Submitted:

31 March 2023

Posted:

31 March 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and methods

2.1. Materials

| Components(wt%) | CaO | Al2O3 | SiO2 | Fe2O3 | P2O5 | SO3 | K2O | Cr | TiO2 | Cl- | MnO |

| P·Ⅱ 52.5 | 68.11 | 4.13 | 18.17 | 3.15 | 0.11 | 3.79 | 0.59 | 0.01 | 0.19 | 0.03 | 0.01 |

| Specific Surface Area | Initial Setting | Final Setting | Compressive Strength | Flexural Strength | |

| P·Ⅱ 52.5 | 338 m2/kg | 199 min | 285 min | 53.5 MPa | 9.5 MPa |

2.2. Experimental methods

2.2.1. Aggregate properties

2.2.2. Morphology of interface

2.2.3. Heat of hydration

2.2.4. Electrical resistivity

3. Results and discussion

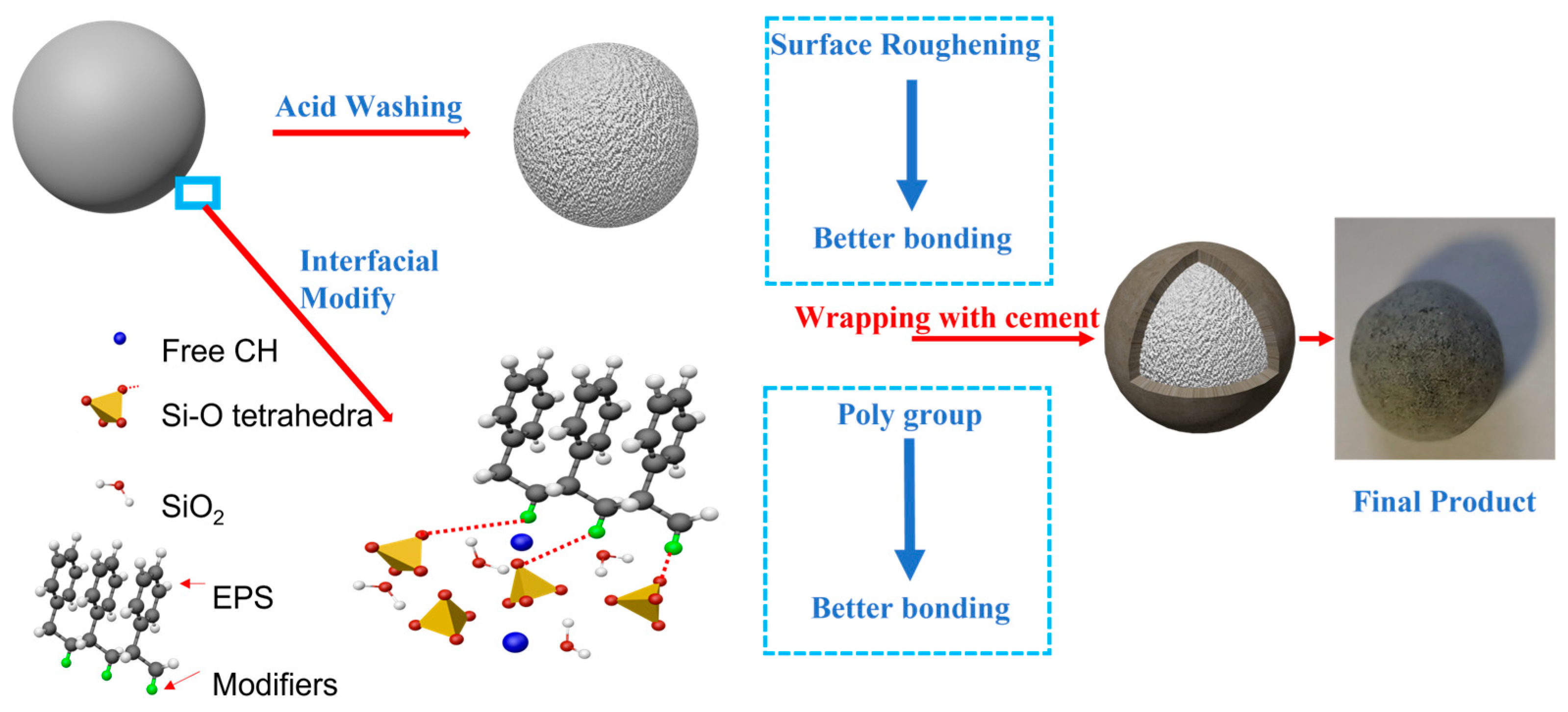

3.1. Effect of interface modifier on EPS-cement interface

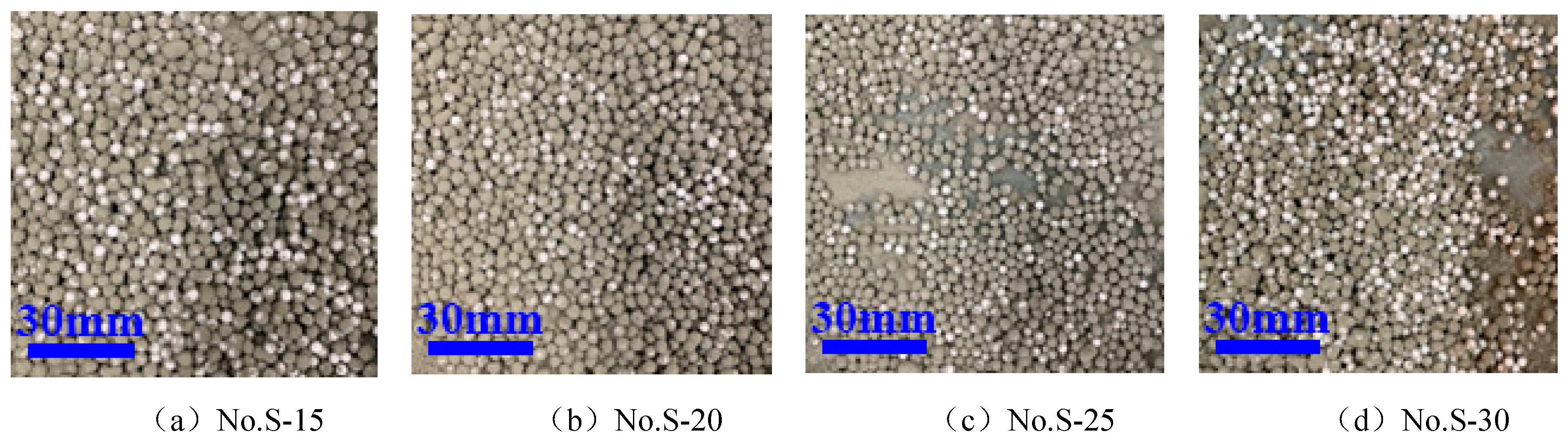

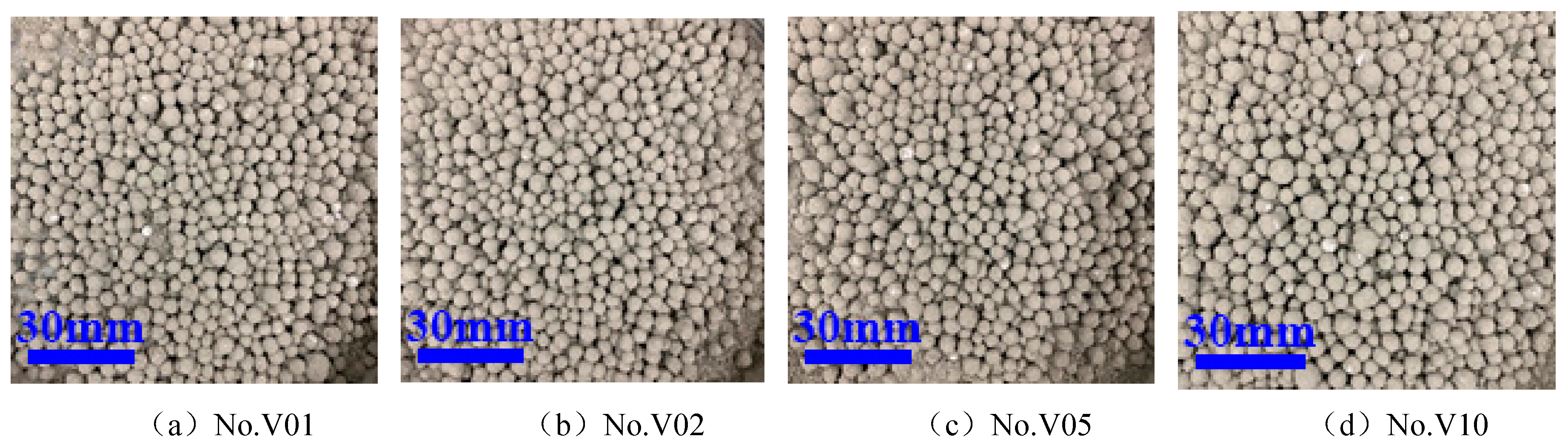

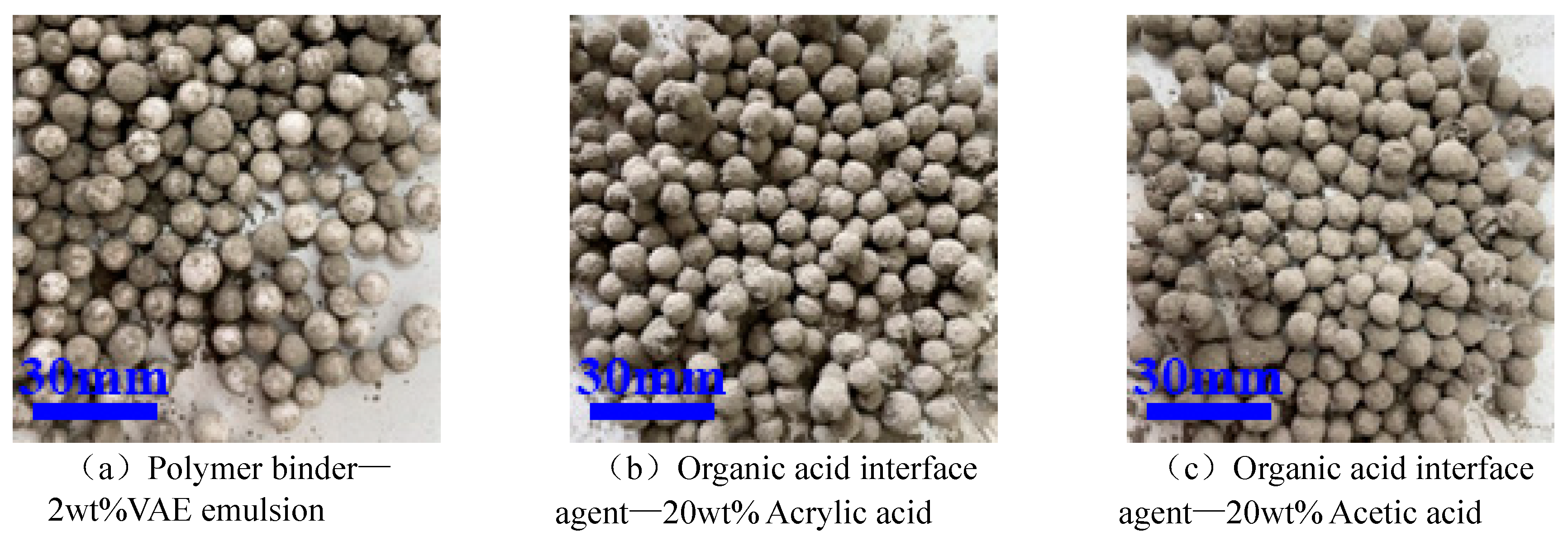

3.1.1. Effect of different interface agents on the moulding properties of CSLA

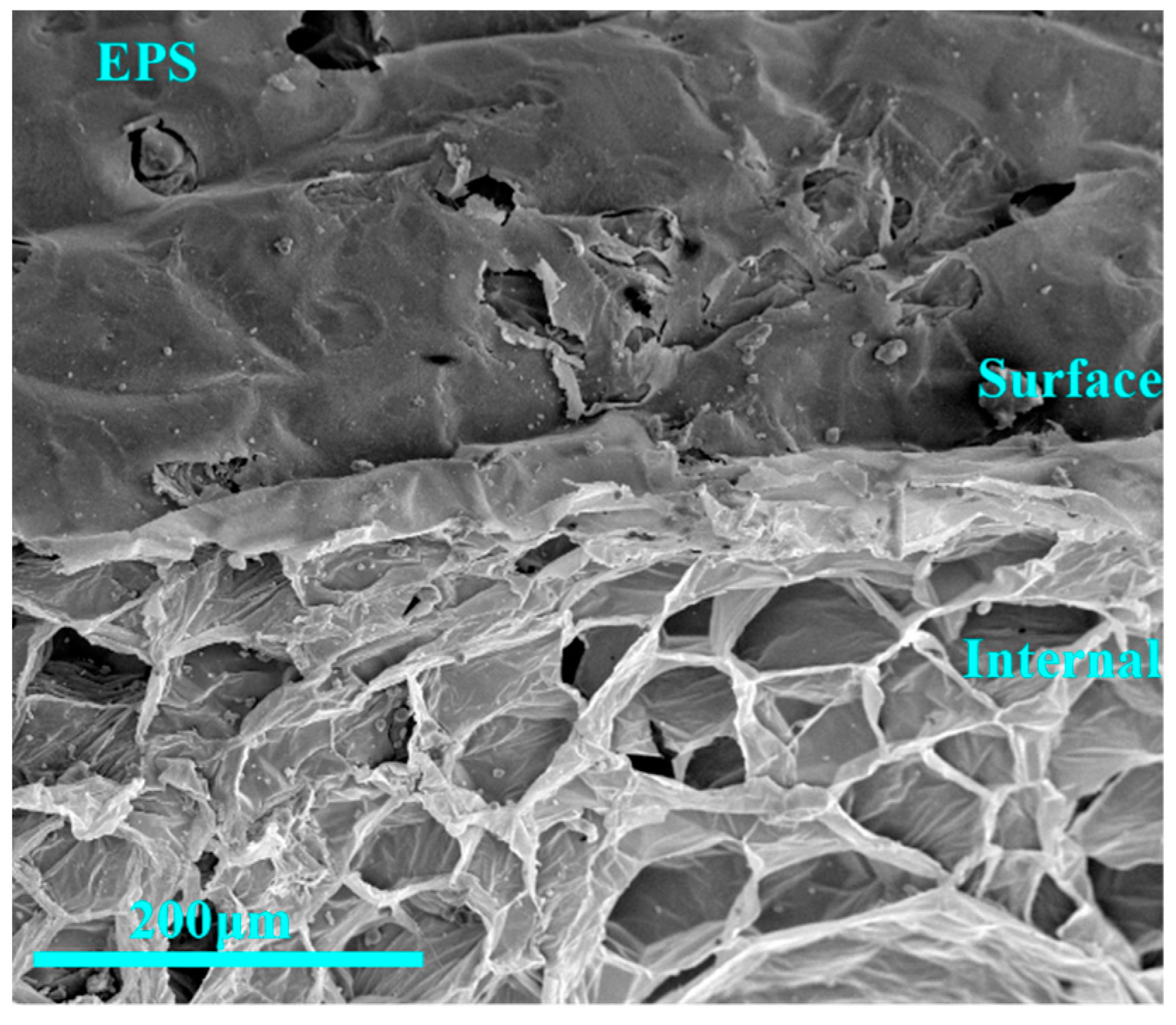

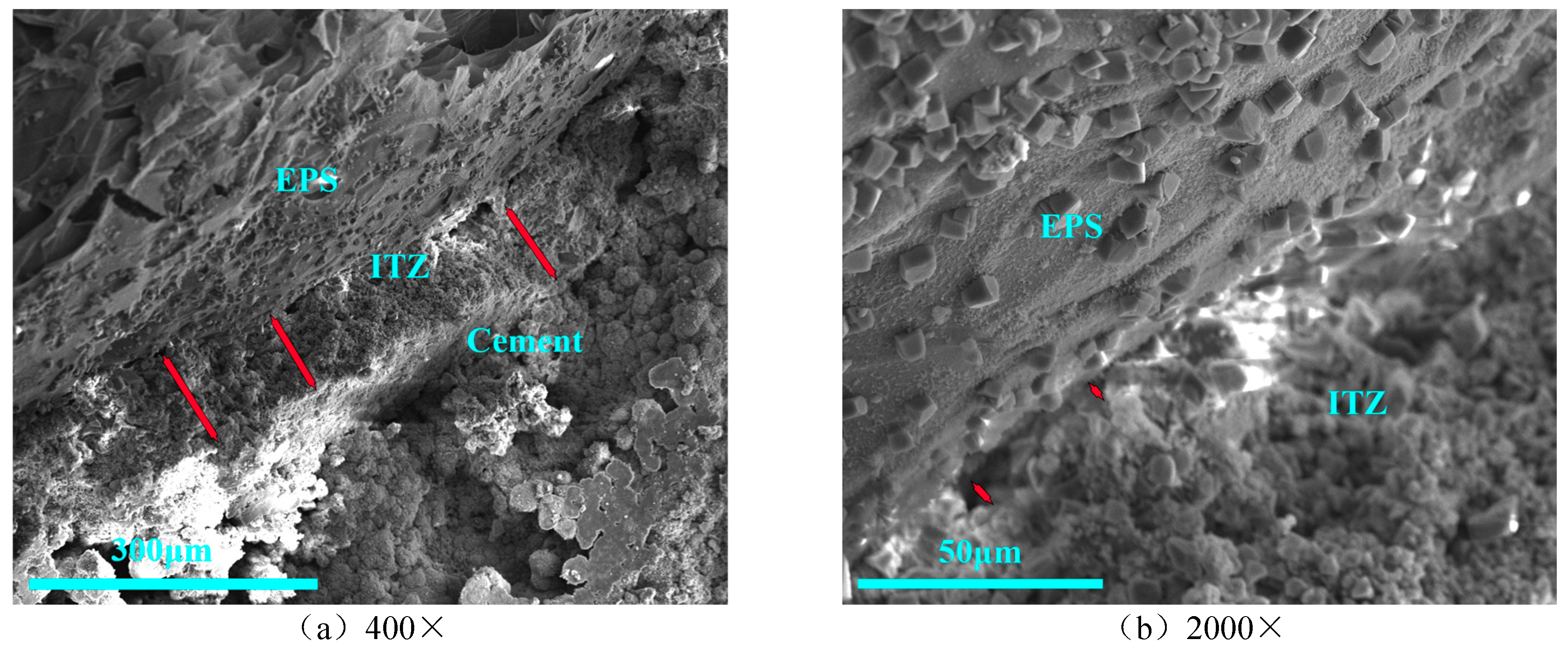

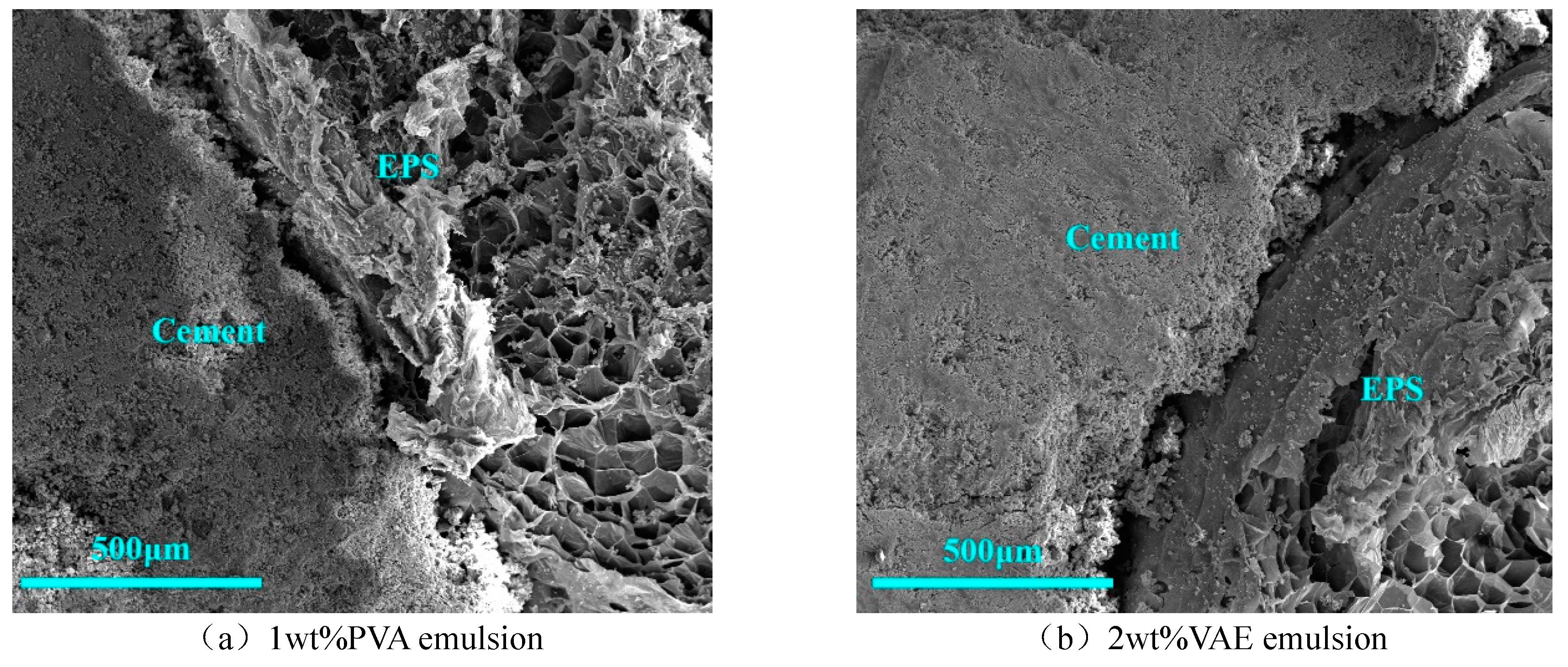

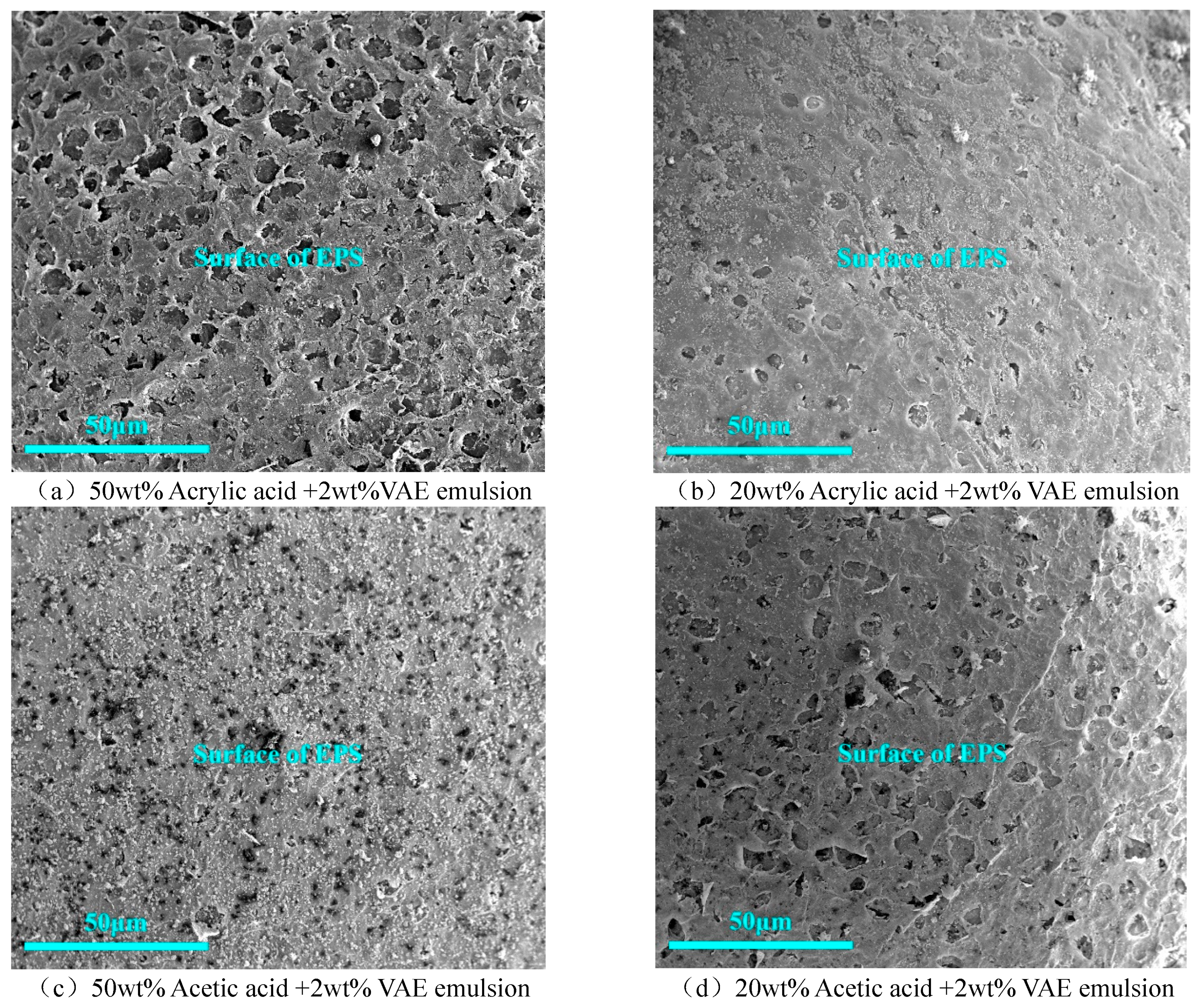

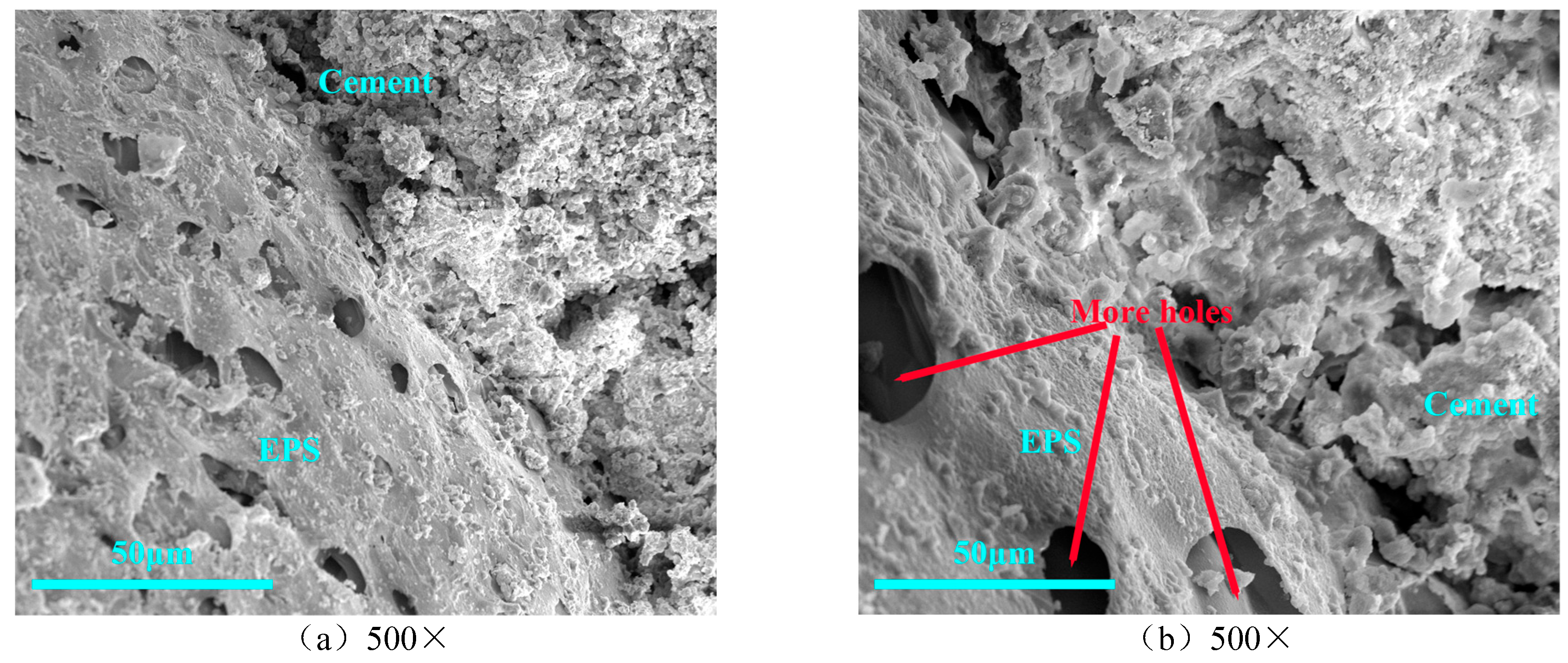

3.1.2. Effect of different interfacial agents on the micromorphology of EPS and cementitious

3.2. Effect of different interface agents on cement hydration

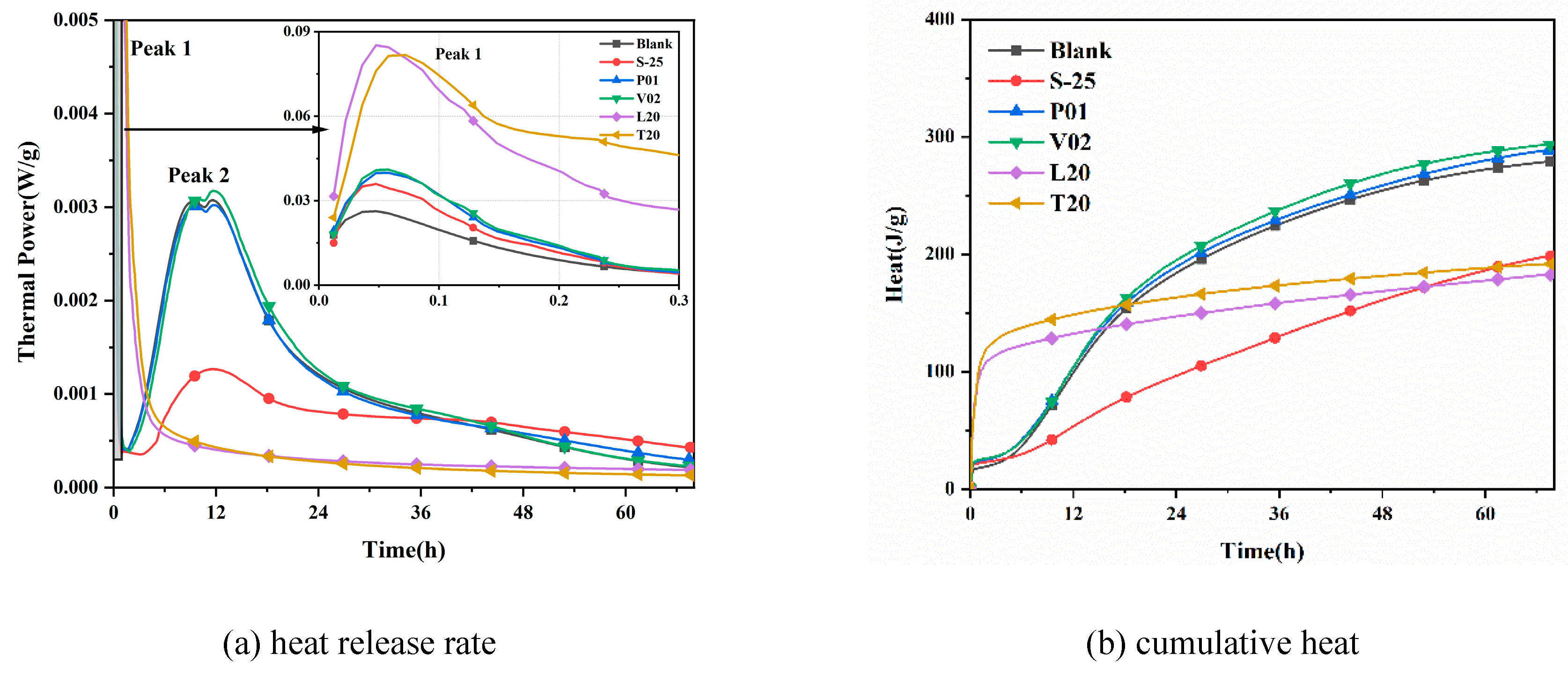

3.2.1. Effect of single interface agent on the heat of hydration of cement

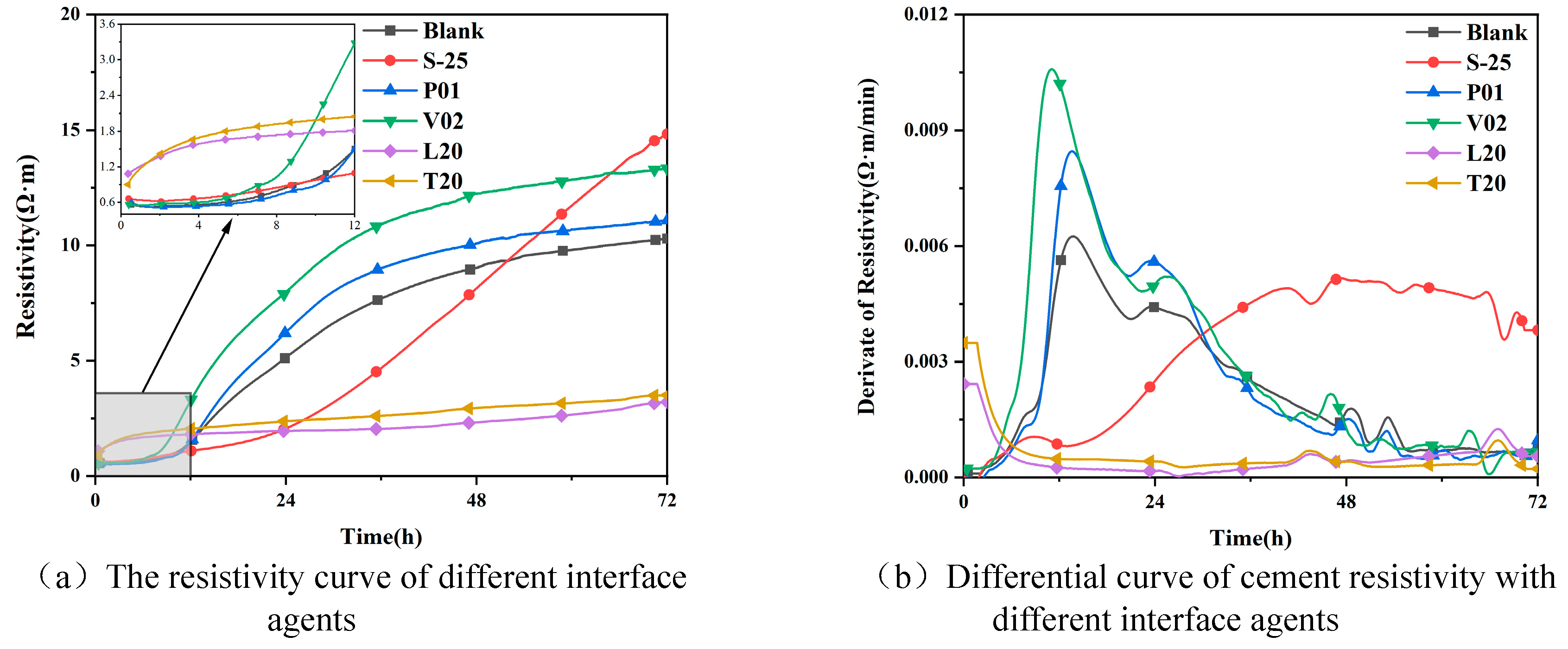

3.2.2. Effect of single interface agent on cement resistivity

3.3. Effect of different interfacial agents on core-shell lightweight aggregates

| Raw Materials | Bulk density / (kg/m3) | Crushing Strength/MPa | Literature |

| 73% coal gasification coarse slag, 15% cement, 1% plaster/NaCl/Al2(SO4)3 | 651 | 1.00 | [37] |

| Titanium slag, sodium silicate | 668 | 3.67 | [38] |

| 71% fly ash, 10% cement, 10% lime, 7% pearlite powder, 2% pore foaming materials | 699 | 3.99 | [39] |

| 2mm~4mm expanded pearlite, fly ash, cement | 500~650 | 2.0~2.7 | [40] |

| Cement, silica fume | 550~608 | 3.1~3.5 | [41] |

4. Conclusion

- With the use of polymer binder as an EPS-cement interface agent, the WER of EPS can be reduced from 10% to 1.25%; the use of an organic acid interface agent can make the EPS initial shell WER from 10% to 0%, pretreatment effect is better.

- Polymer binder treatment EPS-cement microscopic interface is not dense; an organic acid interface agent can make EPS surface corrosion out of uniformly distributed microporous, and the Acetic acid corrosion effect is better than Acrylic acid. 2% VAE emulsion and 20% Acetic acid compound EPS-cement interface at the cement hydration products and EPS surface connection dense, and magnification 2000 times EPS-cement interface without obvious delamination phenomenon.

- Similar patterns can be obtained by using induction resistivity experiments and heat of hydration experiments to study the hydration process. The addition of sodium silicate with modulus 2.5 slows down the process of cement hydration reaction; the binder has little effect on cement hydration; the organic acid interface agent has a hindering effect on cement hydration.

- Prepared by different interface agents core-shell lightweight aggregate, WER of sodium silicate modified EPS is higher, and the mechanical properties of them are lower; mechanical properties of binder and sodium silicate compound group are better, especially the group of VAE emulsion and sodium silicate compound, the bulk density of about 650 kg/m3 core-shell lightweight aggregate have a 28d numerical tube pressure of up to 5.7MPa; organic acid type interface agent added, the WER of EPS initial is lower, EPS cement micro-interfacial properties are better, the fall resistance is significantly improved, but affects the hydration process of the cement so that its overall crushing resistance is reduced instead.

- CSLA in this research did not require sintering process and had a at least 42.5% increase in the crushing strength compared with other cold-bonding lightweight aggregates and had a at least 34.5% decrease in bulk density compared with other cold-bonding lightweight aggregates.

Author Contributions

Funding

Conflicts of Interest

References

- Petrella, A.; Di Mundo, R.; Notarnicola, M. Recycled Expanded Polystyrene as Lightweight Aggregate for Environmentally Sustainable Cement Conglomerates. Materials 2020, 13. [Google Scholar] [CrossRef] [PubMed]

- Dixit, A.; Pang, S.D.; Kang, S.H.; Moon, J. Lightweight Structural Cement Composites with Expanded Polystyrene (EPS) for Enhanced Thermal Insulation. Cem Concr Compos 2019, 102, 185–197. [Google Scholar] [CrossRef]

- Demirel, B. Optimization of the Composite Brick Composed of Expanded Polystyrene and Pumice Blocks. Constr Build Mater 2013, 40, 306–313. [Google Scholar] [CrossRef]

- Wang, G.; Bai, S. Synergistic Effect of Expandable Graphite and Melamine Phosphate on Flame-Retardant Polystyrene. J Appl Polym Sci 2017, 134. [Google Scholar] [CrossRef]

- Cao, B.; Gu, X.; Song, X.; Jin, X.; Liu, X.; Liu, X.; Sun, J.; Zhang, S. The Flammability of Expandable Polystyrene Foams Coated with Melamine Modified Urea Formaldehyde Resin. J Appl Polym Sci 2017, 134. [Google Scholar] [CrossRef]

- Wang, L.; Wang, C.; Liu, P.; Jing, Z.; Ge, X.; Jiang, Y. The Flame Resistance Properties of Expandable Polystyrene Foams Coated with a Cheap and Effective Barrier Layer. Constr Build Mater 2018, 176, 403–414. [Google Scholar] [CrossRef]

- Ali, Y.A.Y.; Fahmy, E.H.A.; AbouZeid, M.N.; Shaheen, Y.B.I.; Mooty, M.N.A. Use of Expanded Polystyrene Wastes in Developing Hollow Block Masonry Units. Constr Build Mater 2020, 241. [Google Scholar] [CrossRef]

- Kan, A.; Demirboǧa, R. A Novel Material for Lightweight Concrete Production. Cem Concr Compos 2009, 31, 489–495. [Google Scholar] [CrossRef]

- Chung, S.Y.; Abd Elrahman, M.; Stephan, D. Effects of Expanded Polystyrene (EPS) Sizes and Arrangements on the Properties of Lightweight Concrete. Materials and Structures/Materiaux et Constructions 2018, 51. [Google Scholar] [CrossRef]

- PANG, C.; LYU, M. A Method for Preparing Core-Shell Type Cement-Based High-Strength Lightweight Aggregate 2016.

- Pang, C.; Zhang, C.; Meng, X.; Pan, J. Preparation of Novel Core-Shell Non-Sintered Lightweight Aggregate and Its Application in Wallboard for Better Properties. Journal Wuhan University of Technology, Materials Science Edition 2022, 37, 840–848. [Google Scholar] [CrossRef]

- Feng, Y.; Qin, D.; Li, L.; Li, Y.; Wang, C.; Wang, P.Y. EVA Enhances the Interfacial Strength of EPS Concrete: A Molecular Dynamics Study. J Exp Nanosci 2021, 16, 383–397. [Google Scholar] [CrossRef]

- Chen, R.; Zeng, Z.; Zhou, K. A Review on the Research of Concrete with Expanded Polystyrene Beads as Aggregate. In Proceedings of the Advanced Materials Research; 2012; Vol. 374–377, pp. 1598–1601.

- Plank, J.; Gretz, M. Study on the Interaction between Anionic and Cationic Latex Particles and Portland Cement. Colloids Surf A Physicochem Eng Asp 2008, 330, 227–233. [Google Scholar] [CrossRef]

- Ohama, Y. 4 - Properties of Latex-Modified Systems. In Handbook of Polymer-Modified Concrete and Mortars; Ohama, Y., Ed.; William Andrew Publishing: Park Ridge, NJ, 1995; pp. 45–156. ISBN 978-0-8155-1358-2. [Google Scholar]

- Maranhão, F.L.; John, V.M. Bond Strength and Transversal Deformation Aging on Cement-Polymer Adhesive Mortar. Constr Build Mater 2009, 23, 1022–1027. [Google Scholar] [CrossRef]

- Pascal, S.; Alliche, A.; Pilvin, P. Mechanical Behaviour of Polymer Modified Mortars. Materials Science and Engineering A 2004, 380, 1–8. [Google Scholar] [CrossRef]

- Silva, D.A.; Roman, H.R.; Gleize, P.J.P. Evidences of Chemical Interaction between EVA and Hydrating Portland Cement. Cem Concr Res 2002, 32, 1383–1390. [Google Scholar] [CrossRef]

- WU, J.; PAN, G.; LIAO, L. Performance Study of Composite Modified EPS Particle Insulation Mortar. Jiangsu Building Materials 2008, 22–24. [Google Scholar]

- Laukaitis, A.; Žurauskas, R.; Keriene, J. The Effect of Foam Polystyrene Granules on Cement Composite Properties. Cem Concr Compos 2005, 27, 41–47. [Google Scholar] [CrossRef]

- CHEN, X.; DONG, J. Relationship between EPS Modification Method and Mechanical Properties of Cement-Based Material. Concrete 2013, 284, 13. [Google Scholar]

- Wang, R.; Wang, P.M.; Li, X.G. Physical and Mechanical Properties of Styrene-Butadiene Rubber Emulsion Modified Cement Mortars. Cem Concr Res 2005, 35, 900–906. [Google Scholar] [CrossRef]

- Alselwi, O.; Li, B.X.; Liu Yue, S.; Zhi wen, W. Efficacy of Sodium Alginate, Xanthan Gum, and Diatomite Admixtures in Improving the Strength and Shrinkage Behaviour of EPS Lightweight Concrete. European Journal of Environmental and Civil Engineering 2022. [CrossRef]

- Wang, L.; Wang, J.; Qian, X.; Chen, P.; Xu, Y.; Guo, J. An Environmentally Friendly Method to Improve the Quality of Recycled Concrete Aggregates. Constr Build Mater 2017, 144, 432–441. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.; Qian, X.; Chen, P.; Xu, Y.; Guo, J. An Environmentally Friendly Method to Improve the Quality of Recycled Concrete Aggregates. Constr Build Mater 2017, 144, 432–441. [Google Scholar] [CrossRef]

- Prajapati, R.; Gettu, R.; Singh, S. Thermomechanical Beneficiation of Recycled Concrete Aggregates (RCA). Constr Build Mater 2021, 310. [Google Scholar] [CrossRef]

- Ramli Sulong, N.H.; Mustapa, S.A.S.; Abdul Rashid, M.K. Application of Expanded Polystyrene (EPS) in Buildings and Constructions: A Review. J Appl Polym Sci 2019, 136. [Google Scholar] [CrossRef]

- Luukkonen, T.; Sreenivasan, H.; Abdollahnejad, Z.; Yliniemi, J.; Kantola, A.; Telkki, V.V.; Kinnunen, P.; Illikainen, M. Influence of Sodium Silicate Powder Silica Modulus for Mechanical and Chemical Properties of Dry-Mix Alkali-Activated Slag Mortar. Constr Build Mater 2020, 233, 117354. [Google Scholar] [CrossRef]

- Gharzouni, A.; Joussein, E.; Samet, B.; Baklouti, S.; Rossignol, S. Effect of the Reactivity of Alkaline Solution and Metakaolin on Geopolymer Formation. J Non Cryst Solids 2015, 410, 127–134. [Google Scholar] [CrossRef]

- DONG, J.; CAO, J.; LI, Y. Experimental Study on Interface Modification of EPS Cement Matrix Composites. Journal of Building Materials 2019.

- Scrivener, K.L.; Juilland, P.; Monteiro, P.J.M. Advances in Understanding Hydration of Portland Cement. Cem Concr Res 2015, 78, 38–56. [Google Scholar] [CrossRef]

- Pan, Z.; Wang, S.; Liu, Y.; Li, B.; Jia, Z.; Zhang, Y.; Wang, J. The Hydration, Pore Structure and Strength of Cement-Based Material Prepared with Waste Soaking Solution from Acetic Acid Treatment of Regenerated Aggregates. J Clean Prod 2019, 235, 866–874. [Google Scholar] [CrossRef]

- Nguyen, D.D.; Devlin, L.P.; Koshy, P.; Sorrell, C.C. Effects of Acetic Acid on Early Hydration of Portland Cement. J Therm Anal Calorim 2016, 123, 489–499. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, Y.; Wang, K.; Bu, Y.; Wang, C.; Ma, C.; Liu, H. Delaying the Hydration of Portland Cement by Sodium Silicate: Setting Time and Retarding Mechanism. Constr Build Mater 2019, 205, 543–548. [Google Scholar] [CrossRef]

- McCarter, W.J.; Chrisp, T.M.; Starrs, G.; Blewett, J. Characterization and Monitoring of Cement-Based Systems Using Intrinsic Electrical Property Measurements. Cem Concr Res 2003, 33, 197–206. [Google Scholar] [CrossRef]

- Dong, X.; Wang, S.; Gong, C.; Lu, L. Effects of Aggregate Gradation and Polymer Modifiers on Properties of Cement-EPS/Vitrified Microsphere Mortar. Constr Build Mater 2014, 73, 255–260. [Google Scholar] [CrossRef]

- Zhang, K; Liu, S; Zhang R; Wang, S; Liu, H; Shi, Z. Research on preparation of non-sintered ceramsite from gasification cinder and its performance. Coal Science and Technology 2018, 46, 222–227.

- Luo J. Preparation and properties of titanium slag sinter-free lightweight aggregates. 2017.

- Li M. Preparation of new type of non-burned ceramic and using it treating domestic sewage research. 2010.

- Tajra, F.; Elrahman, M.A.; Chung, S.Y.; Stephan, D. Performance Assessment of Core-Shell Structured Lightweight Aggregate Produced by Cold Bonding Pelletization Process. Constr Build Mater 2018, 179, 220–231. [Google Scholar] [CrossRef]

- Peng, X.; Zhou, Y.; Jia, R.; Wang, W.; Wu, Y. Preparation of Non-Sintered Lightweight Aggregates from Dredged Sediments and Modification of Their Properties. Constr Build Mater 2017, 132, 9–20. [Google Scholar] [CrossRef]

- Pang, C; Zhou, Y; Li, P; Zhang, C. Review on research status and development of non-sintered lightweight aggregate. Bulletin of the Chinese ceramic society 2022, 41, 1849–1860. [Google Scholar]

| No. | Type of interfacial agent | Pretreatment effect | WER of EPS/% | |||

| Disclosed quantity | More than 1/2 quantity | Less than 1/2 quantity | Undisclosed quantity | |||

| S-15 | Modulus 1.5 of sodium silicate | 0 | 6 | 9 | 5 | 33.75 |

| S-20 | Modulus 2 of sodium silicate | 0 | 1 | 12 | 7 | 18.75 |

| S-25 | Modulus 2.5 of sodium silicate | 0 | 0 | 8 | 12 | 10.0 |

| S-30 | Modulus 3 of sodium silicate | 1 | 8 | 10 | 1 | 40.0 |

| No. | Type of interfacial agent | Pretreatment effect | WER of EPS/% | |||

| Disclosed quantity | More than 1/2 quantity | Less than 1/2 quantity | Undisclosed quantity | |||

| P005 | 0.5% PVA emulsion | 0 | 0 | 6 | 15 | 7.5 |

| P01 | 1%PVA emulsion | 0 | 0 | 2 | 18 | 2.5 |

| P02 | 2% PVA emulsion | 0 | 0 | 1 | 19 | 1.25 |

| V01 | 1%VAE emulsion | 1 | 1 | 1 | 17 | 10.0 |

| V02 | 2%VAE emulsion | 0 | 0 | 2 | 18 | 2.5 |

| V05 | 5%VAE emulsion | 0 | 1 | 1 | 18 | 5.0 |

| V10 | 10%VAE emulsion | 0 | 1 | 2 | 18 | 6.25 |

| No. | Type of interfacial agent | Pretreatment effect | WER of EPS/% | |||

| Disclosed quantity | More than 1/2 quantity | Less than 1/2 quantity | Undisclosed quantity | |||

| L50 | 50wt% Acrylic acid | 0 | 0 | 0 | 20 | 0 |

| L20 | 20wt% Acrylic acid | 0 | 0 | 1 | 19 | 1.25 |

| L10 | 10wt% Acrylic acid | 0 | 1 | 2 | 17 | 6.25 |

| T50 | 50wt% Acetic acid | 0 | 0 | 2 | 18 | 2.5 |

| T20 | 20wt% Acetic acid | 0 | 0 | 3 | 17 | 3.75 |

| T10 | 10wt% Acetic acid | 0 | 1 | 4 | 15 | 7.5 |

| No. | Type of interfacial agent | 1m high drop integrity rate/% | 1.5m high drop integrity rate/% | 2m high drop integrity rate/% |

| S-25 | 10wt% sodium silicate solution | 75 | 70 | 65 |

| P01S25 | 1wt% PVA emulsion+10wt% sodium silicate solution | 85 | 85 | 75 |

| V02S25 | 2wt% VAE emulsion+10wt% sodium silicate solution | 80 | 75 | 75 |

| V02L02 | 2wt% VAE emulsion+20wt% Acrylic acid | 100 | 95 | 85 |

| V02T02 | 2wt% VAE emulsion+20wt% Acetic acid | 95 | 95 | 80 |

| No. | Bulk density /(kg/m3) |

Apparent density /(kg/m3) |

Water absorption /% | Single load-bearing capacity /N | Crushing Resistance/MPa | ||||

| 1h | 24h | 3d | 7d | 28d | 7d | 28d | |||

| S-25 | 612 | 1245 | 18.6 | 19.3 | 142 | 160 | 211 | 3.1 | 3.9 |

| P01S25 | 656 | 1311 | 17.1 | 17.8 | 221 | 244 | 313 | 4.5 | 5.5 |

| V02S25 | 647 | 1296 | 16.3 | 17.4 | 228 | 260 | 334 | 5.0 | 5.7 |

| V02L02 | 641 | 1289 | 16.9 | 18.5 | 161 | 186 | 246 | 3.8 | 4.6 |

| V02T02 | 650 | 1281 | 16.8 | 17.9 | 177 | 198 | 258 | 3.9 | 4.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).