0. Introduction

A number of previous researchers have done corresponding research on the application of variable axial force cable in reinforcement engineering. Firstly, the application of variable axial force cable in bridge reinforcement is widely studied. As Yin,Haiyi; Liu, Shuangyou & Liu,Jianying.(2004) Study on the application of VLM.TS type outer cable in Dongming Huanghe Bridge reinforcement project [

1]. Gong,Zhigang.(2003) made a study on strengthening Pu Shan Wan cantilever Bridge by cable system [

2]. Hu,Jun & Zheng,Qinggang.(2019) studied the application of 2000MPa parallel steel cable in highway and cable bridge [

4]. In addition, the application of the variable axial force cable in bridge reinforcement has attracted the attention and analysis of researchers. He,Binchi; Li,Rui; Liu,Di; He,Yongwei & Li,Dingmei.(2020) Stress and reinforcement analysis of steel truss structure considering the influence of global joint stiffness [

5]. Pan,Bin.(2020) studied the application of cable installation and construction technology of single-tower suspension bridge [

6]. Yu,Yongliang; Zheng, Liubang; Liu,Houneng &Wang,Xixiong.(2019) studied the research and application of cable installation and construction technology of composite beam suspension bridge [

7]. Secondly, a number of scholars have also studied the application of variable axial force cable in concrete bridge reinforcement. Hu,Wenliang.(2021), for example, studied damage inversion analysis and variable system reinforcement of concrete Bridges based on equivalent sandwich beam model [

8]. Zhao,Haiwei; Chai.Xiaopeng & Wang.Zehao.(2021) Related research and application of cable shock absorber in Jiayu Yangtze River Highway Bridge [

9]. In addition, a number of scholars have also cited the variable axial force cable construction and related technology of the standard specification. Such as building structure load calculation code (GB50009-2019) [

10], steel structure construction quality acceptance code (GB50205-2014) [

11], cable construction technical code (JGJ257-2012) [

12], building structure test technical code (GB/T50344-2004) [

13], etc.

Finally, the scholars also use the variable axial force cable application in structural engineering experimental research and finite element analysis. The finite element analysis method is verified by experiments on reinforced concrete beams [

14]. Stiffness evaluation and finite element analysis of fiber reinforced epoxy resin laminates [

15]. To sum up, the variable axial force cable has been widely used in reinforcement engineering, and has achieved good results. In practical engineering, the construction scheme of the cable with variable axial force should be reasonably designed according to the application research of the cable with variable axial force in reinforcement engineering and relevant standards, combined with the actual situation, which can indeed improve the reinforcement effect. However, the application of the variable axial force cable in the reinforcement engineering of steel truss structure is very few, which has also spurred the birth of this research.

Long-span steel structure truss is widely used in industrial buildings in China. With the development of scientific and technological innovation and assembly engineering in China. In this study, based on the application of cable reinforcement technology in bridge engineering, combined with 3D3S finite element modeling, the reinforcement application was carried out on the basis of two workshops of Zhejiang Tonglu Hongcheng Company. Steel trusses are widely used in the world because of their small dead weight, reasonable amount of steel, large stiffness, fast construction speed, factory prefabrication and cost saving. The design load of the early steel truss workshop is relatively loose and the grade is low, and the bearing capacity cannot meet the demand of the current workshop production. It is necessary to improve the bearing capacity of the truss and extend the service life by strengthening. In this study, the two steel truss factory buildings are reinforced by adding the variable axial force cable method, and the variable axial force cable is applied to the steel truss structure for the first time, and the variable load control is used to achieve the reinforcement effect and improve the seismic bearing capacity. Through the test comparison before and after reinforcement, calculation analysis and model fitting, the influence of the two steel trusses on the reinforcement effect is analyzed. Thus, the application results of variable axial force cable in the reinforcement system of powerhouse truss are verified.

1Projectprofile.

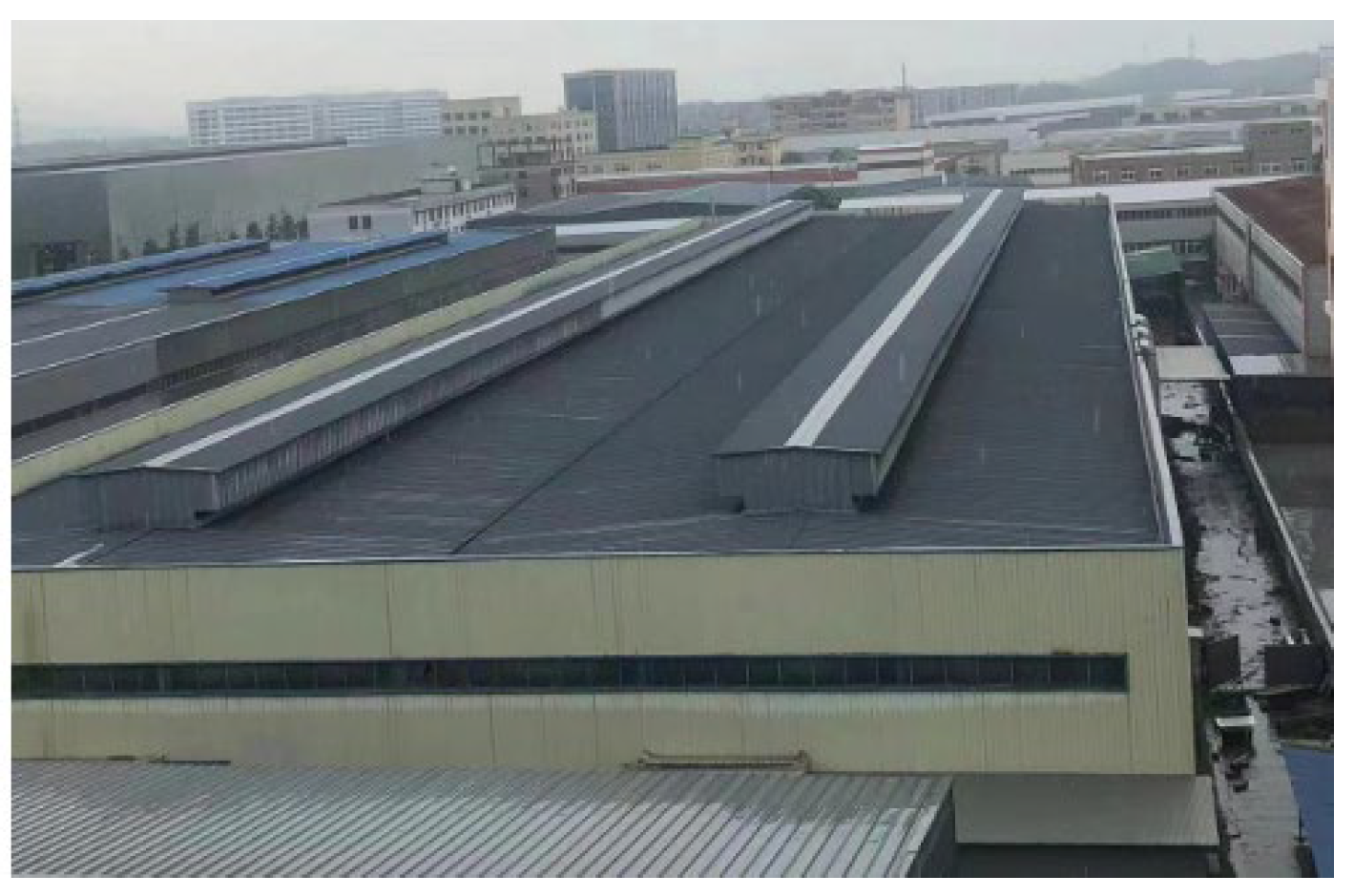

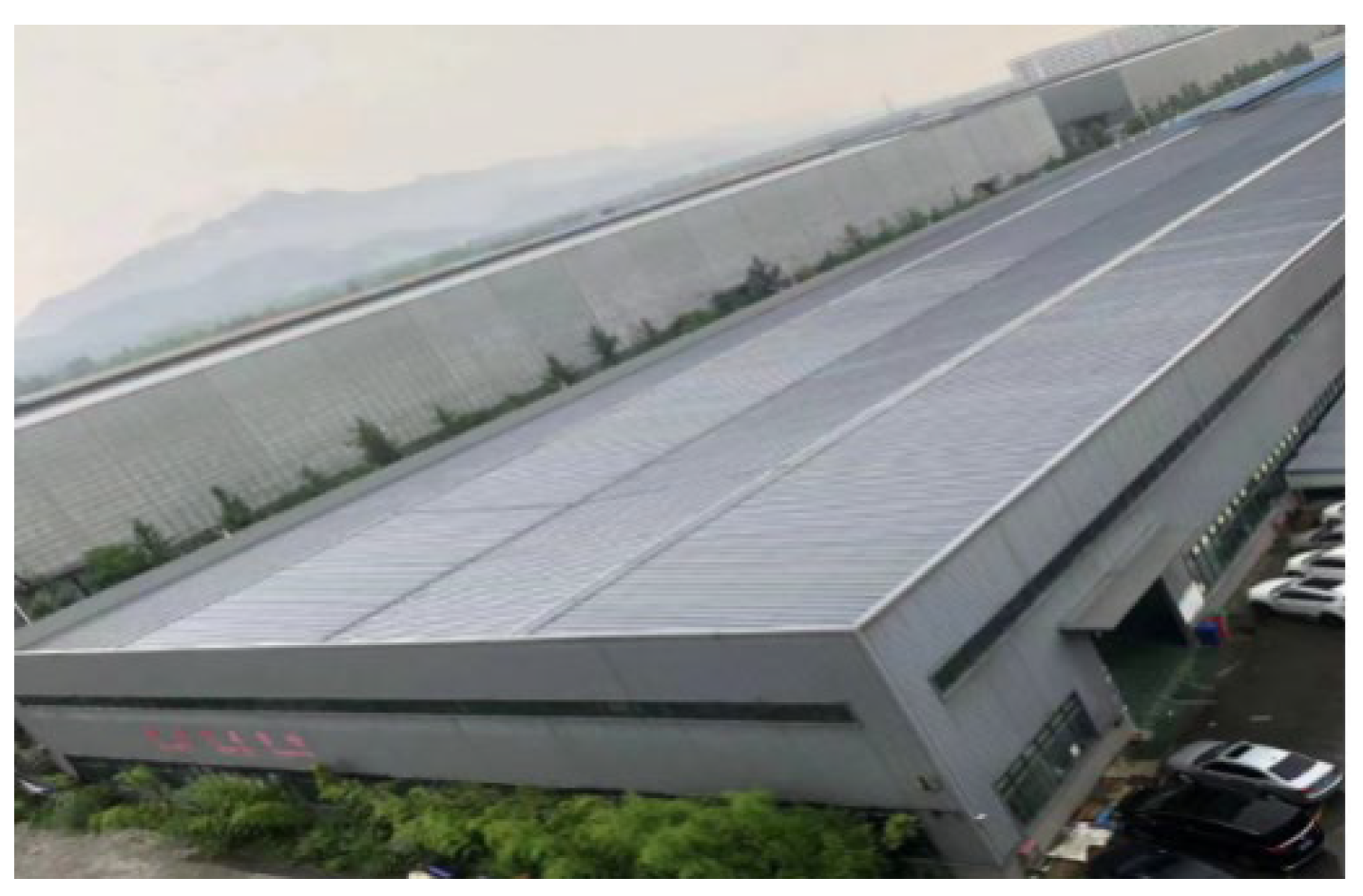

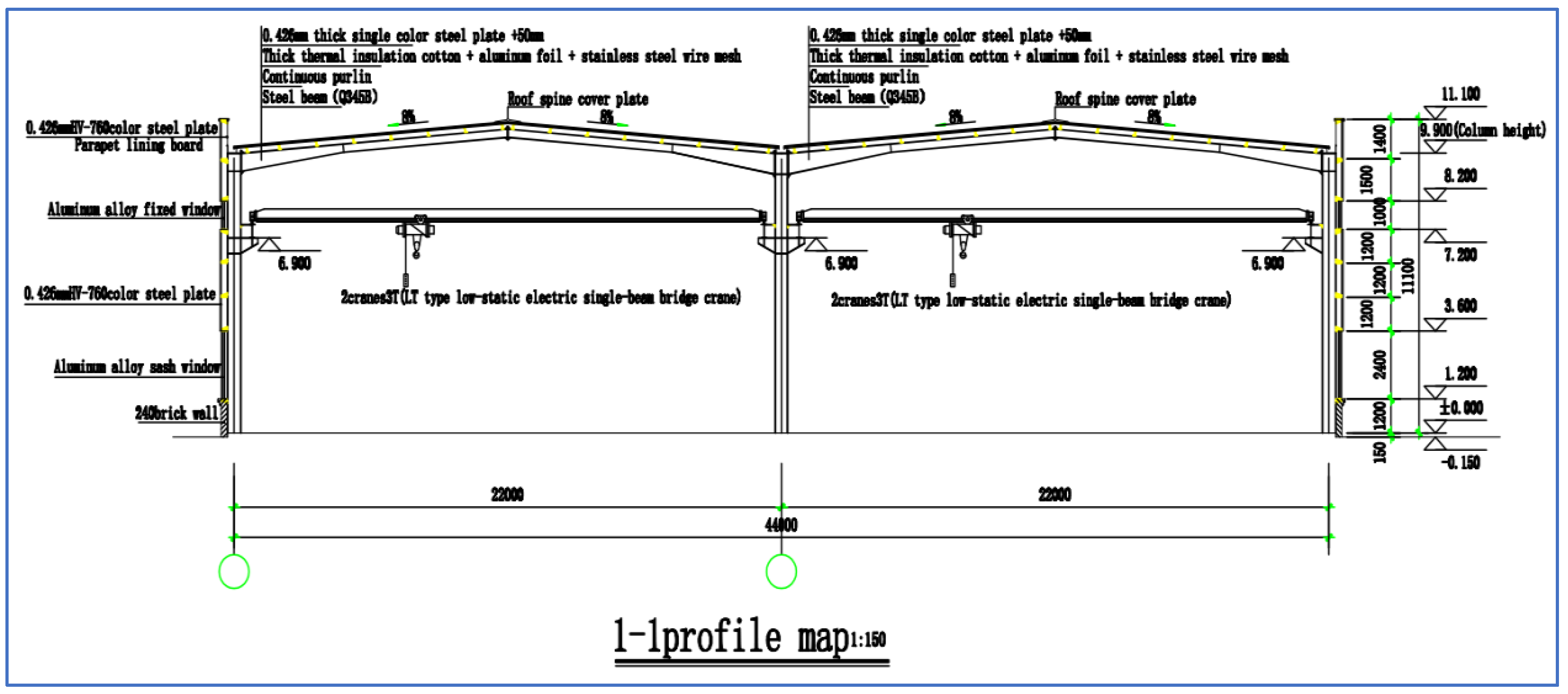

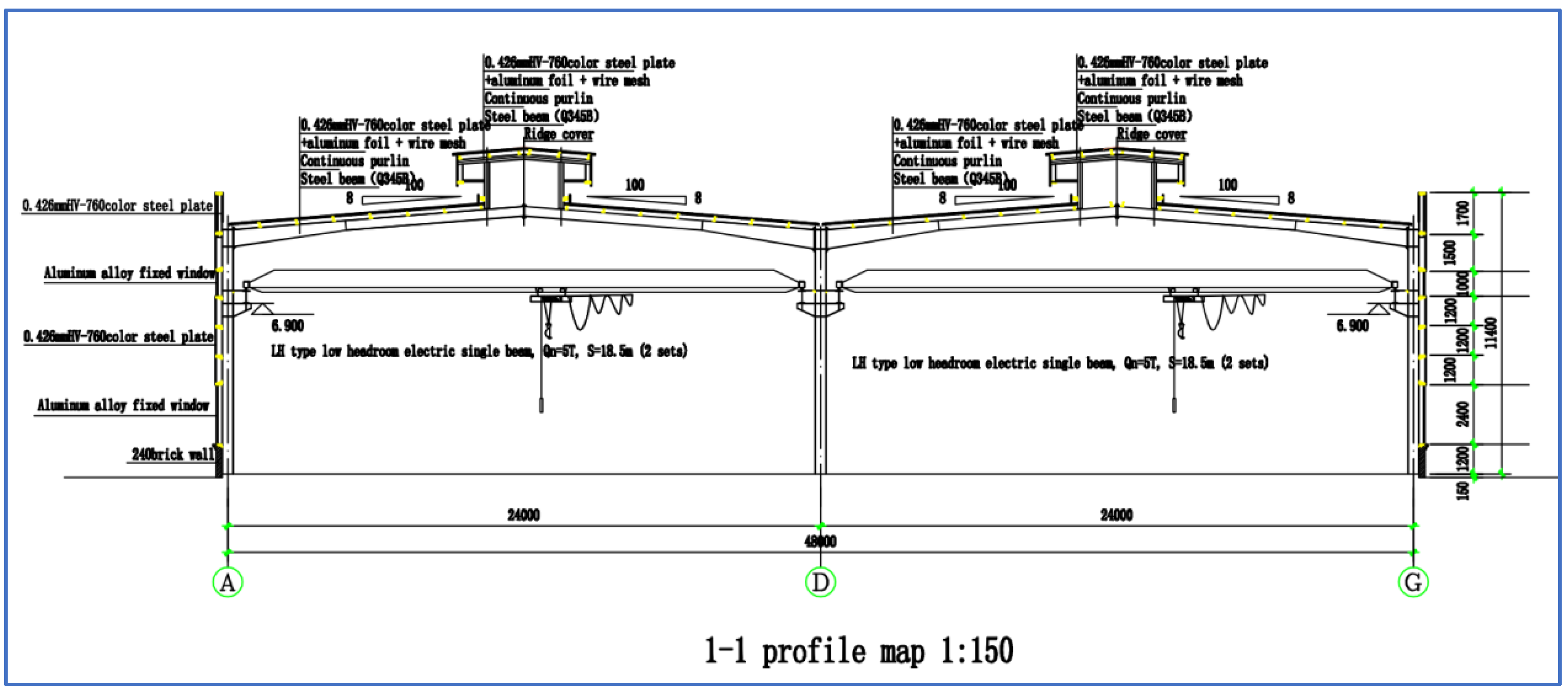

Workshop 1 and Workshop 2 of Zhejiang Hongcheng Industrial Co., Ltd. are double-span gantry rigid frame structure. Workshop 1 was built in 2008, covering an area of 11200.3 square meters, building area of 11200.3 square meters, eaves elevation of 11.100 meters, according to the fire risk classification of class D, fire resistance grade 2, safety grade 2 redesigned, workshop 1 roof waterproof grade III, using molding steel plate for a defensive. The seismic fortification of this project category C, seismic fortification intensity is 6 degrees, the design basic acceleration is 0.05g, engineering design life: steel frame main body for 50 years.

Workshop 2 was also built in 2008, covering an area of 5952 square meters, building area of 5952 square meters, eaves elevation 11.400 meters (slightly higher than Workshop 1), fire risk classification, fire resistance grade, safety grade, waterproof grade, seismic fortification category, seismic fortification intensity, design basic acceleration, engineering design life is the same as Workshop 1. See

Figure 1 and

Figure 2 for the photos of house trusses. See

Figure 3 and

Figure 4 for the section views of Workshop 1 and Workshop 2.

2. Reinforcinganalysis

2.1. Reinforcement scheme

Due to the addition of roof photovoltaic panels in the two plant buildings, the existing plant buildings cannot meet the requirements of the new code according to the requirements of the new code. Therefore, under the influence of the above two factors, it needs to be strengthened comprehensively. At the same time, the roof of the two factory buildings is cracked, which causes water leakage and affects the normal use. The deflection of the truss exceeds the limit, the crane track is seriously worn, and the crane in the lane cannot pass normally. The plant area is reinforced and reformed under the influence of the new regulations.

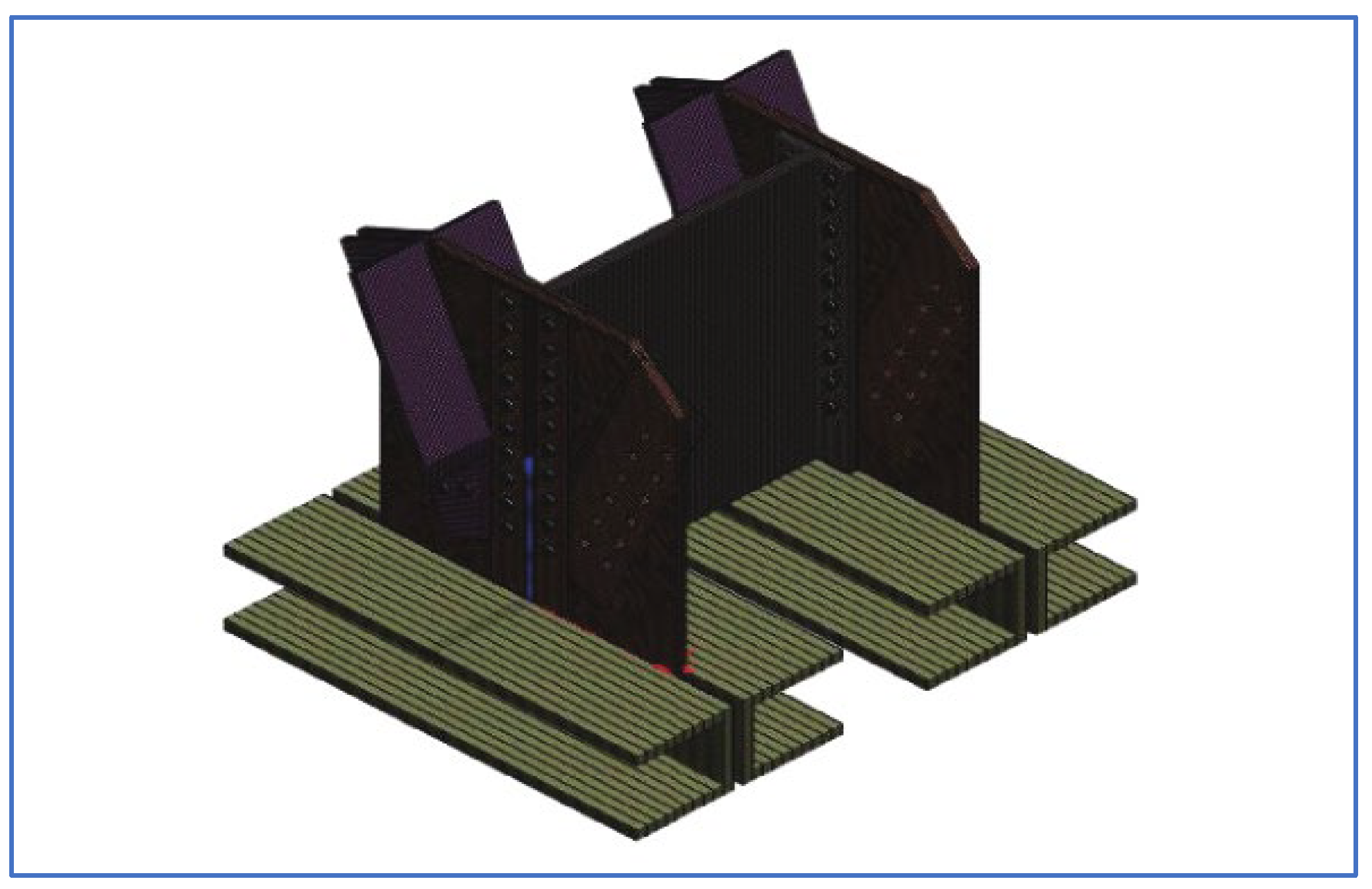

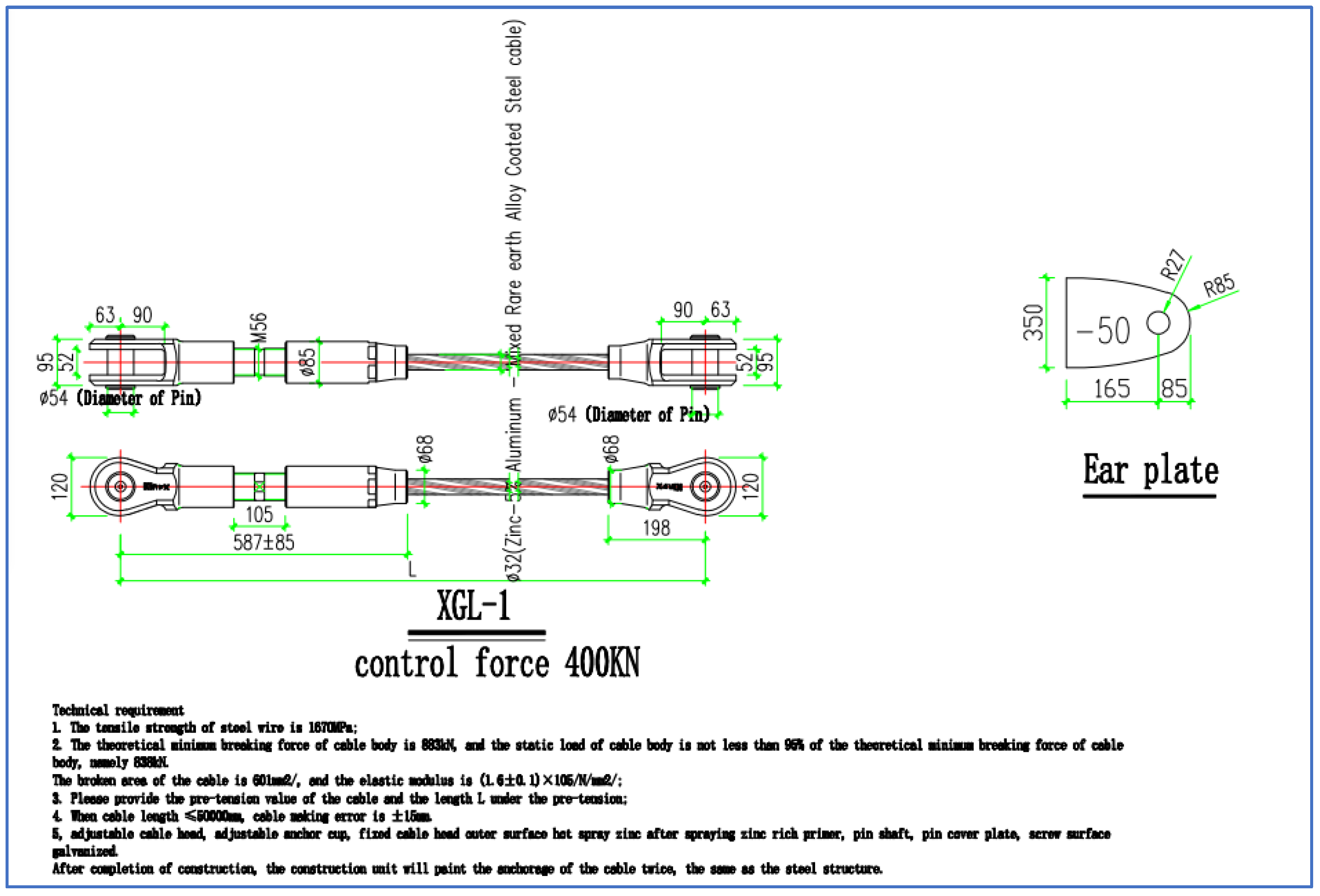

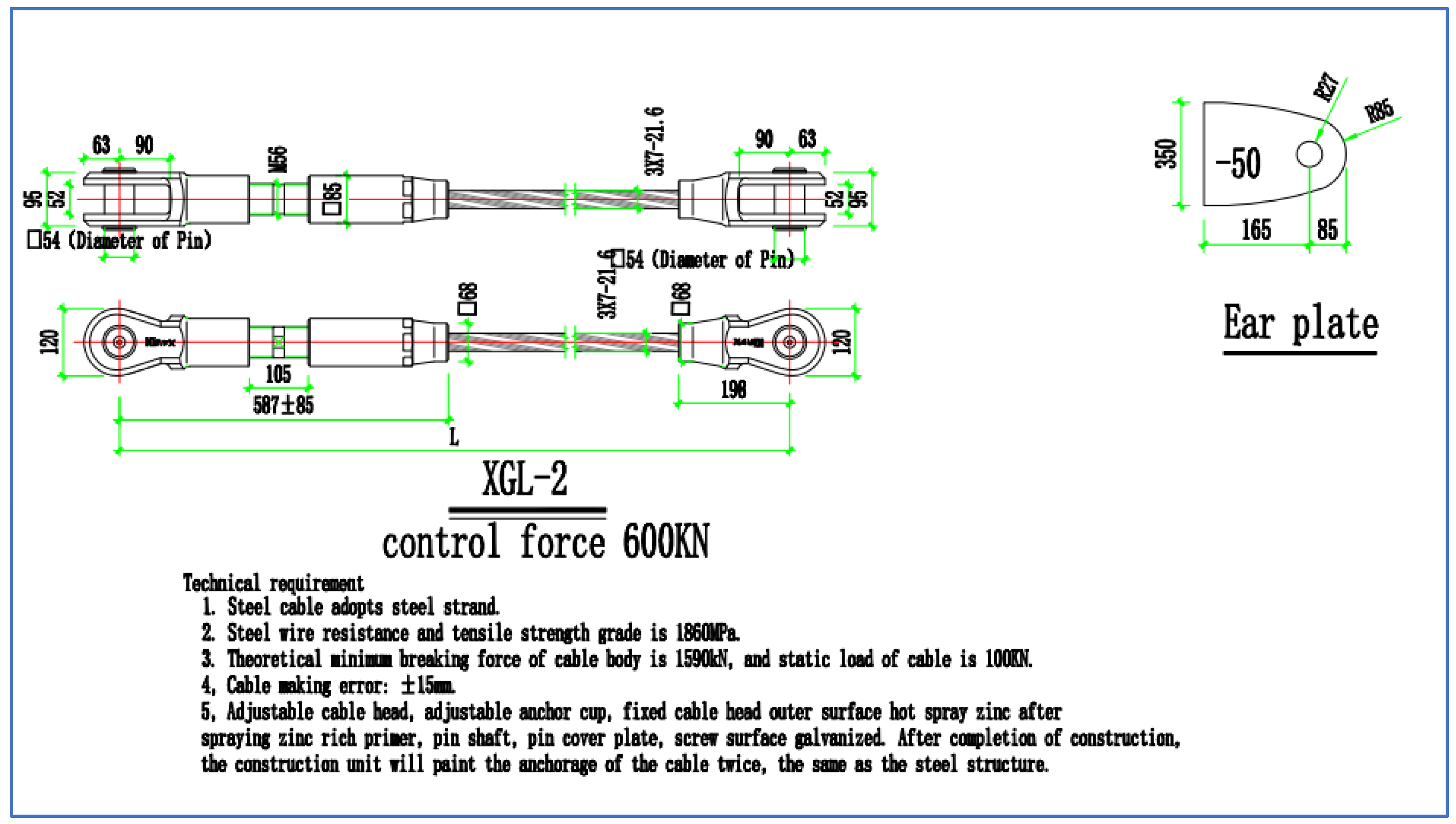

Due to the large span of the trusses in the workshop of Zhejiang Hong Cheng Company, if the conventional increase or increase the force surface of the column is arranged between the rigid trusses, the headroom area of the workshop will be reduced, and the crane and the vehicles inside the workshop cannot be used or passed normally. Therefore, the variable axial force cable is selected for the overall truss reinforcement. The cable is arranged in radial type, and the anchor block is arranged in the purlin of the original rigid frame node. After reinforcement, the original truss only needs to bear the dead weight of the truss, while the new cable with variable axial force bears two parts of the load, mainly the dead weight and tension of the cable, and the additional dead load and other live loads of the truss, so as to improve the overall bearing capacity of the truss. In order to summarize the prestressing force value of cable, this paper chooses two kinds of cable calculation and comparison. Type 1 simulates the cable reinforcement with low controlling force. The span of the original truss is 22m and the controlling force is 400 kN. For cable reinforcement of conventional control force in Type 2 simulation, the span of the original truss is 24m and the control force is 600 kN; See

Figure 5 and

Figure 6. Through theoretical calculation and analysis, the influence of two kinds of cable reinforcement effect is obtained, and the whole and node plate are designed.

2.2. Reinforcementmechanism

The method of cable reinforcement with variable axial force is developed from the bridge system. The cable is a kind of cable-bearing bridge. The force form of the main truss is similar to the continuous beam supported by elastic multi-point position. The span is large, the cross-sectional area of the main beam is small, the overall dead weight is light, and the controlling force is flexible. In truss calculation, the position and controlling force of cable have great influence on the whole force of truss.

The main influence of changing the controlling force and position of the cable is that the height of the cable directly affects the dip Angle of the cable. In the general truss design, the cable is regarded as providing elastic support for the roof structure [

1], so the cable with a larger dip Angle is often selected in order to obtain a larger vertical component. Based on the study of bridge system, it is found that the ratio between the layout height of conventional cable and the span of truss is generally 1/4~1/6, which is the reasonable layout height of cable. If the height of the truss is short, the ratio between the layout height and the path of the truss is generally 1/8~1/12 [

2]. Due to the different layout height, the stress characteristics of the two are also different. At the same time, according to JGJ257-2012 cable structure technical regulations, for the transverse diameter cable tie truss/cover, both ends of the suspension cable can be designed to be equal or unequal height, and the sag should be 1/10~1/20 of the span [

3]. The design value of cable control force is selected and verified in practice according to Article 5.6.1 and 5.6.2 of JGJ257-2012 Cable Structure Technical Regulations.

2.3. Computational analysis and modeling

- (1)

- (2)

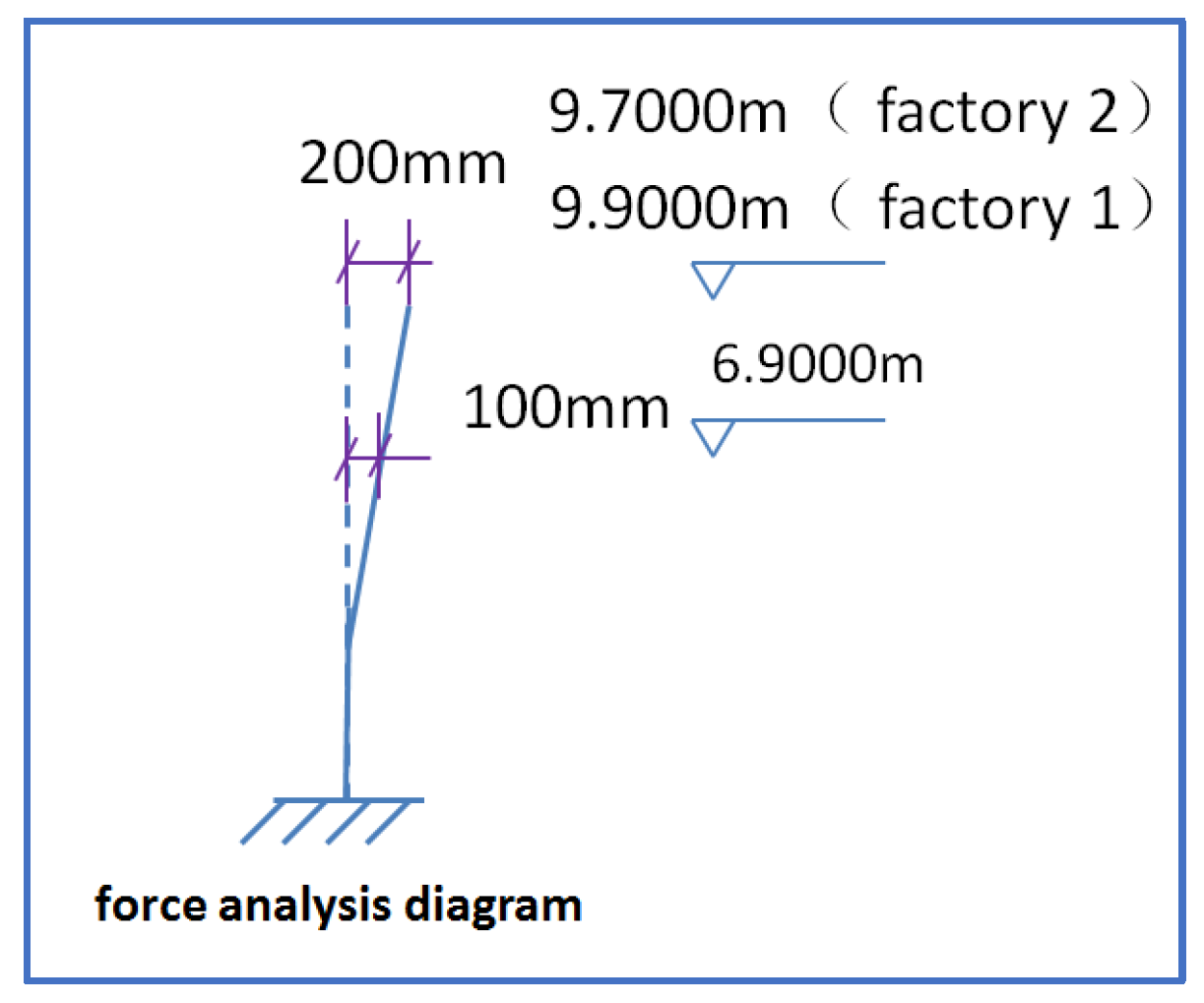

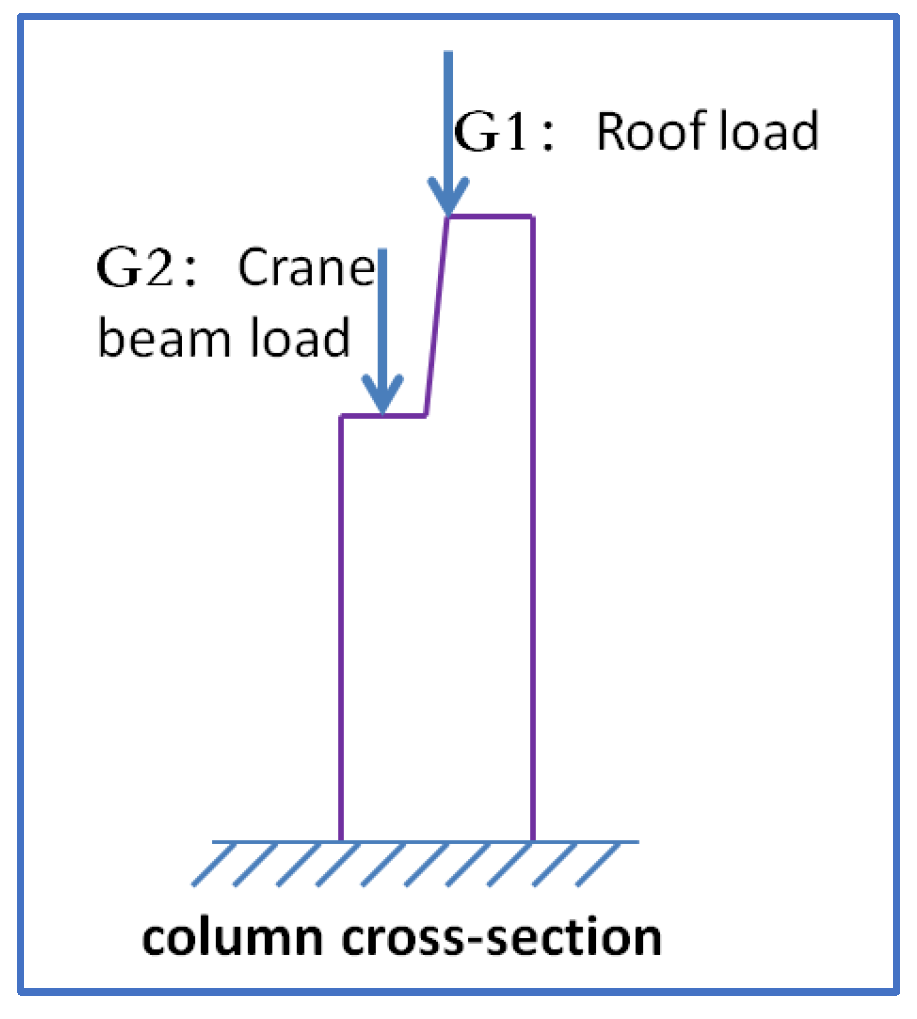

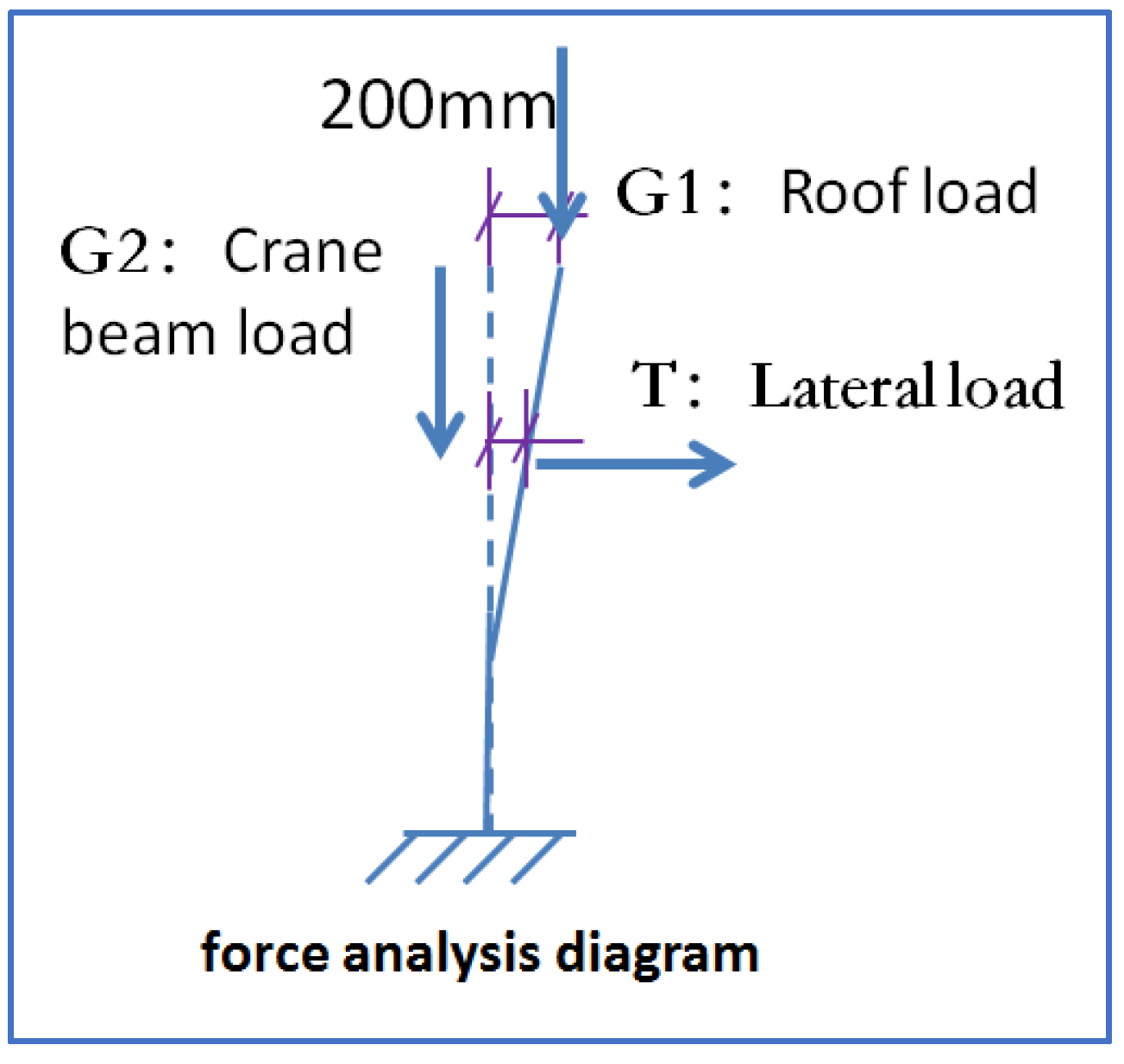

The force analysis of G axis column and the deformation analysis of column section after stress are shown in

Figure 7. The schematic diagram of roof truss load G1 and crane beam load G2 is shown in

Figure 8.

- (3)

Analysis of the upper part: the height of column section is within the height range of 16.9~9.9m. The original eccentricity of G1 is 400mm, and now it turns 100mm to the right, which is favorable to the upper end and will not break. The calculation is based on GB 50009-2019 building structure load code.

- (4)

G1: Original eccentricity+0.3 (positive to the left) G2: original eccentricity-0.5

Deflection due to column force: G1: original eccentricity+0.5= G2: eccentricity becomes-0.4=Based on the calculation of one piece of house truss of Workshop 1:

- ①

-

Roof plate dead load: ; Live load: ;

The span is 22~24,Set: A pin spacing of 8

- ②

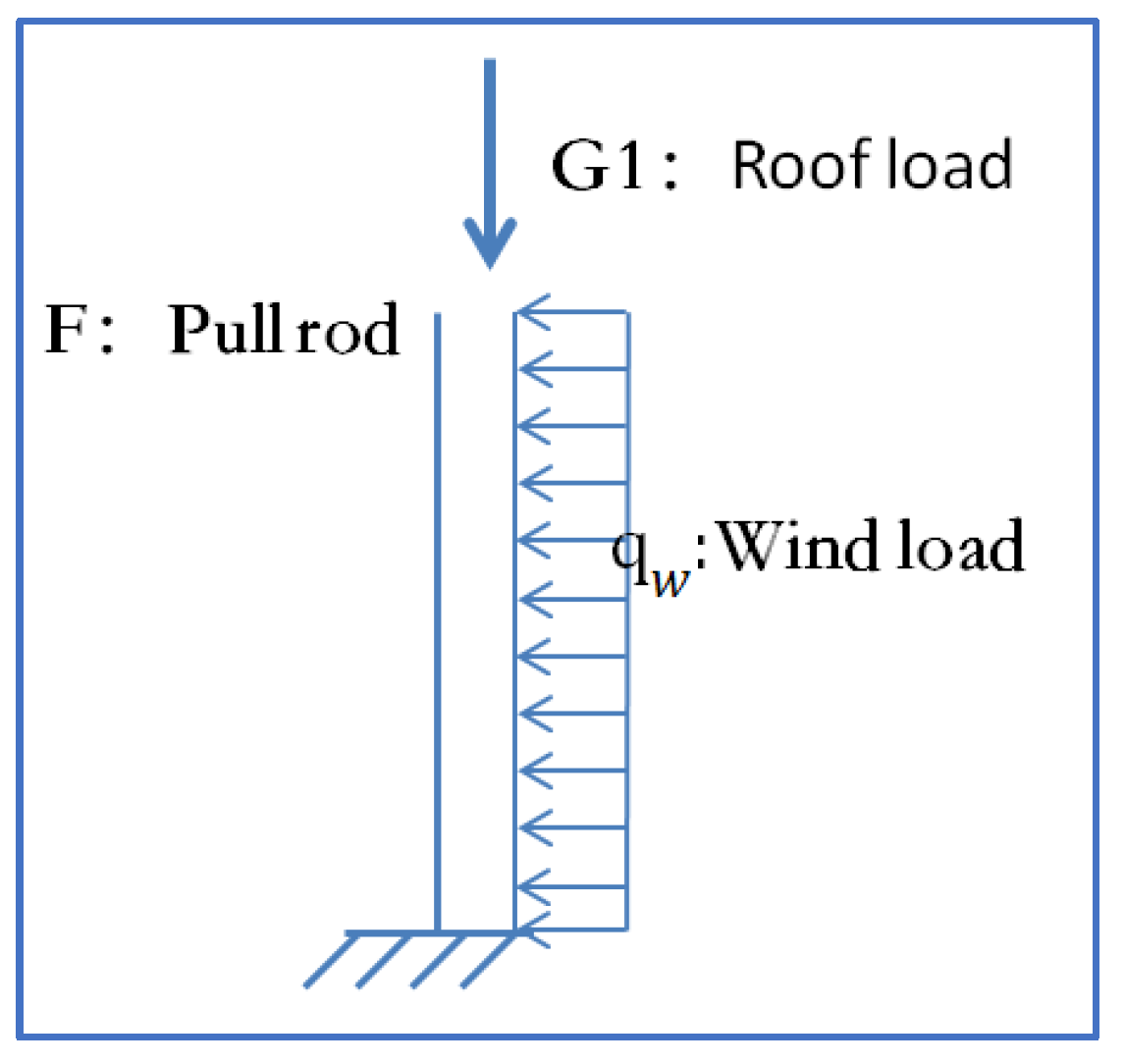

-

Wind load: using simplified calculation, take 1, is uniform load,

Then, line load:

- ③

Vertical crane load (see

Figure 10), because the eccentricity of crane load is negative, the worst case is 0;

- ④

Dead weight of wall:

- ⑤

-

The horizontal load (transverse) of the crane is 2 sets Soft hook crane A6, heavy car

For the convenience of calculation, the roof live load is considered according to the dead load to meet the guarantee rate, which includes:

=

- ⑥

-

Current situation: mm column bending capacity configuration: 10 HRB400 rebar with diameter of 25mm

- ⑦

-

Horizontal tie bar tension

When the current mm can bear part of the bending distance, then

It is considered to add a cable rod between the columns at the elevation of 6.9m. The cable rod coordinates the bending distance between the two ends. It can be removed after reinforcement, or it can be retained permanently (more suitable), so as to reduce the eccentricity of the columns.

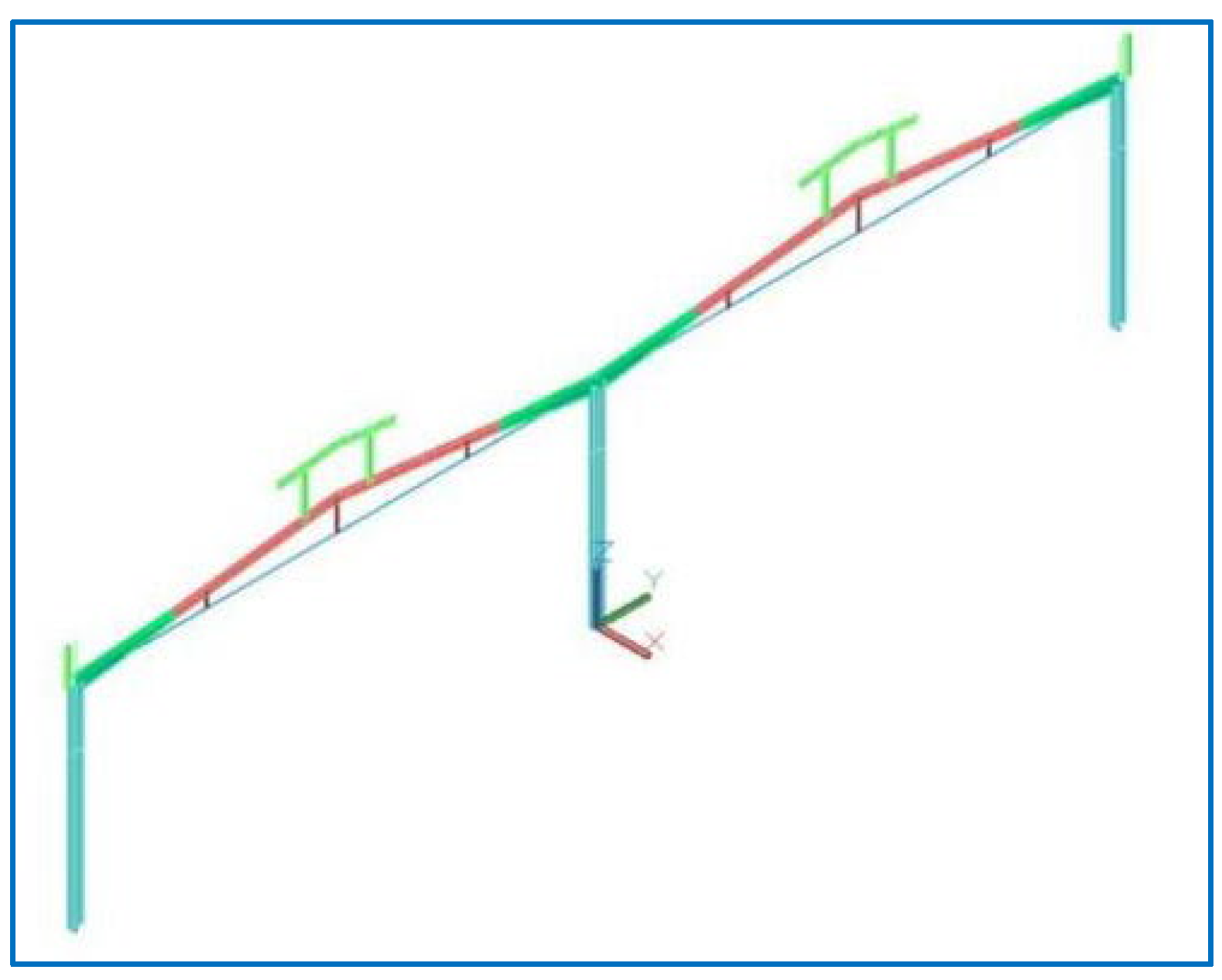

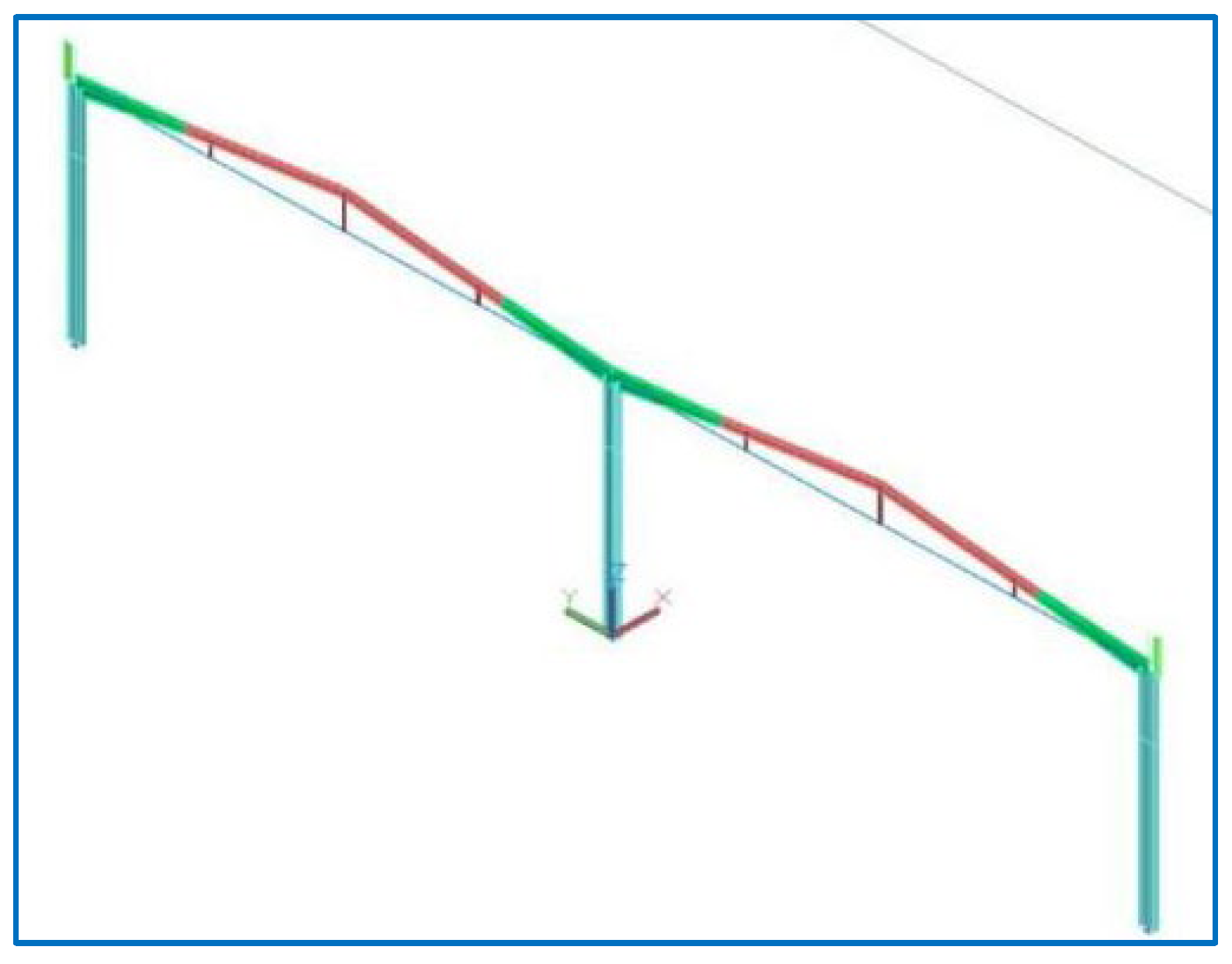

(6) 3D3S modeling after importing the overall calculation data, as shown in

Figure 11 and

Figure 12.

2.3.1. Condition 1: Uniform load

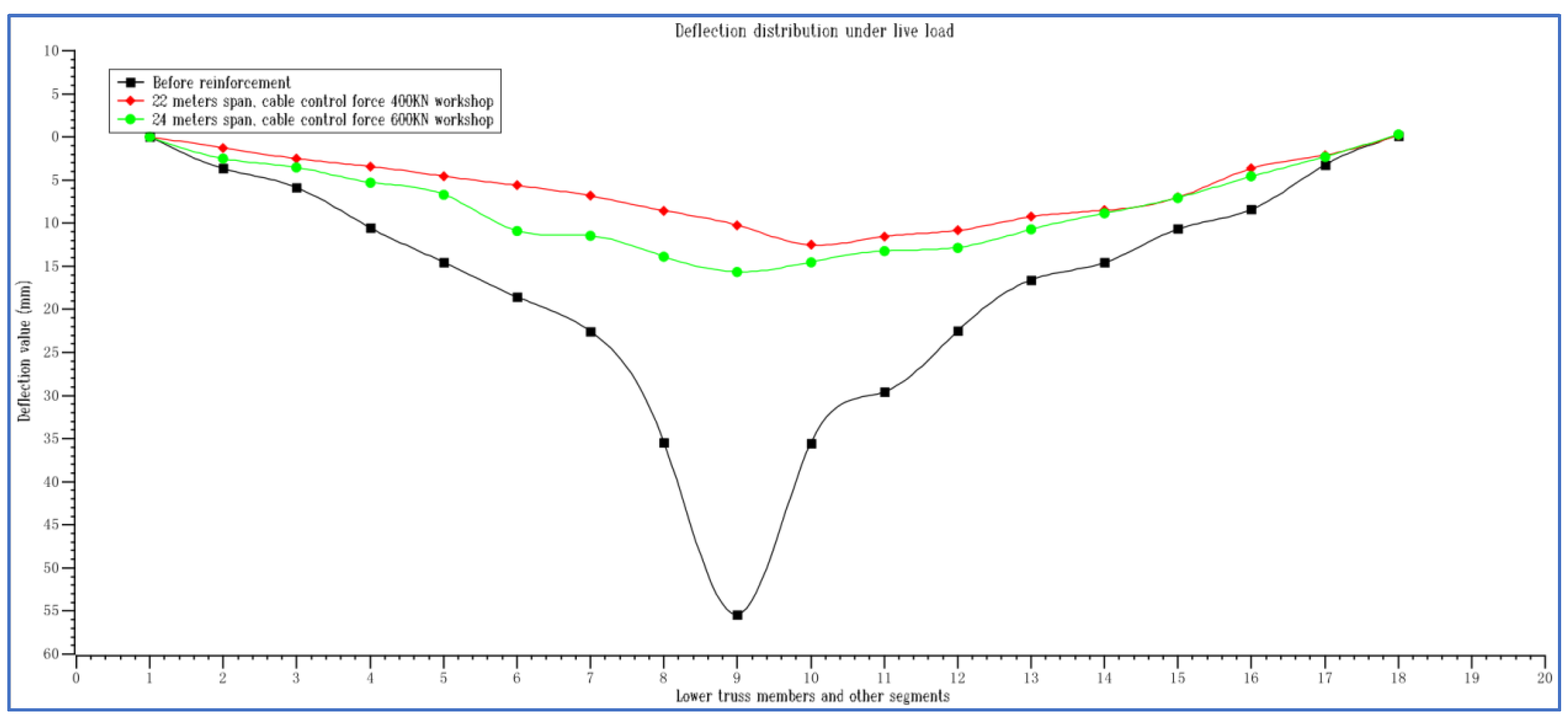

The deflection values of different span trusses before and after reinforcement under uniform load in working condition 1 are compared and analyzed, as shown in

Figure 11

. The maximum deflection value is 55.42mm before reinforcement, and the maximum deflection value is 12.52mm after the span is 22m. Compared with before reinforcement, the deflection value of each component decreases by more than 77.4%. The maximum deflection value of the cable span after reinforcement at 24m is 15.64mm. Compared with before reinforcement, the deflection value of each component decreases by more than 71.8% (see

Figure 13

: Deflection distribution diagram under live load).

The difference of cable span and axial force leads to the change of cable dip Angle. When the span and axial force of the cable change, the component of the cable force along the X axis and the Z axis will also be different. The larger the span, the larger the axial force, that is, the larger the component along the Z axis, the larger the deflection reduction value. Compared with the axial force of 400

kN

with 22 meter span and 600

kN

with 24 meter span, the reduction rate of deflection value of the component strengthened with 600

kN

with 24 meter span is greater than that of 400

kN

with 22 meter span under the same uniform load condition. When the controlling force exceeds 600

kN

, the reduction rate of deflection value becomes smaller.

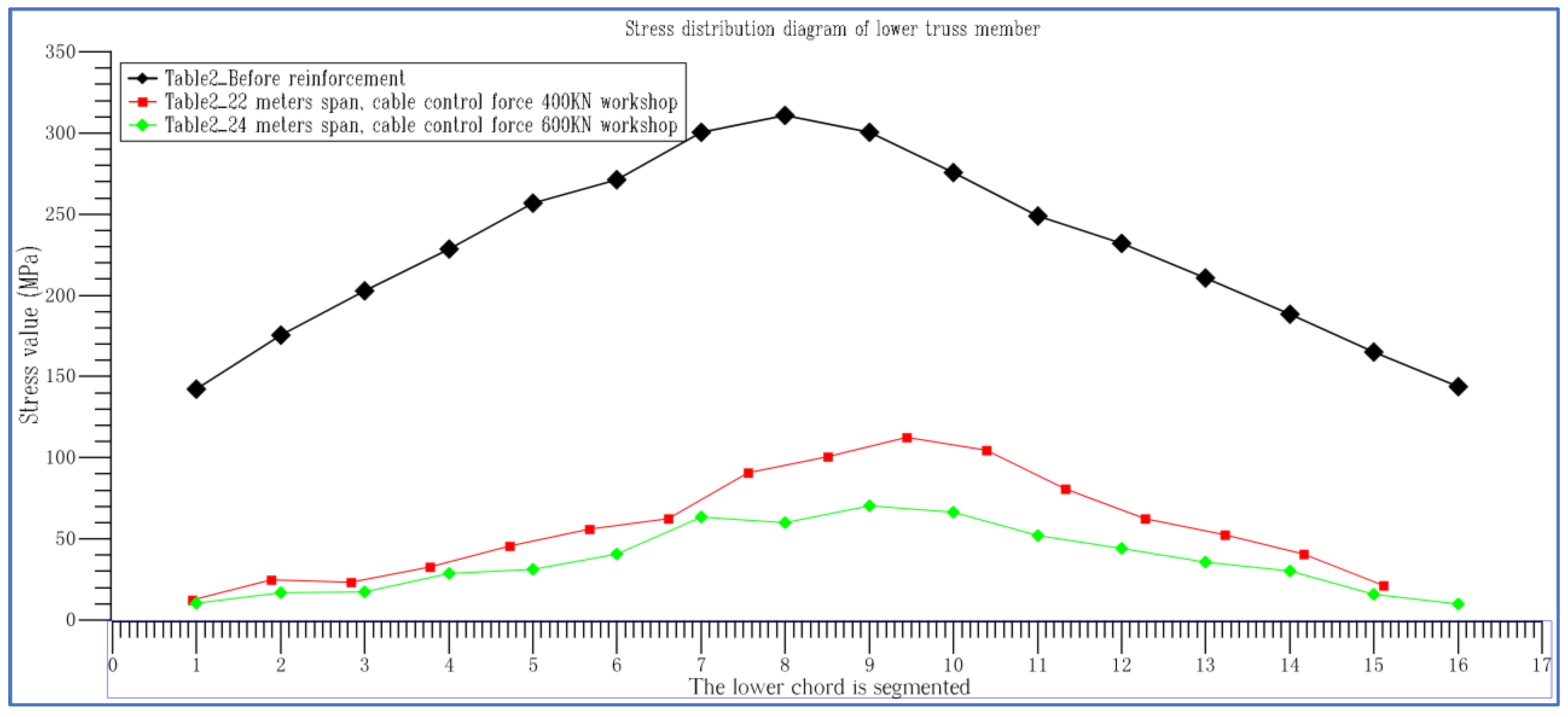

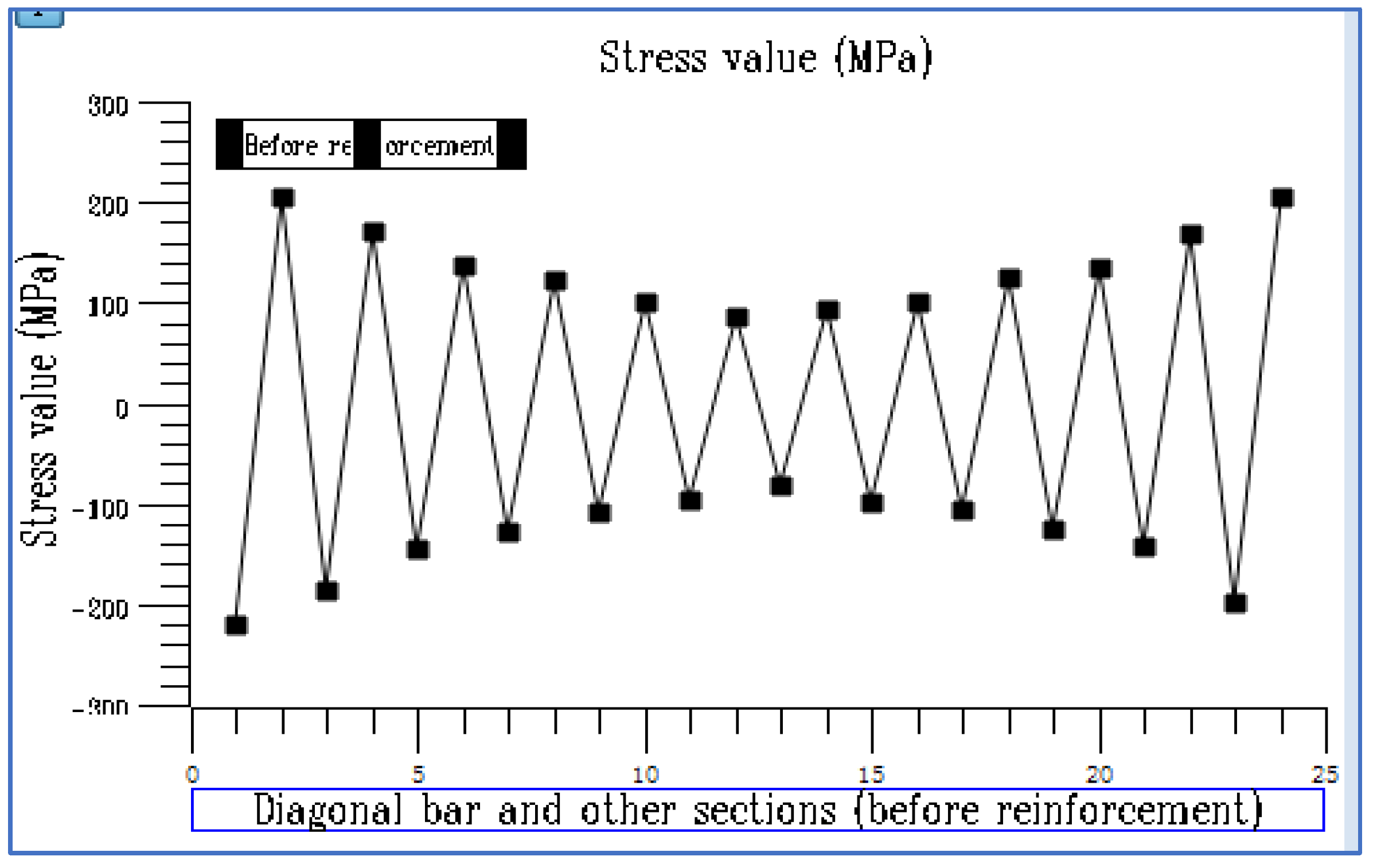

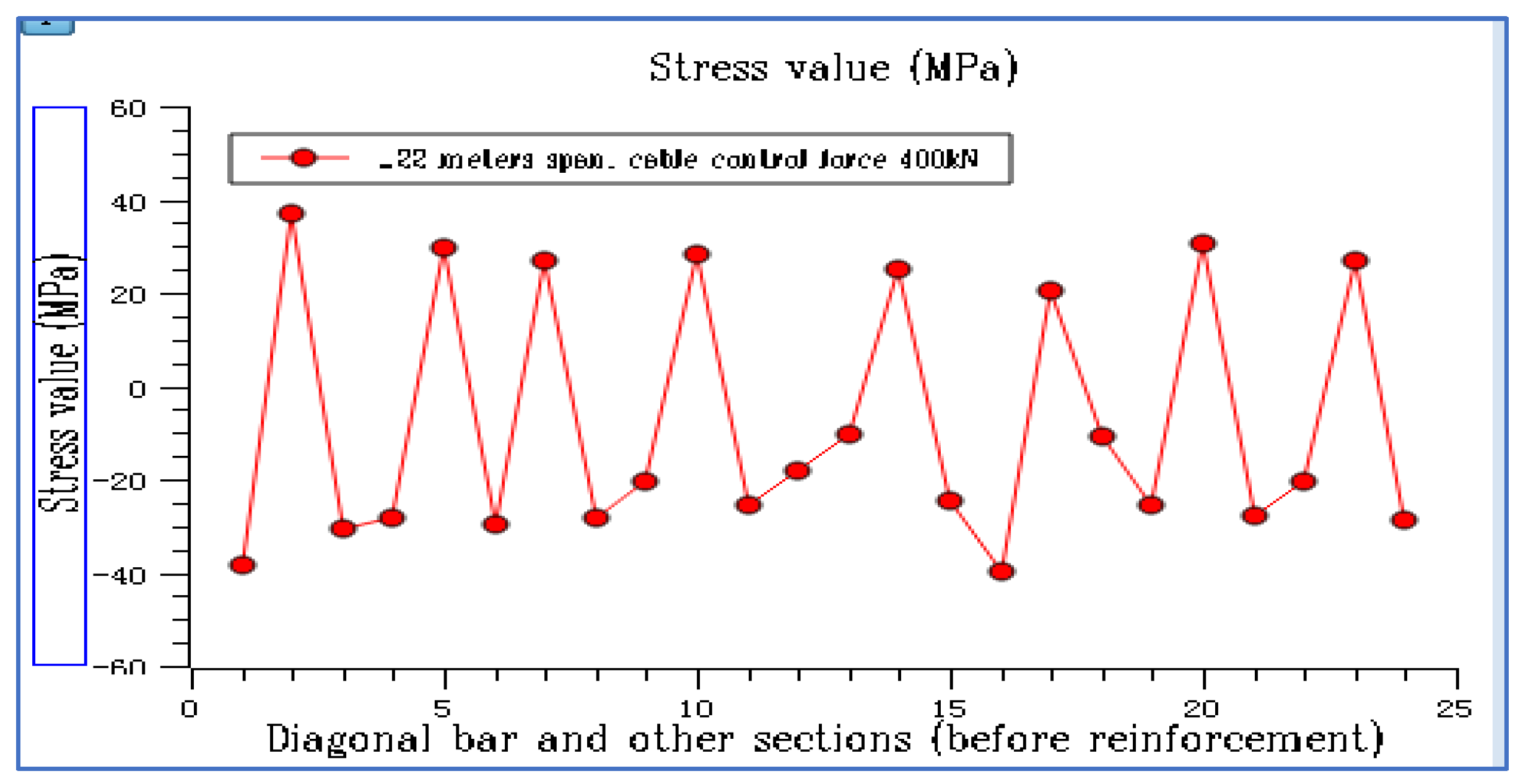

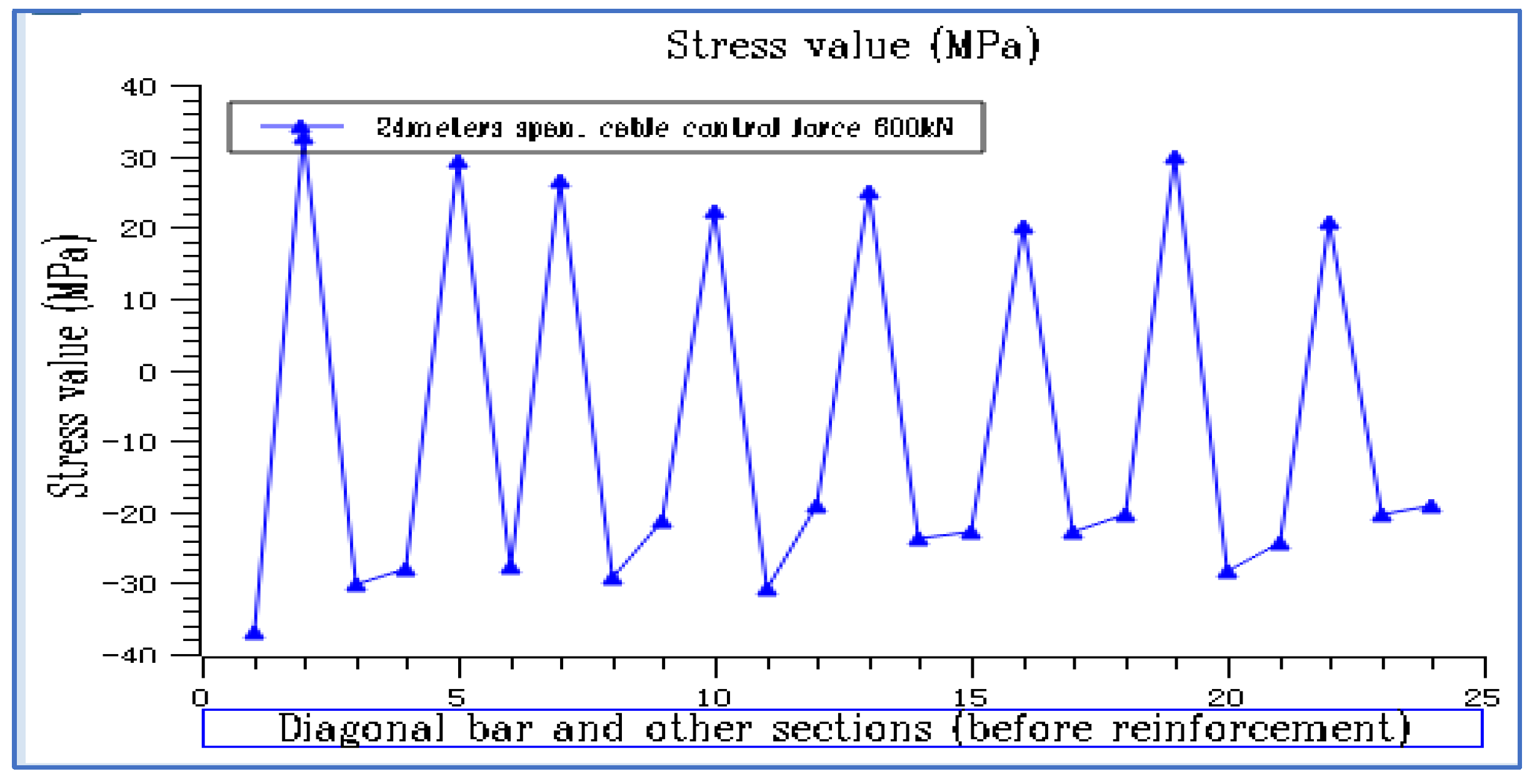

2.3.2. Condition 2: stress value

Table 1 lists the changes of the maximum stress value of the lower member after cable reinforcement. Combined with the data in the table and the stress distribution trend of the lower member of the truss in

Figure 14, it can be seen that the stress system of the original truss changes after reinforcement, and the internal forces of each truss member also change accordingly. Before the original truss reinforcement, it can be regarded as a simply supported truss structure, with the maximum bending moment value at the mid-span. The reinforced cable is similar to the elastic support, which changes the type of the original structure, that is, the 1 span 22m / 24m truss is changed into 4 span 5.5m / 6m continuous beam, and the structural type and single span span are changed, which greatly reduces the internal force value of the reinforced truss. After reinforcement, the initial tension of the cable makes the range of the compression member of the truss expand under the action of dead load, while the tensile stress of the tension rod decreases.

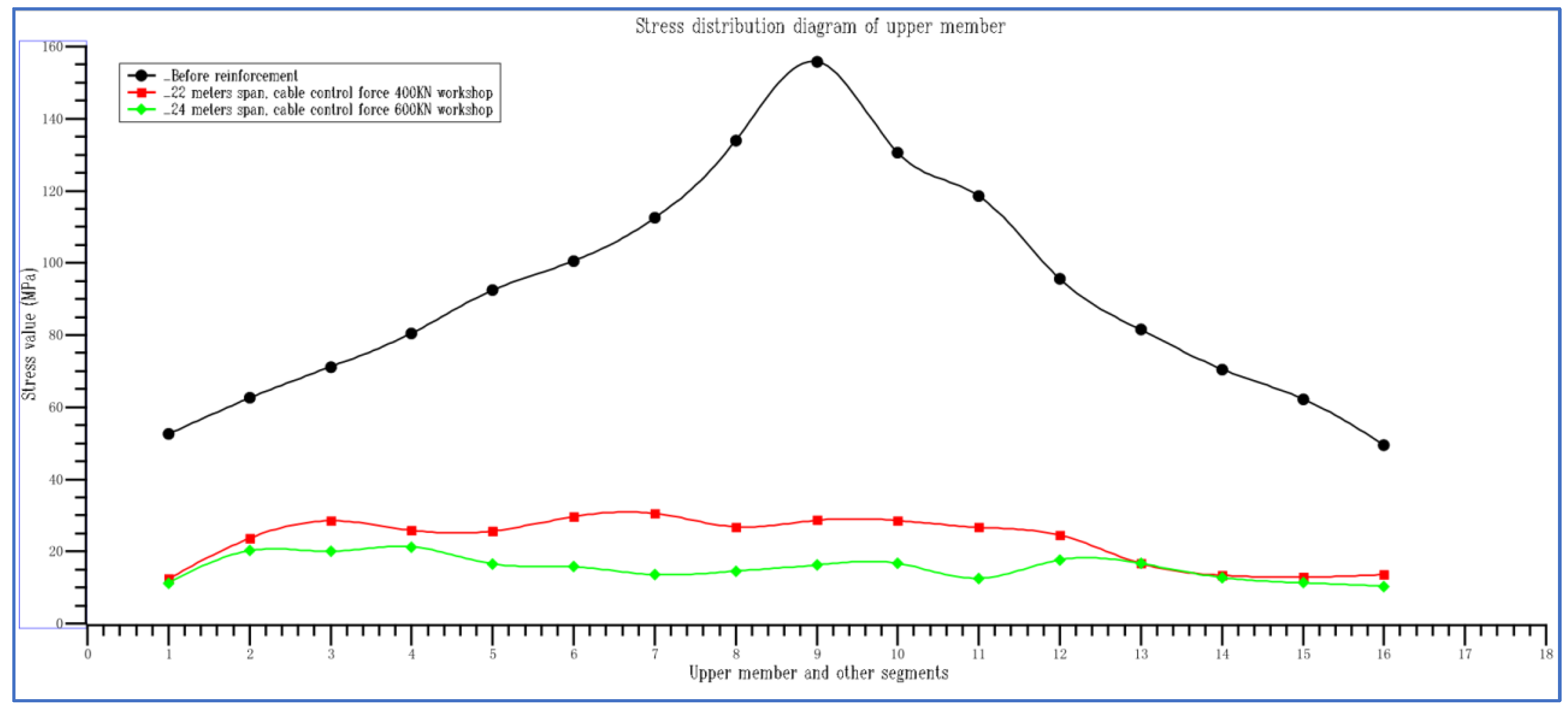

It can be seen from

Figure 15

that the maximum compressive stress of the upper member of the reinforced front truss exceeds the yield strength of the steel used for the upper member, and the value is 155.85MPa. Some members will be damaged. The compressive stress value of the upper member is close to 30MPa, and the stress value is greatly reduced after the reinforcement with variable axial force cable. When the original truss is a single span simply supported structure, the mid-span maximum compressive stress of the upper member is nearly 3 times of the fulcrum. The multi-point elastic support provided by the reinforced cable reduces the span of a single span, reduces the compressive stress difference of the upper component, makes the stress of the component more uniform, and increases the structural life. Due to the influence of the initial tension of the cable, the truss has an upward arch under the action of dead load, and there is a reserve of tensile stress on the upper member. When the strain is applied to the whole truss, the reserve stress generated by the initial tension will offset part of the load effect, resulting in a substantial reduction of the tensile stress value.

It can be seen from

Figure 16

that the stress distribution of the inclined rod of the reinforced front truss is two inclined rods connected to the same node (one under tension and one under pressure), and the absolute value of the stress decreases continuously from the fulcrum to the span. After reinforcement, 8 of the 24 diagonal rods on each side are under tension and 16 are under pressure. The two diagonal rods at the node position of cable anchorage are under pressure, and the tension and pressure of nodes at adjacent positions are alternately.

By comparing the stress changes after the control force changes, the maximum stress value of inclined bar with 22 meter span and 400

kN

control force decreases by 1.7MPa compared with that with 24 meter span and 600

kN

control force. Therefore, the maximum stress value of inclined bar changes with span and control force.

By comparing the deflection, stress values of upper truss member, lower truss member and inclined bar of two kinds of plant truss with variable axial force reinforcement under live load, it can be seen that for the reinforcement of large-span truss, the cable with large controlling force within a reasonable span is better, and the controlling force increases with the increase of span. According to the standard, the 600

kN

control force is the conventional control force. The cable reinforcement will produce a certain inclination Angle, and the Z-component will increase, so that the powerhouse truss can be greatly unloaded. Moreover, the vertical support provided by the cable will transform the large-span simply supported structure into a multi-span continuous structure, which shortens the single-span span span and greatly reduces the internal force value of the structure.

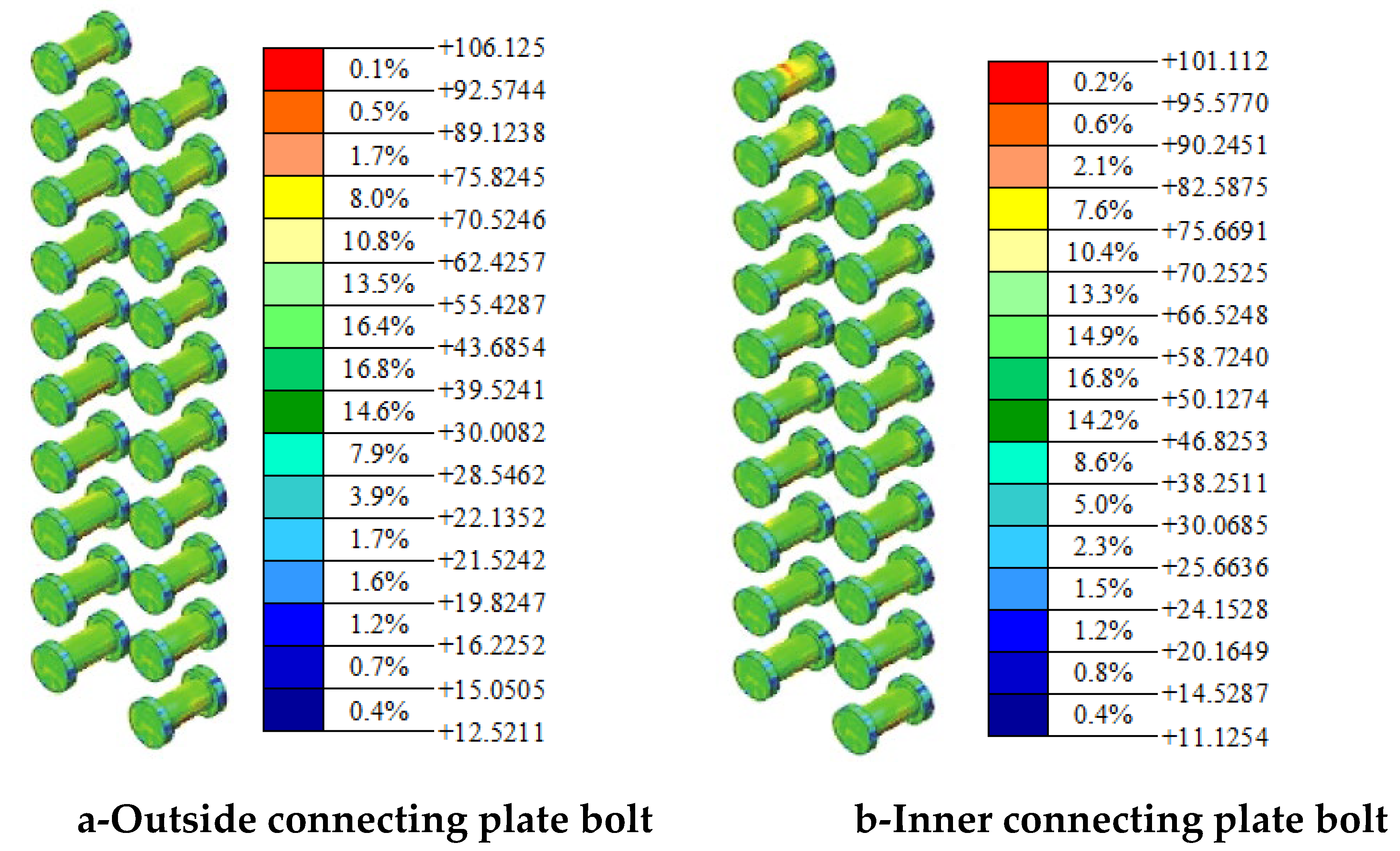

3. Nodalanalysis

3.1. Finiteelementmodeling

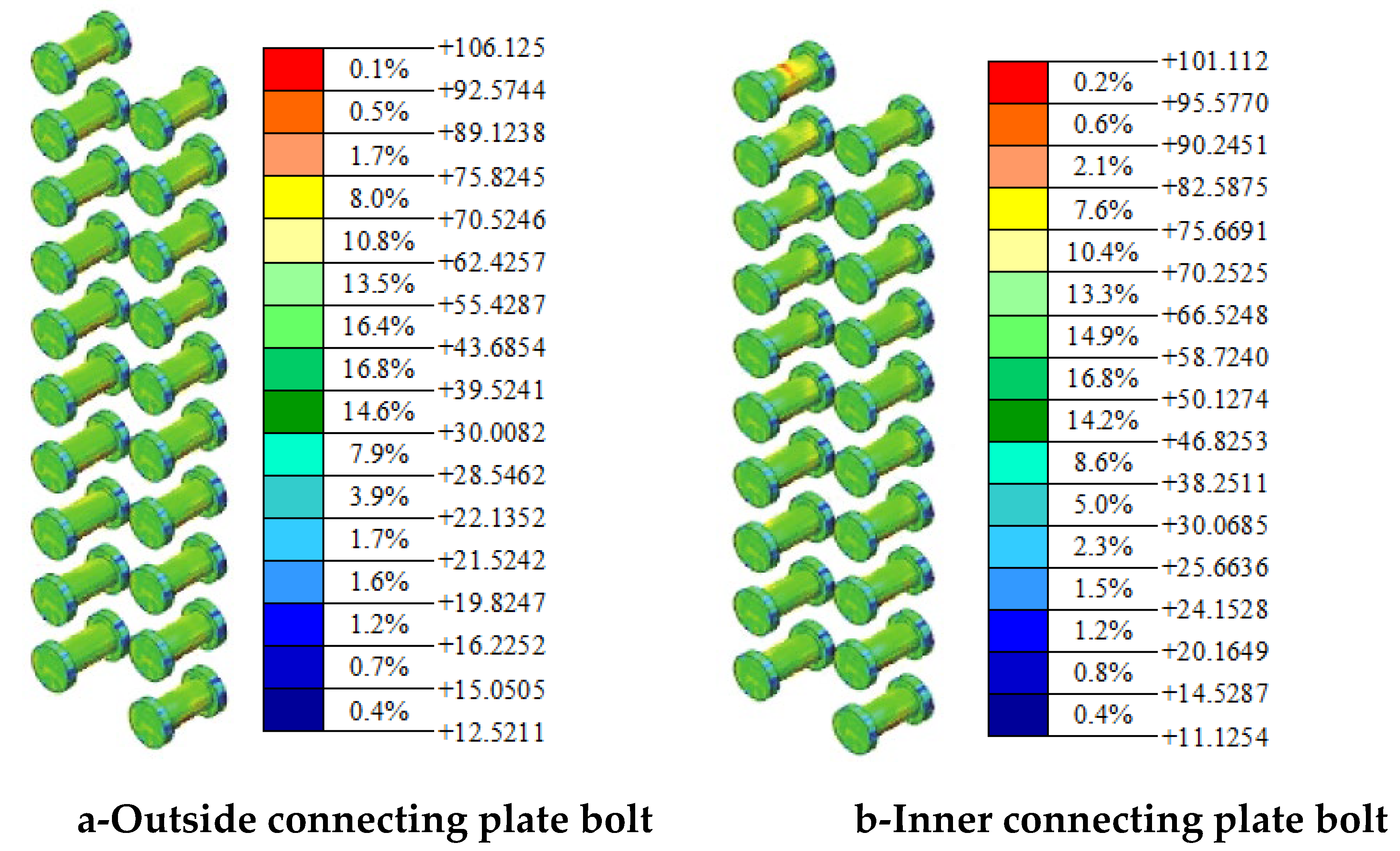

A solid model was established for the lug plate at the joint position of the plant with complex forces (

Figure 16

). The joint plate was made of Q345B, made of steel, and the thic

kN

ess was 20mm. Each side of the roof truss is provided with internal and external node plates, each node plate is provided with a diameter of 20mm large hexagonal head high strength bolts 64, bolt hole diameter of 22mm. The bolt strength class is 10.9S, and the bolt pretension is 155~187 kN, the value of which is specified in Appendix B of GB50205-2020 steel structure engineering construction quality acceptance standard.

Figure 18.

Finite element model of gusset plate.

Figure 18.

Finite element model of gusset plate.

The force of each member of the node is transferred through welded connections such as flange plate and bottom plate, and friction is provided by friction type high-strength bolts [

5]. ASET software was used to establish the model. The material nonlinearity and geometric linearity were considered in the calculation, and the model was loaded in 5 steps according to GB50344-2004 technical standard of building structure inspection, so as to ensure the convergence of the calculation structure. In order to save computing resources, only bolts are established in this paper (the stress test of side plate materials is omitted). The most unfavorable joint plate with the greatest internal force before and after reinforcement is selected for simulation test.

3.2. Node plate analysis

| Condition |

Maximum stress of connecting plate bolt(MPa) |

The stress distribution area above 100MPa accounts for % |

a accounts for % |

accounts for % |

| Before reinforcement |

204 |

25.6 |

68.1 |

6.3 |

| After using 24 meters of control force 600kN cable reinforcement |

106 |

0.1 |

34.6 |

65.3 |

The stress value of bolt group is greatly reduced after adding cable reinforcement, which improves the overall stability of powerhouse truss.

4. Conclusions

4.1 After the cable reinforcement, the stiffness of the building truss increases and the stress distribution trend of each component changes obviously. Under the action of crane and other main live load, the reduction rate of deflection value is more than 50%; The maximum stress reduction rate of the upper and lower truss members is more than 60%, and the overall load increase rate of the first and second workshop trusses is more than 70% after reinforced by the variable axial force cable.

4.2 Before reinforcement, the overall stress level of each node is reasonable, but it is easy to tear and destroy due to the increased load and service life limit after the installation of photovoltaic panels, as well as the second-highest stress concentration at the bolt position of the node plate. After the reinforcement, the stress values of the node plates all decreased significantly, and the stress below 100MPa accounted for more than 90%, while the greater stress accounted for less than 1%. The node plates after the reinforcement were in the stable stress area, without tearing or stress damage.

4.3

The high stress and secondary high stress areas of bolt group are mainly distributed near the load position. After the reinforcement, the stress zone area of 50~100MPa accounts for about 35%, and the stress zone area above 100MPa accounts for less than 1%. The problem of stress concentration has been solved, and the requirements of the new specification have been met.

To sum up,

the reinforcement of the plant truss with variable axial force cable method can play a role in lifting and strengthening the whole truss. Two kinds of cable with different span and controlling force are used to carry out load-lifting reinforcement application practice in workshop 1 and Workshop 2. Through comprehensive comparative analysis, it is concluded that cable reinforcement of powerhouse truss plays an active and effective role in the stress system. When the cable reinforcement of Workshop 2 is used with 24m span and controlling force of 600

kN

, the reinforcement effect of structural system is better than that of Workshop 1.

Acknowledgments

Research Project of Zhejiang Provincial Department of Housing and Urban-Rural Development (2022K010).

References

- Wang, X., Yang, Y., Xin, X., Jia, J., Xu, G., & Chen, Z. (2021, October). Computer Aided Design and Numerical Simulation of Dongming Yellow River Bridge Strengthened by a Cable-Stayed System. In 2021 3rd International Conference on Artificial Intelligence and Advanced Manufacture (pp. 2625-2633).

- Cai, H., & Aref, A. J. (2015). On the design and optimization of hybrid carbon fiber reinforced polymer-steel cable system for cable-stayed bridges. Composites Part B: Engineering, 68, 146-152. [CrossRef]

- Ceballos, M. A., & Prato, C. A. (2008). Determination of the axial force on stay cables accounting for their bending stiffness and rotational end restraints by free vibration tests. Journal of sound and vibration, 317(1-2), 127-141. [CrossRef]

- Simões, L. M. C., & Negrão, J. H. O. (1994). Sizing and geometry optimization of cable-stayed bridges. Computers & structures, 52(2), 309-321. [CrossRef]

- 5. Song, C., Xiao, R., & Sun, B. (2018). Optimization of cable pre-tension forces in long-span cable-stayed bridges considering the counterweight. Engineering Structures, 172, 919-928. [CrossRef]

- 6. Malekinejad, M., & Rahgozar, R. (2013). An analytical approach to free vibration analysis of multi-outrigger–belt truss-reinforced tall buildings. The Structural Design of Tall and Special Buildings, 22(4), 382-398. [CrossRef]

- Khanorkar, A., Sukhdeve, S., Denge, S. V., & Raut, S. P. (2016). Outrigger and belt truss system for tall building to control deflection: A review. GRD Journals-Global Research and Development Journal for Engineering, 1(6).

- Qi, J., & Yang, H. C. (2021). Improvement of a truss-reinforced, half-concrete slab floor system for construction sustainability. Sustainability, 13(7), 3731. [CrossRef]

- Hwang, J. S., & Lee, K. S. (2016). Seismic strengthening effects based on pseudodynamic testing of a reinforced concrete building retrofitted with a wire-woven bulk kagome truss damper. Shock and Vibration, 2016, 1-17. [CrossRef]

- American Society of Civil Engineers. (2017, June). Minimum design loads and associated criteria for buildings and other structures. American Society of Civil Engineers.

- Hou, Zhaoxin; He,Wenhui;Zhou,Jianfeng & Qiu,Linbo.(2014).national standard《Code for acceptance of construction quality of steel structure engineering》GB50205 Introduction of special research results in revision. Standardization of Engineering Construction(12),49-55. [CrossRef]

- Keane, B., Schwarz, G., & Thurnherr, P. (2018). Cables and cable glands for hazardous locations. In 2018 IEEE Petroleum and Chemical Industry Technical Conference (PCIC) (Vol. 42, p. 9).

- Naveen Revanna;Charles K.S.Moy & Theofanis Krevaikas.(2021).Verifying a Finite Element Analysis Methodology with Reinforced Concrete Beam Experiments. Research Press of America.(eds.) Research Press of America 2020 paper collectionⅣ(pp.340-347).Scientific Research Publishing.

- Furkan Ahmad & Pramendra Kumar Bajpai.(2018).Evaluation of stiffness in a cellulose fiber reinforced epoxy laminates for structural applications:Experimental and finite element analysis. Defence Technology(04),278-286. [CrossRef]

- Fitzalan Jake & Mashiri Fidelis.(2022).Finite Element Analysis of Telecommunication Structure Reinforcement. ce/papers(4). [CrossRef]

- Chhushyabaga, B., Karki, S., & Khadka, S. S. (2022, June). Effect of Mechanical Vibration in a Power House Located in the Nepal Himalaya. In IOP Conference Series: Earth and Environmental Science (Vol. 1037, No. 1, p. 012065). IOP Publishing.

- Kiarasi, F., Babaei, M., Sarvi, P., Asemi, K., Hosseini, M., & Omidi Bidgoli, M. (2021). A review on functionally graded porous structures reinforced by graphene platelets. Journal of Computational Applied Mechanics, 52(4), 731-750. [CrossRef]

- Lin, Y. H., Lin, Z. H., Chen, Q. T., Lei, Y. P., & Fu, H. G. (2019). Laser in-situ synthesis of titanium matrix composite coating with TiB–Ti network-like structure reinforcement. Transactions of Nonferrous Metals Society of China, 29(8), 1665-1676. [CrossRef]

- López, D. L., Roca, P., Liew, A., Echenagucia, T. M., Van Mele, T., & Block, P. (2022, January). A three-dimensional approach to the Extended Limit Analysis of Reinforced Masonry. In Structures (Vol. 35, pp. 1062-1077). Elsevier. [CrossRef]

- Koshcheev, A. A., Roshchina, S. I., Naichuk, A. Y., & Vatin, N. I. (2020, July). The effect of eccentricity on the strength characteristics of glued rods made of steel cable reinforcement in solid wood. In IOP conference series: materials science and engineering (Vol. 896, No. 1, p. 012059). IOP Publishing. [CrossRef]

- Ceballos, M. A., & Prato, C. A. (2008). Determination of the axial force on stay cables accounting for their bending stiffness and rotational end restraints by free vibration tests. Journal of sound and vibration, 317(1-2), 127-141. [CrossRef]

Figure 3.

Section view of the Workshop 1.

Figure 3.

Section view of the Workshop 1.

Figure 4.

Section view of the Workshop 2.

Figure 4.

Section view of the Workshop 2.

Figure 5.

Detailed drawing of variable axial force cable in Workshop 1.

Figure 5.

Detailed drawing of variable axial force cable in Workshop 1.

Figure 6.

Detailed drawing of variable axial force cable in Workshop 2.

Figure 6.

Detailed drawing of variable axial force cable in Workshop 2.

Figure 7.

Column stress deformation diagram.

Figure 7.

Column stress deformation diagram.

Figure 8.

Column cross-section.

Figure 8.

Column cross-section.

Figure 9.

Schematic diagram of overall mechanical analysis.

Figure 9.

Schematic diagram of overall mechanical analysis.

Figure 10.

Schematic diagram of vertical crane load mechanics.

Figure 10.

Schematic diagram of vertical crane load mechanics.

Figure 11.

3D3S model of southeast axis.

Figure 11.

3D3S model of southeast axis.

Figure 12.

3D3S model of southwest axis.

Figure 12.

3D3S model of southwest axis.

Figure 13.

Deflection distribution under live load.

Figure 13.

Deflection distribution under live load.

Figure 14.

Stress distribution diagram of lower truss members.

Figure 14.

Stress distribution diagram of lower truss members.

Figure 15.

Stress distribution diagram of upper truss member.

Figure 15.

Stress distribution diagram of upper truss member.

Figure 16.

Before reinforcement.

Figure 16.

Before reinforcement.

Figure 17.

kN control force cable after reinforcement.

Figure 17.

kN control force cable after reinforcement.

Figure 18.

kN control cable after reinforcement.

Figure 18.

kN control cable after reinforcement.

Figure 19.

Stress distribution diagram of bolt before reinforcement.

Figure 19.

Stress distribution diagram of bolt before reinforcement.

Figure 20.

Stress distribution of bolts reinforced with 600kN cable with 24m controlling force.

Figure 20.

Stress distribution of bolts reinforced with 600kN cable with 24m controlling force.

Table 1.

Change of stress value of lower truss members after cable reinforcement.

Table 1.

Change of stress value of lower truss members after cable reinforcement.

| Span m/control force kN |

maximum stress/MPa |

Stress reduction/MPa |

Reduction rate/% |

| Before reinforcement |

310.82 |

0.0 |

0.0 |

| 22m/400kN |

112.52 |

212.54 |

65.38 |

| 24m/600kN |

70.54 |

244.70 |

77.62 |

Table 2.

Stress change of inclined bar of truss after cable reinforcement.

Table 2.

Stress change of inclined bar of truss after cable reinforcement.

| Component name |

Maximum compressive stress (MPa)/position |

Component name |

Maximum compressive stress (MPa)/position |

|

| Reinforce the front inclined bar |

219/Near truss |

Reinforce the rear diagonal bar |

33.8/Near truss |

185.2 |

| Reinforce the front mid-span diagonal bar |

73.5 |

Reinforce the diagonal bar in the middle of the rear span |

38.2 |

34.6 |

| The rear inclined rod is reinforced with 22 m controlling force and 400kN cable |

39.9 |

The rear inclined rod is reinforced with a 24m controlling force of 600kN cable |

38.2 |

1.7 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).