef]

- Dove, C.A.; Bradley, F.F.; Patwardhan, S.V. Seaweed biopolymers as additives for unfired clay bricks. Materials and Structures 2016, 49, 4463–4482. [Google Scholar] [CrossRef]

- Loess improvement methods. Evstatiev, Dimcho. 341-366. Engineering Geology, Vol. 25, p. 1988.

- Guney, Y.; Sari, D.; Cetin, M.; et al. Impact of cyclic wetting–drying on swelling behavior of lime-stabilized soil. Building and Environment 2007, 42, 681–688. [Google Scholar] [CrossRef]

- Zhuang, J.; Peng, J.; Wang, G.; Javed, I.; Wang, Y.; Li, W. Distribution and characteristics of landslide in loess plateau: a case study in shaanxi province. Engineering Geology 2018, 236, 89–96. [Google Scholar] [CrossRef]

- Sturm, T.; Ramos, L.F.; Lourenço, P.B. Characterization of dry-stack interlocking compressed earth blocks. Materials and Structures 2015, 48, 3059–3074. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, G.; Kamai, T.; Chen, W.; Zhang, D.; Yang, J. Undrained shear behavior of loess saturated with different concentration of sodium chloride solution. Engineering geology 2013, 155, 69–79. [Google Scholar] [CrossRef]

- Shao, X.; Zhang, H.; Tan, Y. Collapse behavior and microstructural alteration of remolded loess under graded wetting tests. Engineering Geology 2018, 233, 11–22. [Google Scholar] [CrossRef]

- Prusinski, B. Effectiveness of Portland cement and lime in stabilizing clay soils. Journal of the Transportation Research Record 1999, 215–227. [Google Scholar] [CrossRef]

- Pan, Y.; Yao, K.; Phoon, K.K.; Lee, F.H. Analysis of tunnelling through spatially-variable improved surrounding—A simplified approach. Tunnelling and Underground Space Technology 2019, 93, 103102. [Google Scholar] [CrossRef]

- Yao, K.; et al. A direct assessment for the stiffness development of artificially cemented clay. Geotechnique. Geotechnique. 2019, 741–747. [Google Scholar] [CrossRef]

- Watabe, Y.; Furuno, T.; Tsuchida, T. Mechanical properties of dredged soil treated with low quantity of cement. Doboku Gakkai Ronbunshu 2001, 2001, 331–342. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.T.; Ahn, J.; Han, W.J.; Gabr, M.A. Experimental evaluation of strength characteristics of stabilized dredged soil. Journal of Materials in Civil Engineering 2009, 22, 539–544. [Google Scholar] [CrossRef]

- Wang, H.K.; Qian, H.; Gao, Y. Non-darcian flow in loess at low hydraulic gradient. Engineering geology 2020, 267, 9. [Google Scholar] [CrossRef]

- Sturm, T.; F.Ramos, L.; Lourenço, P.B. Characterization of dry-stack interlocking compressed earth blocks. Materials and Structures 2015, 48, 3059–3074. [Google Scholar] [CrossRef]

- Kaniraj, S.R.; Havanagi, V.G. Compressive strength of cement stabilized fly ash-soil mixtures. Cement and Concrete Research 1999, 673–677. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).