Submitted:

27 February 2023

Posted:

28 February 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

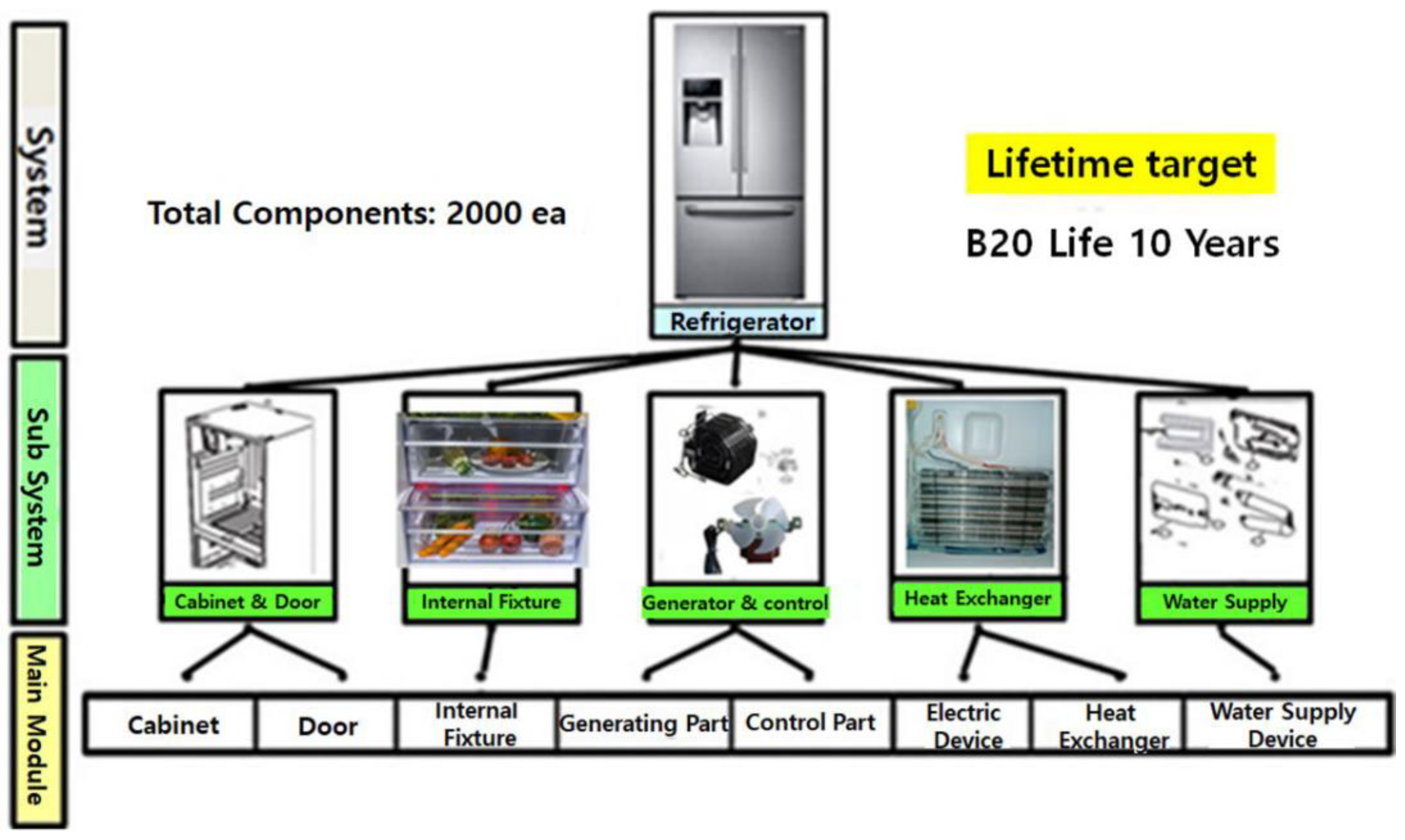

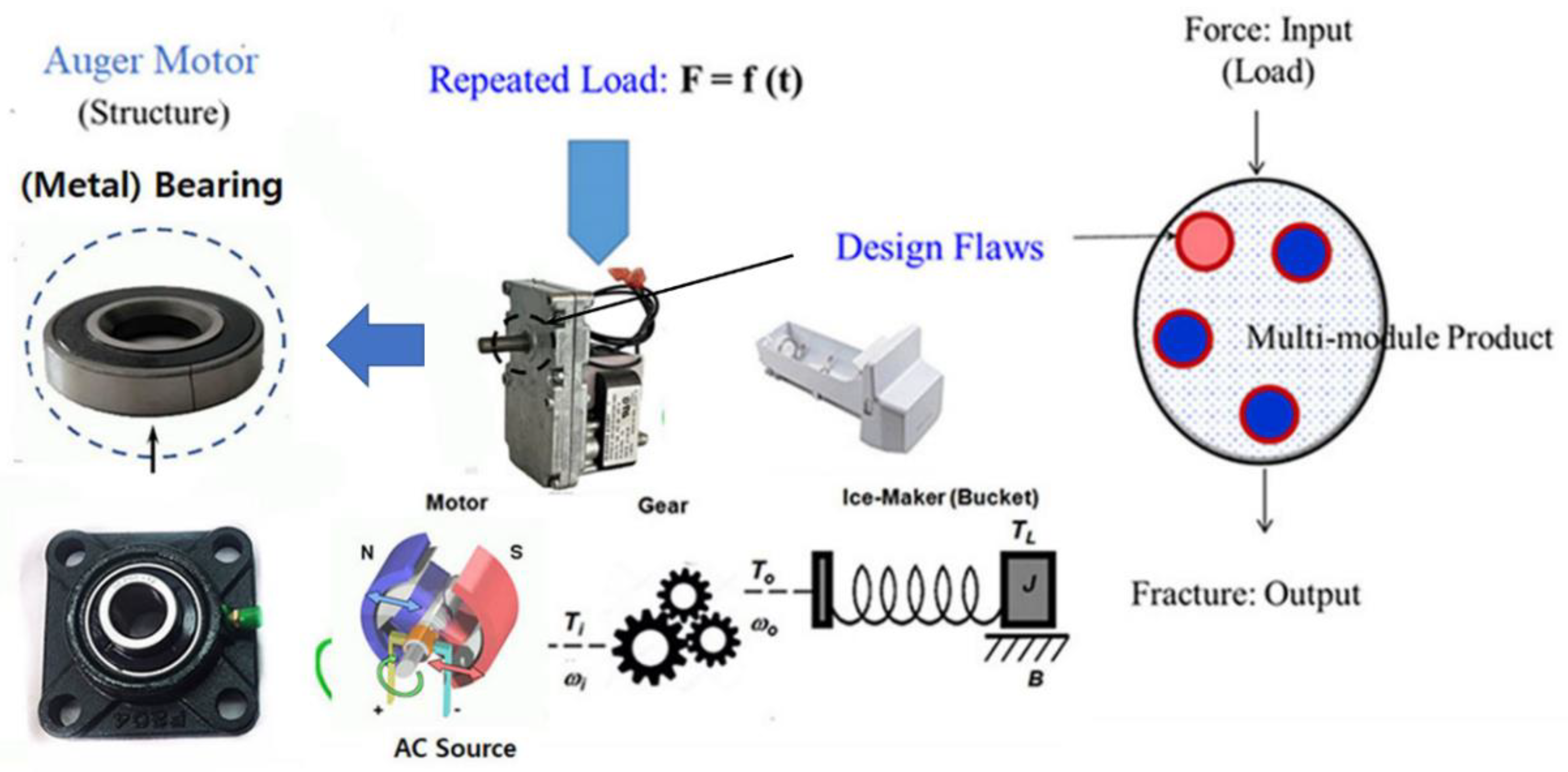

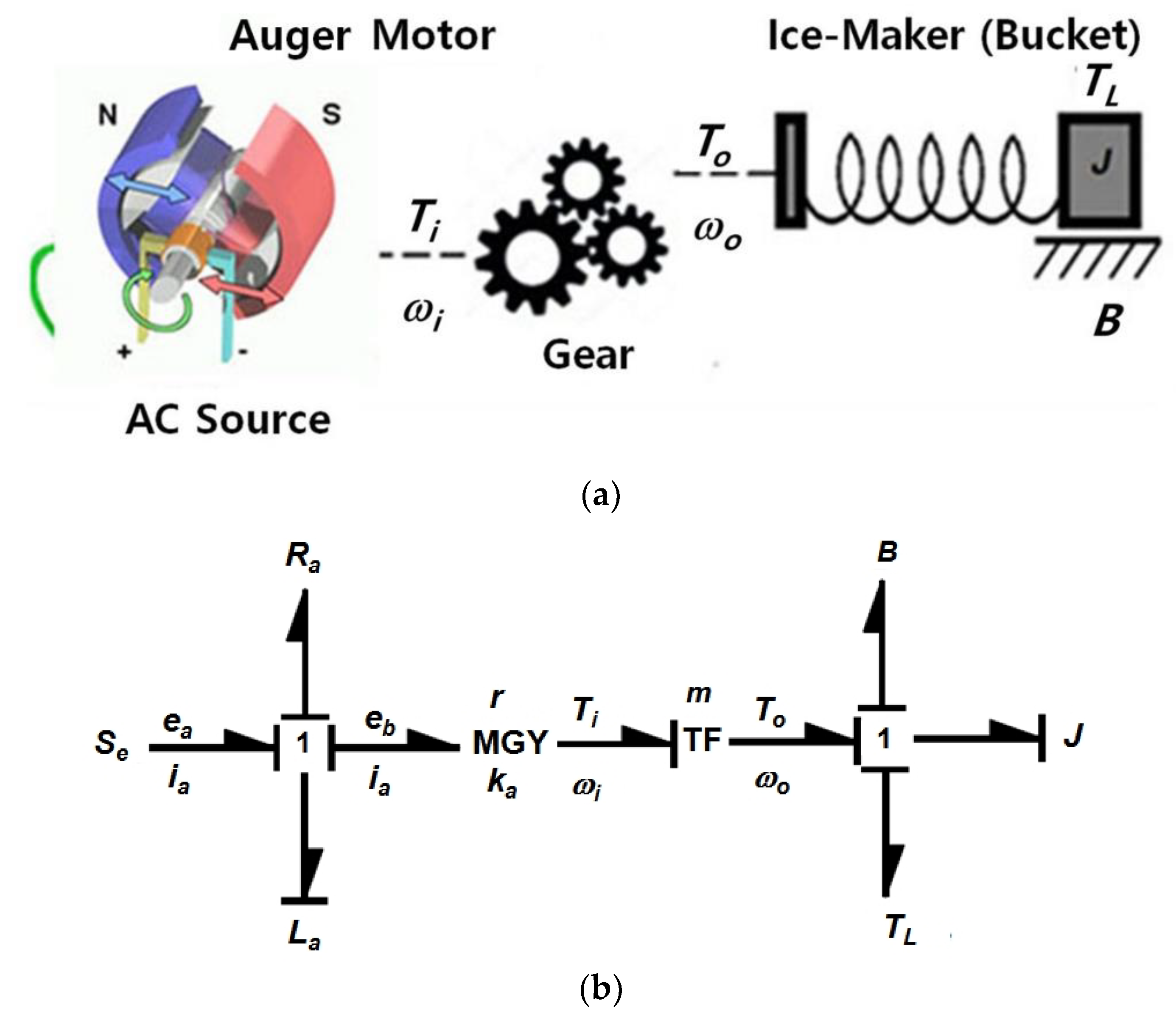

2. Parametric ALT for a System functioned by machine

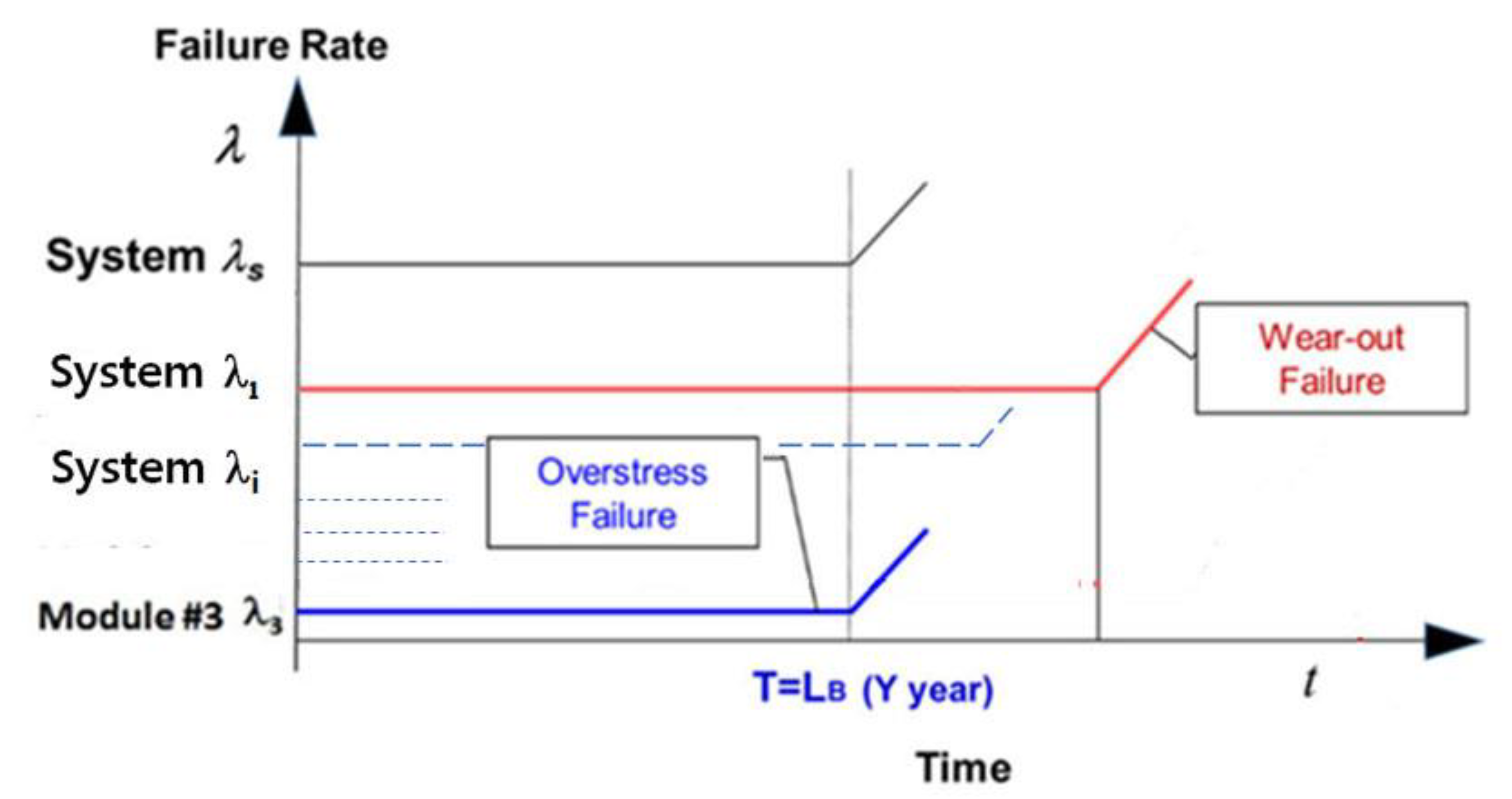

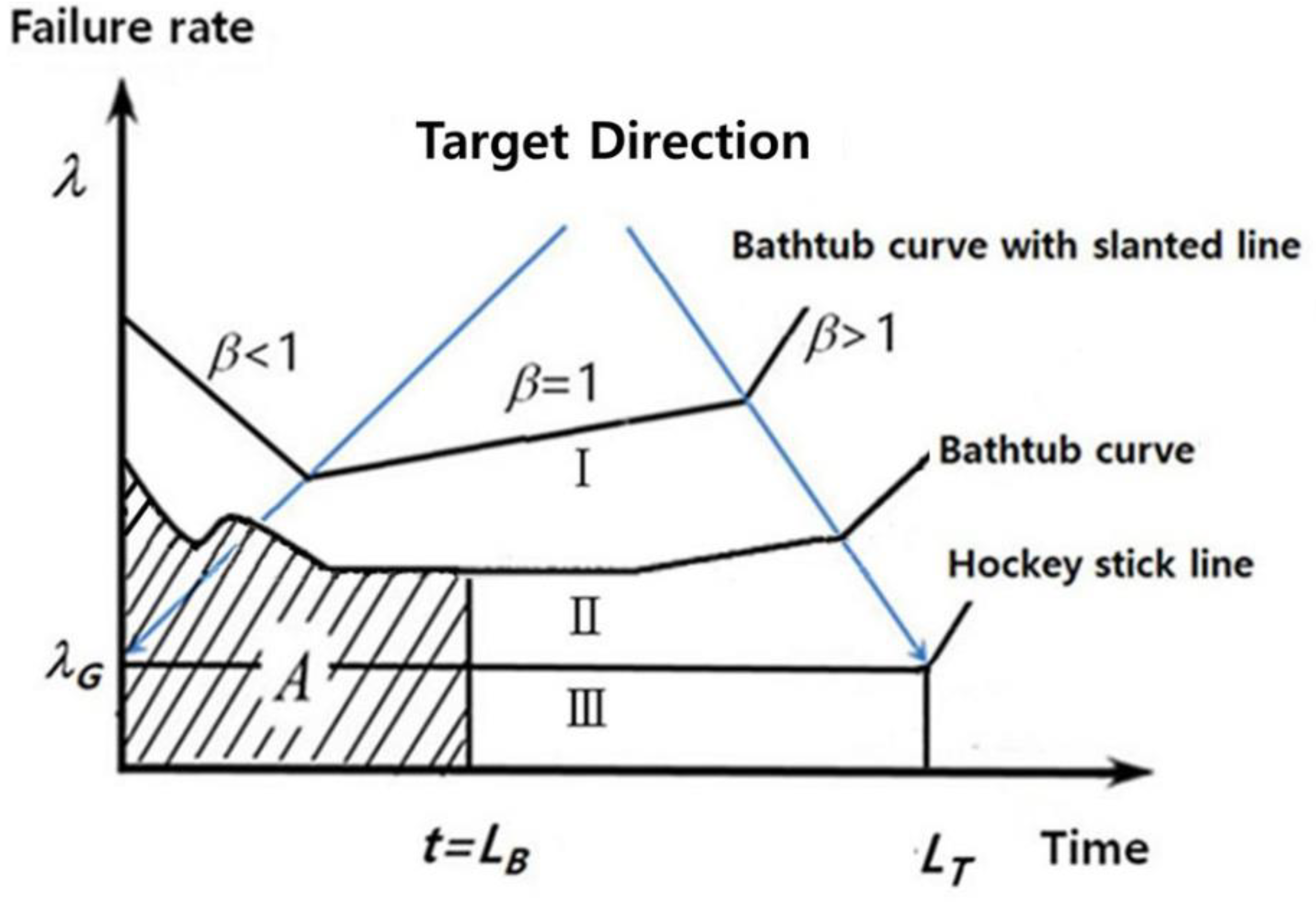

2.1. Meaning of BX life

2.2. Posing an Entire ALT procedure

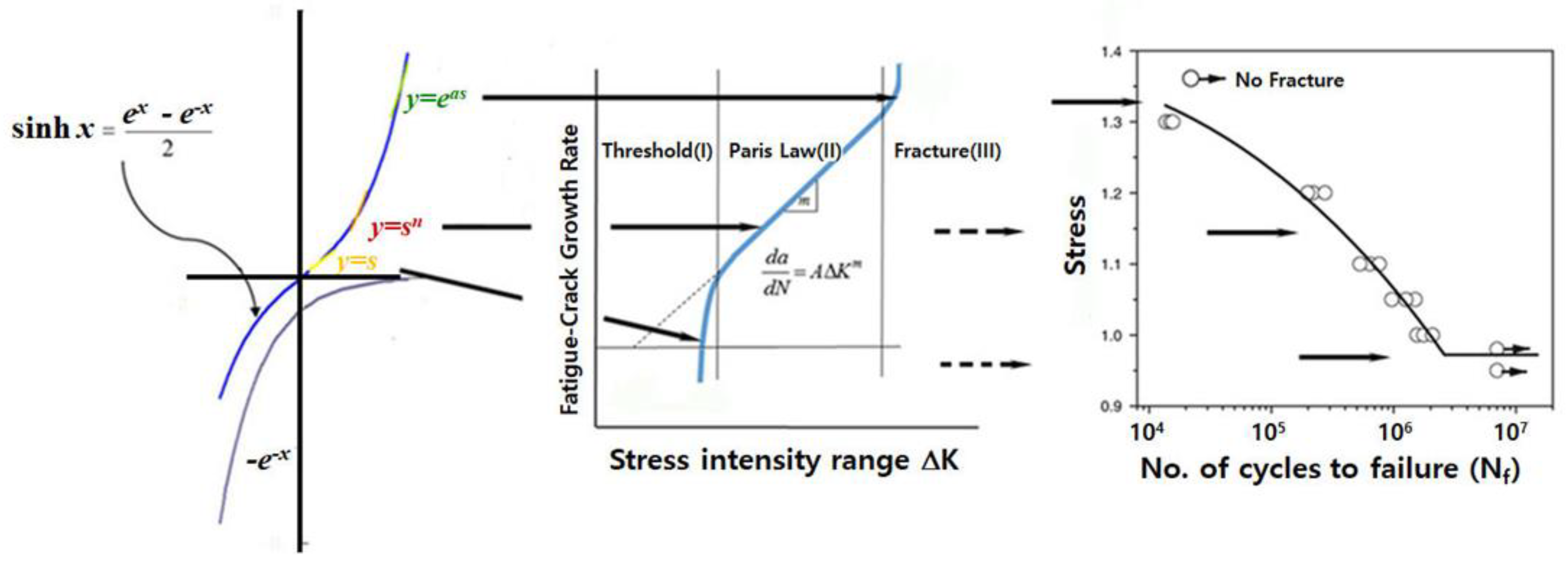

2.3. Deduction of Life-Stress Model

2.4. Obtaining of sample size formulation for ALT

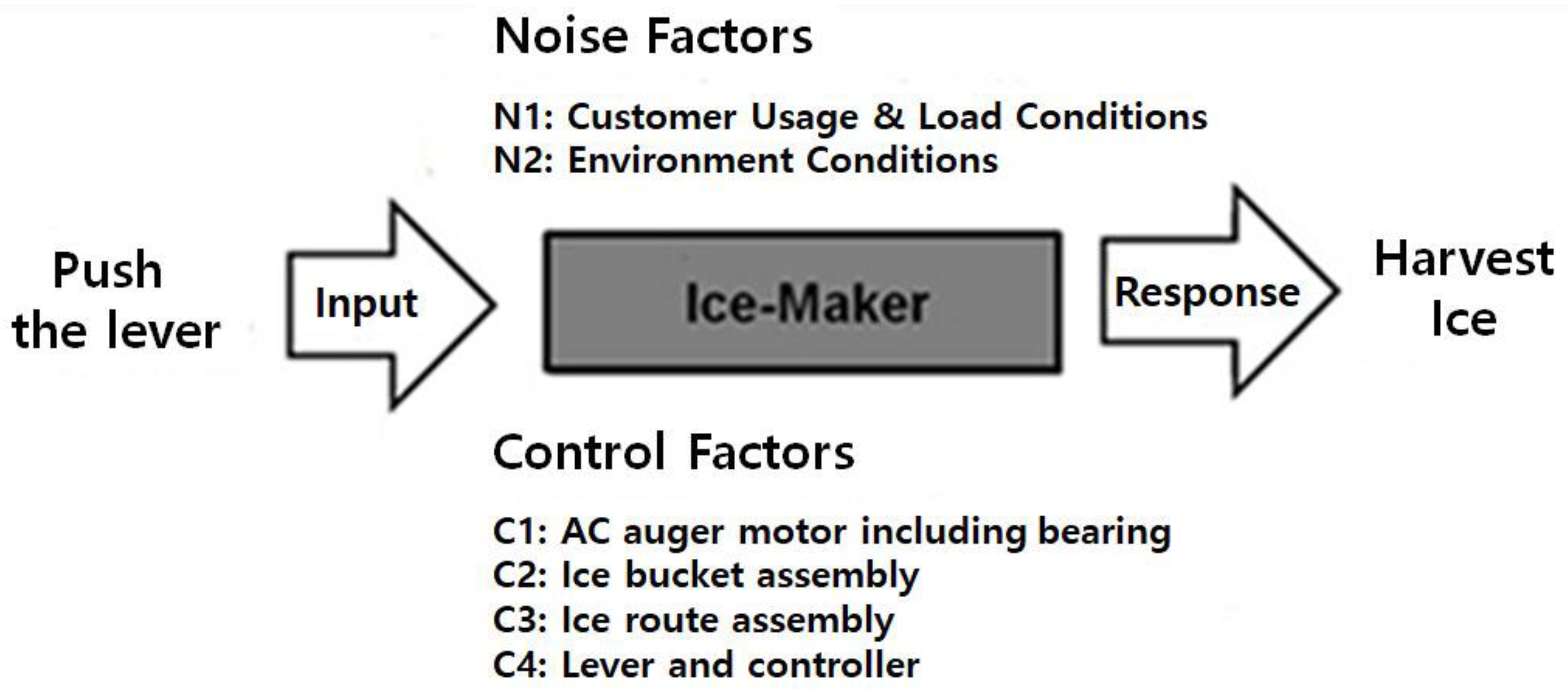

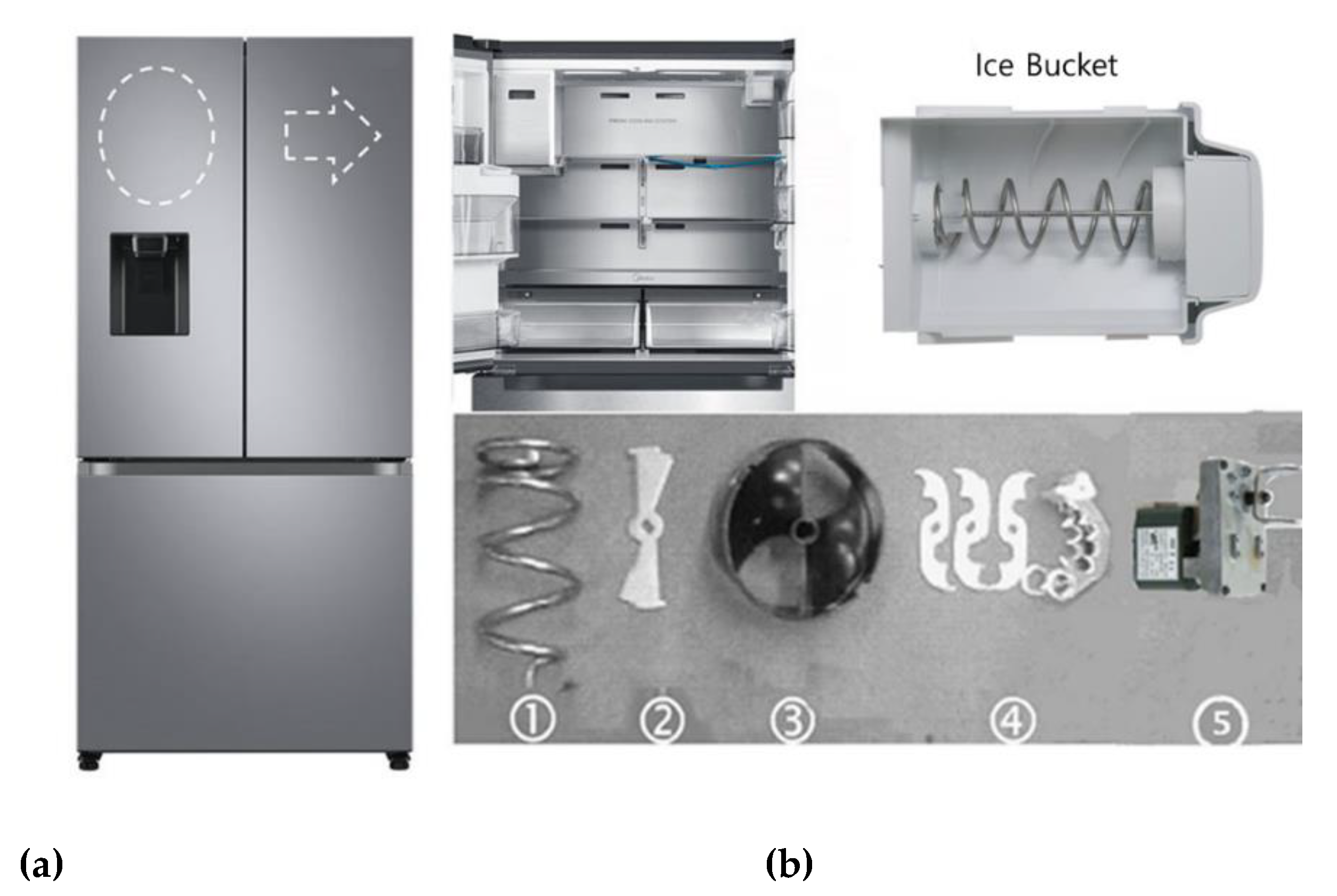

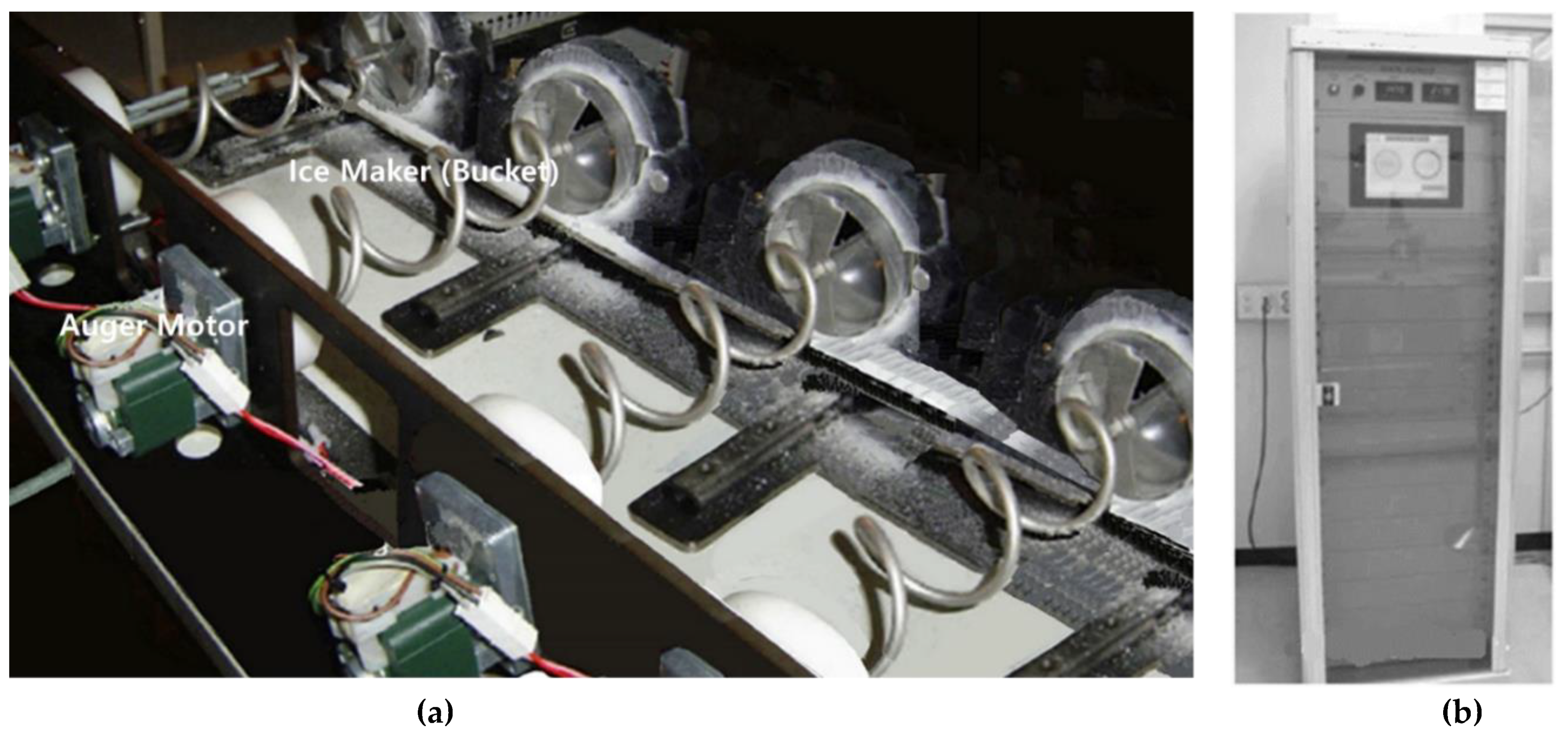

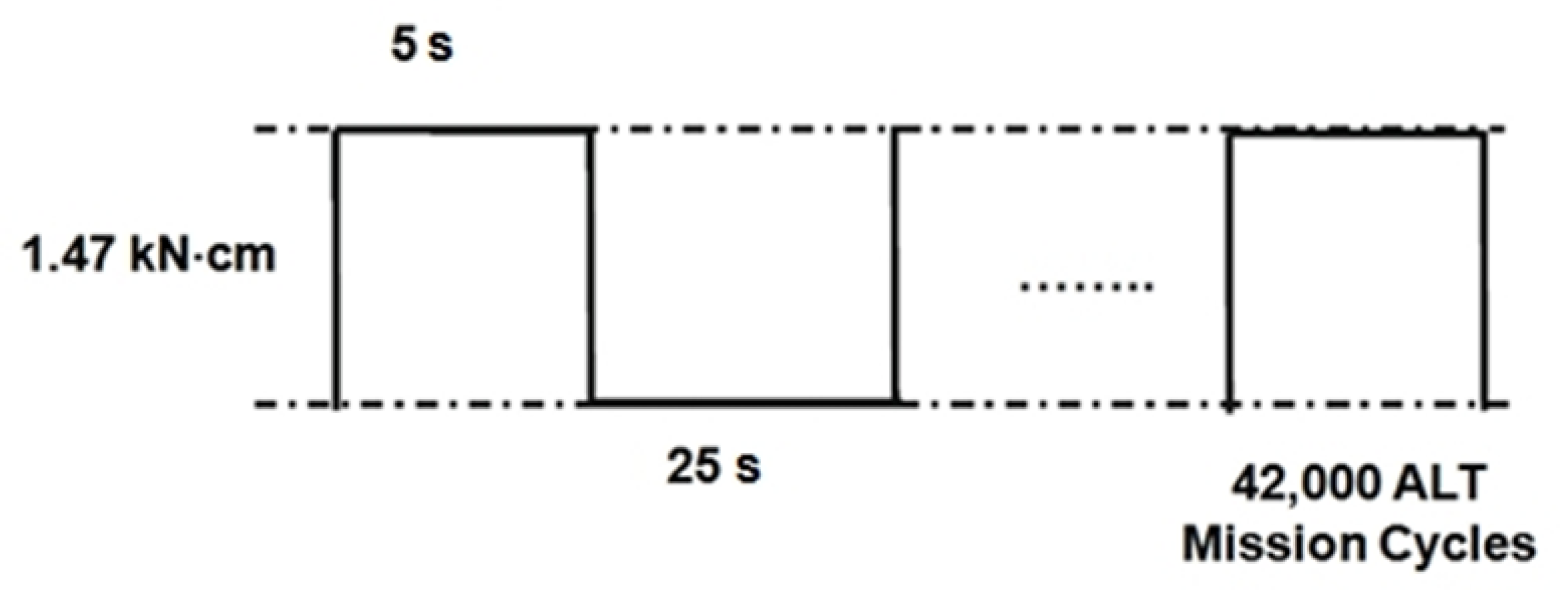

2.5. Case Investigation—Magnifying Lifetime of an Ice-Maker Incorporating Auger Motor with a Bearing in a Household Refrigerator

3. Results and Discussion

4. Summary and Conclusions

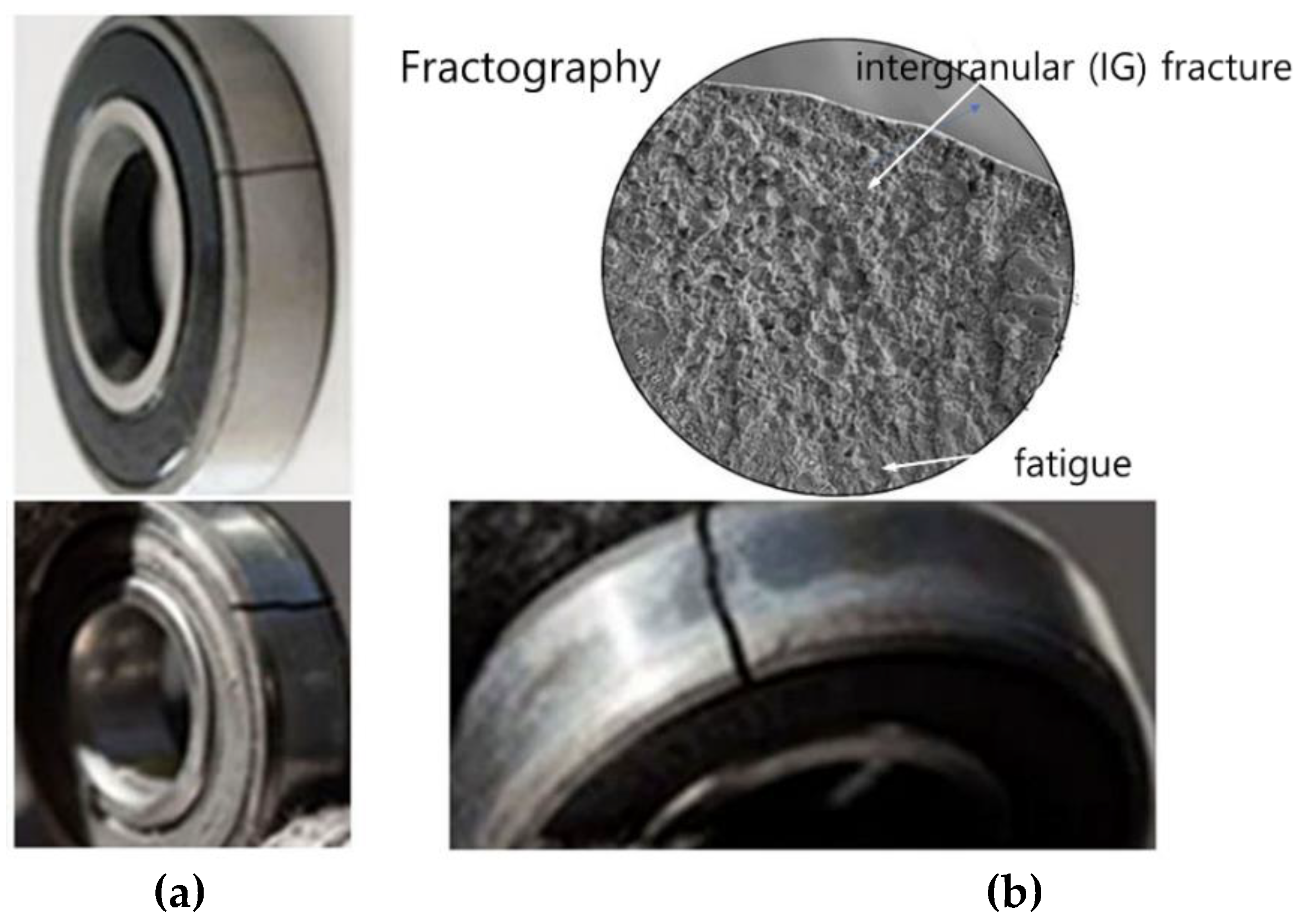

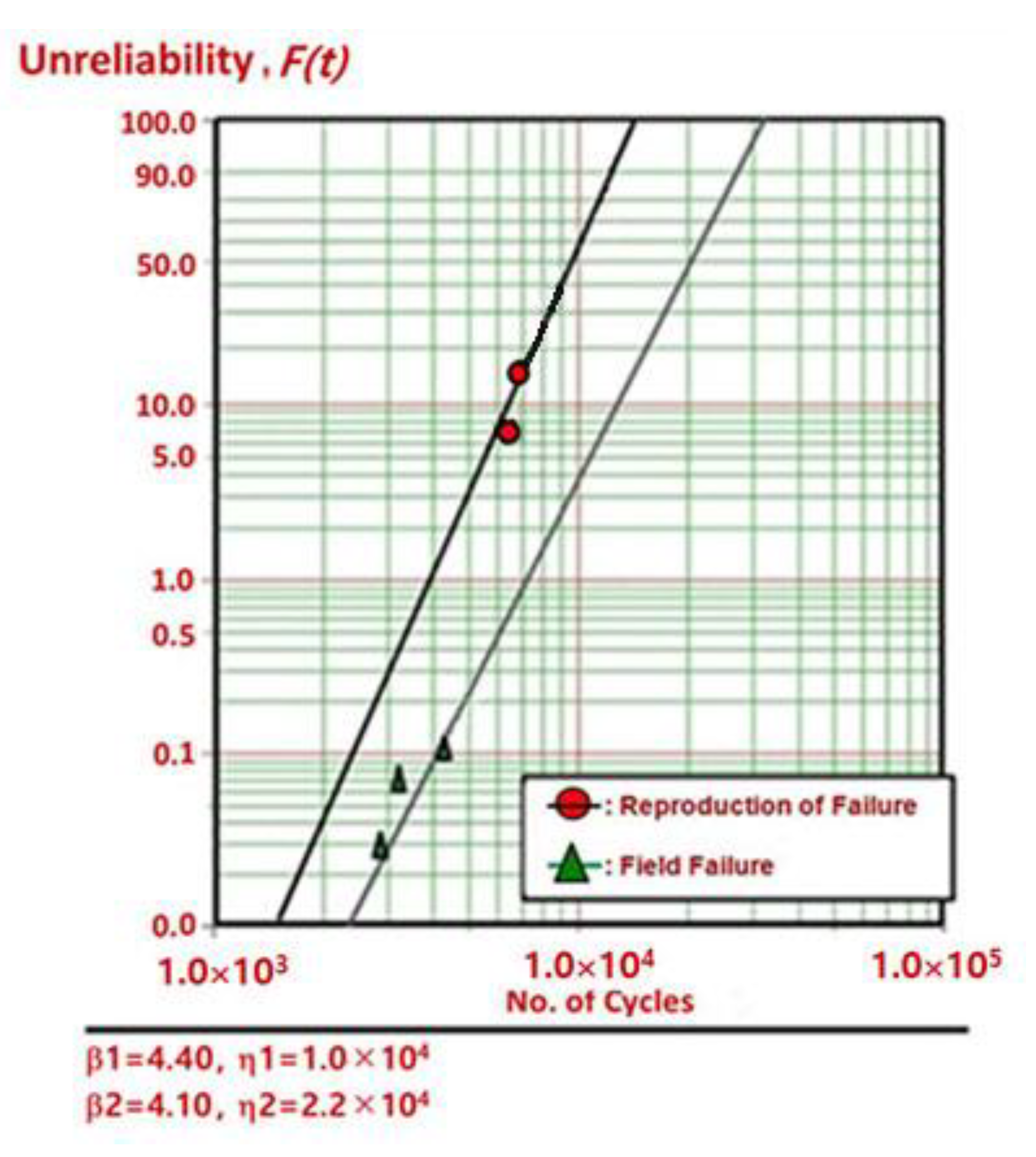

- In the 1st ALT, the auger motor in an ice maker stopped near 6600 cycles and 6900 cycles as exerted for torque 1.47 kN-cm under the freezing temperatures (−20 °C below) in the refrigerator. After disassembling the troublesome samples, we found the fractured outer ring of the bearing in an auger motor. As an action plan, the bearing matter in an ice-maker was altered from AISI 52100 Alloy Steel with 1.30-1.60% chromium to lubricated sliding bearing with sintered and hardened steel (FLC 4608-110HT).

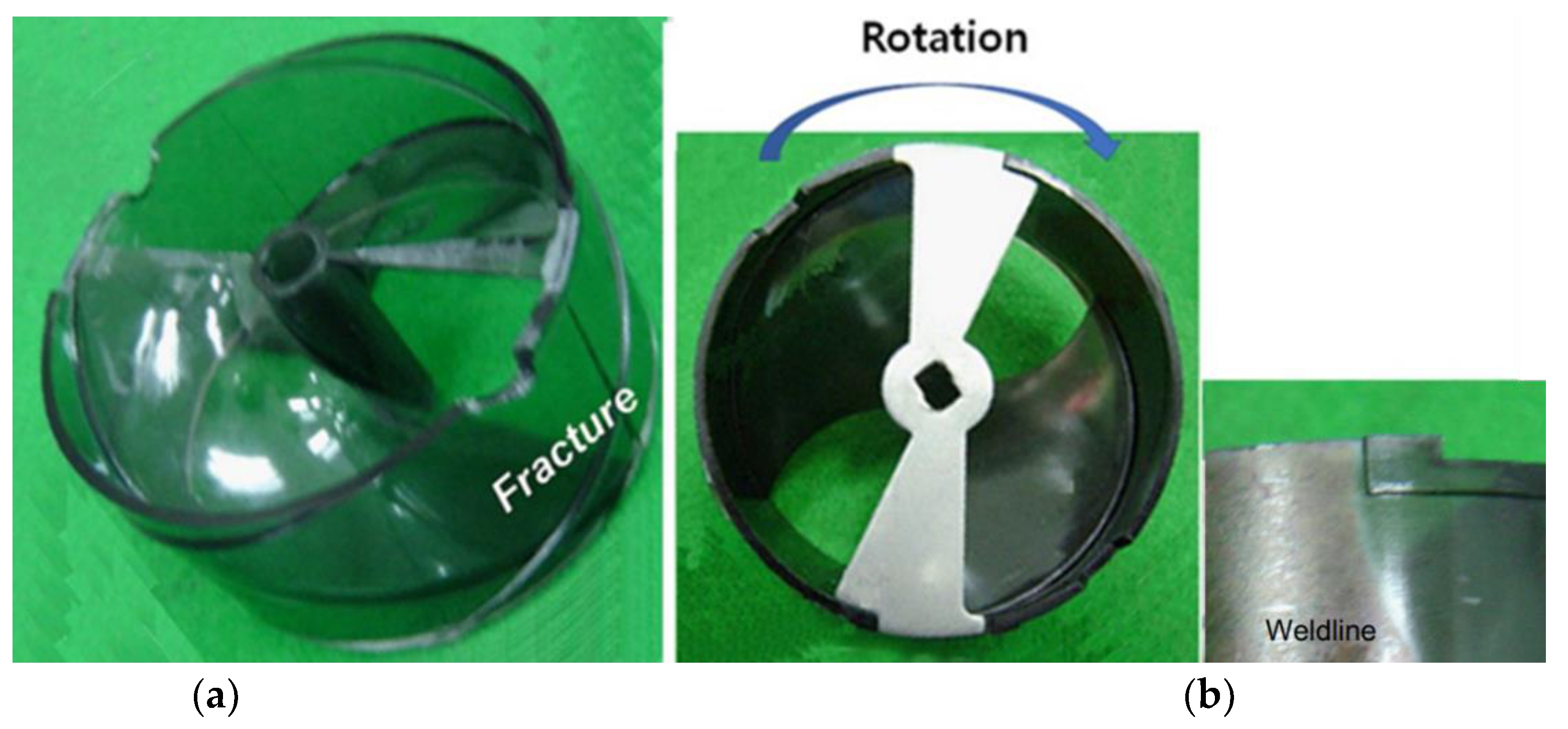

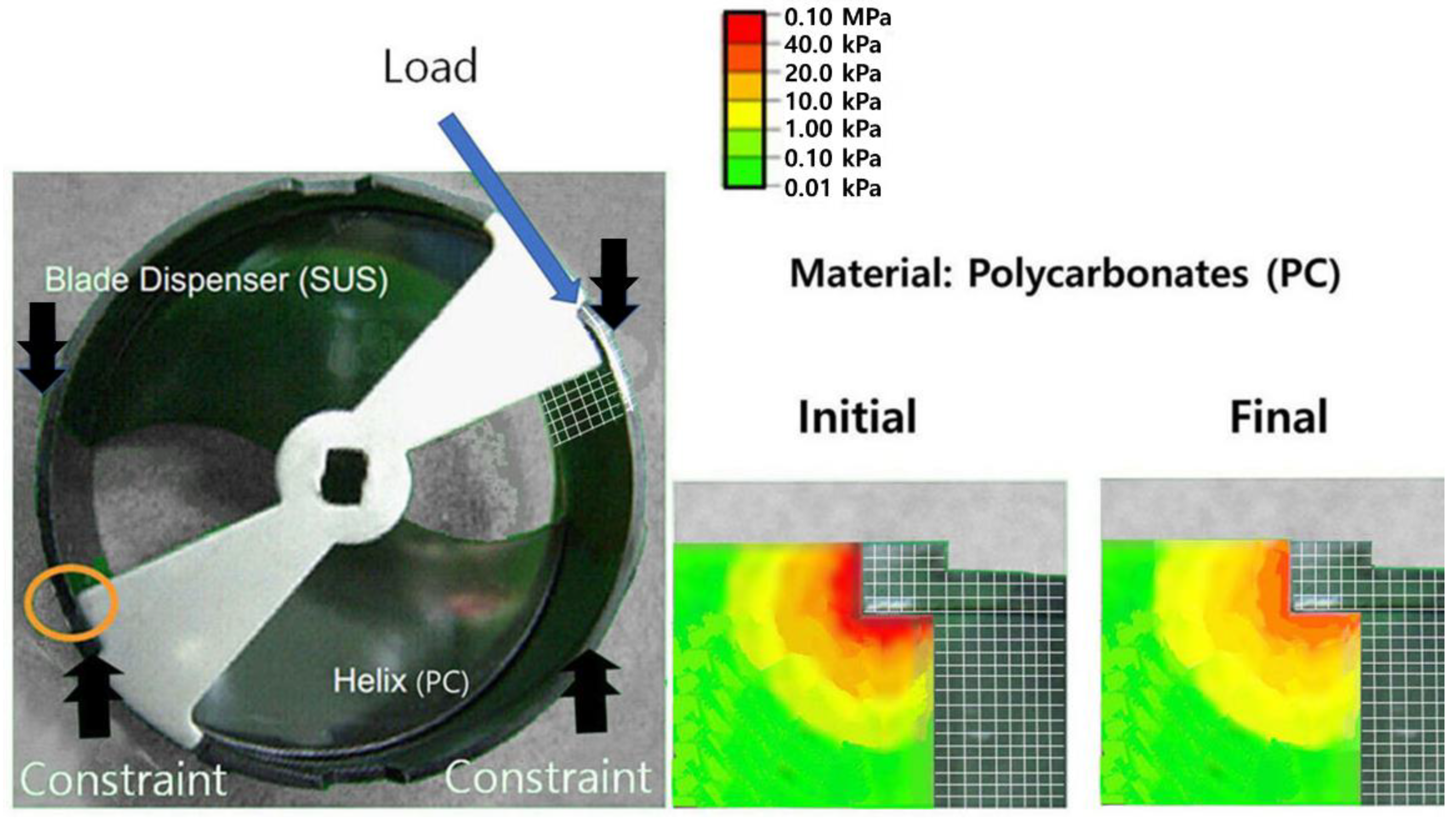

- In the 2nd ALT, the helix (polycarbonates) at 10,000 cycles and 12,000 cycles was fractured because the ice-maker had insufficient fatigue strength for repetitive stress in the freezer department. As an alternative, a reinforced rib of the helix was thickened after plastic injection procedure was modified.

- In the 3rd ALT, no problems were found. The ice-maker, involving an auger motor, will satisfy the life objective—B1 life 10 years. Inspecting controversial field parts and carrying out ALTs with modifications could grow the life of an ice maker, involving an auger motor with a bearing.

- By comprehending the design problems of products failed from the market, we might carry out parametric ALTs with system modifications. As reproducing the market failures, the design defects could be recognized and alter them. Ultimately, we approximated whether the system reached the life targets. In the process, the (generalized) time-to-failure type and sample size also were utilized.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BX | Time which is a cumulated failure rate of X% |

| Ea | Activation energy, eV |

| e | Effort |

| eb | Counterelectromotive force |

| ef | Field voltage, V |

| f | Flow |

| Fc | Ice crushing force, kN |

| F(t) | Unreliability |

| h | Testing time |

| h* | Nondimensional testing time, |

| if | Field current, A |

| J | Momentum of inertia, kg m2 |

| k | Boltzmann’s numerical quantity, 8.62 × 10−5 eV/deg |

| LB | Objective BX lifetime and x = 0.01 X, on the conditions that x ≤ 0.2 |

| m | Gear ratio |

| MGY | Gyrator in causal forms for basic 2-ports and 3-ports |

| n | Sample number |

| Q | Entire number of dopants per unit area |

| R | Ratio for minimum stress to greatest stress in stress cycle, σmin/σmax |

| r | Failed numbers |

| r | Coefficient of gyrator |

| S | Stress |

| T | Temperature, K |

| ti | Test time for each sample |

| TF | Time to failure |

| TL | Ice-crushing torque in bucket, kN cm |

| X | Cumulated failure rate, % |

| x | x = 0.01 X, on condition that x ≤ 0.2. |

| Greek symbols | |

| ξ | Electrical field exerted |

| η | Characteristic life |

| λ | Cumulative damage quantity in Palmgren–Miner’s rule |

| χ2 | Chi-square distribution |

| α | Confidence level |

| ω | Angular velocity in ice bucket, rad/s |

| Superscripts | |

| β | Shape parameter on the Weibull chart |

| n | Stress dependence, |

| Subscripts | |

| 0 | Usual stress conditions |

| 1 | Accelerated stress conditions |

References

- Woo, S.; Pecht, M.; O’Neal, D. Reliability design and case study of the domestic compressor subjected to repetitive internal stresses. Reliab. Eng. Syst. Saf. 2019, 193, 106604. [Google Scholar] [CrossRef]

- Magaziner, I.C.; Patinkin, M. Cold competition: GE wages the refrigerator war. Harv. Bus. Rev. 1989, 89, 114–124. [Google Scholar]

- Bigg, G.; Billings, S. The iceberg risk in the Titanic year of 1912: Was it exceptional? Significance 2014, 11, 6–10. [Google Scholar] [CrossRef]

- Rogers, W.P.; Armstrong, N.A.; Acheson, D.C.; Covert, E.E.; Feynman, R.P.; Hotz, R.B.; Kutyna, D.J.; Ride, S.K.; Rummel, R.W.; Sutter, J.F.; et al. Report of the Presidential Commission on the Space Shuttle Challenger Accident; NASA: Washington, DC, 1986. [Google Scholar]

- ASTM International. Failures of Rolling-Element Bearings. Volume 11 Failure Analysis and Prevention. Metals Handbook, 9th ed.; ASTM International: West Conshohocken, 1990; p. 508. [Google Scholar]

- DVB Bank SE Aviation Research (AR). An Overview of Commercial Jet Aircraft 2013; DVB Bank SE Aviation Research (AR): Schiphol, The Netherlands, 2014; p. 20. [Google Scholar]

- Woo, S.; O’Neal, D.L. Reliability Design of Mechanical Systems Such as Compressor Subjected to Repetitive Stresses. Metals 2021, 11, 1261. [Google Scholar] [CrossRef]

- Woo, S.; O’Neal, D.L.; Matvienko, Y.G.; Mebrahtu, G. Enhancing the Fatigue of Mechanical Systems Such as Dispensers Entrenched on Generalized Life-Stress Models and Sample Sizes. Appl. Sci. 2023, 13, 1358. [Google Scholar] [CrossRef]

- Wang, L.; Li, Y. Boundary for aviation bearing accelerated life test based on quasi-dynamic analysis. Tribol. Int. 2017, 116, 414–421. [Google Scholar] [CrossRef]

- Duga, J.J.; Fisher, W.H.; Buxaum, R.W.; Rosenfield, A.R.; Buhr, A.R.; Honton, E.J.; McMillan, S.C. The Economic Effects of Fracture in the United States; Final Report; Available as NBS Special Publication 647-2; Battelle Laboratories: Columbus, OH, USA, 1982. [Google Scholar]

- Gope, P.C.; Mahar, C.S. Evaluation of fatigue damage parameters for Ni-based super alloys Inconel 825 steel notched specimen using stochastic approach. Fatigue Fract. Eng. Mater. Struct. 2020, 44, 427–443. [Google Scholar] [CrossRef]

- Sola, J.F.; Kelton, R.; Meletis, E.I.; Huang, H. Predicting crack initiation site in polycrystalline nickel through surface topography changes. Int. J. Fatigue 2019, 124, 70–81. [Google Scholar] [CrossRef]

- Campbell, F.C. (Ed.) Fatigue. In Elements of Metallurgy and Engineering Alloys; ASM International: Materials Park, OH, USA, 2008. [Google Scholar]

- Chowdhury, S.; Taguchi, S. Robust Optimization: World's Best Practices for Developing Winning Vehicles, 1st ed.; John Wiley and Son: Hoboken, NJ, USA, 2016. [Google Scholar]

- Montgomery, D. Design and Analysis of Experiments, 10th ed.; John Wiley and Son: Hoboken, NJ, USA, 2020. [Google Scholar]

- Elishakoff, I. Stepan Prokofievich Timoshenko, in Encyclopedia of Continuum Mechanics; Altenbach, H., Öchsner, A., Eds.; Springer: Berlin, Germany, 2020; pp. 2552–2555. [Google Scholar]

- Weingart, R.G.; Stephen, P. Timoshenko: Father of Engineering Mechanics in the U.S. Structure Magazine, 20 August.

- Goodno, B.J.; Gere, J.M. Mechanics of Materials, 9th ed.; Cengage Learning, Inc.: Boston, MA, USA, 2017. [Google Scholar]

- Anderson, T.L. Fracture Mechanics—Fundamentals and Applications, 3rd ed.; CRC: Boca Raton, FL, USA, 2017. [Google Scholar]

- Standard Test Method for Strain-Controlled Fatigue Testing. ASTM E606/E606 M, ASTM International: West Conshohocken, PA, USA, 2019.

- Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness of Metallic Materials. ASTM E399, ASTM International: West Conshohocken, PA, USA, 2020.

- Standard Test Method for Measurement of Fatigue Crack Growth Rates. ASTM E647, ASTM International: West Conshohocken, PA, USA, 2015.

- Standard Practice for Statistical Analysis of Linear or Linearized Stress-Life (S‒N) and Strain-Life (ε-N) Fatigue Data. ASTM E739-10, ASTM International: West Conshohocken, PA, USA, 2015.

- Braco, R.; Prates, P.; Costa, J.D.M.; Berto, F. New methodology of fatigue life evaluation for multiaxially loaded notched components based on two uniaxial strain-controlled tests. Int. J. Fatigue 2018, 111, 308–320. [Google Scholar] [CrossRef]

- McPherson, J. Accelerated Testing, Electronic Materials Handbook Volume 1: Packaging; ASM International Publishing: Materials Park Campus, OH, USA, 1989. [Google Scholar]

- McPherson, J. Reliability Physics and Engineering: Time-to-Failure Modeling; Springer: New York, NY, USA, 2010. [Google Scholar]

- Reddy, J.N. An Introduction to the Finite Element Method, 4th ed.; McGraw-Hill: New York, NY, USA, 2020. [Google Scholar]

- Matsuishi, M.; Endo, T. Fatigue of metals subjected to varying stress. Jpn. Soc. Mech. Eng. 1968. [Google Scholar]

- Palmgren, A.G. Die Lebensdauer von Kugellagern. Z. Ver. Dtsch. Ing. 1924, 68, 339–341. [Google Scholar]

- Cengel, Y.; Boles, M.; Kanoglu, M. Thermodynamics: An Engineering Approach, 9th, ed.; McGraw—Hill: New York, NY, USA, 2018. [Google Scholar]

- IEEE Standard Glossary of Software Engineering Terminology. IEEE STD 610.12-1990. Standards Coordinating Committee of the Computer Society of IEEE. (REAFFIRMED SEPTEMBER 2002). Available online: https://ieeexplore.ieee.org/document/159342 (accessed on 31 December 2020).

- Kreyszig, E. Advanced Engineering Mathematics, 10th ed.; John Wiley and Son: Hoboken, NJ, USA, 2011; p. 683. [Google Scholar]

- Evans, J.W.; Evans, J.Y. Product Integrity and Reliability in Design; Springer: New York, NY, USA, 2001; p. 7. [Google Scholar]

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Transport Phenomena, 2nd ed.; John Wiley and Son: Hoboken, NJ, USA, 2006. [Google Scholar]

- Plawsky, J.L. Transport Phenomena Fundamentals, 4th ed.; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Grove, A. Physics and Technology of Semiconductor Device, 1st ed.; Wiley International Edition: New York, NY, USA, 1967; p. 37. [Google Scholar]

- Karnopp, D.C.; Margolis, D.L.; Rosenberg, R.C. System Dynamics: Modeling, Simulation, and Control of Mechatronic Systems, 6th ed.; John Wiley & Sons: New York, NY, USA, 2012. [Google Scholar]

- Wasserman, G. Reliability Verification, Testing, and Analysis in Engineering Design; Marcel Dekker: New York, NY, USA, 2003; p. 228. [Google Scholar]

- Tang, L.C. Multiple-steps step-stress accelerated life tests: A model and its spreadsheet analysis. Int. J. Mater. Prod. Technol. 2004, 21, 423–434. [Google Scholar] [CrossRef]

- El-Azeem, S.O.A.; Abu-Moussa, M.H.; El-Din, M.M.M.; et al. On Step-Stress Partially Accelerated Life Testing with Competing Risks Under Progressive Type-II Censoring. Ann. Data. Sci. 2022. [Google Scholar] [CrossRef]

- Samanta, D.; Mondal, S.; Kundu, D. Optimal plan for ordered step-stress stage life testing. Statistics 2022, 56, 1–26. [Google Scholar] [CrossRef]

| Modules | Market Reliability | Predicted Reliability | Goal Reliability | |||||

|---|---|---|---|---|---|---|---|---|

| Failure Rate Per Year, %/Year | BX Life, Year | Failure Rate Per Year, %/Year | BX Life, LB (Year) |

Failure Rate Per Year, %/Year | BX Life, Year | |||

| A | 0.34 | 5.3 | New | ×5 | 1.70 | 1.1 | 0.15 | 12(BX = 1.8) |

| B | 0.35 | 5.1 | Same | ×1 | 0.35 | 5.1 | 0.15 | 12(BX = 1.8) |

| C | 0.25 | 4.8 | Modified | ×2 | 0.50 | 2.4 | 0.10 | 12(BX = 1.2) |

| D | 0.20 | 6.0 | Modified | ×2 | 0.40 | 3.0 | 0.10 | 12(BX = 1.2) |

| E | 0.15 | 8.0 | Same | ×1 | 0.15 | 8.0 | 0.10 | 12(BX = 1.2) |

| Miscellaneous | 0.50 | 12.0 | Same | ×1 | 0.50 | 12.0 | 0.50 | 12(BX = 6.0) |

| System | 1.79 | 7.4 | - | - | 3.60 | 3.7 | 1.10 | 12(BX = 13.2) |

| Ohm’s Law: | ||

| J = current density, j (quantity: A/cm2) |

D = electric field, −∇ V (quantity: V/cm, V = potential) |

L = conductivity, σ = 1/ρ (quantity: ρ = resistivity (Ω cm)) |

| Fourier’s Law: q = −κ∇T | ||

| J = heat flux, q (quantity: W/cm2) |

D = thermal force, −∇ T (quantity: °K/cm, T = temperature) |

L = thermal conductivity, κ (quantity : W/°K cm) |

| Fick’s Law: F = −D∇ C | ||

| J = material flux, F (quantity:/sec cm2) |

D = diffusion force, −∇ C (quantity:/cm4, C = concentration) |

L = diffusivity, D (quantity: cm2/sec) |

| Newton’s Law: Fu = −μ∇ u | ||

| J = fluid velocity flux, Fu (quantity:/sec2 cm) |

D = viscous force, −∇ u (quantity:/sec, u = fluid velocity) |

L = viscosity, μ (quantity:/sec cm) |

| Parametric ALT | 1st ALT | 2nd ALT | 3rd ALT |

|---|---|---|---|

| Draft Design | - | Final Design | |

| Over the route of 42,000 cycles, the ice maker system has no issues | 6500 cycles: 1/10 fail 6900 cycles: 1/10 fail (Unsuccessful bearing samples) |

10,000 cycles: 1/10 fail 12,000 cycles: 1/10 fail (Unsuccessful helix samples) |

42,000 cycles: 10/10 60,000 cycles: 10/10 OK |

| Structure |  |

||

| Action plans | C1: from AISI 52100 Alloy Steel to lubricated sliding bearing with sintered and hardened steel (FLC 4608-110HT) | C2: thickened reinforced rib on the side of helix | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).