Submitted:

06 April 2023

Posted:

07 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

- a practical comparison about the efficacy of various signal-based condition monitoring techniques, from the most elementary and general-purpose statistical parameters to complex cyclostationary methods, touching all the three phases involved in predictive maintenance, included signal pre-treatment strategies;

- a detailed study of IMS bearing dataset 1 which echoes the results of prolific research works on the theme, but proves to be innovative for the ample amount of techniques applied successfully, highlighting fault signatures with remarkable clarity, without resorting to data-driven techniques;

- a concrete proof of the validity of two of the most fruitful tools used for the study, which are Cepstrum Pre-Whitening (CPW) and the cyclostationary technique of the Improved Envelope Spectrum (IES), never applied before for the analysis of IMS dataset 1, to the best of the Authors’ knowledge.

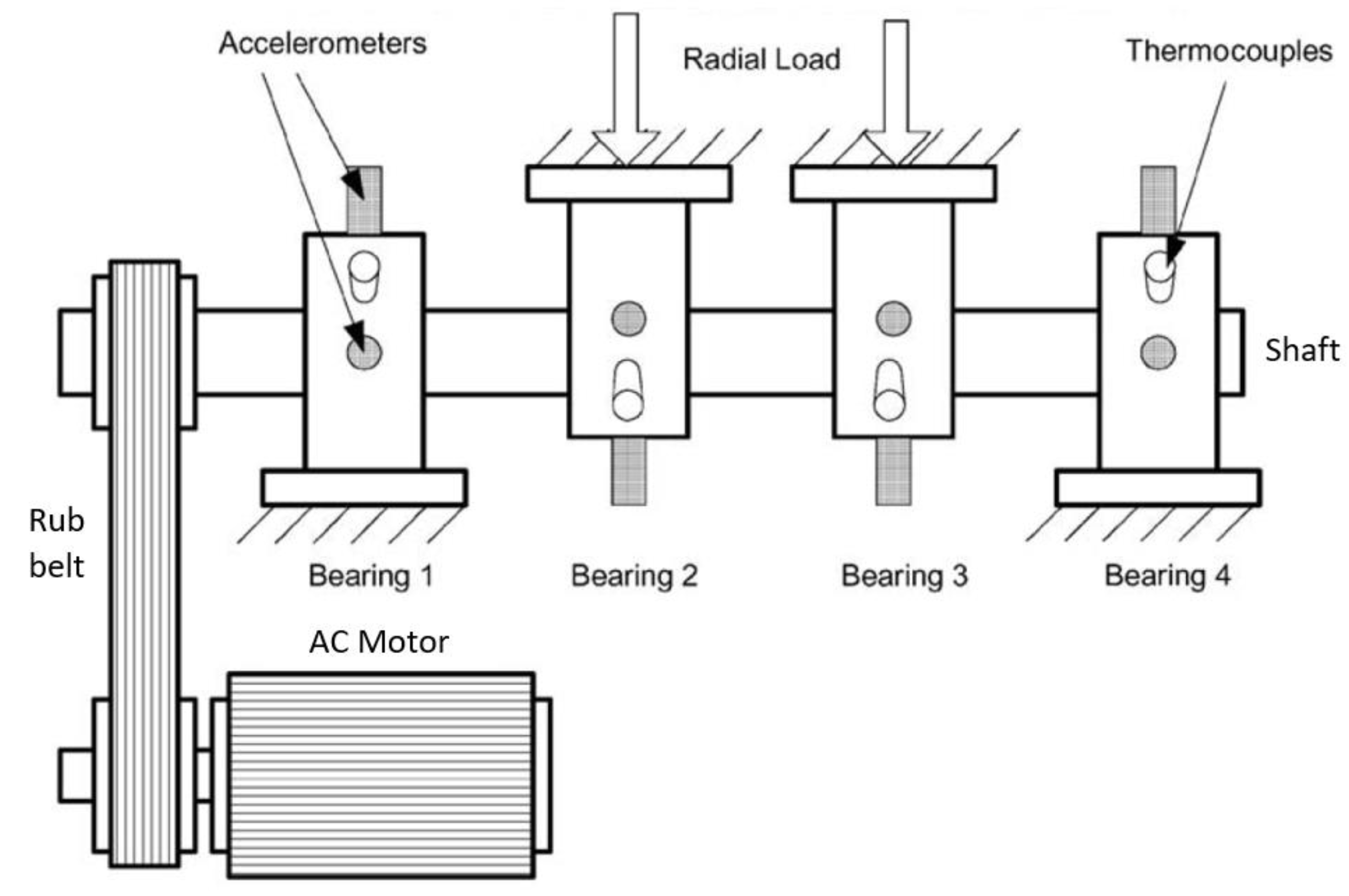

2. IMS bearing dataset and signal analysis techniques

2.1. Description of IMS dataset 1

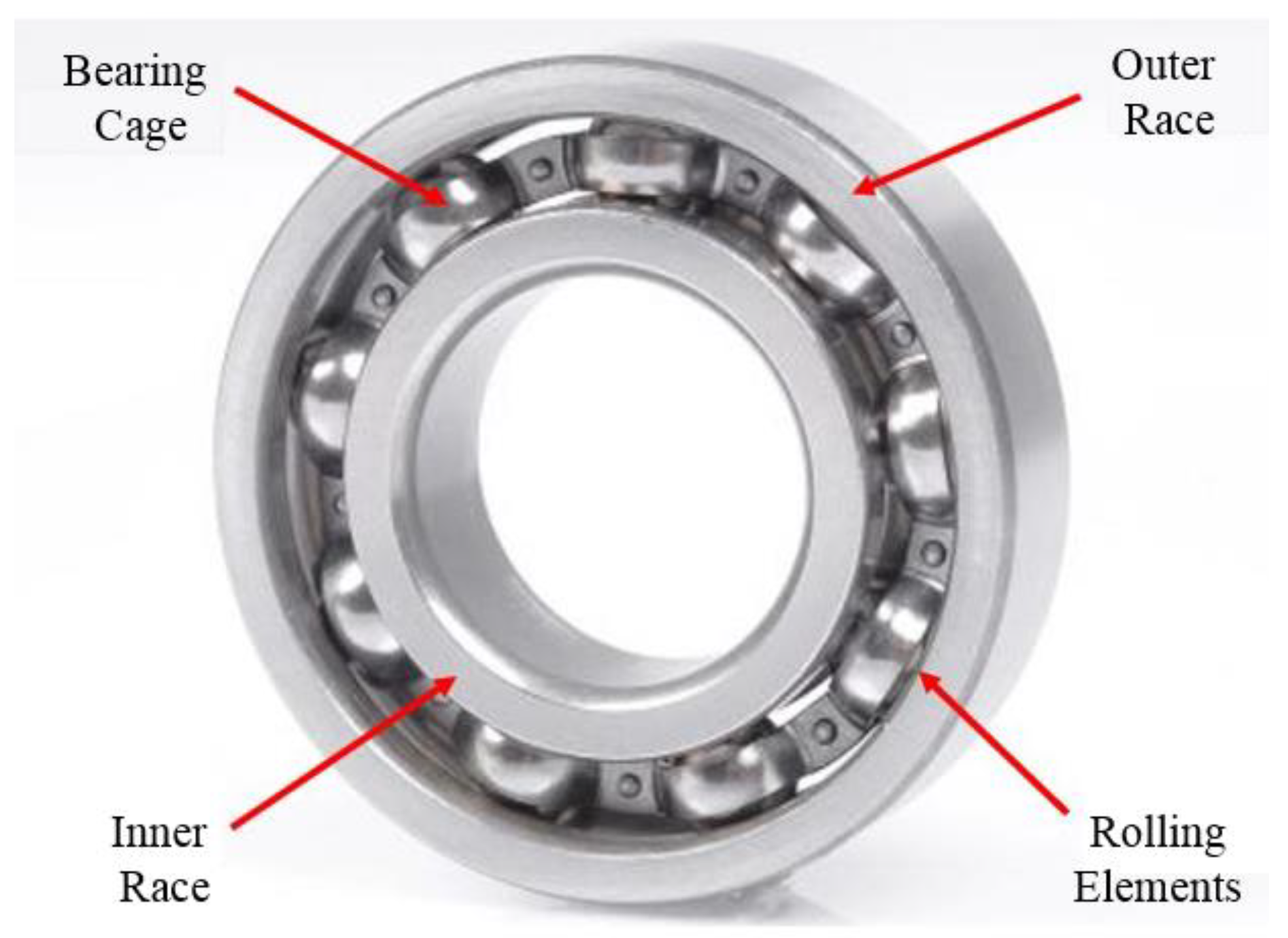

| Model | Rexnord ZA-2115 |

| Pitch diameter D | 71.5 mm (2.815 inch) |

| Rolling element diameter d | 8.4 mm (0.331 inch) |

| Number of rolling elements per row n | 16 |

| Load contact angle ϕ | 15.17° |

| Static load Q | 26690 N (6000 lbs.) |

| Shaft angular velocity ω | 2000 rpm |

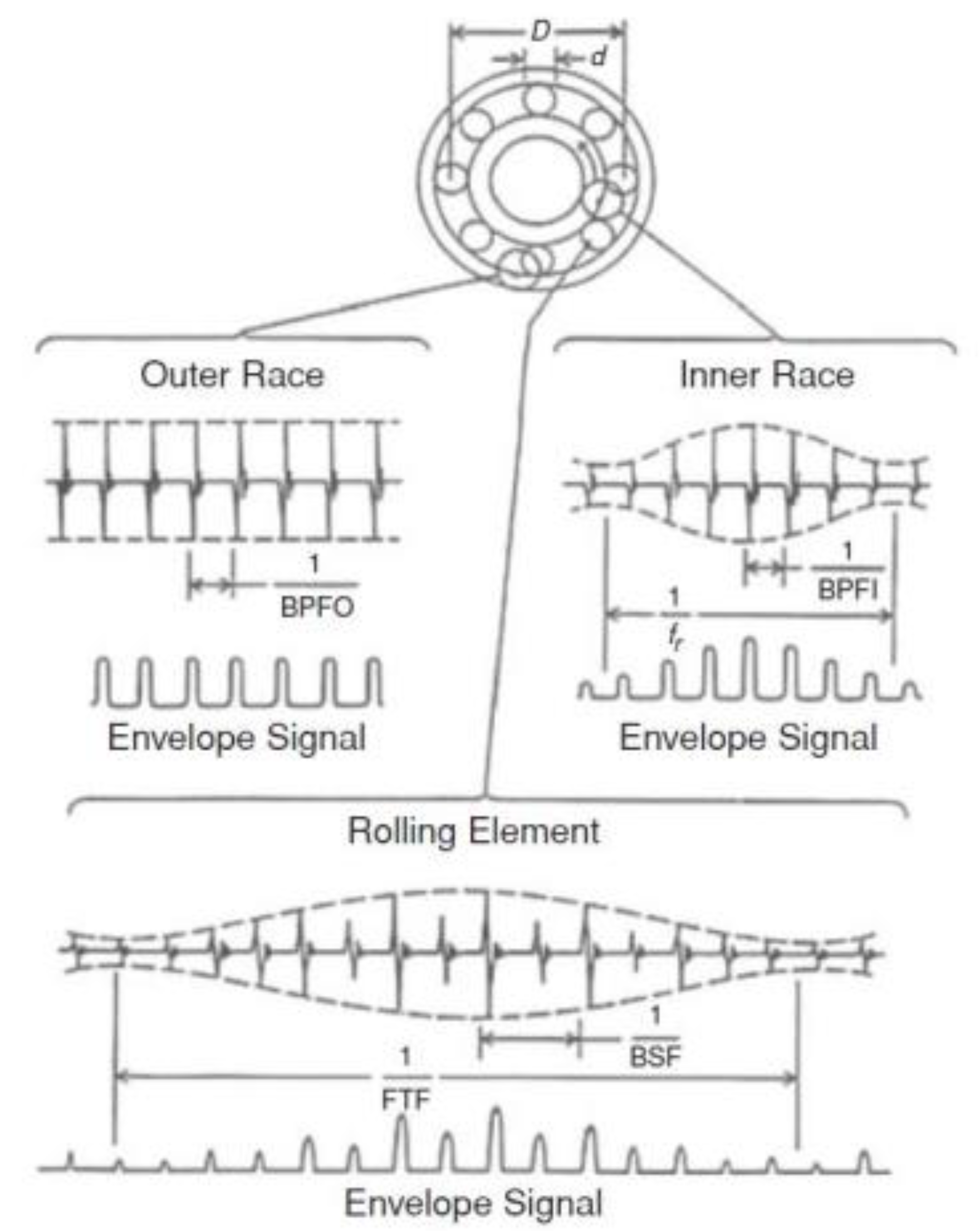

- is the frequency representing the fault signature on the outer race,

- is the frequency representing the fault signature on the inner race,

- is the frequency representing the fault signature on the bearing cage,

- is the frequency representing the fault signature on the rolling element,

2.2. Signal analysis techniques

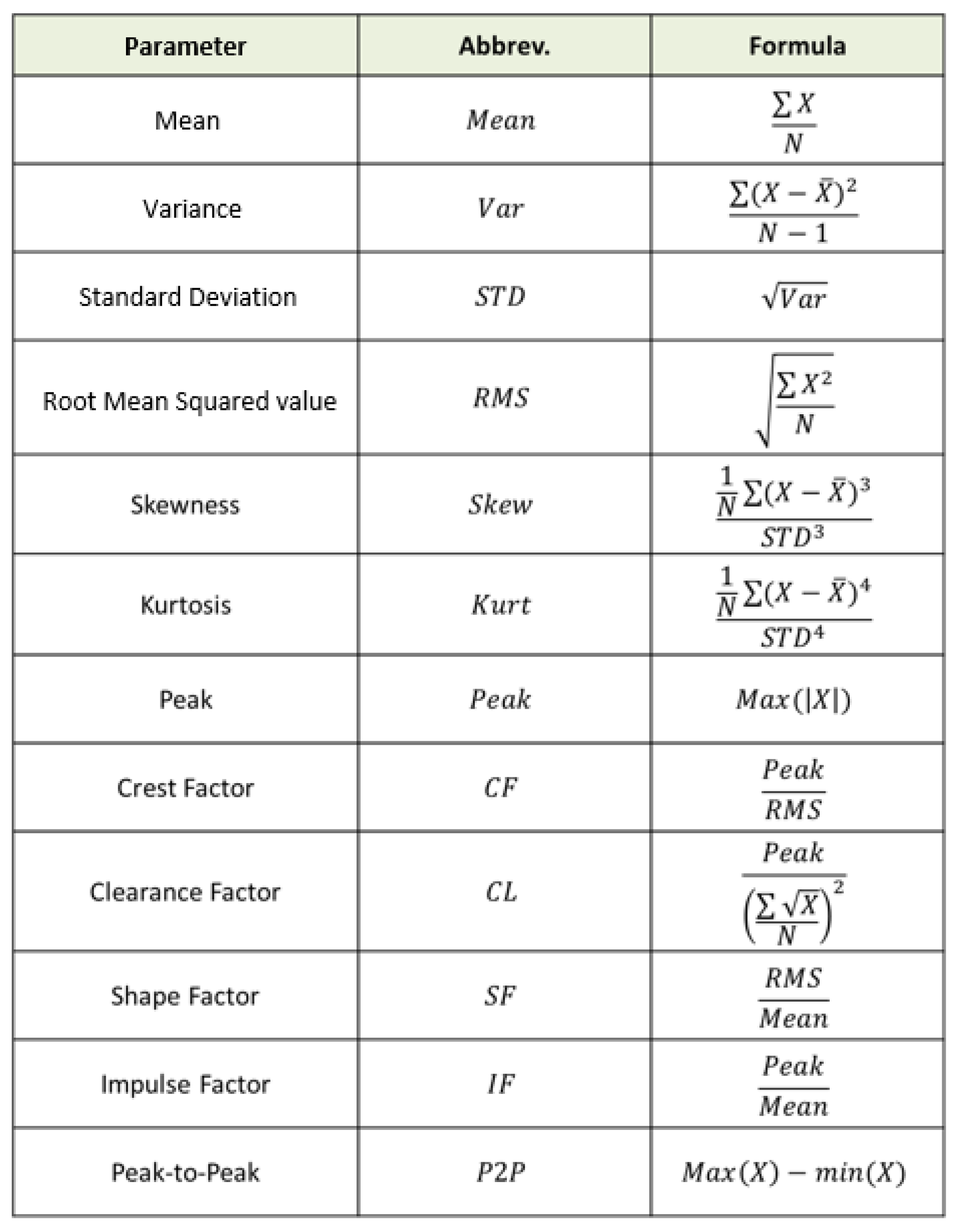

- Mean;

- Variance;

- Standard Deviation;

- Peak;

- Root Mean Squared value (RMS);

- Skewness;

- Crest Factor;

- Clearance Factor;

- Shape Factor;

- Impulse Factor;

- Peak-to-Peak;

- Hjorth’s Parameters;

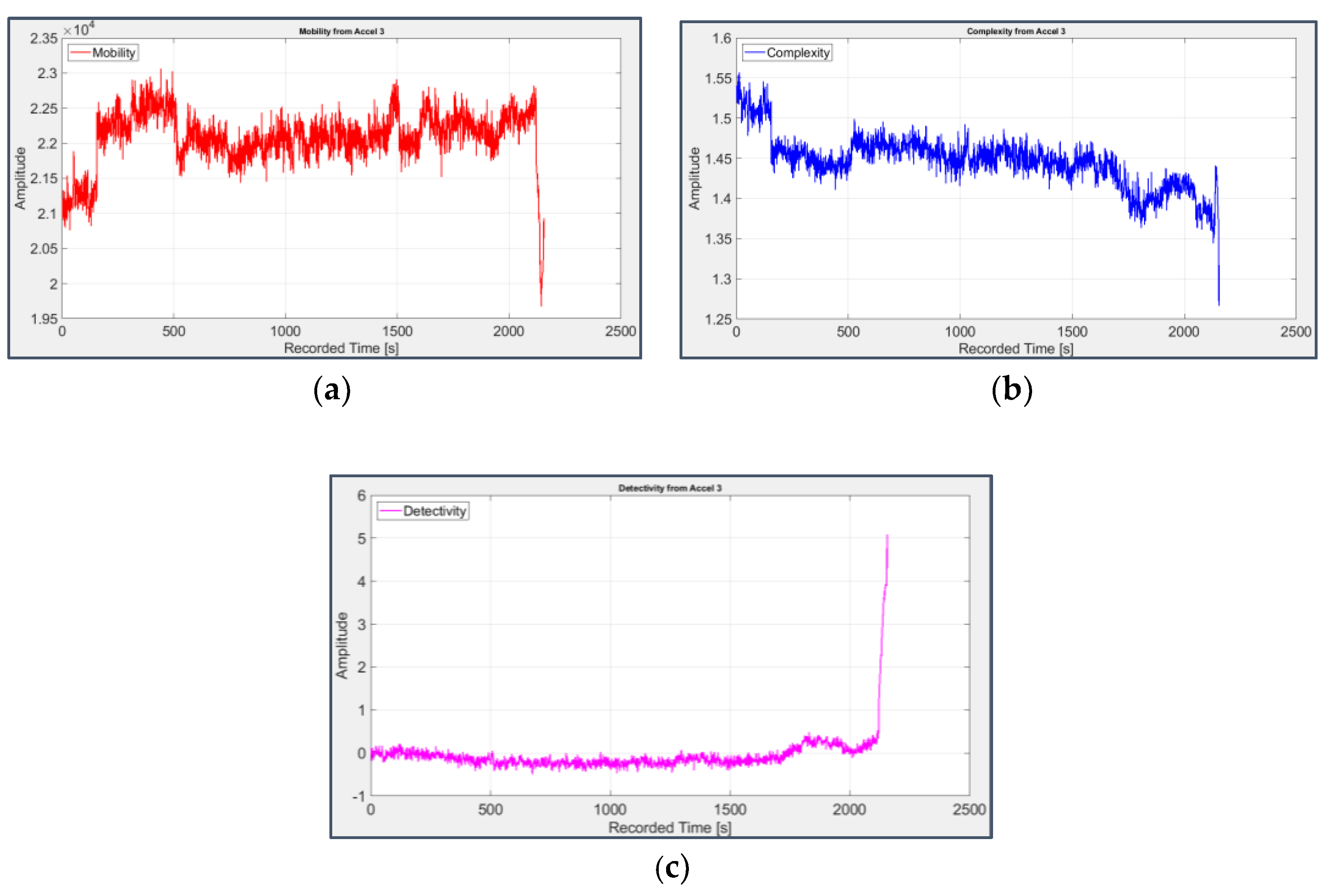

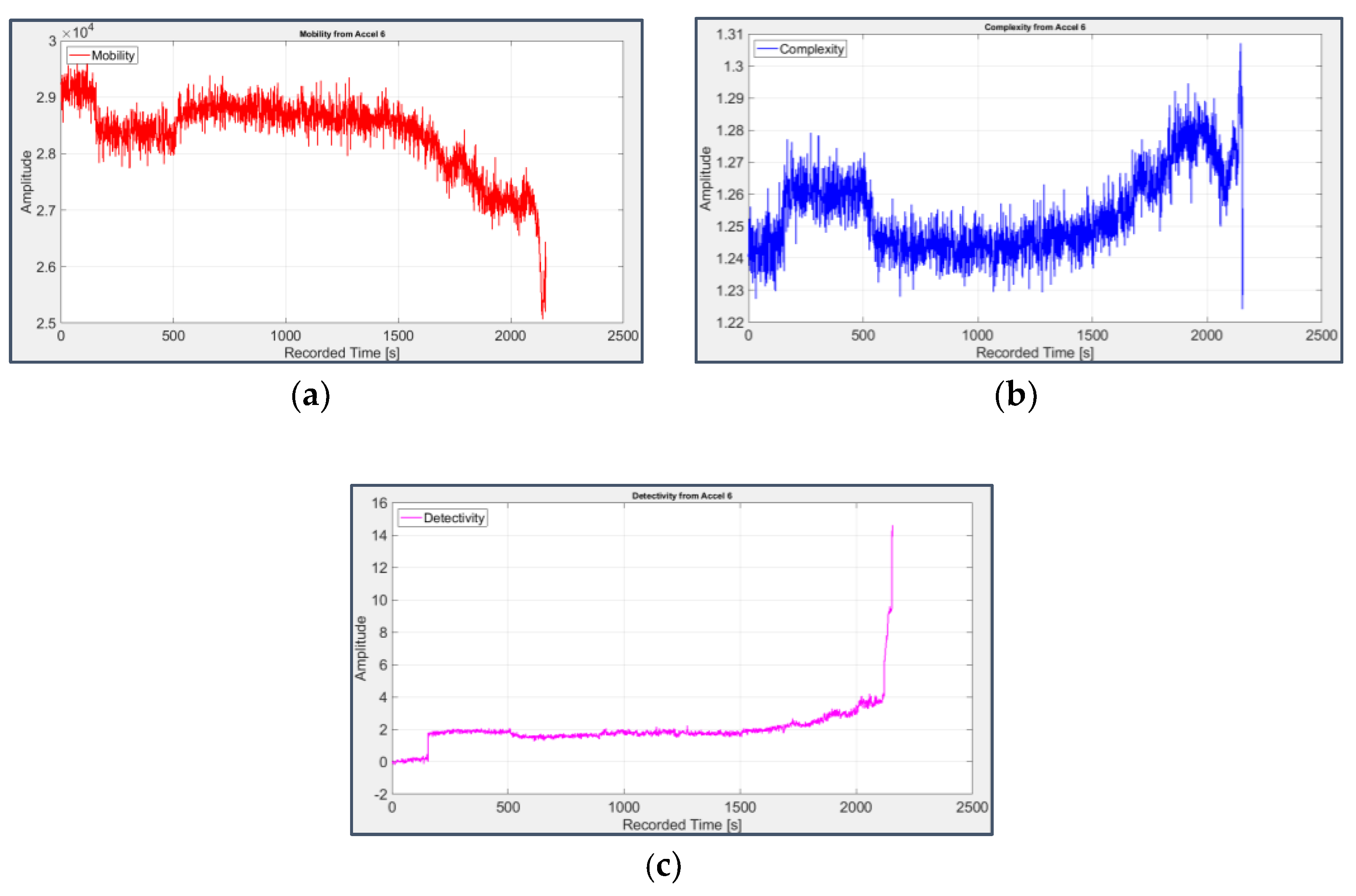

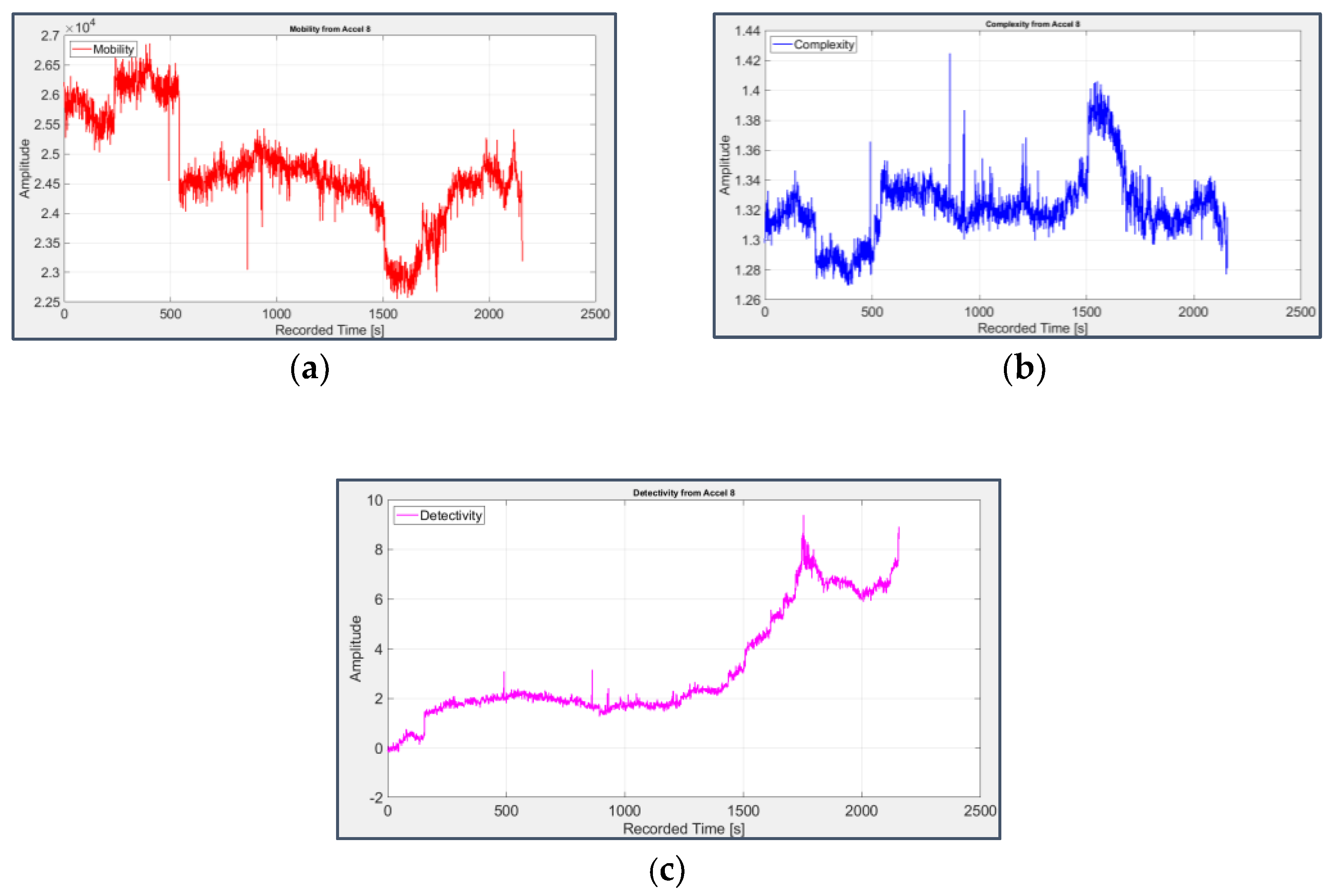

- Detectivity.

- Short-Time Fourier Transform (STFT);

- Power Spectral Density (PSD);

- Squared Envelope Spectrum (SES);

- Autoregressive Linear Prediction (ALP);

- Time-Synchronous Averaging (TSA);

- Kurtosis (time domain);

- Kurtogram.

- Daubechies’ Wavelets;

- Cepstrum Pre-Whitening (CPW);

- FIR;

- Adaptive;

- Spectral Correlation (SC);

- Cyclic Spectral Coherence (CSC);

- Improved Envelope Spectrum (IES);

- Wigner-Ville Distribution (WVD).

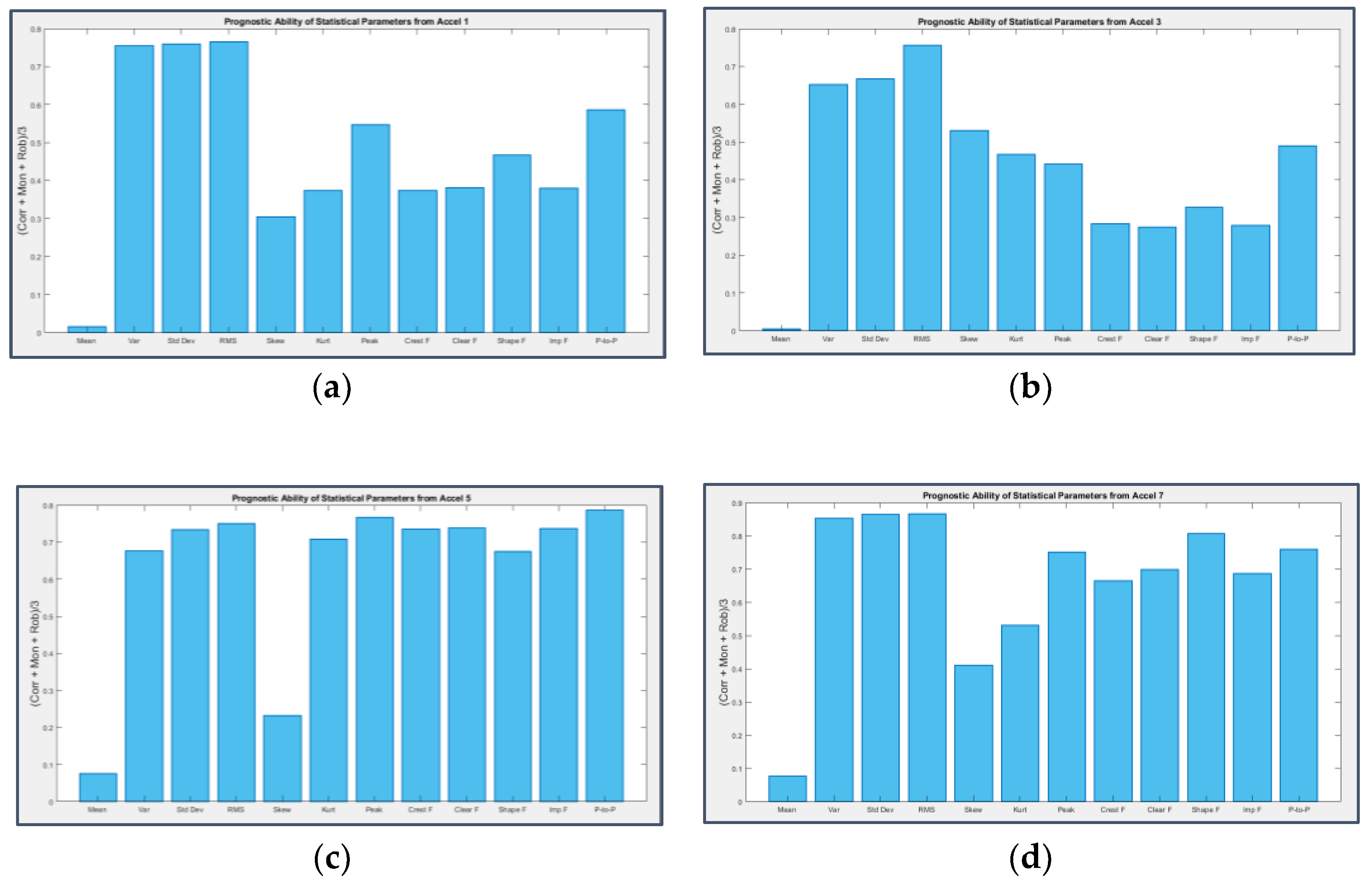

- Correlation;

- Monotonicity;

- Robustness.

3. Results

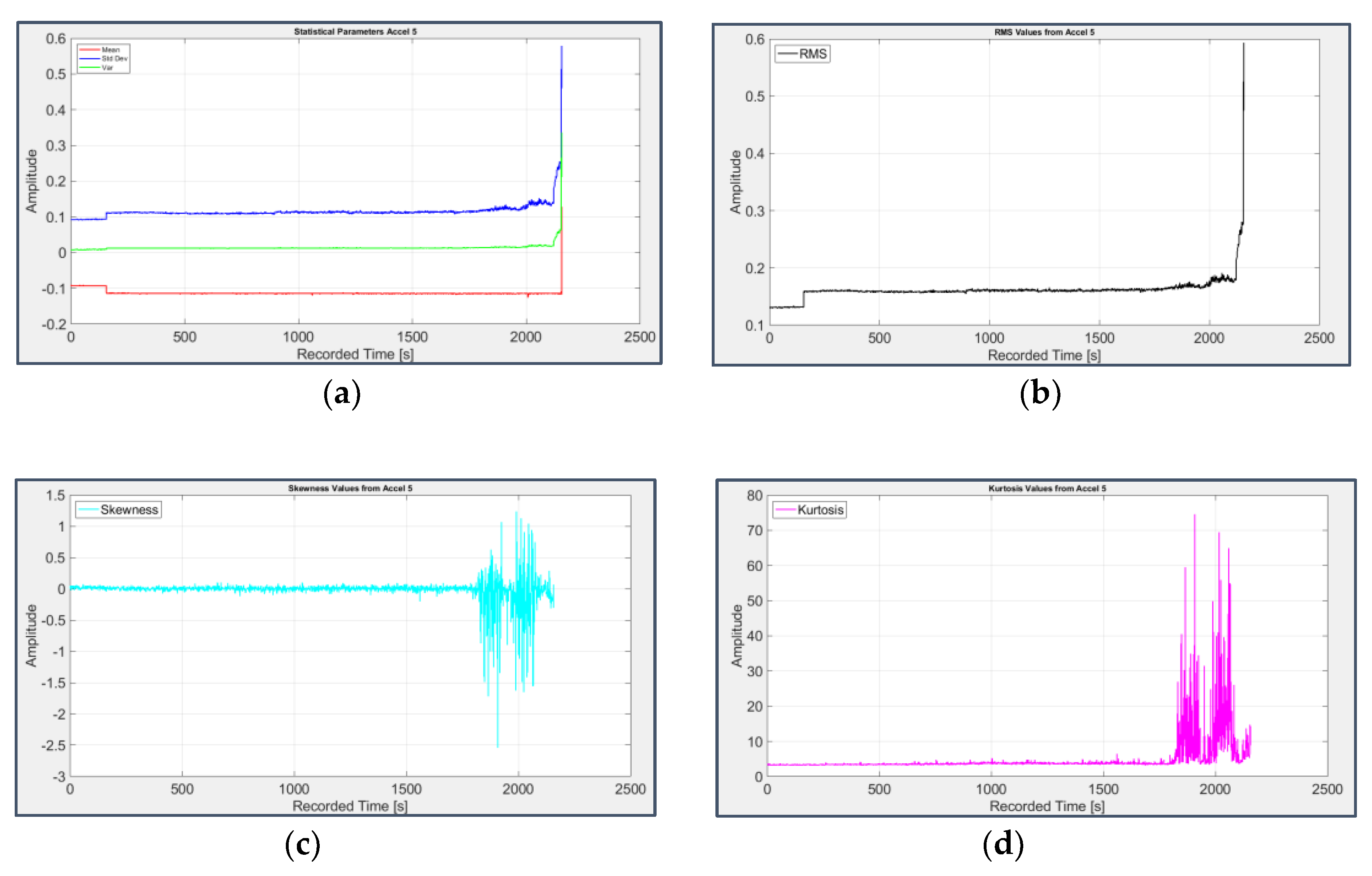

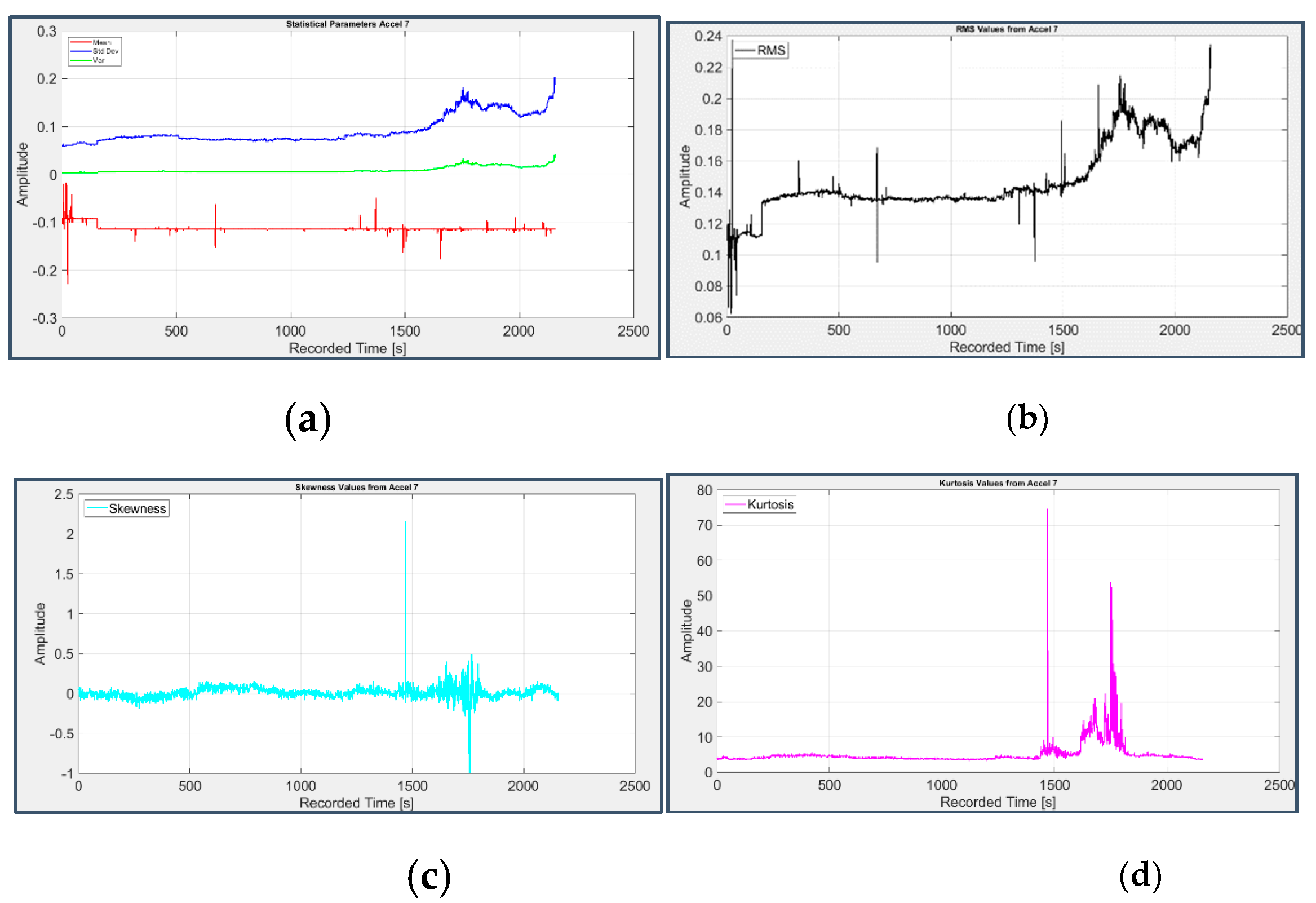

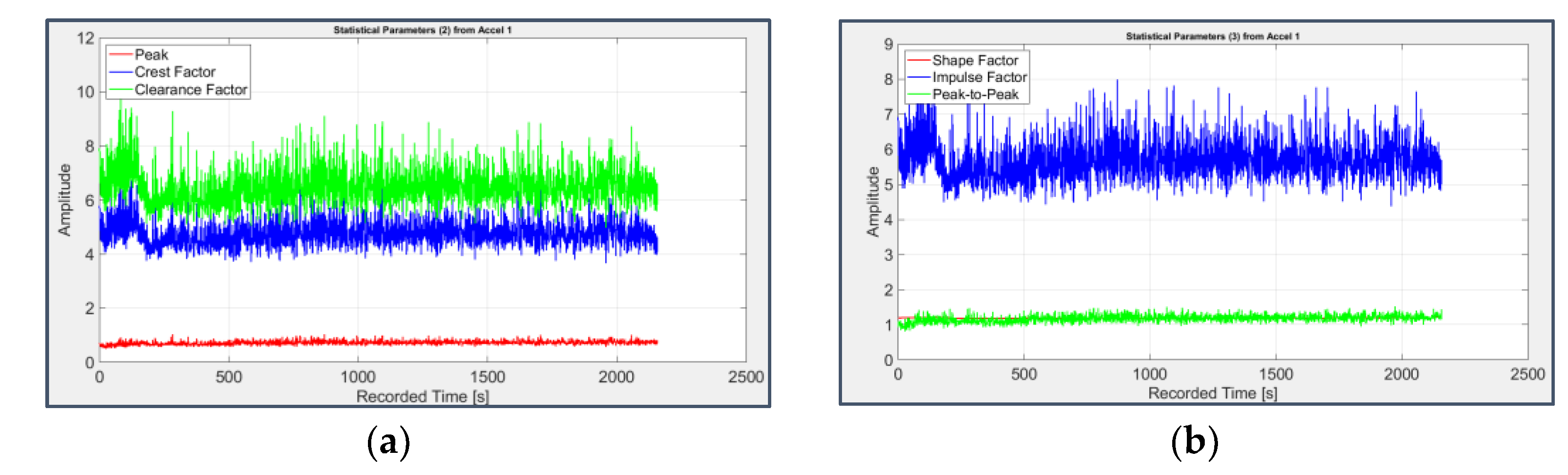

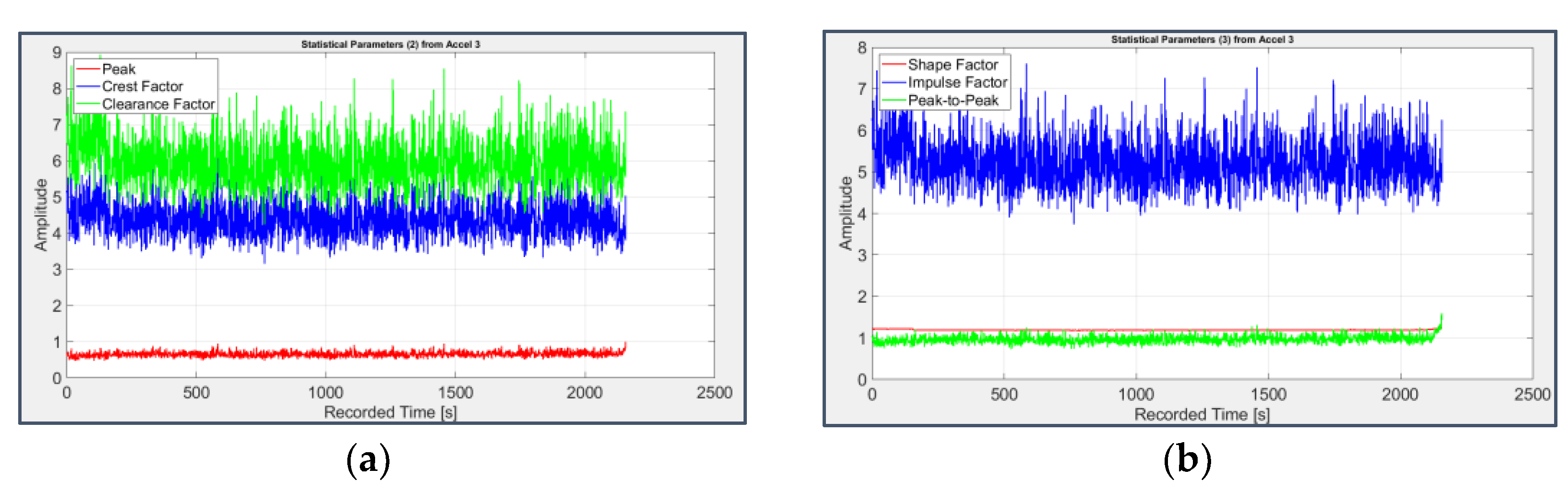

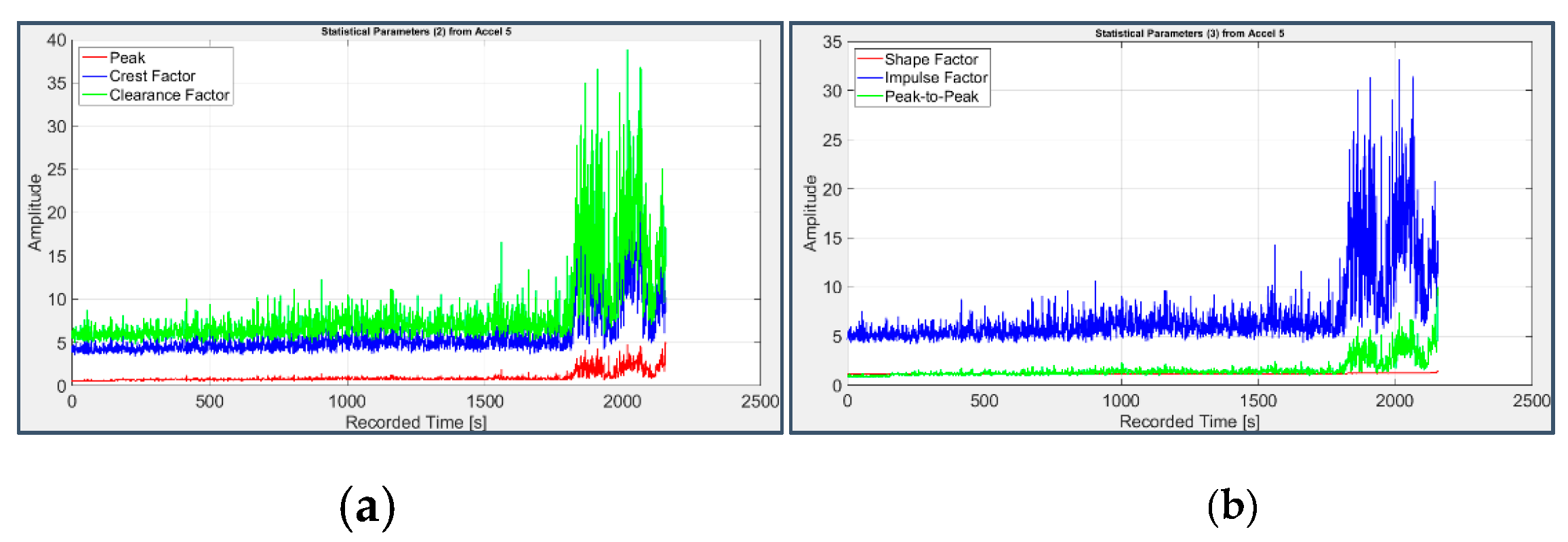

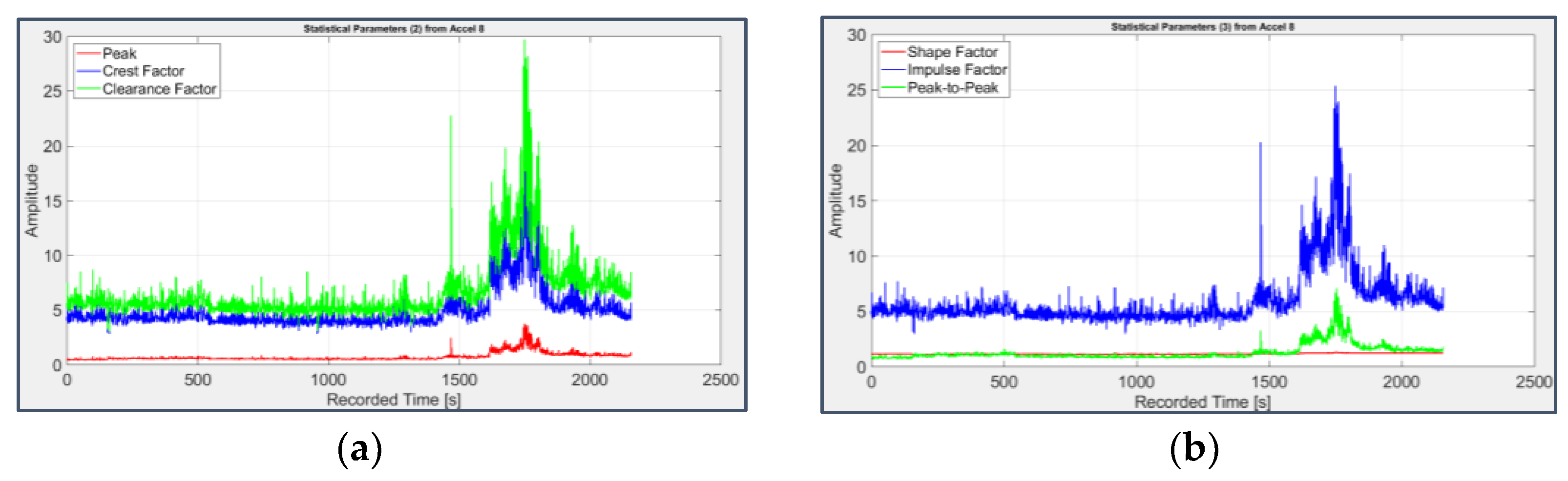

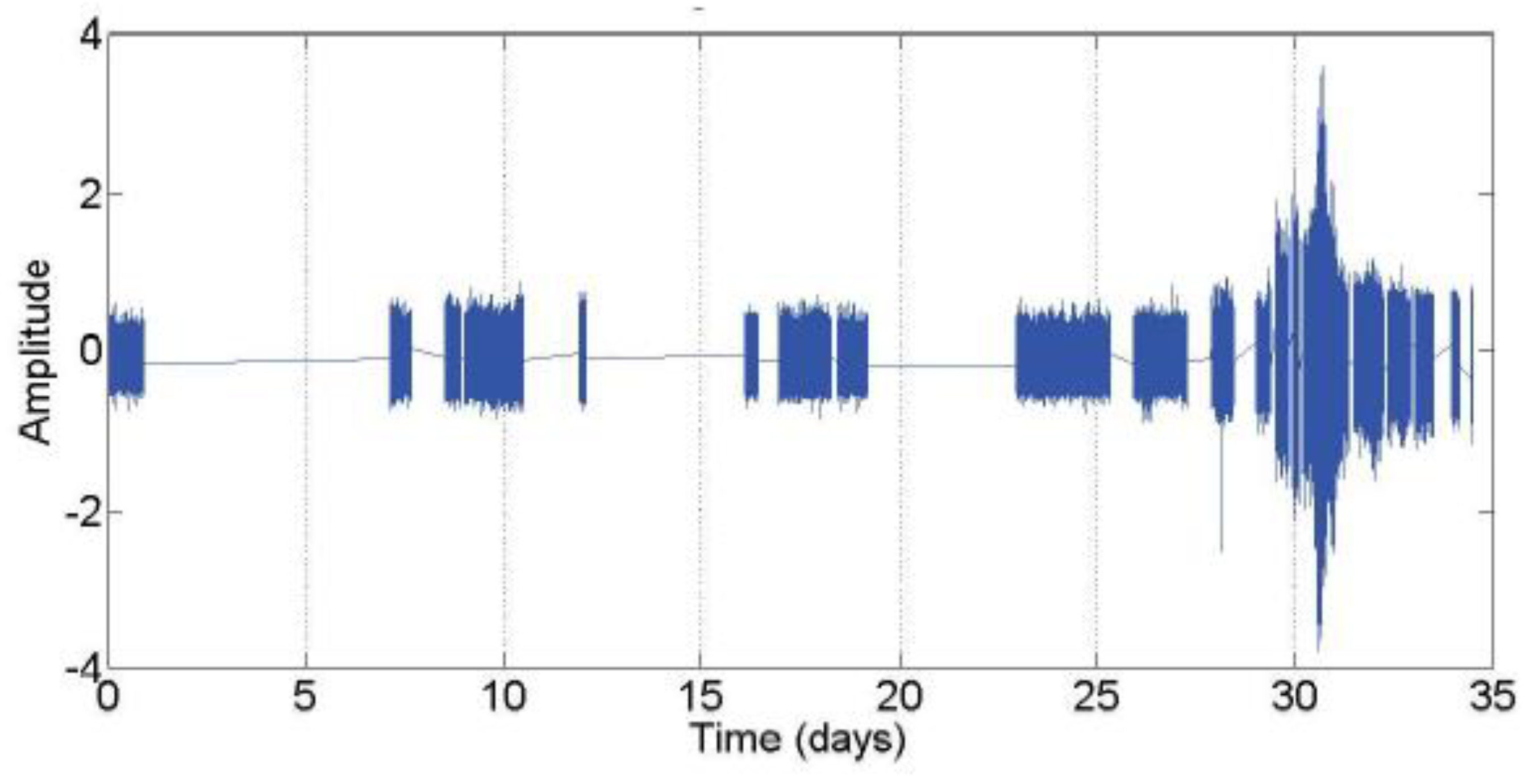

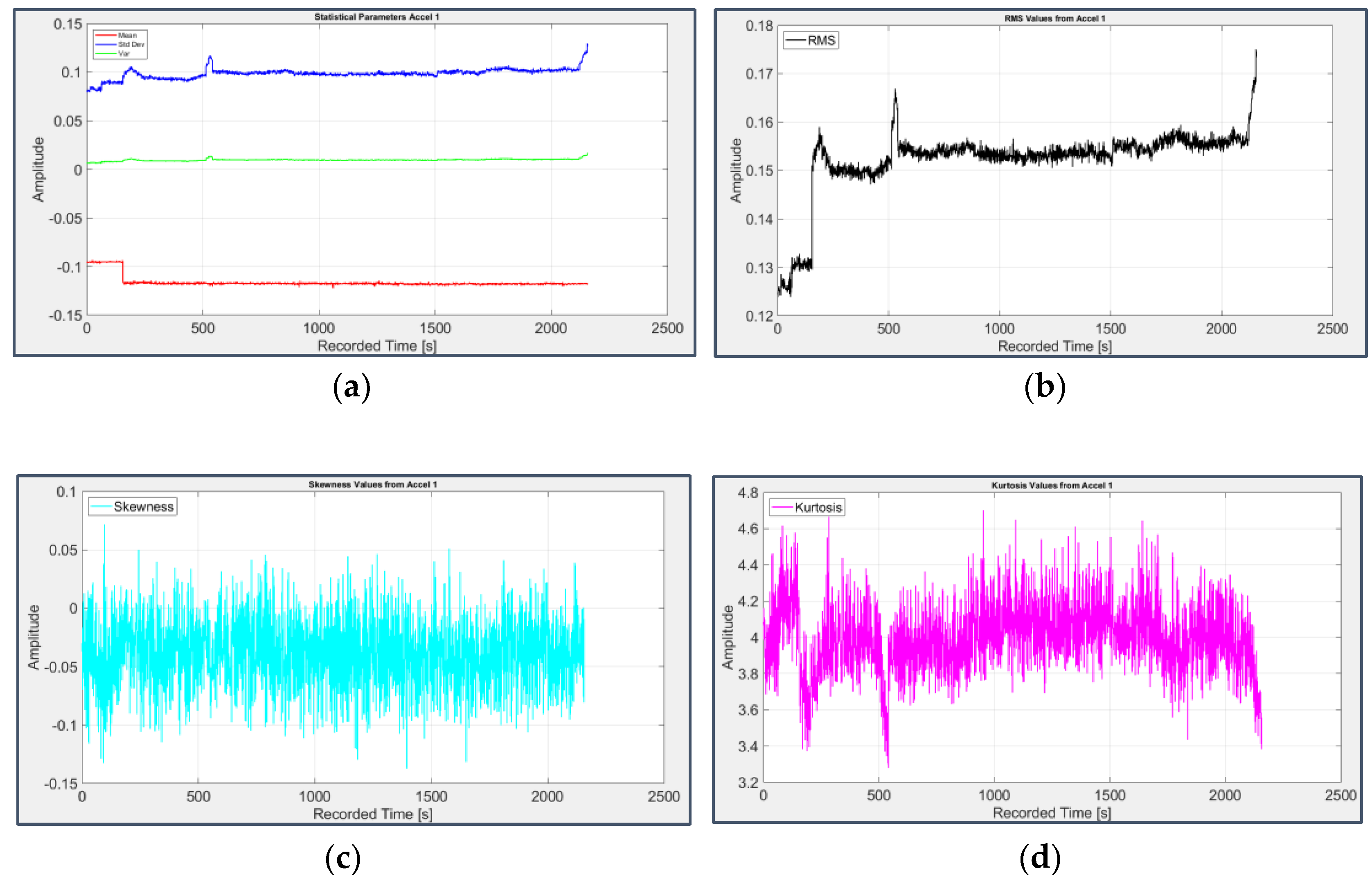

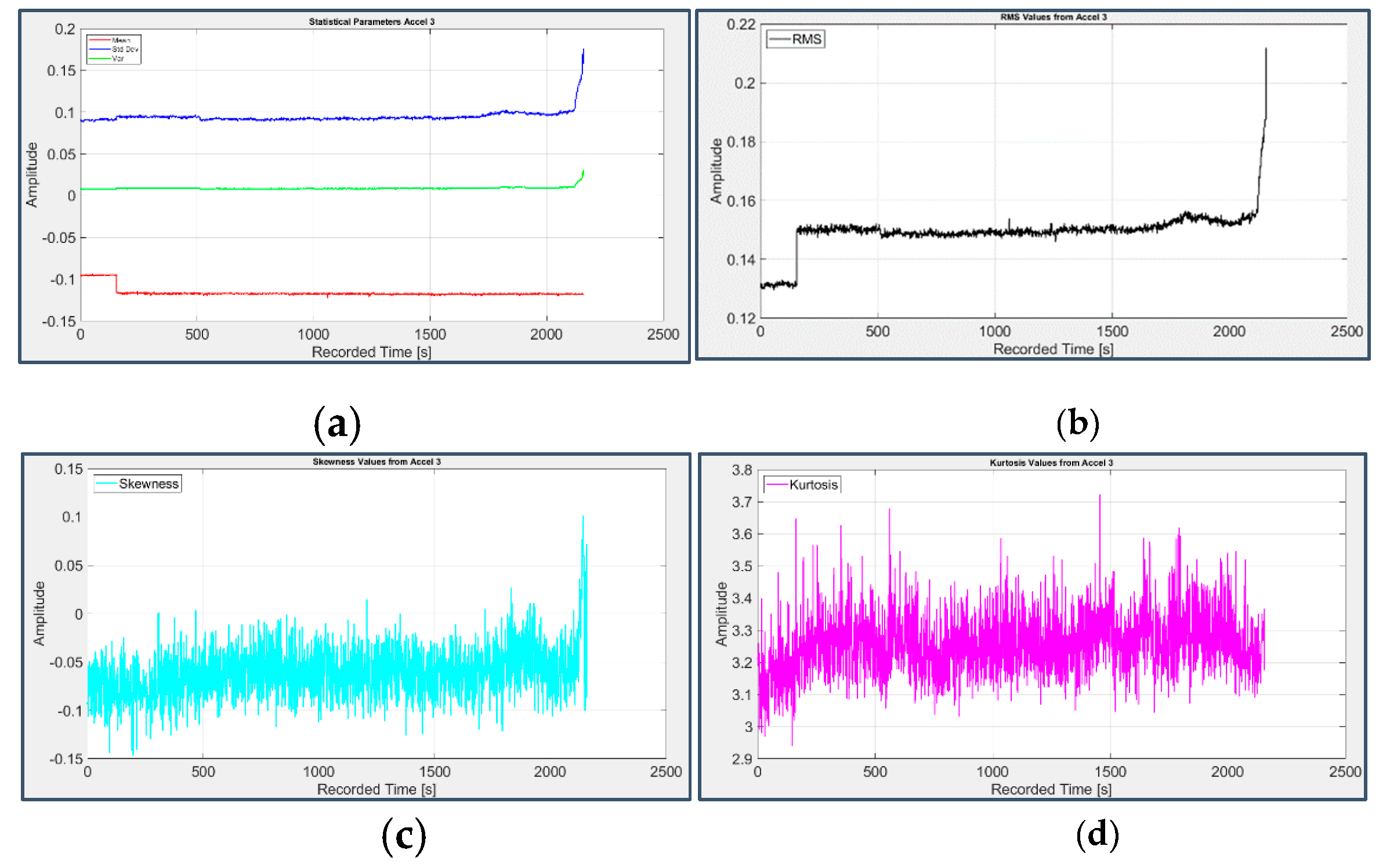

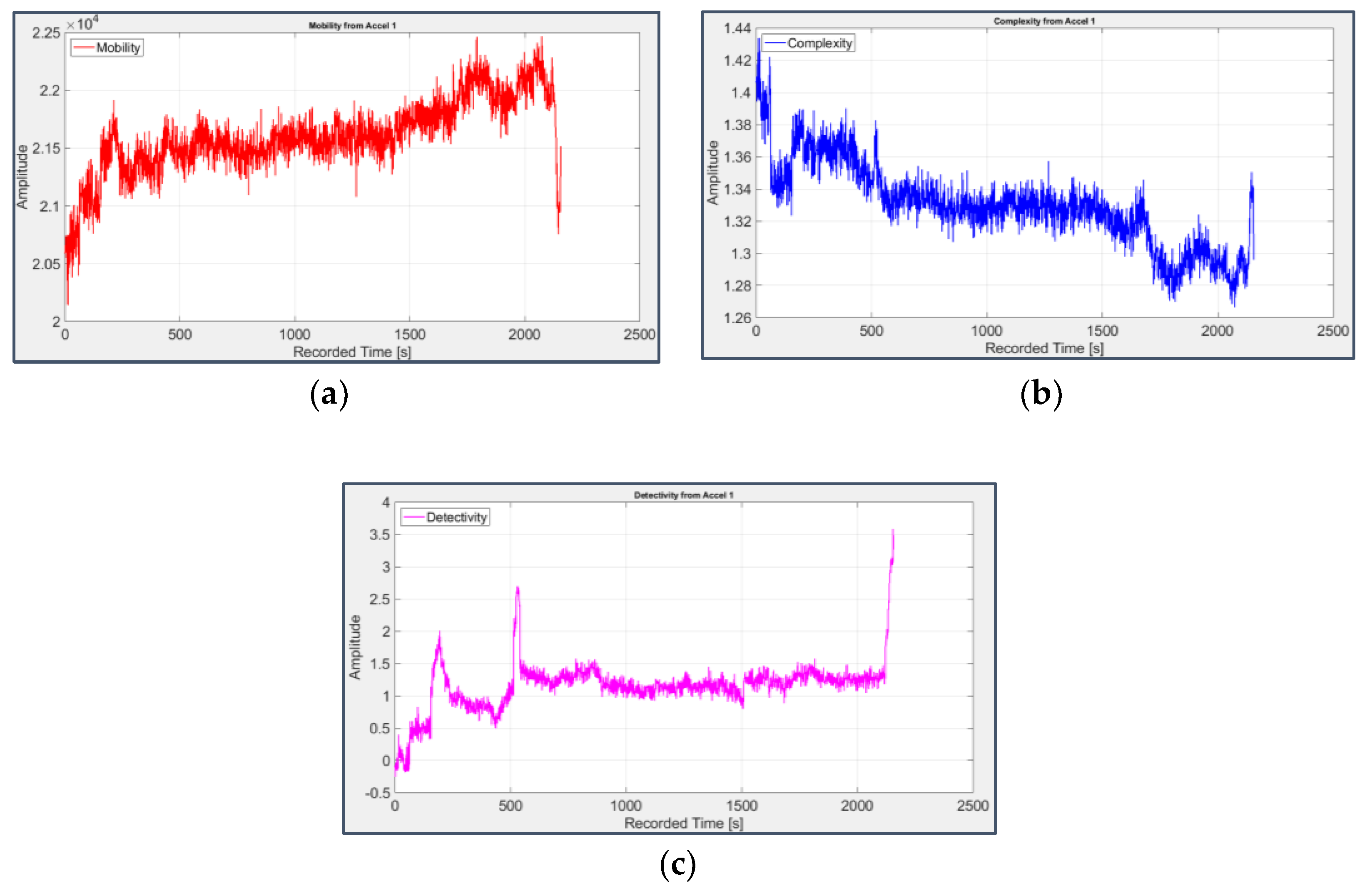

3.1. Fault detection

3.2. Fault diagnosis

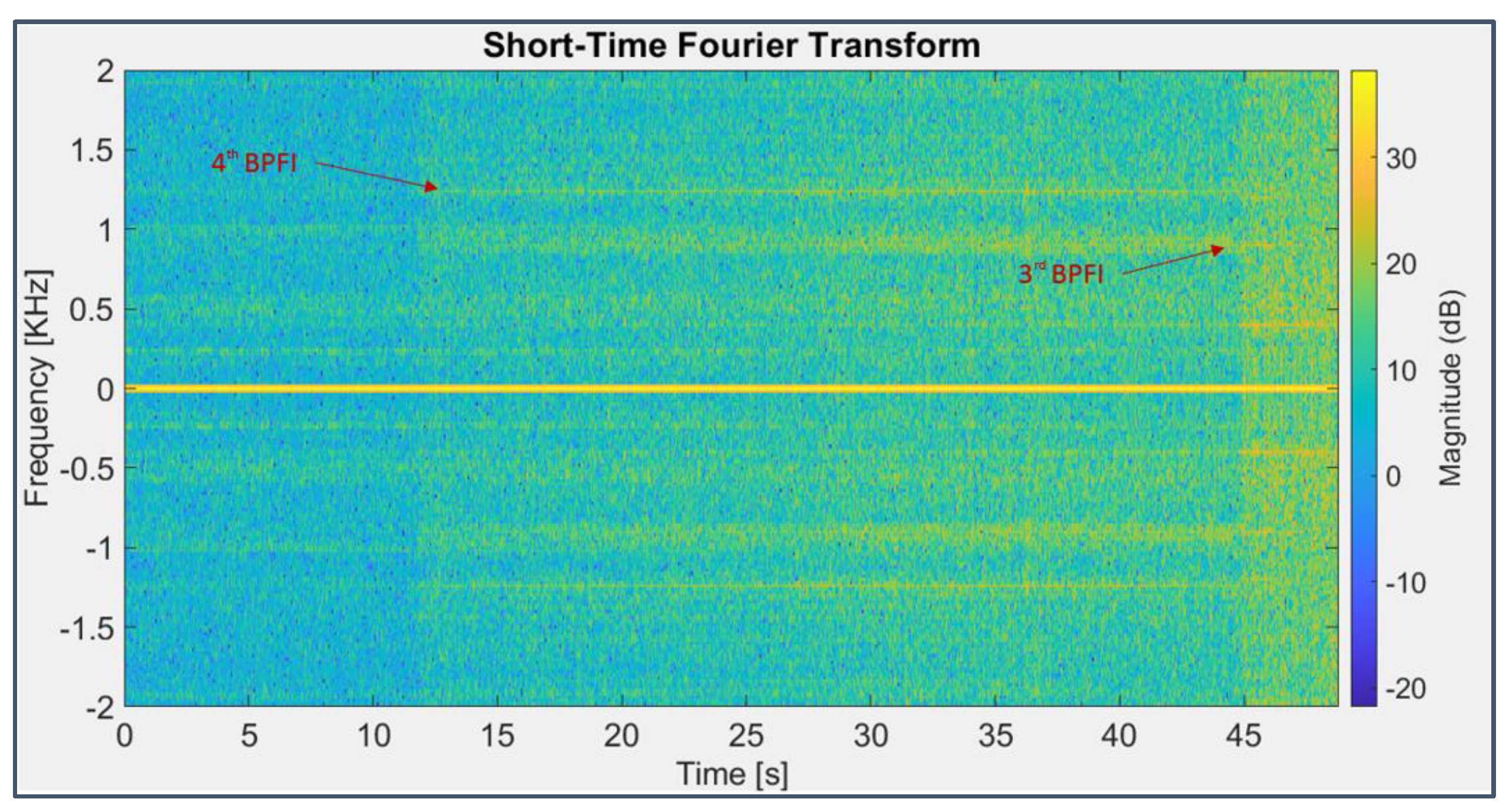

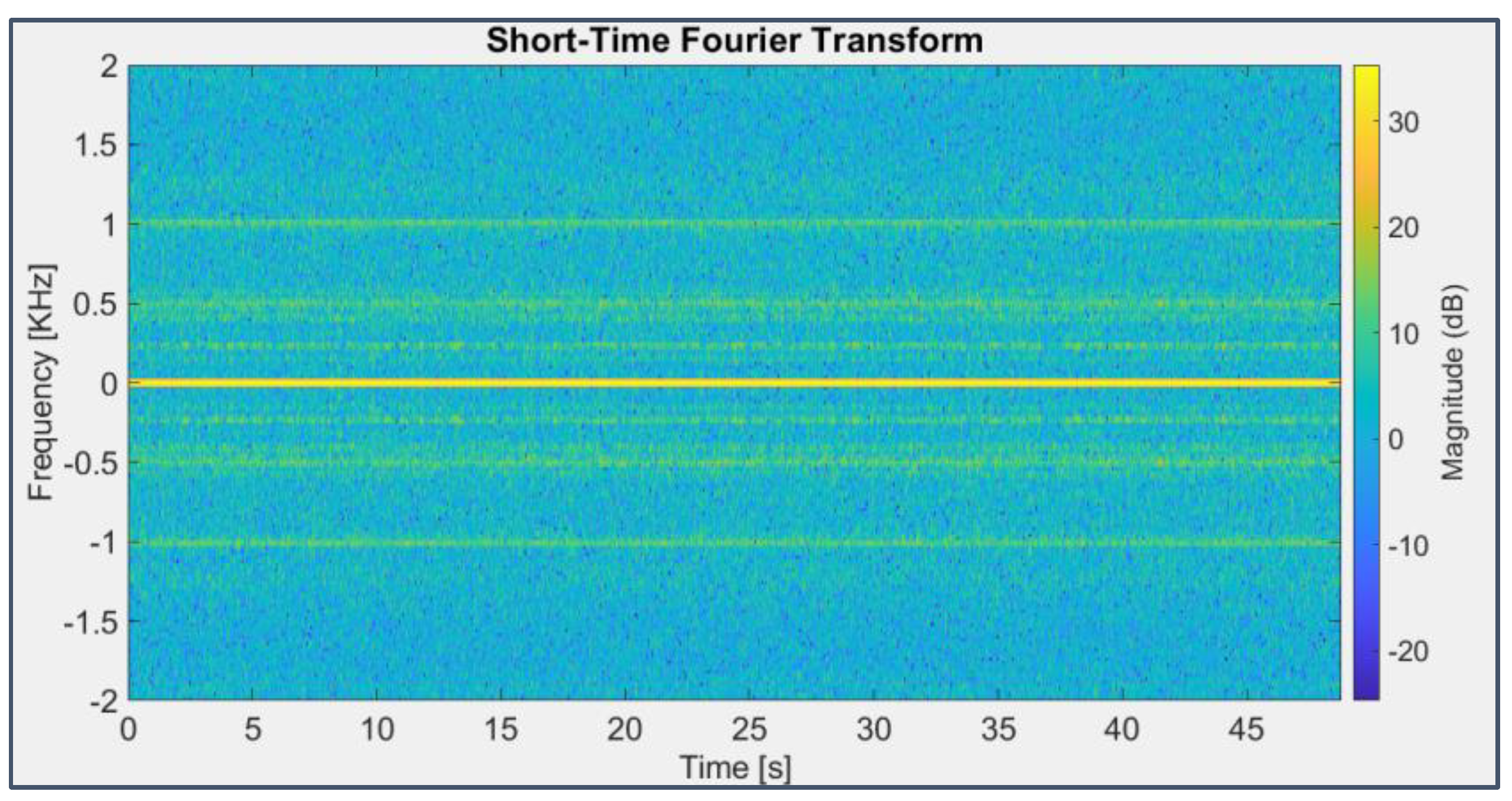

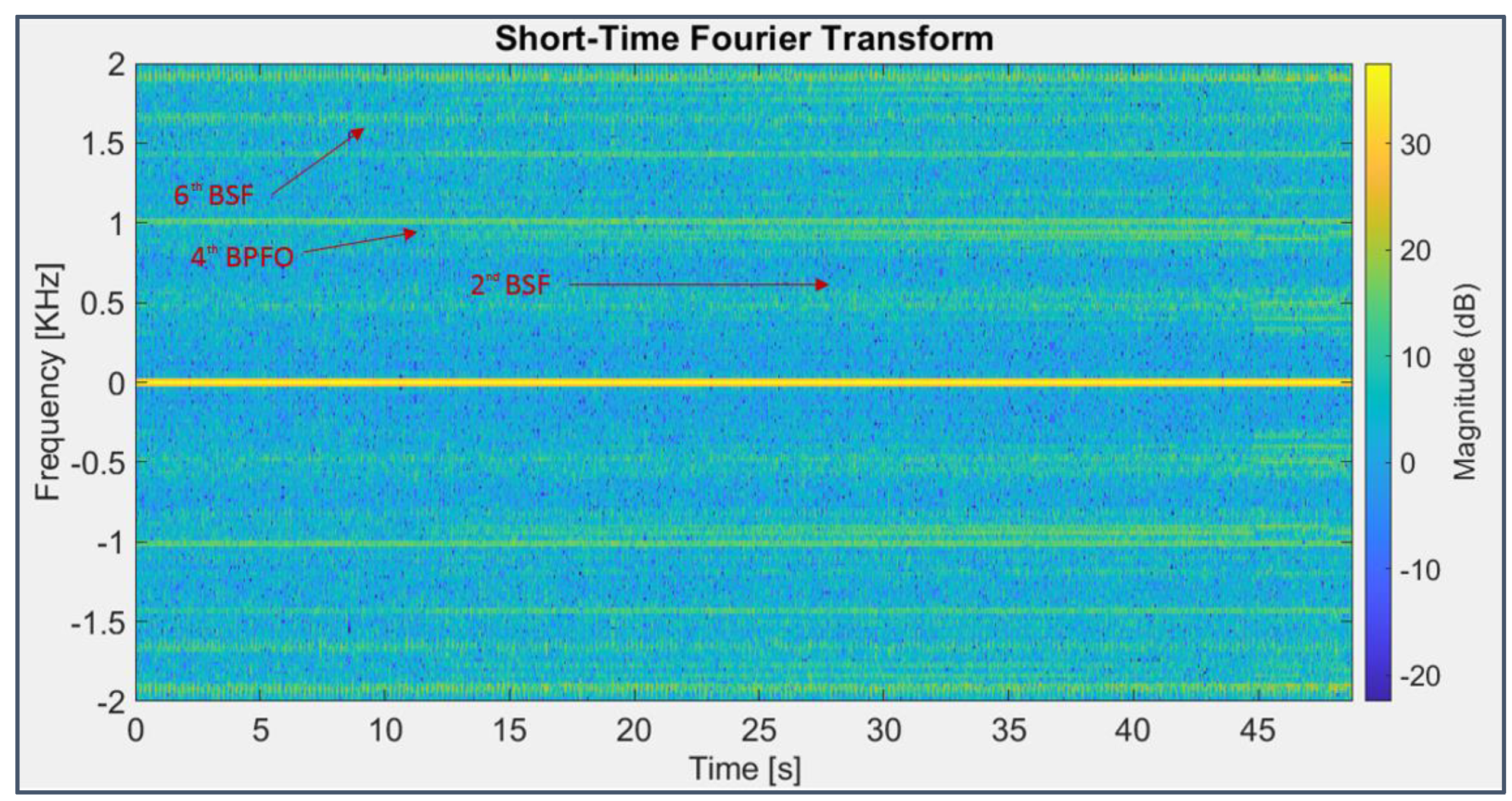

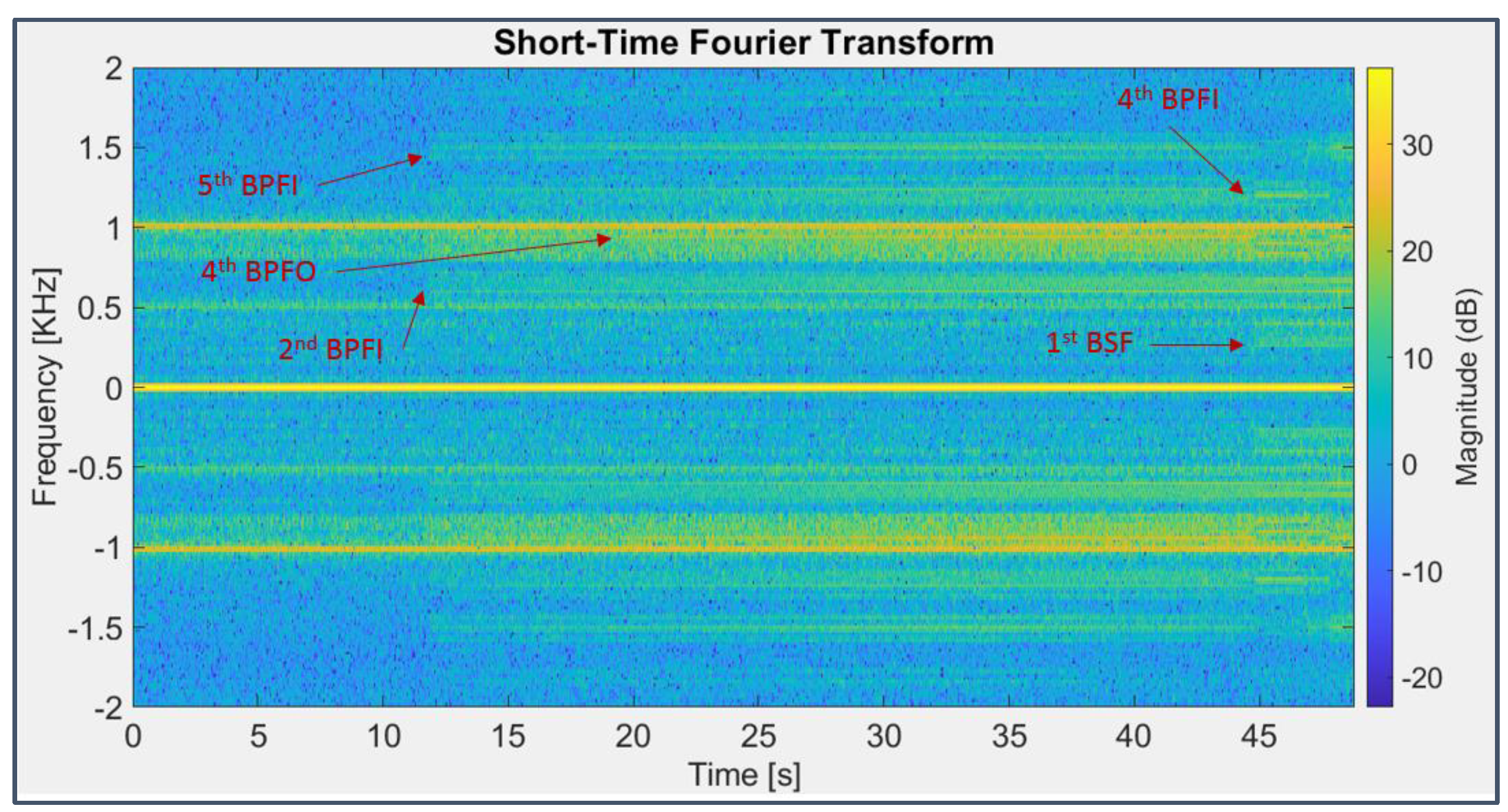

3.2.1. Short-Time Fourier Transform (STFT)

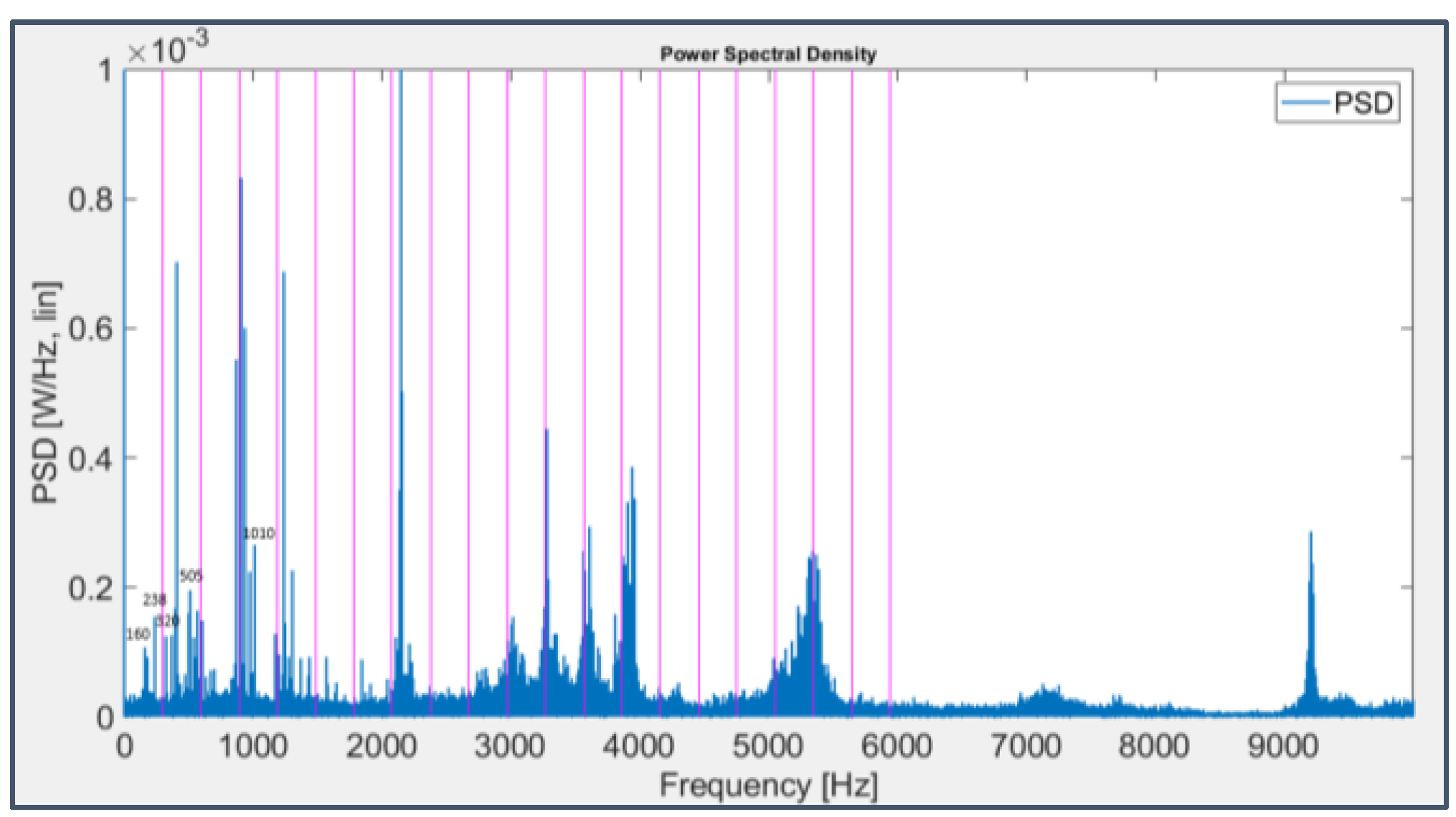

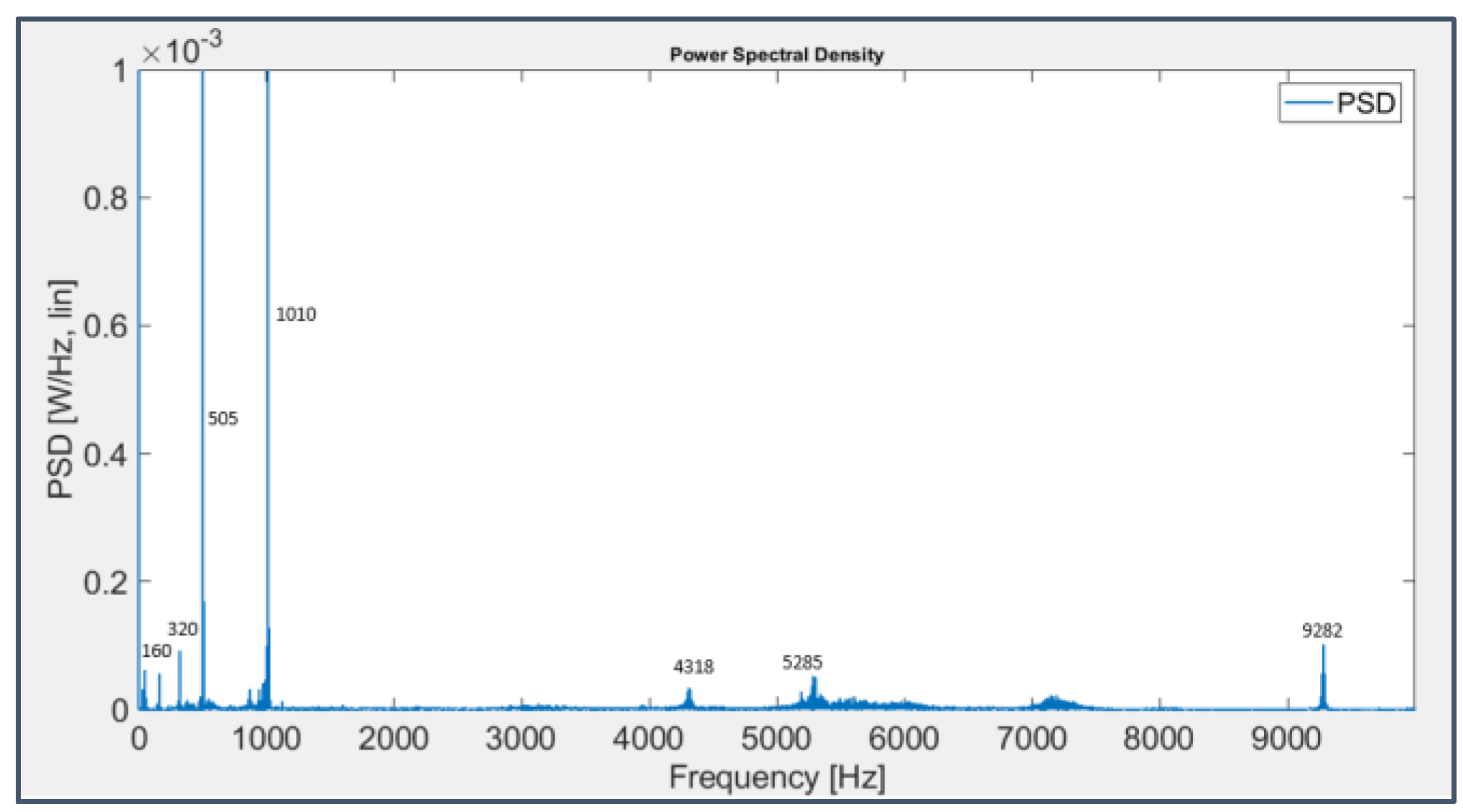

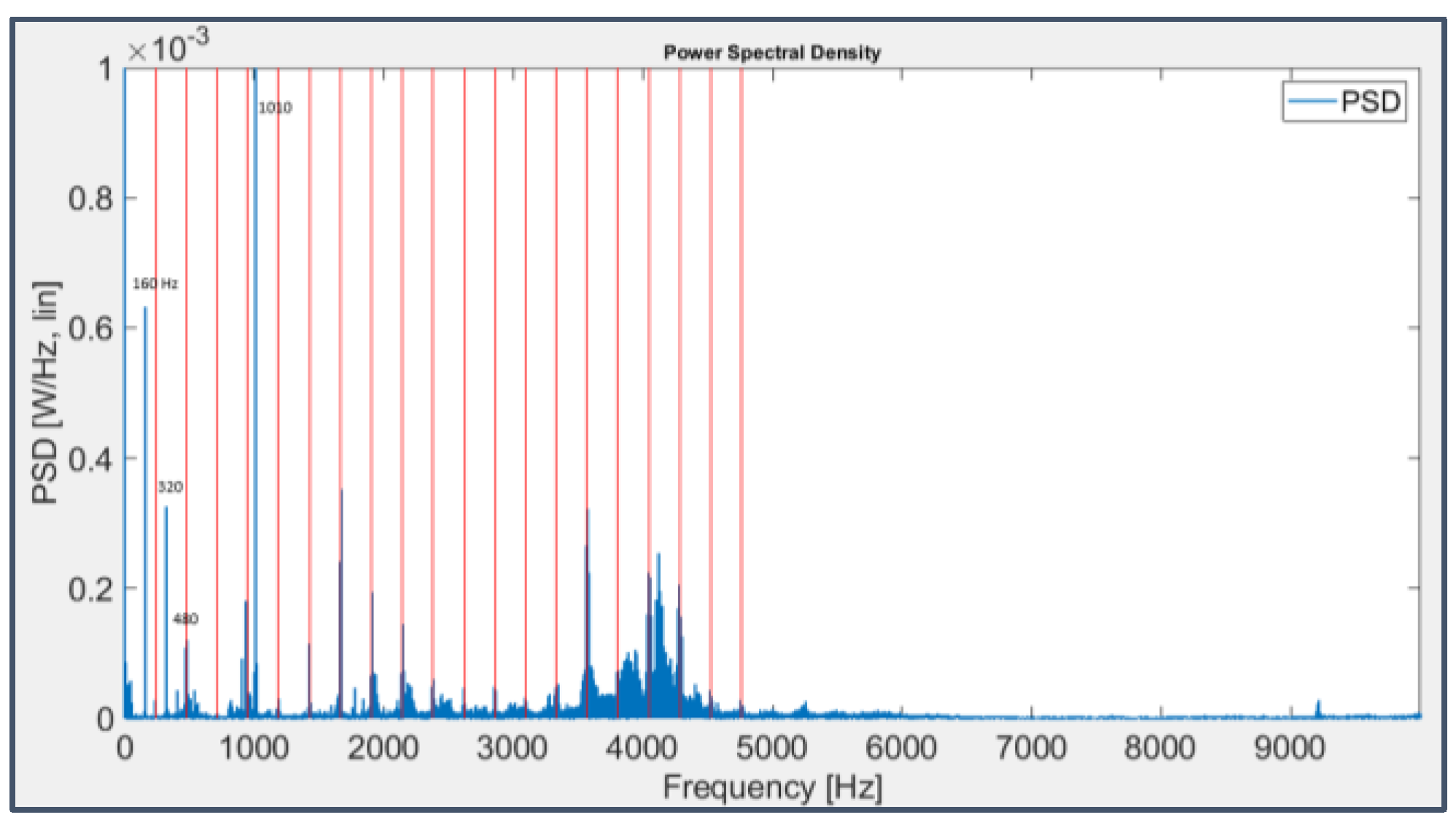

3.2.2. Power Spectral Density (PSD)

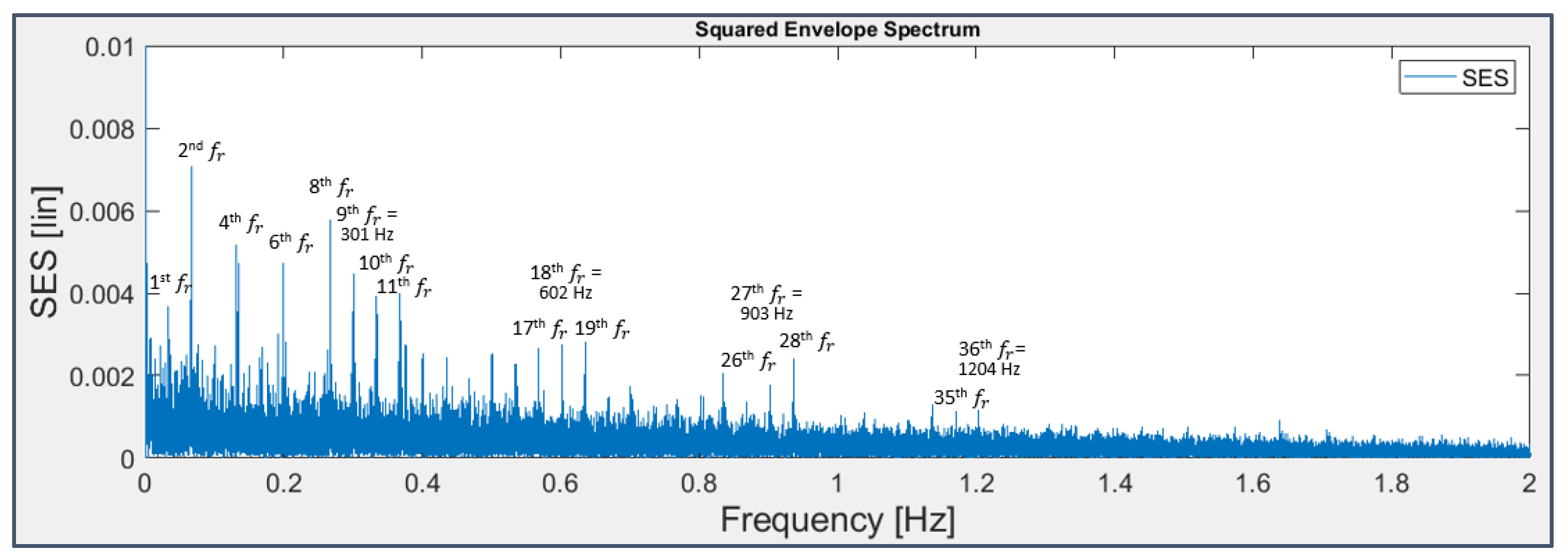

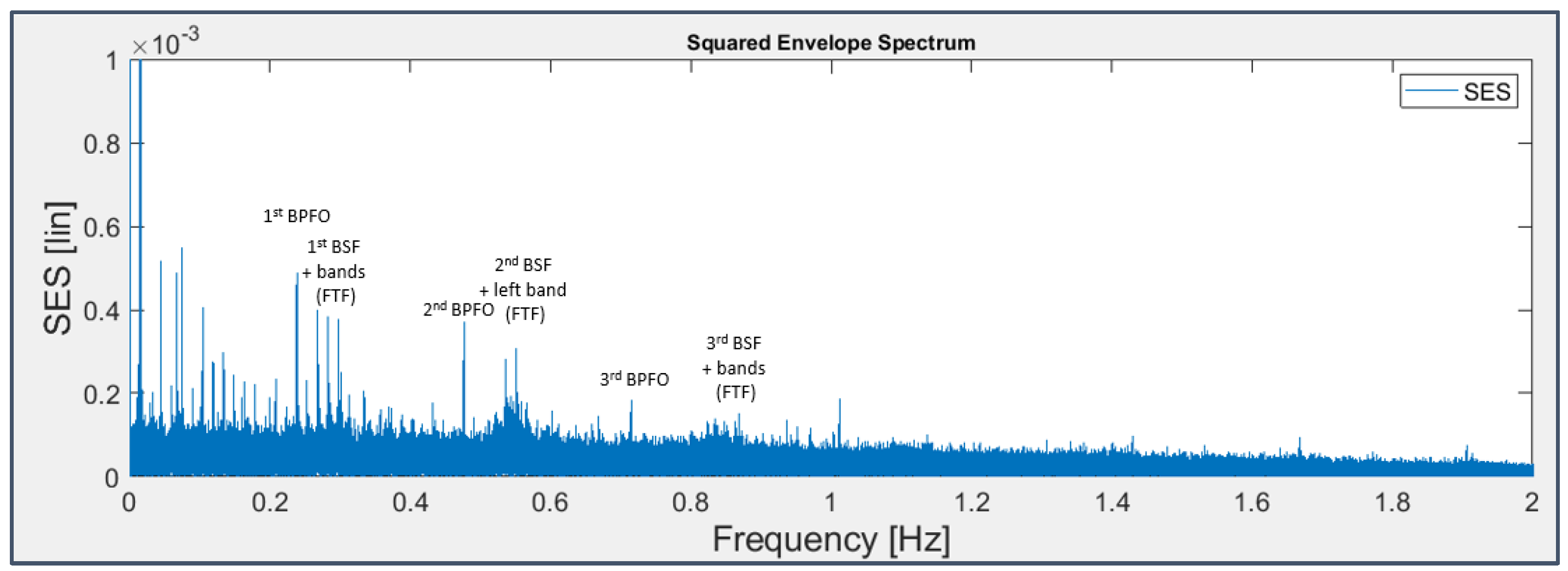

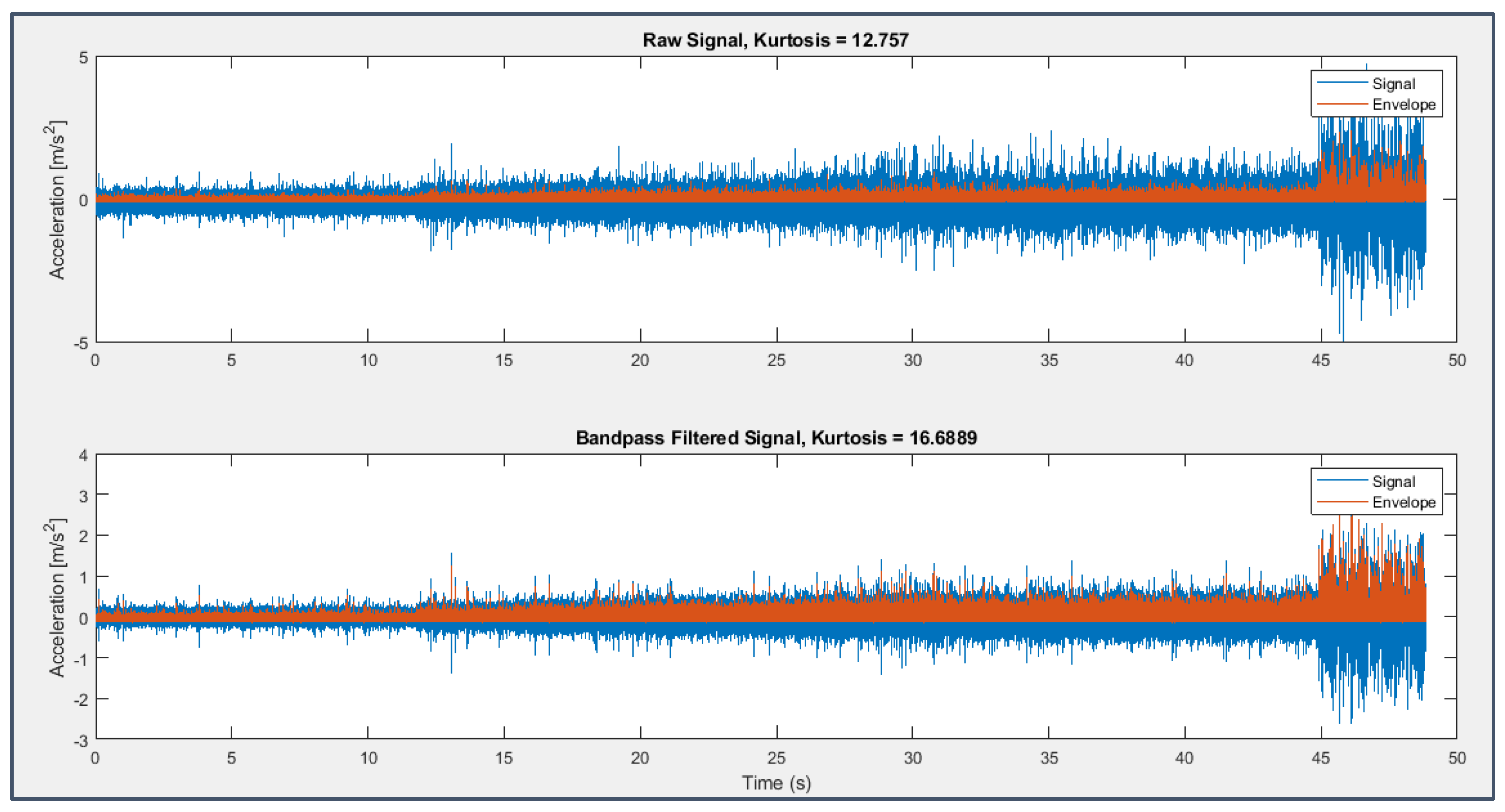

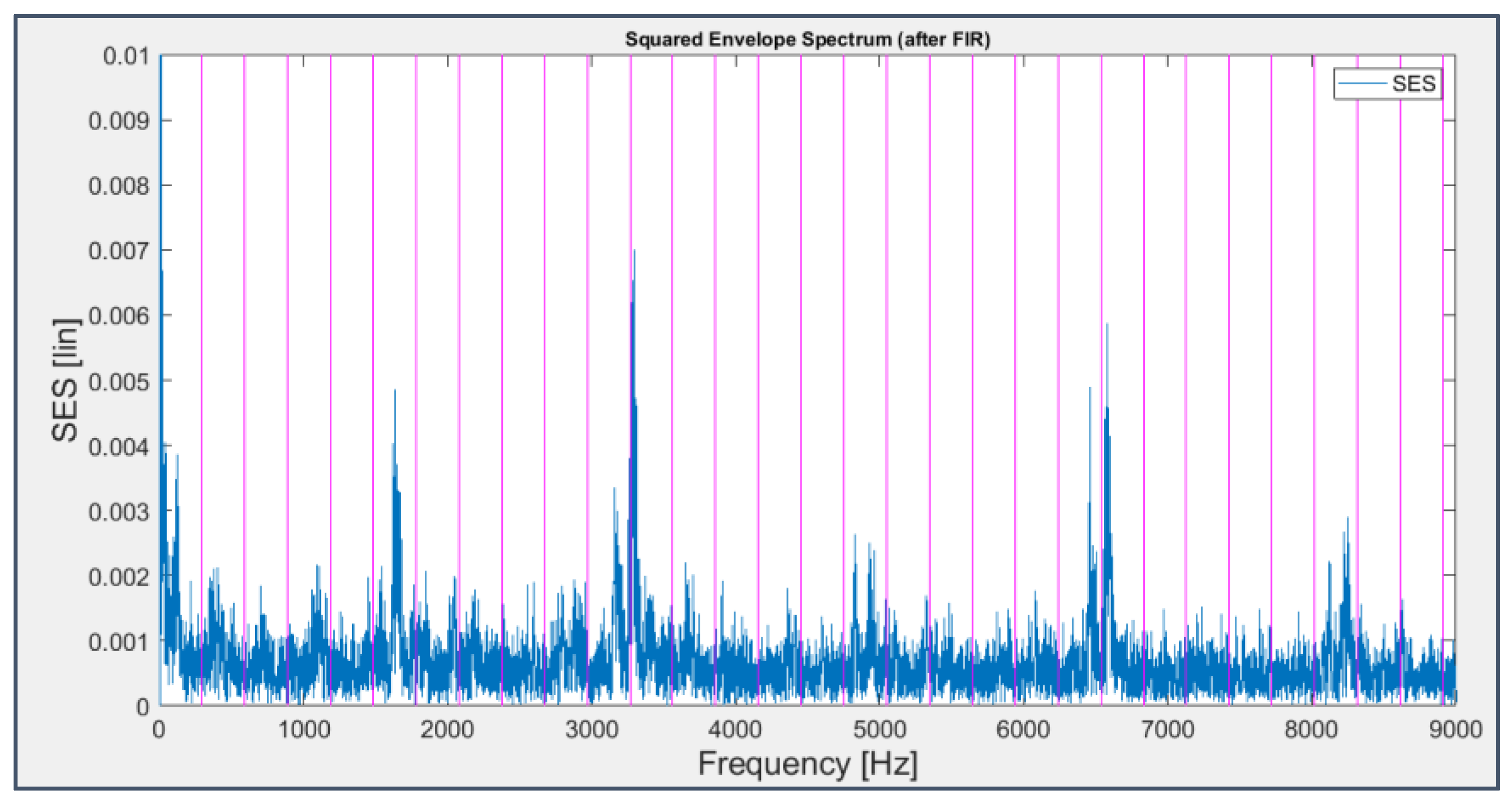

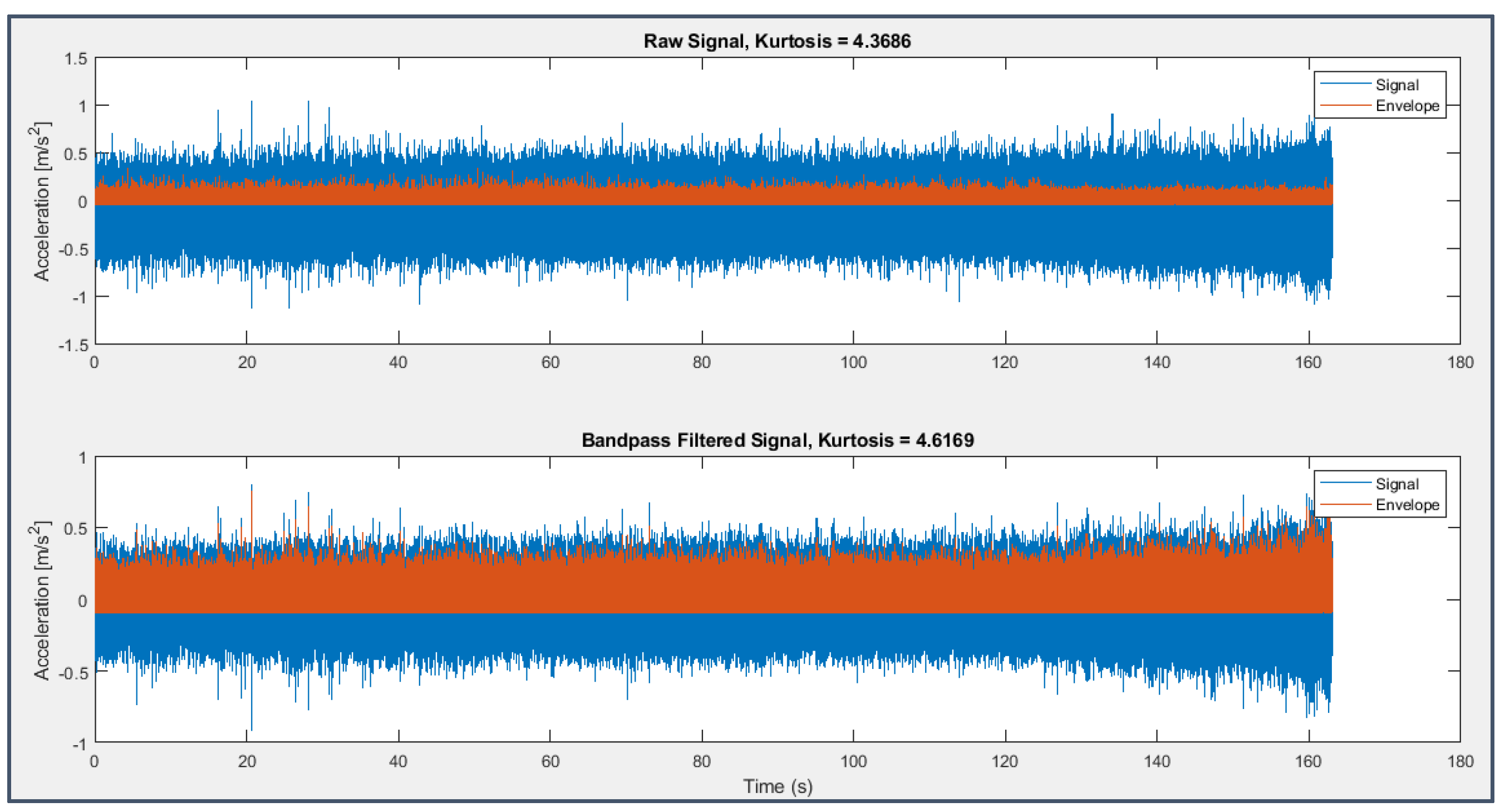

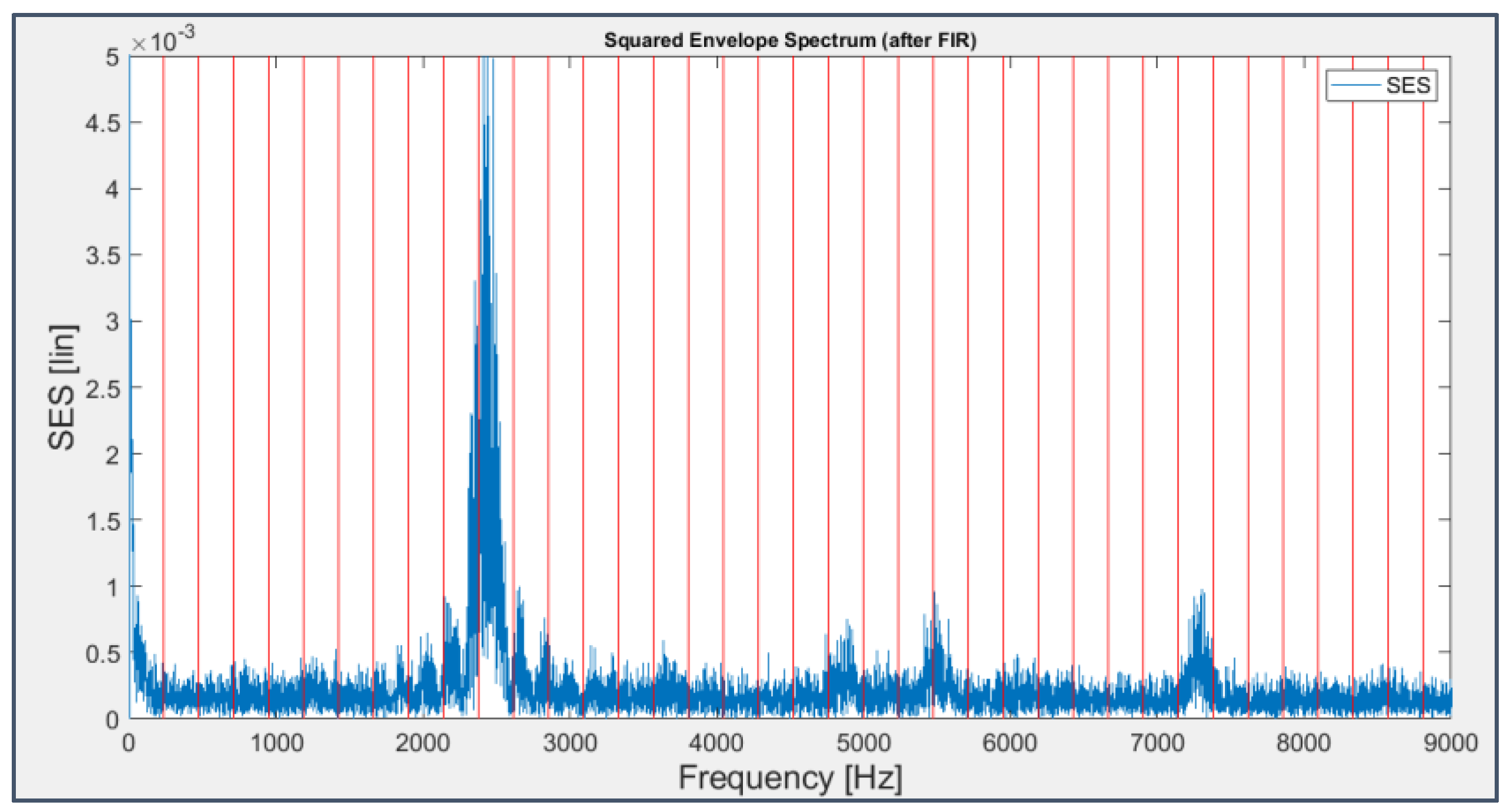

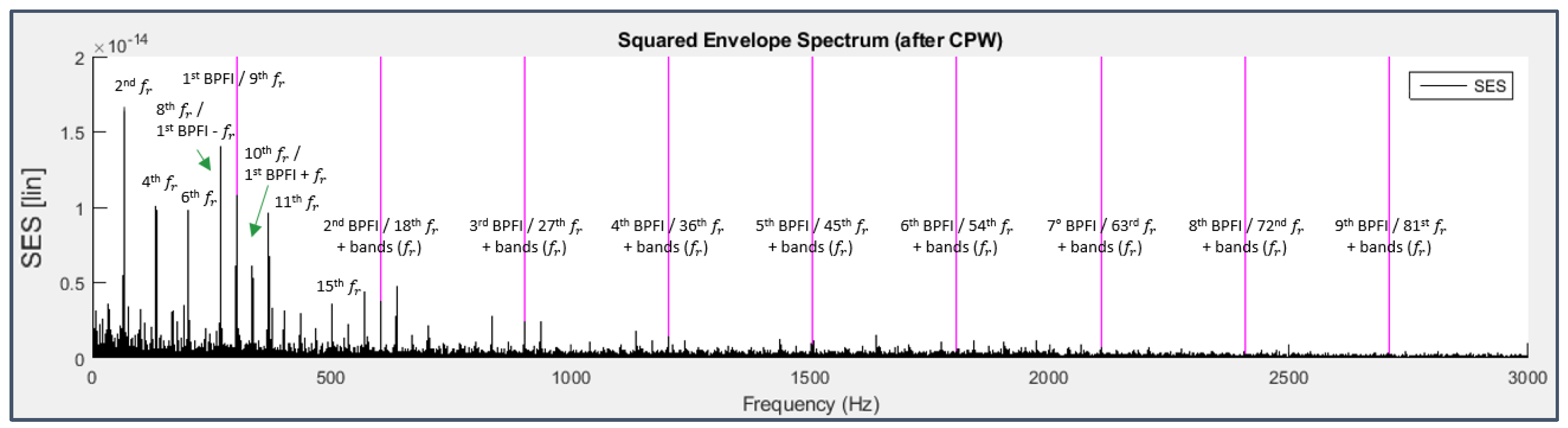

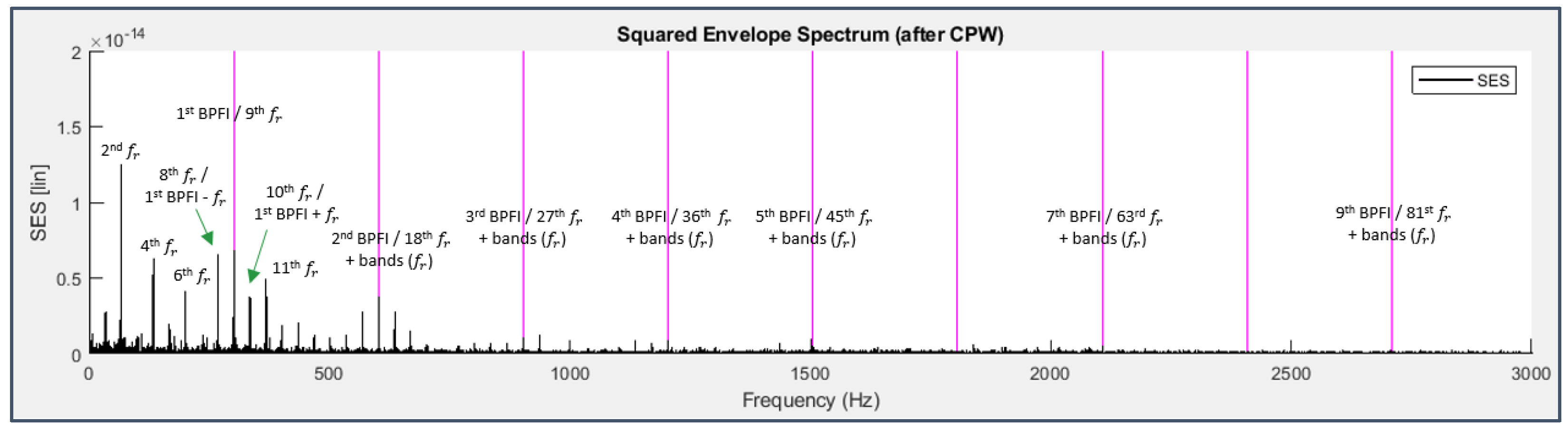

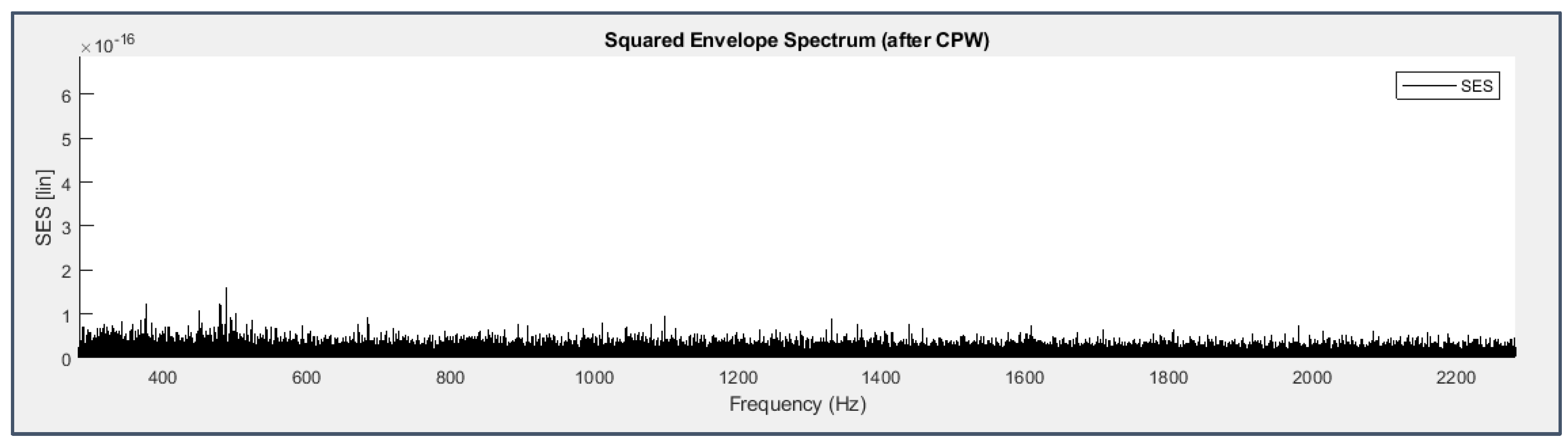

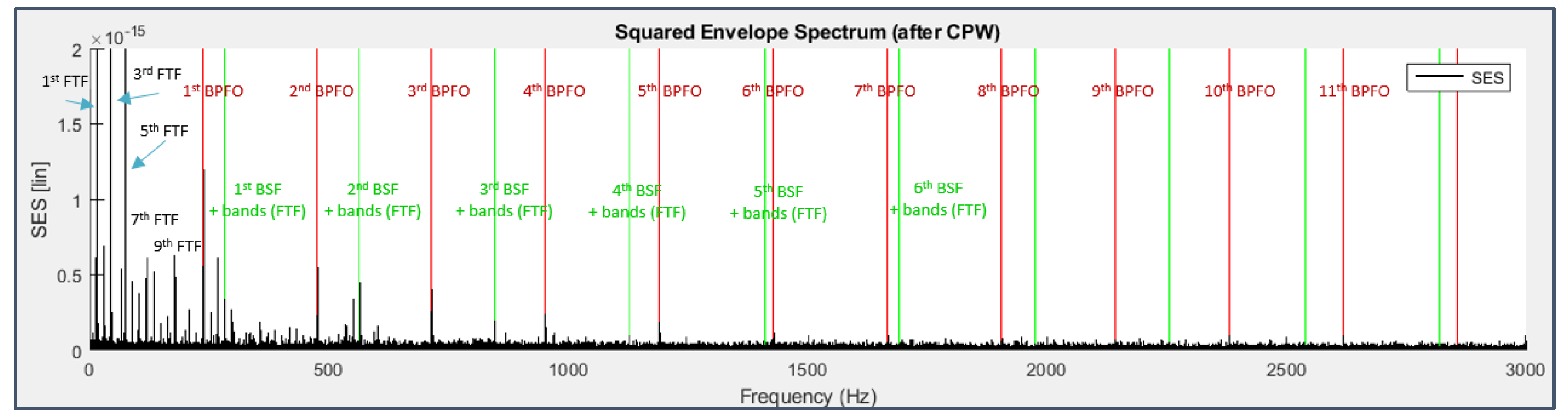

3.2.3. Squared Envelope Spectrum (SES)

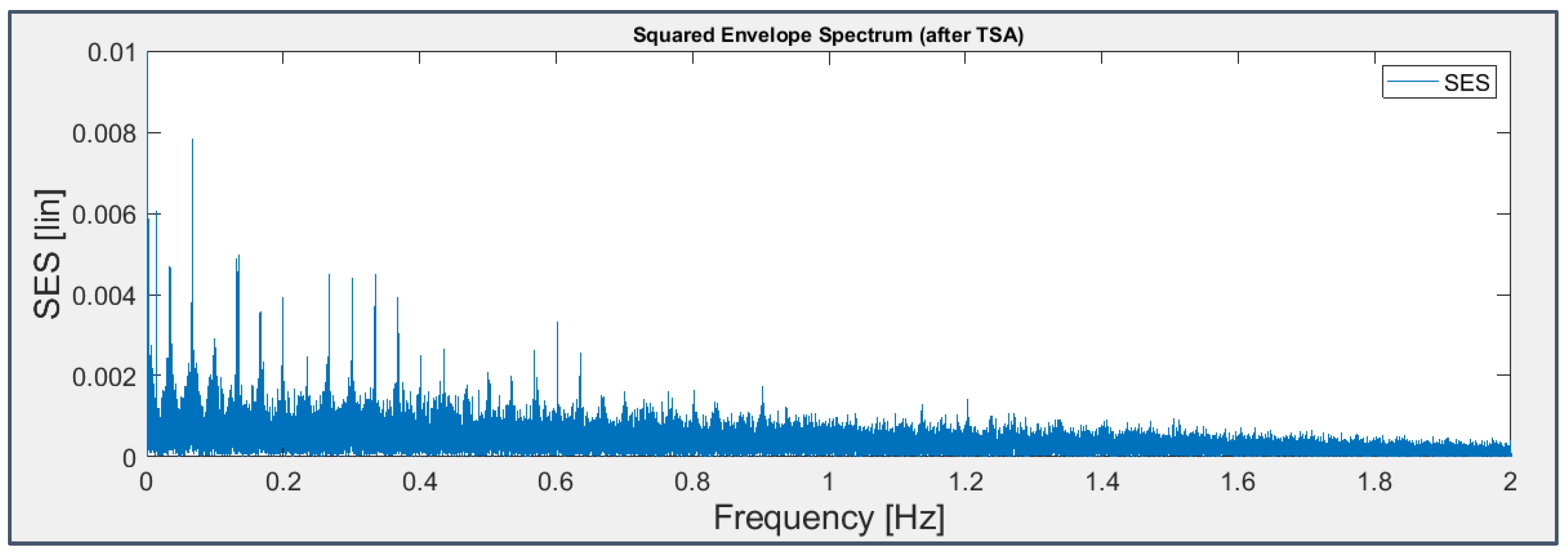

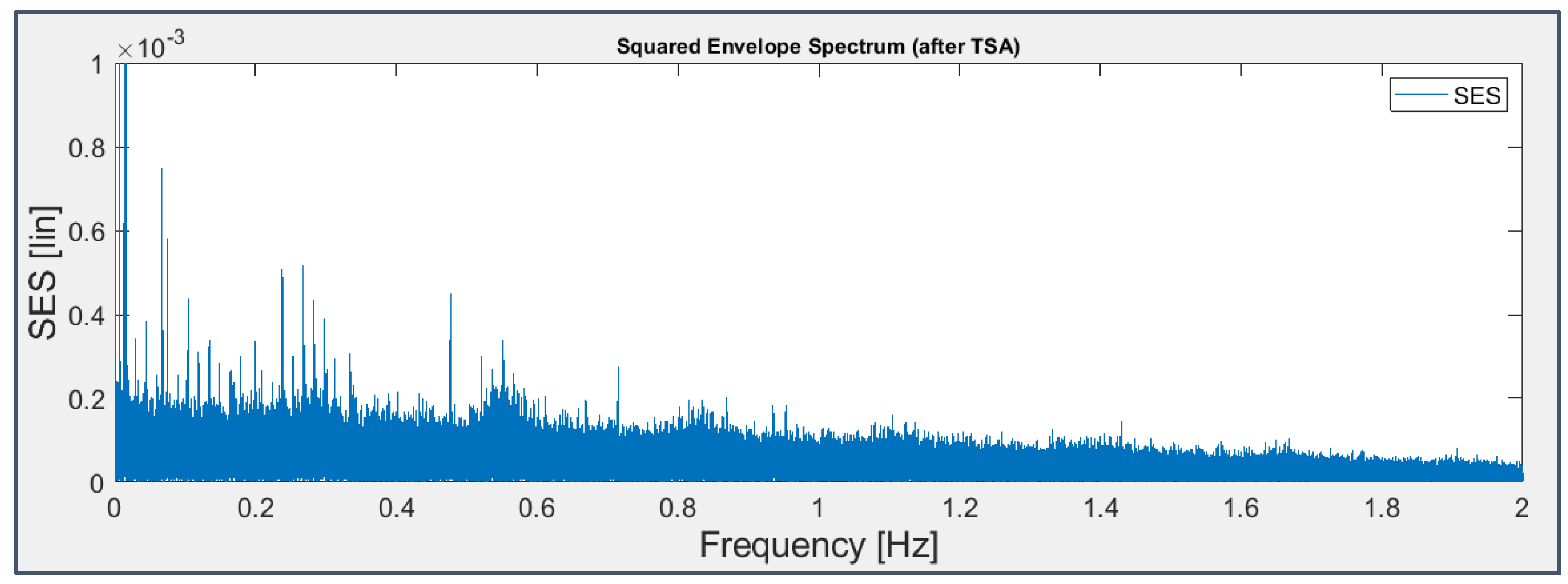

3.2.4. Time-Synchronous Average (TSA)

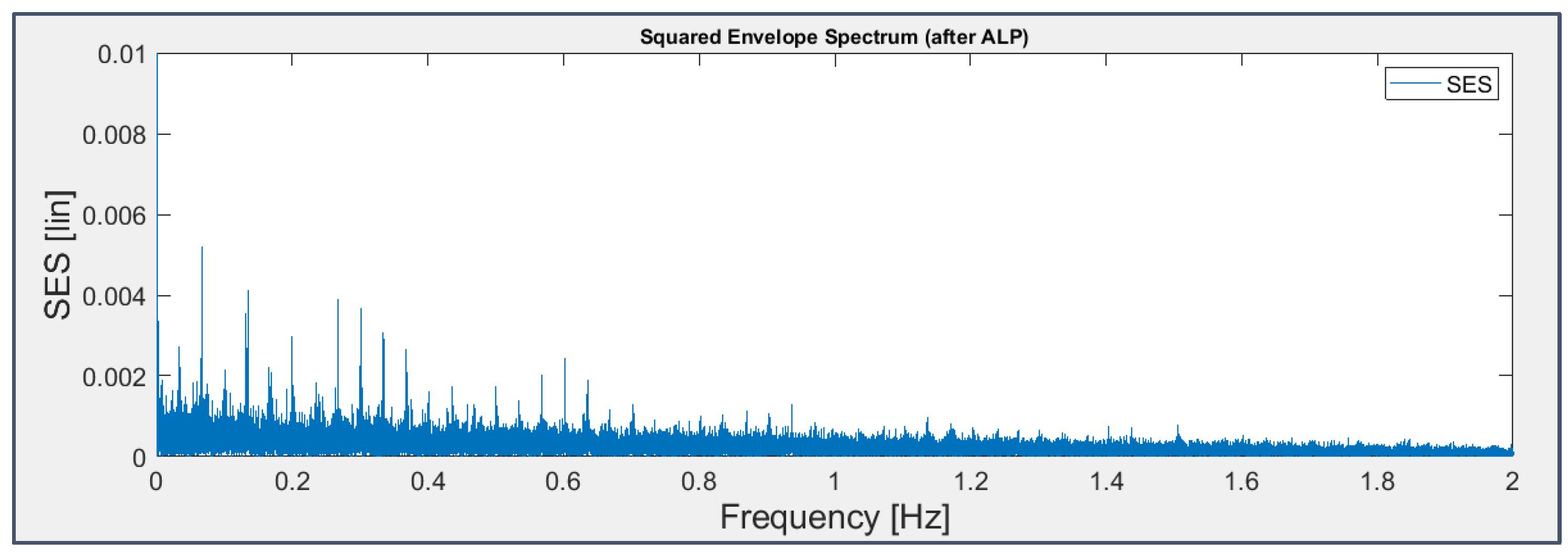

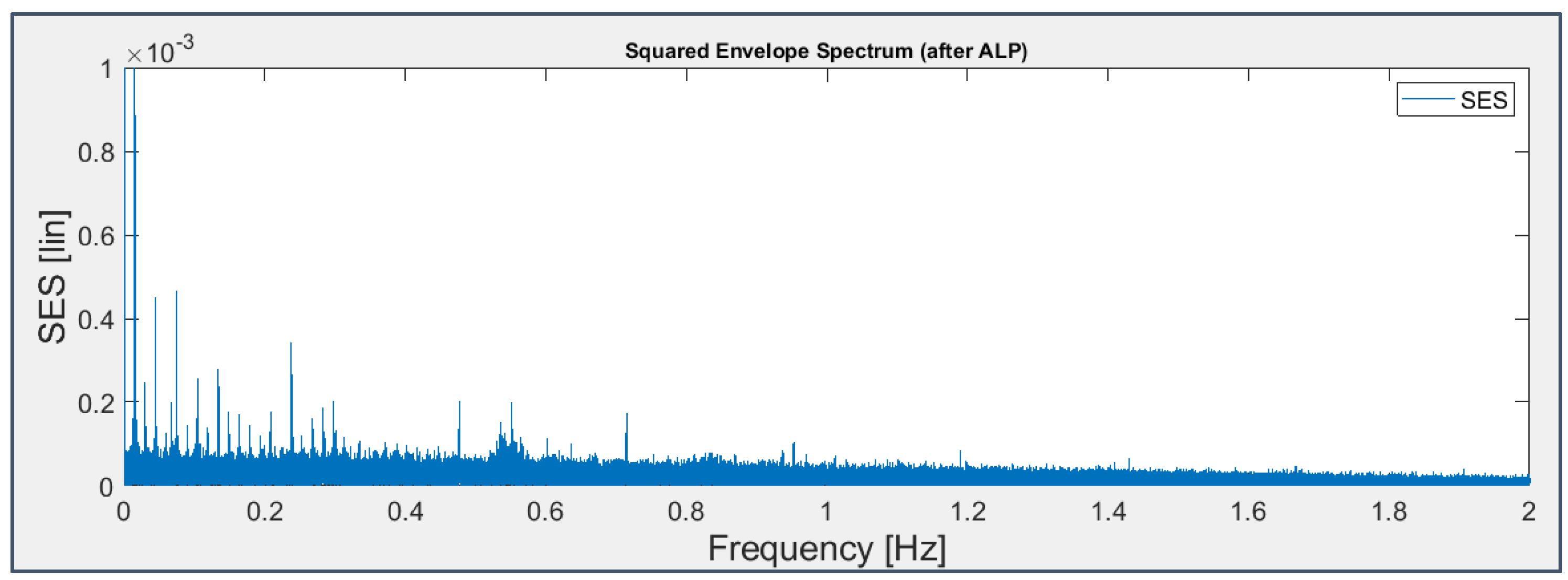

3.2.5. Autoregressive Linear Prediction (ALP)

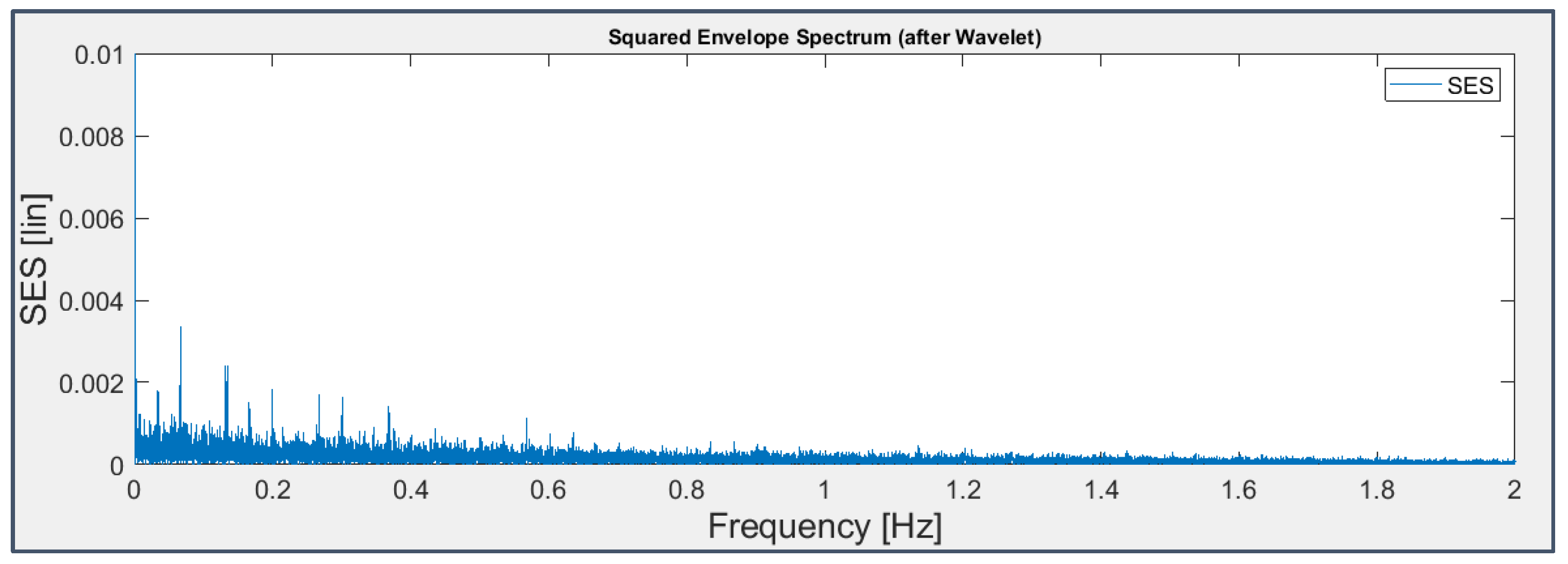

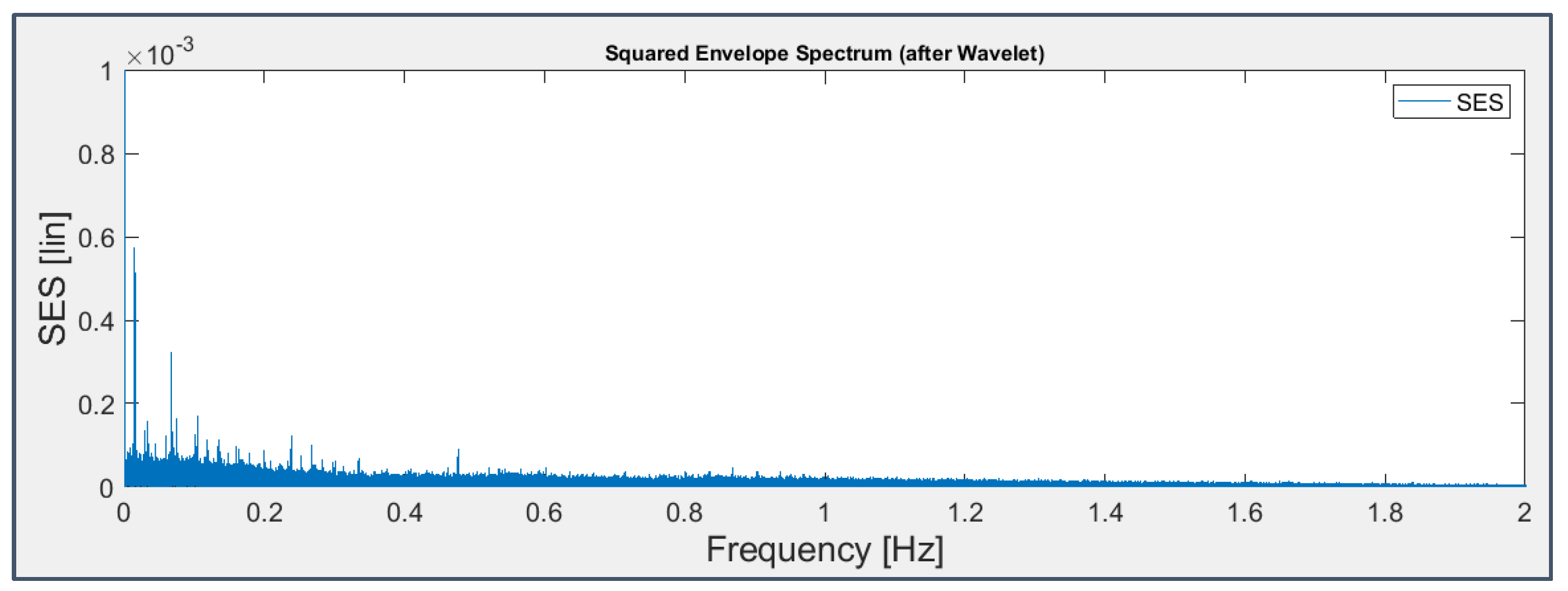

3.2.6. Daubechies’ Wavelets

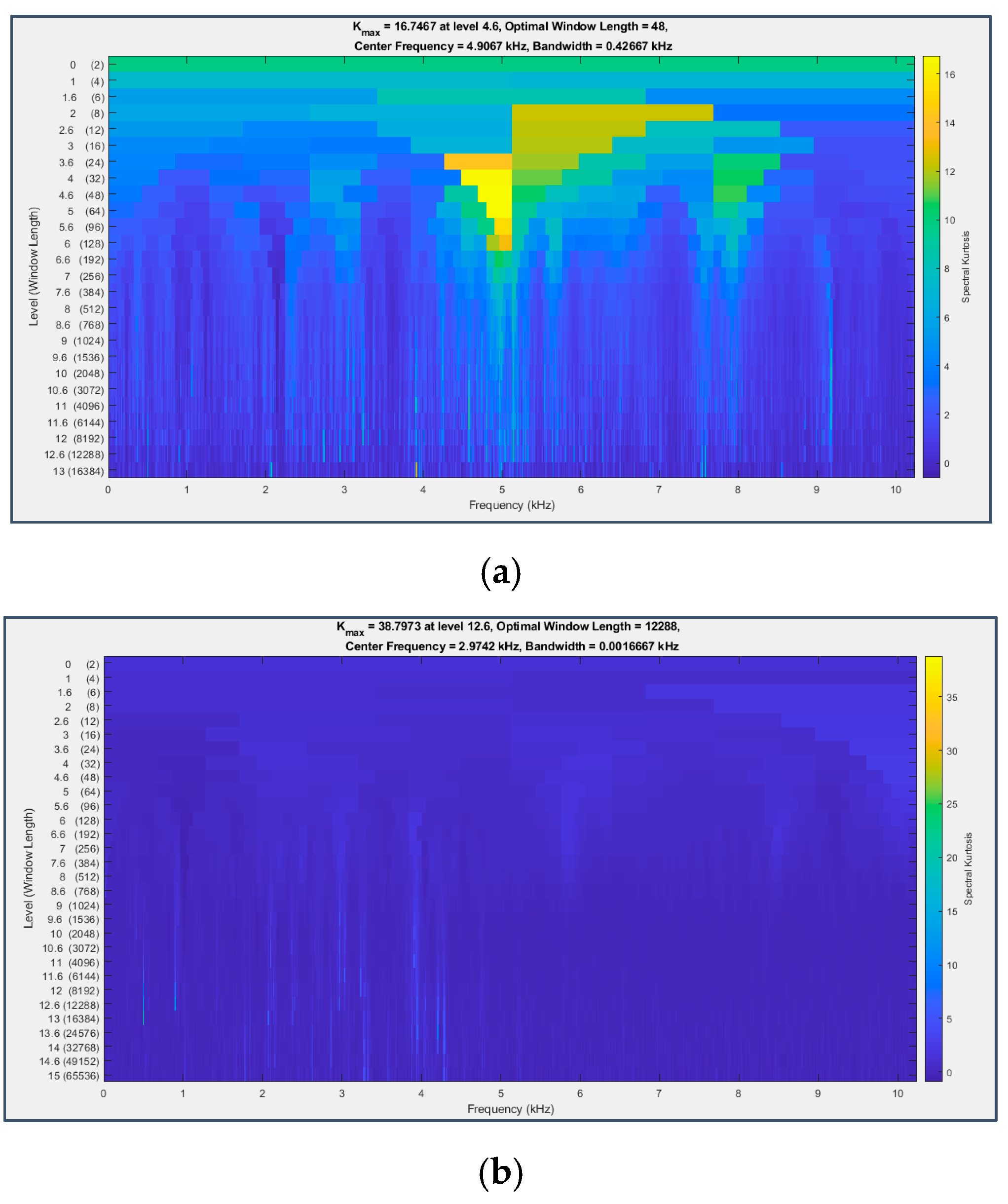

3.2.7. Kurtogram and Filters

3.2.8. Cepstrum Pre-Whitening (CPW)

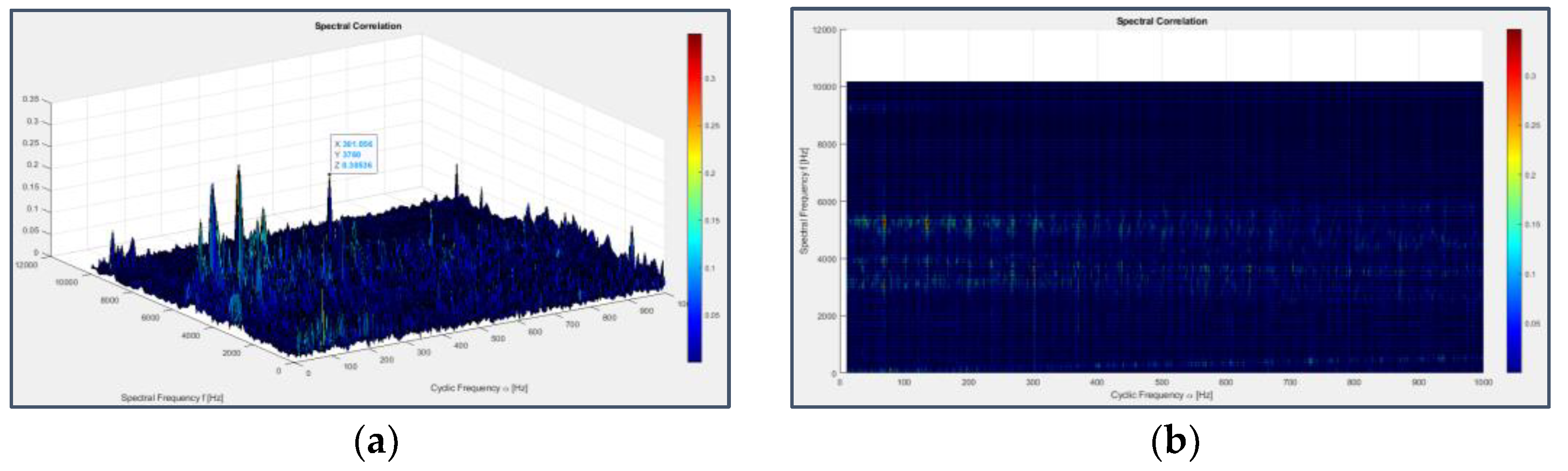

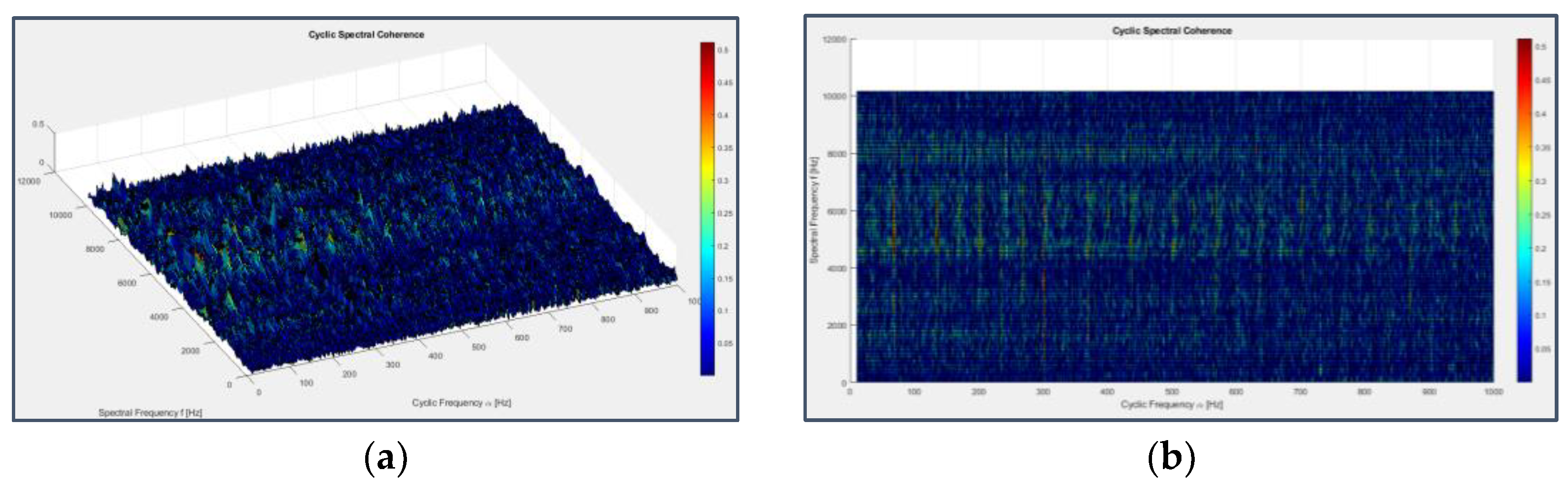

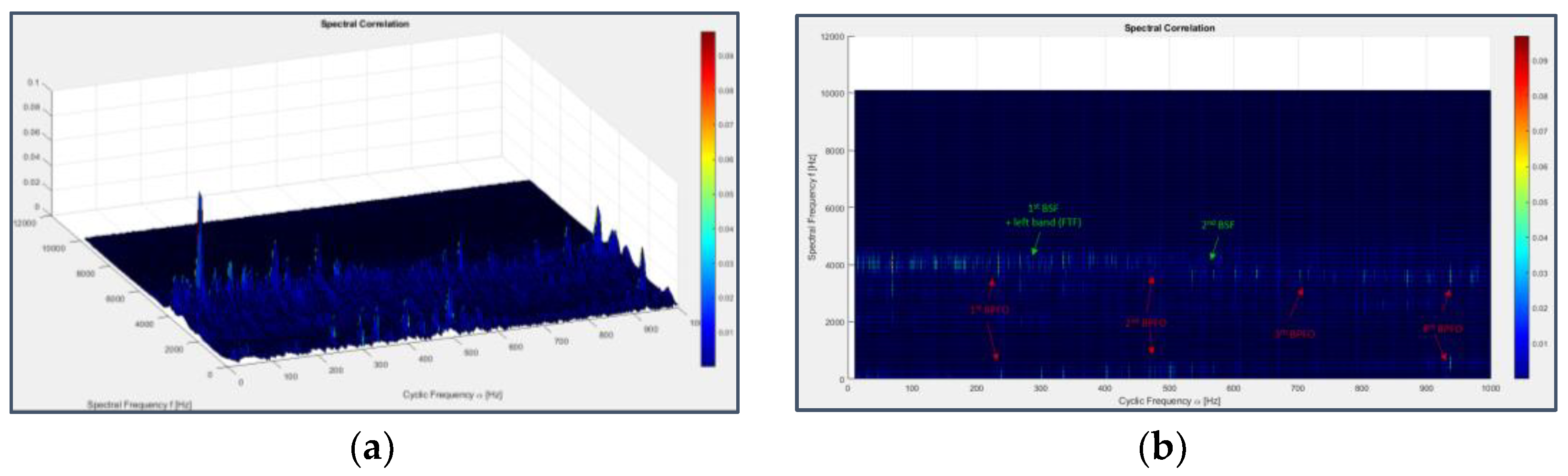

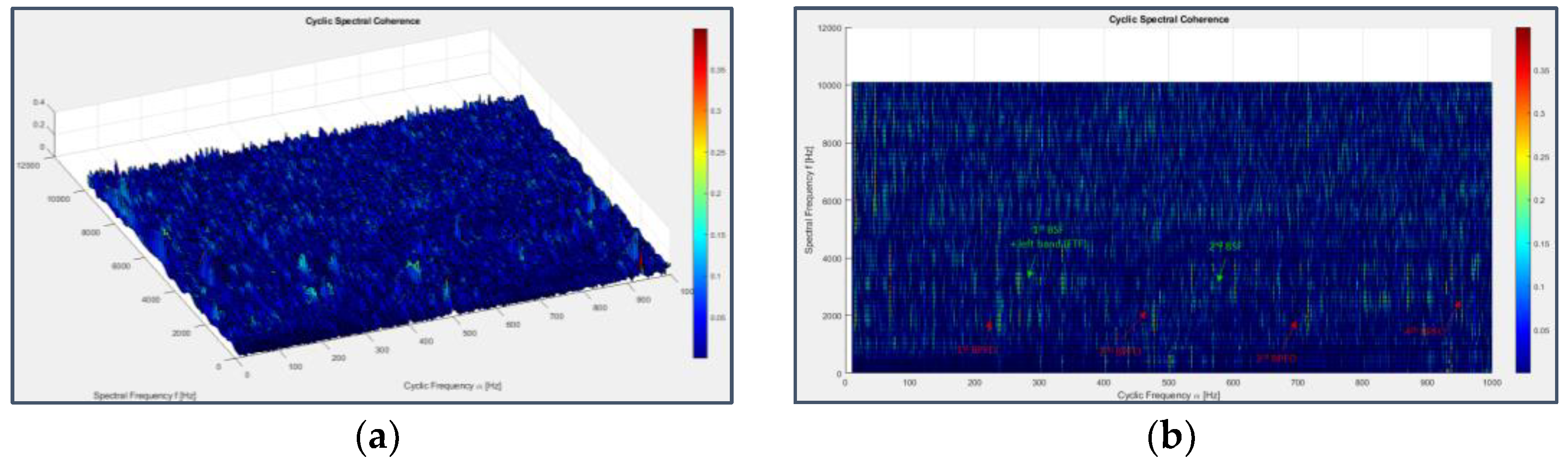

3.2.9. Cyclostationary Analysis

3.2.10. Wigner-Ville Distribution (WVD)

3.3. Fault prognosis

4. Discussion

- The first statistical approach allowed to execute the fault detection phase, bringing to light the occurrence of different faults on bearings 3 and 4 and suggesting the time excerpts of signal to focus on in the following analysis: in particular, RMS value, Kurtosis and Detectivity proved to be the most informative quantities.

-

Diagnostic techniques such as STFT, PSD and SES, even individually, gave a fundamental contribution to identify the exact faults’ nature and their temporal location throughout the experiment, also taking advantage from comparison with faultless signals, at the beginning of the test or coming from healthy bearings; it was then possible to confirm the diagnostic report diffused by the IMS Center itself which attests the presence of:

- -

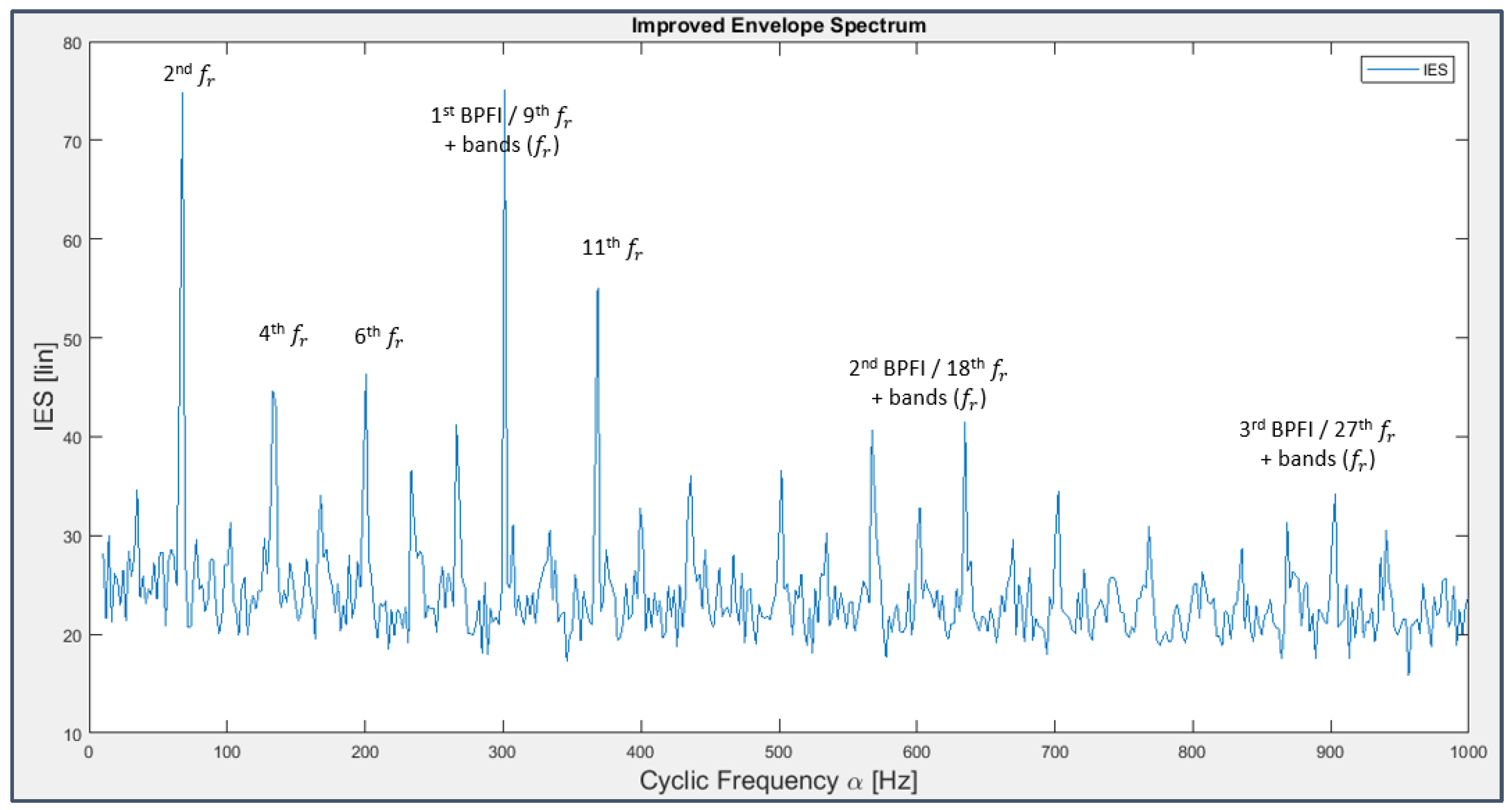

- a rather late inner race fault on bearing 3, occurring since day 32, which does not show directly, but through the excitation of the spectral harmonics of the shaft rotation frequency; the latter has also modulation effects on the BPFI (even though the interpretation of this fault as located at multiple frequencies of 301 Hz instead of the nominal 297 Hz is still potentially acceptable),

- -

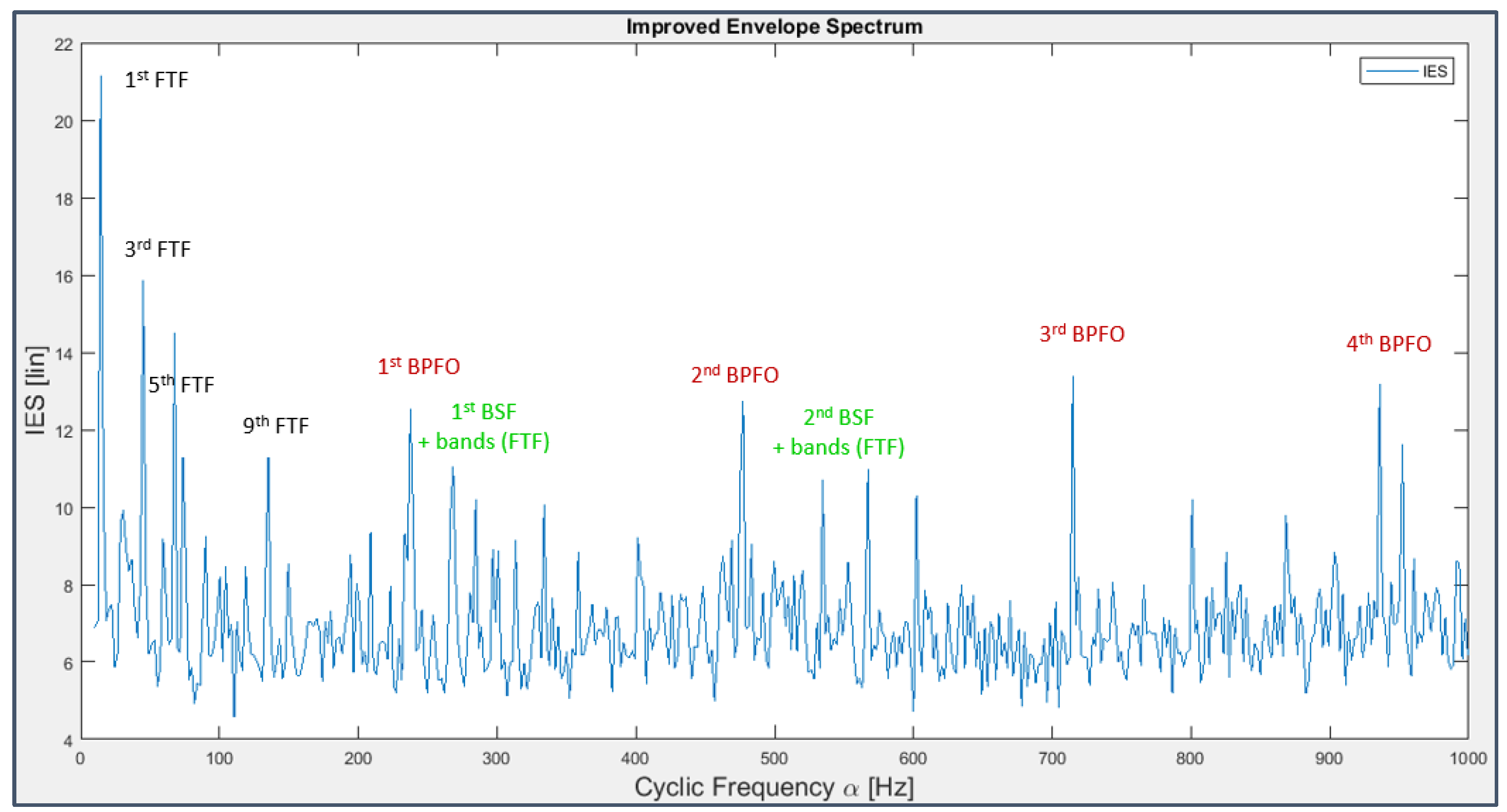

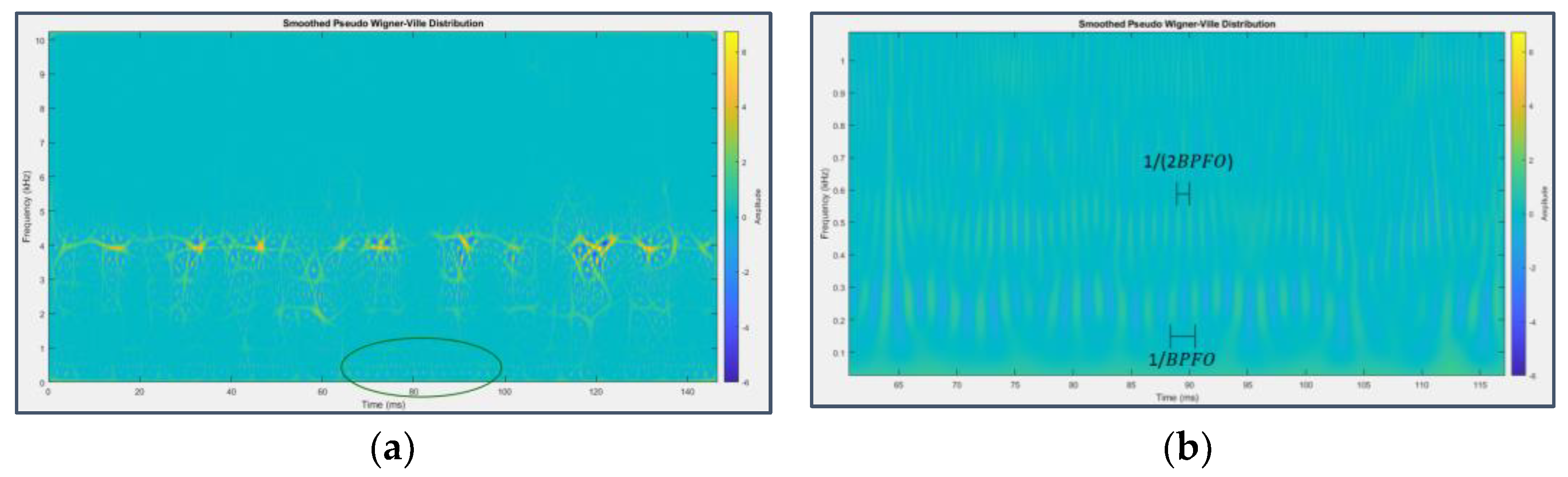

- an outer race fault on bearing 4 detectable for certain from day 28 due to the emergence of various harmonics of the BPFO, without modulating phenomena,

- -

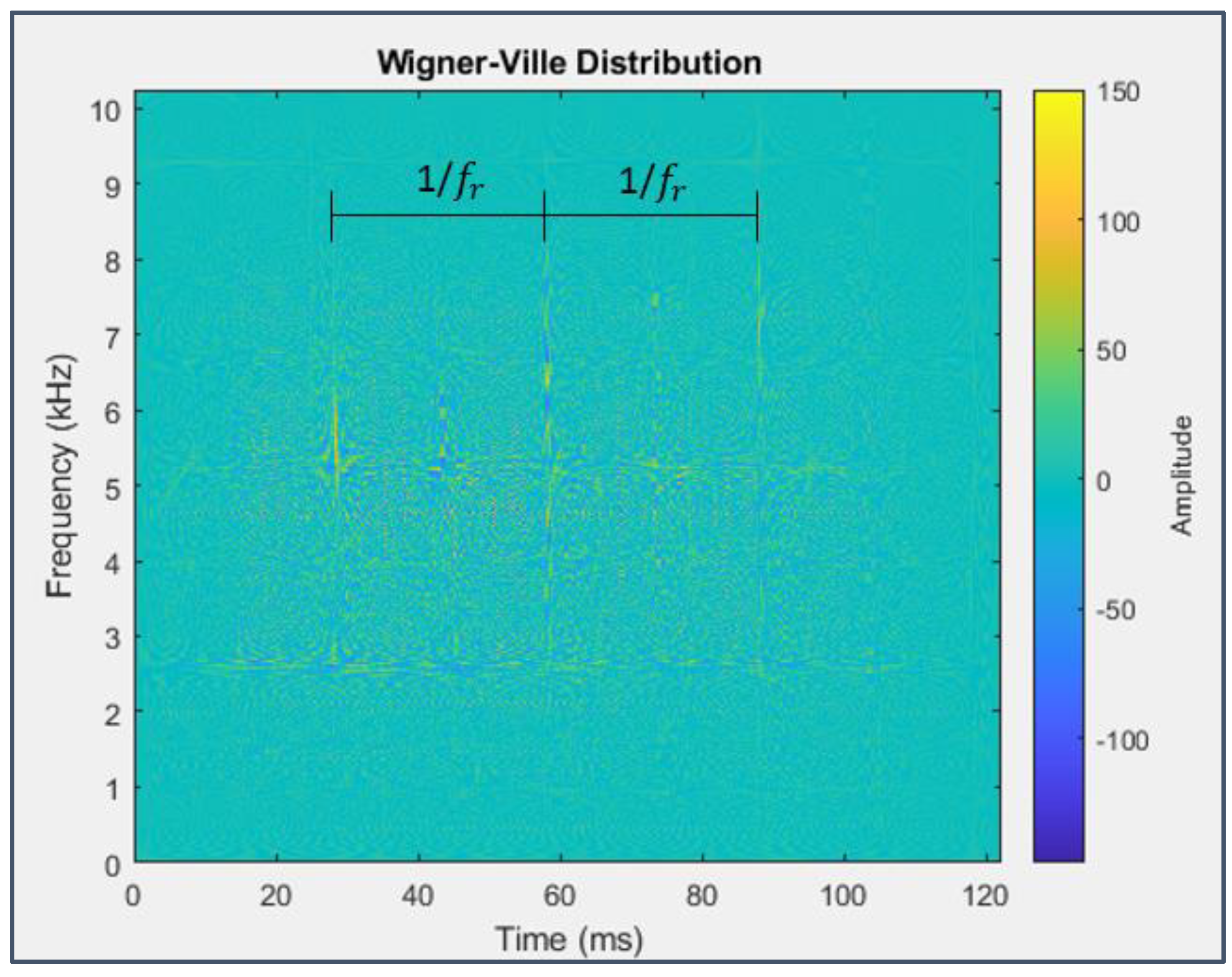

- a rolling element fault on bearing 4, detectable from day 26 with the appearance of the harmonics of the BSF, modulated by those of the cage rotation (FTF), raised themselves by the fault.

- The CPW technique turned out to be a powerful and efficient tool to whiten signal, removing all the masking components and noise, and highlighting fault signatures.

- TSA, ALP and Daubechies’ Wavelets didn’t prove to be sufficiently useful as signal pre-treatment techniques.

- FIR and adaptive filters based on Kurtogram were not able to select the frequency band dominated by fault signs.

- The second order cyclostationary techniques, directly applied on the raw signal, enabled to further confirm the previous conclusions, providing detailed and articulate plots from a different point of view, deeply related to the true nature of the signal under test, qualifying themselves as useful means to use alongside the more traditional ones and justifying their higher complexity.

- The brief insight made into the prognosis domain, to quantify the suitability of statistical parameters to make predictions on the signal future trends, represents an interesting starting point which may be worthy to be further developed.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Randall, R.B. Vibration-based Condition Monitoring: Industrial, Aerospace and Automotive Applications, 1st ed., John Wiley & Sons, Ltd: Chichester, West Sussex, UK, 2011.

- Andhare, A. Condition Monitoring of Rolling Element Bearings: Vibration analysis and diagnostics of tapered roller bearings, using time and frequency domain methods, 1st ed., Lambert Academic Publishing: London, UK, 2010.

- Randall, R.B.; Antoni J. Rolling element bearing diagnostics – A tutorial. Mech. Syst. Signal Process. 2011, 25, 485-520. [CrossRef]

- Tiboni, M.; Remino, C.; Bussola, R.; Amici, C. A Review on Vibration-Based Condition Monitoring of Rotating Machinery. Appl. Sci. 2022, 12, 972. [CrossRef]

- Golafshan, R.; Jacobs, G.; Berroth, J. Investigation of Rolling Bearing Condition Monitoring Techniques Based on Long Term Run-to-Failure Vibration Data. Bearing Journal Vol. 2018, 3, 107-118. [CrossRef]

- Moshrefzadeh, A. Condition monitoring and intelligent diagnosis of rolling element bearings under constant/variable load and speed conditions. Mech. Syst. Signal Process. 2021, 149, 107-153. [CrossRef]

- Borghesani, P.; Shahriar, R. Cyclostationary analysis with logarithmic variance stabilization. Mech. Syst. Signal Process. 2016, 70-71, 51-72. [CrossRef]

- Gousseau, W.; Antoni, J.; Girardin, F.; Griffaton, J. Analysis of the Rolling Element Bearing data set of the Center for Intelligent Maintenance Systems of the University of Cincinnati. CM2016, Charenton, France, Oct 2016. https://hal.science/hal-01715193.

- Qiu, H.; Lee, J.; Lin, J. Wavelet filter-based weak signature detection method and its application on rolling element bearing prognostics, J. Sound Vib. 2006, 289, 1066-1090. [CrossRef]

- Zhichao, W.; Hong, X.; Shaomin, Z.; Bo, Y.; Binsen, P.; Jiyu, Z.; Yingying, J. Research on Fault Diagnosis Method of Rotating Machinery Based on EWT-Threshold Denoising and Teager Energy Spectrum. Proceedings of the 30th European Safety and Reliability Conference and the 15th Probabilistic Safety Assessment and Management Conference, Venice, Italy, Nov 2020.

- Cavalaglio Camargo Molano, J.; Strozzi, M.; Rubini, R.; Cocconcelli, M. Analysis of NASA Bearing Dataset of the University of Cincinnati by Means of Hjorth’s Parameters. Proceedings of the International Conference on Structural Engineering Dynamics ICEDyn 2019, Viana do Castelo, Portugal, Jun 2019. https://hdl.handle.net/11380/1203704.

- Jiyu, Z.; Hong, X.; Zhichao, W. Research on Identification Method of Bearing Performance Degradation in NPP Based on GG Clustering. Proceedings of the 30th European Safety and Reliability Conference and the 15th Probabilistic Safety Assessment and Management Conference, Venice, Italy, Nov 2020.

- Mortada, M.-A.; Yacout, S.; Lakis, A. Diagnosis of rotor bearings using logical analysis of data. J. Qual. Maint. Eng. 2011, 17, 371-397. [CrossRef]

- Hosseinpour, F.; Behzad, M.; Zio, E. Model-based Prognostic of the Remaining Useful Life of Bearings Considering Model Parameter Uncertainty, Proceedings of the 30th European Safety and Reliability Conference and the 15th Probabilistic Safety Assessment and Management Conference, Venice, Italy, Nov 2020.

- Sim, J.; Kim, S.; Park, H.J., Choi J.-H. A Tutorial for Feature Engineering in the Prognostics and Health Management of Gears and Bearings. Appl. Sci. 2020, 10, 5639. [CrossRef]

- Wang, J.; Wang, D.; Wang, S.; Li, W.; Song, K. Fault Diagnosis of Bearings Based on Multi-Sensor Information Fusion and 2D Convolutional Neural Network. IEEE Access 2021, 9, 23717– 23725. [CrossRef]

- Eren, L.; Ince, T.; Kiranyaz, S. A Generic Intelligent Bearing Fault Diagnosis System Using Compact Adaptive 1D CNN Classifier. J. Signal Process. Syst. 2019, 91, 179–189. [CrossRef]

- Peng, Y.; Liu, Y.; Cheng, J.; Yang, Y.; He, K.; Wang, G.; Liu, Y. Remaining useful life prediction of rolling bearing using adaptive sparsest narrow-band decomposition and locality preserving projections. Adv. Mech. Eng. 2019, 11, 1-13. [CrossRef]

- Roller element bearing Datasets (2014). Center for Intelligent Maintenance Systems (IMS), University of Cincinnati, Ohio, USA. https://www.kaggle.com/datasets/vinayak123tyagi/bearing-dataset.

- MATLAB Documentation and Online Guide, 1994-2022, The MathWorks, Inc©.

- Vidaurre, C.; Krämer, N.; Blankertz, B.; Schlögl, A. Time Domain Parameters as a feature for EEG-based Brain–Computer Interfaces, Neural Netw 2009, 22, 1313–1319. [CrossRef]

- Salgado Patrón, J.; Barrera, C. Robotic arm controlled by a hybrid brain computer interface. ARPN J. Eng. Appl. Sci. 2016, 11, 7313-7321.

- Cocconcelli, M.; Strozzi, M.; Rubini, R.; Cavalaglio Camargo Morano, J., Detectivity: A combination of Hjorth’s parameters for condition monitoring of ball bearings, Mech. Syst. Signal Process. 2022, 164, 108247. [CrossRef]

- Antoni, J. Cyclic spectral analysis in practice. Mech. Syst. Signal Process. 2007, 21, 597-630. [CrossRef]

- Peeters, C.; Helsen, J.; Guillaume, P. Signal pre-processing using cepstral editing for vibration-based bearing fault detection, Proceedings of the International Conference on Noise and Vibration Engineering (ISMA), Leuven, Belgium, Sept 2016.

- Borghesani, P.; Pennacchi, P; Randall, R.B.; Sawalhi, N.; Ricci, R. Application of cepstrum pre-whitening for the diagnosis of bearing faults under variable speed conditions. Mech. Syst. Signal Process. 2013, 36, 370-384. [CrossRef]

| Start-stop time and date | From 22/10/2003 at 12:06:24 pm To 25/11/2003 at 11:39:56 pm |

| Entire experiment timespan | 49680 minutes (34 days and 12 hours) |

| Effective data acquisition duration | 36 minutes |

| Number of files | 2156 |

| Number of channels (accelerometers) | 8 |

| Channel arrangement | Bearing 1: channels 1 and 2 Bearing 2: channels 3 and 4 Bearing 3: channels 5 and 6 Bearing 4: channels 7 and 8 |

| File recording interval | 10 minutes (5 minutes for the first 43 files) |

| Location of detected faults at the end of the experiment | Bearing 3: inner race Bearing 4: rolling element and outer race |

| Nominal rotation frequency of the shaft | 33.3 Hz |

| Ball Pass Frequency Outer Race (BPFO) | 236 Hz |

| Ball Pass Frequency Inner Race (BPFI) | 297 Hz |

| Ball Spin Frequency (BSF) | 278 Hz (2x139 Hz) |

| Fundamental Train Frequency (FTF) | 15 Hz |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).