1. Introduction

Today's cities have underground network, electric, and drainage systems. To manage these systems, many well chambers with manhole covers have been drilled in the road. Due to the displacement, loss, and damage of these manhole covers, however, vehicles and pedestrians on the road suffer severe injuries and property damage, and manhole cover accidents occur on occasion. Traditional management requires a large number of personnel to inspect manhole covers, which makes it impossible to detect problems promptly and creates significant safety risks. Intelligent manhole cover management systems have been developed in response to manhole cover management and safety issues [

1]. Intelligent manhole cover management systems effectively reduce the average maintenance time, thereby improving personnel and manhole cover safety. Intelligent manhole cover management systems are effective due to their self-awareness, active real-time alarm, real-time response, low management cost, and short average maintenance time [

2,

3,

4,

5].

The sensors currently used in intelligent manhole covers to monitor posture abnormalities are mechanical springs, MPU6050 sensors, electromagnetic sensors, tilt ball switches, and acceleration sensors [

2,

6,

7,

8], categorized as mechanical or digital IC sensors. In the complex environment of intelligent manhole covers, mechanical sensors have only two signal states, on and off. It is difficult to distinguish precisely between normal and abnormal attitude states based on the data they monitor. Digital IC sensors are used in the literature [

2,

8] to monitor the intelligent manhole cover's attitude. To achieve the goal of real-time monitoring of the intelligent manhole cover, the MCU must constantly fuse the data collected by the digital IC, resulting in high power consumption. The Intelligent manhole cover is powered by battery maintenance, and its continuous operation time is limited by the battery capacity and power consumption of the device. To make an intelligent manhole cover with real-time response capability, the MCU is used in the current study to solve data from the motion sensor to monitor the manhole cover for abnormal posture, which reduces the device endurance of the intelligent manhole cover because the MCU is always in non-low-power mode [

8]. Intelligent manhole cover national standards [

9] require that the dormant current of the Intelligent manhole cover device is less than 20 μA and that the continuous operation time is greater than three years. Current research on intelligent manhole cover continuous operation time is 3-5 years, whereas the dormant current is 30-70 μA [

8,

10], which does not meet the national standard requirement in full.

To address the abovementioned issues, we suggest an exception recognition technique that considers real-time response and minimal power consumption in this paper. By designing the hardware system of the intelligent manhole cover monitoring signal and the overall low-power management program, it is hoped to reduce the system's power consumption. The Intelligent manhole cover terminal MCU is in low-power mode when there are no abnormal events in the manhole cover. The motion sensor wakes the MCU for real-time alarm after detecting the abnormality. For the intelligent manhole cover device to meet the characteristics of real-time response, its power consumption is decreased to increase its endurance. The improved battery life of the intelligent manhole cover will reduce the amount of time and money required to replace the battery.

2. Manhole cover attitude recognition circuit

For posture monitoring, the intelligent manhole cover requires sensors that monitor abnormal posture to actively report abnormal status, thereby reducing the MCU load and differentiating between tilt and vibration. In this paper, digital IC motion sensors are used to monitor the intelligent manhole cover's posture. In contrast, the sensor's data fusion capability actively reports abnormal MCU conditions, thereby drastically reducing the MCU's resource consumption.

2.1. Scheme of Attitude Sensor

The comparative analysis led to the selection of ST's 3-axis MEMS digital output motion sensor (LIS2DH12), whose performance parameters are listed in

Table 1.

The LIS2DH12 digital output motion sensor has a wide operating voltage to accommodate more embedded system applications, an operating temperature range that meets industry standards, a minimum power consumption as low as 2 μA, a programmable range, a resolution of up to 1 mg/digit, and I2C/SPI interfaces for MCU communication. Among these are the sensor's two independent programmable interrupt interfaces, which allow the sensor to actively report two different data fusion states to the MCU, thereby facilitating the MCU's acquisition of additional sensor information. Its ultra-low power consumption reduces the device's overall endurance strain.

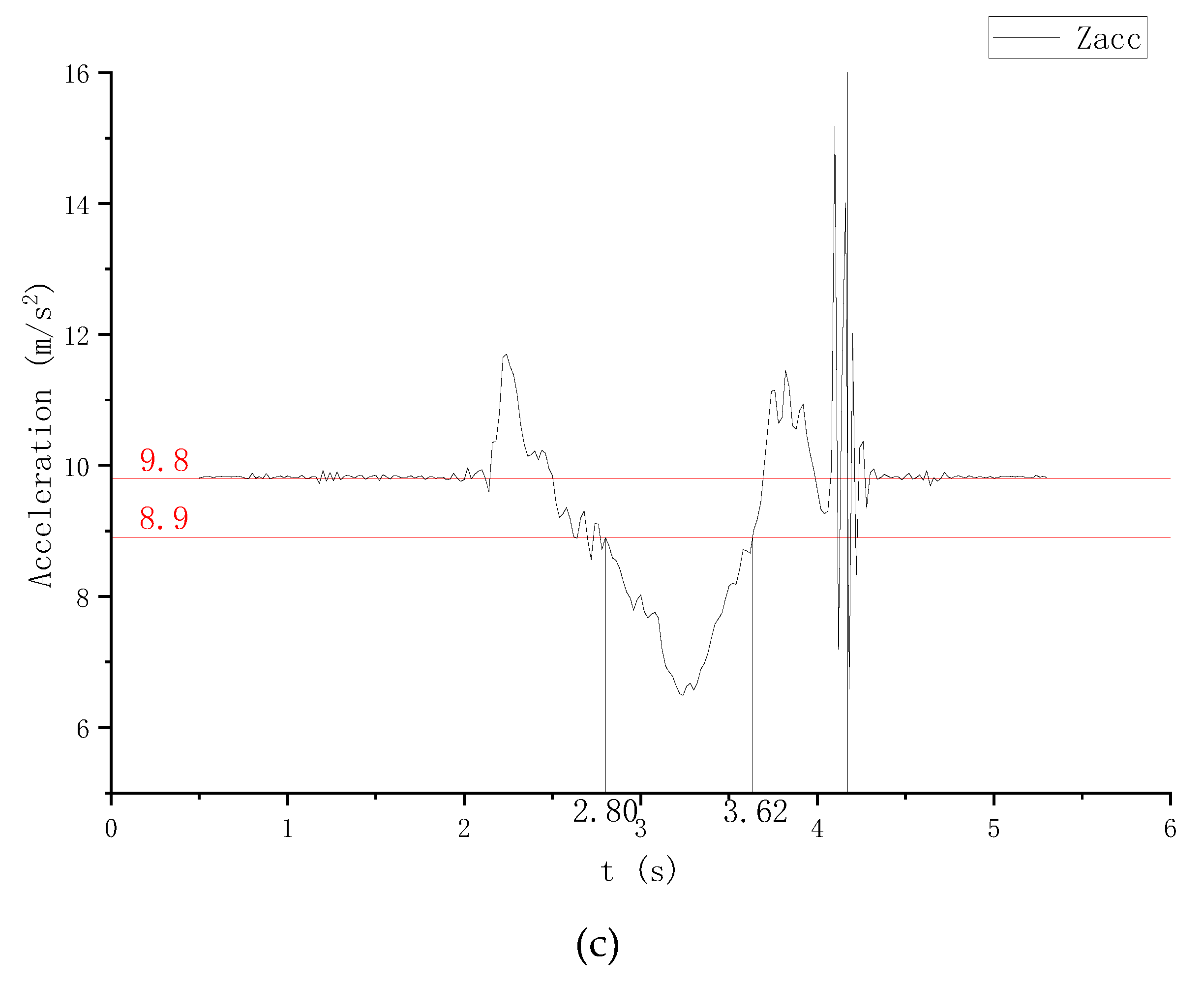

2.2. Circuit Design

Figure 1 depicts the LIS2DH12 digital output motion sensor's circuit design. The LIS2DH12's SCL and SDA pins are used as I2C communication interfaces to exchange data with MCUs, and the INT 1 and INT 2 pins are used as interrupt interfaces to report the status to MCUs. INT1 and INT2 can independently generate the event interrupt for anomaly recognition and the tilt of the smart manhole cover, respectively. Other power supplies are made under LIS2DH12's design, following official manual standards.

3. Low-power management for posture recognition

3.1. Pose data fusion analysis in dormant state

The Intelligent manhole cover must have the ability to respond in real-time to external events, so it must also be able to do so when it detects an abnormality in its posture. The MCU is typically in sleep mode under normal device status in low-power applications, which makes it difficult for intelligent manhole covers to strike a balance between real-time response and low-power operation [

2,

4,

6,

7,

8,

10,

11,

12,

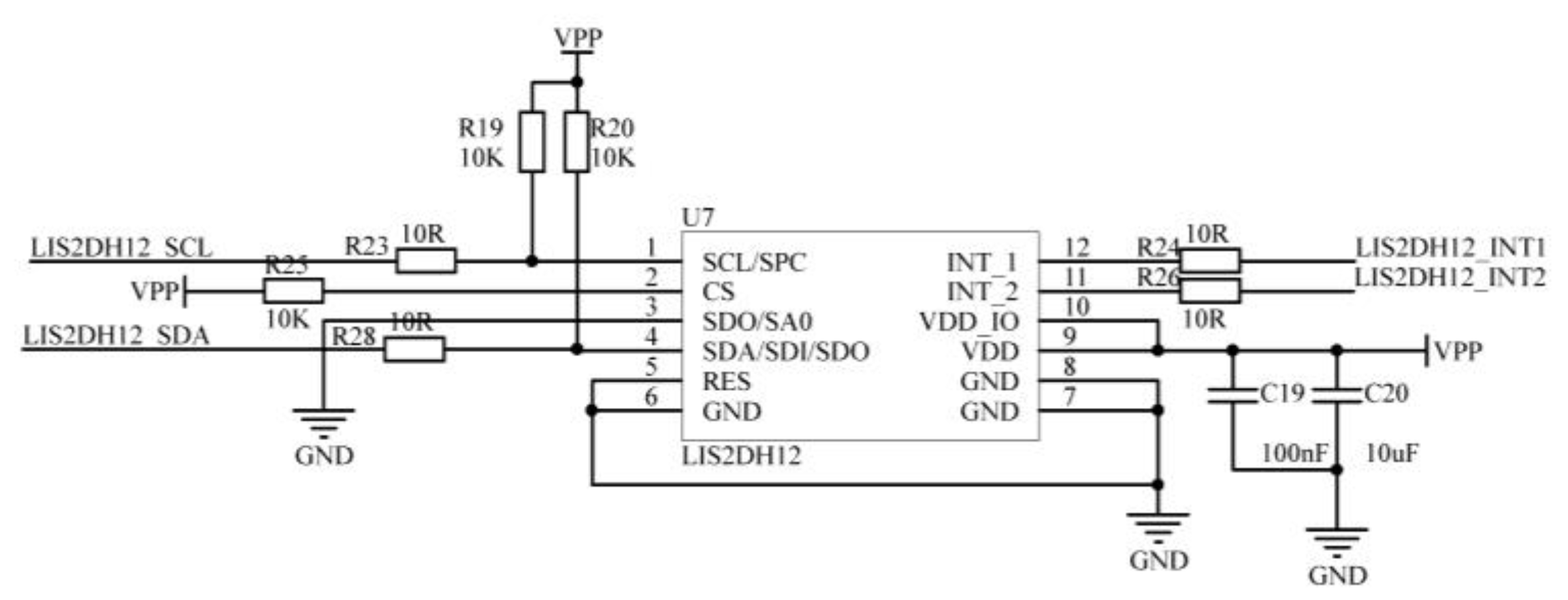

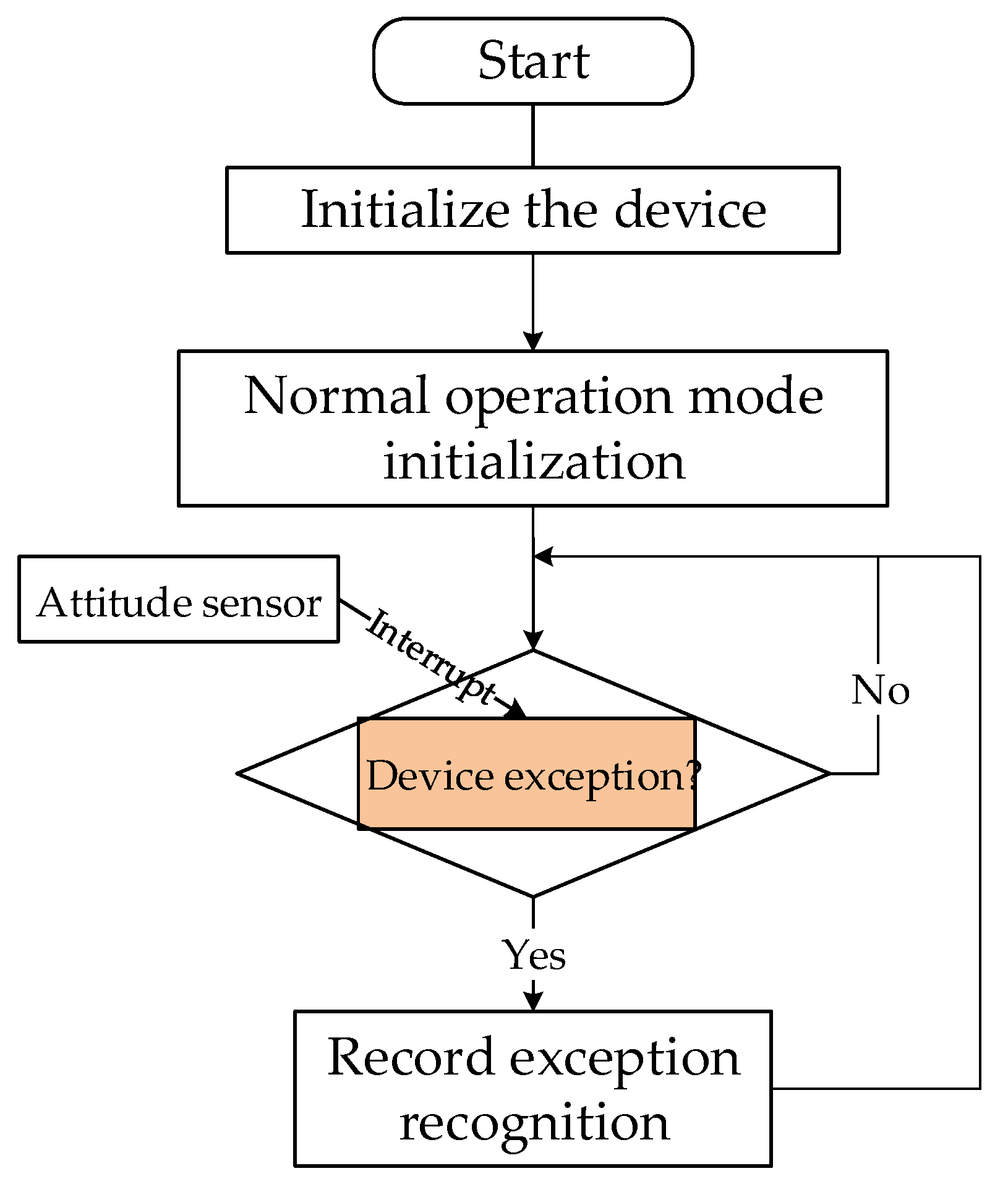

13]. As depicted in

Figure 2's flow, this paper employs the motion sensor LIS2DH12 to achieve autonomous data fusion. When the intelligent manhole cover usually operates, the MCU is in low-power mode. However, when the intelligent manhole cover tilts or vibrates abnormally, the motion sensor-LIS2DH12 interrupt pin generates an interrupt signal, waking the MCU and causing it to enter normal operation mode. The MCU then assesses the real-time Alarm. This solution considers the device's real-time response and low-power operation. The dual wake-up mechanism of timing and abnormality must be used by the intelligent manhole cover to report the Intelligent manhole cover monitoring data periodically.

3.2. Intelligent manhole cover abnormal event recognition

This paper employs the LIS2DH12 autonomous data fusion method to determine whether or not the vibration pattern of the intelligent manhole cover is abnormal in order to realize the posture sensor that actively reports posture abnormalities. For the characteristics of vibration patterns in Intelligent manhole cover application scenarios, this paper collects and analyzes acceleration data to determine the characteristics of vibration patterns of Intelligent manhole covers in different modes.

Figure 3 depicts a schematic of the acquisition environment for vibration signals.

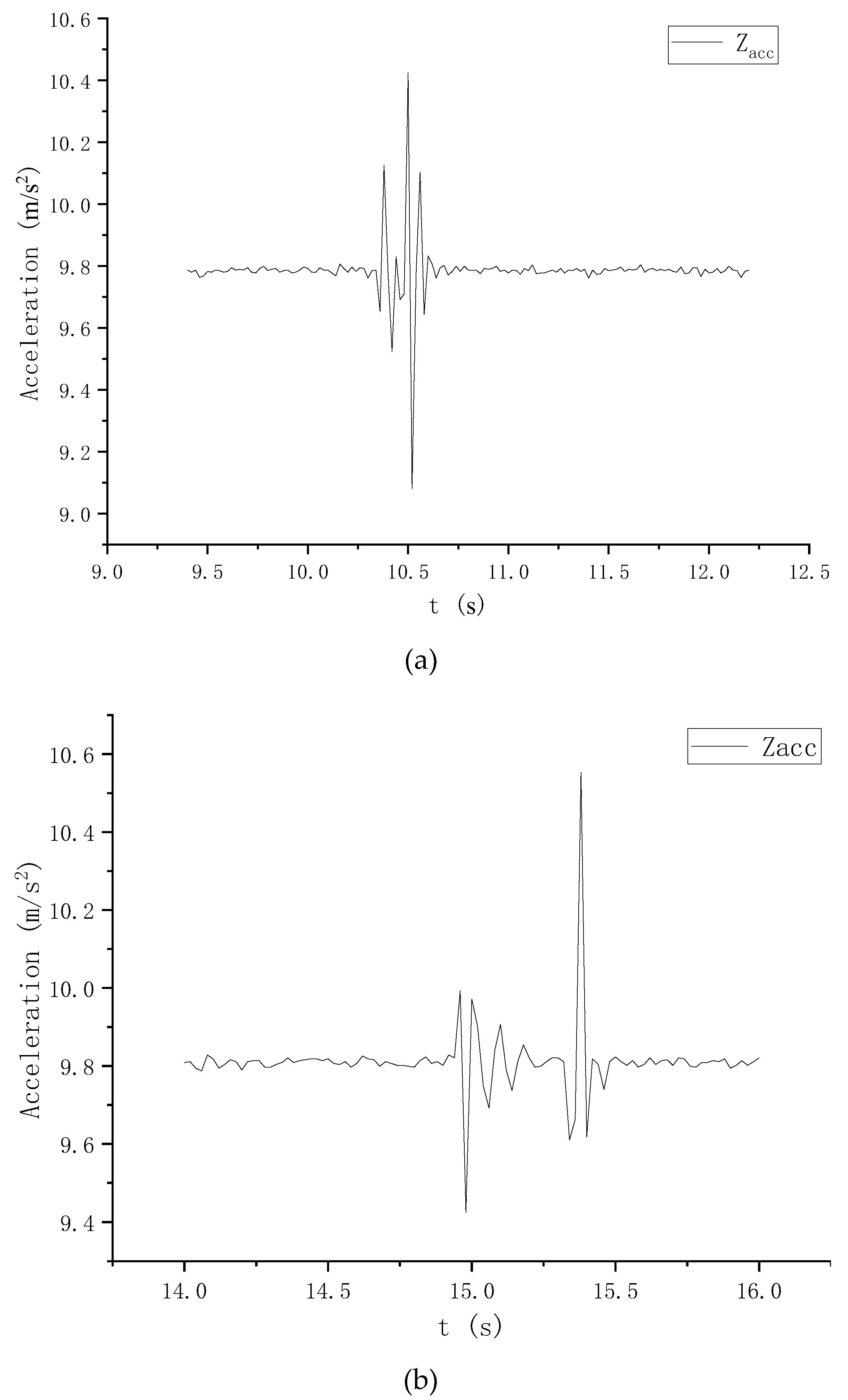

The Z-axis direction acceleration monitored by the intelligent manhole cover has greater discrimination than the X- and Y-axis directions. The Z-axis direction acceleration data is more conducive to the Intelligent manhole cover's pattern recognition of normal and abnormal conditions. The collected data can be categorized into three groups, as depicted in Figures 4. The gravitational acceleration at the location of the intelligent manhole cover can be monitored along the Z-axis when no event occurs, and the gravitational acceleration measured during the experiment is g = 9.80 m/s².

When a vehicle or pedestrian crushed and stepped on the manhole cover, the intelligent manhole cover observed a large fluctuation in Z-axis acceleration. However, the time window for a single fluctuation to deviate from gravitational acceleration was short (t = 0.04 s).

In this paper, the abnormal opening of the manhole cover is simulated by opening the manhole cover, and Figure 6 displays the monitored vibration data. In the vibration case of abnormal opening of the manhole cover, the monitored acceleration deviates from the gravitational acceleration (a = |g-8.90 m/s²| = 0.90 m/s²) with a time window of 0.82 s, unlike the events of vehicle crushing and pedestrian stepping, in which the duration of acceleration deviation is longer.

In the application scenario of Intelligent manhole cover, the difference between the normal event (vehicle crushing manhole cover, pedestrian stepping on manhole cover) and abnormal event (manhole cover being opened illegally) lies in the different time window of acceleration deviation from gravitational acceleration in Z-axis direction; therefore, segmenting the boundary where the acceleration of intelligent manhole cover deviates from the set threshold range and lasts for a certain amount of time can detect abnormal events. By analyzing monitoring data, this paper establishes Ths = 0.90 m/s² as the threshold and Duration = 0.40 s = 400 ms as the duration. When the acceleration deviation from gravitational acceleration in the Z-axis direction of the intelligent manhole cover exceeds Ths, and the duration exceeds Duration, the Intelligent manhole cover is considered illegally opened, and an abnormal event is deemed to have occurred.

Current research on vibration signal recognition focuses on feature extraction and classification algorithms, such as IMF, wavelet analysis, and convolutional neural networks[

3,

8,

14,

15,

16,

17,

18]; however, the complex processing algorithms place high demands on the processing platform. For the application scenario of Intelligent manhole cover, the recognition method proposed in this paper has very little computation and can achieve digital IC autonomous data fusion, which effectively reduces the calculation of MCU, avoids the contradiction between the need for MCU to permanently fuse motion sensor data and the low-power requirement of the device, and reduces the power consumption of the system based on the recognition of target events.

Figure 4.

Vehicle crushing Intelligent manhole cover vibration data (a), vibration data of pedestrian stepping on manhole cover (b) and intelligent manhole cover abnormal open cover monitoring data (c).

Figure 4.

Vehicle crushing Intelligent manhole cover vibration data (a), vibration data of pedestrian stepping on manhole cover (b) and intelligent manhole cover abnormal open cover monitoring data (c).

This paper uses the hardware comparator and counter embedded in the MEMS digital output motion sensor to generate interrupt signals for abnormal events, thereby realizing the pattern recognition of autonomous data fusion of motion sensors.

The data to be processed is the Z-axis acceleration, which includes gravitational acceleration. The high-pass filter embedded in the motion sensor removes the DC component from the data, allowing the gravitational acceleration to be filtered. The Z-axis acceleration is output as 0 when no event occurs after passing the high-pass filter.

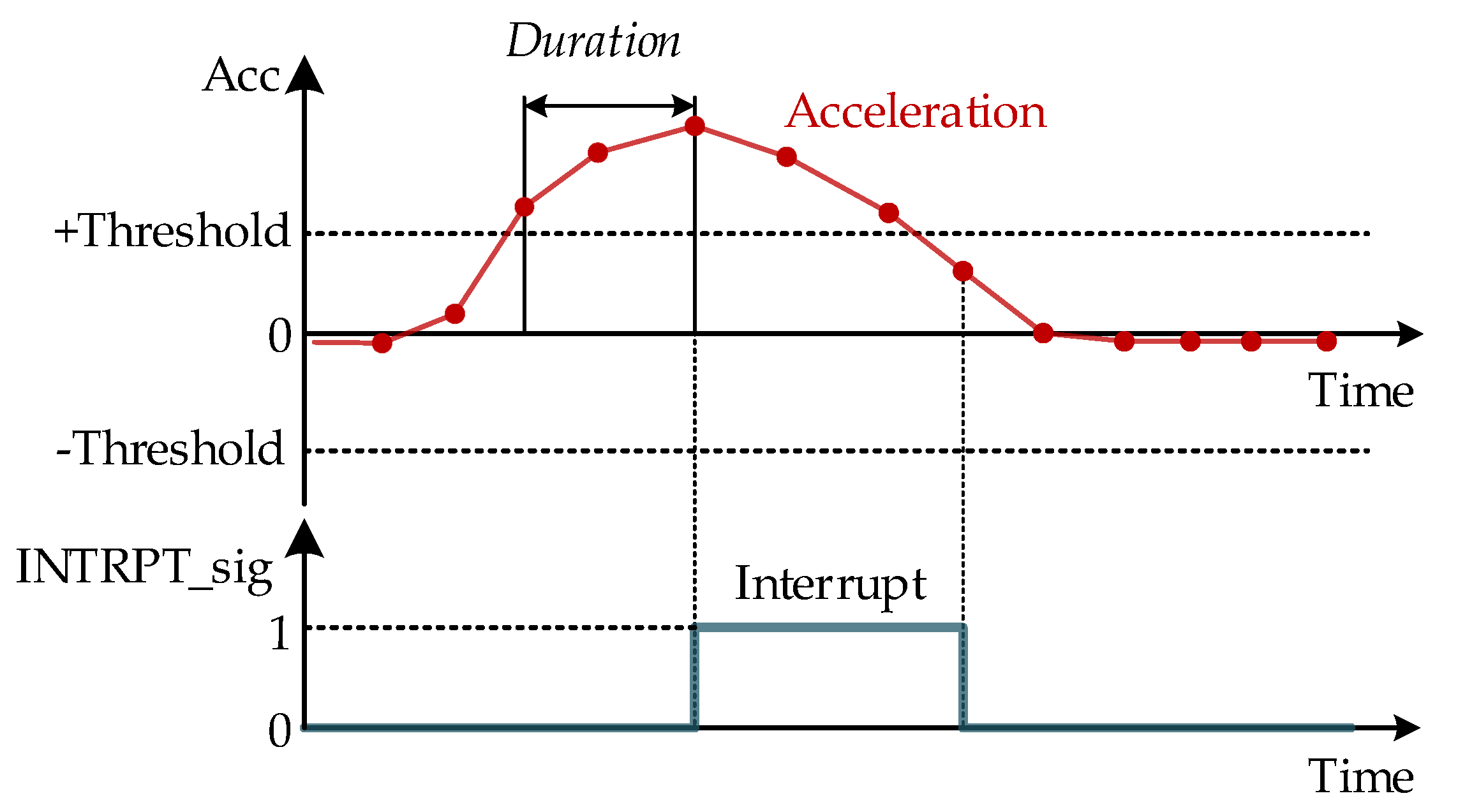

As depicted in

Figure 5, the principle of anomaly recognition through the motion sensor in this paper, the acceleration data applied to anomaly recognition is 0 after passing the high-pass filter. When vibration occurs, the monitored acceleration deviates from the initial 0 levels. Acceleration is compared to the threshold value stored in the THS reg register, and the Duration register begins counting when the absolute value exceeds the threshold value. When the number of consecutive acceleration samples above the threshold exceeds the duration setting, the motion sensor generates an interrupt, deems an abnormal event to have occurred, and wakes the MCU from sleep mode.

In the application scenario of an intelligent manhole cover, the motion sensor is utilized to achieve autonomous data fusion and reduce the MCU's computing and running time to conserve energy. This is accomplished by analyzing the difference in acceleration between normal and abnormal times. In the event of an anomaly, the motion sensor generates an interrupt to wake up the MCU, realizing the device's real-time response and balancing the Intelligent manhole cover's low power consumption and real-time response capability.

3.3. Algorithm for pose recognition in wake state

This paper proposes the motion sensor autonomous data fusion method to monitor the abnormality of the Intelligent manhole cover. Still, it fails to obtain the attitude information of the intelligent manhole cover. Therefore, this paper proposes to complete the solution of the attitude of the intelligent manhole cover under the mechanism of the Intelligent manhole cover timed wake-up to achieve the reporting of the attitude state of the intelligent manhole cover.

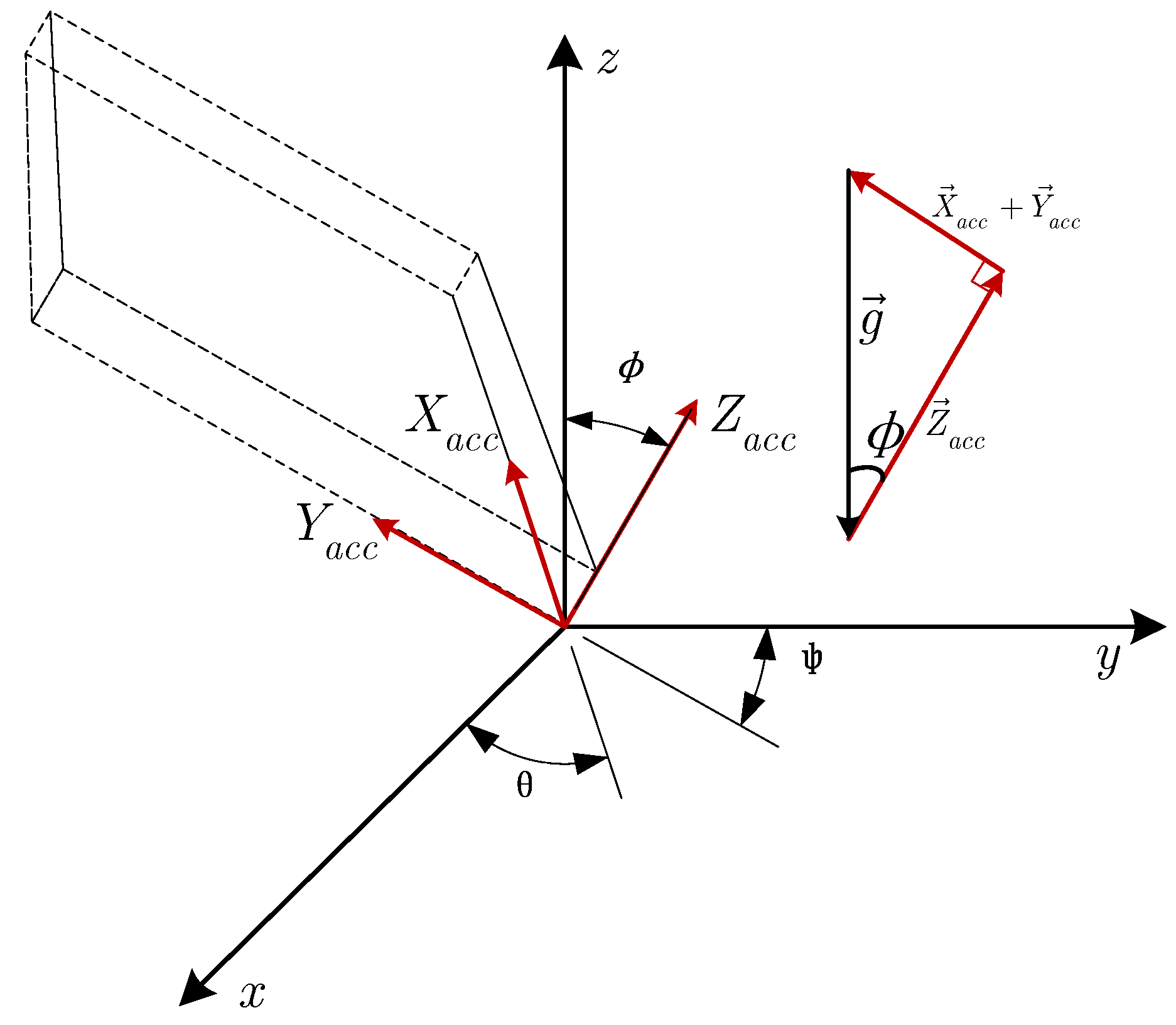

As depicted in

Figure 6, the X-Y-Z coordinate system represents the three-dimensional space in which the intelligent manhole cover is located, the XOY plane represents the horizontal plane, and the Z axis represents the opposite direction of gravitational acceleration. The rectangle in the figure represents the tilted state of the motion sensor in three-dimensional space,

is the vertical acceleration of the three axes measured by the motion sensor, and

are the angles between the measured acceleration, and the three axes of the three-dimensional space X-Y-Z, respectively. The angle between the plane where the motion sensor is located and the horizontal plane of the three-dimensional space XOY is the tilt angle of the intelligent manhole cover

, which can be obtained by calculating the angle normal to the two planes, so the angle

between the Z axis and

can be calculated.

The three axes'

combined accelerations are equal to the acceleration of gravity because the intelligent manhole cover is at rest. The following calculation of the tilt angle of the smart manhole cover can be obtained thanks to the implied relationship:

.

4. Low power management of the system

4.1. System low-power implementation

This paper also adopts a low-power design on hardware other than the motion sensor, combined with the software control, aiming to achieve an overall more minor power consumption to achieve the overall low-power design of the intelligent manhole cover.

While the application scenario requires low energy consumption, the intelligent manhole cover must have the following characteristics: monitoring the environment, self-awareness, active real-time alarm, and real-time response. Texas Instruments (TI) designed MSP430FR5962 was chosen as the MCU because it has a high data processing capacity and scalability and a broader range of applications in low-power scenarios. As a result of the system's use of the motion sensor's autonomous data fusion of abnormal event recognition algorithm, which enables the motion sensor to react in real-time, the MCU can operate in LPM3.5 sleep mode while consuming only 0.30-0.45 μA of power.

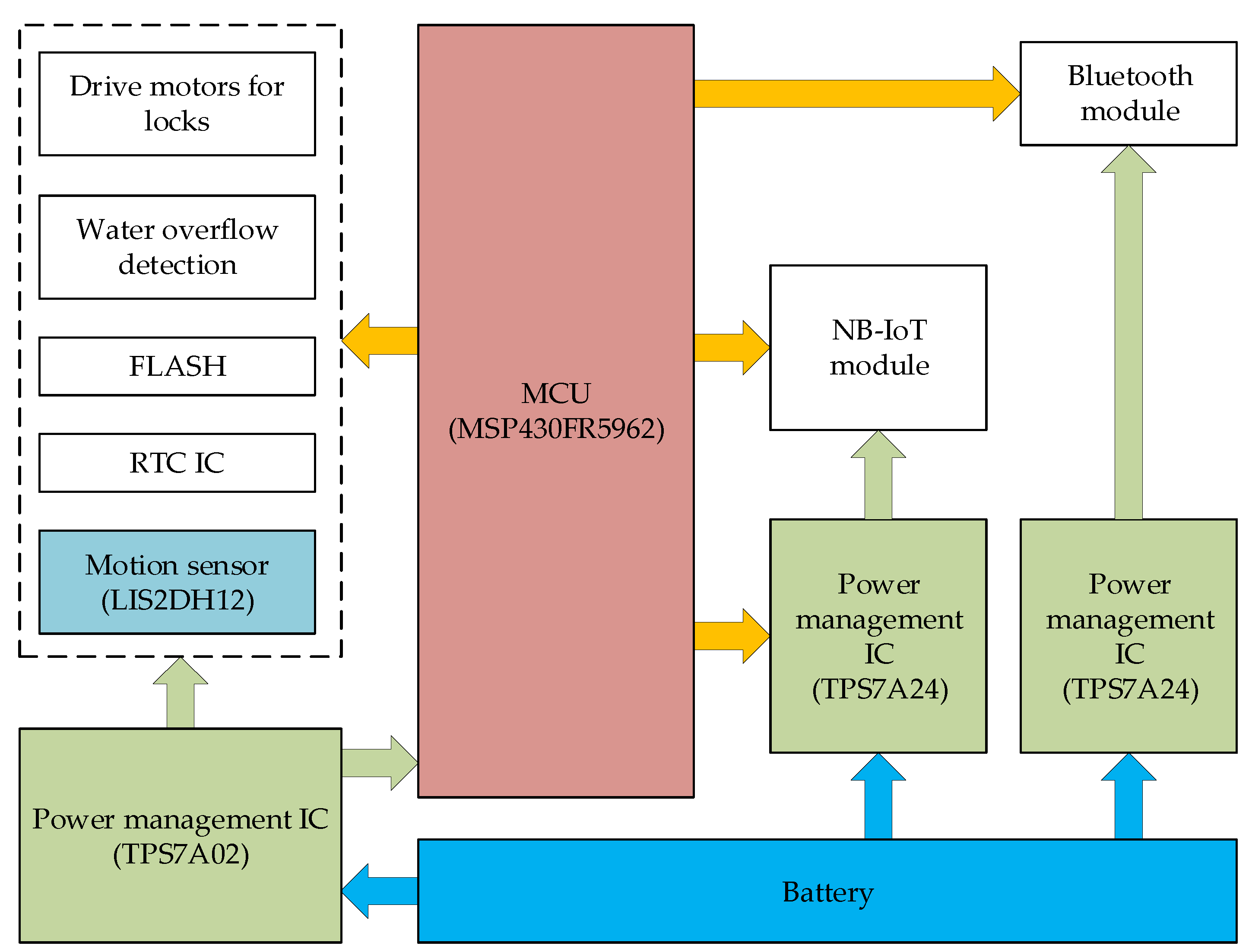

The system takes the following actions to manage its overall power consumption. The

Figure 7 depicts the overall hardware block diagram. The circuit includes a power management chip, the main control MCU, a Bluetooth communication module, an NB communication module, and digital integrated circuits (ICs) for related functions. The circuit power management is divided into three ways: one way powers the MCU and digital IC, one way powers the NB communication module and is controlled by the MCU on and off, and one way powers the Bluetooth communication module, which is also controlled by the MCU.

When a peripheral, like a Bluetooth module or an NB-IOT module, is not in use, the control power switch, hardware configuration, and MCU shut off the peripheral power. This paper chooses TPS7A02 as the MCU power supply because of its low quiescent current of 25 nA and high conversion efficiency of up to 99.6%, both of which guarantee the power supply chip's own low power consumption. The TPS7A24 peripheral power supply, managed by a microcontroller, has an off current as low as 325 nA and a conversion efficiency of up to 92.8%, ensuring the system peripheral power supply uses little power.

Control the MCU clock frequency by adjusting it under the task the MCU is performing. MCU wake-up state, internal clock set to 8 MHz main frequency, for data reporting and acquisition tasks. Only the external low-speed crystal clock (ƒ = 32768 Hz) is enabled during the MCU's sleep mode. The MCU only manages external interrupt service functions to react to abnormal alarms or timed wake-ups.

Control the GPIO status and MCU on-chip peripherals. When the associated on-chip and off-chip peripherals, like the ADC module, aren't in use, they should be turned off. Control the GPIO in sleep mode to reduce power consumption, taking into account the hardware features and the type of peripherals connected to the MCU's GPIO. In this paper, the MSP430FR5962 MCU is configured with LPM3.5 as the sleep mode; the MCU consumes only 0.30-0.45uA of power while in sleep mode, and the corresponding GPIO is configured with input mode; the IO is in a high resistance state, and the GPIO leakage current is only 50 nA.

4.2. Identification test of the system

In this paper, we evaluate the recognition of an intelligent manhole cover in its virtual environment, which includes vehicle crushing, pedestrian stepping, and abnormal opening time. As seen in

Figure 2, the intelligent manhole cover takes the initiative to report the anomaly after recognizing it, and the time to enter sleep mode again after the process of reporting data is 100 s, which reduces the test's efficiency. To increase the efficiency of the test, the test program cancels the report data process and stores the identified abnormality in the external FLASH, as depicted in

Figure 8.

The intelligent manhole cover was installed in the actual environment and removed after 100 consecutive occurrences of

Table 1's events. The abnormal records recorded in the FLASH chip were read, with the recorded results shown in

Table 2.

4.3. Actual power consumption test

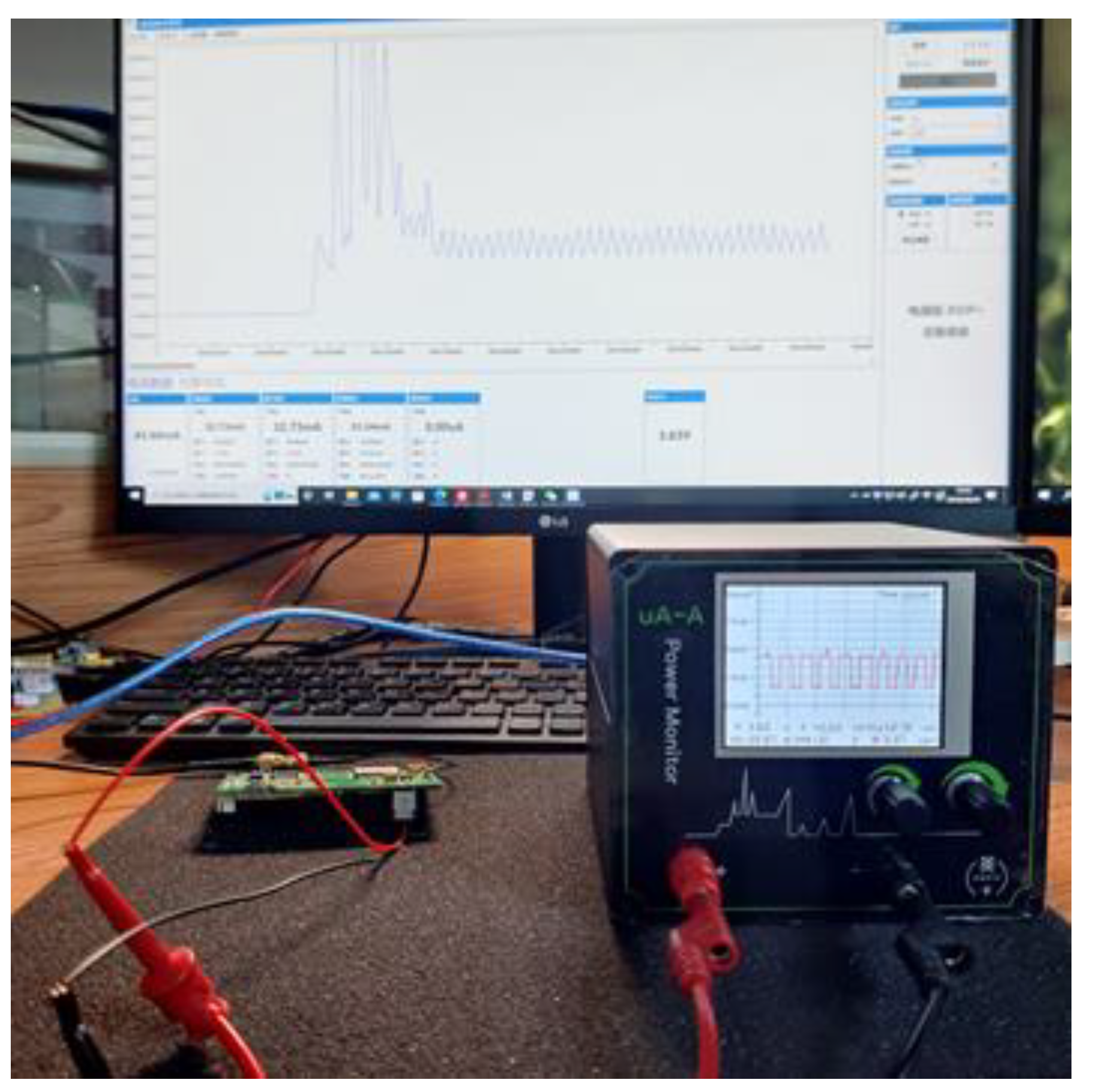

To verify the actual low power consumption of the intelligent manhole cover, as depicted in

Figure 9, the Emkia Technology Precision Low Power Analyzer is utilized to test the device actual low power consumption.

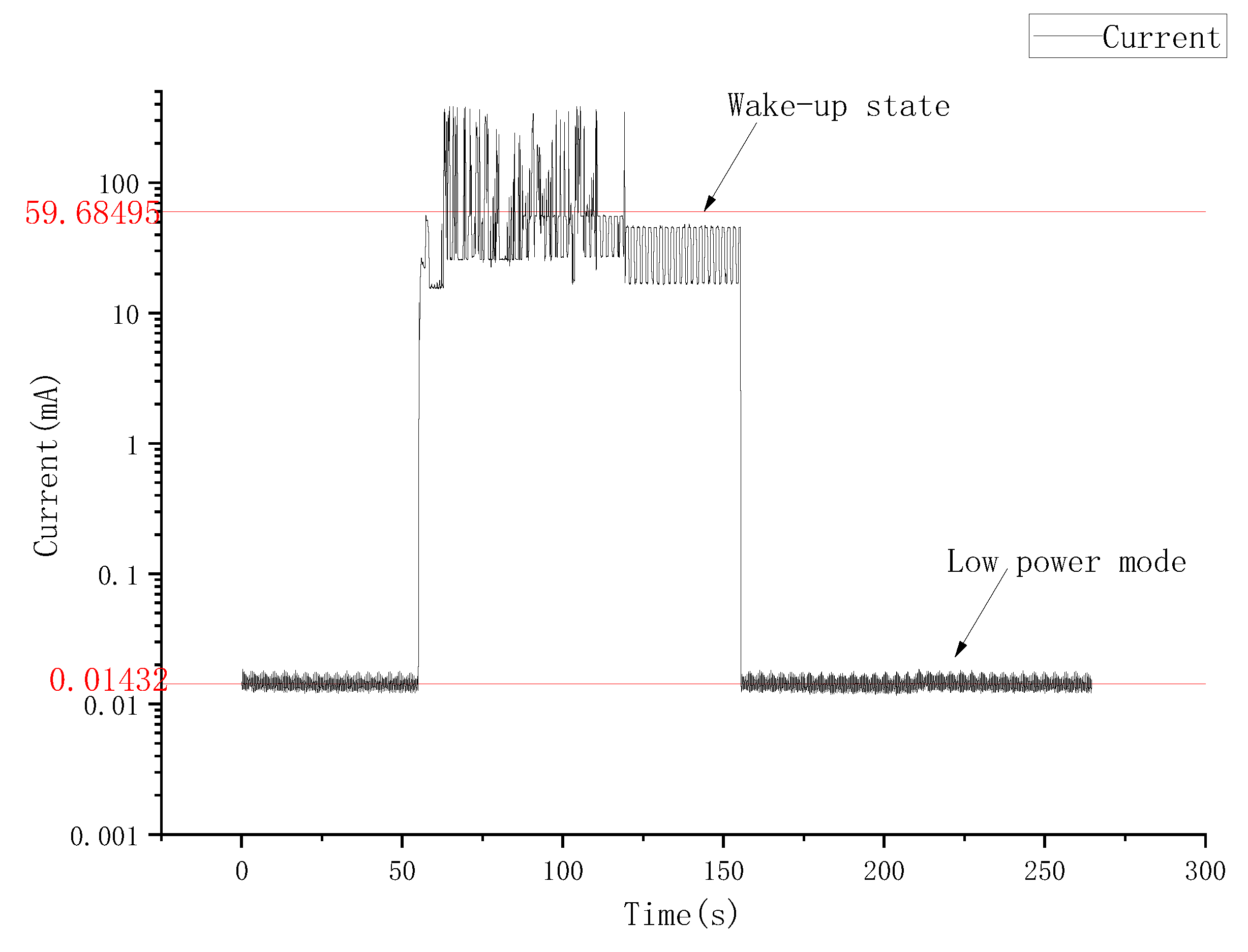

Figure 10 illustrates the actual test device's low power consumption current, and the average hibernation power consumption when the Intelligent manhole cover enters the low power consumption state is 14.32 uA.

Based on the actual tested power consumption level, the Intelligent manhole cover's power consumption in sleep mode for one year is

:

The intelligent manhole cover must upload data via NB-IoT during the wake-up state. The NB module consumes more power when registering the network and sending data [

19,

20,

21,

22], and the average power consumption is 59.68495 mA. The time required for the system to report data is 100 s. Excluding the alarm for an abnormal device, the system configures the Intelligent manhole cover to report data daily. When the intelligent manhole cover operates for one year, the amount of energy it consumes in the awake state is

.

The Intelligent manhole cover's total power consumption over a year is

, considering its power requirements during sleep and when it wakes up.

The 3.7 V, 8500 mAh, and 82% small current discharge efficiency (Data from reports by battery manufacturers) of the power supply battery for the intelligent manhole cover in this paper are its specifications. The Intelligent manhole cover can operate continuously for a period of time

based on the above analysis of the total power consumption.

Comprehensive test results show the device's sleep power consumption is 14.32 uA and can operate continuously for 9.5 (or more) years. As a result, the device's low power consumption index far exceeds the requirements of the current national standard, which is an improvement over the current study.

4.4. Experimental Discussion

By altering the smart manhole cover anomaly wake-up method with the hardware circuit design, this research reduces the smart manhole cover's power consumption while still enabling real-time response. The research's test results demonstrate that: 1. The proposed method for anomaly recognition has a guaranteed correct rate of anomaly recognition with an error rate of zero. 2. With the low-power anomaly recognition technique suggested in this study, the smart manhole cover's power usage is significantly reduced; the device's hibernation power consumption is 14.32 μA, and its continuous working time can be extended to 9.5 years.

The experimental findings of this study demonstrate that, while maintaining the high accuracy and real-time response capability of the smart manhole cover anomaly recognition, the method proposed in this study significantly lowers the level of power consumption of the device. As a result, the device can be used for longer, which lowers the smart manhole cover's maintenance workload and associated labor and material costs.

This study's method has good generalizability and is adaptable to other uses for intelligent manhole covers.

In addition to regularly uploading data, the smart manhole cover also wakes up to upload alarm information and associated detection data when something is abnormal. The power consumption derived from the experiment does not accurately reflect the real power consumption of the smart manhole cover because there is no empirical data on the frequency of abnormal alarm of the smart manhole cover. The results of the power consumption analysis of intelligent manhole covers will be more accurate if further research is conducted to gather data on the frequency distribution of abnormal alarms of intelligent manhole covers.

5. Summary

This paper suggests a method for the autonomous fusion of motion sensor data compatible with the intelligent manhole cover's low power consumption and real-time response capability. The system program design combines good universality with the most popular mainstream schemes.

Concerning computing power, the current research on vibration signal recognition necessitates complex feature extraction algorithms and even more complex classifiers. These processing algorithms place high demands on the processing platform. This paper suggests a low-power recognition method tailored to the intelligent manhole cover application scenario, and the test results indicate that the recognition rate in this scenario is high.

Based on fulfilling the abnormal recognition and real-time response functions of the intelligent manhole cover, the method based on the autonomous fusion of digital output motion sensors proposed in this paper lowers the power consumption level of the intelligent manhole cover. Under the application scenario of a Intelligent manhole cover, the system can clearly distinguish and identify normal events from abnormal events through practical testing. The low power consumption index tested far exceeds the national standard's requirements, increasing the device's durability.

Author Contributions

Conceptualization, K.W. and J.G.; methodology, K.W., J.G., J.S. and Y.J.; soft-ware, K.W. and J.G.; validation, K.W. and J.G.; formal analysis, K.W. and J.G.; investigation, K.W. J.S. and J.G.; resources, K.W. and J.G.; writing—original draft preparation, K.W. and J.G.; writing—review and editing, K.W. and J.G.; visualization, K.W. and J.G.; supervision, K.W., J.G., J.S. and Y.J.; project administration, K.W. and J.G.; funding acquisition, K.W. and J.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The study did not report any data.

Acknowledgments

The Emkia low-power test equipment that supported the experiments in this study was sponsored by Shenzhen REJOE Technology Co., Ltd. and the authors are grateful for their assistance.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, C.; Gu, S.; Guo, G.; Liu, X.; Liu, L.; Zhao, J. Alarm method of communication intelligent manhole cover based on multiple event fusion. Eurasip Journal on Wireless Communications and Networking 2021, 2021. [Google Scholar] [CrossRef]

- Jia, G.; Han, G.; Rao, H.; Shu, L. Edge Computing-Based Intelligent Manhole Cover Management System for Smart Cities. Ieee Internet of Things Journal 2018, 5, 1648–1656. [Google Scholar] [CrossRef]

- Savic, D.A.; Bicik, J.; Morley, M.S.; Duncan, A.; Kapelan, Z.; Djordjevic, S.; Keedwell, E.C. Intelligent Urban Water Infrastructure Management. Journal of the Indian Institute of Science 2013, 93, 319–336. [Google Scholar]

- Xie, Y.; Wang, H.; Liu, J.; Zhang, R.; Guo, Y. On A Working Monitoring System of Manhole Wells Based on Technology of Internet of Things. In Proceedings of the 2021 6th International Conference on Intelligent Computing and Signal Processing (ICSP), 9-11 April 2021; pp. 1452–1455. [Google Scholar]

- Luo, M.; Zhou, Z.; Li, H.; Yan, L. Research and development of the smart telemonitor system for power cable tunnel. In Proceedings of the IEEE PES T&D 2010, 19-22 April 2010; pp. 1–5. [Google Scholar]

- Ke, B.; Mao, D. Design of manhole covers missing alarm monitoring and management system. In Proceedings of the 2017 IEEE 2nd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC),, 15-17 Dec. 2017, 2017; pp. 682–686. [Google Scholar]

- Liu, Y.; Du, M.; Jing, C.; Bai, Y. Design of supervision and management system for ownerless manhole covers based on RFID. In Proceedings of the 2013 21st International Conference on Geoinformatics, 20-22 June 2013; pp. 1–4. [Google Scholar]

- Chongbiao, Z.; Mingbo, Q.; Long, C.; Qi, G.; Jiajia, S.; Jinbo, Z. Research on an Intelligent Monitoring Device for Cable Manhole Covers. In Proceedings of the 2018 2nd IEEE Advanced Information Management, Communicates, Electronic and Automation Control Conference (IMCEC), 25-27 May 2018, 2018; pp. 103–106. [Google Scholar]

- Co., F.S.I.T.D.; Co., H.X.I.T.; Co., A.W.W.T.; Co., Z.Z.E.C.E.; Co., X.J.C.G.; Co., J.H.B.M.T.; Co., S.U.C.D.a.R.I.; Co., H.G.D.S.T.; Co., G.M.E.D.a.R.I.; Co., Z.D.T.; et al. Intelligent manhole cover: GB/T 41401-2022. 2022, GB/T 41401-2022, 24.

- Xuan, L.; Hesheng, Z.; Lei, L. Research on LoRa Communication Performance in Manhole Cover Monitoring. In Proceedings of the 2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), 20-23 May 2019; pp. 1–6. [Google Scholar]

- Guo, X.; Liu, B.; Wang, L. Design and Implementation of Intelligent Manhole Cover Monitoring System Based on NB-IoT. In Proceedings of the 2019 International Conference on Robots & Intelligent System (ICRIS), 15-16 June 2019; pp. 207–210. [Google Scholar]

- Guan, Y.; Hou, Q. Design of Intelligent Well Cover Monitoring System Based on Lora. In Proceedings of the 2021 5th International Conference on Communication and Information Systems (ICCIS), 15-17 Oct. 2021; pp. 119–123. [Google Scholar]

- Tang, N.; Mu, X.; Li, L.; Ce, L.; Jiang, X. Manhole detection and location for urban pavement. In Proceedings of the Proceedings of the 2003 IEEE International Conference on Intelligent Transportation Systems, 12-15 Oct. 2003; vol.1552, pp. 1552–1555. [Google Scholar]

- Jayasuriya, M.; Ranasinghe, R.; Dissanayake, G. Active Perception for Outdoor Localisation with an Omnidirectional Camera. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), 24 Oct.-24 Jan. 2021, 2020; pp. 4567–4574. [Google Scholar]

- Sultani, W.; Mokhtari, S.; Yun, H. Automatic Pavement Object Detection Using Superpixel Segmentation Combined With Conditional Random Field. IEEE Transactions on Intelligent Transportation Systems 2018, 19, 2076–2085. [Google Scholar] [CrossRef]

- Wei, Z.; Yang, M.; Wang, L.; Ma, H.; Chen, X.; Zhong, R. Customized Mobile LiDAR System for Manhole Cover Detection and Identification. Sensors 2019, 19. [Google Scholar] [CrossRef] [PubMed]

- Chung, K.L.; Cheng, Y.Y. Effective Source-Aware Domain Enhancement and Adaptation for CNN-Based Object Segmentation. IEEE Access 2020, 8, 149931–149939. [Google Scholar] [CrossRef]

- Chhabra, R.; Krishna, C.R.; Verma, S. A survey on state-of-the-art road surface monitoring techniques for intelligent transportation systems. International Journal of Sensor Networks 2021, 37, 81–99. [Google Scholar] [CrossRef]

- Jeong, S.; Chappell, W.J. Adaptive composite antennas for a city-wide sensor network. Iet Microwaves Antennas & Propagation 2010, 4, 1916–1926. [Google Scholar] [CrossRef]

- Jeong, S.; Chappell, W.J. A City-Wide Smart Wireless Sewer Sensor Network Using Parasitic Slot Array Antennas. Ieee Antennas and Wireless Propagation Letters 2010, 9, 760–763. [Google Scholar] [CrossRef]

- Seongheon, J.; Chin-Lung, Y.; Courter, J.R.; Seung-il, K.; Pipes, R.B.; Chappell, W.J. Multilayer composite for below ground embedded sensor networking. In Proceedings of the 2008 IEEE Antennas and Propagation Society International Symposium, 5-11 July 2008; pp. 1–4. [Google Scholar]

- Mastarone, J.F.; Chappell, W.J. Urban sensor networking using thick slots in manhole covers. In Proceedings of the 2006 IEEE Antennas and Propagation Society International Symposium, 9-14 July 2006; pp. 779–782. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).