1. Introduction

The ACPs evaluation plays a fundamental role in the safety assessment of fusion reactors [

1]. When considering the radioactive contamination of a cooling system of a nuclear plant, the ACPs study is helpful for the optimization of plant operation and, at the same time, the reduction of occupational radiation exposure when the source term is considered. Moreover, the source term, including ACP, can be mobilized during accident scenarios [

2,

3].

The ACPs generation and transport processes depend on several physical phenomena involving neutronics, thermal-hydraulic, chemical, and geometry aspects. There are several computational tools for the evaluation of ACPs generation and transport. One of these is OSCAR-Fusion [

4], developed by the CEA to study the contamination of cooling circuits in the PHTS of a tokamak reactor.

In each region of the loop, there are two different oxide layers above the base metal: the inner one is adherent to the base metal and is a chromite layer, an oxide mineral composed of chromium oxide with iron oxide (Cr

2FeO

4). The second layer, located above the chromite layer, is a ferrite porous medium layer, an oxide mineral rich in ferric oxide (Fe

2O

3). In the coolant, there are also particles and ions which are produced by erosion and dissolution mechanism. These particles and ions transported throughout the loop may precipitate or dissolve depending on the equilibrium concentration of elements or particles [

5].

In a closed loop of a tokamak reactor, because of coolant transport, the corrosion products are carried from the Out-Flux (OF) region to the In-Flux (IF) region and vice versa. The corrosion products produced in the OF region will be activated in the IF region, and the ones produced in the IF region, activated under direct neutron flux, will contaminate the structural material in the OF region.

OSCAR-Fusion allows the study of generation, transport, and activation phenomena to assess the mass associated with an isotope in a given medium at a specific time for each region of the loop. The mass variation is correlated to the various physical mechanisms considered in OSCAR-Fusion and the chemical characteristic of both materials and coolant.

Radiolysis is caused by the presence of radiation fields, which result in high oxidizing products [

6]. The minimization of the corrosion product built up into a loop can be achieved by optimizing the coolant water chemistry, which can control corrosion phenomena through alkalizing agents and elements able to suppress the oxidizing environment established because of radiolysis.

The alkalizing agents considered for the reducing environment of a PWR, as described in [

7], are lithium hydroxide (LiOH), potassium hydroxide (KOH), and ammonia (NH

3) with variable concentrations, depending on boric acid concentration (H

3BO

3) used for reactivity control. In a nuclear fusion reactor, the presence of H

3BO

3 is not foreseen, but radiolysis is expected because of the high neutron flux.

For this reason, an alkalizing agent is expected [

8] for pH control and oxidizing environment suppression.

Different experimental analysis has been performed [

9] to optimize the water chemistry of tokamak reactors.

The aim of this paper is to study the impact of water chemistry on ACPs generation and transport for a closed loop by perturbing specific parameters that characterize the coolant's chemical composition. This analysis can be done thanks to a code interface OSCAR-Fusion/RAVEN described in [

10] and a Python-based post-processing script.

2. OSCAR-Fusion V1.3

OSCAR-Fusion is a one-dimensional code that can use physical models implemented for corrosion products to study the mass exchange between the media and the control volumes modelled. Like the previous versions of the code as PACTITER, or the ones used in fission (e.g., OSCAR and PACTOLE), described in [

4,

11,

12], the evaluation of ACPs is based on the masses balance equation. The variation of a mass M, of the isotope i in a given medium j at time t, for a control volume, comes from the mass balances conservation equation [

5]:

where

and

are the control volumes inlet and outlet flow rates.

As described in [

5], the media considered are the base metal, the inner oxide layer, the deposit/outer oxide layer, ions, particles, filters, and resins.

Each control volume can describe a closed-loop region, considering given input parameters as thermal-hydraulic, neutronic, power distribution, and water chemistry.

The thermal-hydraulic data of the OSCAR-Fusion V1.3 are evaluated by the same formulation of the CATHARE code, which is optionally used to evaluate the fluid velocity and the density, both temperature dependent. The PHREEQCEA module evaluates the chemical data.

In OSCAR-Fusion V1.3, the water chemistry characteristics can be evaluated by setting lithium, boron, hydrogen, and oxygen concentration for each period. In OSCAR-Fusion, the lithium concentration corresponds to a lithium hydroxide (LiOH) concentration in water, the boron concentration corresponds to a boric acid (H3BO3) concentration in water, and hydrogen and oxygen concentration correspond respectively to molecular hydrogen (H2) and molecular oxygen (O2) in water. It must be highlighted that OSCAR-Fusion V1.3 does not foresee physical models for radiolysis, which is caused by the radiation field.

In OSCAR-Fusion V1.3, corrosion and release rates can be evaluated by setting specific parameters, such as the standardized coefficients for the Short Term Corrosion Rate (STCR) and the Long Term Corrosion Rate (LTCR), the temperature of the coolant and the water chemistry characteristics.

In the OSCAR-Fusion code, the default correlations for corrosion rate and release rate are the Moorea laws. The Moorea laws are empirical laws and, for both corrosion rate and release rate, depending on four factors: the standardized coefficient STCR and LTCR, a function of the temperature of the fluid, a function related to pH of the fluid, and an attenuation factor which in turn depends on ion concentration of a metal species with respect to its equilibrium concentration.

3. EU-DEMO Divertor Plasma Facing Unit

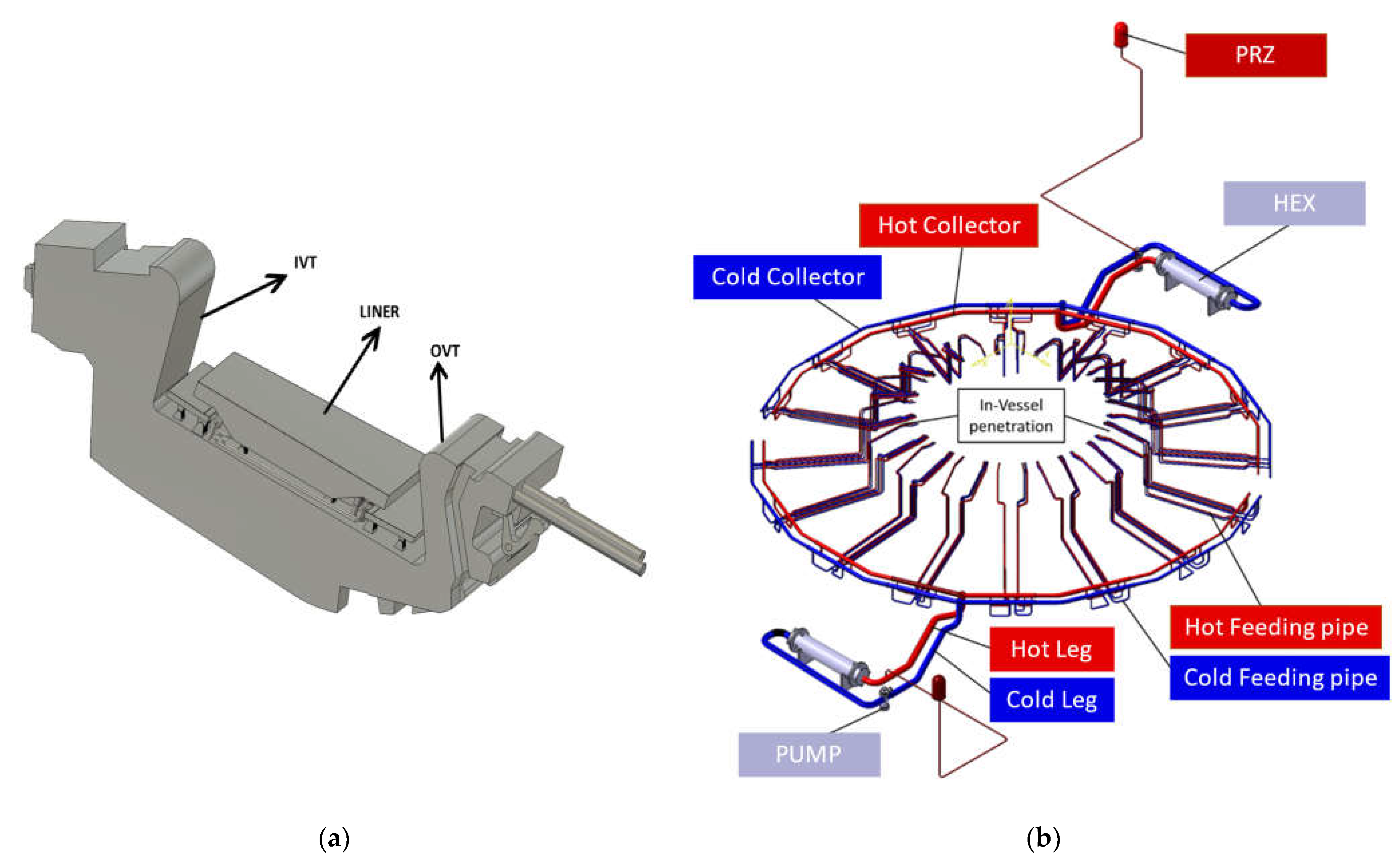

The EU-DEMO divertor component is located in the bottom region of the torus. The divertor role is to reduce the heat flux on the first wall and the helium ashes from the plasma's outer layer, avoiding its build-up and dilution of the plasma ion density and preventing the impurities from entering the plasma core. The DEMO divertor system, as described in [

13], is composed of two independent systems, as shown in

Figure 1a, the DIVertor CASsette (DIV-CAS) and the DIVertor Plasma Face Unit (DIV-PFU). Both systems are composed of two independent loops, each of them serving 8 of 16 sectors, according to the 2019 design of the Divertor PHTS. A single system of the loop comprises 24 divertor cassettes, three for each sector of the torus.

The EU-DEMO divertor system PHTS components are shown in

Figure 1b. Each PHTS loop consists of: one Heat EXchanger (HEX), one Main Coolant Pump (MCP), one PRessuriZer (PRZ), 8 distributors (DIS), 8 collectors (COL), 24 Hot Feeding Pipe (HFP), 24 Cold Feeding Pipes (CFP), one Hot Leg (HL), one Cold Leg (CL) and one Cross Over pipe (COV).

Each cooling loop of the divertor PFU PHTS is operated at a pressure of 3.8 MPa with a mass flow rate of 5319.3 kg/s 13 distributed over the 24 divertor cassette. The cooling water is distributed at 130 °C and is collected at 136 °C.

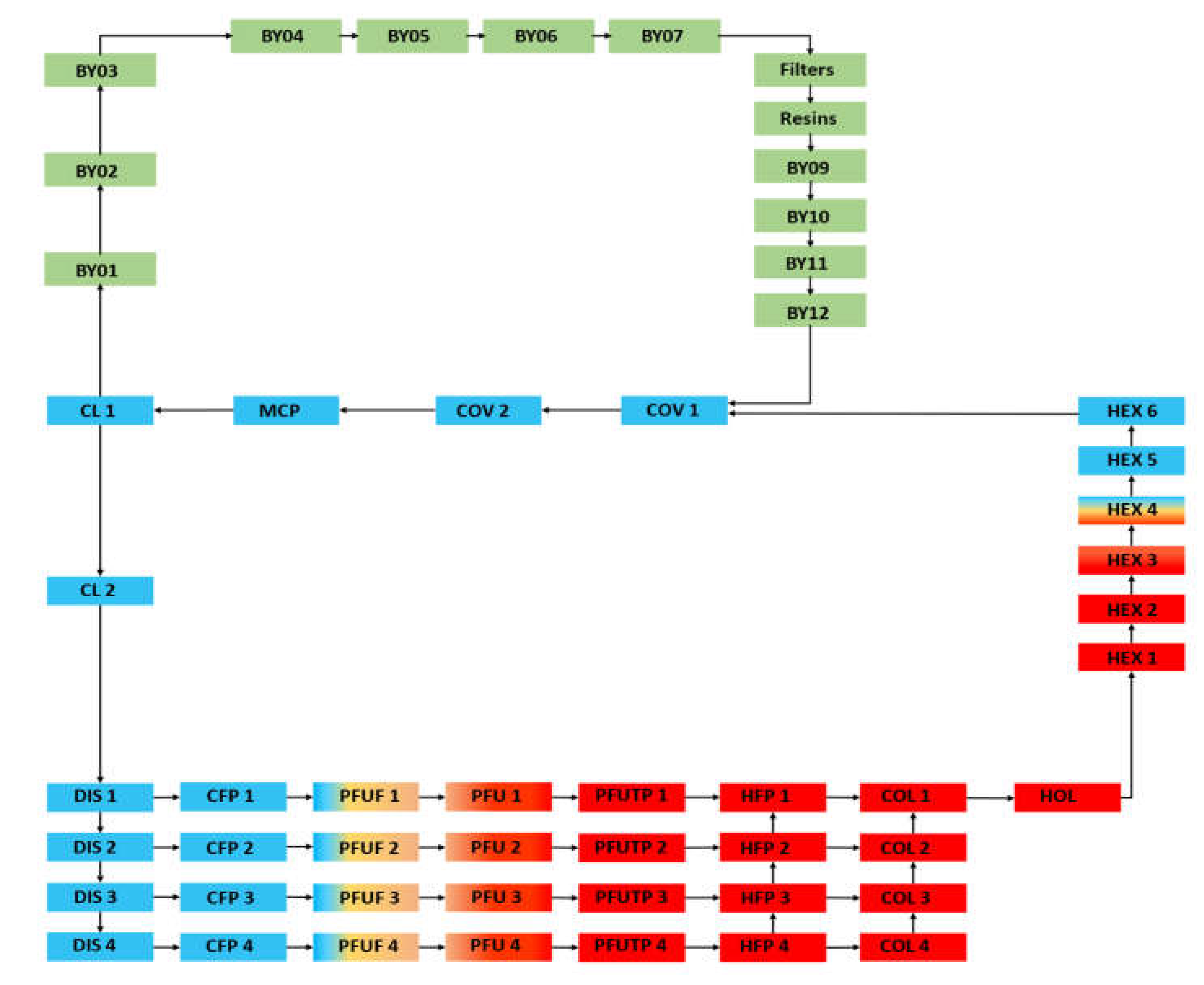

The divertor system PHTS also presents the Chemical Volume Control System (CVCS, named as BY in

Figure 2), with mechanical filters and ion exchange resins, to maintain the coolant purity and chemical composition.

4. OSCAR-Fusion Model of EU-DEMO Divertor PFU

The OSCAR-Fusion model of the divertor PFU PHTS is shown in

Figure 2. The model is a simplified closed loop subdivided into 53 regions. Each region has assigned conditions of temperature, pressure, wetted surface, hydraulic diameter, and coolant velocity.

As described in [

14], since the CVCS design is not confirmed, some assumptions have been made during the modelling phase. The cooling loops are collapsed in half of a single cooling loop using equivalent thermal-hydraulic data. The filters and resin efficiency have been set to 99 %.

In the OSCAR-Fusion model of the divertor PFU PHTS, four different materials are considered as base metals: Inconel 660, stainless steel SS 316 LN, Metal Cu, and the CuCrZr alloy. For each material, the input chemical parameters are the base metal, the inner/outer oxide layers, and the normalized corrosion coefficients for the evaluation of the corrosion rate and release rate. The default normalized coefficients are shown in

Table 1, where it can be seen that the coefficients are defined before 2 months, which is the STCR, and after 12 months, which is the LTCR. In the interval 2 - 12 months, coefficients are correlated between SCTR and LCTR values.

The temperature and pressure variations inside the loop are imposed as input parameters. The temperature trend in the loop lies in a range of 130°C – 136°C. The pressure drop has been evaluated as 1.960 MPa, as described in 13. The water volume is about 114 m

3, and its composition is reported in

Table 2. The DEMO water chemistry optimization is preliminarily evaluated and has a pH of around 7 at 300°C [

15]. The operational scenario adopted for the simulation is a lumped continuous scenario of 1888 days.

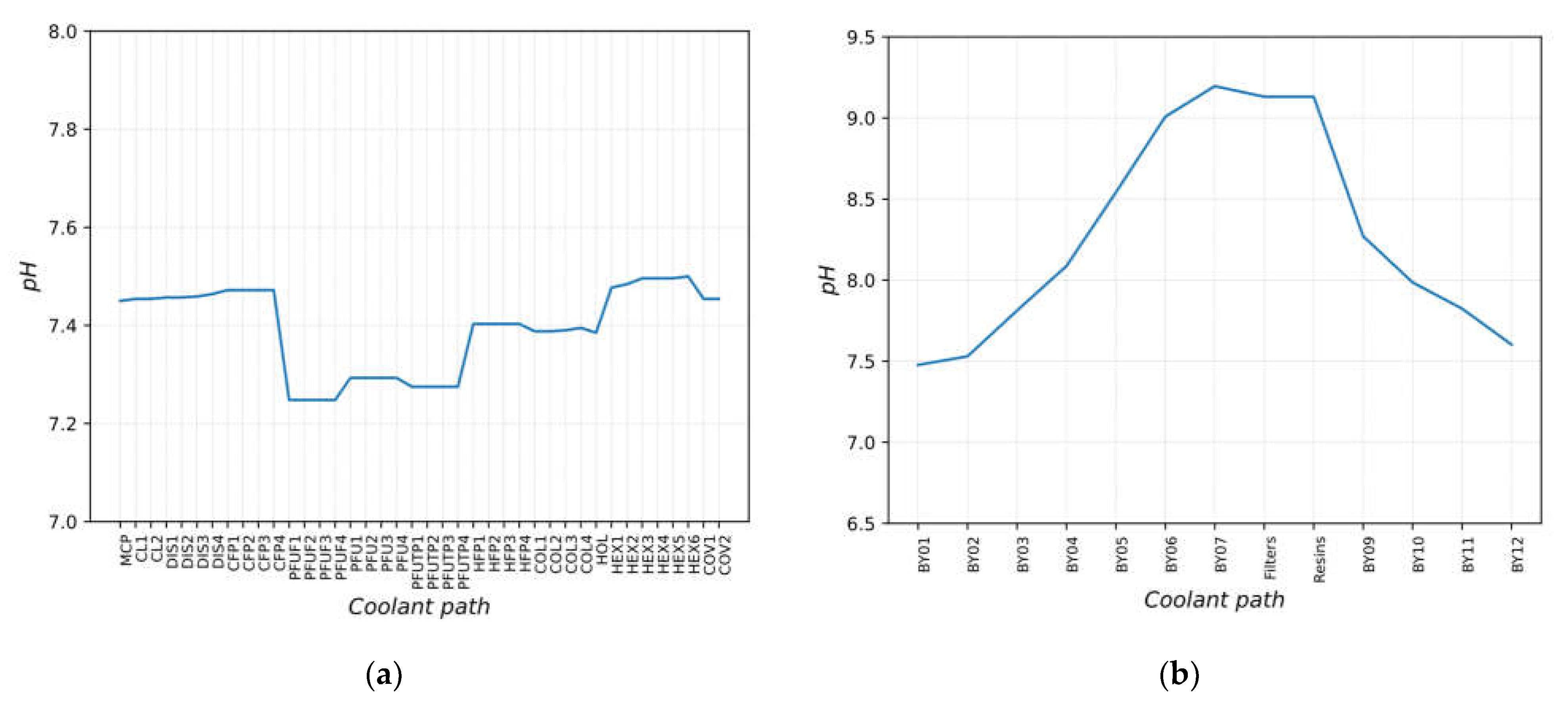

Using the parameters shown in

Table 2 as input, the pH trend in the loop, at the initial time of the considered scenario, assumes the values depicted in

Figure 3a and

Figure 3b. The pH values range in

Figure 3a is kept close to neutrality, because the pH target is in range of 7.0 at the operating temperature of the loop.

A difference from neutrality is therefore preferable to a slightly alkaline environment because an acid pH can be reached during operating conditions due to temperature variations and radiolysis reactions.

5. RAVEN/OSCAR-Fusion Analyses

A statistical study with RAVEN/OSCAR-Fusion has been performed to assess the impact of water chemistry on ACPs generation and transport.

RAVEN is a multi-purpose, probabilistic, and uncertainty framework developed at the Idaho National Laboratory (INL), which can be coupled with any system code [

16,

17]. The RAVEN/OSCAR-Fusion interface has already been tested for a preliminary study, as reported in [

10].

To perform the sensitivity analysis, the parameters that have to be studied and perturbed must be identified. This study's parameters are the lithium concentration and hydrogen concentration in the cooling water. The Figure of Merit (FOM) chosen to evaluate the perturbation's effect is the Mn-54 in the deposit/outer oxide layer medium. The Mn-54 reactions, decay mode, and energy of the γ emitted are summarised in

Table 3.

For both case studies, 100 runs were performed. The total number of runs has been evaluated using Wilk's formula, as described in [

18,

19]. Pearson's and Spearman's coefficients have been used to quantify the correlation between the variables 2021.

6. Results for Case Study 1: Lithium Concentration

The lithium concentration has been perturbed starting from the divertor system's water chemistry parameters summarized in

Table 2.

The lithium concentration represents the only alkalizing agent which can be simulated in OSCAR-Fusion V1.3. The perturbation of LiOH concentration in water means a variation in pH and, therefore, the increase or reduction of the corrosion rate. The perturbation of lithium concentration is reported in

Table 4.

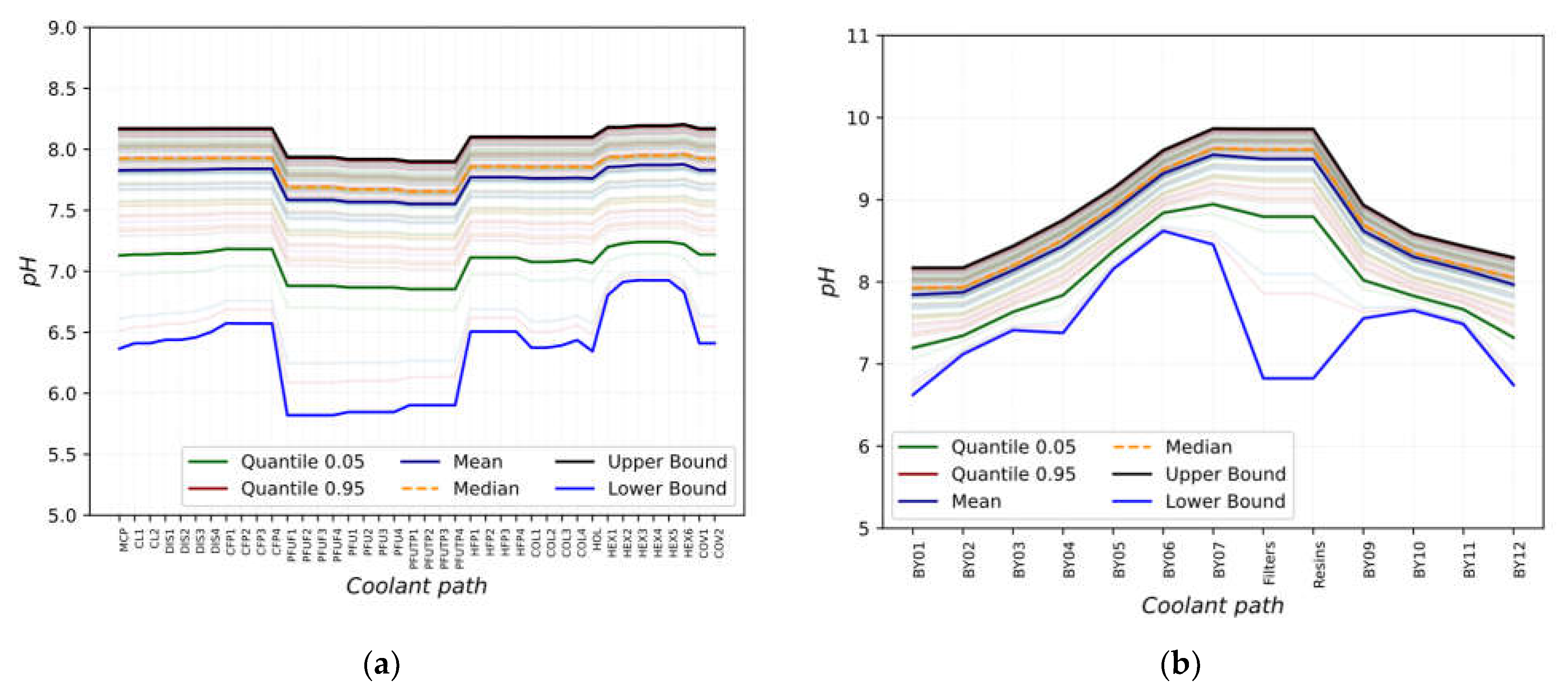

The 100 runs completed by the code have been statistically analyzed, showing that the lithium concentration perturbation has led to a range of values depicted in

Figure 4a and

Figure 4b. It is possible to notice a trend in which the pH increases when the concentration of LiOH increases.

Because Mn-54 can also be obtained from Fe-54, both Mn and Fe corrosion rates must be considered. During the entire simulation, there is a variation in the corrosion rate of both Mn and Fe in the deposit/outer oxide layer medium caused by pH variation. By varying the corrosion rate, the deposit/outer oxide layer formation mechanism increases.

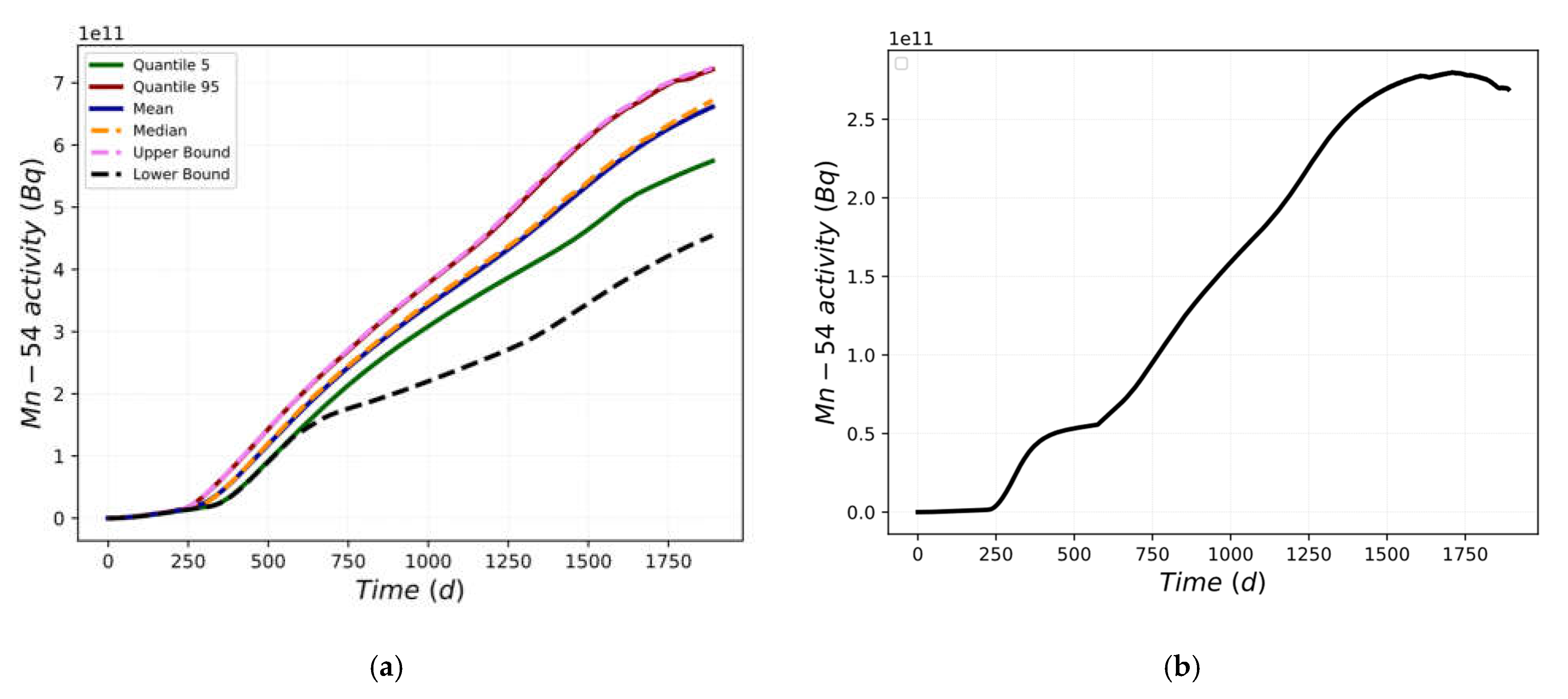

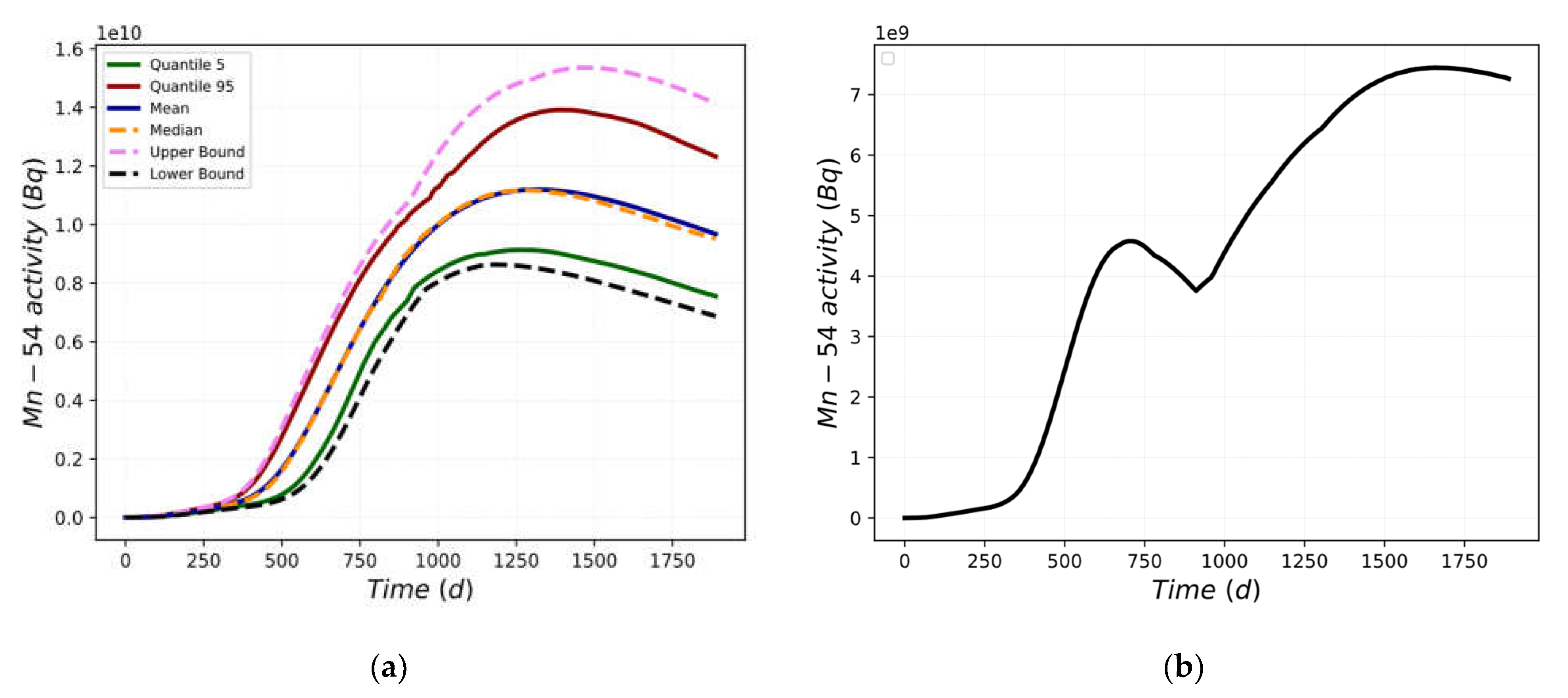

Figure 5a shows the main statistical parameters evaluated for the FOM.

As can be seen in

Figure 5b the difference between the UB trend and the LB trend is time-dependent.

Figure 5b shows a maximum difference of 2.79E+11 Bq and a difference at the end of the scenario of 2.69E+11 Bq.

The analyzed data increasingly deviate from the trend of the mean value.

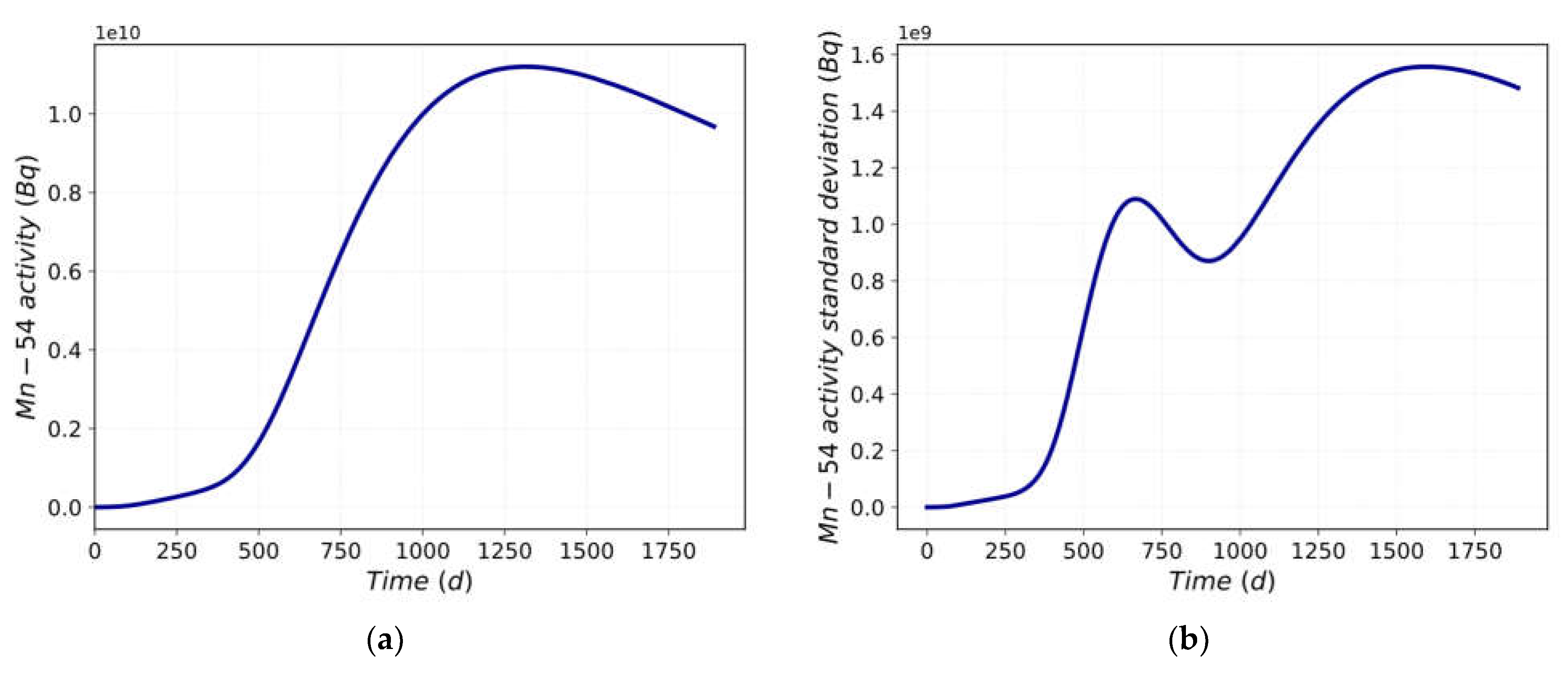

Figure 6a shows the mean value trend, while

Figure 6b depicts the standard deviation trend of the Mn-54 activity into the loop. The standard deviation trend is also predictable from

Figure 5a. The data's variability increases at about 600 days and tends to reduce at about 1500 days. This reduction is also confirmed by the variation in the slope of the first derivative in the same moments as in

Figure 5b.

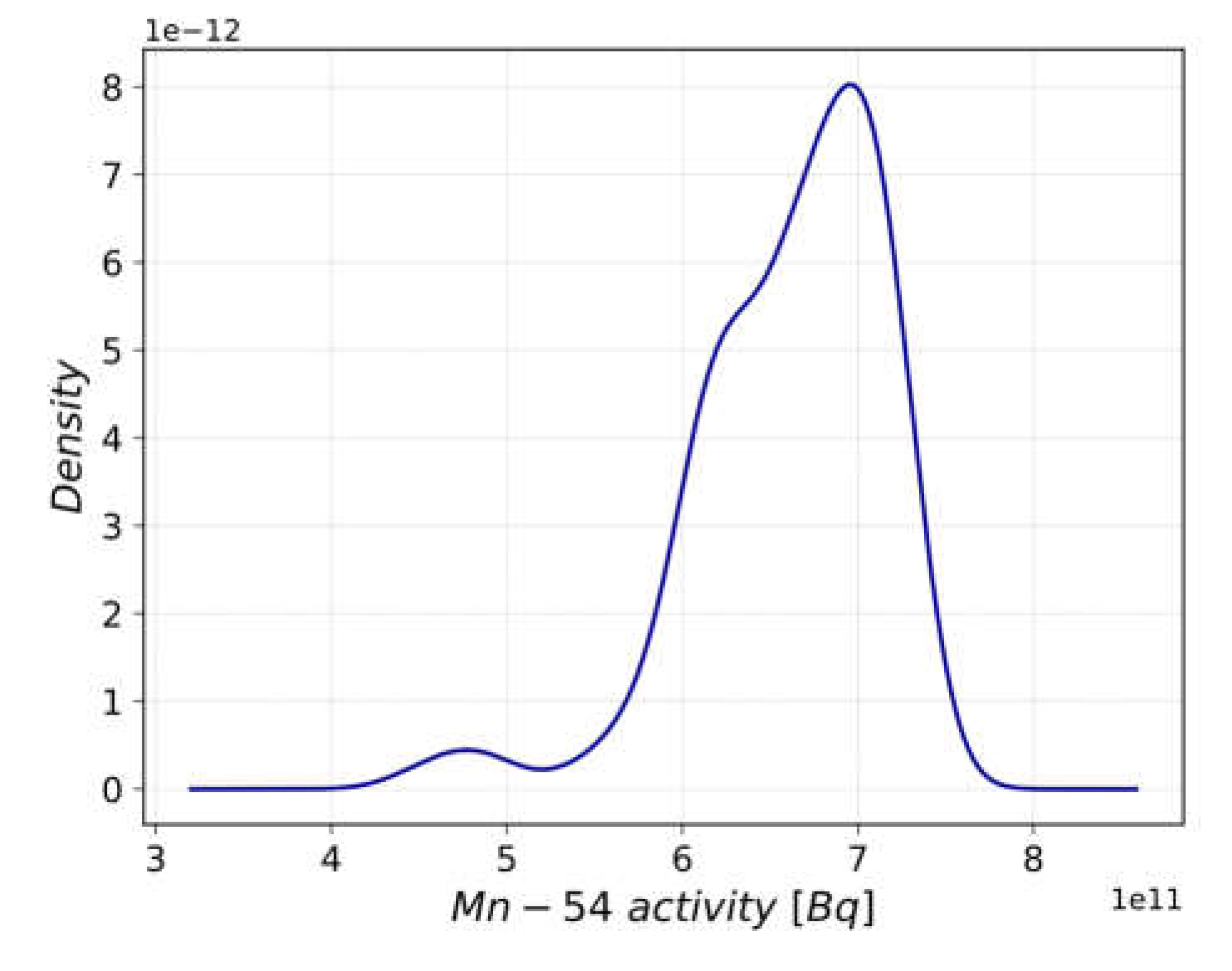

In

Figure 7, the Probability Density Function (PDF) evaluated at the end of the scenario is shown. A platykurtic and non-symmetric distribution, centered in 6.61E+11 Bq, is obtained. The PDF characteristics are confirmed by the Kurtosis and Skewness values reported in

Table 5.

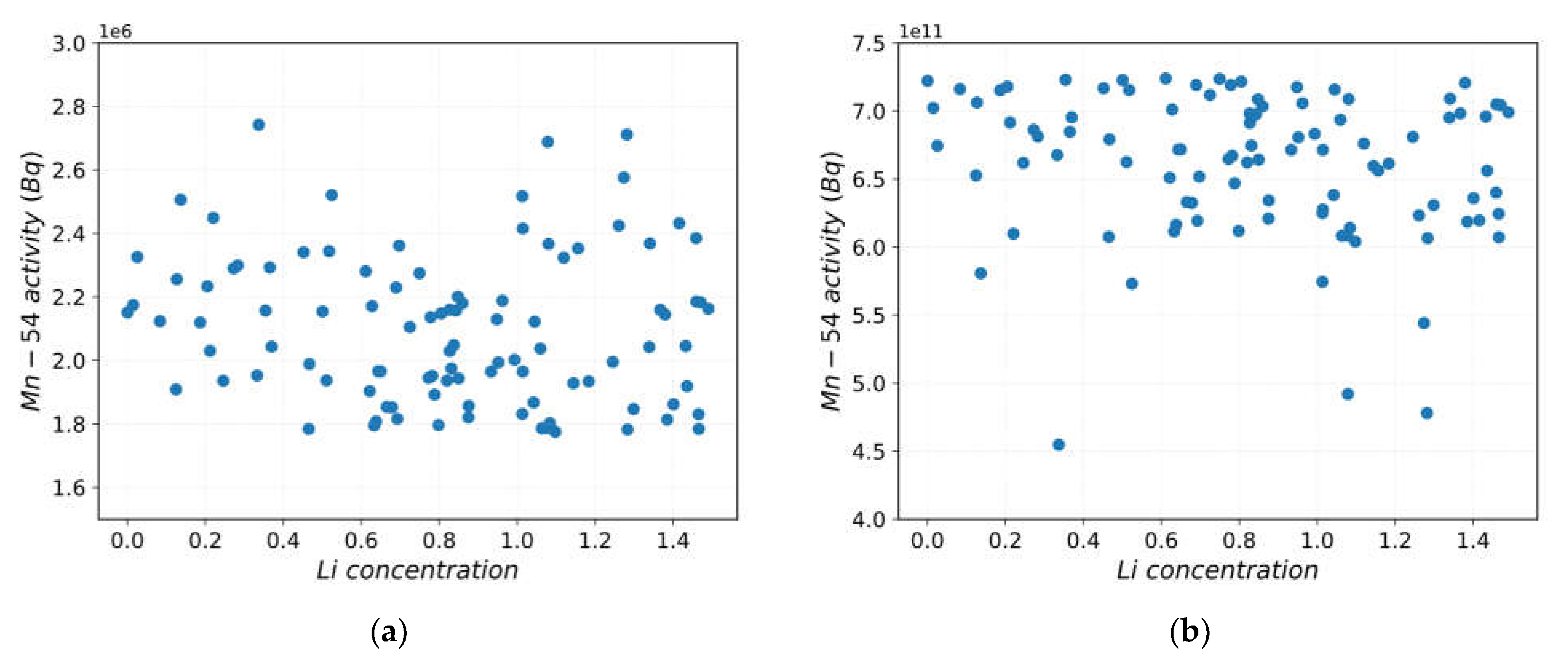

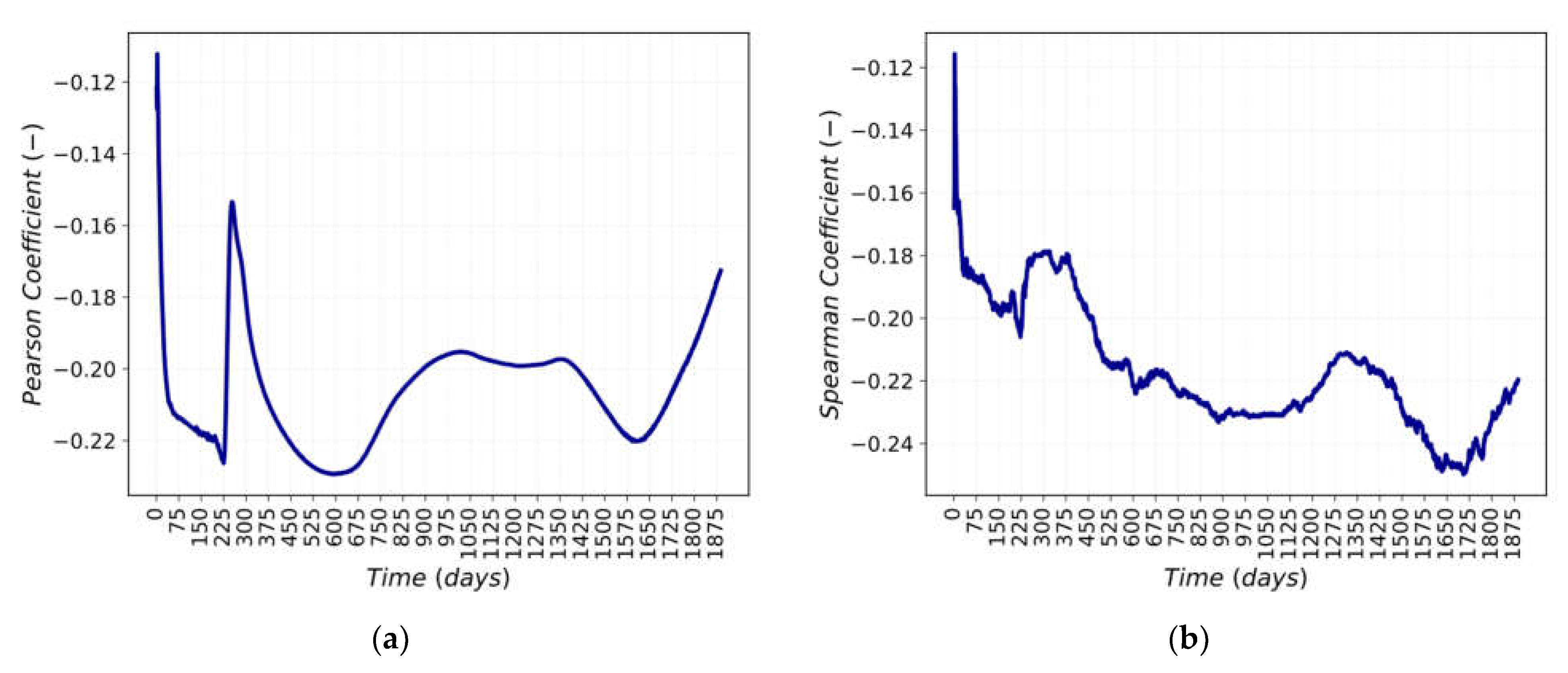

Figure 8a and

Figure 8b highlight that perturbing the LiOH concentration, there is a variation in the Mn54 activity in the deposit medium. After 3 days from the beginning of the scenario, the correlation between the perturbed parameter and the FOM is at the highest value, as shown in

Figure 9a and

Figure 9b by Pearson's and Spearman's correlation coefficients. Pearson's correlation is a measure of linear correlation between two sets of data [

21], instead the Spearman's correlation is the measure of monotonic relation between the ranked values of two sets of data [

20]. This means that the correlation between the LiOH concentration perturbation and Mn – 54 activity in the deposit/outer oxide layer is neither linear nor monotonic, and there is a weak correlation between the LiOH concentration and the FOM.

7. Results for Case Study 2: Corrosion Rates

When editing the laws of corrosion and release models, the OSCAR-Fusion code requires several parameters, some of which are the standardized coefficient for corrosion rates for copper-based alloy and stainless steel. The default parameters are shown

Table 2.

In order to evaluate the CPs formation and activation, the standardized coefficients for corrosion rates has been taken into account. The perturbation of the standardized coefficient for corrosion rates is reported in

Table 6. For Cu-based alloy, the UB and LB have been chosen considering the oxidizing condition described in [

22] at 130°C and a fluid velocity of 13

m/s. The UB and LB values have been selected in order to have a not negligible perturbation on the corrosion rate and release rate of the materials considered into the loop.

The 100 runs completed by the code have been statistically analyzed and, as in the previous case, Mn and Fe corrosion rates have been considered. During the entire simulation, there is a variation in the corrosion rate in the deposit/outer oxide layer caused by the induced perturbation. By varying the corrosion rate, the deposit/outer oxide layer formation mechanism increases.

Figure 10a shows the main statistical parameters evaluated for the selected FOM, the Mn-54 activity in the deposit/outer oxide layer, while

Figure 10b shows the difference in the activity of UB and LB. A maximum difference of 7.45E+09 Bq and of 7.26E+09 Bq at the end of the considered scenario have been obtained.

In

Figure 11a is shown the mean value trend, while

Figure 11b depicts the standard deviation trend of the Mn-54 activity into the loop. It can be seen that the analyzed data deviation increases with time. The standard deviation trend is predictable, taking into account the statistical parameters. In

Figure 10a, at about 400 days, there is an increase in the variability of the data up to the first point of maximum at about 700 days. After 700 days, there is a decrease until 900 days. After that, the standard deviation increases again until the second maximum point is reached, at about 1550 days. After 1550 days the variability of the data tends to reduce.

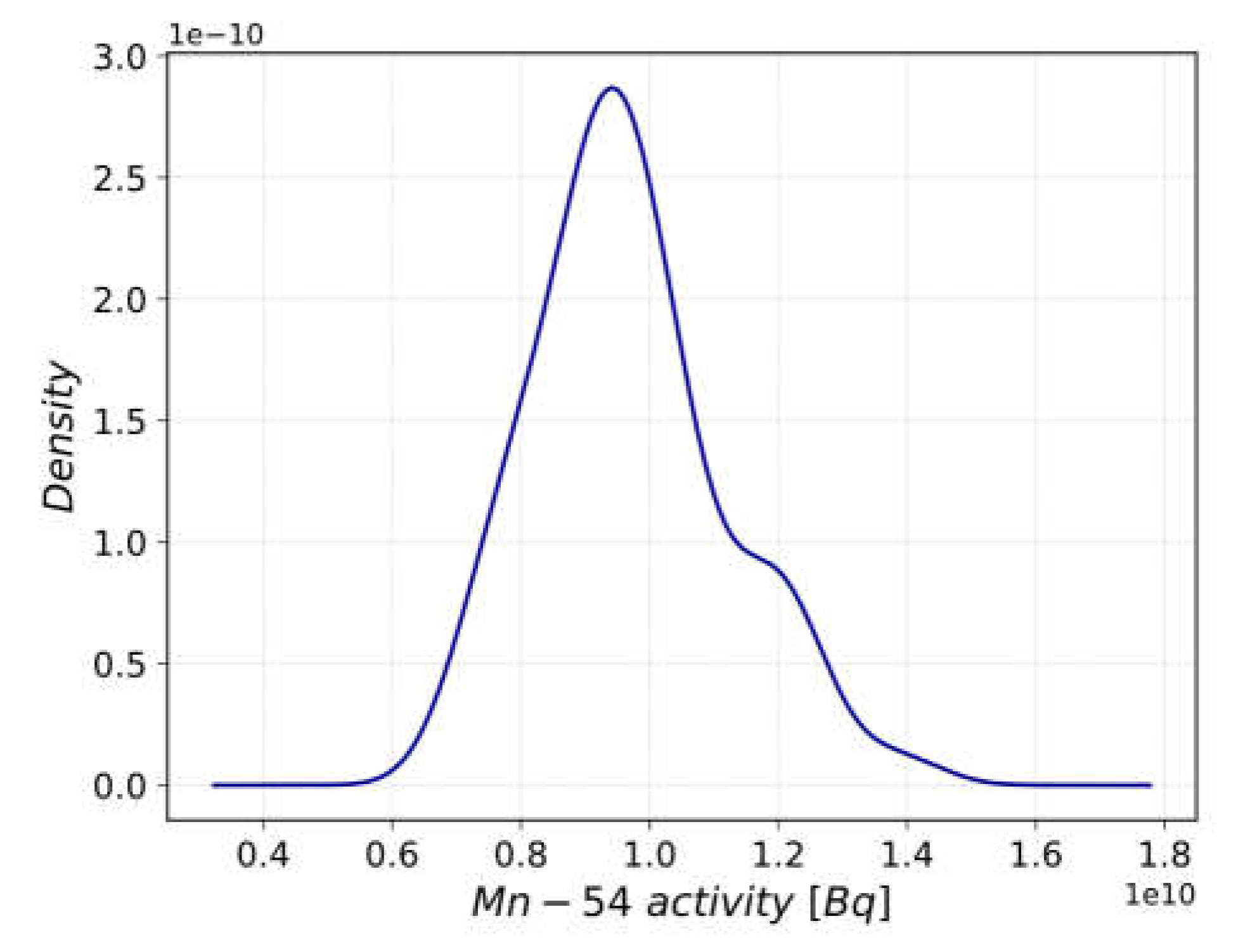

In

Figure 12 the PDF evaluated at the end of the scenario is reported, showing a platykurtic and quasi-symmetric distribution, centered in 9.67E+09, which is the mean value. The PDF characteristics are confirmed by the Kurtosis and Skewness values in

Table 7.

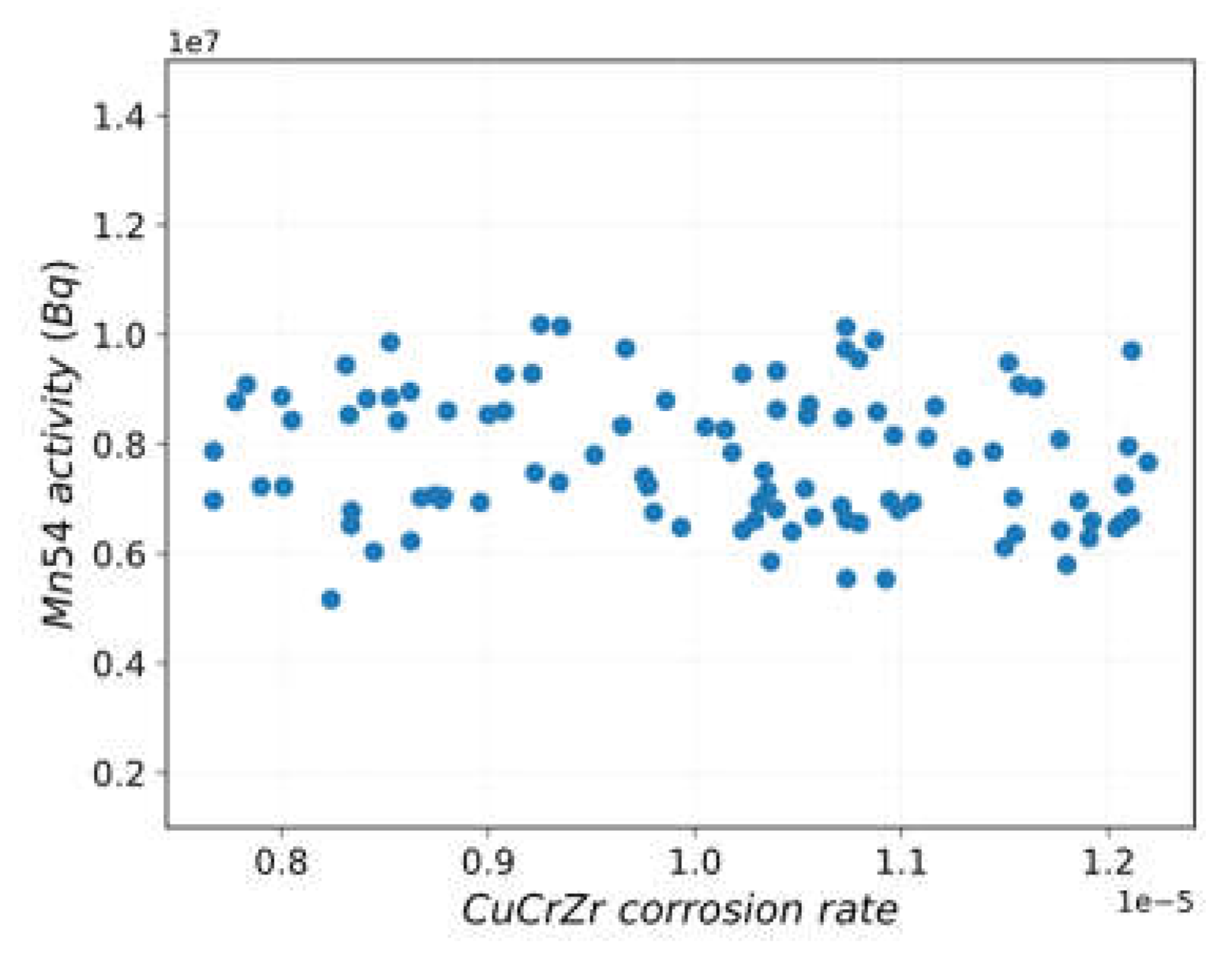

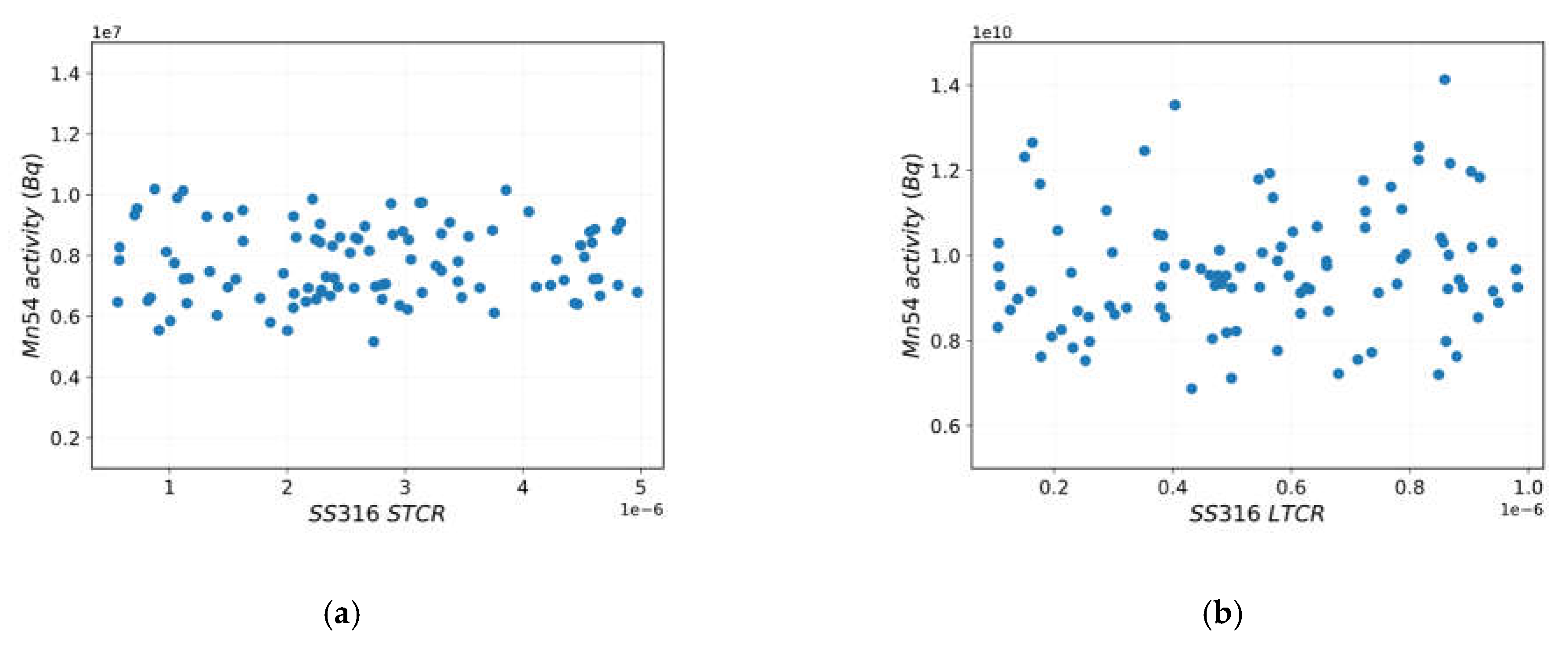

Figure 13,

Figure 14a and

Figure 14b highlight that perturbing the standardised coefficients for corrosion rate, there is a variation in the Mn-54 activity in the deposit medium.

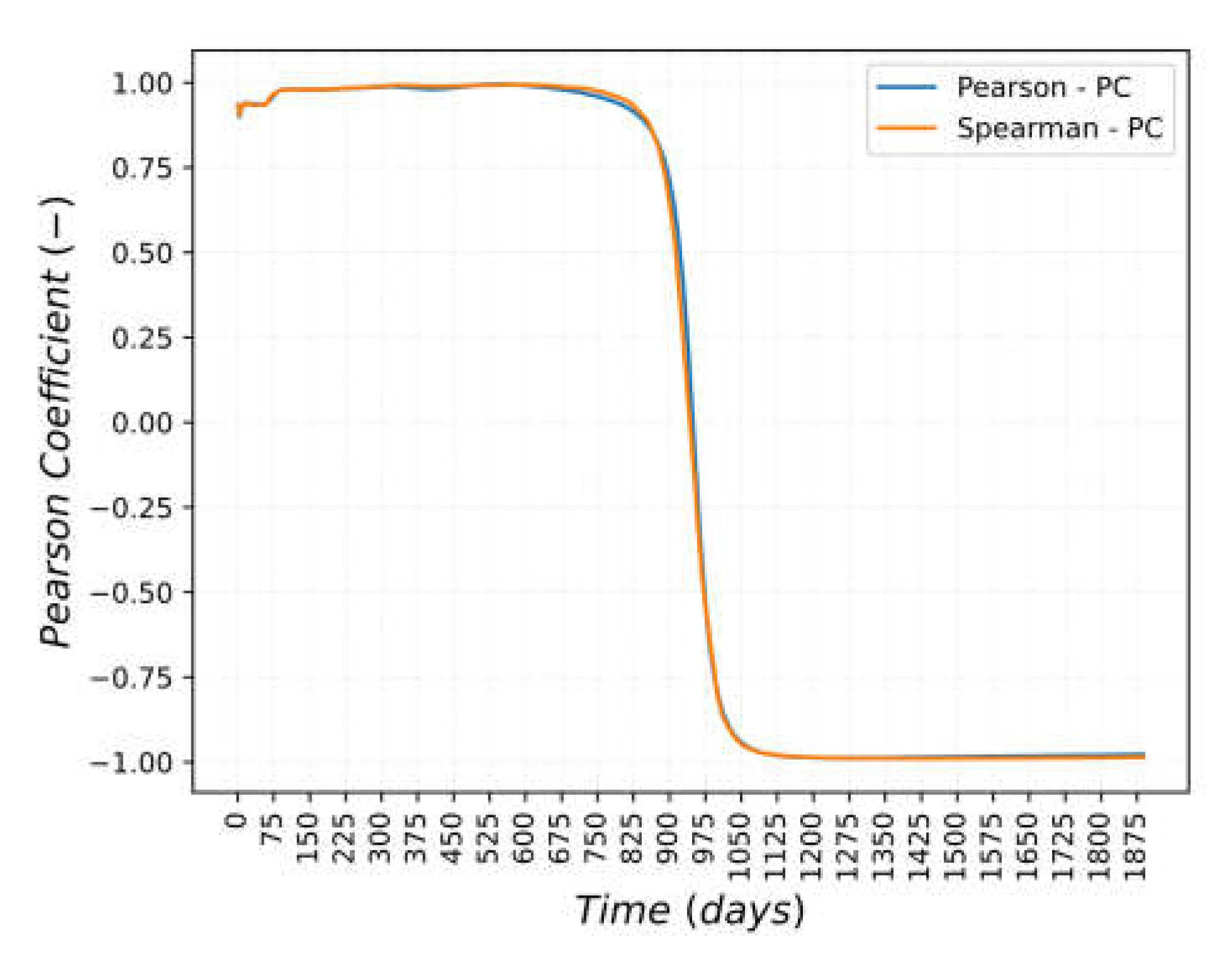

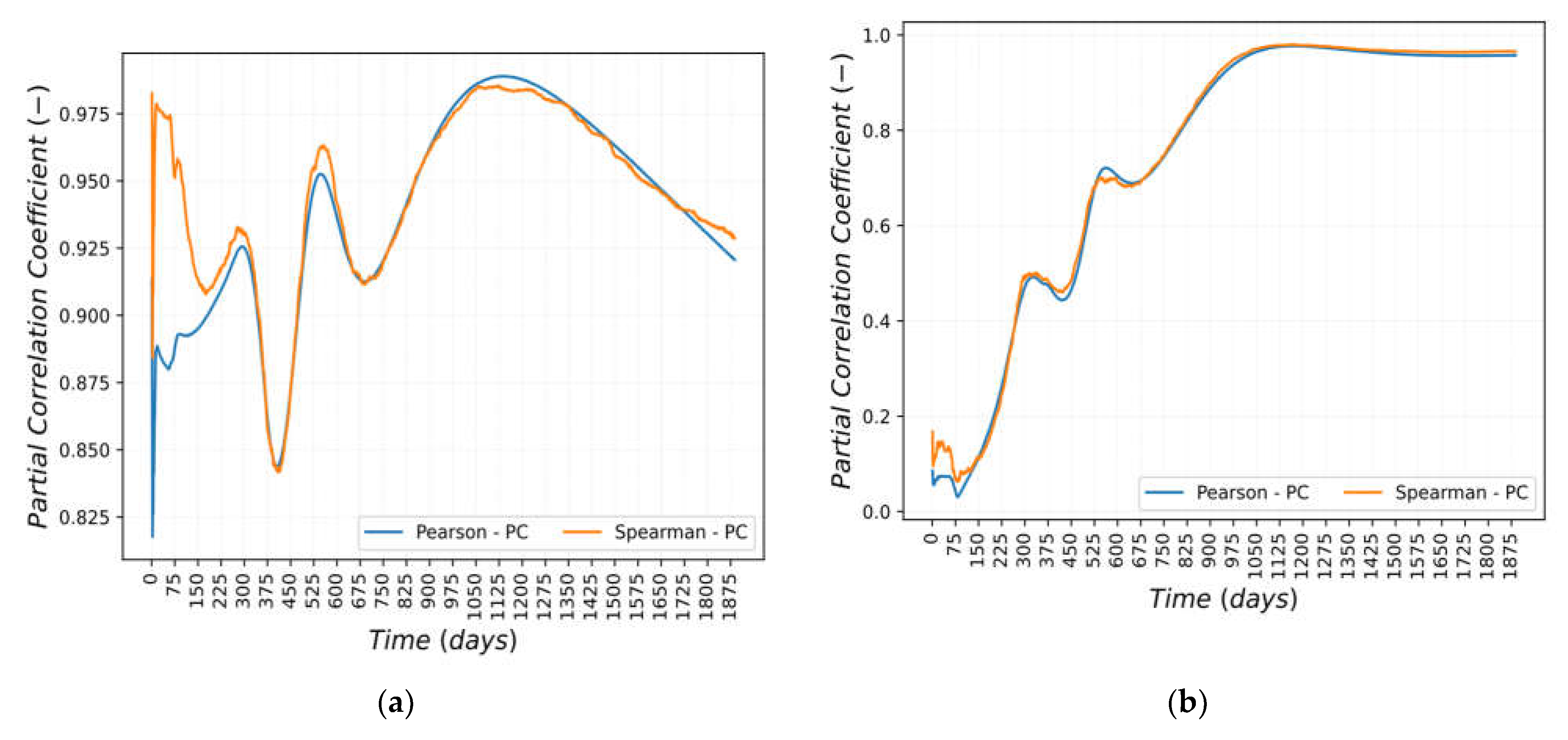

Pearson's and Spearman's partial correlations coefficients are shown in

Figure 15,

Figure 16a and

Figure 16b. The correlation between the normalized coefficients of Cu-based alloy and Mn – 54 activity in the deposit/outer oxide layer is linear and monotonic from the beginning of the simulation until 800 days, and from 1000 days until the end of the scenario.

The correlation between the STCR and the Mn-54 activity in deposit/outer oxide layer is strong for the entire scenario considered, therefore it can be concluded that the correlation is both linear and monotonic.

The correlation between the LTCR and the Mn-54 activity in the deposit/outer oxide layer is linear and monotonic from about 900 days until the end of the scenario considered.

8. Conclusions and Future Work

The impact of water chemistry on ACPs has been studied through the perturbation of chemical parameters, such as the LiOH concentration and the corrosion rates of different materials. The model used in OSCAR-Fusion V1.3 is a simplified but representative reproduction of the EU-DEMO PFU.

Two different case studies have been analyzed. Case Study 1 demonstrates that, due to the LiOH concentration perturbation, there is an impact on Mn-54 activity in the deposit/outer oxide layer of the whole loop. Case Study 2 shows how the perturbation of normalized corrosion coefficients can significantly impact the Mn-54 activity in the deposit/outer oxide layer.

It has to be noted that the perturbation on LiOH leads to a pH variation in the cooling circuit. The pH is a parameter on which the corrosion rate depends when the Moorea law is set as the corrosion release law. The perturbation of normalized corrosion coefficients leads to a variation in the cooling circuit's corrosion rate and release rate. The corrosion rate formulation depends on four different parameters: temperature, pH, equilibrium concentration, and normalized corrosion coefficients for the STCR and LTCR.

For Case Study 1, the statistical analysis has shown that the correlation between the perturbed parameter and the Mn-54 activity in the loop's deposit/outer oxide layer is not linear or monotonic. For Case Study 2, the statistical analysis has shown that the correlation between the perturbed parameters and the Mn-54 activity in the deposit/outer oxide layer in the loop is linear and monotonic in most of the scenario considered.

These analyses suggest that the perturbation of the water chemistry composition has an impact on the ACPs but is not always observable with the Pearson and Spearman correlations and Pearson and Spearman partial correlations.

Optimizing the water chemistry leads to a reduction of corrosion products into a coolant loop; this means a reduction of the build-up of ACPs and so the specific activity of one or more components during planned maintenance or at the end of their life cycle. Consequently, with water chemistry control, it is possible to reduce occupational radiation exposure during both the maintenance and the decommissioning phases.

As previously said, OSCAR-Fusion V1.3 does not foresee physical models for radiolysis. As described in [

23], there is a more oxidizing environment due to radiolysis with respect to the one modeled by OSCAR-Fusion V1.3; this is due to the presence of free radicals and molecules more oxidizing than O

2, like hydrogen peroxide or hydroperoxide.

Considering the preliminary nature of this water chemistry analysis, more detailed studies will be performed to analyze the impact of oxygen perturbation and other alkalizing agents with a new version of the computer code, OSCAR-Fusion V1.4.

Acknowledgments

This work was carried out within the framework of the EUROfusion Consortium, funded by the European Union via the Euratom Research and Training Program (Grant Agreement No 101052200—EUROfusion). Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or the European Commission. Neither the European Union nor the European Commission can be held responsible for them.

List of Abbreviation

| ACP |

Activated corrosion products |

| CB |

Cassette body |

| CFP |

Cold feeding pipes |

| CL |

Cold leg |

| COV |

Cross over pipe |

| CVCS |

Chemical volume control system |

| FOM |

Figure of merit |

| HEX |

Heat exchanger |

| HFP |

Hot feeding pipe |

| HL |

Hot leg |

| IF |

In flux |

| INL |

Idaho National Laboratory |

| IVT |

Inner vertical target |

| LBLTCR |

Lower boundLong Term Corrosion Rate |

| MCP |

Main coolant pump |

| OF |

Out of flux |

| OSCAR |

Tool for simulating contamination in reactors |

| OVT |

Outer vertical target |

| PFU |

Plasma facing units |

| PHTS |

Primary heat transfer system |

| PRZ |

Pressurizer |

| PWR |

Pressurized water reactor |

| RP |

Reflector plates |

| SLSTCR |

Shielding linerShort Term Corrosion Rate |

| UB |

Upper bound |

References

- Caruso G. et al., "DEMO – The main achievements of the Pre – Concept phase of the safety and environmental work package and the development of the GSSR", Fusion Engineering and Design, 2022. [CrossRef]

- Dongiovanni D.N. et al., "DEMO Divertor Cassette and Plasma facing Unit in Vessel Loss-of-Coolant Accident", Energies 2022, 15(23), 8879. [CrossRef]

- D'Onorio M. et al., "Development of a Thermal-Hydraulic Model for the EU-DEMO Tokamak Building and LOCA Simulation", Energies 2023, 16(3), 1149. [CrossRef]

- Rafique M. et al., "Review of computer codes for modelling corrosion product transport and activity build-up in light water reactors", Nukleonika, 55 (2010), pp. 263-269.

- Daquait F. et al., "Modelling of the contamination transfer in nuclear reactors: The OSCAR code – applications to SFR and ITER", 1st IAEA Workshop on Challenges for Coolants in Fast Neutron Spectrum Systems, 2017.

- Digby D. M. et al., "A critical review of radiolysis issues in water-cooled fission and fusion reactors: part I, assessment of radiolysis models", Corrosion and Materials Degradation, 2022, pp. 470-535. [CrossRef]

- IAEA, "Reactor water chemistry relevant to coolant-cladding interaction", IAEA-TECDOC-429, 1987.

- Platts L. et al., "Corrosion and chemistry control for the WCLL system with investigation of corrosion mechanisms of Eurofer in aqueous solutions 2020", Report IDM, EDFA_D_2PL25H, 2021.

- Lo Piccolo E. et al., "Preliminary assessment of cooling water chemistry for fusion power plants", Corrosion and Materials Degradation, 2021, 512-530. [CrossRef]

- D'Onorio M. et al., "RAVEN/OSCAR-Fusion coupling for activated corrosion products assessments, sensitivity and uncertainty quantification", IEEE Transactions on Plasma Science, 2022 (accepted for publication). [CrossRef]

- CEA, “La corrosion et l’altération des matèriaux du nuclèaire”, CEA Saclay et Group Moniteur (Éditions du Moniteur), Paris, 2010.

- Di Pace L., "Activated corrosion products assessment in fusion reactors", 2019.

- Narcisi V. et al., "WCLL DIV-PFU PHTS DDD (Direct Coupling Option with Small ESS)", Report IDM EDFA_D_2ND5SH, 2020.

- Terranova N., "Activation corrosion products (ACP) assessment", Report IDM, EDFA_D_XYZ123, 2020.

- Terranova N., "ACPs assessment for DEMO Divertor Cooling loop", Report IDM, EDFA_D_2P9QUG, 2022.

- Rabiti C. et al., “RAVEN User Manual”, INL/EXT-15-34123,.

- https://inldigitallibrary.inl.gov/sites/sti/sti/Sort_4450.pdf.

- Wilks S. S., "Determination of sample size for setting tolerance limits", The Annals of Mathematical Statistics 12(1), pp. 91-96 (1941).

- Wilks S. S., "Statistical prediction with special reference to the problem of tolerance limits", The Annals of Mathematical Statistics 13(4), pp. 400-409 (1942).

- Dodge Y., "Spearman Rank Correlation Coefficient", The Concise Encyclopedia of Statistics, pp. 502-505 (2008). [CrossRef]

- Kirch W., "Pearson's Correlation Coefficient", The Encyclopedia of Public Health, pp. 1090-1091(2008). [CrossRef]

- Obitz C. et al., "Erosion corrosion of CuCrZr specimens exposed for simulater ITER operation conditions", Nuclear Materials and Energy, 9 (2016) 261-266. [CrossRef]

- Harrington C. et al., "Chemistry and corrosion research and development for the water cooling circuits of European DEMO", Fusion Engineering and Design, 146 (2019) 478-481. [CrossRef]

Figure 1.

(a) Divertor assembly; (b) Divertor PFU PHTS.

Figure 1.

(a) Divertor assembly; (b) Divertor PFU PHTS.

Figure 2.

EU-DEMO divertor PFU PHTS model.

Figure 2.

EU-DEMO divertor PFU PHTS model.

Figure 3.

pH trend of the reference case (a) in the loop; (b) bypass line.

Figure 3.

pH trend of the reference case (a) in the loop; (b) bypass line.

Figure 4.

pH trend after Li concentration perturbation (a) in the loop; (b) bypass line.

Figure 4.

pH trend after Li concentration perturbation (a) in the loop; (b) bypass line.

Figure 5.

(a) Mn-54 activity in the deposit/outer oxide layer; (b) Mn-54 activity difference between UB and LB.

Figure 5.

(a) Mn-54 activity in the deposit/outer oxide layer; (b) Mn-54 activity difference between UB and LB.

Figure 6.

Mn-54 activity (a) mean value trend; (b) standard deviation trend.

Figure 6.

Mn-54 activity (a) mean value trend; (b) standard deviation trend.

Figure 8.

Mn-54 activity vs. Li concentration (a) after 3 days; (b) after 1888 days.

Figure 8.

Mn-54 activity vs. Li concentration (a) after 3 days; (b) after 1888 days.

Figure 9.

Correlations between Mn-54 activity in deposit and Li concentration (a) Pearson; (b) Spearman.

Figure 9.

Correlations between Mn-54 activity in deposit and Li concentration (a) Pearson; (b) Spearman.

Figure 10.

Mn-54 activity (a) statistical parameters; (b) difference between UB and LB.

Figure 10.

Mn-54 activity (a) statistical parameters; (b) difference between UB and LB.

Figure 11.

Mn-54 activity trend (a) mean value; (b) standard deviation.

Figure 11.

Mn-54 activity trend (a) mean value; (b) standard deviation.

Figure 13.

Mn-54 activity vs. CuCrZr corrosion rate sampling.

Figure 13.

Mn-54 activity vs. CuCrZr corrosion rate sampling.

Figure 14.

Mn-54 activity vs. SS316 sampling (a) STCR; (b) LTCR.

Figure 14.

Mn-54 activity vs. SS316 sampling (a) STCR; (b) LTCR.

Figure 15.

Partial Correlation trend for CuCrZr perturbation.

Figure 15.

Partial Correlation trend for CuCrZr perturbation.

Figure 16.

Partial Correlation trend for (a) STCR perturbation; (b) LTCR perturbation.

Figure 16.

Partial Correlation trend for (a) STCR perturbation; (b) LTCR perturbation.

Table 1.

Normalized coefficients for corrosion rate and release rate.

Table 1.

Normalized coefficients for corrosion rate and release rate.

| Time [months] |

Stainless Steel

[g/s/m2] |

Copper based alloy

[g/s/m2] |

| t ≤ 2 |

1.6E-06 |

1.33E-06 |

| t >12 |

4.6E-07 |

1.33E-06 |

Table 2.

Divertor PFU water chemistry parameter.

Table 2.

Divertor PFU water chemistry parameter.

| Chemical parameter |

Concentration |

| Lithium |

0.275 ppm |

| Boron |

0.011 ppm |

| Hydrogen |

25 ml/kgw

|

| Oxygen |

0 ppm |

Table 3.

Mn-54 reactions and decay characteristics.

Table 3.

Mn-54 reactions and decay characteristics.

| Reactions |

Father |

Decay mode |

Daughter |

Energy [keV] |

[d] |

| Mn-53(n, γ) Mn-54 |

Mn-54 |

Electronic capture |

Cr-54 |

834.855 |

312.19 |

| Mn-55(n, 2n) Mn-54 |

| Fe-54(n, p) Mn-54 |

| Fe-54(n, np)Mn-53(n, γ) Mn-54 |

Table 4.

Case Study 1 - sampling.

Table 4.

Case Study 1 - sampling.

| Lithium concentration (Uniform distribution) [ppm] |

|---|

| Lower Bound (LB) |

Upper Bound (UB) |

| 0.0 |

1.52

|

Table 5.

PDF description factors.

Table 5.

PDF description factors.

|

Kurtosis

|

-1.38

|

k<0: the PDF is platykurtic

|

| Skewness |

0.54 |

s>0: data are skewed to the righ |

Table 6.

Case Study 2 - sampling.

Table 6.

Case Study 2 - sampling.

Standardised coefficients for corrosion rates

(Uniform distribution) [g/m2/s]

|

|---|

| Coefficient |

UB |

LB |

| Copper based alloy |

1.22E-05 |

7.67E-06 |

| Stainless Steel STCR |

5E-06 |

5E-07 |

| Stainless Steel LTCR |

1E-06 |

1E-07 |

Table 7.

PDF description factors.

Table 7.

PDF description factors.

|

Kurtosis

|

-1.441

|

k<0: the PDF is platykurtic

|

| Skewness |

0.02 |

s>0: data are skewed to the righ |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).