Submitted:

11 April 2023

Posted:

12 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Granularity-evaluation Model to Measure Traceability

3. Materials and Method

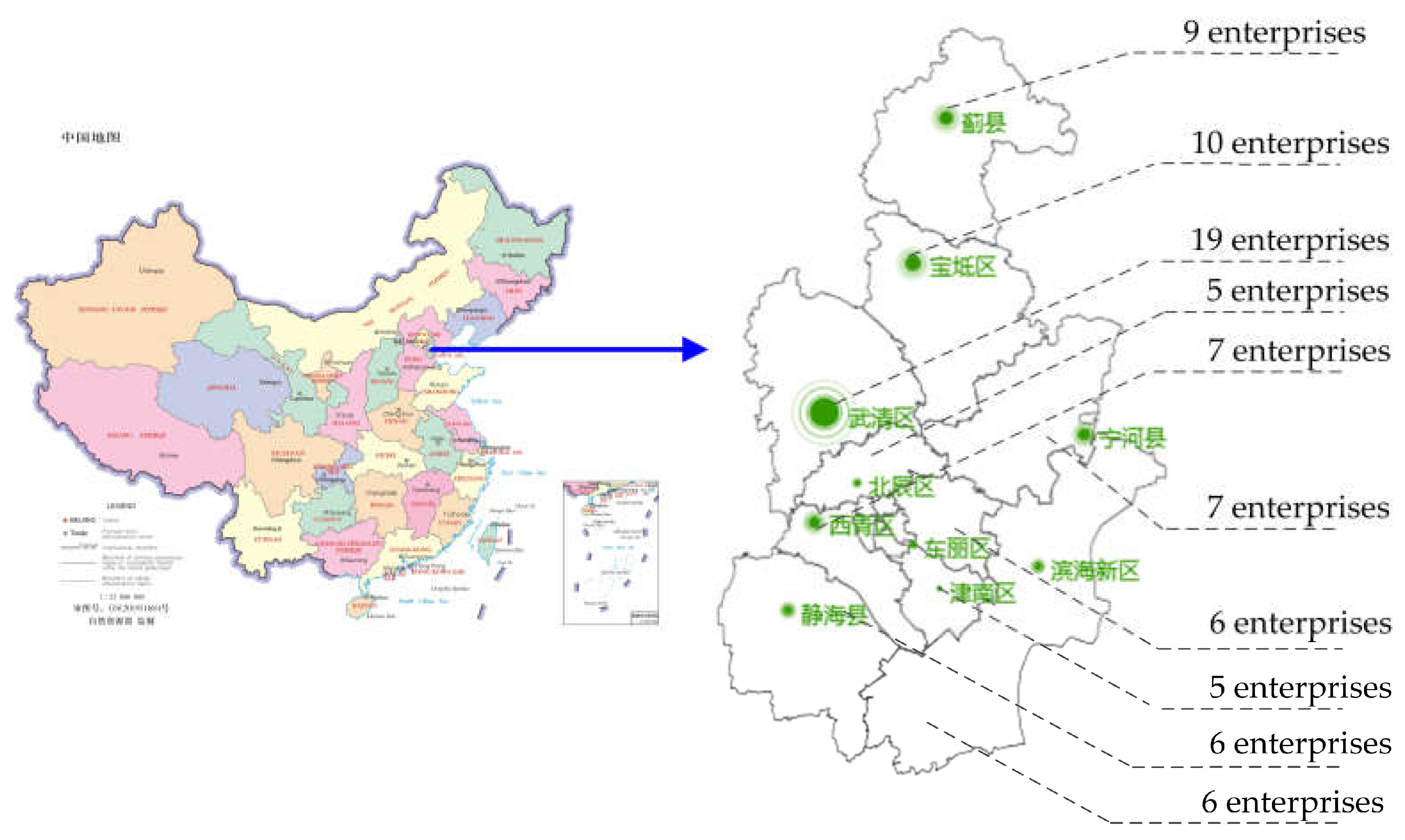

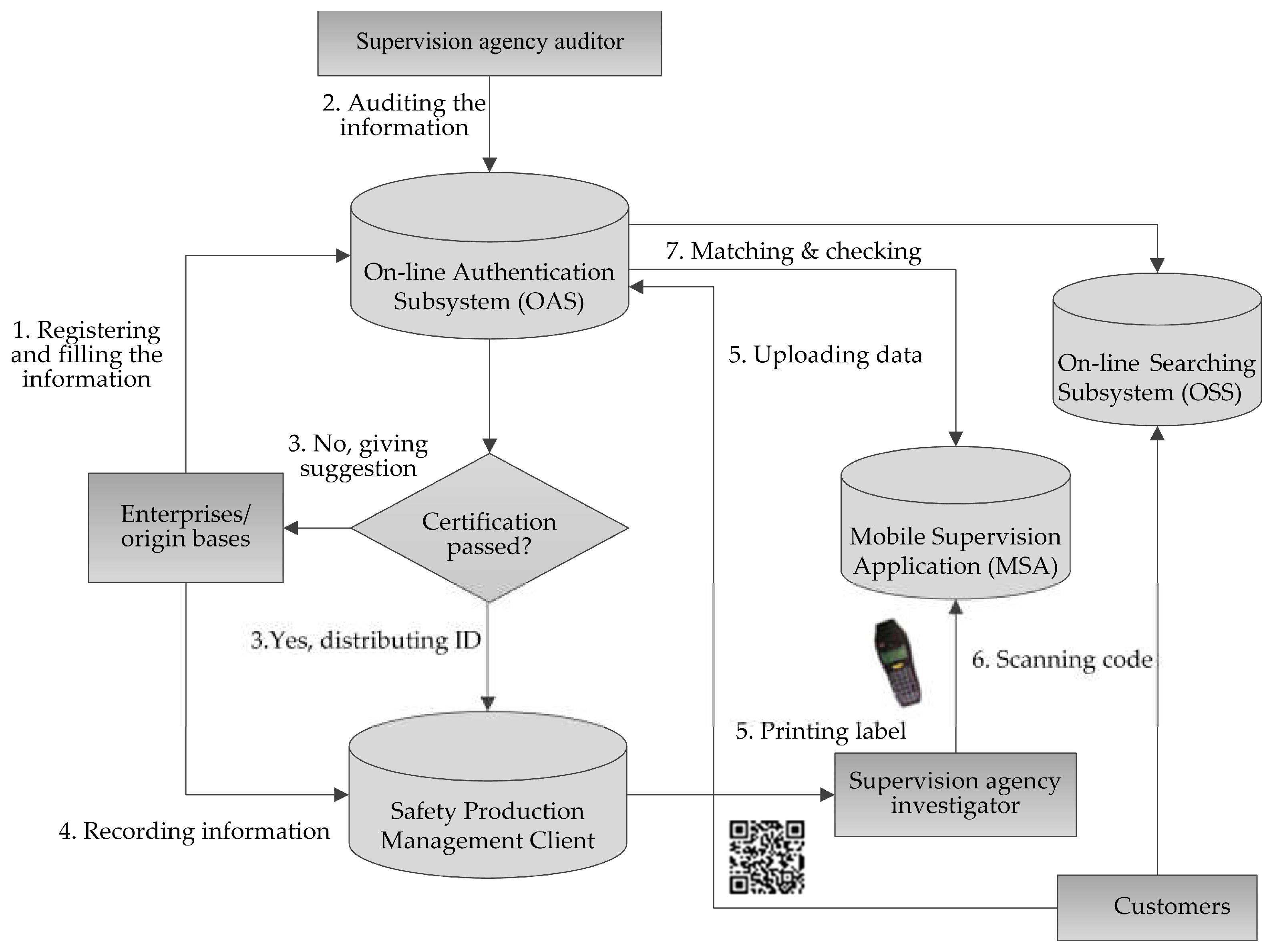

3.1. Study-case Overview

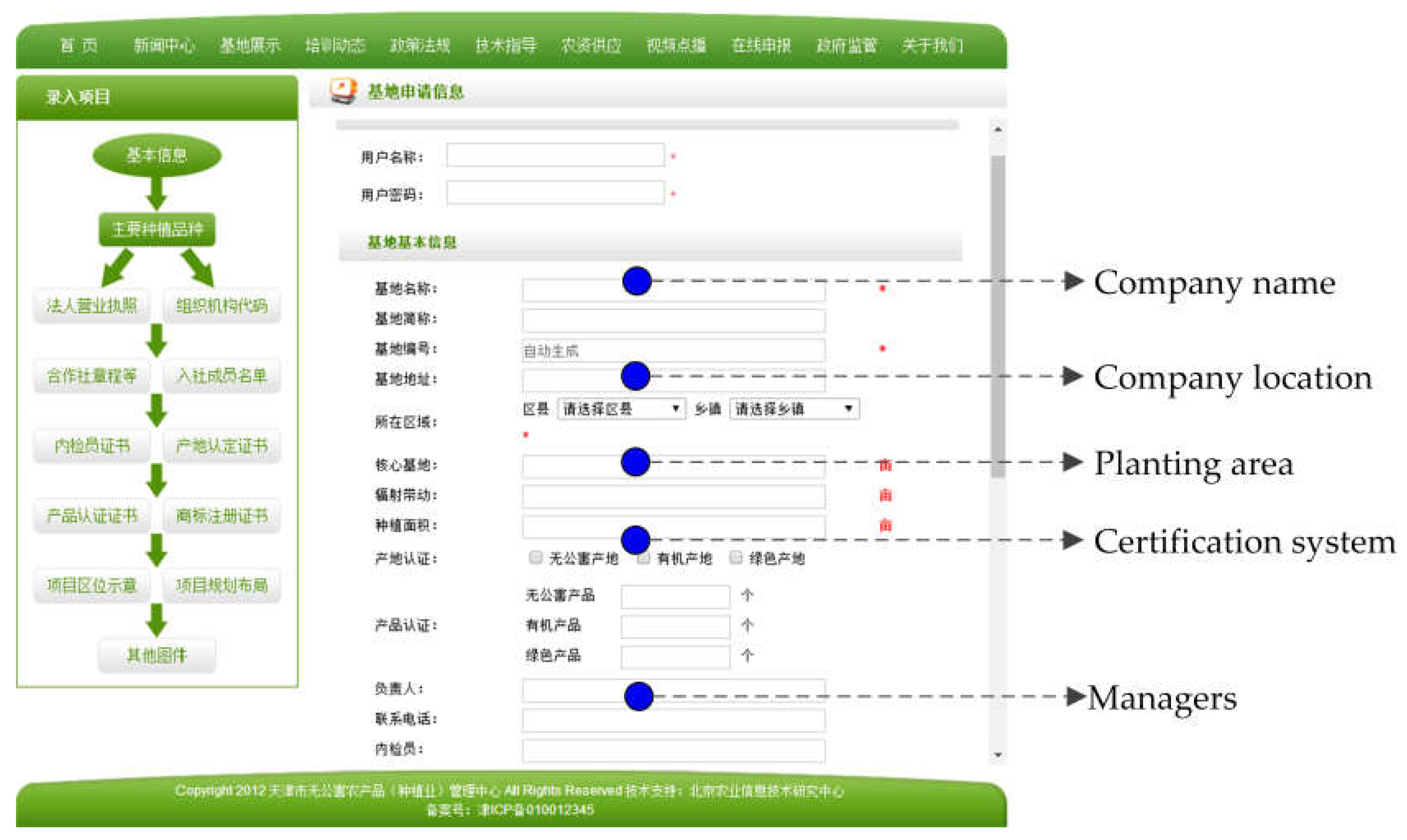

3.2. Data Collection to Evaluate Granularity

3.3. Selection of Factors that Influence Traceability

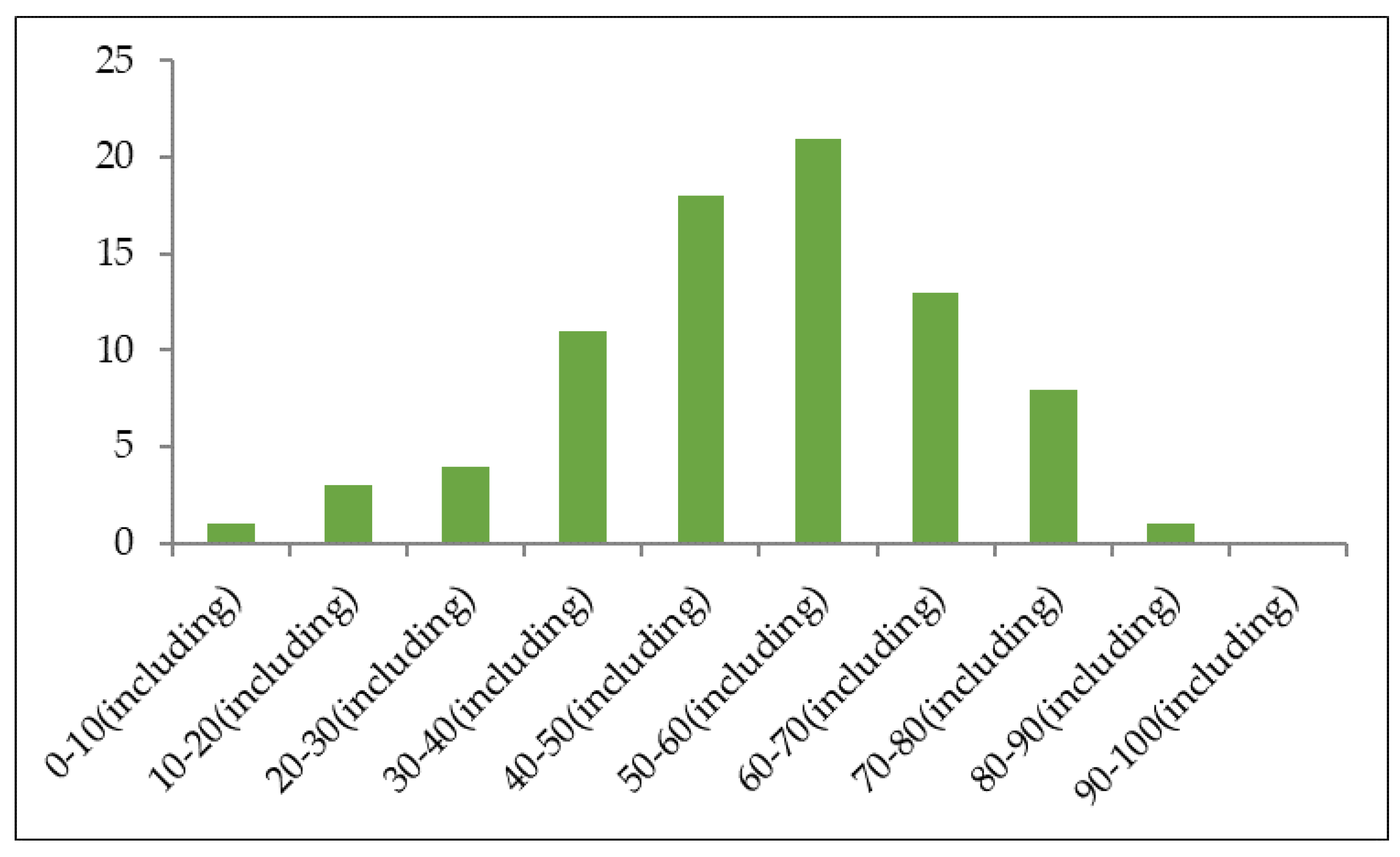

3.4. Characteristics of Companies Surveyed

3.5. Rough Set Method

3.5.1. Information system

3.5.2. Equivalence relation

3.5.3. Approximations and positive region

3.5.4. Attribute importance

4. Results Analysis

4.1. Comparison of Granularity

4.2. Attribute Reduction

4.3. Analysis of Importance of Attribute

5. Main Conclusions and Implications

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qian, J.; Ruiz-Garcia, L.; Fan, B.; Robla Villalba, J.I.; McCarthy, U.; Zhang, B.; Yu, Q.; Wu, W. Food Traceability System from Governmental, Corporate, and Consumer Perspectives in the European Union and China: A Comparative Review. Trends Food Sci. Technol. 2020, 99, 402–412. [Google Scholar] [CrossRef]

- García-Díez, J.; Moura, D.; Nascimento, M.M.; Saraiva, C. Performance Assessment of Open-Access Information about Food Safety. J. fur Verbraucherschutz und Leb. 2018, 13, 113–124. [Google Scholar] [CrossRef]

- Corallo, A.; Latino, M.E.; Menegoli, M.; Striani, F. What Factors Impact on Technological Traceability Systems Diffusion in the Agrifood Industry? An Italian Survey. J. Rural Stud. 2020, 75. [Google Scholar] [CrossRef]

- Munasinghe, J.; de Silva, A.; Weerasinghe, G.; Gunaratne, A.; Corke, H. Food Safety in Sri Lanka: Problems and Solutions. Qual. Assur. Saf. Crop. Foods 2014, 7, 37–44. [Google Scholar] [CrossRef]

- Cozzolino, D. An Overview of the Use of Infrared Spectroscopy and Chemometrics in Authenticity and Traceability of Cereals. Food Res. Int. 2014, 60, 262–265. [Google Scholar] [CrossRef]

- Mehannaoui, R.; Mouss, K.N.; Aksa, K. IoT-Based Food Traceability System: Architecture, Technologies, Applications, and Future Trends. FOOD Control 2023, 145. [Google Scholar] [CrossRef]

- Heyder, M.; Theuvsen, L.; Hollmann-Hespos, T. Investments in Tracking and Tracing Systems in the Food Industry: A PLS Analysis. Food Policy 2012, 37, 102–113. [Google Scholar] [CrossRef]

- Olsen, P.; Borit, M. How to Define Traceability. Trends Food Sci. Technol. 2013, 29, 142–150. [Google Scholar] [CrossRef]

- Latino, M.E.; Menegoli, M.; Lazoi, M.; Corallo, A. Voluntary Traceability in Food Supply Chain: A Framework Leading Its Implementation in Agriculture 4.0. Technol. Forecast. Soc. Change 2022, 178. [Google Scholar] [CrossRef]

- Jin, S.; Zhou, L. Consumer Interest in Information Provided by Food Traceability Systems in Japan. Food Qual. Prefer. 2014, 36, 144–152. [Google Scholar] [CrossRef]

- Kim, Y.G.; Woo, E. Consumer Acceptance of a Quick Response (QR) Code for the Food Traceability System: Application of an Extended Technology Acceptance Model (TAM). Food Res. Int. 2016, 85, 266–272. [Google Scholar] [CrossRef] [PubMed]

- Boys, K.A.; Fraser, A.M. Linking Small Fruit and Vegetable Farmers and Institutional Foodservice Operations: Marketing Challenges and Considerations. Renew. Agric. Food Syst. 2019, 34, 226–238. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Mishra, P.; Ruiz-García, L. Food Traceability: New Trends and Recent Advances. A Review. Food Control 2015, 57, 393–401. [Google Scholar] [CrossRef]

- Montet, D.; El Shobaky, A.; Barreto Crespo, M.T.; Payrastre, L.; Mansour, H.; Othman, Y.; Morshdy, A.; El Zayat, M.; Ibrahim, H.; El-Arabi, T.; et al. Future Topics of Common Interest for EU and Egypt in Food Quality, Safety and Traceability. Qual. Assur. Saf. Crop. Foods 2015, 7, 401–108. [Google Scholar] [CrossRef]

- Mainetti, L.; Patrono, L.; Stefanizzi, M.L.; Vergallo, R. An Innovative and Low-Cost Gapless Traceability System of Fresh Vegetable Products Using RF Technologies and EPCglobal Standard. Comput. Electron. Agric. 2013, 98, 146–157. [Google Scholar] [CrossRef]

- Qian, J.; Yang, X.; Wang, X.; Lian, J.; Xing, B.; Fan, B.; Li, M. Framework for an IT-Based Vegetable Traceability System Integrated Two Different Operating Mechanisms in China on Comparison with Two Cities. J. Food, Agric. Environ. 2013, 11, 317–323. [Google Scholar]

- Souza Monteiro, D.M.; Caswell, J.A. Traceability Adoption at the Farm Level: An Empirical Analysis of the Portuguese Pear Industry. Food Policy 2009, 34, 94–101. [Google Scholar] [CrossRef]

- Porto, S.M.C.; Arcidiacono, C.; Cascone, G. Developing Integrated Computer-Based Information Systems for Certified Plant Traceability: Case Study of Italian Citrus-Plant Nursery Chain. Biosyst. Eng. 2011, 109, 120–129. [Google Scholar] [CrossRef]

- Reyes, J.F.; Correa, C.; Esquivel, W.; Ortega, R. Development and Field Testing of a Data Acquisition System to Assess the Quality of Spraying in Fruit Orchards. Comput. Electron. Agric. 2012, 84, 62–67. [Google Scholar] [CrossRef]

- Violino, S.; Pallottino, F.; Sperandio, G.; Figorilli, S.; Ortenzi, L.; Tocci, F.; Vasta, S.; Imperi, G.; Costa, C. A Full Technological Traceability System for Extra Virgin Olive Oil. Foods 2020, 9. [Google Scholar] [CrossRef]

- Parreño-Marchante, A.; Alvarez-Melcon, A.; Trebar, M.; Filippin, P. Advanced Traceability System in Aquaculture Supply Chain. J. Food Eng. 2014, 122, 99–109. [Google Scholar] [CrossRef]

- Wu, Q.; Zhou, G.; Yang, S.; Abulikemu, B.T.; Luo, R.; Zhang, Y.; Li, X.; Xu, X.; Li, C. SNP Genotyping in Sheep from Northwest and East China for Meat Traceability. J. fur Verbraucherschutz und Leb. 2017, 12, 125–130. [Google Scholar] [CrossRef]

- Shew, A.M.; Snell, H.A.; Nayga, R.M.; Lacity, M.C. Consumer Valuation of Blockchain Traceability for Beef in the United States. Appl. Econ. Perspect. Policy 2022, 44, 299–323. [Google Scholar] [CrossRef]

- Ardeshiri, A.; Rose, J.M. How Australian Consumers Value Intrinsic and Extrinsic Attributes of Beef Products. Food Qual. Prefer. 2018, 65, 146–163. [Google Scholar] [CrossRef]

- Dabbene, F.; Gay, P. Food Traceability Systems: Performance Evaluation and Optimization. Comput. Electron. Agric. 2011, 75, 139–146. [Google Scholar] [CrossRef]

- Golan, E.; Krissoff, B.; Kuchler, F.; Calvin, L.; Nelson, K.; Price, G. Traceability in the U.S. Food Supply: Economic Theory and Industry Studies. Agric. Econ. Rep. - Econ. Res. Serv. US Dep. Agric. 2004; 4, 1–48. [Google Scholar]

- Bertolini, M.; Bevilacqua, M.; Massini, R. FMECA Approach to Product Traceability in the Food Industry. Food Control 2006, 17, 137–145. [Google Scholar] [CrossRef]

- Karlsen, K.M.; Dreyer, B.; Olsen, P.; Elvevoll, E.O. Granularity and Its Role in Implementation of Seafood Traceability. J. Food Eng. 2012, 112, 78–85. [Google Scholar] [CrossRef]

- Bollen, A.F.; Riden, C.P.; Cox, N.R. Agricultural Supply System Traceability, Part I: Role of Packing Procedures and Effects of Fruit Mixing. Biosyst. Eng. 2007, 98, 391–400. [Google Scholar] [CrossRef]

- Mgonja, J.T.; Luning, P.; Van Der Vorst, J.G.A.J. Diagnostic Model for Assessing Traceability System Performance in Fish Processing Plants. J. Food Eng. 2013, 118, 188–197. [Google Scholar] [CrossRef]

- Qian, J.; Fan, B.; Wu, X.; Han, S.; Liu, S.; Yang, X. Comprehensive and Quantifiable Granularity: A Novel Model to Measure Agro-Food Traceability. Food Control 2017, 74, 98–106. [Google Scholar] [CrossRef]

- Banterle, A.; Stranieri, S. The Consequences of Voluntary Traceability System for Supply Chain Relationships. An Application of Transaction Cost Economics. Food Policy 2008, 33, 560–569. [Google Scholar] [CrossRef]

- Liao, P.; Chang, H.; Chang, C. Why Is the Food Traceability System Unsuccessful in Taiwan? Empirical Evidence from a National Survey of Fruit and Vegetable Farmers. Food Policy 2011, 36, 686–693. [Google Scholar] [CrossRef]

- Jose, A.; Prasannavenkatesan, S. Traceability Adoption in Dry Fish Supply Chain SMEs in India: Exploring Awareness, Benefits, Drivers and Barriers. SADHANA-ACADEMY Proc. Eng. Sci. 2023, 48. [Google Scholar] [CrossRef]

- Mattevi, M.; Jones, J.A. Food Supply Chain Are UK SMEs Aware of Concept, Drivers, Benefits and Barriers, and Frameworks of Traceability? Br. FOOD J. 2016, 118, 1107–1128. [Google Scholar] [CrossRef]

- Meuwissen, M.P.M.; Velthuis, A.G.J.; Hogeveen, H.; Huirne, R.B.M. Traceability and Certification in Meat Supply Chains. J. Agribus. 2003, 21, 167–181. [Google Scholar]

- Du Plessis, H.J.; Du Rand, G.E. The Significance of Traceability in Consumer Decision Making towards Karoo Lamb. Food Res. Int. 2012, 47, 210–217. [Google Scholar] [CrossRef]

- Schulz, L.L.; Tonsor, G.T. Cow-Calf Producer Preferences for Voluntary Traceability Systems. J. Agric. Econ. 2010, 61, 138–162. [Google Scholar] [CrossRef]

- Zhou, J.; Jin, Y.; Liang, Q. Effects of Regulatory Policy Mixes on Traceability Adoption in Wholesale Markets: Food Safety Inspection and Information Disclosure. Food Policy 2022, 107. [Google Scholar] [CrossRef]

- Souza-Monteiro, D.M.; Caswell, J.A. The Economics of Voluntary Traceability in Multi-Ingredient Food Chains. AGRIBUSINESS 2010, 26, 122–142. [Google Scholar] [CrossRef]

- Wu, L.; Wang, S.; Hu, W. Consumers’ preferences and willingness-to-pay for traceable food-pork as an example. Chinese Rural Econ. 2014, 58–75. [Google Scholar]

- Bosona, T.; Gebresenbet, G. Food Traceability as an Integral Part of Logistics Management in Food and Agricultural Supply Chain. Food Control 2013, 33, 32–48. [Google Scholar] [CrossRef]

- Mattevi, M.; Jones, J.A. Traceability in the Food Supply Chain: Awareness and Attitudes of UK Small and Medium-Sized Enterprises. Food Control 2016, 64, 120–127. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Liu, F.; Fu, Z.; Mu, W. Strengths and Limitations on the Operating Mechanisms of Traceability System in Agro Food, China. Food Control 2010, 21, 825–829. [Google Scholar] [CrossRef]

- Qian, J.; Wu, X.; Yang, X.; Xing, B.; Wang, F. Farm Products Quality Safety Emergency Management System Based on Rough Set and WebGIS. Nongye Jixie Xuebao/Transactions Chinese Soc. Agric. Mach. 2012, 43, 123–129. [Google Scholar] [CrossRef]

- Regattieri, A.; Gamberi, M.; Manzini, R. Traceability of Food Products: General Framework and Experimental Evidence. J. Food Eng. 2007, 81, 347–356. [Google Scholar] [CrossRef]

- Pelegrino, B.O.; Silva, R.; Guimaraes, J.T.; Coutinho, N.F.; Pimentel, T.C.; Castro, B.G.; Freitas, M.Q.; Esmerino, E.A.; Sant’Ana, A.S.; Silva, M.C.; et al. Traceability: Perception and Attitudes of Artisanal Cheese Producers in Brazil. J. Dairy Sci. 2020, 103, 4874–4879. [Google Scholar] [CrossRef]

- Narsimhalu, U.; Potdar, V.; Kaur, A. A Case Study to Explore Influence of Traceability Factors on Australian Food Supply Chain Performance. Oper. Manag. Digit. Econ. 2015, 189, 17–32. [Google Scholar] [CrossRef]

- Pawlak, Z.; Wong, S.K.M.; Ziarko, W. Rough Sets: Probabilistic versus Deterministic Approach. Int. J. Man. Mach. Stud. 1988, 29, 81–95. [Google Scholar] [CrossRef]

- Kumar, S.; Jain, N.; Fernandes, S.L. Rough Set Based Effective Technique of Image Watermarking. J. Comput. Sci. 2017, 19, 121–137. [Google Scholar] [CrossRef]

- Azam, N.; Zhang, Y.; Yao, J.T. Evaluation Functions and Decision Conditions of Three-Way Decisions with Game-Theoretic Rough Sets. Eur. J. Oper. Res. 2017, 261, 704–714. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, X.; Wu, L.; Yin, S.; Lu, J. Resource Basis, Ecosystem and Growth of Grain Family Farm in China: Based on Rough Set Theory and Hierarchical Linear Model. Agric. Syst. 2017, 154, 157–167. [Google Scholar] [CrossRef]

| First layer indexes | Second layer indicators | Weight | Indicators description | Scores | |

|---|---|---|---|---|---|

| Precision | External trace unit | Single product | 5 | ||

| 0.1985 | Single batch | 3 | |||

| Mixed batch | 1 | ||||

| Internal flow unit | Single product | 5 | |||

| 0.1141 | Single batch | 3 | |||

| Mixed batch | 1 | ||||

| IU conversion | One-to-one | 5 | |||

| 0.0872 | One-to-many | 4 | |||

| Many-to-one | 2 | ||||

| Many-to-many | 1 | ||||

| Breadth | Information collection content | 0.1870 | Basic information, forward source information, backward direction information, process information | 5 | |

| All information except process information | 4 | ||||

| Basic information, forward source information or backward direction information | 3 | ||||

| only basic information | 1 | ||||

| Information update frequency | 0.1248 | Hourly level | 5 | ||

| Daily level | 3 | ||||

| Monthly level | 1 | ||||

| Depth | Backward tracing distance | Tracking more than 3 levels | 5(at the front of the supply chain is default to 5) | ||

| 0.1442 | Tracking 2 levels | 4 | |||

| Tracking 1 level | 3 | ||||

| Tracking less than 1 level | 1 | ||||

| Forward tracking distance | Tracking more than 3 levels | 5(at the end of the supply chain is default to5) | |||

| 0.1442 | Tracking 2 levels | 4 | |||

| Tracking 1 level | 3 | ||||

| Tracking less than 1 level | 1 |

| Factors type | Influencing factors | Mainly literature |

|---|---|---|

| External factors | Expected revenue | [36,37] |

| Government policy | [26,38,39] | |

| Market requirement | [17,40] | |

| Internal factors | Certification system | [41] |

| SC integration degree | [42] | |

| Manager education level | [40] | |

| Enterprise turnover | [43] | |

| TS operation staff ratio | [44] | |

| Informationization management level | [45] | |

| Cognition of TS | [46,47] | |

| System maintenance investment | [48] |

| Influencing factors | Factors feature | Enterprise number | Percentage (%) |

|---|---|---|---|

| Expected revenue | <0% | 5 | 6.25 |

| 0-5% | 24 | 30 | |

| 5-10% | 37 | 46.25 | |

| 10-20% | 12 | 15 | |

| >20% | 2 | 2.5 | |

| Certification system | No certification | 0 | 0 |

| ISO 9000 certification | 12 | 15 | |

| GAP/HACCP | 10 | 12.5 | |

| Other certification | 43 | 53.75 | |

| ISO9000/GAP/HACCP + other certification | 15 | 18.75 | |

| SC integration degree | Very low | 16 | 20 |

| Low | 38 | 47.5 | |

| Medium | 12 | 15 | |

| High | 9 | 11.25 | |

| Very high | 5 | 6.25 | |

| Manager education level | Less than senior high school | 4 | 5 |

| Senior high school | 11 | 13.75 | |

| College level | 48 | 60 | |

| Master degree | 15 | 18.75 | |

| Doctor degree | 2 | 2.5 | |

| Enterprise turnover | <5 million Yuan | 21 | 26.25 |

| 5-10 million Yuan | 24 | 30 | |

| 10-30 million Yuan | 18 | 22.5 | |

| 30-50 million | 14 | 17.5 | |

| >50 million | 3 | 3.75 | |

| TS operation staff | No special operation staff | 12 | 15 |

| One person | 36 | 45 | |

| Two persons | 22 | 27.5 | |

| 3-5 persons | 8 | 10 | |

| >5 persons | 2 | 2.5 | |

| Informationization management level | Very low | 8 | 10 |

| Low | 22 | 27.5 | |

| Medium | 32 | 40 | |

| High | 13 | 16.25 | |

| Very high | 5 | 6.25 | |

| Cognition of TS | Very low | 4 | 5 |

| Low | 9 | 11.25 | |

| Medium | 40 | 50 | |

| High | 21 | 26.25 | |

| Very high | 6 | 7.5 | |

| System maintenance investment | 0% | 2 | 2.5 |

| 0-1% | 14 | 17.5 | |

| 1-3% | 42 | 52.5 | |

| 3-5% | 19 | 23.75 | |

| >5% | 3 | 3.75 |

| U | C | D | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | ||

| 1 | 2 | 1 | 3 | 2 | 1 | 1 | 2 | 4 | 2 | 2 |

| 2 | 2 | 3 | 1 | 1 | 1 | 2 | 2 | 1 | 3 | 1 |

| 3 | 4 | 2 | 3 | 4 | 2 | 5 | 3 | 4 | 5 | 4 |

| ... | ||||||||||

| 78 | 1 | 5 | 3 | 4 | 2 | 1 | 2 | 5 | 1 | 2 |

| 79 | 3 | 2 | 2 | 1 | 4 | 3 | 5 | 1 | 1 | 4 |

| 80 | 3 | 2 | 3 | 5 | 3 | 2 | 1 | 2 | 4 | 3 |

| POS assortment | Assortment number | Importance degree | Normalized importance degree |

|---|---|---|---|

| POSC(D) | 58 | ||

| POSC-C1(D) | 54 | 0.931 | 0.205 |

| POSC-C2(D) | 33 | 0.569 | 0.126 |

| POSC-C3(D) | 48 | 0.828 | 0.182 |

| POSC-C4(D) | 15 | 0.259 | 0.057 |

| POSC-C5(D) | 30 | 0.517 | 0.114 |

| POSC-C7(D) | 25 | 0.431 | 0.095 |

| POSC-C8(D) | 41 | 0.707 | 0.156 |

| POSC-C9(D) | 17 | 0.293 | 0.065 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).