Submitted:

05 April 2023

Posted:

06 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results

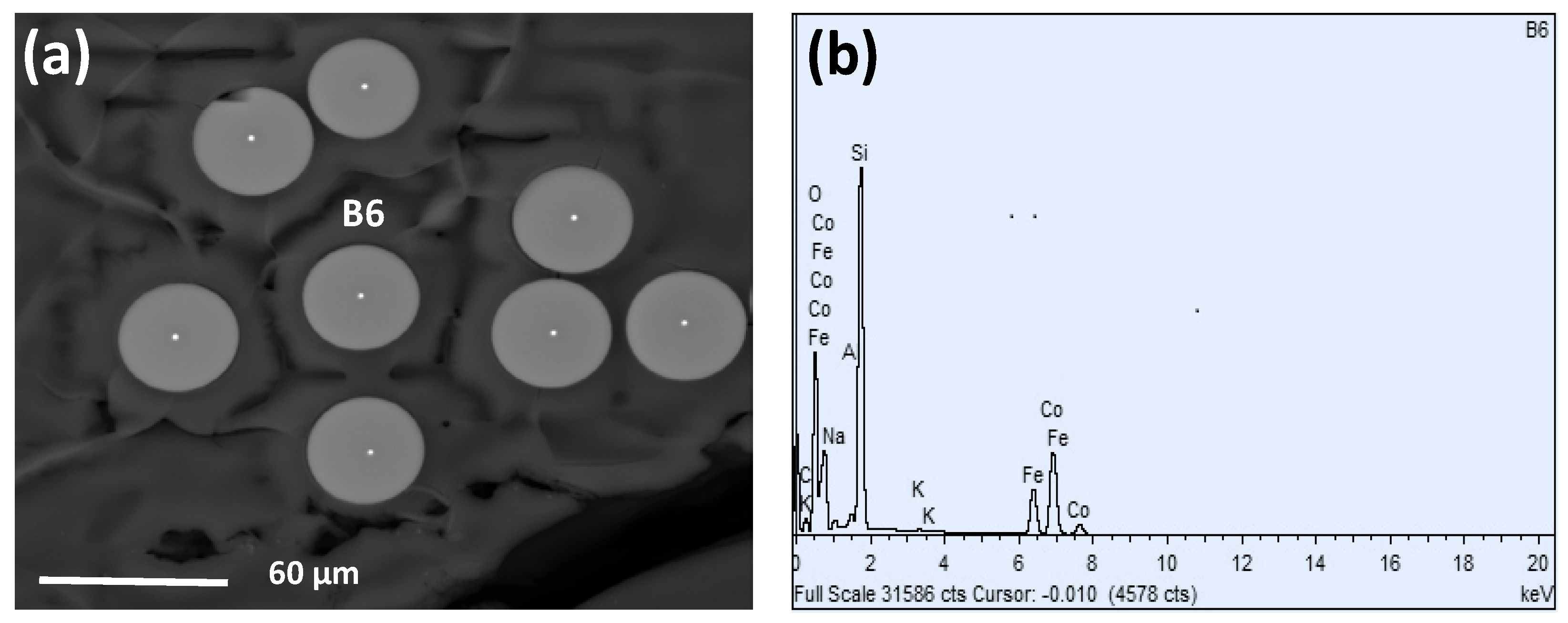

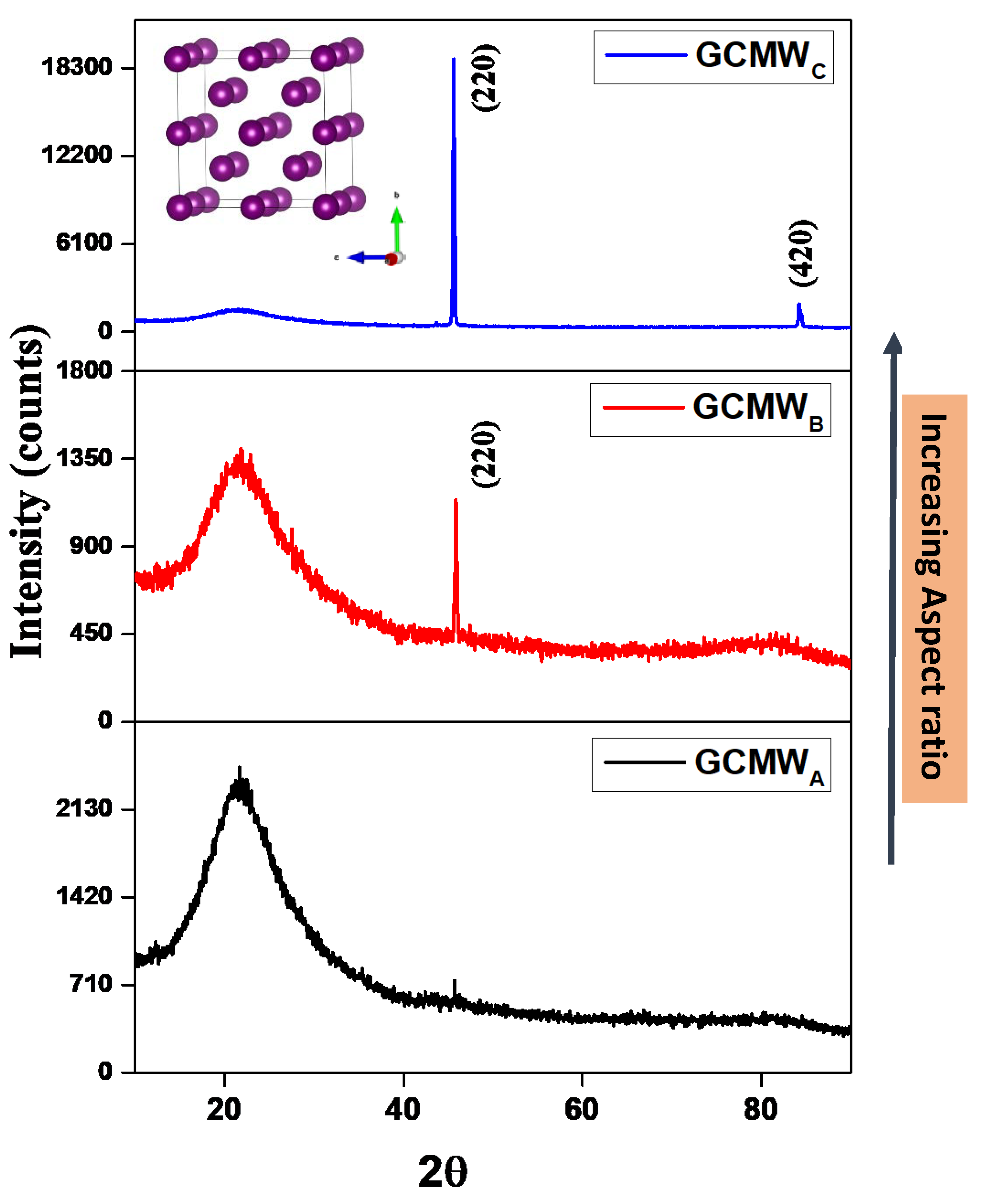

3.1. Analysis of Chemical and Structural Data

3.2. Magnetic Characterization

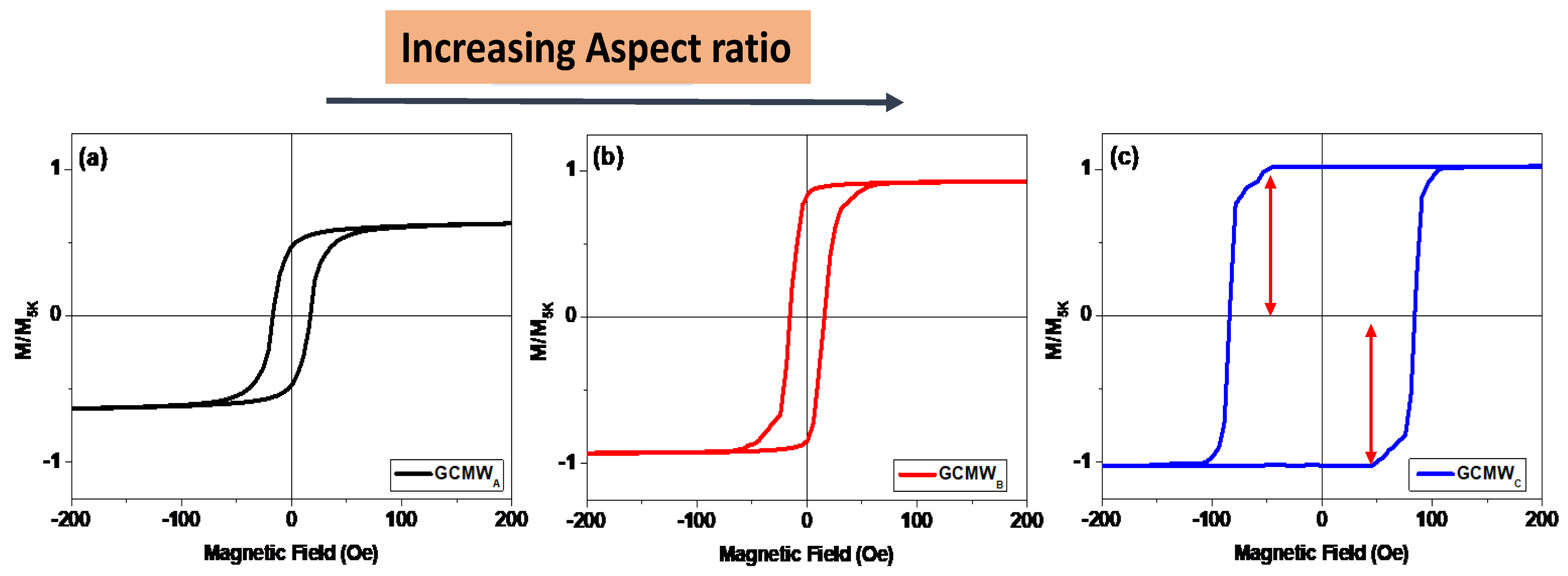

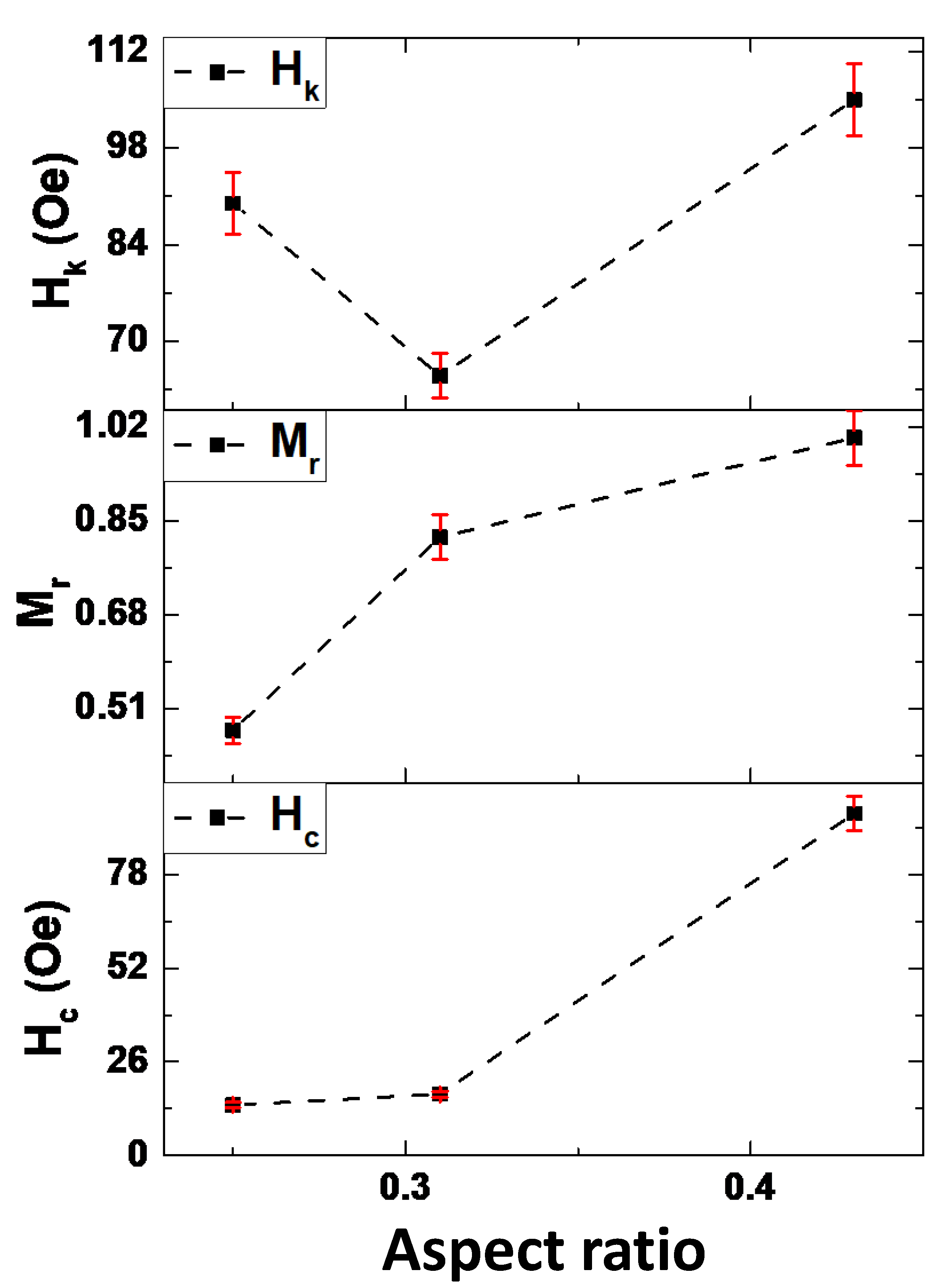

3.2.1. Room Temperature Magnetic Properties

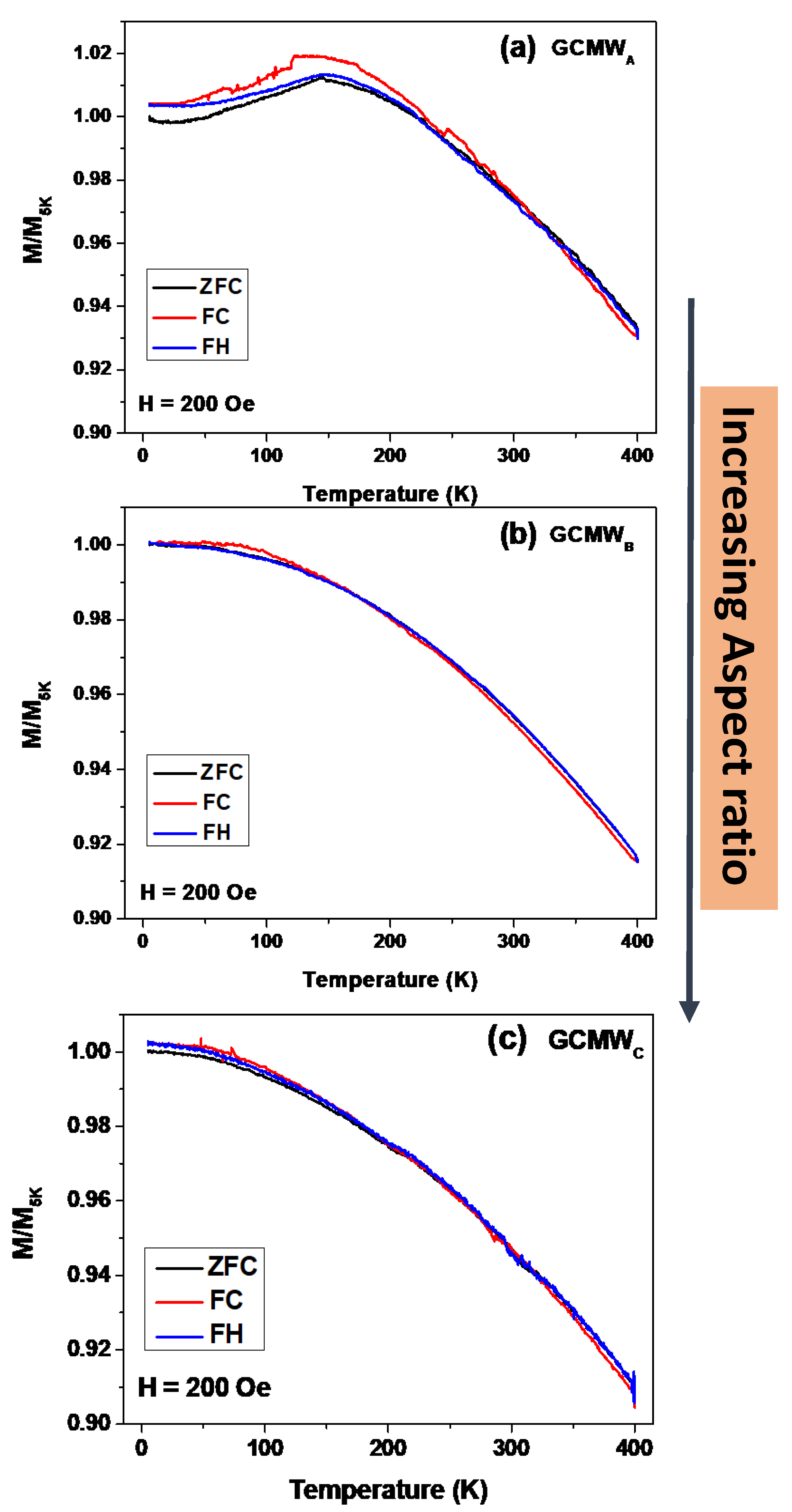

3.2.2. Thermomagnetic Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, T.; Pickel, A.D.; Yao, Y.; Chen, Y.; Zeng, Y.; Lacey, S.D.; Li, Y.; Wang, Y.; Dai, J.; Wang, Y.; et al. Thermoelectric properties and performance of flexible reduced graphene oxide films up to 3,000 K. Nat. Energy 2018, 3, 148–156. [Google Scholar] [CrossRef]

- Hoop, M.; Ribeiro, A.S.; Rösch, D.; Weinand, P.; Mendes, N.; Mushtaq, F.; Chen, X.Z.; Shen, Y.; Pujante, C.F.; Puigmartí-Luis, J.; et al. Mobile Magnetic Nanocatalysts for Bioorthogonal Targeted Cancer Therapy. Adv. Funct. Mater. 2018, 28, 1705920. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Vega, V.; Fernández, A.; Prida, V.M. Anomalous In-Plane Coercivity Behaviour in Hexagonal Arrangements of Ferromagnetic Antidot Thin Films. J. Magn. Magn. Mater. 2019, 491, 165572. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Nafady, A.; Abu-Dief, A.M.; Díaz Crespo, R.; Fernández-García, M.P.; Andrés, J.P.; López Antón, R.; Blanco, J.A.; Álvarez-Alonso, P. Enhancement of Exchange Bias and Perpendicular Magnetic Anisotropy in CoO/Co Multilayer Thin Films by Tuning the Alumina Template Nanohole Size. Nanomaterials 2022, 12, 2544. [Google Scholar] [CrossRef] [PubMed]

- Salaheldeen, M.; Martínez-Goyeneche, L.; Álvarez-Alonso, P.; Fernández, A. Enhancement the Perpendicular Magnetic Anisotropy of Nanopatterned Hard/Soft Bilayer Magnetic Antidot Arrays for Spintronic Application. Nanotechnology 2020, 31, 485708. [Google Scholar] [CrossRef] [PubMed]

- Skjærvø, S.H.; Marrows, C.H.; Stamps, R.L.; Heyderman, L.J. Advances in artificial spin ice. Nat. Rev. Phys. 2019, 2, 13–28. [Google Scholar] [CrossRef]

- Maniv, E.; Murphy, R.A.; Haley, S.C.; Doyle, S.; John, C.; Maniv, A.; Ramakrishna, S.K.; Tang, Y.-L.; Ercius, P.; Ramesh, R.; et al. Exchange bias due to coupling between coexisting antiferromagnetic and spin-glass orders. Nat. Phys. 2021, 17, 525–530. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Abu-Dief, A.M.; Martínez-Goyeneche, L.; Alzahrani, S.O.; Alkhatib, F.; Álvarez-Alonso, P.; Blanco, J.Á. Dependence of the Magnetization Process on the Thickness of Fe70Pd30 Nanostructured Thin Film. Materials 2020, 13, 5788. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Méndez, M.; Vega, V.; Fernández, A.; Prida, V.M. Tuning Nanohole Sizes in Ni Hexagonal Antidot Arrays: Large Perpendicular Magnetic Anisotropy for Spintronic Applications. ACS Appl. Nano Mater. 2019, 2, 1866–1875. [Google Scholar] [CrossRef]

- Elphick, K.; Frost, W.; Samiepour, M.; Kubota, T.; Takanashi, K.; Sukegawa, H.; Mitani, S.; Hirohata, A. Heusler Alloys for Spintronic Devices: Review on Recent Development and Future Perspectives. Sci. Technol. Adv. Mate. 2021, 22, 235–271. [Google Scholar] [CrossRef]

- Sheron Tavares; Kesong Yang; Marc A. Meyers. Heusler alloys: Past, properties, new alloys, and prospects. Progress in Materials Science 2023, 132, 101017. [CrossRef]

- De Groot, R.A.; Mueller, F.M.; Engen, P.G.V.; Buschow, K.H.J. New Class of Materials: Half-Metallic Ferromagnets. Phys. Rev. Lett. 1983, 50, 2024. [Google Scholar] [CrossRef]

- Bai, Z.; Shen, L.E.I.; Han, G.; Feng, Y.P. Data Storage: Review of Heusler Compounds. Spin 2012, 2, 1230006. [Google Scholar] [CrossRef]

- Balke, B.; Wurmehl, S.; Fecher, G.H.; Felser, C.; Kübler, J. Rational Design of New Materials for Spintronics: Co2FeZ (Z=Al, Ga, Si, Ge). Sci Technol Adv Mater 2008, 9. [Google Scholar] [CrossRef]

- Hirohata, A.; Sagar, J.; Lari, L; et al. Heusler-alloy films for spintronic devices. Appl. Phys. A 2013, 111, 423–430. [CrossRef]

- Li, P.; Koo, J.; Ning, W.; Li, J.; Miao, L.; Min, L.; Zhu, Y.; Wang, Y.; Alem, N.; Liu, C.X.; et al. Giant Room Temperature Anomalous Hall Effect and Tunable Topology in a Ferromagnetic Topological Semimetal Co2MnAl. Nat. Commun. 2020, 11, 1–8. [Google Scholar] [CrossRef]

- Jourdan, M.; Minár, J.; Braun, J.; Kronenberg, A.; Chadov, S.; Balke, B.; Gloskovskii, A.; Kolbe, M.; Elmers, H.J.; Schönhense, G.; et al. Direct Observation of Half-Metallicity in the Heusler Compound Co2MnSi. Nat. Commun. 2014, 5, 3974. [Google Scholar] [CrossRef]

- Guillemard, C.; Petit-Watelot, S.; Pasquier, L.; Pierre, D.; Ghanbaja, J.; RojasSánchez, J.C.; Bataille, A.; Rault, J.; le Fèvre, P.; Bertran, F.; et al. Ultralow Magnetic Damping in Co2Mn-Based Heusler Compounds: Promising Materials for Spintronics. Phys. Rev. Appl. 2019, 11, 064009. [Google Scholar] [CrossRef]

- Nehla, P.; Ulrich, C.; Dhaka, R.S. Investigation of the Structural, Electronic, Transport and Magnetic Properties of Co2FeGa Heusler Alloy Nanoparticles. J. Alloys Compd. 2019, 776, 379–386. [Google Scholar] [CrossRef]

- Patra, N.; Prajapat, C.L.; Babu, P.D.; Rai, S.; Kumar, S.; Jha, S.N.; Bhattacharyya, D. Pulsed Laser Deposited Co2FeSi Heusler Alloy Thin Films: Effect of Different Thermal Growth Processes. J. Alloys Compd. 2019, 804, 470–485. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Ipatov, M.; Zhukova, V.; García-Gomez, A.; Gonzalez, J.; Zhukov, A. Preparation and magnetic properties of Co2-based Heusler alloy glass-coated microwires with high Curie temperature. AIP Adv. 2023, 13, 025325. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia, A.; Corte-Leon, P.; Ipatov, M.; Zhukova, V.; Zhukov, A. Unveiling the Effect of Annealing on Magnetic Properties of Nanocrystalline Half-Metallic Heusler Co2FeSi Alloy Glass-Coated Microwires. J. Mater. Res. Technol. 2022, 20, 4161–4172. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Ipatov, M.; Corte-Leon, P.; Zhukova, V.; Zhukov, A. Effect of Annealing on the Magnetic Properties of Co2MnSi-Based Heusler Alloy Glass-Coated Microwires. Metals 2023, 13, 412. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia-Gomez, A.; Ipatov, M.; Corte-Leon, P.; Zhukova, V.; Blanco, J.M.; Zhukov, A. Fabrication and MagnetoStructural Properties of Co2-Based Heusler Alloy Glass-Coated Microwires with High Curie Temperature. Chemosensors 2022, 10. [Google Scholar] [CrossRef]

- Khovaylo, V.V.; Rodionova, V.V.; Shevyrtalov, S.N.; Novosad, V. Magnetocaloric Effect in “Reduced” Dimensions: Thin Films, Ribbons, and Microwires of Heusler Alloys and Related Compounds. Phys. Status Solidi 2014, 251, 2104–2113. [Google Scholar] [CrossRef]

- Belmeguenai, M.; Tuzcuoglu, H.; Gabor, M.S.; Petrisor, T.; Tiusan, C.; Zighem, F.; Chérif, S.M.; Moch, P. Co2FeAl Heusler Thin Films Grown on Si and MgO Substrates: Annealing Temperature Effect. J. Appl. Phys. 2014, 115, 043918. [Google Scholar] [CrossRef]

- Zhukov, A.; Corte-Leon, P.; Gonzalez-Legarreta, L.; Ipatov, M.; Blanco, J.M.; Gonzalez, A.; Zhukova, V. Advanced Functional Magnetic Microwires for Technological Applications. J. Phys. D Appl. Phys. 2022, 55, 253003. [Google Scholar] [CrossRef]

- H. Chiriac H and T.A. Ovari, Amorphous glass-covered magnetic wires: Preparation, properties, applications. Prog. Mater. Sci. 1996, 40, 333–407. [CrossRef]

- O. Mitxelena-Iribarren, J. Campisi, I. Martínez de Apellániz, S. Lizarbe-Sancha, S. Arana, V. Zhukova, M. Mujika, A. Zhukov, Glass-coated ferromagnetic microwire-induced magnetic hyperthermia for in vitro cancer cell treatment. Mater. Sci. Eng. C 2020, 106, 110261. [CrossRef]

- Salaheldeen, M.; Garcia-Gomez, A.; Corte-León, P.; Gonzalez, A.; Ipatov, M.; Zhukova, V.; Gonzalez, J.M.; López Antón, R.; Zhukov, A. Manipulation of Magnetic and Structure Properties of Ni2FeSi Glass-Coated Microwires by Annealing. J Alloys Compd 2023, 942, 169026. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Talaat, A.; Ipatov, M.; Zhukova, V.; Zhukov, A. Preparation and Magneto-Structural Investigation of Nanocrystalline CoMn-Based Heusler Alloy Glass-Coated Microwires. Processes 2022, 10, 2248. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia-Gomez, A.; Corte-Leon, P.; Ipatov, M.; Zhukova, V.; Gonzalez, J.; Zhukov, A. Anomalous Magnetic Behavior in Half-Metallic Heusler Co2FeSi Alloy Glass-Coated Microwires with High Curie Temperature. J Alloys Compd 2022, 923, 166379. [Google Scholar] [CrossRef]

- Hennel, M.; Varga, M.; Frolova, L.; Nalevanko, S.; Ibarra-Gaytán, P.; Vidyasagar, R.; Sarkar, P.; Dzubinska, A.; Galdun, L.; Ryba, T.; et al. Heusler-Based Cylindrical Micro- and Nanowires. Phys. Status Solidi A 2022, 219, 2100657. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Wederni, A.; Ipatov, M.; Gonzalez, J.; Zhukova, V.; Zhukov, A. Elucidation of the Strong Effect of the Annealing and the Magnetic Field on the Magnetic Properties of Ni2-Based Heusler Microwires. Crystals 2022, 12, 1755. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Wederni, A.; Ipatov, M.; Zhukova, V.; Zhukov, A. Preparation and Magneto-Structural Investigation of High Ordered (L21 Structure) Co2MnGe Microwires. Preprints.org 2023, 2023020494. [Google Scholar] [CrossRef]

- A.F. Cobeño, A. Zhukov, A.R. de Arellano - Lopez, F. Elías. J.M. Blanco, V. Larin and J. González, “Physical properties of nearly zero magnetostriction Co-rich glass-coated amorphous microwires” J. Mater. Res. 14 (1999) 3775-3783. [CrossRef]

- Ulitovsky AV, Maianski I M, Avramenco A I 1960 Method of continuous casting of glass coated microwire, Patent No 128427 (USSR), 15.05.60, Bulletin, No 10, p. 14.

- Zhukov, A.; Ipatov, M.; Talaat, A.; Blanco, J.M.; Hernando, B.; Gonzalez-Legarreta, L.; Suñol, J.J.; Zhukova, V. Correlation of Crystalline Structure with Magnetic and Transport Properties of Glass-Coated Microwires. Crystals 2017, 7, 41. [Google Scholar] [CrossRef]

- Chiriac, H.; Lupu, N.; Stoian, G.; Ababei, G.; Corodeanu, S.; Óvári, T.A. Ultrathin Nanocrystalline Magnetic Wires. Crystals 2017, 7, 48. [Google Scholar] [CrossRef]

- Corte-Leon, P.; Zhukova, V.; Ipatov, M.; Blanco, J.M.; González, J. Churyukanova, M.; Taskaev, S.; Zhukov, A. The effect of annealing on magnetic properties of “Thick” microwires. J. Alloys Compd. 2020, 831, 150992. [Google Scholar] [CrossRef]

- Goto, T.; Nagano, M.; Wehara, N. Mechanical properties of amorphous Fe80P16C3B1 filament produced by glass-coated melt spinning. Trans. JIM 1977, 18, 759–764. [Google Scholar] [CrossRef]

- Zhukova, V.; Cobeño, A.F.; Zhukov, A.; de Arellano Lopez, A.R.; López-Pombero, S.; Blanco, J.M.; Larin, V.; Gonzalez, J. Correlation between magnetic and mechanical properties of devitrified glass-coated Fe71.8Cu1Nb3.1Si15B9.1 microwires. J. Magn. Magn. Mater. 2002, 249, 79–84. [Google Scholar] [CrossRef]

- Talaat, A.; Alonso, J.; Zhukova, V.; Garaio, E.; García, J.A.; Srikanth, H.; Phan, M.H.; Zhukov, A. Ferromagnetic Glass-Coated Microwires with Good Heating Properties for Magnetic Hyperthermia. Sci. Rep. 2016, 6, 39300. [Google Scholar] [CrossRef] [PubMed]

- Kozejova, D.; Fecova, L.; Klein, P.; Sabol, R.; Hudak, R.; Sulla, I.; Mudronova, D.; Galik, J.; Varga, R. Biomedical applications of glass-coated microwires. J. Magn. Magn. Mater. 2019, 470, 2–5. [Google Scholar] [CrossRef]

- Kudryavtsev, Y. V.; Lee, Y.P.; Lee, N.N.; Huang, M.D. Effect of Structural Disordering on the Magnetic, Magneto-Optical and Optical Properties of the Ni2MnIn Heusler Alloy Films. Mater. Sci. Forum. 2005, 480–481, 623–628. [CrossRef]

- Dubowik, J.; Kudryavtsev, Y.; Lee, Y.P.; Lee, N.N.; Hong, B.S. INFLUENCE OF STRUCTURAL ORDER ON MAGNETIC PROPERTIES OF Ni2MnIn HEUSLER ALLOY FILMS. Mol. Phys. Report. 2004, 40, 55–61. [Google Scholar]

- Wang, K.; Xu, Z.; Fu, X.; Lu, Z.; Xiong, R. Magnetic and Structural Properties of Sputtered Thick Co2FeSi Alloy Films. J. Magn. Magn. Mater. 2023, 570, 170557. [Google Scholar] [CrossRef]

- Zhang, X.; Han, L.; Dehm, G.; Liebscher, C.H. Microstructure and Physical Properties of Dual-Phase Soft Magnetic Fe-Co-Ti-Ge Alloys. J. Alloys Compd. 2023, 945, 169282. [Google Scholar] [CrossRef]

- Zhang, H.G.; Song, B.T.; Chen, J.; Yue, M.; Liu, E.K.; Wang, W.H.; Wu, G.H. Magnetization Variation in Fe–Cr-Ga System. Intermetallics 2019, 113, 106580. [Google Scholar] [CrossRef]

- Xiao, A.; Zhou, Z.; Qian, Y.; Wang, X. Direct Observation of Evolution from Amorphous Phase to Strain Glass. Mater. 2022, 15, 7900. [Google Scholar] [CrossRef]

- Zhukov, J. Gonzalez, A. Torcunov, E. Pina, M.J. Prieto, A.F. Cobeño, J.M. Blanco, V. Larin and S. Baranov, Ferromagnetic resonance and Structure of Fe-based glass-coated Microwires, J. Magn. Magn. Mater., 203 (1999) 238-240.

- H. Chiriac, T.A. Ovari, Gh. Pop, F. Barariu, Internal stresses in highly magnetostrictive glass-covered amorphous wires, J. Magn. Magn. Mater., 160 (1996) 237-238.

| Sample | Aspect ratio (ρ) | Chemical composition |

|---|---|---|

| GCMWA | 0.23 | Co44Fe23Si33 |

| GCMWB | 0.30 | Co44Fe23Si33 |

| GCMWC | 0.43 | Co44Fe23Si33 |

| Sample | Average grain size (nm) | Lattice parameters |

|---|---|---|

| GCMWA | - | - |

| GCMWB | 45.8 | 5.63 |

| GCMWC | 37.6 | 2.81 |

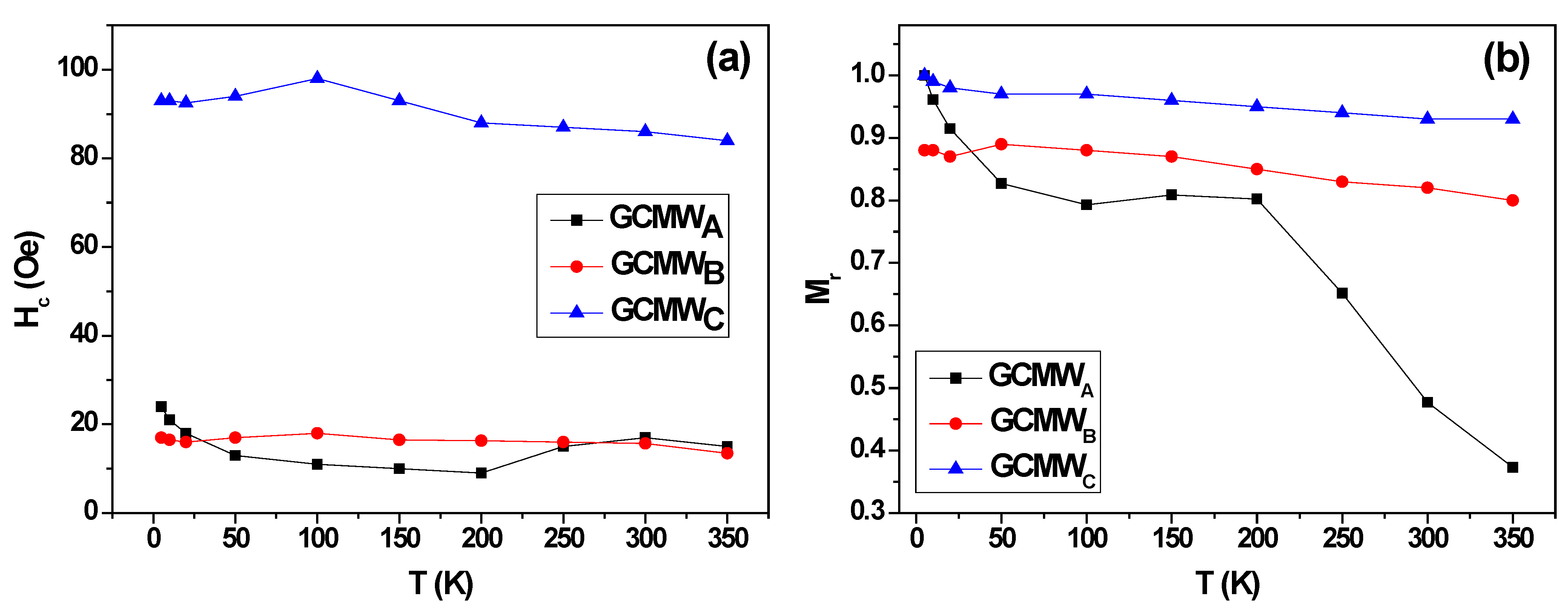

| Sample | ΔHc (Hc (max) - Hc (min)) | ΔMr (Mr (max) – Mr (min)) |

|---|---|---|

| GCMWA | 15 ± 2 Oe | 0.7 ± 0.1 |

| GCMWB | 3.5 ± 0.5 Oe | 0.06 ± 0.01 |

| GCMWC | 9 ± 2 Oe | 0.05 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).