1. Introduction

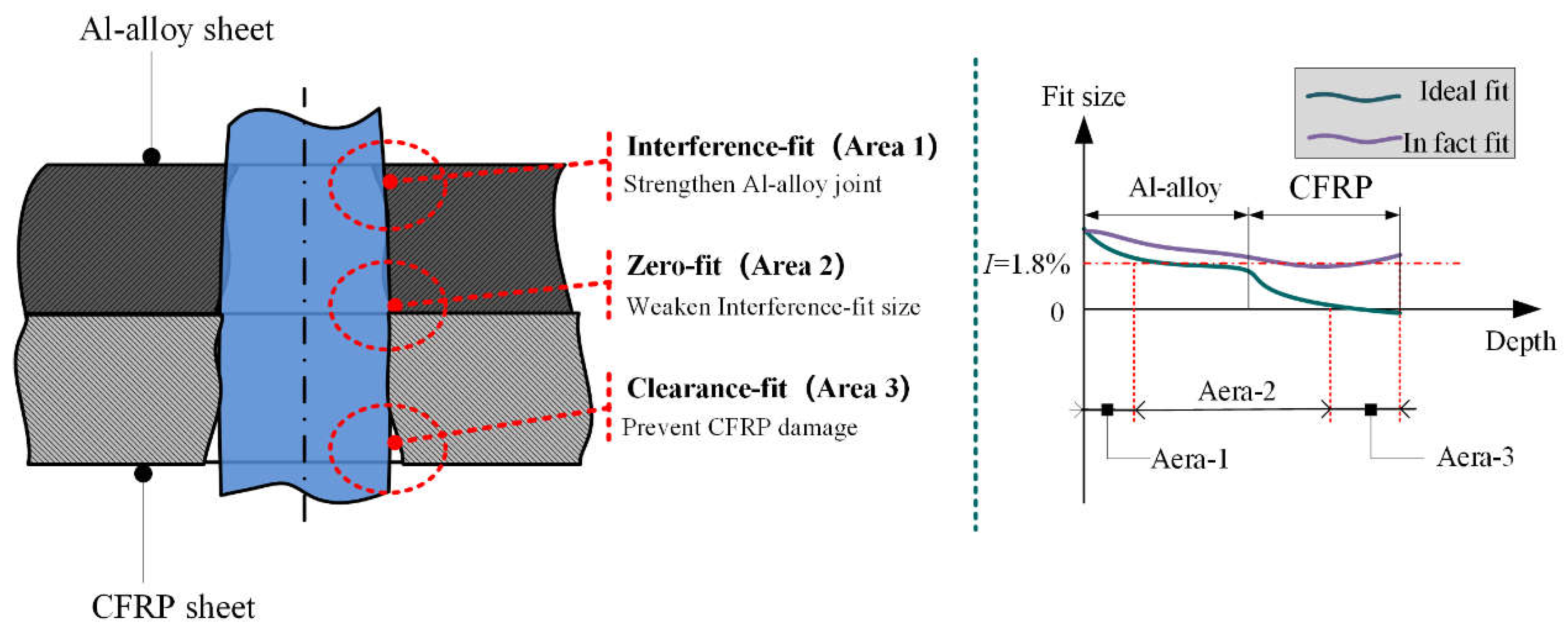

Due to its high specific strength and modulus of characteristics of Carbon fiber reinforced plastics (CFRP), which has been wildly applied in the transportation industry [1]. At present, the CFRP/Al-alloy riveted lap joints are used the 2%~3% of interference-fit size[2], which validly improves the Al-alloy sheet connection performance[3]. Mirzajanzadeh et al. [4] found that large interference-fit size can increase the fatigue life of Al alloy sheets in fretting fatigue crack properties. Abazadeh et al. [5] investigated the Al-alloy sheets bolted joints, the results proved that a larger interference-fit size is beneficial to improving Al-alloy sheets bolted joint’s performance.

However, it’s a double-edged sword of larger inference-fit size for CFRP/Al-alloy riveted lap joint, because the interference-fit size of CFRP sheet riveted lap joint is adopted less than 1.6% [6,7]. Large interference-fit size can induce extrusion, instability, and delamination of CFRP’s hole surface, particularly the entrance of connection surface is over 2% [8,9]. Khashaba et al. [10] proposed a predicated 3D progressive damage model between clearance-fit sizes and static strength of CFRP joint. Chen et al. [11] studied the effects of zero-fit, clearance-fit, and interference-fit size on the CFRP joints’ mechanical performance, the results showed that the zero-fit or clearance-fit of joints had a better shear performance than the interference-fit. Zou et al. [12] developed a FEM model to predicate the effect of interference-fit size on delamination defect, the result showed that the increase of interference-fit size worsened the delamination of CFRP.

The abovementioned studies are homogeneous laminates, hence the interference-fit size could be adjusted to suit them, simply. Nevertheless, during the heterogeneous laminates of CFRP/Al-alloy riveting, its interference-fit size is different from the homogeneous laminates’[13]. It still adopted the traditional riveting process, which easily leads to an excessive interference-fit size for CFRP or an undersize interference-fit size for Al-alloy. Therefore, researchers have studied the way to improve the mechanical performance of CFRP/Al-alloy laminates riveting lap joints. Cui et al. [13] investigated the effect of trapezoid riveting mold on interference-fit size, the result proved that mold angle had a significant effect on interference-fit size. Jiang et al. [15] studied the CFRP/Al-alloy laminates by electromagnetic riveting with different riveting molds, the result showed that the 80° trapezoid riveting mold can not only improve the interference-fit size but also promote the fatigue performance. Ma et al. [16] developed an effective way to avoid the joints cracking by riveting mold structure optimization. Although scholars have adopted the riveting mold design to investigate the interference-fit size and achieve a better mechanical performance, the interference-fit sizes of CFRP sheet and Al-alloy sheet are still the same without considering the material difference. How to make the interference-fit size of CFRP/Al-alloy more suitable still need further research. Therefore, the optimal design of die not only can improve material flow and mechanical properties, but also reduce the forming load [17–19]. Besides, for the purpose of shorting the cycle and saving cost, lots of scholars adopted the FEM and experiment method to carry out research [20–23].

It is acknowledged that the interference fit of CFRP riveted lap joints lead to instability of fiber and weaken the performance with it increase [24,25]. Therefore, in this paper, not only the design parameters of riveting mold are researched, but also the assembly types of riveting mold. Primarily, the design parameters of the riveting mold are analyzed by FEM, and the significant effect parameter is confirmed. Furthermore, the riveting experiments are carried out, and the interference-fit size is measured. Finally, the tensile test is performed to ensure the structure of the riveting mold, and the fatigue failure types and microstructure performance are observed.

2. Materials and Methods

2.1. Sample preparation

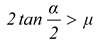

The T700 CFRP and 2024 Al-alloy were selected for adapting piece, the material of the rivet is Ti-45Nb. T700 CFRP was using a unidirectional carbon fiber/epoxy with a thickness of 0.15mm per ply (provided by GW COMPOS Company Ltd., China). The fabricated T700 CFRP laminate processes a thickness of 2.3 mm with 16 piles, the ply orientation of T700 CFRP is [0°/90°/45°/-45°/-45°/45°/90°0°]2s, and the weight fraction of carbon fiber is about 60%. Material properties of the fabricated CFRP laminates are presented in

Table 1. Moreover, the Fabricated Ti-45Nb rivets (provided by CAG Company Ltd., China) were annealed by heating in a vacuum (less than 0.1um mercury) to a temperature within the range of 1450 °F to 1600 °F, holding at heat for sufficient time to produce a recrystallized structure that will meet the requirements of 3.5. Material properties of the Ti-45Nb rivets are presented in

Table 1. In addition, the diameter of the Ti-45Nb rivet is 4mm, and the prefabricated hole diameters of CFRP laminates were drilled by dagger drill with a diameter of 4.1mm, and the aperture of the sample was measured using a plug gauge. The sizes of CFRP riveted specimens according to the ASTM D5661 are shown in

Figure 3, and W/D≥6, E/D≥3.

Figure 1.

Dimensions of the CFRP laminates riveted lap joint (dimension in mm).

Figure 1.

Dimensions of the CFRP laminates riveted lap joint (dimension in mm).

2.2. Experimental results handling method

It acknowledged that the large interference-fit size induced the CFRP damage, hence, the ideal interference-fit size for CFRP/Al-alloy laminates is as shown in

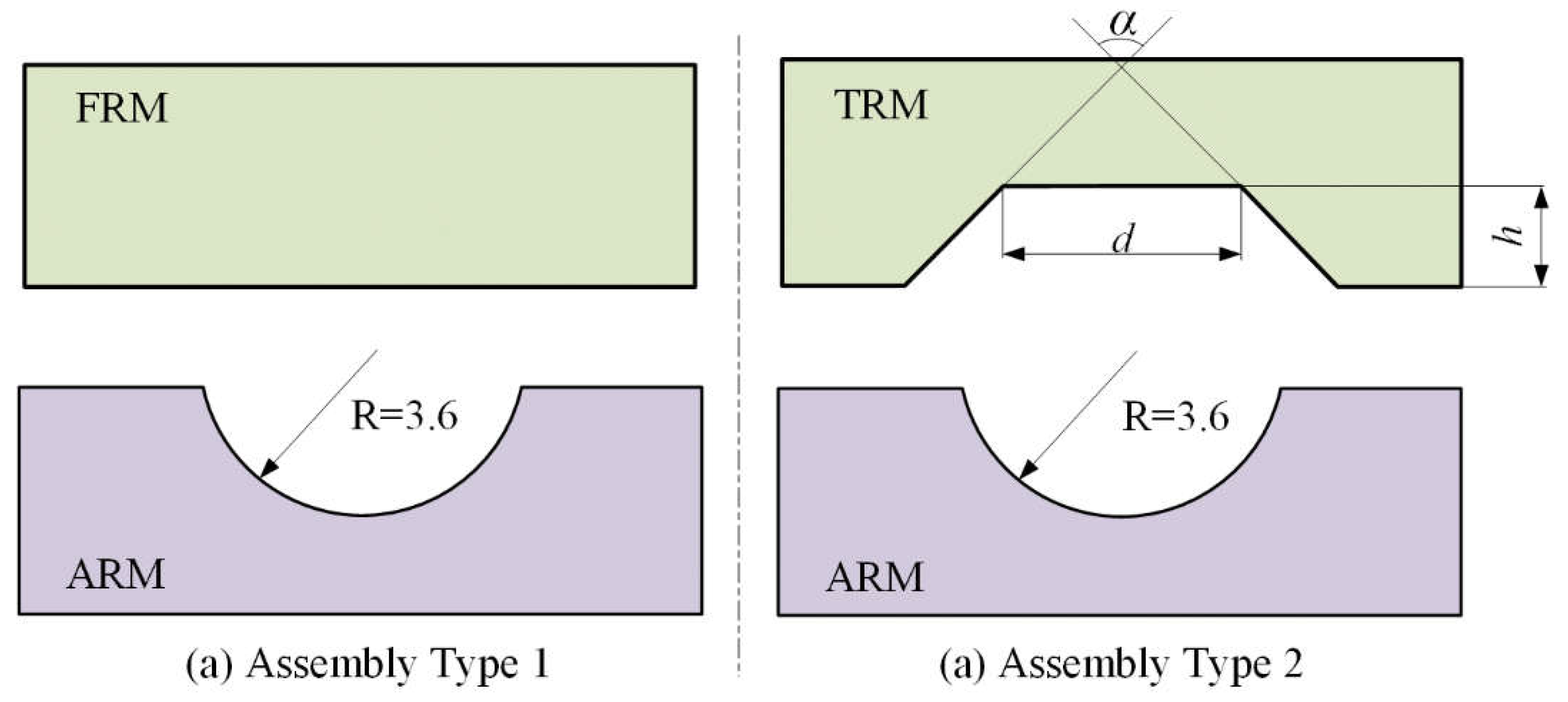

Figure 2. The interference-fit size of CFRP should be less than Al-alloy’s. Therefore, to acquire the ideal fit of CFRP/Al-alloy riveted lap joint, the mold of the rivet mechanical head (bottom mold) is used as an arc riveting mold (ARM) to prevent the deformation of rivet mechanical head, so fit at the entrance of CFRP connection surface is clearance. The mold of the rivet bar (top mold) is used flat riveting mold (FRM) or trapezoid riveting mold (TRM), hence, the assembly types of riveting mold are shown in

Figure 3. In the riveting process, the interface slip of the die and rivet would produce the radial constraint force which can promote material filling the hole. Considering the larger interference-fit size of Al-alloy, assembly type 2 of riveting mold is adopted to research the variation of interference-fit size.

After the riveting, the deformed rivet specimens are cut with diamond blades. The interference-fit size of the deformed rivet bar is measured by a Vernier caliper with an accuracy of 0.01mm. subsequently, the DBSL-10t tensile test machine was used to test the mechanical properties of riveted specimens under pull-out loading based on the ASTM-5961 standard. Finally, microstructures of fracture morphology were observed by the RH-2000 super-depth microscopy system.

3. Results

3.1. The combination type of rivet dies

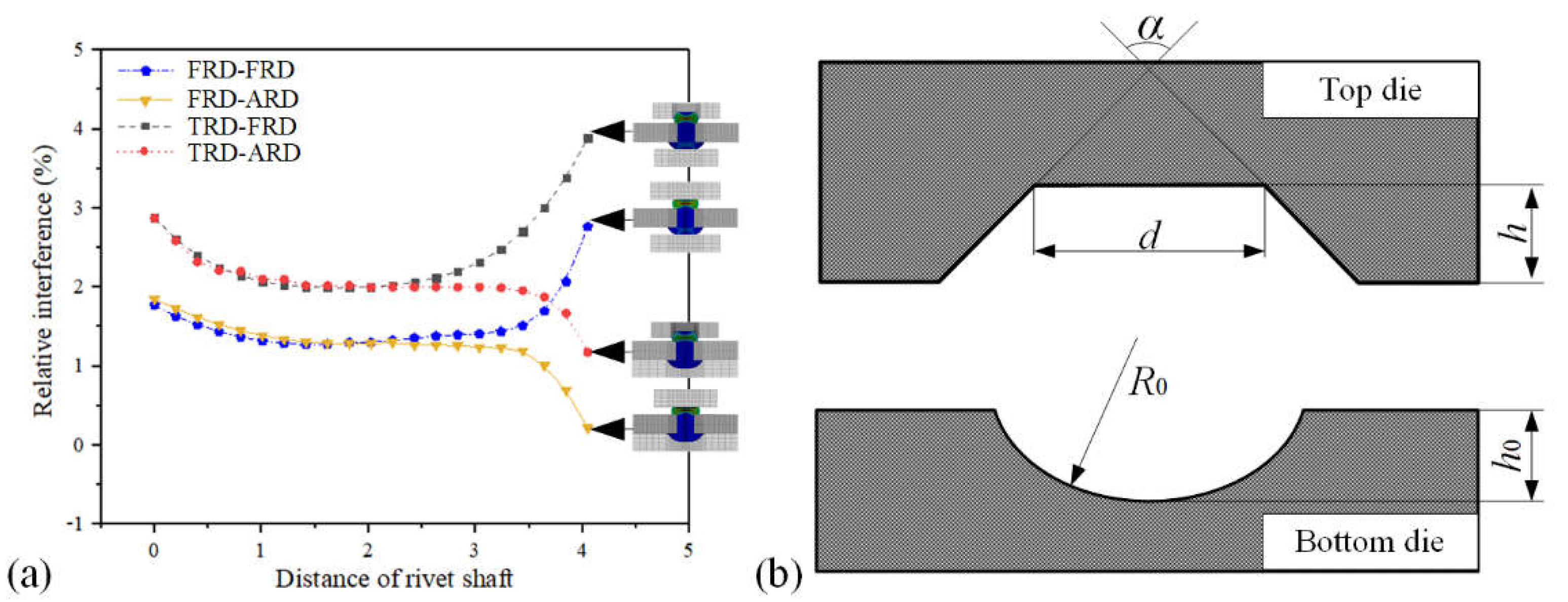

Combination type design of rivet die is an effective way to achieve the non-uniform interference fit of CFRP/Al alloy sheets. As shown in

Figure 3a, the effect of rivet die combination types on interference sizes tendency was preliminarily analyzed by FEM, which included four kinds of types, i.e. flat rivet die (FRD) to flat rivet die, flat rivet die to arc rivet die (ARD), trapezoid rivet die (TRD) to flat rivet die, trapezoid rivet die to arc flat die. It could be seen that the type of TRD-ARD or FRD-ARD could obtain the non-uniform interference fit. Meanwhile, to ensure the non-uniform interference sizes are reasonable, the TRD-ARD type need be optimized.

Figure 3b showed the structure of TRD-ARD type. The trapezoid rivet die parameters include the sidewall intersection angle (

α), sidewall height (

h) and upper diameter of sidewall (

d). According to the constant volume principle, the structure parameters of TRD had significant influences on the material filling into the pre-drilled hole. The arc rivet die matched with the rivet manufactured head, the radial is 3.6mm, depth is 2.0mm.

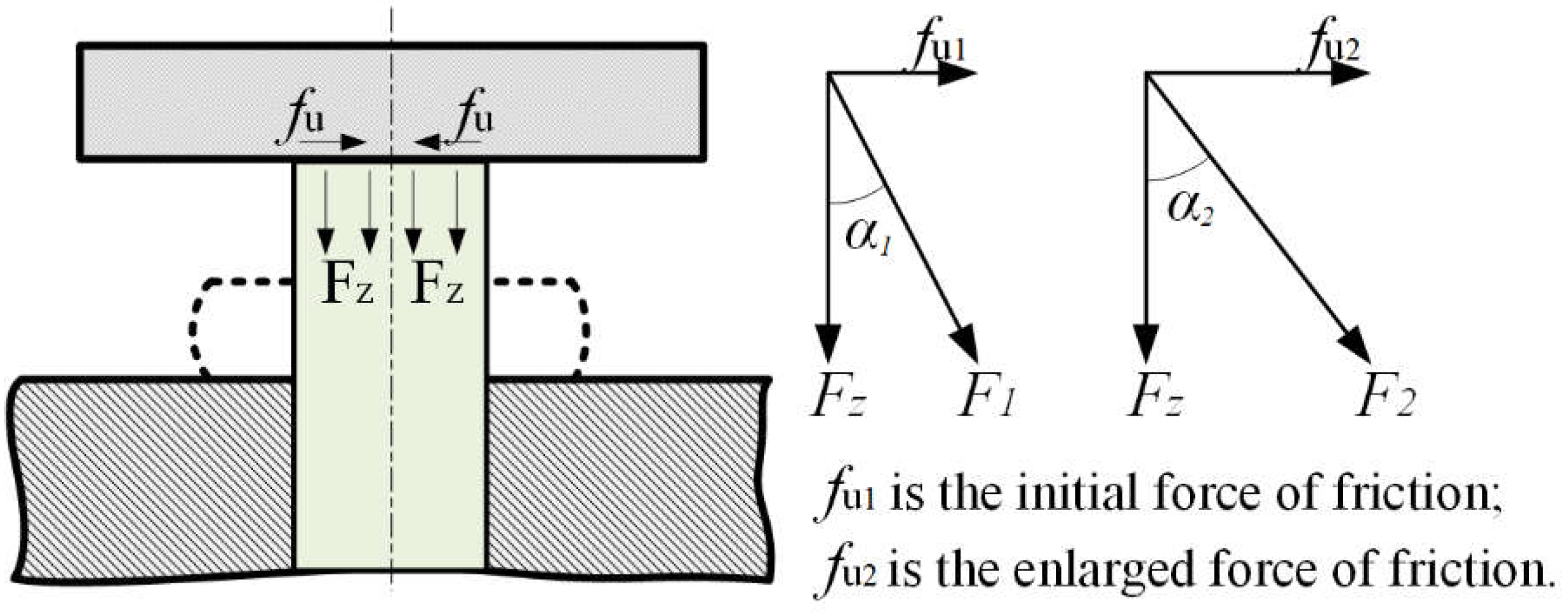

3.2. Rivet radial force constrain modelling

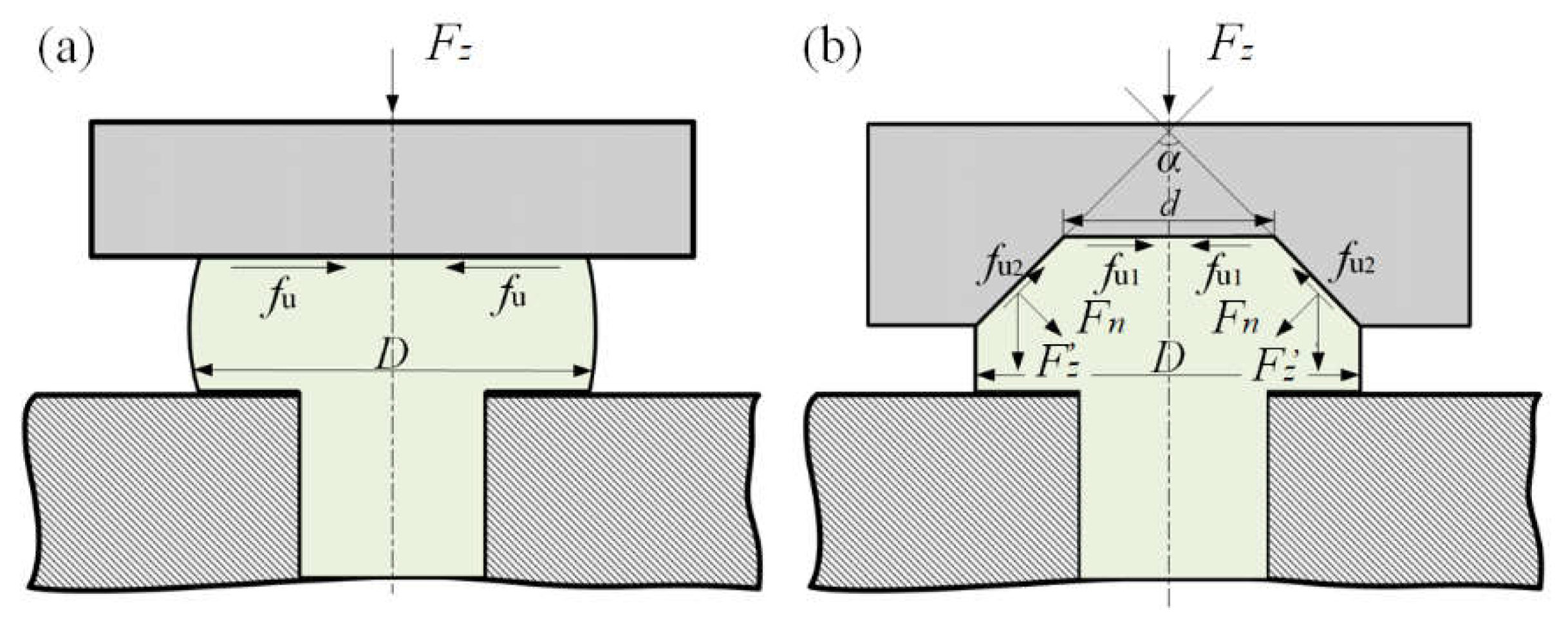

In riveting process, the interface slip of die and rivet would produce the radial constraint force which can promote material filling the hole. Considering the isotropic material and axisymmetric structure of rivet, the radial force is as homogeneous distribution. The diagram of central section radial force was presented in

Figure 5. Rivet shaft subjects to the axial force (

Fz) and radial force (

Fr), the

Fr is

fu in flat rivet die which can improve the interference size. The

Fz is a constant, hence adopting concave rivet die structure to increase

Fr is as an effective way.

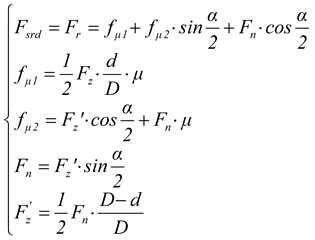

In

Figure 6, the comparison of radial constrain force between FRD and TRD will be analyzed as follows. As shown in

Figure 7a, the radial constrain force of flat rivet die (

Ffrd) is simple friction (

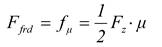

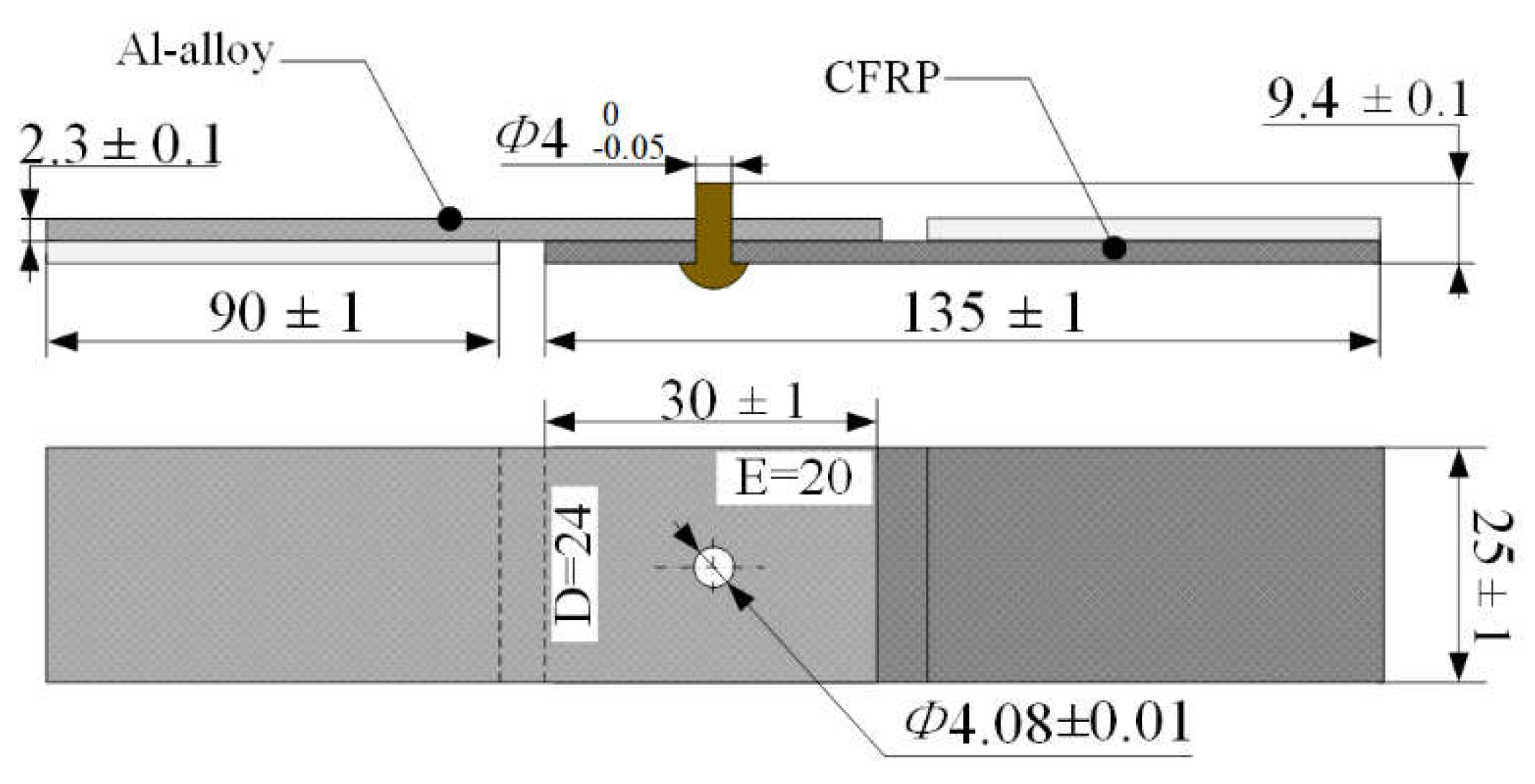

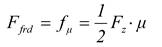

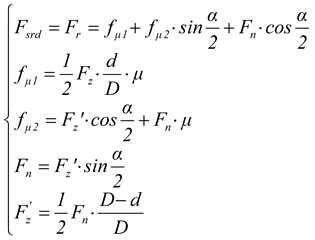

fu), as following Eq. (1):

(1)

As shown in

Figure 7b, the radial constrain force of trapezoid rivet die (

Ftrd) includes horizontal friction (

fu1), horizontal component of

fu2 and

Fn, as following Eq. (2):

(2)

Therefore, when the Ftrd is larger than Ffrd, combined Eq. (1) with Eq. (2) to obtain the function of α and μ, as following Eq. (3):

(3)

where 0 ˂α˂180ᵒ, and μ≈0.2 (Normally, the friction coefficient of upsetting is 0.2.), then substitute them into Eq. (3), we obtained 12ᵒ˂α˂180ᵒ.

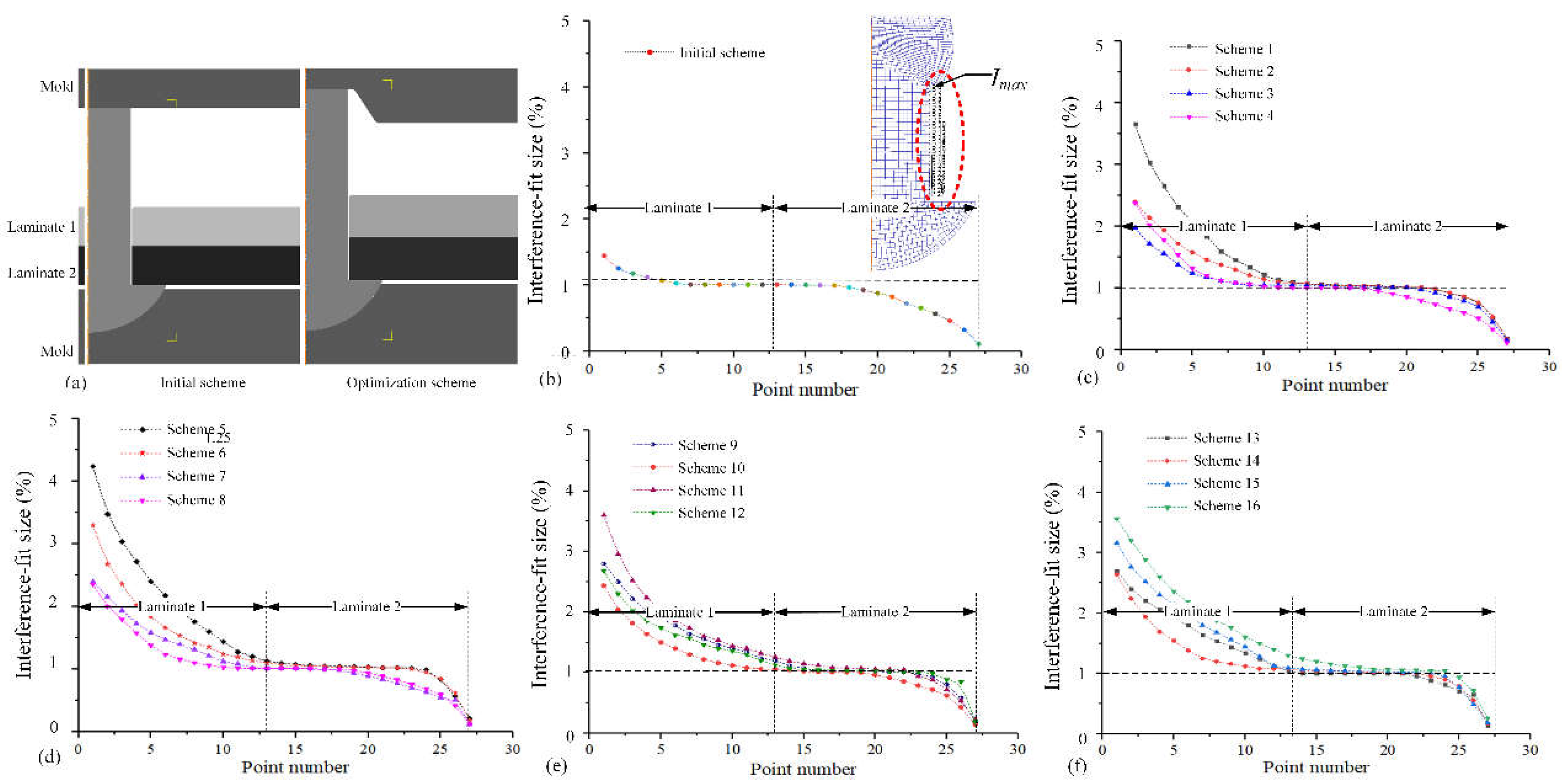

4. Discussion

According to the size of the rivet mechanical head, the radius of ARM is 3.6 mm, and they remain the same. However, the parameters of TRM include the sidewall intersection angle (

α), sidewall height (

h), and upper diameter of sidewall (

d), the level of the parameters is shown in

Table 2, and total schemes are 16 (L3

4). The FEM model is established by Deform-3D, as shown in

Figure 8a, and the variation of interference-fit sizes is shown in

Figure 8b–f. The maximum interference-fit size (

Imax) is counted in

Table 3.

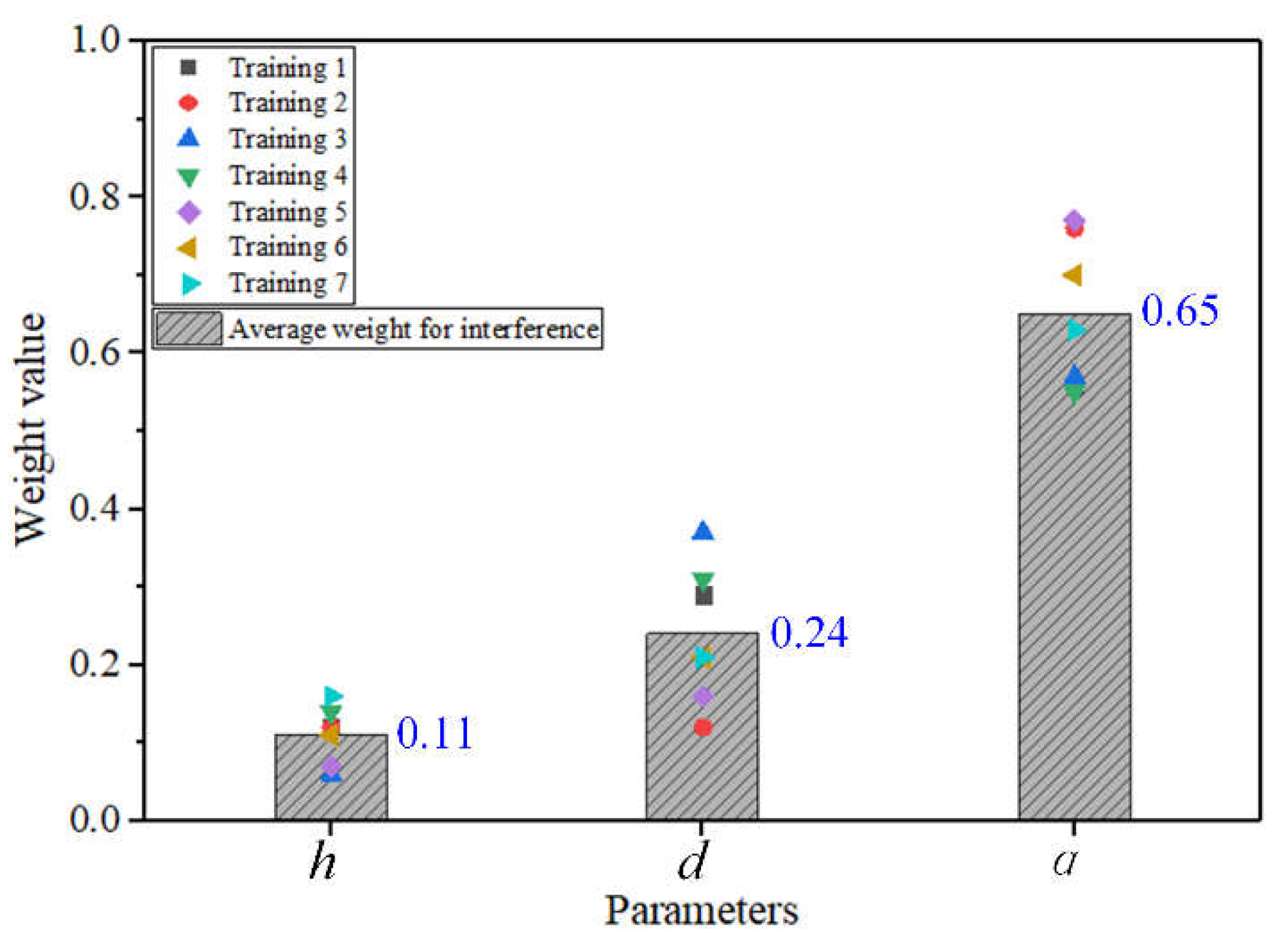

The deviations of the parameters are listed in

Table 4, it could be seen that the significance of parameters on interference-fit size is

α>

d>

h, which is consistent with the before research. In

Figure 8, the collecting points of the rivet bar are shown in the red circle, comparing FRM with the TRM, the TRM improves the interference-fit size, significantly, and the interference-fit size in the entrance of the CFRP connection surface is reduced by ARM. Then the decision tree model is developed and adopted to repetitively train the data of

Table 3, the trained weight for variables are displayed in

Figure 7. It could be seen that The average weight value of

α,

d, and

h for interference-fit size are 0.65, 0.24, 0.11 respectively. To sum up, the weight values of

α for load and interference are the most significant.

According to

Figure 8c~f, the reasonable schemes of interference-fit size are scheme 2, scheme 6, scheme 9, and scheme 15. Considering the significance of parameters, schemes 6, 9, 15 are adopted to implement the experimental verification. Finally,

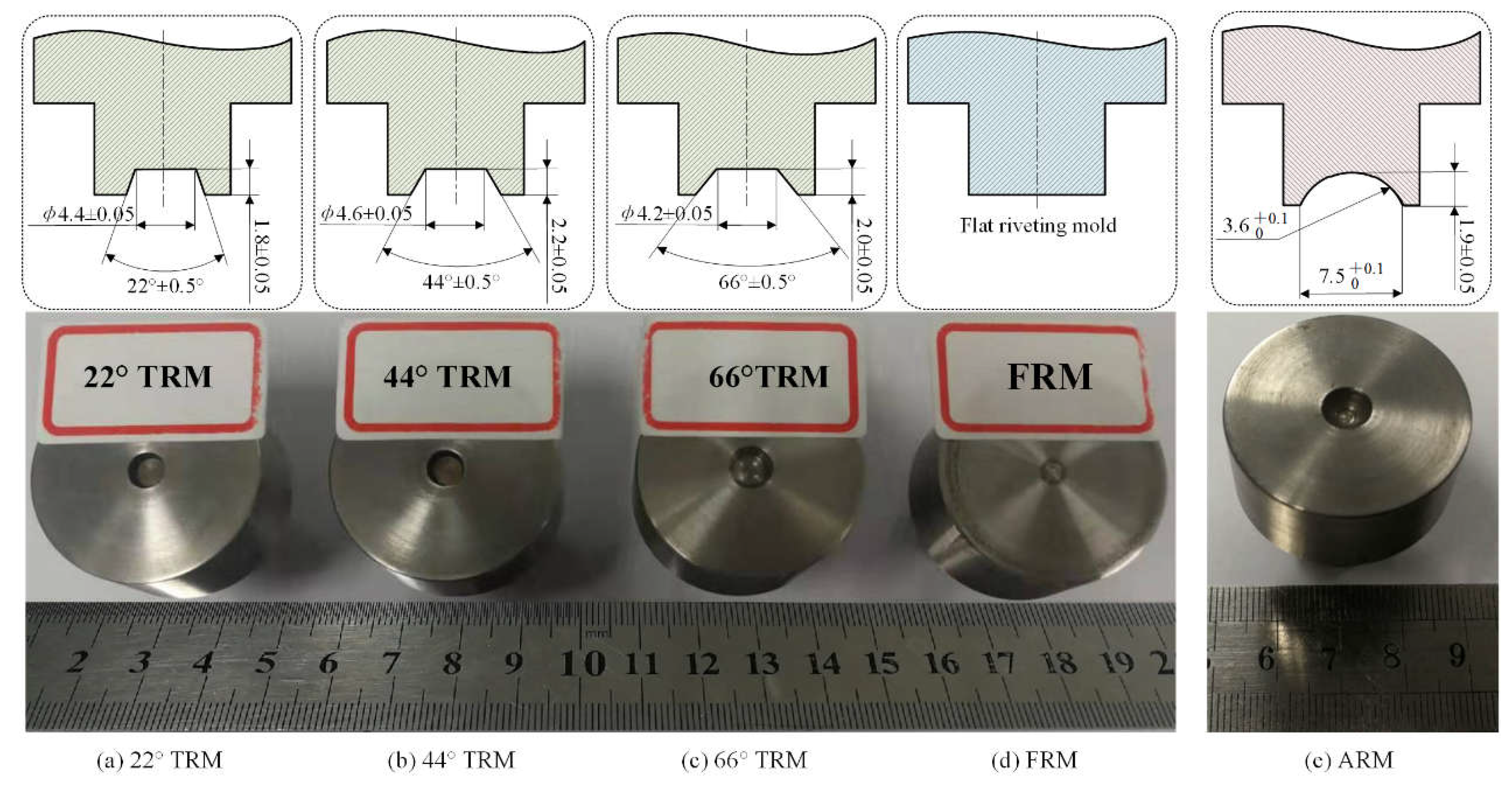

4.1. Non-uniform interference-fit size

According to the interference sizes effect analysis, the TRM based on the parameters of scheme 6, scheme 9, and scheme 15 are manufactured, and the manufactured FRM is as the contrast experiment, as shown in

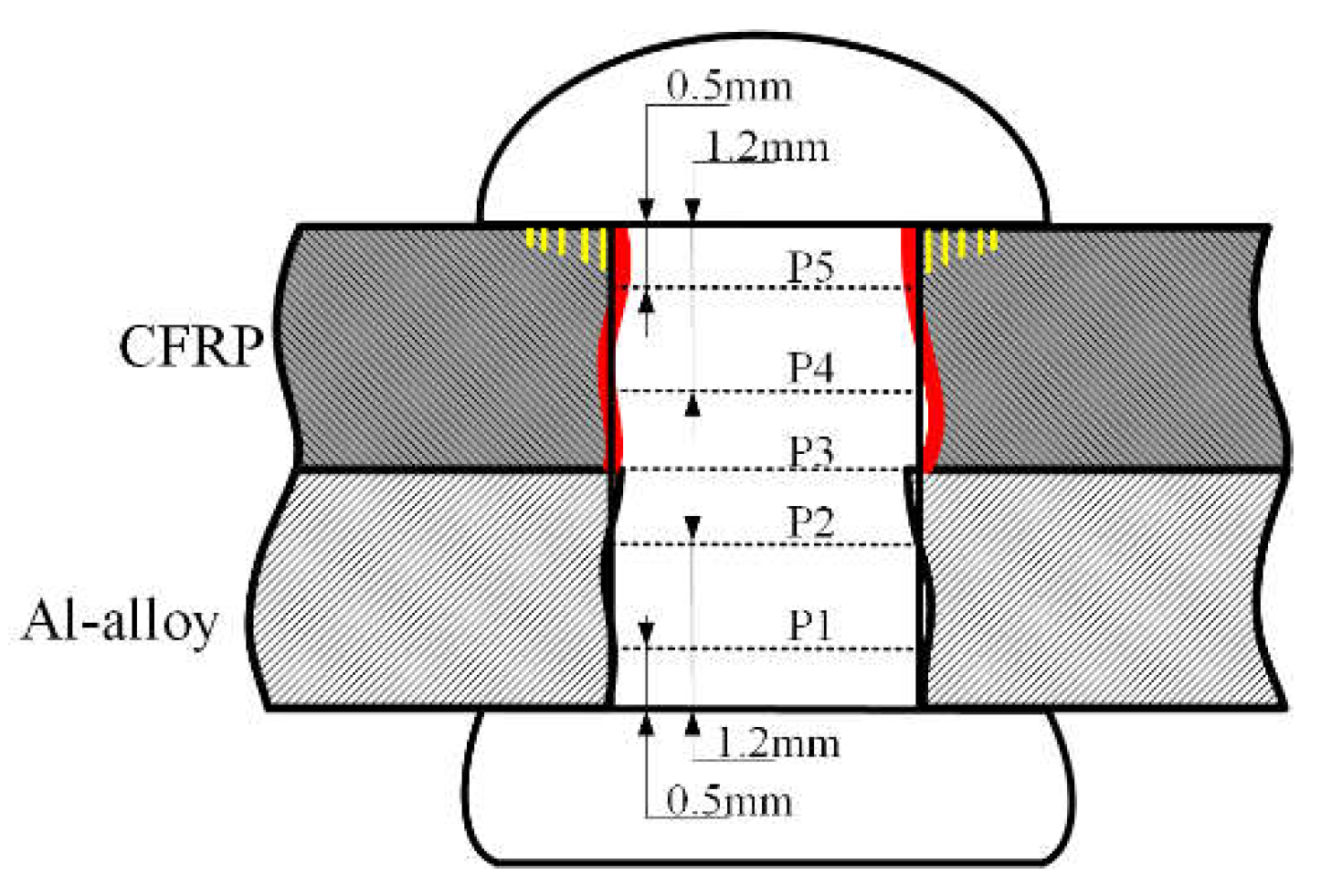

Figure 9. The force and speed of riveting process are 14.5KN and 10mm/s, respectively. After riveting, the interference-fit size of each specimen is measured with five positions, as shown in

Figure 10. The measured interference-fit size is listed in

Table 5 with three times of repetition, then taking an average of interference-fit size (

IA).

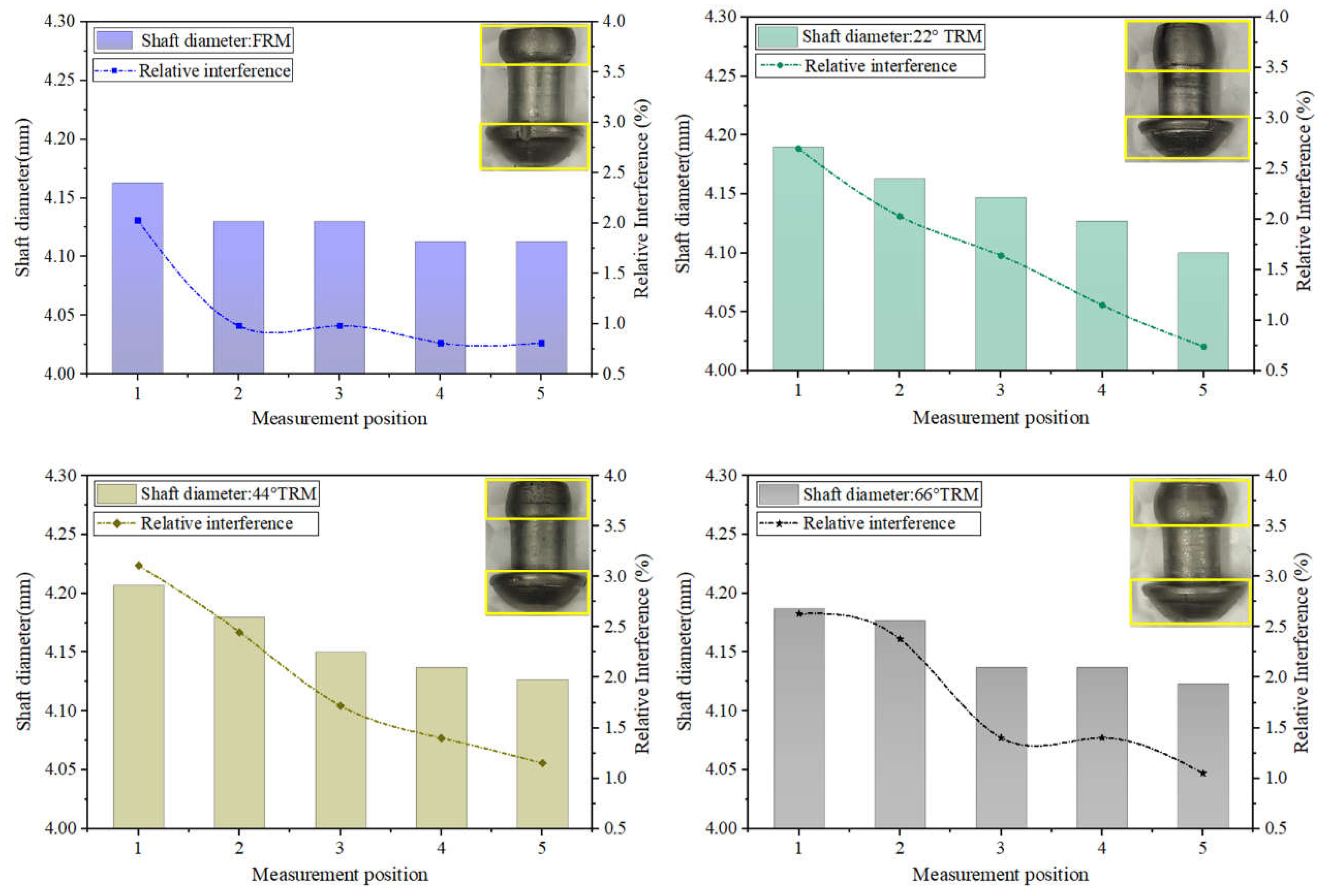

To intuitively analyze the data in

Table 5, the date histograms of different riveting molds are implemented in

Figure 11.

Figure 11a displayed the interference-fit size of FRM-ARM, it could be seen that the max interference-fit size is lower than 2%, and the CFRP sheet fit well. However, the interference-fit size of the Al-alloy sheet was not satisfied with the requirement. In

Figure 11b,c, the results show that the variation tendency of interference-fit size by 22° TAM-ARM and 44° TAM-ARM have a good consistency. However, both of them were non-uniform interference-fit sizes in independent Al-ally and CFRP. In

Figure 11e, the variation tendency of interference-fit size by 66° TAM-ARM presents a good consistency with the ideal interference-fit size. In addition, the interference-fit size is relatively uniform for each laminate. Therefore, based on the variation tendency of interference-fit size, the 66° TAM-ARM is a better assembly type than others.

4.2. Strength and fracture modes

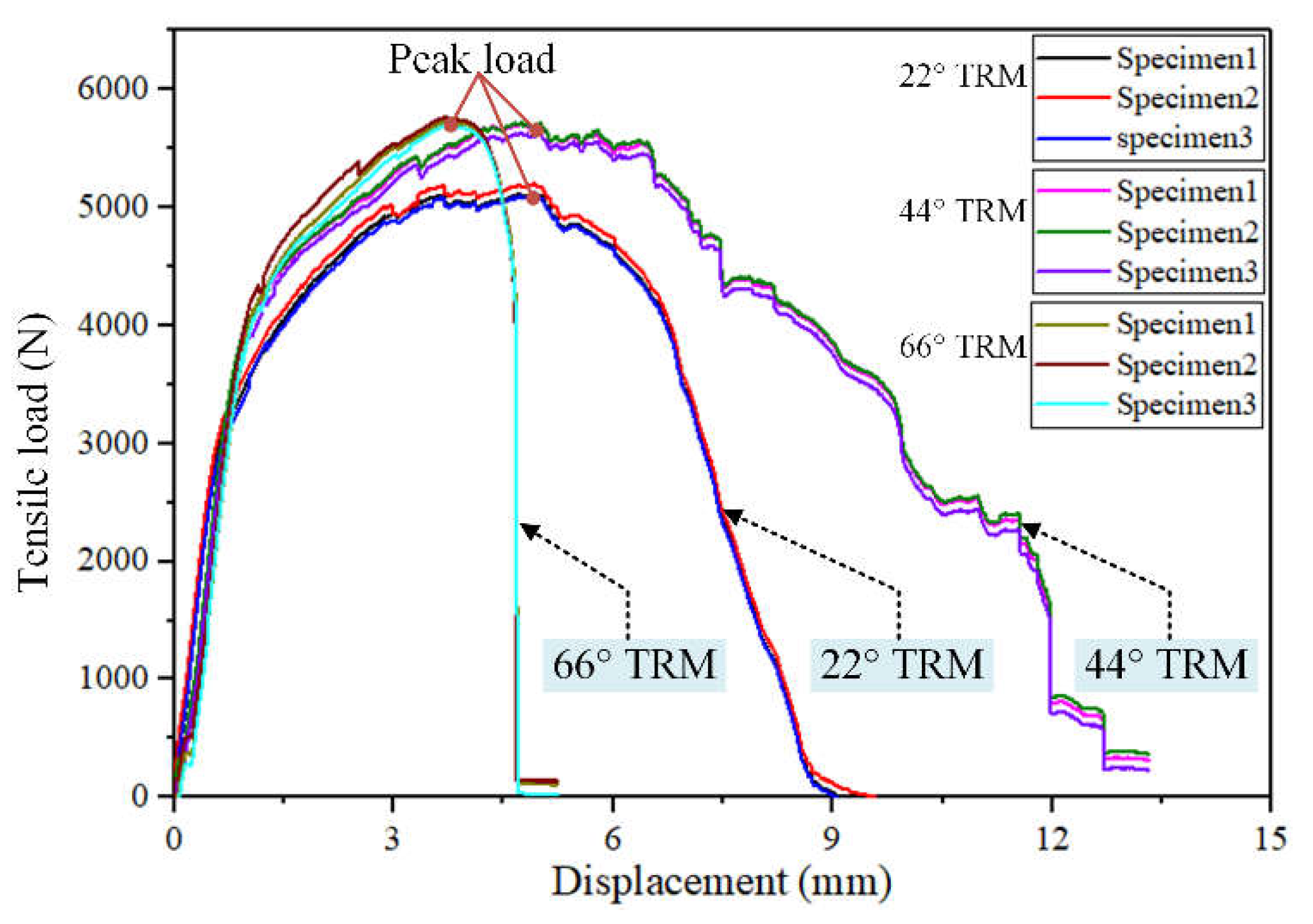

To research the effect of interference-fit size with different riveting molds on the strength of CFRP/Al-alloy riveted lap joints, the tensile test is carried out at a speed of 5mm/min. The tensile load-displacement curves of 22°-TRM, 44°-TRM, and 66°-TRM are displayed in

Figure 12. It could be seen that the tensile load rises rapidly with the increase of displacement in the elastic deformation stage. However, the load-displacement curves in the failure stage presented distinct differences, especially the riveted specimen by 66°-TRM. For the riveted specimens by 22°-TRM and 44°TRM, the pulled-off failure displacement is longer than 66°-TRM. In addition, the max tensile load (5734N) of the specimen is riveted by 66°-TRM, which is a litter higher than 44°-TRM’s (5709N), both of them are larger than the max tensile load (5118N) by 22°-TRM.

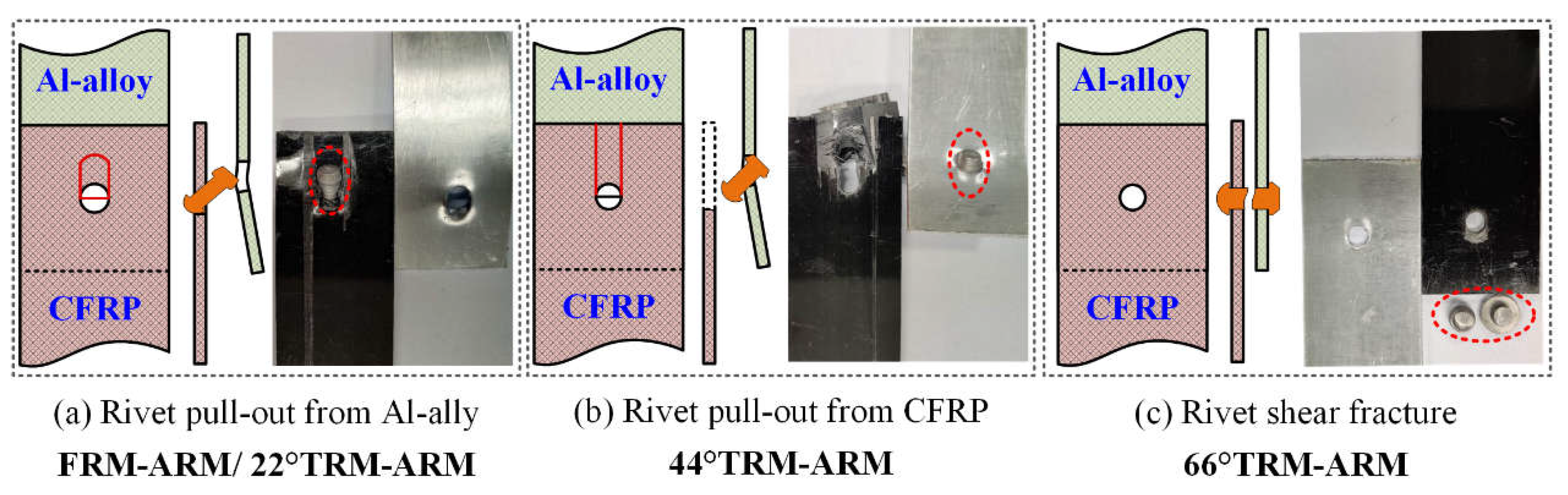

Furtherly, the failure types of specimens by different TRM are shown in

Figure 13. It could be seen that the failure type of specimens by 22°-TRM and 44°-TRM is rivet pull-out, but the failure type of specimens by 66°-TRM is rivet shear fracture. This induces a longer failure displacement of tensile test of specimens by 22°-TRM and 44°-TRM, and the failure displacement of specimens by 66°-TRM is short. Combined with

Figure 11 to reveal the difference in failure type, for specimens 22°-TRM and 44°-TRM, the interference-fit size in the entrance of Al-alloy by 44°-TRM’s specimen is larger than 22°-TRM’s under the same riveting force. Hence, the strength of the Al-alloy riveted lap joint by 44°-TRM is larger than 22°-TRM’s, and the strength of the Al-alloy riveted lap joint is larger than the CFRP riveted lap joint by 44°-TRM, and the strength of Al-alloy and CFRP by 22°-TRM is on the contrary. In addition, the interference-fit size is non-uniform for each sheet. Both reasons induce the rivet pull-out from the sheet. However, the relative uniform interference-fit size by 66°-TRM well reinforces the fit strength of Al-alloy and CFRP, and the interference-fit size is satisfied with the requirement, both reasons induce the rivet shear fracture.

4.3. Fracture microstructure

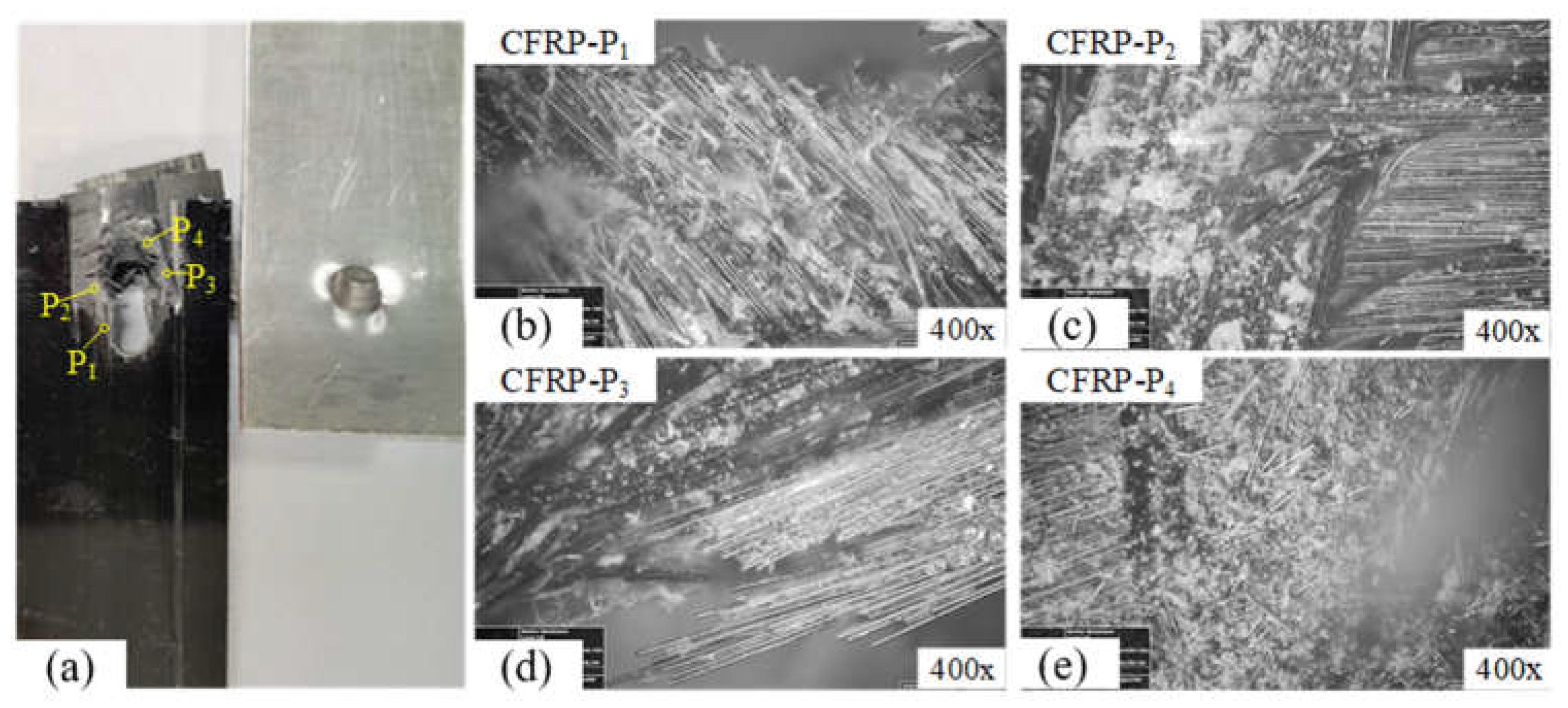

The failure morphology is observed by microscope. In

Figure 14, the microstructure of the specimens’ pull-out hole by 22°-TRM is observed. The hole of Al-alloy is stretched, and the hole shows relatively smooth and does not appear to crack, which stays in the plastic deformation extension stage. The observed CFRP’s positions are shown in

Figure 14a, corresponding to

Figure 14d–g, respectively. It could be seen that the carbon fiber of the P

1 position does not occur delamination or extrusion damage. P

2 position shows that the 45°/-45°/90° carbon fibers are suffered from extrusion. Carbon fibers of the P

3 position are subjected to tension and extrusion, which induced a part of the carbon fibers to snap. In the P

4 position, the CFRP hole occurs severe extrusion, and delamination and carbon fiber breakage appear.

The failure microtopography of specimens by 44°-TRM is shown in

Figure 15. It could be seen that the CFRP’s damage is much more serious than the specimens by 22°-TRM, the observed positions are shown in

Figure 15a. In

Figure 15b, it could be seen that the carbon fibers in P1 are peeled off. As the rivet is pulled out, the carbon fibers were sheared, and severe delamination defect of CFRP is occurred, as shown in

Figure 15c,d. In

Figure 15e, the P

4 position of CFRP sheet occurs severe fracture, where carbon fibers are seriously snapped and crushed.

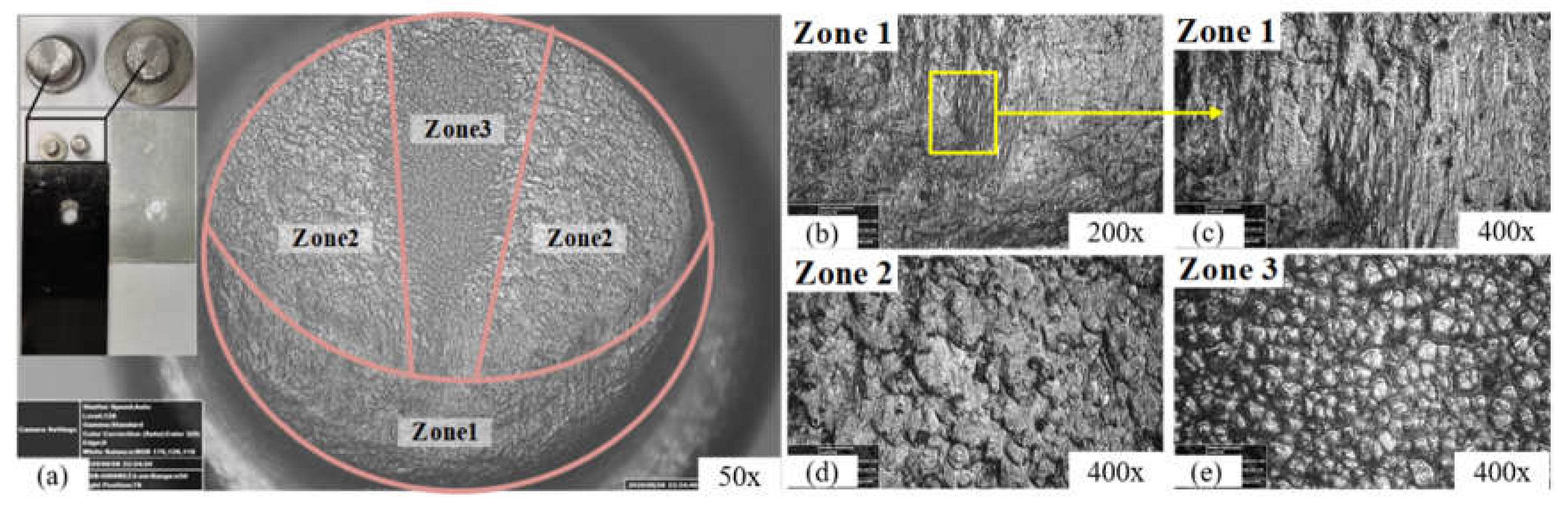

The failure mode of the specimen by 66°-TRM is shown in

Figure 16. It could be seen that the CFRP and Al-alloy keep well, and the rivet occurs shear fracture. In

Figure 16a, according to the symmetrical fracture surface of the rivet, it is divided into three zones, i.e., shear source (zone 1), ductile fracture (zone 2), and brittle fracture (zone 3). In

Figure 16b, the fracture microstructure in zone 1 is relatively smooth and has a distinct transition area. The transition area displays an elongating shear-long micro-pit, then gradually develops into a ductile fracture area and brittle fracture area, as shown in

Figure 16c. The ductile fracture in zone 2 is a shear-long micro-pit, as shown in

Figure 16c. It indicates that the material has undergone the severe shear deformation under low strain ratio. The brittle fracture morphology in zone 3 is shown in

Figure 16d. It is a typical inter-crystalline delamination fracture, which indicates poor plasticity of the Ti-45Nb rivet.

5. Conclusions

In this research, the assembly types of rivet mold are used to investigate the effect of interference-fit size on the mechanical performance of CFRP/Al-alloy riveted lap joints. The main conclusions are as follows:

The FEM results show: the assembly type of TRM-ARM can acquire a similar ideal fit for CFRP/Al-alloy riveted lap joint; the most significant effect of the design parameter of TRM on interference-fit size is the sidewall intersection angle (α); the average weight value of α for interference-fit size arrives 0.65.

The experiment results show: the TRM-ARM can acquire a larger interference-fit size in an Al-alloy sheet than FAM-ARM; the assembly type of 66° TRM-ARM has a more uniform interference-fit size for each laminate of CFRP and Al-alloy, and the fit surface of hole well reinforce than 22° TRM-ARM and 44° TRM-ARM.

The tensile tests show that the 66° TRM-ARM achieves a better shearing performance than the 22°TRM-ARM and 44°TRM-ARM.

Funding

The authors would like to acknowledge the editors and the anonymous referees for their insightful comments. This work was supported by the Basic Science Research Project of Jiangsu Province (22KJB460008); the Basic Research Plan Natural Science Fund of Suqian Science and Technology Plan Project (K202210); Suqian Science and Technology Plan Guiding Project (Z2021139).

Conflicts of Interest

The authors declare no conflict of interest.

References

- M. Skorupa, A. Skorupa, T. Machniewicz, Korbel A, Effect of production variables on the fatigue behavior of riveted lap joints. Int. J. Fatigue 2010, 32, 996–1003. [Google Scholar] [CrossRef]

- X. Zhang, H. Jiang, T. Luo, L. Hu, G.Y. Li, J.J. Cui, Theoretical and experimental investigation on interference fit in electromagnetic riveting. Int. J. Mech. Sci. 2019, 156, 261–271. [Google Scholar] [CrossRef]

- C. Y. Lei, Y.B. Bi, J.X. Li, Y.L. Ke, Experiment and numerical simulations of a slug rivet installation process based on different modeling methods. Int. J. Adv. Manuf. Technol. 2018, 97, 1481–1496. [Google Scholar] [CrossRef]

- M. Mirzajanzadeh, T.N. Chakherlou, J. Vogwell, The effect of interference-fit on fretting fatigue crack initiation and DK of a single pinned plate in 7075 Al alloy. Eng. Fract. Mech. 2011, 78, 1233–1246. [Google Scholar] [CrossRef]

- B. Abazadeh, T.N. Chakherlou, R.C. Alderliesten, Effect of interference fitting and/or bolt clamping on the fatigue behavior of Al alloy 2024-T3 double shear lap joints in different cyclic load ranges. Int. J. Mech. Sci. 2013, 72, 2–12. [Google Scholar] [CrossRef]

- Chakherlou T, Mirzajanzadeh M, Abazadeh B, at al. An investigation about interference fit effect on improving fatigue life of a holed single plate in joints. Eur. J. Mech. A/Solids 2010, 29, 675–682. [Google Scholar] [CrossRef]

- B. G. Kiral, Effect of the clearance and interference-fit on failure of the pin-loaded composites. Mater. Des. 2010, 31, 85–93. [Google Scholar] [CrossRef]

- Zeng C, Tian W, Liao WH. The effect of residual stress due to interference fit on the fatigue behavior of a fastener hole with edge cracks. Eng. Fail. Anal. 2016, 66, 72–87. [Google Scholar] [CrossRef]

- J. H. Deng, C. Tang, M.W. Fu, Y.R. Zhan, Effect of discharge voltage on the deformation of Ti Grade 1 rivet in electromagnetic riveting. Mater. Sci. Eng. A 2014, 591, 26–32. [Google Scholar] [CrossRef]

- U. A. Khashaba, T.A. Sebaey, A.I. Selmy, Experimental verification of a progressive damage model for composite pinned-joints with different clearances. Int. J. Mech. Sci. 2019, 152, 481–491. [Google Scholar] [CrossRef]

- C. Chen, D. Hua, Q.M. Liu, X. Han, Evaluation on the interval values of tolerance fit for the composite bolted joint. Compos. Struct. 2018, 206, 628–636. [Google Scholar] [CrossRef]

- P. Zou, Y. Li, K. Zhang, P. Liu, H. Zhong, Mode I delamination mechanism analysis on CFRP interference-fit during the installation process. Mater. Des. 2017, 116, 268–277. [Google Scholar] [CrossRef]

- Wang Z, Chang Z, Luo Q, et al. Optimization of riveting parameters using Kriging and particle swarm optimization to improve deformation homogeneity in aircraft assembly. Adv. Mech. Eng. 2017, 9, 1–13. [Google Scholar] [CrossRef]

- J. J. Cui, L. Qi, H. Jiang, G.Y. Li, X. Zhang, Numerical and experimental investigations in electromagnetic riveting with different rivet dies. Int. J. Mater. Form. 2018, 11, 839–853. [Google Scholar] [CrossRef]

- H. Jiang, Y. Cong, J. Zhang, X. Wu, G. Li, J. Cui, Fatigue response of electromagnetic riveted joints with different rivet dies subjected to pull-out loading. Int. J. Fatigue 2019, 129, 1–13. [Google Scholar] [CrossRef]

- Y. Ma, M. Lou, Y. Li, Z. Lin, Effect of rivet and die on self-piercing rivetability of AA6061-T6 and mild steel CR4 of different gauges. J. Mater. Process. Technol. 2018, 251, 282–294. [Google Scholar] [CrossRef]

- X. Wang, Z. Qi, K. Chen, Y. Liu, E. Wang, Study on the forming accuracy of the three-cylinder crankshaft using a specific die with a preformed dressing. Int. J. Adv. Manuf. Technol. 2019, 104, 551–564. [Google Scholar] [CrossRef]

- Y. X. Liu, B. Tang, L. Hua, H.J. Mao, Investigation of a novel modified die design for fine-blanking process to reduce the die-roll size. J. Mater. Process. Tech. 2018, 260, 30–37. [Google Scholar] [CrossRef]

- Y. Lu, K. Ripplinger, X.J. Huang, Y. Mao, D. Detwiler, A.A. Luo A new fatigue life model for thermally-induced cracking in H13 steel dies for die casting. J. Mater. Process. Tech. 2019, 271, 444–454. [Google Scholar] [CrossRef]

- Z. Qi, X. Wang, W. Chen, A new forming method of straight bevel gear using a specific die with a flash. Int. J. Adv. Manuf. Technol. 2018, 100, 3167–3183. [Google Scholar] [CrossRef]

- G. P. Syrcos, Die casting process optimization using Taguchi methods. J. Mater. Process. Technol. 2004, 135, 68–74. [Google Scholar] [CrossRef]

- X. Zhang, M. Zhang, L. Sun, C. Li, Numerical simulation and experimental investigations on TA1 titanium alloy rivet in electromagnetic riveting. Arch. Civ. Mech. Eng. 2018, 18, 887–901. [Google Scholar] [CrossRef]

- J. Mucha, The numerical analysis of the effect of the joining process parameters on self-piercing riveting using the solid rivet. Arch. Civ. Mech. Eng. 2014, 14, 444–454. [Google Scholar] [CrossRef]

- Y. Zuo, Z. Cao, Y. Cao, Q. Zhang, W. Wang, Dynamic behavior of CFRP/Ti single-lap pinned joints under longitudinal electromagnetic dynamic loading. Compos. Struct. 2018, 184, 362–371. [Google Scholar] [CrossRef]

- J. Hu, K. Zhang, Q. Yang, H. Cheng, P. Liu, Y. Yang, An experimental study on mechanical response of single-lap bolted CFRP composite interference-fit joints. Compos. Struct. 2018, 196, 76–88. [Google Scholar] [CrossRef]

Figure 2.

Two interference fit curves of composite/Al alloy sheets.

Figure 2.

Two interference fit curves of composite/Al alloy sheets.

Figure 3.

Different assembly types of riveting mold.

Figure 3.

Different assembly types of riveting mold.

Figure 4.

a) Interference fit tendency for different combination of rivet dies. (b) The combination type rivet dies for non-uniform interference fit.

Figure 4.

a) Interference fit tendency for different combination of rivet dies. (b) The combination type rivet dies for non-uniform interference fit.

Figure 5.

A diagram of central section radial force.

Figure 5.

A diagram of central section radial force.

Figure 6.

The comparison analysis of radial force. (a) Flat rivet die. (b) Special rivet die.

Figure 6.

The comparison analysis of radial force. (a) Flat rivet die. (b) Special rivet die.

Figure 7.

The weight for interference-fit size by decision-making tree.

Figure 7.

The weight for interference-fit size by decision-making tree.

Figure 8.

The variation process of the interference-fit size.

Figure 8.

The variation process of the interference-fit size.

Figure 9.

Dimensions and products of different riveting molds.

Figure 9.

Dimensions and products of different riveting molds.

Figure 10.

Measurement positions of Interference-fit size.

Figure 10.

Measurement positions of Interference-fit size.

Figure 11.

Diameter and interference-fit size analysis with different riveting molds.

Figure 11.

Diameter and interference-fit size analysis with different riveting molds.

Figure 12.

The tensile load-displacement curves with different angles of TRM.

Figure 12.

The tensile load-displacement curves with different angles of TRM.

Figure 13.

The typical fracture modes for different riveting molds.

Figure 13.

The typical fracture modes for different riveting molds.

Figure 14.

The specimen fracture morphology of 22° TRM.

Figure 14.

The specimen fracture morphology of 22° TRM.

Figure 15.

The specimen fracture morphology of 44° TRM.

Figure 15.

The specimen fracture morphology of 44° TRM.

Figure 16.

The specimen fracture morphology of 66° TRM.

Figure 16.

The specimen fracture morphology of 66° TRM.

Table 1.

Mechanical properties of the sample.

Table 1.

Mechanical properties of the sample.

| CFRP laminates |

Ti-45Nb rivets |

| Property |

Value |

Property |

Value |

| Resin content(%) |

40 |

Density [g/cm3] |

5.7 |

| Tensile strength(Mpa) |

2300 |

Poisson ratio |

0.34 |

| Tensile modulus(Gpa) |

115 |

Tensile modulus [GPa] |

62 |

| Flexural strength (Mpa) |

1250 |

Yield strength [MPa] |

425 |

| Compressive strength (Mpa) |

1050 |

Tensile strength [MPa] |

570 |

| Interlaminar shear strength (Mpa) |

55 |

|

|

Table 2.

Parameters level of TRM structure.

Table 2.

Parameters level of TRM structure.

| Variable |

Level 1 |

Level 2 |

Level 3 |

Level 4 |

|

H/mm |

1.6 |

1.8 |

2.0 |

2.2 |

|

d/mm |

4.2 |

4.4 |

4.6 |

4.8 |

| α |

22° |

44° |

66° |

88° |

Table 3.

The schemes and results of the research design.

Table 3.

The schemes and results of the research design.

| Scheme |

h/mm |

d/mm |

α/° |

Imax /% |

| 1 |

1.6 |

4.2 |

22 |

3.70 |

| 2 |

1.6 |

4.4 |

44 |

2.49 |

| 3 |

1.6 |

4.6 |

66 |

2.01 |

| 4 |

1.6 |

4.8 |

88 |

2.45 |

| 5 |

1.8 |

4.2 |

44 |

4.37 |

| 6 |

1.8 |

4.4 |

22 |

3.41 |

| 7 |

1.8 |

4.6 |

88 |

2.34 |

| 8 |

1.8 |

4.8 |

66 |

2.30 |

| 9 |

2.0 |

4.2 |

66 |

2.92 |

| 10 |

2.0 |

4.4 |

88 |

2.48 |

| 11 |

2.0 |

4.6 |

22 |

3.65 |

| 12 |

2.0 |

4.8 |

44 |

2.81 |

| 13 |

2.2 |

4.2 |

88 |

2.72 |

| 14 |

2.2 |

4.4 |

66 |

2.70 |

| 15 |

2.2 |

4.6 |

44 |

3.15 |

| 16 |

2.2 |

4.8 |

22 |

3.58 |

Table 4.

The Imax average of each variable.

Table 4.

The Imax average of each variable.

| Level |

h/mm |

d/mm |

α |

| 1 |

2.662 |

3.428 |

3.585 |

| 2 |

3.105 |

2.770 |

3.205 |

| 3 |

2.965 |

2.788 |

2.482 |

| 4 |

3.038 |

2.785 |

2.498 |

| Deviation max-min |

0.443 |

0.657 |

1103 |

Table 5.

the measured results of relative interference for different rivet dies.

Table 5.

the measured results of relative interference for different rivet dies.

| Type |

Position |

Repeat 1(mm) |

Repeat 2(mm) |

Repeat 3(mm) |

Average value (mm) |

IA (%) |

| |

1 |

4.16 |

4.17 |

4.16 |

4.163 |

2.03 |

| |

2 |

4.13 |

4.13 |

4.13 |

4.130 |

0.98 |

| FRM |

3 |

4.12 |

4.10 |

4.12 |

4.130 |

0.98 |

| |

4 |

4.11 |

4.12 |

4.11 |

4.113 |

0.809 |

| |

5 |

4.10 |

4.12 |

4.12 |

4.113 |

0.809 |

| |

1 |

4.19 |

4.20 |

4.18 |

4.190 |

2.70 |

| |

2 |

4.17 |

4.16 |

4.16 |

4.163 |

2.03 |

| 22° TRM |

3 |

4.14 |

4.15 |

4.15 |

4.147 |

1.64 |

| |

4 |

4.13 |

4.12 |

4.13 |

4.127 |

1.15 |

| |

5 |

4.10 |

4.10 |

4.10 |

4.100 |

0.74 |

| |

1 |

4.21 |

4.20 |

4.21 |

4.207 |

3.11 |

| |

2 |

4.18 |

4.17 |

4.19 |

4.180 |

2.45 |

| 44° TRM |

3 |

4.15 |

4.15 |

4.15 |

4.150 |

1.72 |

| |

4 |

4.14 |

4.13 |

4.14 |

4.137 |

1.40 |

| |

5 |

4.12 |

4.13 |

4.13 |

4.127 |

1.15 |

| |

1 |

4.19 |

4.18 |

4.19 |

4.187 |

2.63 |

| |

2 |

4.18 |

4.18 |

4.17 |

4.177 |

2.38 |

| 66° TRM |

3 |

4.14 |

4.14 |

4.13 |

4.137 |

1.40 |

| |

4 |

4.14 |

4.13 |

4.14 |

4.137 |

1.40 |

| |

5 |

4.13 |

4.11 |

4.13 |

4.123 |

1.05 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

(1)

(1) (2)

(2) (3)

(3)