Submitted:

03 April 2023

Posted:

03 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Motivation

1.2. Literature Review

1.3. Main Contributions

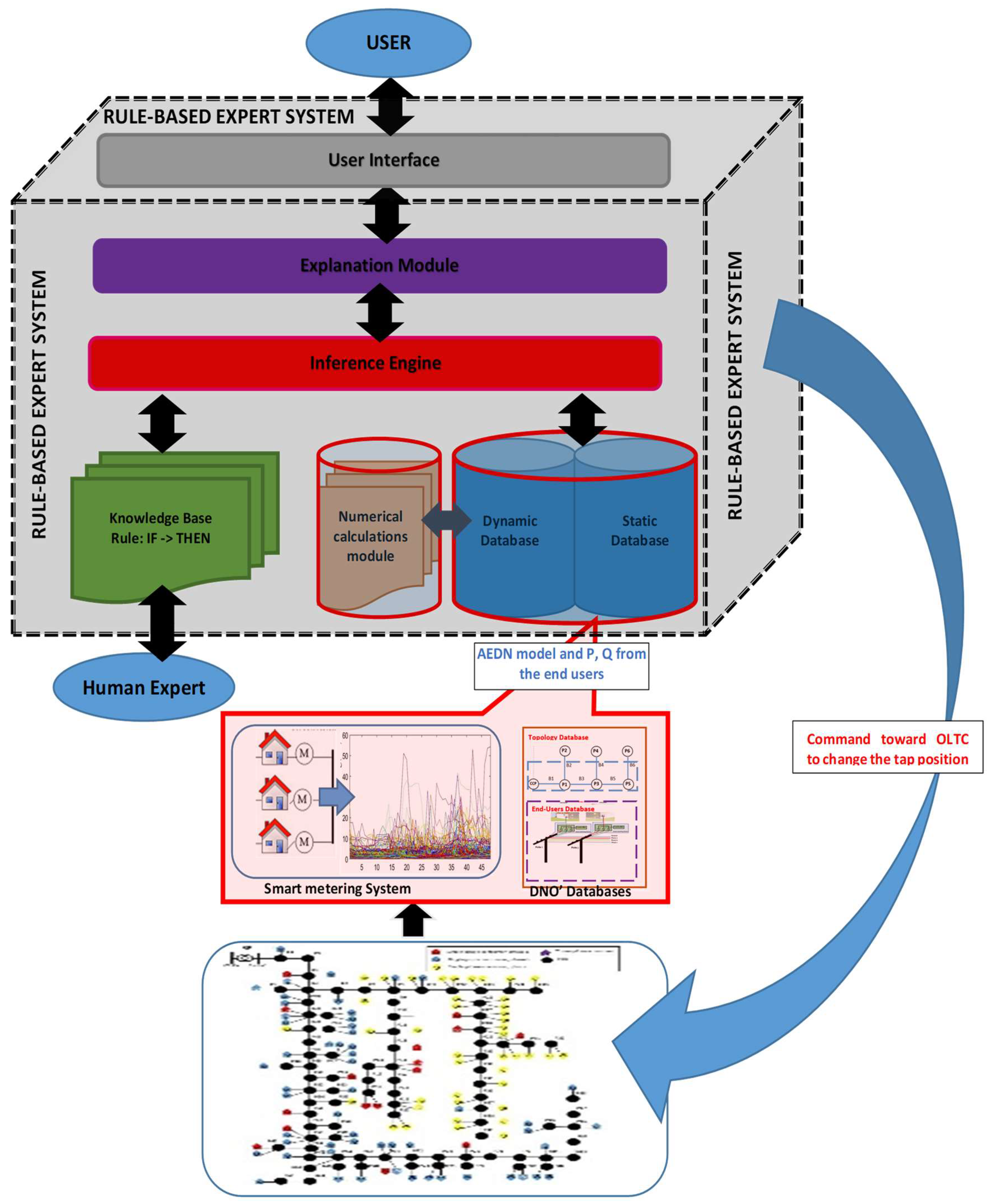

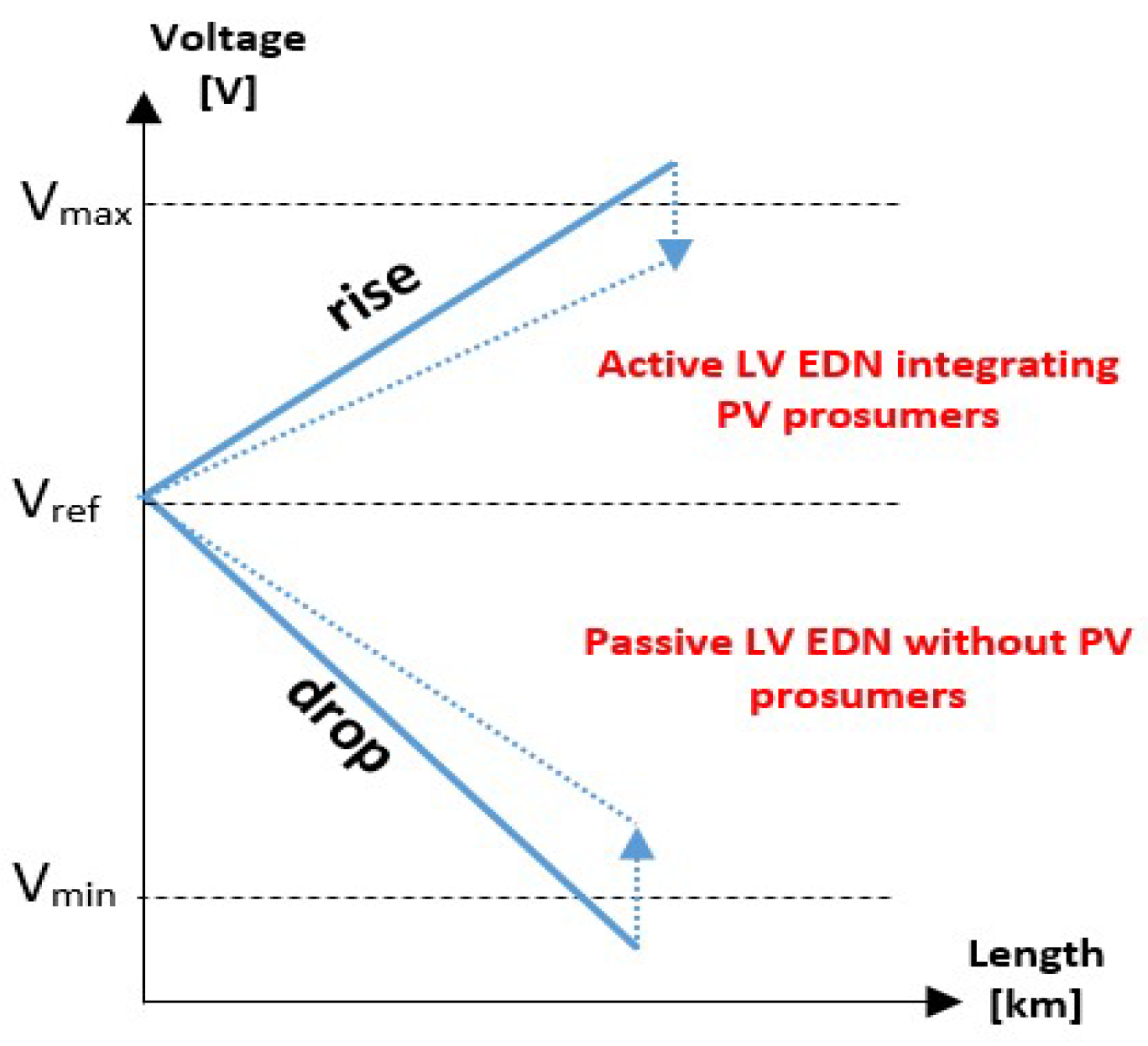

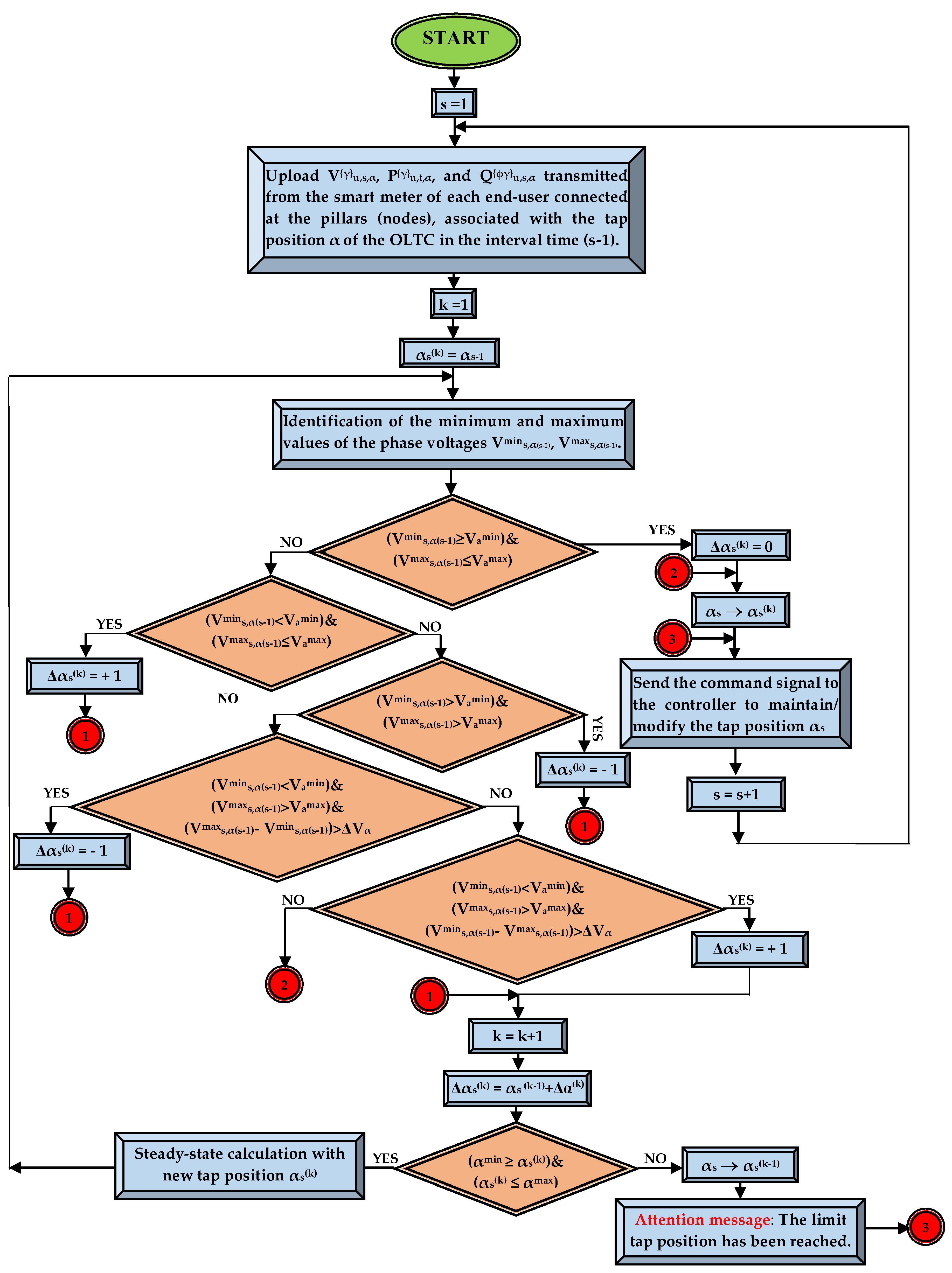

- Developing an expert system, including rule-based reasoning, with the main advantages: the "fast-scanning" of the input data, identification of voltage issues that come up, determination of a solution associated with the tap position of the OLTC that does not violate the voltage constraints in the PV-rich LV EDN based on the deviations between the reference voltage and the voltages recorded in the nodes in each time slot recognizing the excesses of the allowable limits, regardless of the power flow's direction. The main characteristics of the proposed system are efficiency and resilience. Efficiency has associated with the ability to meet the demands of the end-users regarding voltage quality. Regarding the second characteristic, it covers the capacity to respond to sudden voltage variations due to the intermittent regime of the PV prosumers.

- Designing a data management framework including a real-time query procedure that uploads data from the smart metering and network data systems and saves them in two partitions (static and dynamic) from the knowledge database. The design allows a high speed of data processing.

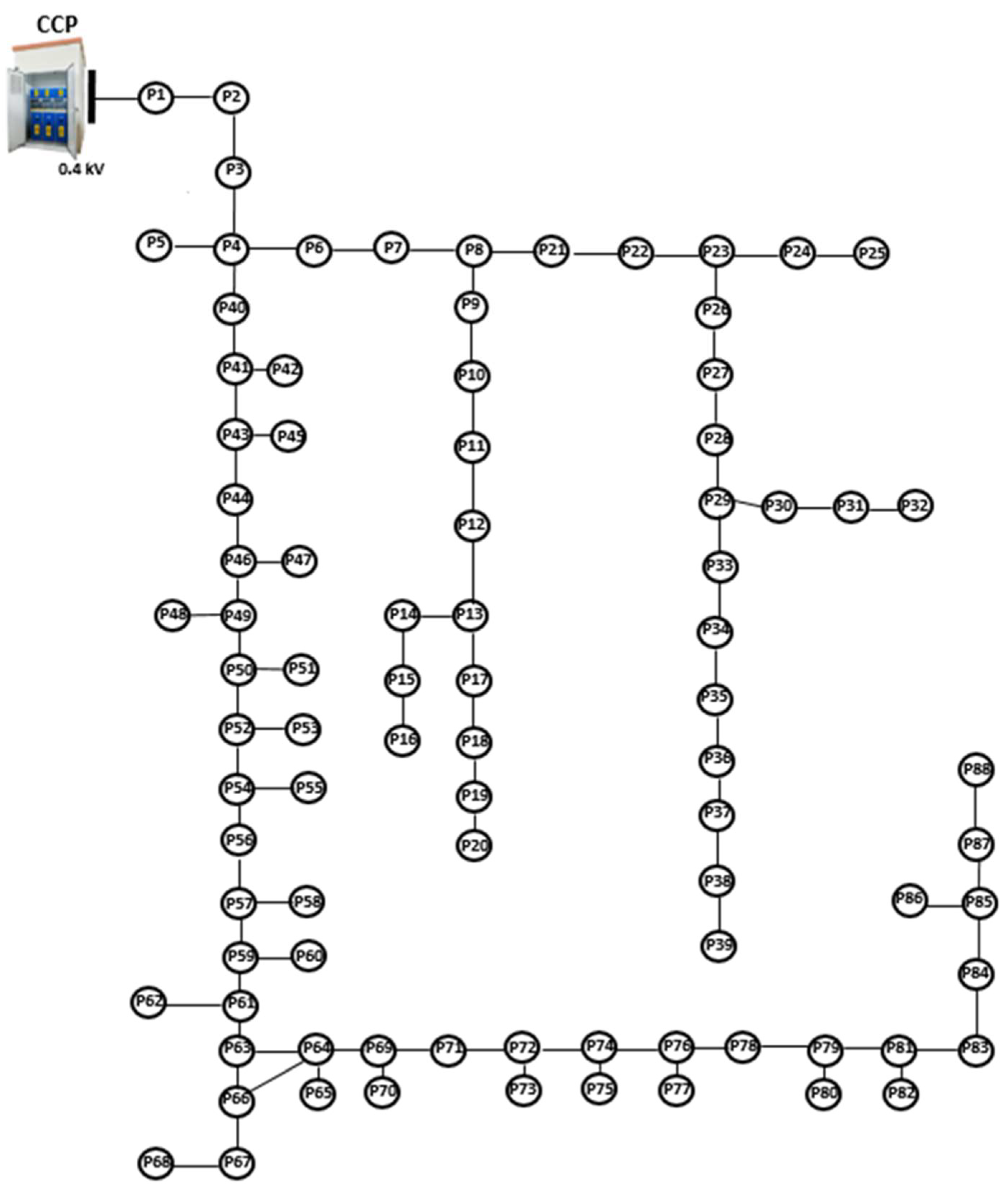

- Performing an in-depth analysis in a real LV EDN belonging to a Romanian DNO based on more scenarios characterized by the three indicators: penetration degree of the PV prosumers, consumption evolution associated with the consumers, and energy production of the PV systems installed to the prosumers. The number of combinations between the possible values of the three indicators led to 75 scenarios that cover all spectrums of the operating regimes of the LV EDNs.

1.4. Paper Organization

2. Materials and Methods

- line sections characterized by the input and end nodes, type (aerial/underground), cross-sections of the phase, and neutral conductors;

- MV/LV distribution transformers from the EDSs characterized by rated power, performance standards identified through the commissioning year, tap changer type (NLTC/OLTC), and tap positions;

- reactive power compensation devices identified through the installed capacity, type (capacitor banks or static VAR compensator) and their locations;

- energy storage systems are identified through the installed capacity and their locations.

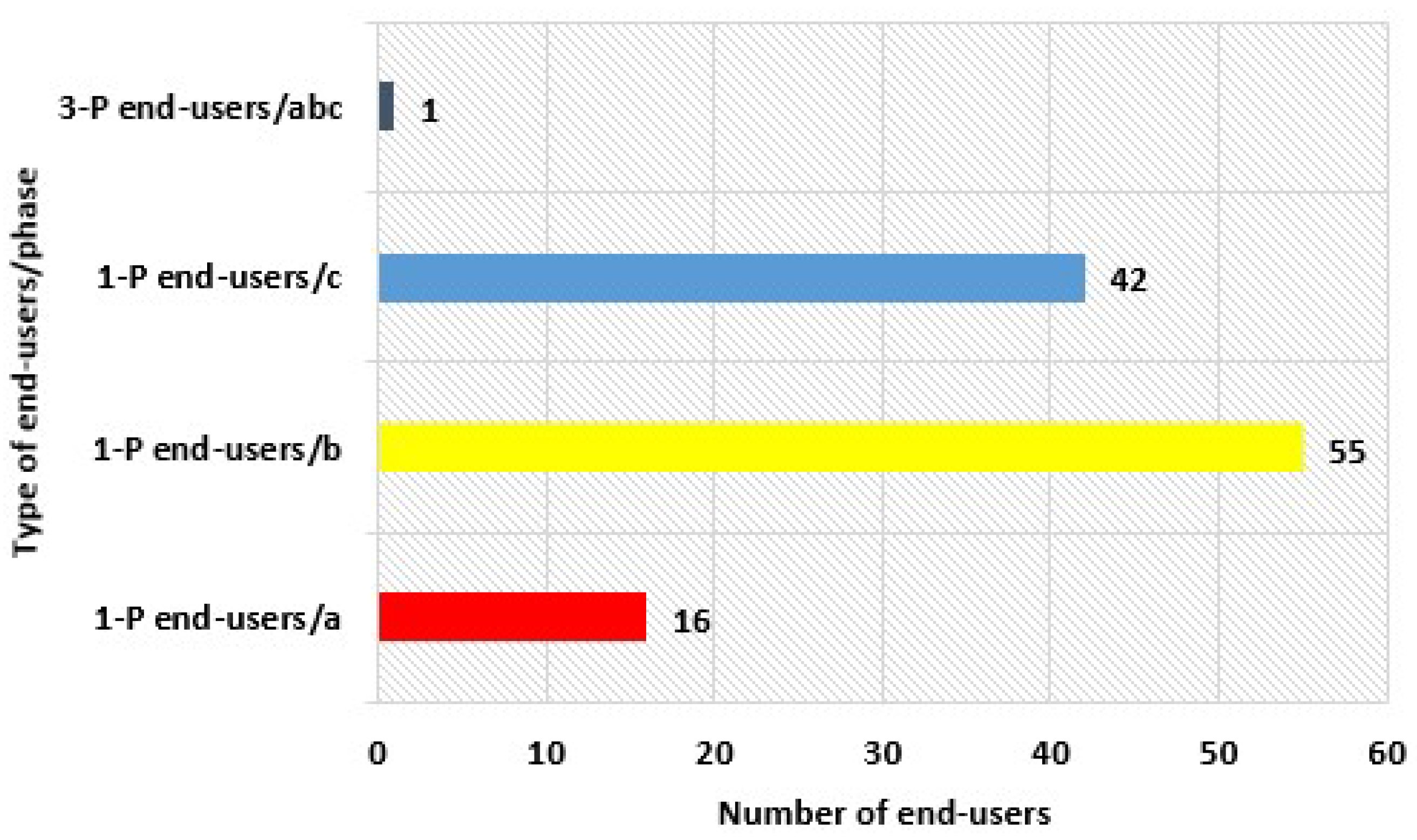

- end-users characterized by type (single-phase/three-phase), the location in the AEDNs (the connection pillars), the connection phase (for single-phase end-users);

- energy generation systems installed to the prosumers characterized by the installed capacity.

- upper and lower allowable limits of the voltages imposed by the quality power standards;

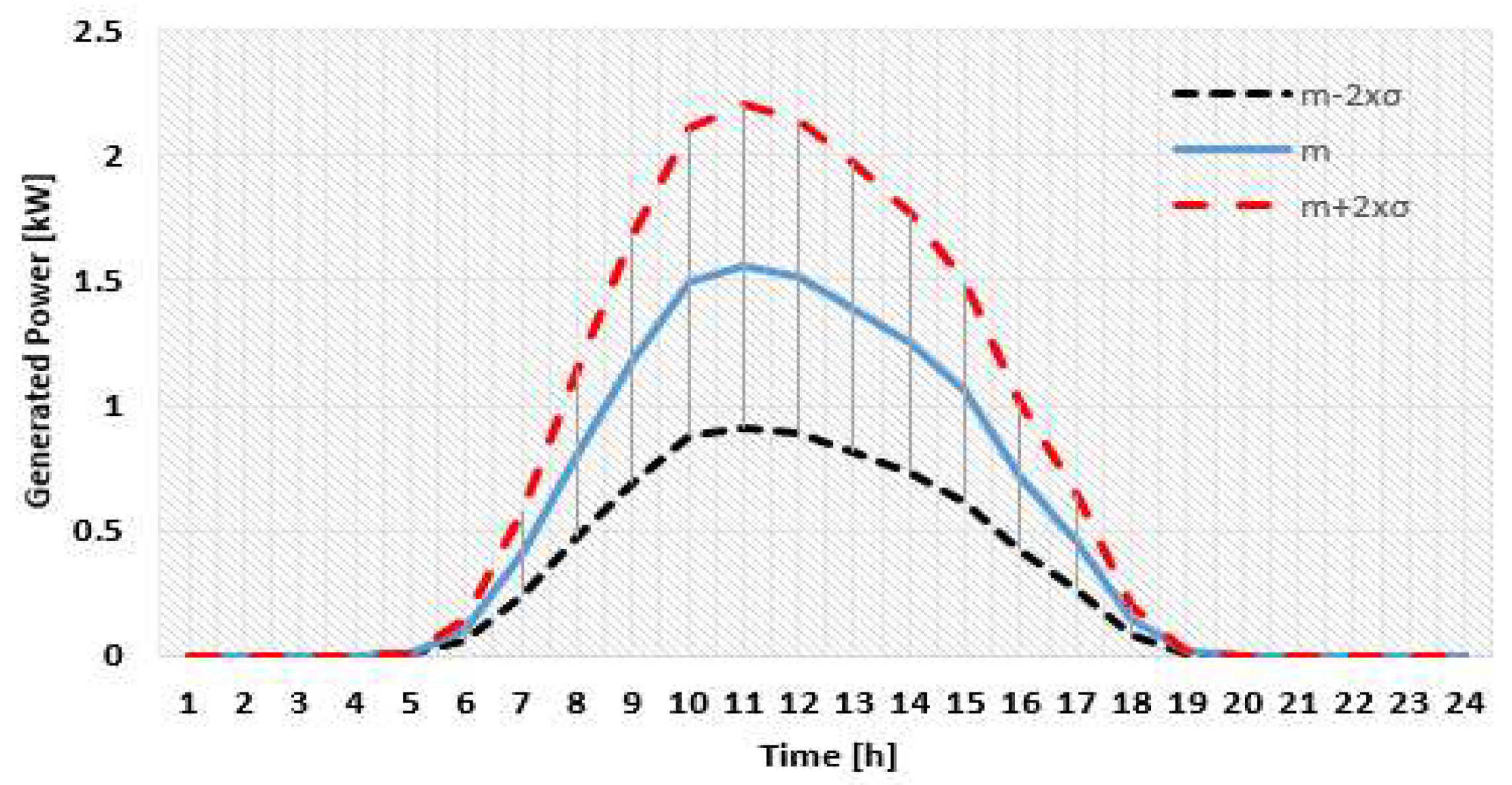

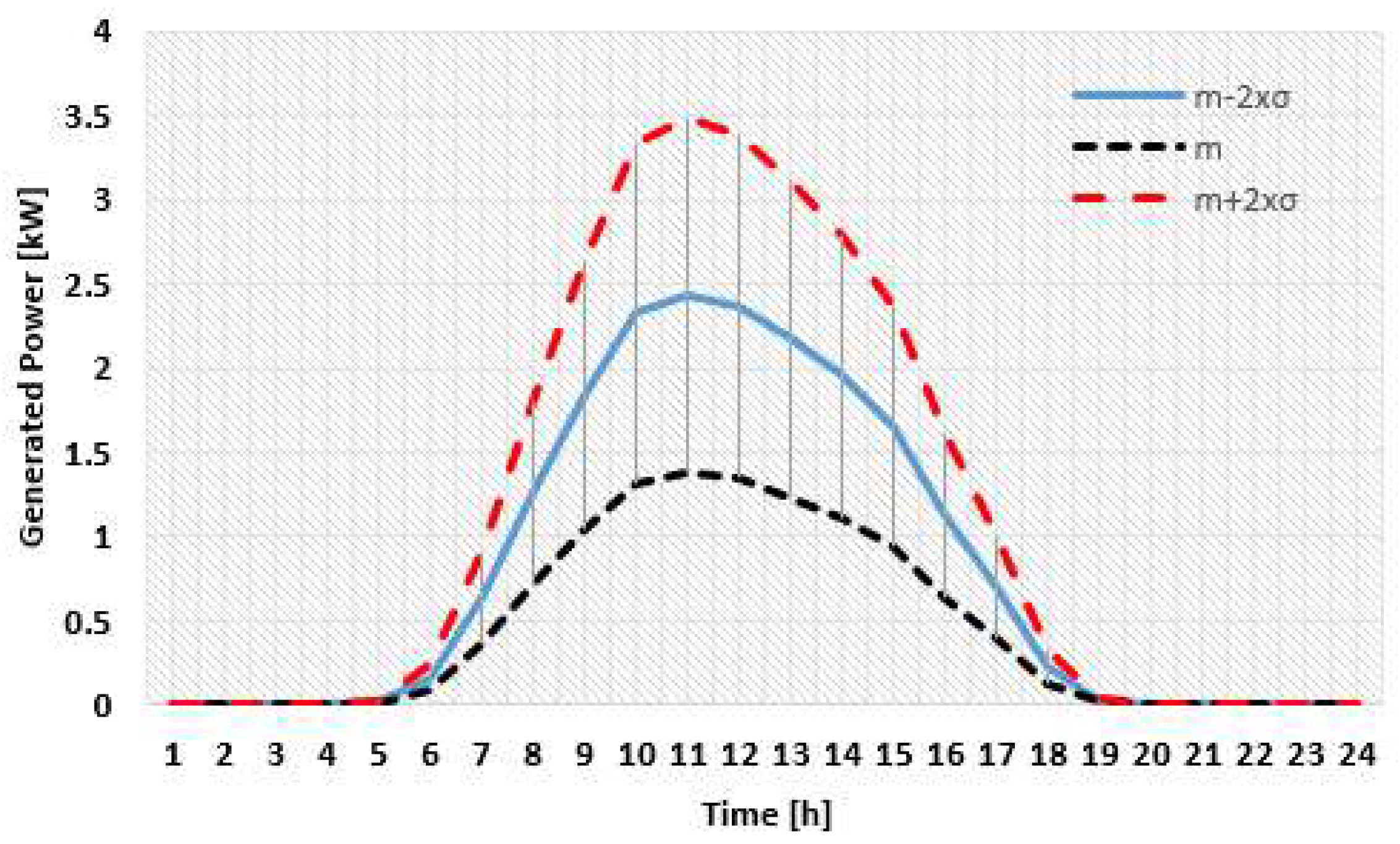

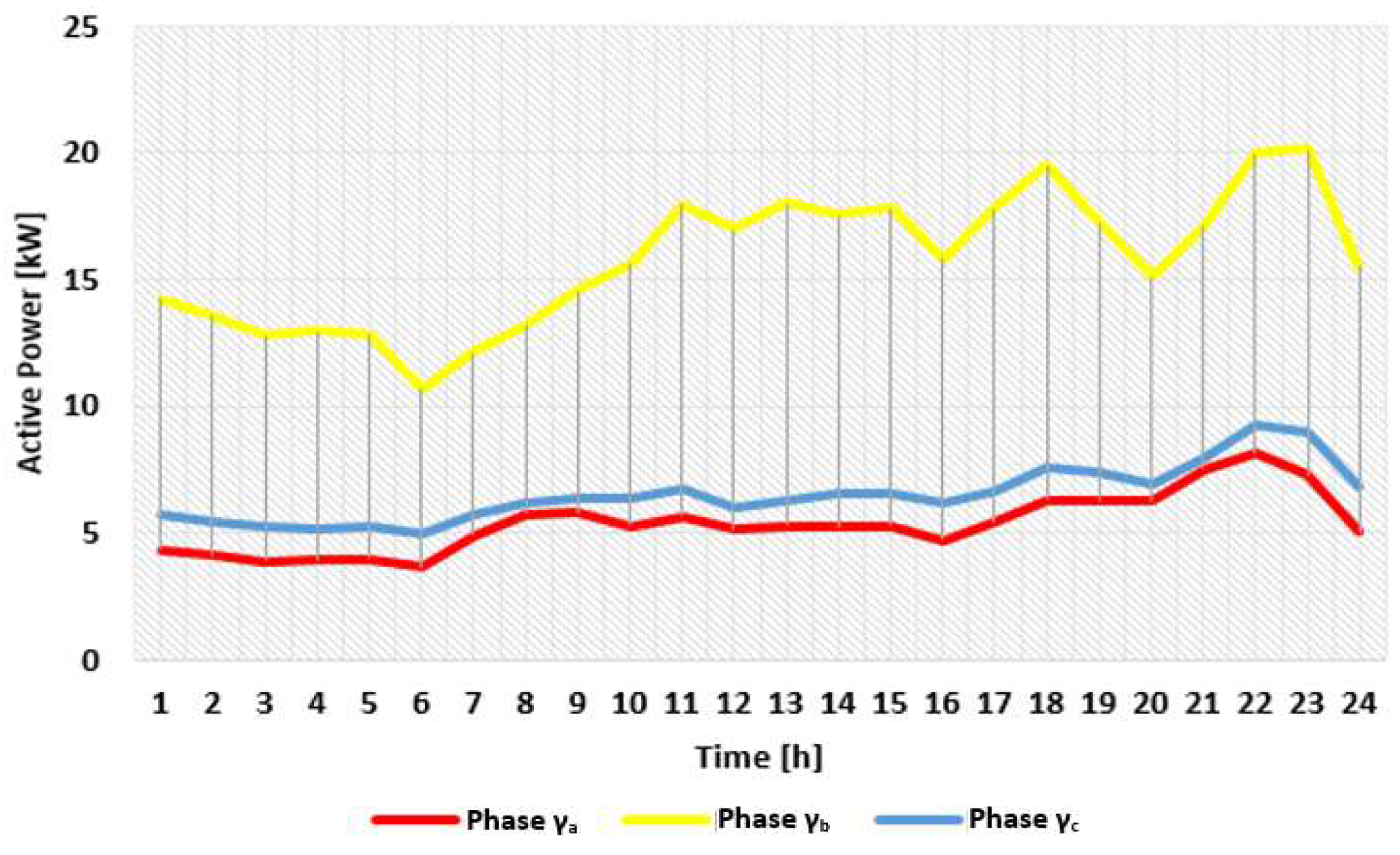

- information from the smart metering system associated with the injected/requested powers by the end-users (prosumers/consumers) at the fixed time slots (depending on setting the sampling step of the smart meters), the annual energy production/consumption;

- values of the nodal voltages, power flows, and power losses resulted from the steady-state calculations performed with a performance algorithm characterized by fast convergence and reduced calculation time considering the topology of the AEDNs identified through the data recorded in the static database at the request of the inference engine.

3. Results

- rated power, Sr = 250 kVA;

- load power loss, ΔPl = 2.35 kW;

- no-load power loss, ΔPnl = 0.27 kW;

- OLTC with 9 taps (tapping range ±10%), where the median tap is 5, voltage step 2.5%, and the number of tap operations without maintenance is 700,000 [43].

4. Discussions and conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Pillar | 0% | 10% | 20% | 30% | 40% | 50% | Pillar | 0% | 10% | 20% | 30% | 40% | 50% | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | P | C | P | C | P | C | P | C | P | C | P | C | P | C | P | C | P | C | P | C | P | C | P | ||||

| P1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | P41 | 3 | 0 | 3 | 0 | 3 | 0 | 3 | 0 | 2 | 1 | 2 | 1 | ||

| P3 | 2 | 0 | 2 | 0 | 1 | 1 | 1 | 1 | 0 | 2 | 0 | 2 | P42 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | ||

| P4 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | P43 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | ||

| P5 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | P45 | 2 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| P6 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | P46 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | ||

| P7 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | P47 | 5 | 0 | 3 | 2 | 2 | 3 | 2 | 3 | 0 | 5 | 0 | 5 | ||

| P8 | 2 | 0 | 2 | 0 | 2 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | P48 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | ||

| P10 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | P51 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | ||

| P11 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 1 | 1 | 1 | 1 | P52 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | ||

| P12 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | P53 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | ||

| P13 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | P55 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | ||

| P16 | 2 | 0 | 2 | 0 | 2 | 0 | 1 | 1 | 1 | 1 | 0 | 2 | P56 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | ||

| P19 | 2 | 0 | 2 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | P58 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | ||

| P20 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | P59 | 3 | 0 | 2 | 1 | 0 | 3 | 0 | 3 | 0 | 3 | 0 | 3 | ||

| P21 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 1 | 1 | P60 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | ||

| P22 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 1 | 1 | P61 | 2 | 0 | 2 | 0 | 1 | 1 | 0 | 2 | 0 | 2 | 0 | 2 | ||

| P23 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 1 | 1 | P62 | 2 | 0 | 2 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| P24 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | P63 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | ||

| P25 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | P65 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | ||

| P26 | 4 | 0 | 4 | 0 | 4 | 0 | 3 | 1 | 3 | 1 | 1 | 3 | P68 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | ||

| P27 | 3 | 0 | 3 | 0 | 2 | 1 | 2 | 1 | 2 | 1 | 0 | 3 | P69 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | ||

| P28 | 3 | 0 | 3 | 0 | 3 | 0 | 3 | 0 | 3 | 0 | 2 | 1 | P71 | 4 | 0 | 4 | 0 | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | ||

| P30 | 3 | 0 | 1 | 2 | 1 | 2 | 1 | 2 | 0 | 3 | 0 | 3 | P72 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | ||

| P31 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | P73 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | ||

| P32 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 1 | 1 | 1 | 1 | P75 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | ||

| P33 | 2 | 0 | 2 | 0 | 2 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | P76 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | ||

| P34 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | P77 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | ||

| P35 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | P80 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | ||

| P36 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 1 | 1 | P81 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | ||

| P37 | 2 | 0 | 2 | 0 | 1 | 1 | 0 | 2 | 0 | 2 | 0 | 2 | P82 | 2 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | ||

| P38 | 3 | 0 | 3 | 0 | 3 | 0 | 2 | 1 | 2 | 1 | 2 | 1 | P85 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | ||

| P39 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | P86 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 1 | 1 | 1 | 1 | ||

| P40 | 2 | 0 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | 0 | 2 | P88 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | ||

| *C – consumer; P - prosumer | |||||||||||||||||||||||||||

| CEC [%] |

PD [%] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | |||||||||||

| EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | |

| -10 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 4 | 10 | 0 | 8 | 14 | 4 | 13 | 14 |

| -5 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 4 | 12 | 0 | 10 | 14 | 4 | 13 | 14 |

| 0 | 0 | 0 | 0 | 0 | 0 | 3 | 0 | 3 | 11 | 0 | 7 | 13 | 7 | 11 | 13 |

| 5 | 0 | 0 | 0 | 0 | 0 | 3 | 0 | 3 | 9 | 0 | 7 | 13 | 5 | 11 | 13 |

| 10 | 0 | 0 | 0 | 0 | 0 | 7 | 0 | 7 | 13 | 0 | 11 | 17 | 9 | 15 | 17 |

| CEC [%] |

PD [%] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | |||||||||||

| EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | |

| -10 | 0 | 0 | 0 | 0 | 0 | 8 | 0 | 8 | 14 | 0 | 12 | 14 | 10 | 14 | 14 |

| -5 | 0 | 0 | 0 | 0 | 0 | 8 | 0 | 8 | 14 | 0 | 12 | 14 | 8 | 14 | 14 |

| 0 | 0 | 0 | 0 | 0 | 0 | 7 | 0 | 7 | 13 | 0 | 11 | 13 | 7 | 13 | 13 |

| 5 | 0 | 0 | 0 | 0 | 0 | 7 | 0 | 7 | 11 | 0 | 11 | 13 | 7 | 13 | 13 |

| 10 | 0 | 0 | 0 | 0 | 0 | 11 | 0 | 11 | 15 | 0 | 13 | 17 | 11 | 17 | 17 |

References

- Spertino, F.; Ciocia, A.; Mazza, A.; Nobile, M.; Russo, A.; Chicco, G. Voltage Control in Low Voltage Grids with Independent Operation of On-Load Tap Changer and Distributed Photovoltaic Inverters. Electric Power Systems Research 2022, 211, 108187. [CrossRef]

- Li, C.; Disfani, V,; Pecenak, Z.; Mohajeryami, S.; Kleissl, J. Optimal OLTC Voltage Control Scheme to Enable High Solar Penetrations. Electric Power Systems Research 2018, 160, 318-326. [CrossRef]

- Yuan, J.; Weng, Yang; Tan, Chin-Woo. Determining Maximum Hosting Capacity for PV Systems in Distribution Grids. International Journal of Electrical Power & Energy Systems 2022, 135, 107342. [CrossRef]

- Fatima, S.; Püvi, V.; Lehtonen, M. Review on the PV Hosting Capacity in Distribution Networks. Energies 2020, 13, 4756. [CrossRef]

- Majeed, I.B.; Nwulu, N.I. Impact of Reverse Power Flow on Distributed Transformers in a Solar-Photovoltaic-Integrated Low-Voltage Network. Energies 2022, 15, 9238. [CrossRef]

- Noroc, L.; Grigoras, G.; Dandea, V.; Chelaru, E.; and Neagu, B An Efficient Voltage Control Methodology in LV Networks Integrating PV Prosumers Using Distribution Transformers with OLTC. . In Proceedings of the IEEE 20th International Power Electronics and Motion Control Conference (PEMC), Brasov, Romania, 25 – 28 September 2022.

- Sarimuthu, C.; Ramachandaramurthy, V.; Agileswari, K.R.; Mokhlis, H. A Review on Voltage Control Methods Using On-Load Tap Changer Transformers for Networks with Renewable Energy Sources. Renewable and Sustainable Energy Reviews 2016, 62(C), 1154-1161. [CrossRef]

- Belaid, Y.N.; Coudray, P.; Sanchez-Torres, J.; Fang, Y.; Zeng, Z. et al.. Resilience Quantification of Smart Distribution Networks-A Bird’s Eye View Perspective. Energies 2021, 14, 2888. [CrossRef]

- Bedawy, A.; Yorino, N.; Mahmoud, K.; Management of Voltage Regulators in Unbalanced Distribution Networks Using Voltage/Tap Sensitivity Analysis. In Proceedings of the International Conference on Innovative Trends in Computer Engineering, Aswan, Egypt, 19 - 21 February 2018.

- Liu, Y.; Guo, L.; Lu, C.; Chai, Y. Gao, S.; Xu, B. A Fully Distributed Voltage Optimization Method for Distribution Networks Considering Integer Constraints of Step Voltage Regulators. IEEE Access 2019, 7, 60055-60066. [CrossRef]

- Li, X.; Wang, L; Yan, N.; Ma, R. Cooperative Dispatch of Distributed Energy Storage in Distribution Network with PV Generation Systems. IEEE Transactions on Applied Superconductivity 2021, 31, 1-4. [CrossRef]

- Wang, S.; Gao, S.; Niu, X.; Chen, J. The influence of multi-level energy storage on the access of distributed renewable energy. In Proceedings of the 5th Asia Conference on Power and Electrical Engineering (ACPEE), Chengdu, China, 4 – 7 June 2020.

- Leghari, Z.H.; Kumar, M.; Shaikh, P.H.; Kumar, L.; Tran, Q.T. A Critical Review of Optimization Strategies for Simultaneous Integration of Distributed Generation and Capacitor Banks in Power Distribution Networks. Energies 2022, 15, 8258. [CrossRef]

- Sadeghian, O.; Oshnoei, A.; Kheradmandi, M.; Mohammadi-Ivatloo, B. Optimal Placement of Multi-Period-Based Switched Capacitor in Radial Distribution Systems. Computers & Electrical Engineering 2020, 82, 106549. [CrossRef]

- Grigoraș, G.; Noroc, L.; Chelaru, E.; Scarlatache, F.; Neagu, B.-C.; Ivanov, O.; Gavrilaș, M. Coordinated Control of Single-Phase End-Users for Phase Load Balancing in Active Electric Distribution Networks. Mathematics 2021, 9, 2662. [CrossRef]

- Tenti, P.; Caldognetto, T. Integration of Local and Central Control Empowers Cooperation among Prosumers and Distributors towards Safe, Efficient, and Cost-Effective Operation of Microgrids. Energies 2023, 16, 2320. [CrossRef]

- Soe, N.N; Lwin, K.S.; Advance OLTC Control for Improving Power System Voltage Stability. International Journal of Scientific Engineering and Technology Research 2014, 3, 2487-2493.

- Rogers, D., Green, T. Silversides, R. A Low-Wear Onload Tap Changer Diverter Switch for Frequent Voltage Control on Distribution Networks. IEEE Transactions on Power Delivery 2013, 99, 1-10. [CrossRef]

- Procopiou A. T.; Ochoa, L.F. Voltage Control in PV-Rich LV Networks Without Remote Monitoring, IEEE Trans. Power Syst. 2017, 32, 1224–1236. [CrossRef]

- Heinrich, C.; Fortenbacher, P.; Fuchs, A. Andersson, G. PV Integration Strategies for Low Voltage Networks. In Proceedings of the IEEE Int. Energy Conf. (ENERGYCON), Leuven, Belgium, April 2016.

- Weisshaupt, M.J.; Schlatter, B.; Korba, P.; Kaffe, E.; Kienzle, F. Evaluation of Measures to Operate Urban Low Voltage Grids Considering Future PV Expansion. IFAC-Papers-On-Line 2016, 49, 336–341. [CrossRef]

- Feng, F.; Liu, Y.; Zhang, J. A Taxonomical Review on Recent Artificial Intelligence Applications to PV Integration into Power Grids. International Journal of Electrical Power & Energy Systems 2021, 132, 107176. [CrossRef]

- Rohit Trivedi, Shafi Khadem, Implementation of Artificial Intelligence Techniques in Microgrid Control Environment: Current Progress and Future Scopes. Energy and AI 2022, 8, 100147. [CrossRef]

- Mulenga, E., Bollen, M.; Etherden, N. Limits Set By Component Loadability on Solar Power Integration in Distribution Networks, Electric Power Systems Research 2022, 209, 107951. [CrossRef]

- Bendík, J.; Cenký, M.; Cintula, B.; Beláń, A.; Eleschová, Ž.; Janiga, P. Stochastic Approach for Increasing the PV Hosting Capacity of a Low-Voltage Distribution Network. Processes 2023, 11, 9. [CrossRef]

- Noroc, L.; Grigoras, G.; Chelaru, E.; Dandea, V.; Neagu, B. Voltage Control Strategy Using the Rule-Based Reasoning in LV Distribution Networks with PV Penetration Integrating OLTC-Fitted Transformer, In Proceedings of the International Conference and Exposition on Electrical And Power Engineering (EPE), Iasi, Romania, 29-22 October 2022.

- Cipcigan, L.M.; Taylor, P.C. Taylor Investigation of The Reverse Power Flow Requirements of High Penetrations Of Small-Scale Embedded Generation. IET Renew. Power Gener. 2007, 1, 160–166. [CrossRef]

- Yoon, K.-H.; Shin, J.-W.; Nam, T.-Y.; Kim, J.-C.; Moon, W.-S. Operation Method of On-Load Tap Changer on Main Transformer Considering Reverse Power Flow in Distribution System Connected with High Penetration on Photovoltaic System. Energies 2022, 15, 6473. [CrossRef]

- Neagu B. C.; Grigoras, G. Optimal Voltage Control in Power Distribution Networks Using an Adaptive On-Load Tap Changer Transformers Techniques," In Proceedings of the International Conference on Electromechanical and Energy Systems (SIELMEN), Craiova, Romania, 9 – 11 October 2019.

- Nakamura, M.; Yoshizawa, S.; Ishii, H. et al. Advanced Voltage Control Method for Improving the Voltage Quality of Low-Voltage Distribution Networks with Photovoltaic Penetrations. Energy Inform 2021, 4 (Suppl 2), 31.

- Lee, H.; Yu, W.; Oh, J.; Kim, H.; Kim, J. Development of an Intelligent Voltage Control System for Bulk Power Systems. Appl. Sci. 2021, 11, 9233. [CrossRef]

- Pimpa C. and Premrudeepreechacharn, S. Voltage control in power system using expert system based on SCADA system, In Proceeding of the 2002 IEEE Power Engineering Society Winter Meeting. Conference Proceedings, New York, NY, USA, 27 - 31 January 2002.

- Enemuo, F.O.; Chukwura O.I. An Enhanced Scheme for Detecting Under-Voltage and Over-Voltage Using Fuzzy Logic Based System in a Low Voltage Grid Network. International Research Journal of Engineering and Technology 2018, 5, 1334 - 1338.

- Mariaraja, P.; Manigandan, T.; Thiruvenkadam, S. An Expert System for Distribution System Reconfiguration through Fuzzy Logic and Flower Pollination Algorithm. Measurement and Control 2018, 51, 371-382. [CrossRef]

- Chen Y. and Zhang X., Voltage Balancing Method on Expert System for 51-Level MMC in High Voltage Direct Current Transmission. Mathematical Problems in Engineering 2016, 2016, 2968484.

- Perera, A. T. D.; Mauree, D.; Scartezzini J. -L.; Nik, V. M. Optimum Design and Control of Grid Integrated Electrical Hubs Considering Lifecycle Cost and Emission, In Proceedings of the 2016 IEEE International Energy Conference (ENERGYCON), Leuven, Belgium, 4 - 8 April 2016.

- Bennett, C.; Stewart, R.; Lu, J.W. Forecasting Low Voltage Distribution Network Demand Profiles Using a Pattern Recognition Based Expert System. Energy 2014, 67, 200-212. [CrossRef]

- Faia, R.; Pinto, T.; Abrishambaf, O.; Fernandes, F.; Vale, Z.; Corchado, J.M. Case Based Reasoning with Expert System and Swarm Intelligence to Determine Energy Reduction in Buildings Energy Management, Energy and Buildings 2017, 155, 269-281. [CrossRef]

- Kirgizov, A. K.; Dmitriev, S.A.; Safaraliev, M. Kh.; Pavlyuchenko, D. A.; Ghulomzoda, A. H.; Ahyoev, J. S. Expert System Application for Reactive Power Compensation in Isolated Electric Power Systems, International Journal of Electrical and Computer Engineering 2021, 11, 3682-3691. [CrossRef]

- Chelaru E. and Grigoraş G. Decision Support System to Determine the Replacement Ranking of the Aged Transformers in Electric Distribution Networks, 2020 12th International Conference on Electronics, Computers and Artificial Intelligence (ECAI), Bucharest, Romania, 25 – 27 June 2020.

- Grosan, C. and Abraham, A. Rule-Based Expert Systems. In: Intelligent Systems. Springer, Berlin, Heidelberg, 2011; Volume 17, pp. 149 – 185.

- Grigoras, G. and Neagu, B., Smart meter data-based three-stage algorithm to calculate power and energy losses in low voltage distribution networks, Energies 2019, 12, 3008. [CrossRef]

- Efkarpidis, N., Wijnhoven, T., Gonzalez, C. et. al., Coordinated voltage control scheme for Flemish LV distribution grids utilizing OLTC transformers and D-STATCOM's, In Proceedings of the IET Conference on Developments in Power System Protection, Copenhagen, Denmark, 31 March – 3 April 2014.

- Ciocia, A., Boicea, V., Chicco, G., Di Leo, P., Mazza, A., Pons, E., Spertino, F., Hadj-Said, N. Voltage Control in Low-Voltage Grids Using Distributed Photovoltaic Converters and Centralized Devices. IEEE Trans. on Ind. Appl. 2019, 55, 225 - 237. [CrossRef]

- Siemens, EU Requirements for Transformers Ecodesign Directive from the European Commission Tier 2 - July 1st, 2021, Available on-line: https://assets.siemens-energy.com/siemens/assets/api/uuid:796c2680-c8bb-4186-b338-245865d85a45/ ecodesignleaflet.pdf.

- Romanian Energy Regulatory Authority, "Report on monitoring the activities of prosumators in 2021 (in Romanian), 2022, Available on-line: www.anre.ro.

- Romanian Energy Regulatory Authority, Reports on the results of monitoring electricity markets (in Romanian), 2022, available on-line: www.anre.ro.

- Currel G. and Dowman A. Essential Mathematics and Statistics, 2nd ed., Publisher: John Wiley & Sons, Chichester, United Kingdom, 2009; pp. 211 – 242.

- Photovoltaic Geographical Information System - PVGIS, Available on-line: https://re.jrc.ec.europa.eu/pvg_tools/en/.

- Eurelectric, Power Quality in European Electricity Supply Networks, 2nd ed., Network of Experts for Standardization, 2003.

- Grigoras, G., Noroc, L., Chelaru, E., Scarlatache, F., Neagu, B.C., Ivanov, O., Gavrilas, M. Coordinated control of single-phase end-users for phase load balancing in active electric distribution networks. Mathematics 2021, 9, 2662. [CrossRef]

| Type of section |

Conductor | Type of conductor | Length [km] | ||

|---|---|---|---|---|---|

| Cross-section of phase conductor | Number of phases | Cross-section of neutral conductor | |||

| 1 | 50 | 3 | 50 | C* | 2.08 |

| 2 | 50 | 3 | 50 | S** | 0.12 |

| 3 | 35 | 3 | 35 | C* | 0.68 |

| 4 | 35 | 1 | 35 | C* | 0.28 |

| 5 | 25 | 1 | 25 | C* | 0.28 |

| 6 | 25 | 1 | 16 | C* | 0.08 |

| * C – classical conductor (aluminium conductor steel-reinforced cable) **S - Stranded conductor | |||||

| SC | PD [%] |

EPPV [kWh] |

CEC [%] |

SC | PD [%] |

EPPV [kWh] |

CEC [%] |

SC | PD [%] |

EPPV [kWh] |

CEC [%] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 10 | - | -10% | S26 | 10 | -10% | S51 | 10 | + | -10% | |

| S2 | 10 | - | -5% | S27 | 10 | -5% | S52 | 10 | + | -5% | |

| S3 | 10 | - | 0% | S28 | 10 | 0% | S53 | 10 | + | 0% | |

| S4 | 10 | - | +5% | S29 | 10 | +5% | S54 | 10 | + | +5% | |

| S5 | 10 | - | +10% | S30 | 10 | +10% | S55 | 10 | + | +10% | |

| S6 | 20 | - | -10% | S31 | 20 | -10% | S56 | 20 | + | -10% | |

| S7 | 20 | - | -5% | S32 | 20 | -5% | S57 | 20 | + | -5% | |

| S8 | 20 | - | 0% | S33 | 20 | 0% | S58 | 20 | + | 0% | |

| S9 | 20 | - | +5% | S34 | 20 | +5% | S59 | 20 | + | +5% | |

| S10 | 20 | - | +10% | S35 | 20 | +10% | S60 | 20 | + | +10% | |

| S11 | 30 | - | -10% | S36 | 30 | -10% | S61 | 30 | + | -10% | |

| S12 | 30 | - | -5% | S37 | 30 | -5% | S62 | 30 | + | -5% | |

| S13 | 30 | - | 0% | S38 | 30 | 0% | S63 | 30 | + | 0% | |

| S14 | 30 | - | +5% | S39 | 30 | +5% | S64 | 30 | + | +5% | |

| S15 | 30 | - | +10% | S40 | 30 | +10% | S65 | 30 | + | +10% | |

| S16 | 40 | - | -10% | S41 | 40 | -10% | S66 | 40 | + | -10% | |

| S17 | 40 | - | -5% | S42 | 40 | -5% | S67 | 40 | + | -5% | |

| S18 | 40 | - | 0% | S43 | 40 | 0% | S68 | 40 | + | 0% | |

| S19 | 40 | - | +5% | S44 | 40 | +5% | S69 | 40 | + | +5% | |

| S20 | 40 | - | +10% | S45 | 40 | +10% | S70 | 40 | + | +10% | |

| S21 | 50 | - | -10% | S46 | 50 | -10% | S71 | 50 | + | -10% | |

| S22 | 50 | - | -5% | S47 | 50 | -5% | S72 | 50 | + | -5% | |

| S23 | 50 | - | 0% | S48 | 50 | 0% | S73 | 50 | + | 0% | |

| S24 | 50 | - | +5% | S49 | 50 | +5% | S74 | 50 | + | +5% | |

| S25 | 50 | - | +10% | S50 | 50 | +10% | S75 | 50 | + | +10% |

| CEC [%] |

PD [%] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | |||||||||||

| EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | |

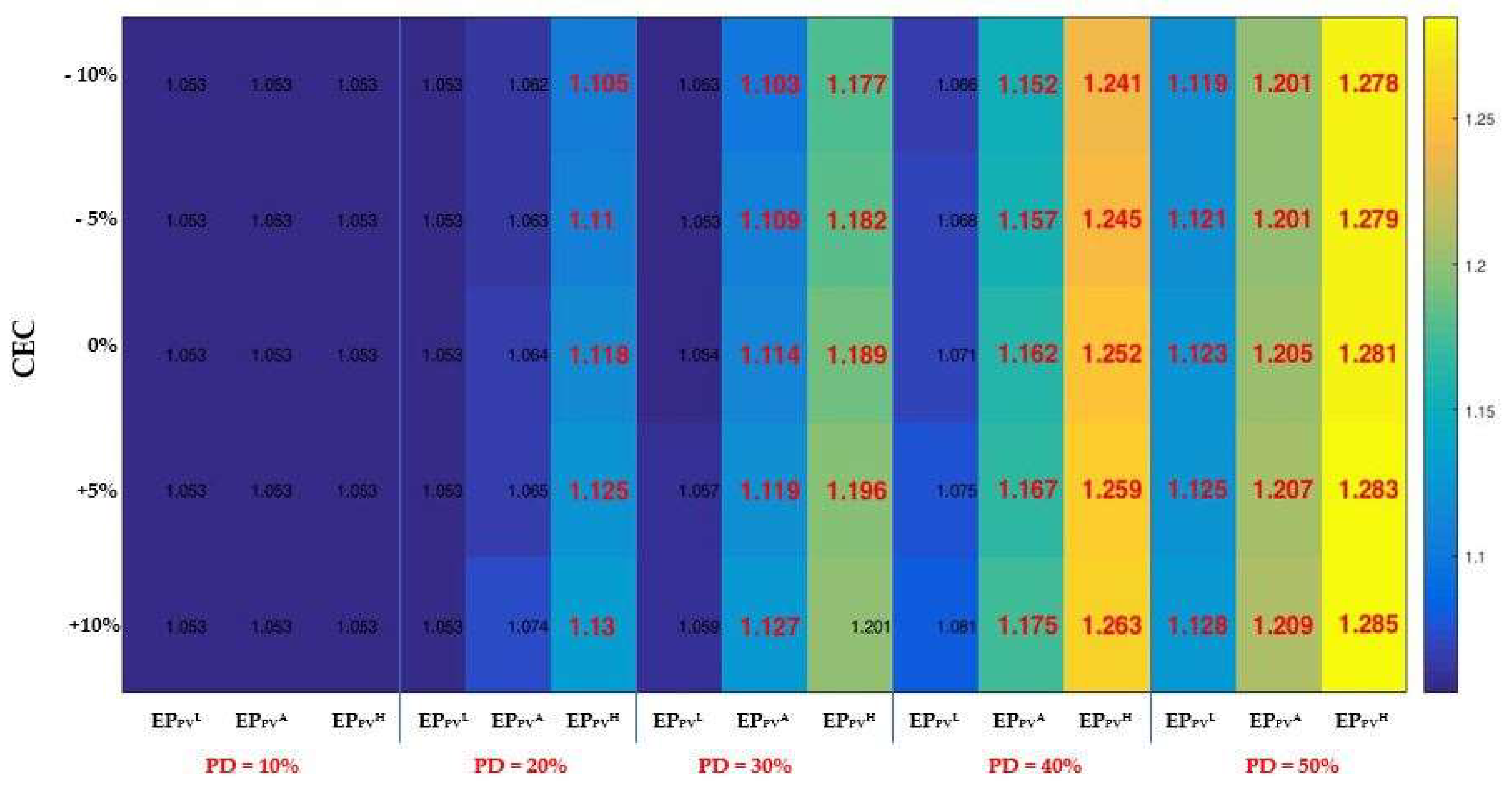

| -10 | 1.053 | 1.053 | 1.053 | 1.053 | 1.074 | 1.130 | 1.059 | 1.127 | 1.201 | 1.081 | 1.175 | 1.263 | 1.128 | 1.209 | 1.285 |

| -5 | 1.053 | 1.053 | 1.053 | 1.053 | 1.065 | 1.125 | 1.057 | 1.119 | 1.196 | 1.075 | 1.167 | 1.259 | 1.125 | 1.207 | 1.283 |

| 0 | 1.053 | 1.053 | 1.053 | 1.053 | 1.064 | 1.118 | 1.054 | 1.114 | 1.189 | 1.071 | 1.162 | 1.252 | 1.123 | 1.205 | 1.281 |

| 5 | 1.053 | 1.053 | 1.053 | 1.053 | 1.063 | 1.110 | 1.053 | 1.109 | 1.182 | 1.068 | 1.157 | 1.245 | 1.121 | 1.201 | 1.279 |

| 10 | 1.053 | 1.053 | 1.053 | 1.053 | 1.062 | 1.105 | 1.053 | 1.103 | 1.177 | 1.066 | 1.152 | 1.241 | 1.119 | 1.201 | 1.278 |

| CEC [%] |

PD [%] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | |||||||||||

| EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | |

| -10 | 39.4 | 42.5 | 48.0 | 41.8 | 42.8 | 48.2 | 39.4 | 47.6 | 70.8 | 40.0 | 62.0 | 107.5 | 46.1 | 85.4 | 157.1 |

| -5 | 44.4 | 48.5 | 54.3 | 46.6 | 48.3 | 51.9 | 44.2 | 51.3 | 73.0 | 44.1 | 64.7 | 108.5 | 49.9 | 87.6 | 157.4 |

| 0 | 50.0 | 54.9 | 61.2 | 51.8 | 54.4 | 56.2 | 49.5 | 55.2 | 75.8 | 48.7 | 67.6 | 110.2 | 54.1 | 90.0 | 158.2 |

| 5 | 56.1 | 61.3 | 68.5 | 57.1 | 60.9 | 60.9 | 55.1 | 59.4 | 79.0 | 53.6 | 70.9 | 112.1 | 58.7 | 92.8 | 159.5 |

| 10 | 62.2 | 68.3 | 76.2 | 62.9 | 65.6 | 67.8 | 61.5 | 64.0 | 82.3 | 59.3 | 74.5 | 114.3 | 64.0 | 95.9 | 161.0 |

| CEC [%] |

PD [%] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | |||||||||||

| EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | |

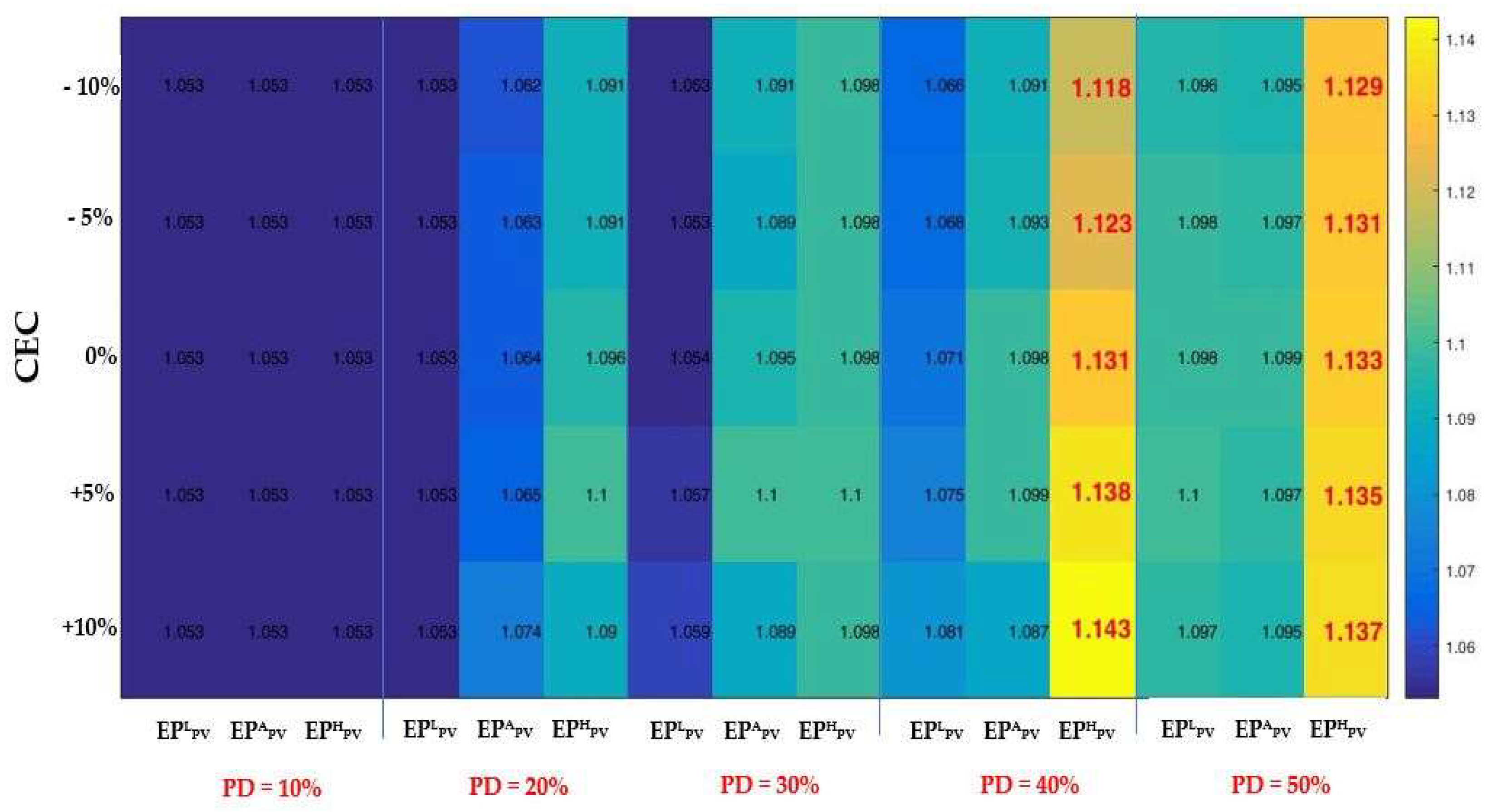

| -10 | 1.053 | 1.053 | 1.053 | 1.053 | 1.074 | 1.090 | 1.059 | 1.089 | 1.098 | 1.081 | 1.087 | 1.143 | 1.097 | 1.095 | 1.137 |

| -5 | 1.053 | 1.053 | 1.053 | 1.053 | 1.065 | 1.100 | 1.057 | 1.100 | 1.100 | 1.075 | 1.099 | 1.138 | 1.100 | 1.097 | 1.135 |

| 0 | 1.053 | 1.053 | 1.053 | 1.053 | 1.064 | 1.096 | 1.054 | 1.095 | 1.098 | 1.071 | 1.098 | 1.131 | 1.098 | 1.099 | 1.133 |

| 5 | 1.053 | 1.053 | 1.053 | 1.053 | 1.063 | 1.091 | 1.053 | 1.089 | 1.098 | 1.068 | 1.093 | 1.123 | 1.098 | 1.097 | 1.131 |

| 10 | 1.053 | 1.053 | 1.053 | 1.053 | 1.062 | 1.091 | 1.053 | 1.091 | 1.098 | 1.066 | 1.091 | 1.118 | 1.096 | 1.095 | 1.129 |

| CEC [%] |

PD [%] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | |||||||||||

| EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | |

| -10 | 39.4 | 42.5 | 48.0 | 41.8 | 42.8 | 48.1 | 39.4 | 47.5 | 77.4 | 40.0 | 65.8 | 127.8 | 46.6 | 95.5 | 191.3 |

| -5 | 44.4 | 48.5 | 54.3 | 46.6 | 48.3 | 51.7 | 44.2 | 51.1 | 78.6 | 44.1 | 67.8 | 128.0 | 49.9 | 97.1 | 190.5 |

| 0 | 50.0 | 54.9 | 61.2 | 51.8 | 54.4 | 55.6 | 49.5 | 54.6 | 80.3 | 48.7 | 69.1 | 128.5 | 53.7 | 97.9 | 190.0 |

| 5 | 56.1 | 61.3 | 68.5 | 57.1 | 60.9 | 60.2 | 55.1 | 58.7 | 82.6 | 53.6 | 72.1 | 129.9 | 58.1 | 100.2 | 190.6 |

| 10 | 62.2 | 68.3 | 76.2 | 62.9 | 65.6 | 64.3 | 61.5 | 62.7 | 84.9 | 59.3 | 75.1 | 130.0 | 62.8 | 102.5 | 190.5 |

| PD [%] | CEC [%] | ||||

| -10 | -5 | 0 | 5 | 10 | |

| 40 | 2.86 / S57 | 2.48 / S56 | 2.11 / S58 | 1.87 / S59 | 1.73 / S60 |

| 50 | 4.98 / S71 | 4.91 / S72 | 4.71 / S73 | 4.60 / S74 | 4.49 / S75 |

| CEC [%] |

PD [%] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | |||||||||||

| EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | |

| -10 | 2.50 | 2.85 | 2.96 | 2.84 | 3.54 | 2.87 | 3.19 | 3.32 | 1.60 | 3.46 | 2.05 | 0.00 | 3.04 | 1.04 | 0.00 |

| -5 | 2.18 | 2.10 | 2.10 | 2.08 | 2.78 | 2.99 | 2.29 | 3.60 | 1.56 | 3.02 | 2.28 | 0.00 | 2.90 | 1.02 | 0.00 |

| 0 | 1.89 | 1.77 | 1.64 | 1.75 | 2.31 | 2.68 | 1.91 | 2.60 | 1.61 | 2.14 | 2.05 | 0.00 | 2.18 | 1.16 | 0.00 |

| 5 | 1.50 | 1.78 | 1.68 | 1.77 | 2.19 | 2.60 | 1.84 | 2.50 | 1.41 | 2.10 | 1.77 | 0.00 | 2.31 | 0.94 | 0.00 |

| 10 | 1.34 | 1.61 | 1.47 | 1.79 | 1.84 | 2.32 | 1.60 | 2.21 | 1.38 | 1.80 | 1.50 | 0.00 | 2.08 | 0.85 | 0.00 |

| CEC [%] |

PD [%] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | |||||||||||

| EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | |

| -10 | 0.08 | 0.08 | 0.08 | 0.08 | 1.98 | 0.53 | 0.62 | 0.91 | 0.35 | 2.62 | 0.00 | 0.00 | 1.35 | 0.00 | 0.00 |

| -5 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 1.83 | 0.00 | 2.27 | 0.00 | 0.85 | 1.68 | 0.00 | 1.85 | 0.00 | 0.00 |

| 0 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 1.68 | 0.00 | 1.57 | 0.00 | 0.17 | 0.17 | 0.00 | 1.87 | 0.00 | 0.00 |

| 5 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 1.23 | 0.00 | 1.11 | 0.00 | 0.24 | 0.24 | 0.00 | 1.89 | 0.00 | 0.00 |

| 10 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.44 | 0.00 | 0.00 | 0.00 | 0.45 | 0.00 | 0.00 |

| CEC [%] |

PD [%] | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | |||||||||||

| EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | EPLPV | EPAPV | EPHPV | |

| -10 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 4 | 4 | 0 | 4 | 0 | 6 | 1 | 0 |

| -5 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 4 | 2 | 0 | 2 | 0 | 4 | 1 | 0 |

| 0 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 4 | 2 | 0 | 4 | 0 | 0 | 2 | 0 |

| 5 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 4 | 2 | 0 | 4 | 0 | 2 | 2 | 0 |

| 10 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 4 | 2 | 0 | 2 | 0 | 2 | 2 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).