Submitted:

06 March 2023

Posted:

06 March 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

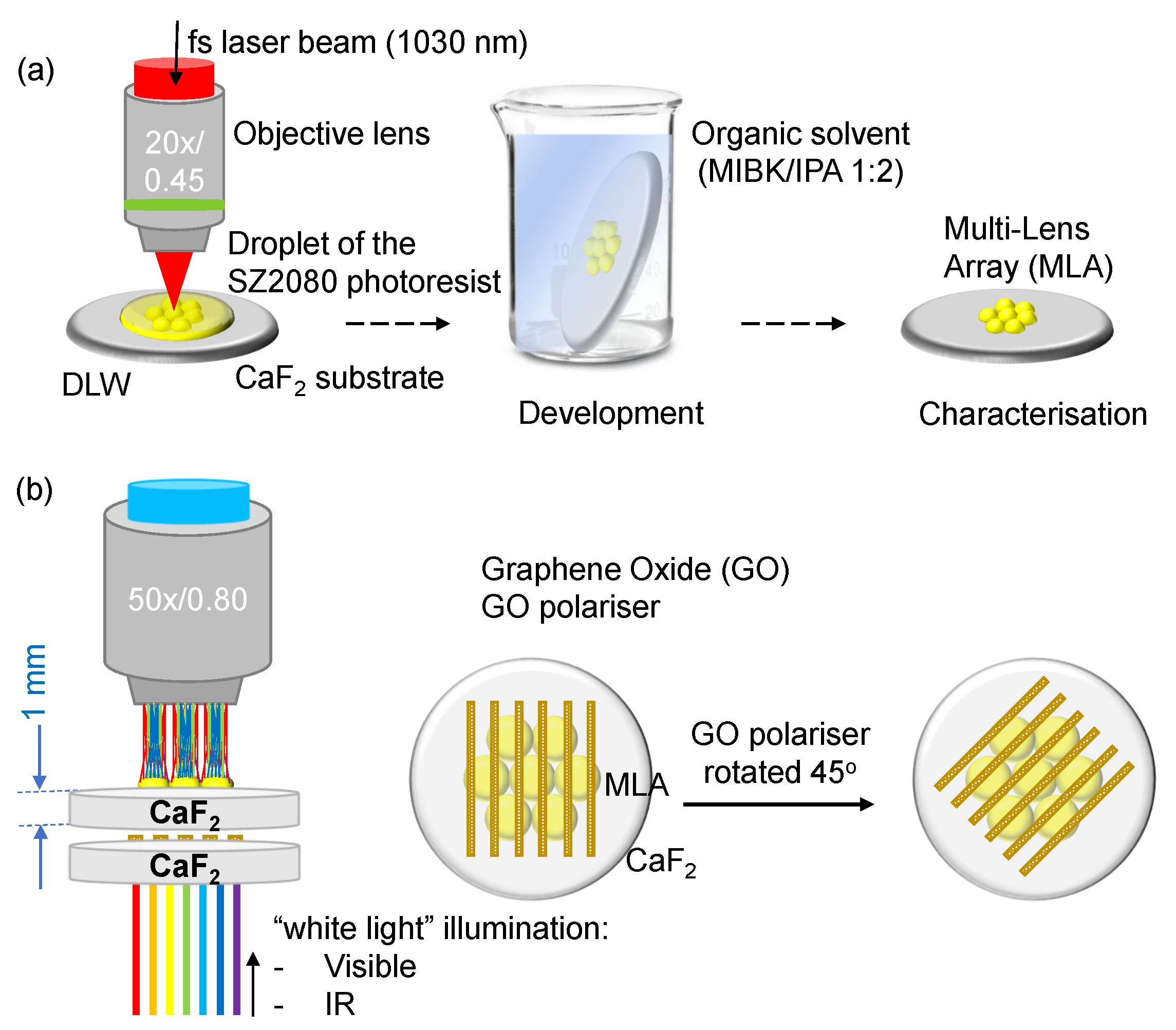

2. Samples and Methods

2.1. Materials

2.2. Femtosecond direct laser writing

2.3. Structural and optical characterisation

2.4. Numerical modeling

3. Results and discussion

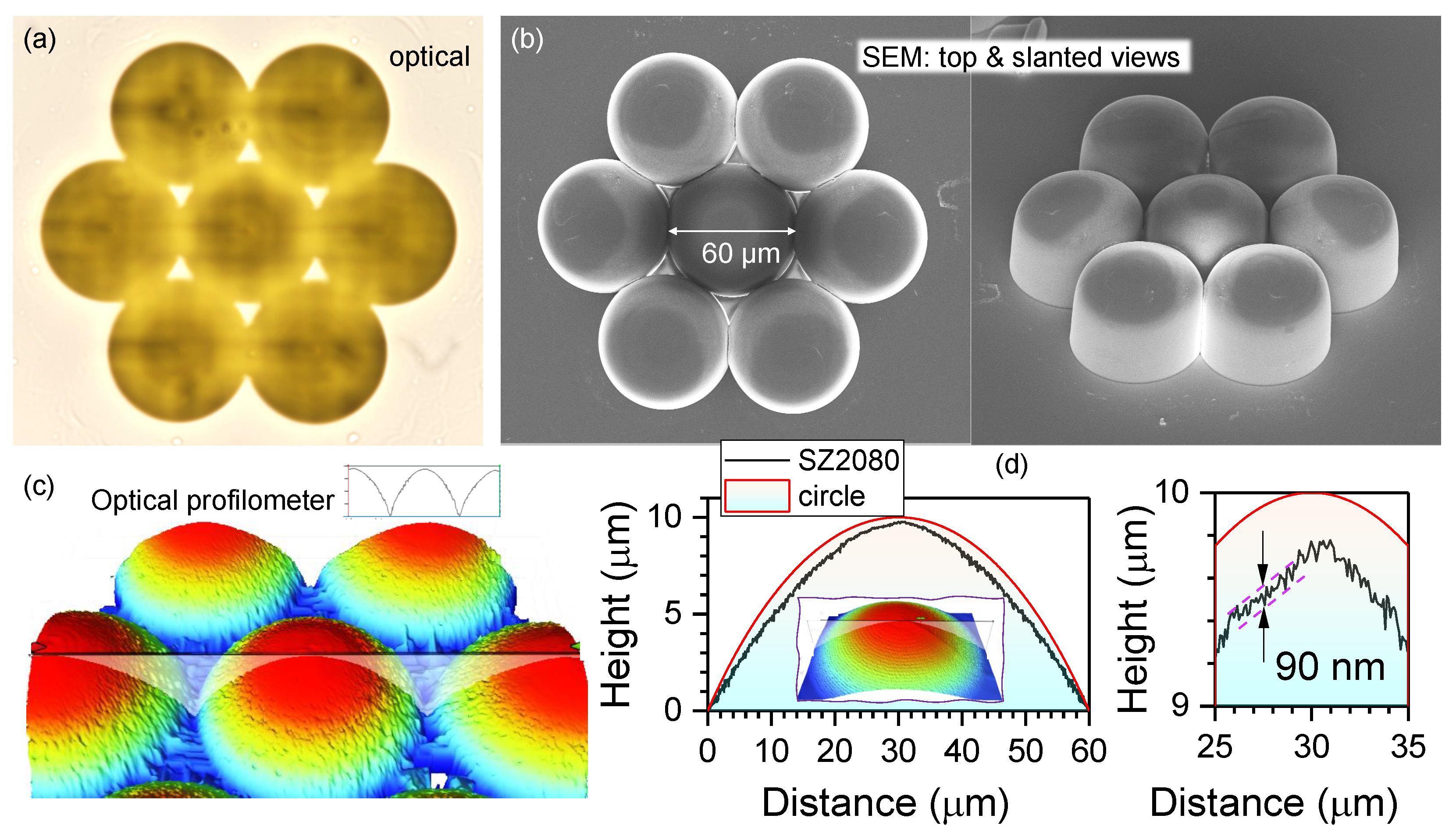

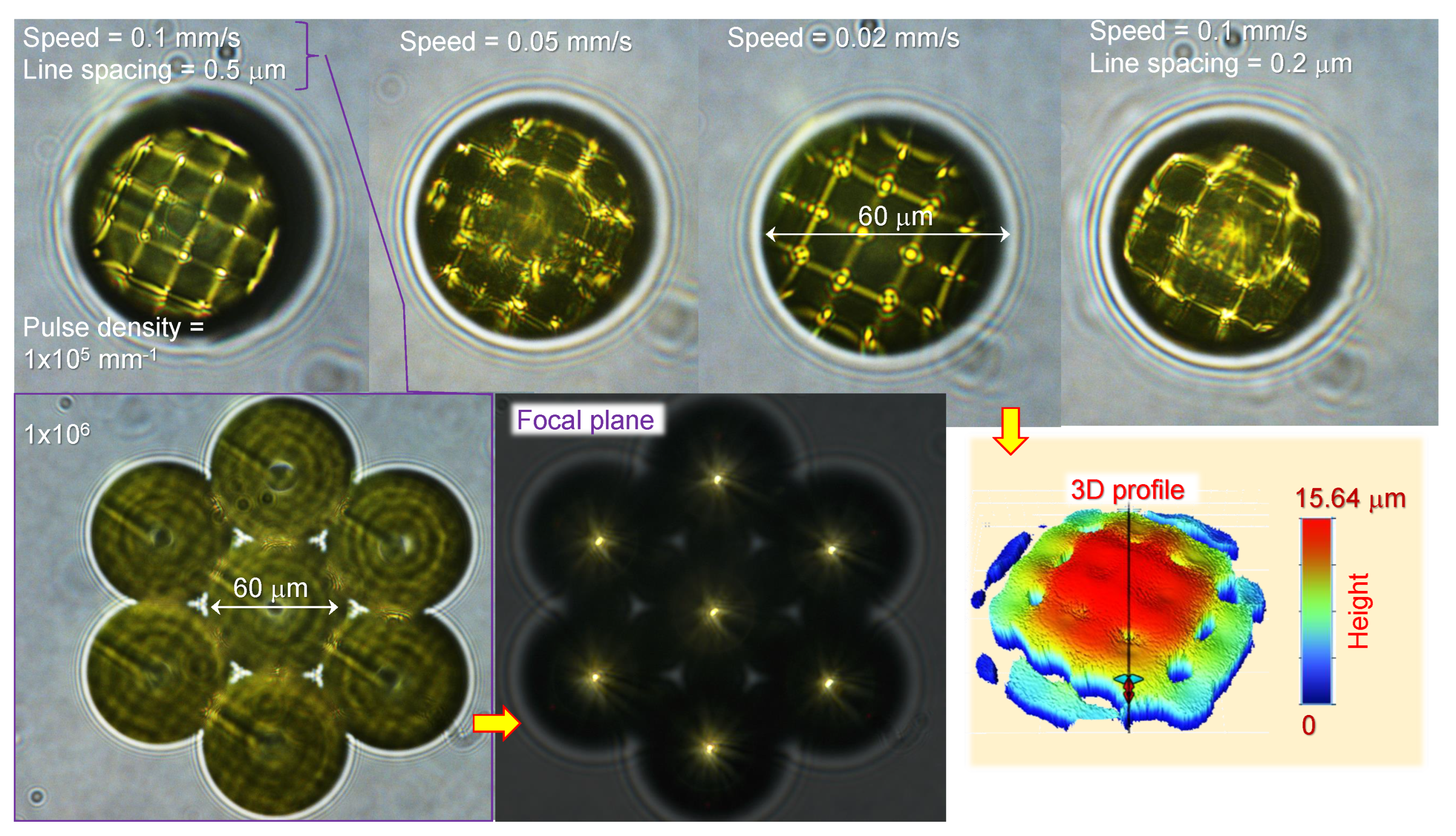

3.1. Structural characterisation of MLA

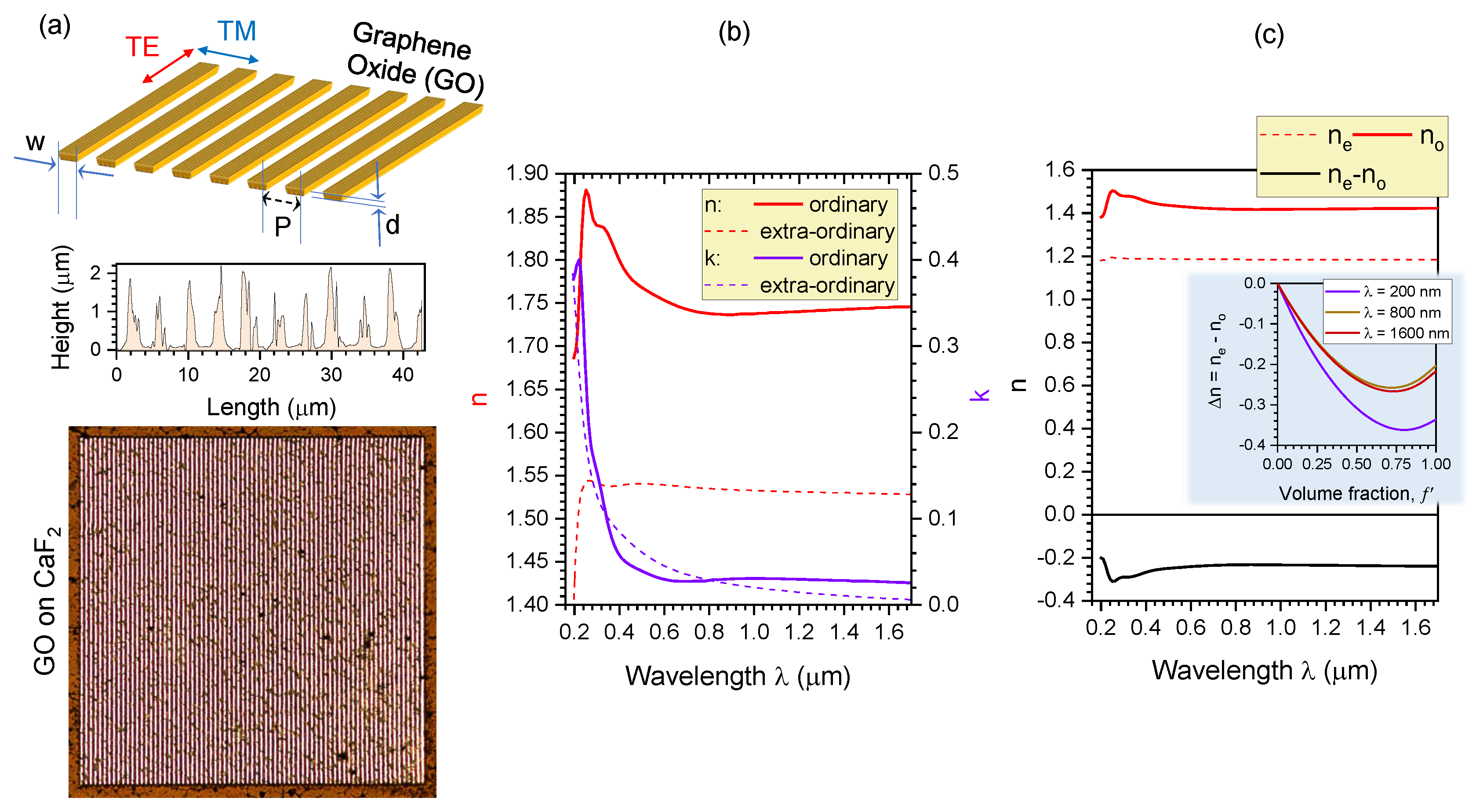

3.2. Structural characterisation of the GO polariser

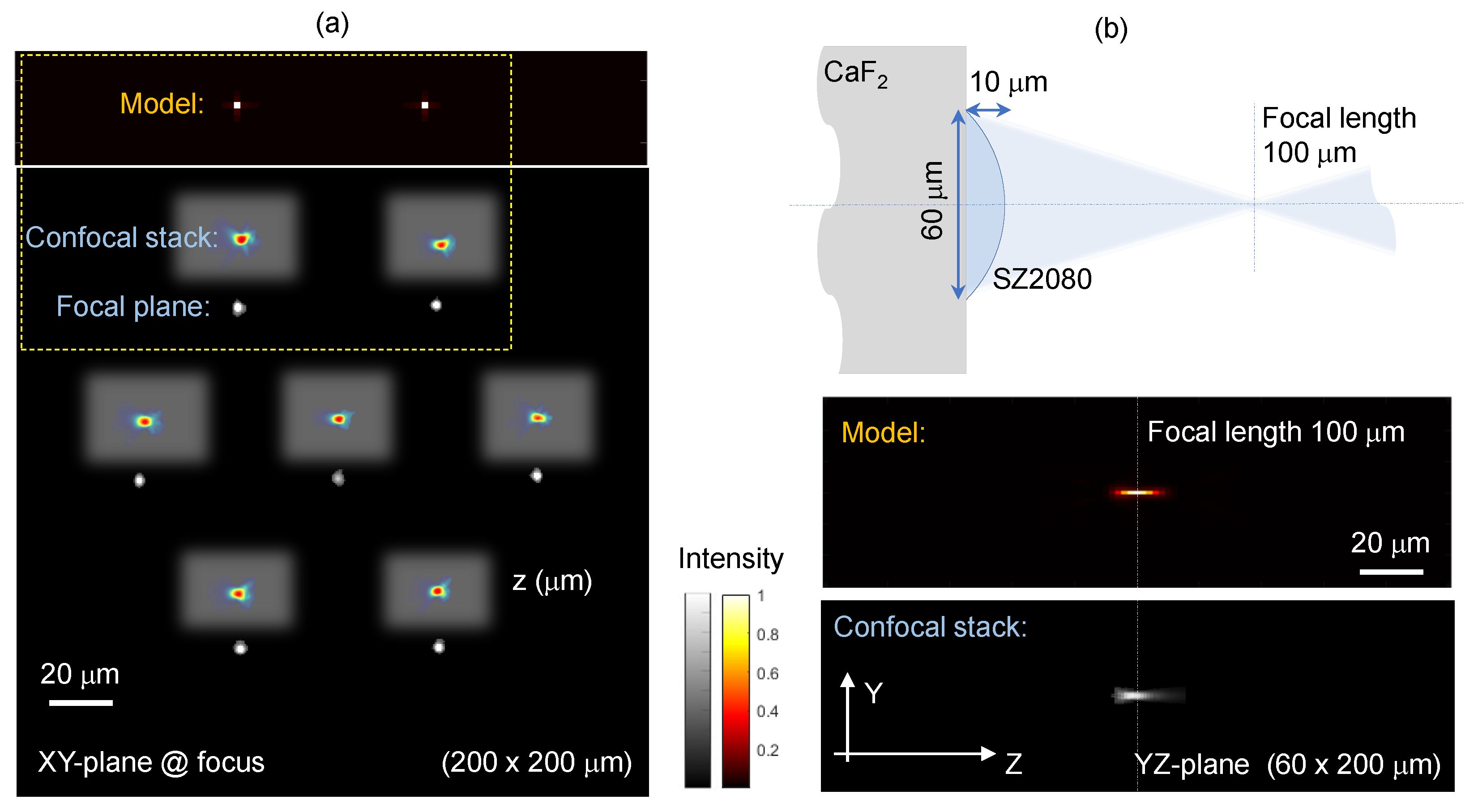

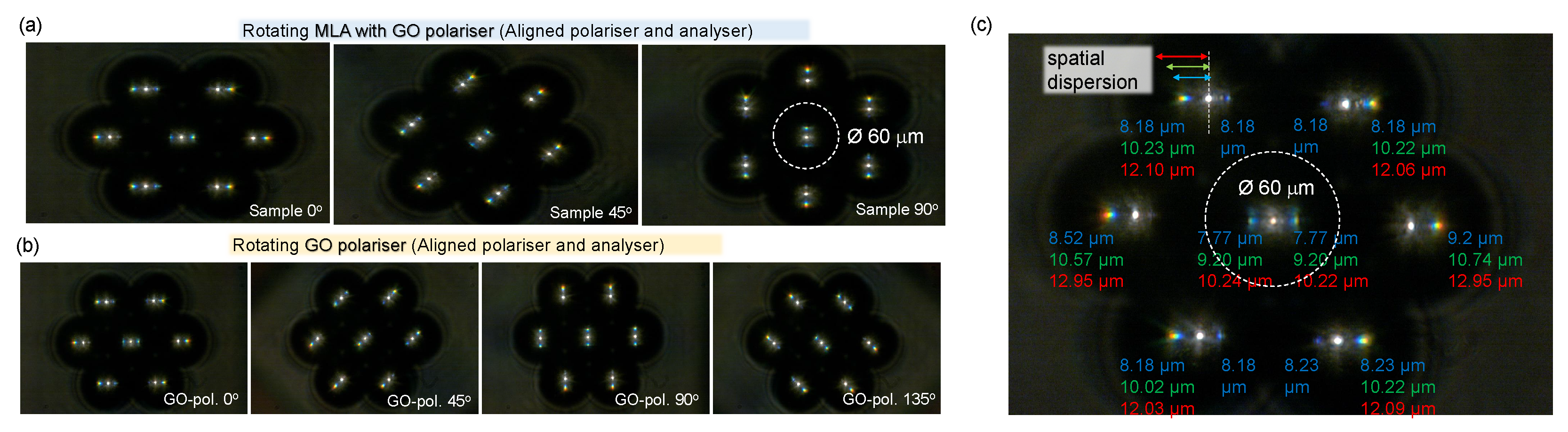

3.3. MLA focal spots characterisation

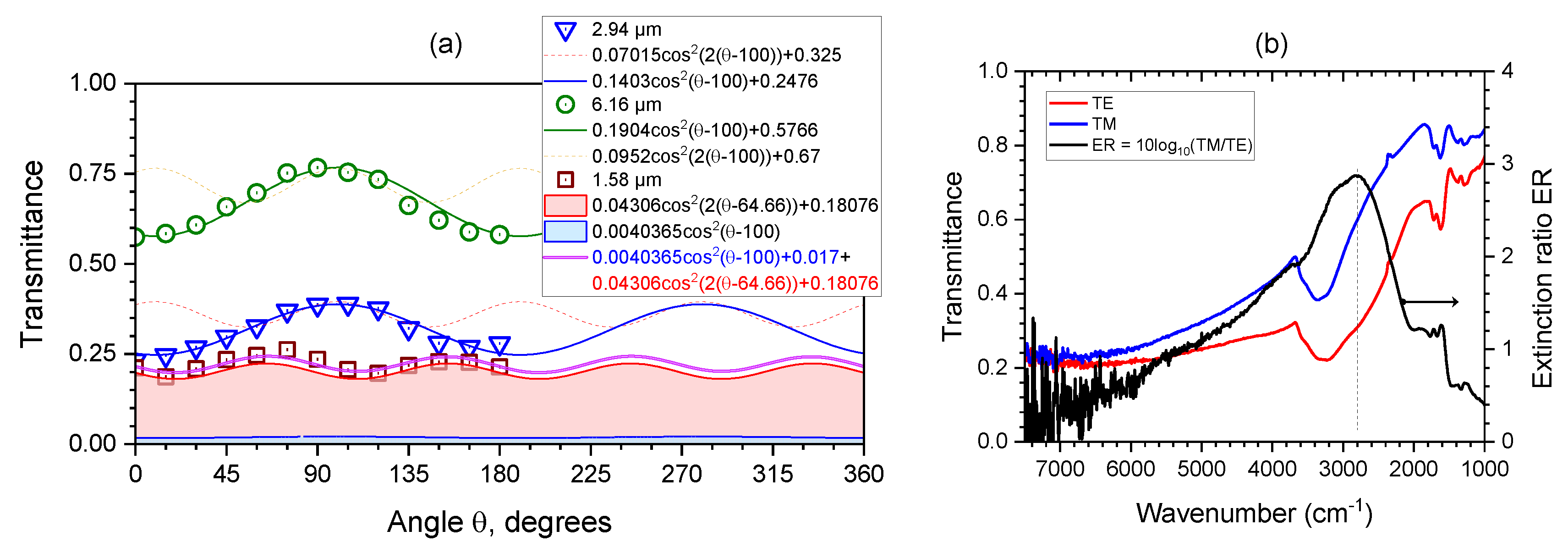

3.4. Form birefringence of GO

3.5. Angular dispersion tuning

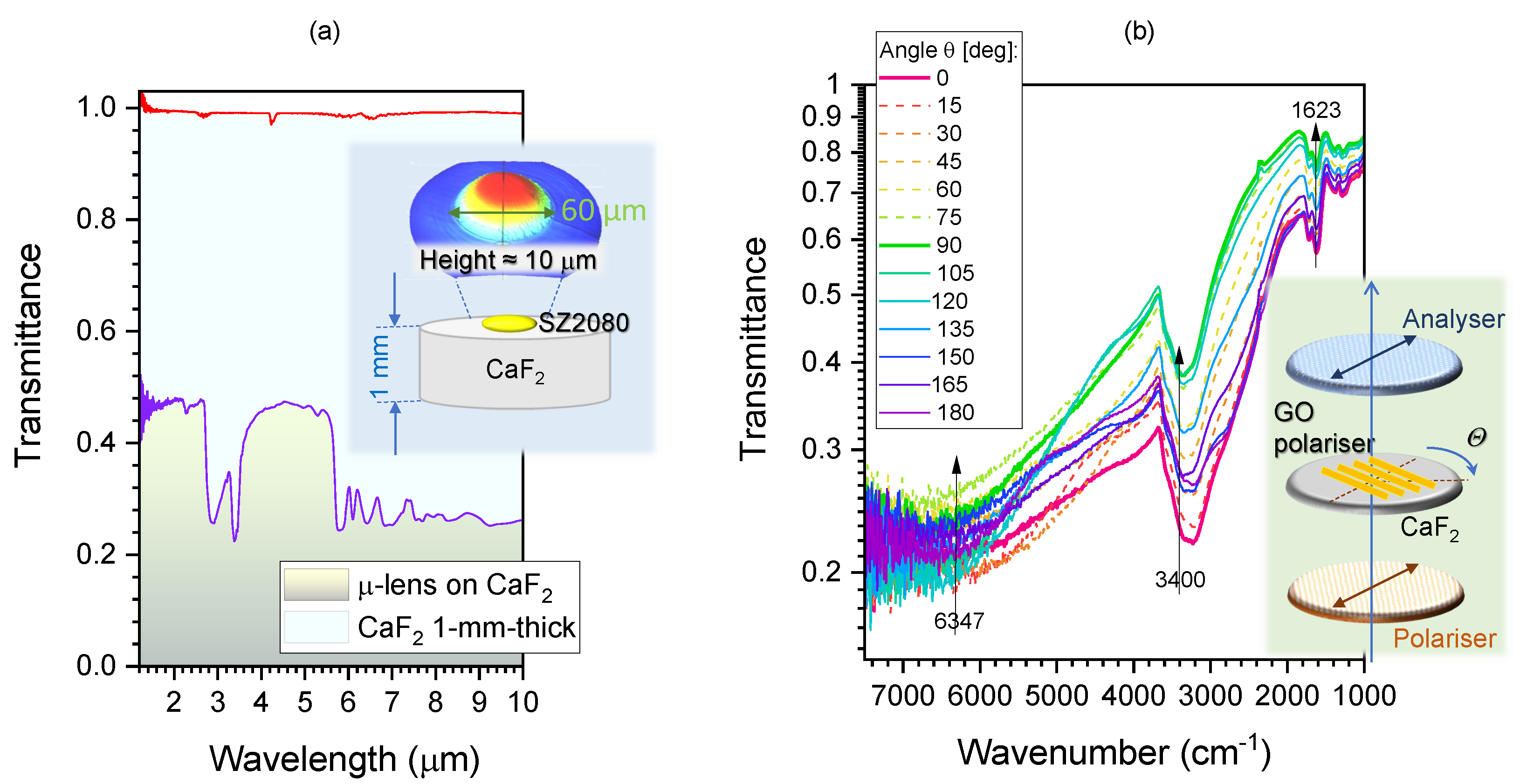

3.6. FTIR characterisation of MLA and GO polariser

3.7. FDTD modeling of GO polariser for IR region

4. Conclusions and outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Critical exposure parameters

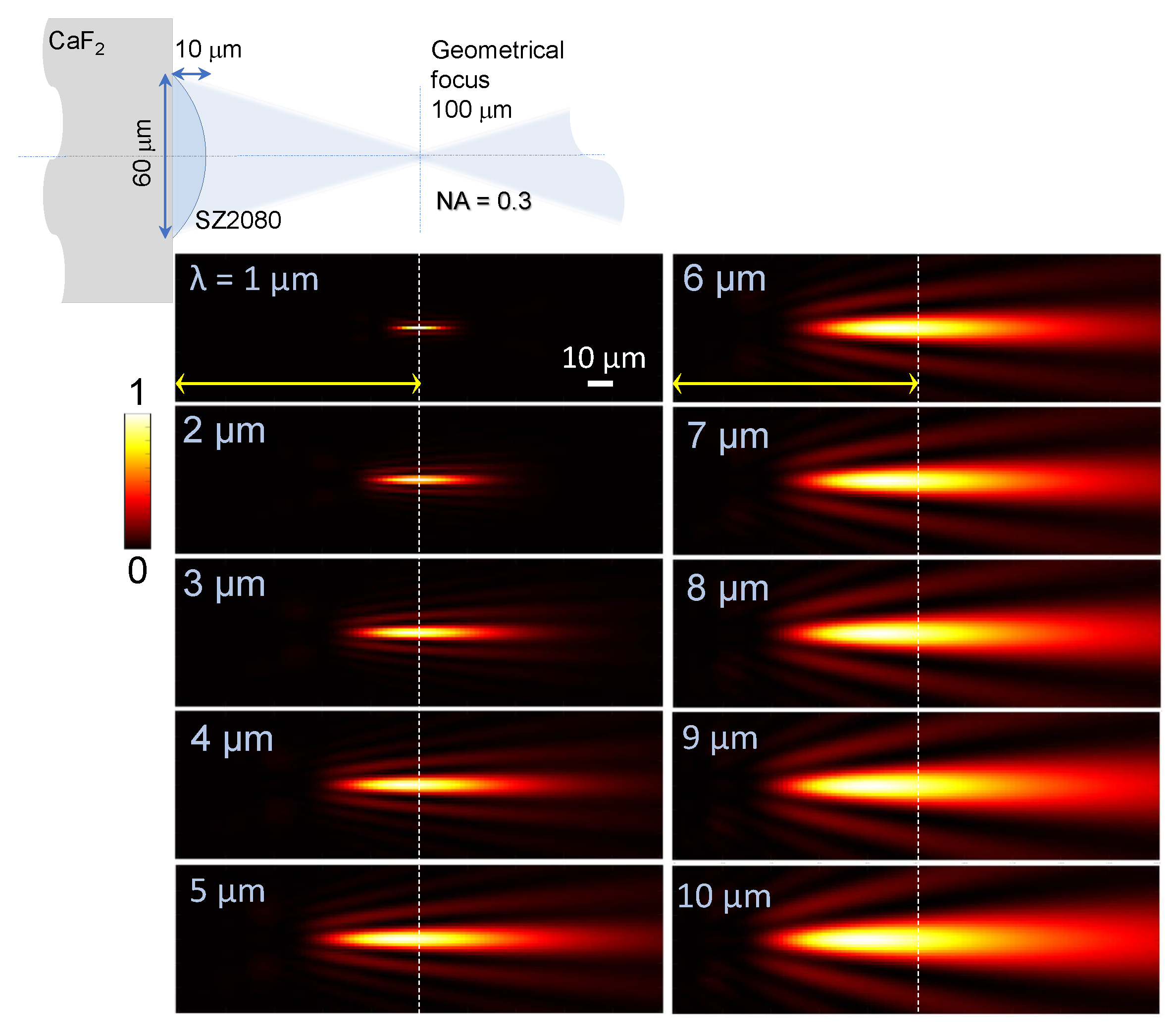

Appendix B. NA = 0.3 lens focusing at IR 1 − 10 μm wavelengths

References

- Zimmermann, M.; Lindlein, N.; Voelkel, R.; Weible, K.J. Microlens laser beam homogenizer: from theory to application. Laser Beam Shaping VIII. SPIE, 2007, Vol. 6663, pp. 9–21.

- Liang, Y.; Zhu, T.; Xi, M.; Abbasi, H.N.; Fu, J.; Su, R.; Song, Z.; Wang, H.; Wang, K. Fabrication of a diamond concave microlens array for laser beam homogenization. Optics & Laser Technology 2021, 136, 106738. [Google Scholar] [CrossRef]

- Lin, V.; Wei, H.C.; Hsieh, H.T.; Hsieh, J.L.; Su, G.D. Design and fabrication of long-focal-length microlens arrays for Shack–Hartmann wavefront sensors. Micro & Nano Letters 2011, 6, 523–526. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, W.; Naples, N.J.; Allen, Y.Y. Fabrication of an infrared Shack–Hartmann sensor by combining high-speed single-point diamond milling and precision compression molding processes. Applied optics 2018, 57, 3598–3605. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Xu, J.; Niu, L.G.; Wu, S.Z.; Midorikawa, K.; Sugioka, K. In-channel integration of designable microoptical devices using flat scaffold-supported femtosecond-laser microfabrication for coupling-free optofluidic cell counting. Light: Science & Applications 2015, 4, e228–e228. [Google Scholar] [CrossRef]

- Park, H.S.; Hoskinson, R.; Abdollahi, H.; Stoeber, B. Compact near-eye display system using a superlens-based microlens array magnifier. Optics Express 2015, 23, 30618–30633. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.F.; Liu, Z.; Liu, Z.; Li, F.; Zhang, M.; Wang, W.; Wen, F.; Wang, J.; Bu, R.; Zhang, J.; et al. Fabrication of monolithic diamond photodetector with microlenses. Optics Express 2017, 25, 31586–31594. [Google Scholar] [CrossRef]

- Qu, Y.; Kim, J.; Coburn, C.; Forrest, S.R. Efficient, nonintrusive outcoupling in organic light emitting devices using embedded microlens arrays. ACS photonics 2018, 5, 2453–2458. [Google Scholar] [CrossRef]

- Duparré, J.; Dannberg, P.; Schreiber, P.; Bräuer, A.; Tünnermann, A. Artificial apposition compound eye fabricated by micro-optics technology. Applied optics 2004, 43, 4303–4310. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Liu, H.; Yang, Q.; Wang, X.; Hou, C.; Bian, H.; Liang, W.; Si, J.; Hou, X. Maskless fabrication of concave microlens arrays on silica glasses by a femtosecond-laser-enhanced local wet etching method. Optics express 2010, 18, 20334–20343. [Google Scholar] [CrossRef]

- Liu, W.; Ma, D.; Li, Z.; Cheng, H.; Choi, D.Y.; Tian, J.; Chen, S. Aberration-corrected three-dimensional positioning with a single-shot metalens array. Optica 2020, 7, 1706–1713. [Google Scholar] [CrossRef]

- Yuan, W.; Li, L.H.; Lee, W.B.; Chan, C.Y. Fabrication of microlens array and its application: a review. Chinese Journal of Mechanical Engineering 2018, 31, 1–9. [Google Scholar] [CrossRef]

- Syms, R.R.; Yeatman, E.M.; Bright, V.M.; Whitesides, G.M. Surface tension-powered self-assembly of microstructures-the state-of-the-art. Journal of Microelectromechanical systems 2003, 12, 387–417. [Google Scholar] [CrossRef]

- Yang, H.; Chao, C.K.; Wei, M.K.; Lin, C.P. High fill-factor microlens array mold insert fabrication using a thermal reflow process. Journal of micromechanics and microengineering 2004, 14, 1197. [Google Scholar] [CrossRef]

- Moore, S.; Gomez, J.; Lek, D.; You, B.H.; Kim, N.; Song, I.H. Experimental study of polymer microlens fabrication using partial-filling hot embossing technique. Microelectronic Engineering 2016, 162, 57–62. [Google Scholar] [CrossRef]

- Zhang, X.; Fang, F.; Yu, L.; Jiang, L.; Guo, Y. Slow slide servo turning of compound eye lens. Optical Engineering 2013, 52, 023401. [Google Scholar] [CrossRef]

- Hong, G.S.; San Wong, Y.; others. Profile error compensation in fast tool servo diamond turning of micro-structured surfaces. International Journal of Machine Tools and Manufacture 2012, 52, 13–23. [Google Scholar] [CrossRef]

- Kley, E.B.; Possner, T.; Göring, R. Realization of micro-optic and integrated optic components by electron-beam-lithographic surface profiling and ion exchange in glass. International Journal of Optoelectronics 1993, 8, 513–513. [Google Scholar]

- Fujita, T.; Nishihara, H.; Koyama, J. Fabrication of micro lenses using electron-beam lithography. Optics letters 1981, 6, 613–615. [Google Scholar] [CrossRef]

- Ovsianikov, A.; Viertl, J.; Chichkov, B.; Oubaha, M.; MacCraith, B.; Sakellari, I.; Giakoumaki, A.; Gray, D.; Vamvakaki, M.; Farsari, M.; others. Ultra-low shrinkage hybrid photosensitive material for two-photon polymerization microfabrication. ACS nano 2008, 2, 2257–2262. [Google Scholar] [CrossRef]

- Merkininkaitė, G.; Aleksandravičius, E.; Malinauskas, M.; Gailevičius, D.; Šakirzanovas, S. Laser additive manufacturing of Si/ZrO2 tunable crystalline phase 3D nanostructures. Opto-electronic advances 2022, 5, 1–11. [Google Scholar] [CrossRef]

- Ovsianikov, A.; Gaidukeviciute, A.; Chichkov, B.; Oubaha, M.; MacCraith, B.; Sakellari, I.; Giakoumaki, A.; Gray, D.; Vamvakaki, M.; Farsari, M.; others. Two-photon polymerization of hybrid sol-gel materials for photonics applications. Laser Chemistry 2008, 2008. [Google Scholar] [CrossRef]

- Malinauskas, M.; Žukauskas, A.; Purlys, V.; Belazaras, K.; Momot, A.; Paipulas, D.; Gadonas, R.; Piskarskas, A.; Gilbergs, H.; Gaidukevičiūtė, A.; others. Femtosecond laser polymerization of hybrid/integrated micro-optical elements and their characterization. Journal of Optics 2010, 12, 124010. [Google Scholar] [CrossRef]

- Qiu, L.; Liu, J.Z.; Chang, S.L.; Wu, Y.; Li, D. Biomimetic superelastic graphene-based cellular monoliths. Nature communications 2012, 3, 1–7. [Google Scholar] [CrossRef]

- Bose, S.; Drzal, L.T. Role of thickness and intercalated water in the facile reduction of graphene oxide employing camera flash. Nanotechnology 2014, 25, 075702. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.B.; Kawata, S. Two-photon photopolymerization and 3D lithographic microfabrication. NMR• 3D Analysis• Photopolymerization 2004, pp. 169–273.

- Seet, K.K.; Mizeikis, V.; Juodkazis, S.; Misawa, H. Three-Dimensional Horizontal Circular Spirals Photonic Crystals with stop gaps below 1μm. Appl. Phys. Lett. 2006, 88, 221101. [Google Scholar] [CrossRef]

- Kondo, T.; Juodkazis, S.; Mizeikis, V.; Matsuo, S.; Misawa, H. Fabrication of three-dimensional periodic microstructures in photoresist SU-8 by phase-controlled holographic lithography. New J. Phys. 2006, 8, 250. [Google Scholar] [CrossRef]

- Juodkazis, S.; Matsuo, S.; Misawa, H.; Mizeikis, V.; Marcinkevicius, A.; Sun, H.B.; Tokuda, Y.; Takahashi, M.; Yoko, T.; Nishii, J. Application of femtosecond laser pulses for microfabrication of transparent media. Appl. Surf. Sci. 2002, 197-198, 705–709. [Google Scholar] [CrossRef]

- Mack, C. Optical lithography; field guides, SPIE, 2006.

- Skliutas, E.; Lebedevaite, M.; Kabouraki, E.; Baldacchini, T.; Ostrauskaite, J.; Vamvakaki, M.; Farsari, M.; Juodkazis, S.; Malinauskas, M. Polymerization mechanisms initiated by spatio-temporally confined light. Nanophotonics 2021, 10, 1211–1242. [Google Scholar] [CrossRef]

- Nishiyama, H.; Hirata, Y. Femtosecond Laser Nonlinear Lithography. In Lithography; Wang, M., Ed.; IntechOpen: Rijeka, 2010; chapter 4. [Google Scholar] [CrossRef]

- Malinauskas, M.; Žukauskas, A.; Bičkauskaitė, G.; Gadonas, R.; Juodkazis, S. Mechanisms of three-dimensional structuring of photo-polymers by tightly focussed femtosecond laser pulses. Opt. Express 2010, 18, 10209–10221. [Google Scholar] [CrossRef]

- Fischer, J.; Mueller, J.; Kaschke, J.; Wolf, T.; Unterreiner, A.N.; Wegener, M. Three-dimensional multi-photon direct laser writing with variable repetition rate. Optics Express 2013, 21, 26244–26260. [Google Scholar] [CrossRef]

- Murazawa, N.; Juodkazis, S.; Misawa, H.; Kamada, K. Two-photon excitation of dye-doped liquid crystal by a cw-laser irradiation. Mol. Cryst. Liq. Cryst. 2008, 489, 310–319. [Google Scholar] [CrossRef]

- Gamaly, E.G.; Rode, A.V. Ultrafast re-structuring of the electronic landscape of transparent dielectrics: new material states (Die-Met). Appl. Phys. A 2018, 124, 1–11. [Google Scholar] [CrossRef]

- Ng, S.; Juodkazis, S. Nanoscale plasmonic printing (in Ultrafast Laser Nanostructuring: the Pursuit of Extreme Scales; Eds. R Stoian and J Bonse); Springer Series in Optical Science, 2023; Vol. 239, p. Chapter 25.

- Samsonas, D.; Skliutas, E.; Čiburys, A.; Kontenis, L.; Gailevičius, D.; Berzinš, J.; Narbutis, D.; Jukna, V.; Vengris, M.; Juodkazis, S.; Malinauskas, M. 3D nanopolymerization and damage threshold dependence on laser wavelength and pulse duration. Nanophotonics 2023. [Google Scholar] [CrossRef]

- Schöche, S.; Hong, N.; Khorasaninejad, M.; Ambrosio, A.; Orabona, E.; Maddalena, P.; Capasso, F. Optical properties of graphene oxide and reduced graphene oxide determined by spectroscopic ellipsometry. Applied Surface Science 2017, 421, 778–782. [Google Scholar] [CrossRef]

- El-Sayed, M.A.; Ermolaev, G.A.; Voronin, K.V.; Romanov, R.I.; Tselikov, G.I.; Yakubovsky, D.I.; Doroshina, N.V.; Nemtsov, A.B.; Solovey, V.R.; Voronov, A.A.; others. Optical constants of chemical vapor deposited graphene for photonic applications. Nanomaterials 2021, 11, 1230. [Google Scholar] [CrossRef] [PubMed]

- Gu, M. Advanced optical imaging theory; Vol. 75, Springer Science & Business Media, 2000.

- Wei, S.; Cao, G.; Lin, H.; Mu, H.; Liu, W.; Yuan, X.; Somekh, M.; Jia, B. High tolerance detour-phase graphene-oxide flat lens. Photonics Research 2021, 9, 2454–2463. [Google Scholar] [CrossRef]

- Hecht, E. Optics 2nd edition. Optics 2nd edition by Eugene Hecht Reading 1987.

- Sally, J.D. Roots to research: a vertical development of mathematical problems; Vol. 48, American Mathematical Soc., 2007.

- Kondo, T.; Matsuo, S.; Juodkazis, S.; Mizeikis, V.; Misawa, H. Multiphoton fabrication of periodic structures by multibeam interference of femtosecond pulses. Appl. Phys. Lett. 2003, 82, 2758–2760. [Google Scholar] [CrossRef]

- Fan, S.; Joannopoulos, J.D. Analysis of guided resonances in photonic crystal slabs. Physical Review B 2002, 65, 235112. [Google Scholar] [CrossRef]

- Lousse, V.; Suh, W.; Kilic, O.; Kim, S.; Solgaard, O.; Fan, S. Angular and polarization properties of a photonic crystal slab mirror. Optics express 2004, 12, 1575–1582. [Google Scholar] [CrossRef]

- Hermannsson, P.G.; Vannahme, C.; Smith, C.L.; Kristensen, A. Absolute analytical prediction of photonic crystal guided mode resonance wavelengths. Applied Physics Letters 2014, 105, 071103. [Google Scholar] [CrossRef]

- Hermannsson, P.G.; Sørensen, K.T.; Vannahme, C.; Smith, C.L.; Klein, J.J.; Russew, M.M.; Grützner, G.; Kristensen, A. All-polymer photonic crystal slab sensor. Optics Express 2015, 23, 16529–16539. [Google Scholar] [CrossRef] [PubMed]

- Gailevičius, D.; Ryu, M.; Honda, R.; Lundgaard, S.; Suzuki, T.; Maksimovic, J.; Hu, J.; Linklater, D.P.; Ivanova, E.P.; Katkus, T.; others. Tilted black-Si: 0.45 form-birefringence from sub-wavelength needles. Optics express 2020, 28, 16012–16026. [Google Scholar] [CrossRef] [PubMed]

- Acik, M.; Lee, G.; Mattevi, C.; Chhowalla, M.; Cho, K.; Chaba, Y.J. Unusual infrared-absorption mechanism in thermally reduced graphene oxide. Nature Materials 2010, 9, 840–845. [Google Scholar] [CrossRef] [PubMed]

- Ryu, M.; Honda, R.; Balčytis, A.; Vongsvivut, J.; Tobin, M.J.; Juodkazis, S.; Morikawa, J. Hyperspectral mapping of anisotropy. Nanoscale Horizons 2019, 4, 1443–1449. [Google Scholar] [CrossRef]

- Gordon, S.; Mohamed, A.; Harry-O’Kuru, R.; Imam, S. A chemometric method for correcting Fourier transform infrared spectra of biomaterials for interference from water in KBr discs. Applied spectroscopy 2010, 64, 448–457. [Google Scholar] [CrossRef] [PubMed]

- Vu, T.; Ha, T.; Tran, T.; Thuy, T.; Le, T.; Ngan, H.; Nguyen, T.; Hoa Bui, P.; Quynh, N.; Essayem, N. A new green approach for the reduction of graphene oxide nanosheets using caffeine. Bull. Materials Science 2015, 38, 667–671. [Google Scholar]

- Noda, I. Recent advancement in the field of two-dimensional correlation spectroscopy. J. Molecular Structure 2008, 883, 2–26. [Google Scholar] [CrossRef]

- Demydenko, Y.; Juodkazis, S.; Lozovski, V. Composite Au-on-SiC nanorods for sensing. J. Opt. Soc. Am. B 2014, 31, 2893–2900. [Google Scholar] [CrossRef]

- Lozovski, V.; Lysenko, V.; Rusinchuk, N. Ponderomotive forces in the system of two nanoparticles. Scientific Reports 2022, 12, 17768. [Google Scholar] [CrossRef]

- Aerotech Npaq Hardware Manual. Available online: https://www.aerotech.com/wp-content/uploads/2020/09/Npaq.pdf (accessed on 26 January 2023).

- Jonušauskas, L.; Gailevičius, D.; Rekštytė, S.; Baldacchini, T.; Juodkazis, S.; Malinauskas, M. Mesoscale laser 3D printing. Optics Express 2019, 27, 15205–15221. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).