1. Introduction

Since 2015, the Circular Economy concept has dynamically entered the conversation and has been introduced in legislative form by the European Commission [

1]. Among other sectors of economic activities, the Circular Economy action plan aims to restructure the waste management industry by simultaneously aiming to prevent the waste generation in the first place and to prolong the utilization of each material in the value chains before final disposal. At the same time, biomass resources include several different subcategories of organic material, from the typical woody biomass to food waste and liquid biowaste. In most cases, the locally developed valorization scenarios are entangled with the locally available biomass. An interesting parameter is that biowaste resources can be converted – except from electricity and heat – into biofuels and valuable bioproducts [

2]. The crucial importance of integrating food waste (and generally biowaste) management solutions into a “Circular Economy Concept” has been denoted by Loizidou et al., 2019 due to the significant and readily available quantities. The authors presented several case studies where amongst others biofuels and especially bioethanol has been developed by treating and valorizing food waste [

3]. Another interesting point that has been presented in the recent literature is that in the framework of Circular Economy, the valorization of food waste can also target the recovery of nutrients [

4]. In addition, the added benefit of using biomaterials downstream in the value chain is the aspect of carbon neutrality that may assist the effort for an overall reduction of the carbon footprint [

5]. A critical parameter to be considered is that biomass cannot be considered carbon neutral per se, since advanced cultivation and transportation activities can be very impactful. But the utilization of food waste, as an end-use material with no further value, can be considered to have a positive effect on the overall carbon balance particularly when considering landfill as the alternative scenario [

6].

Biowaste valorization strategies may vary significantly due to local biowaste characteristics and availability. The issue gets exacerbated for the case of islands with, arguably, finite quantities of biowaste feedstock. In most cases the necessary volume that could justify big investments - and take advantage of the economy of scale - is not there. Thus, the case of Lesvos island is particularly interesting due to the significant sizes of the olive mills and the dairy industries (comparatively to the size of the island). The year-round population has been measured to be slightly higher than 100.000 inhabitants, a number that includes both local citizens and tourists. Two different sources have assessed the tree plantation areas of the island to be between 37 - 47 thousand hectares, with olive trees occupying almost the totality of these areas [

7]. Thus, agro waste (primarily pruning) can be a significant source of biomass on the island. At national level, a recent study showcased a calculative method for assessing the pruning available potential from agricultural biomass and it could be interesting to investigate the applicability of the approach in Lesvos island, where several tree plantation areas are not easily accessible [

8]. Overall, at the level of the European Union, agricultural practices emit approximately 10% of the overall GHG emissions [

9]. In respect to the municipal waste, the metropolitan area of Mytilene (capital of Lesvos) has been measured to produce a little bit less than 20.000 tons of solid waste per year [

10], and the whole island is projected to annually produce approximately 40.000 tons of MSW by 2030 according to the Regional Authority of North Aegean [

7]. Biowastes account for approximately 50% of the total MSW. The same source estimated the annual dehydrated sludge production (20-25% solids) at around 1.800 tons. At the same time, Lesvos island has been reported to have 18 dairy processing facilities and more than 50 olive mills, both of which have wastewater effluents at the level of hundreds of tons per day. A recent study assessed that the main available biowaste for the island of Lesvos (except the clear-cut case of olive tree pruning) would be olive oil pomace (at around 19 thousand cubic meters), whey from dairy processing facilities and garden waste, which are assessed to be around 9.000 tons/ year [

11].

The main valorization strategy for food waste has primarily been a biological process, i.e. anaerobic digestion (AD), which is an economically viable pathway toward bioenergy production [

12]. Negri et al. (2020) presented an interesting argument that AD of food waste could be a more environmentally sustainable alternative to energy crops and mentioned the potential performance improvements that can be achieved by means of pretreatment [

13]. Angelidaki et al. (2018) studied biogas production from sludge and suggested the option of enzymatic treatment for the case of sludge as well. In addition, the authors went slightly further downstream and discussed the potential of biogas upgrade into fuels of higher purity and quality like biomethane [

14]. A recent interesting development has been the co-treatment in AD of food waste and sludge with the nuance of microwave pretreatment [

15]. Similarly, co-AD with food waste and wastewater from horticultural activities was presented by Zhang et al. (2020) [

16]. Apart from blending different types of biowaste, biochar has been utilized for enhancing biogas production [

17]. This approach appears to be promising for using novel carbonaceous products in co-digestion processes. Investigating the pathway of biochar production, it is straightforward that it can be produced from pyrolysis of carbon-rich feedstock of relatively low-moisture [

18]. Thus, material with high water content, like the available biowaste in Lesvos Island cannot be treated conventionally with thermal technologies, except if excessive amounts of energy are utilized for drying the material. Hydrothermal Carbonization (HTC) is a process that utilizes high pressures and intermediate temperatures for converting (primarily) wet biomass into hydrochar and other by-products like phenols and syngas [

19]. The process works well with food waste and can also be used for the co-treatment of food waste with other fuels [

20,

21]. An interesting recent development has been the ability to co-treat mixtures of municipal solid biowaste and agricultural waste by means of hydrothermal carbonization [

22].

This study takes into consideration the recently published academic literature and has identified an abundance of high-level studies on specific technical applications but very few (practically nonexistent) studies that approach the issue of biowaste holistically by taking into account different applied waste management chains for co-treated biowaste. The design of a complete guide for biowaste management and utilization requires the inclusion of practical methods for treating organic food waste which, at the moment, are aerobic (composting) and anaerobic biodegradation (AD). In addition, most studies focus only on one parameter (usually biogas or hydrochar production) and have not investigated complex liquid mediums for HTC. On the contrary, this present study utilizes OMWW not only as a feedstock but also as a hydrothermal medium for co-treating food waste. The raw material that is investigated is organic fraction of MSW, which occupies a large fraction of the annual biowaste production on the island.

2. Materials and Methods

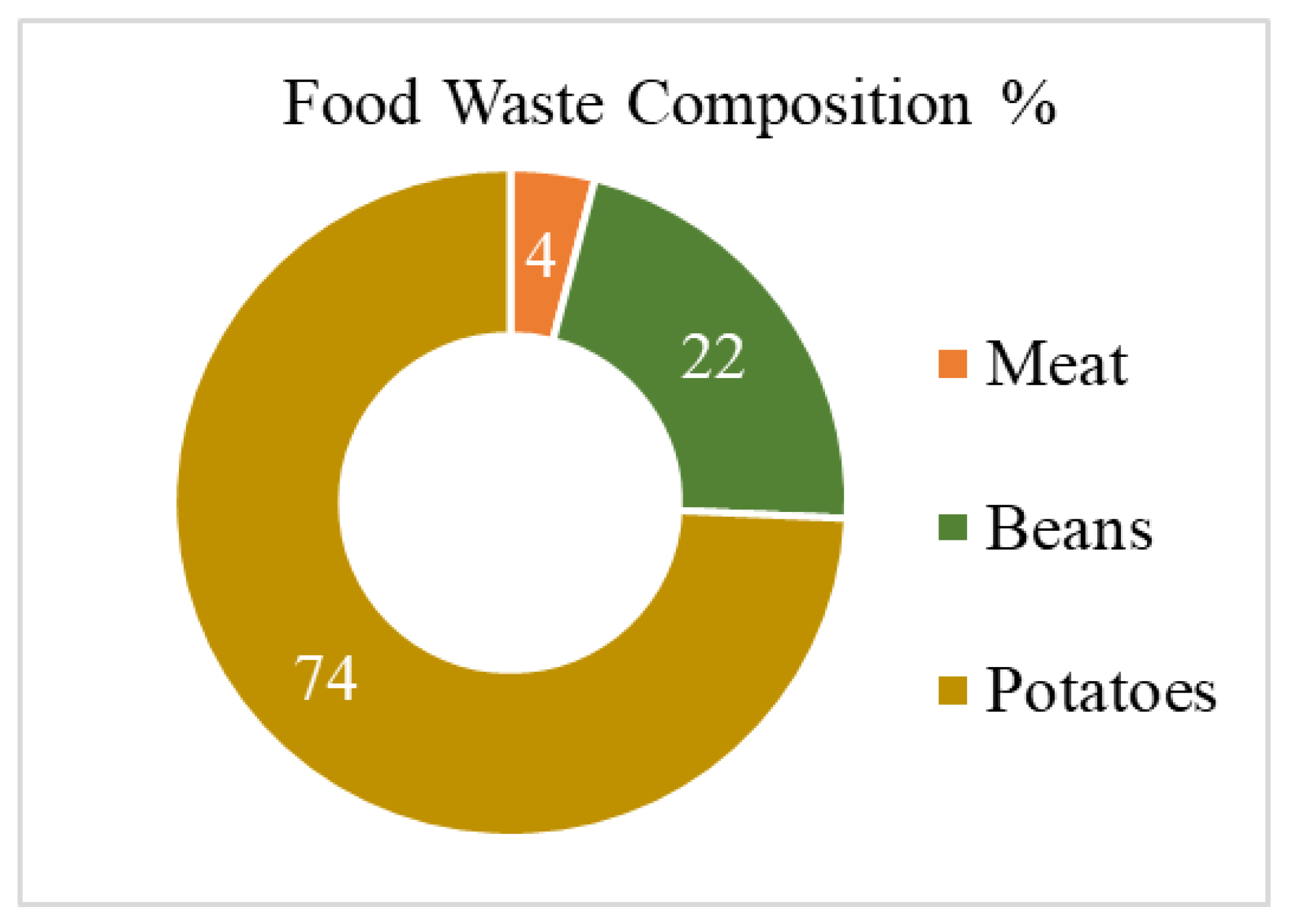

This study presents a combined pathway in biowaste valorization with a focus on anaerobic digestion of mixed biowaste and on the hydrothermal carbonization of the AD solid residues. As mentioned in the section “Introduction”, food waste was used as the main component in the study. The raw material as shown in

Figure 1, consisted of cooked potatoes (74%), beans (22%) and meat (4%).

2.1. Waste Valorization Technologies

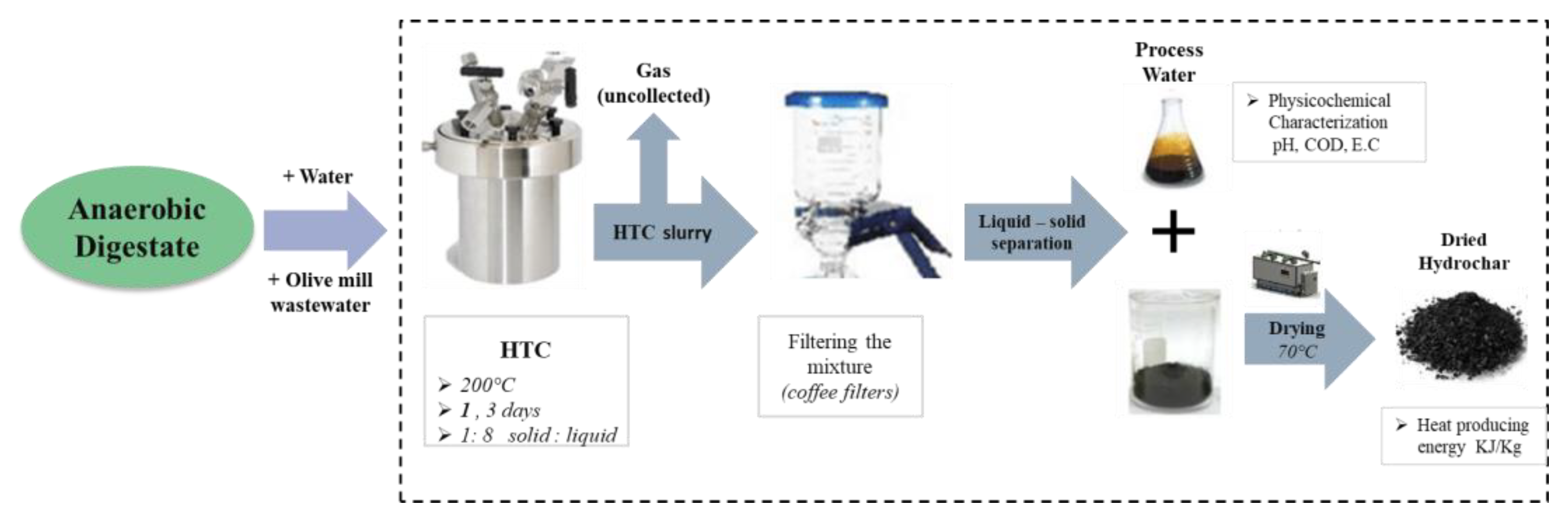

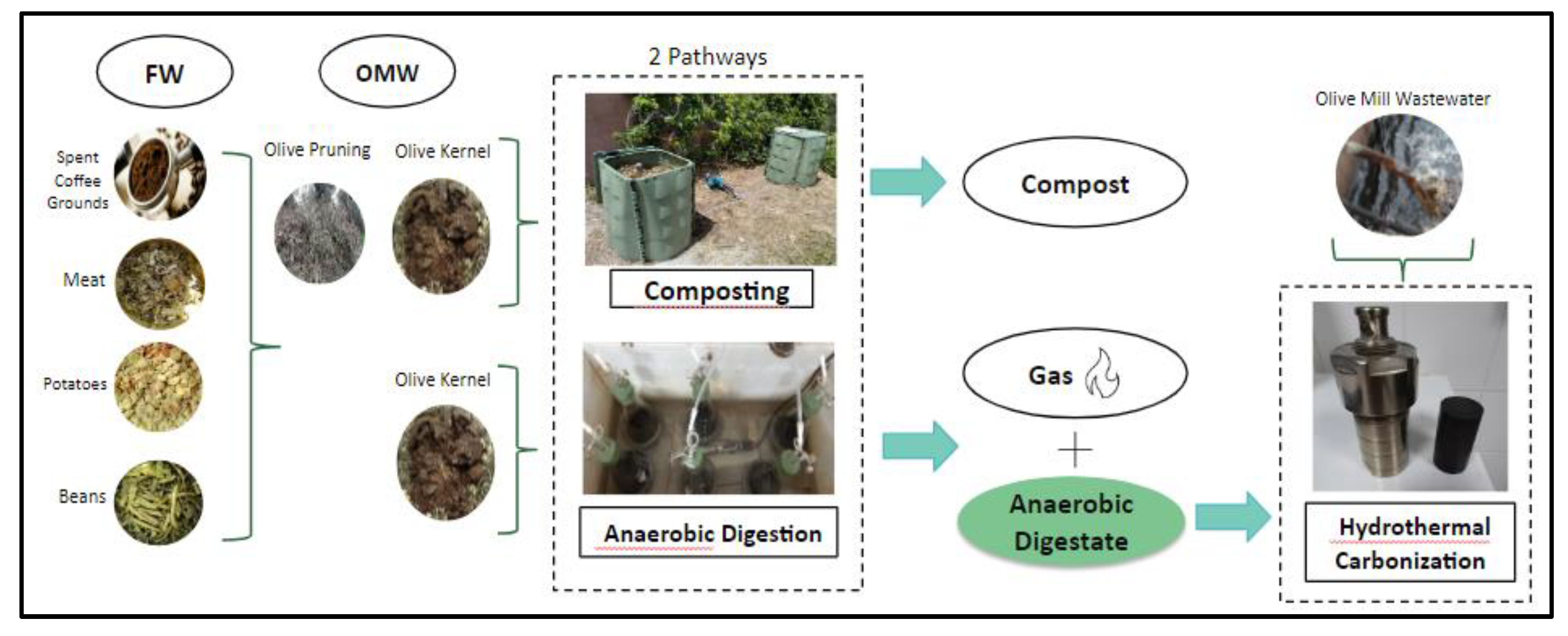

The overall waste management scheme is presented in

Figure 2 where all the materials, processes and end products are described. The idea as presented in this study, is to use, treat and eventually valorize several - if possible all types of biomass available on the island - in order to optimally design an holistic action plan with increased performance. Therefore, we are analyzing two main pathways - aerobic and anaerobic - that can result in different end products or by-products respectively.

Composting has been applied - as the aerobic pathway - but is not at the focus of this present study and thus, the experimental process is briefly presented here. With the method of aerobic biodegradation (i.e., composting), the recovery of nutrients is achieved through the mineralization of organic substances in biowaste. The maturation of the final product was completed in 120 days in a closed composter (home composting bin) with an active ventilation system that supplied the compost at regular intervals. Both temperature and oxygen content was monitored daily, while pH and humidity on a weekly basis. The composting process was applied in two modified composting bins with different composition in the treated materials - the one with food waste and the second food waste mixed with olive mill pomace - (14% of the total mass). In both cases, food waste was mixed with prunings to provide optimal ventilation conditions, and also enhance the structure of the final compost.

Anaerobic digestion (pathway) is proposed as a diverse option that both produces biogas (end product) as well as digestate (byproduct) in the overall scheme. An experimental setup was organized in the facilities of the Waste Management Laboratory of the Department of Environment (University of the Aegean), where a set of six 2L bottles was placed in a heating bath of 40 °C for supporting dry anaerobic digestion. The water content was removed by compression and the bottles were filled with nitrogen in order to create an inert environment. The composition of the three different samples is presented in

Table 1. As seen in the Table, the tested samples were a) sludge, b) sludge + food waste, c) sludge + food waste + spent coffee grounds (SCG). Gas sampling bags were air-tightly connected to the bottles and the gas was measured directly from the sampling bags by means of a GEOTECH BIOGAS 5000 portable biogas analyzer.

Hydrothermal Carbonization. The digestate from the above samples was subsequently treated in a hydrothermal autoclave. The external reactor is designed from SS304L stainless steel and is air tightly closed with a screw-seal. The inner reactor vessel is 25 ml, is constructed from PPL and has maximum safe operating temperature of 280 °C and maximum operating pressure of 3 MPa . The inert PPL chamber can withstand acidic corrosion and is leakproof. In the present study the digestate residues from the tested samples (TAble 1) were treated along with liquid mediums, which were either water or olive mill wastewater (OMWW). The composition of the feedstock introduced in the HTC reactor vessel was:

- ➢

1 g of digestate (all the available samples)

- ➢

8 ml H2O or 8 ml olive mill wastewater

The experimental tests were performed in the oven at 200 °C and elevated pressure that reached 2.2 MPa. The standard temperature of the method ranges between 170°C - 200 °C. The duration of each experiment was set to 1 or 3 days. The profile of all the different combinations of samples that were used in the hydrothermal reactor is presented in

Table 2. As follows, the definition of samples is explained in

Table 2 with an expanded description. The first part of the sample name is the sample ID from anaerobic digestion, i.e., 0, 101 and 801. The second part corresponds to the liquid medium, with N representing water and K representing olive mill wastewater. Finally, the last number of the ID corresponds to the days of the hydrothermal carbonization experiment, with 1 corresponding to one day and 3 corresponding to three days.

As the main target object of this research, solid residue is one of the final fractions in hydrothermal carbonization. This solid product named “hydrochar” lacking moisture in carbon form could have a high heating potential as an alternative fuel resource. To investigate the ratio of dry carbon in HTC treatment, it needs a mass balance between input and output substances. The mass balance of the hydrothermal treatment is determined by the variance in weight between the initial quantity and the final quantity held in the HTC autoclave reactor. As a result, the three fractions of the treatment were isolated.

In order to estimate the mass balance, it is mandatory to calculate all samples and the testing chamber weight before. After processing in the heated oven, the sealed container is weighed and opened. Τhe gaseous fraction that has been produced after the reaction is released immediately out of the closed system. The gas fraction is measured as the weight difference before and after the treatment due to the release of gases from the container. There are also gas losses, which can be approximated through the deduction balance of final chamber weight. As for the remaining fractions into the inner PPL chamber - solid & liquid - they are included in the final sample mass. The solid mass was determined by filtering the mixture using filter paper (20μm) and then drying at 105°C. The weight difference of the filter before and after filtration is the weight of the solid fuel fraction.. The liquid fraction of the mixture is estimated indirectly after the measurement of solid and gas fractions. The pH acidity was measured at the non-filtered supernatant fluid with a PH meter. The electrical conductivity of E. C was tested with a CONSORT C932 electrochemical analyzer in an undiluted supernatant liquid sample.

To estimate the calorific value of the produced hydrochars, the solid fraction of the samples was measured in a PARR 6400 Calorimeter. The conversion of the hydrochar samples into pellets in a small-scale pelletizer was proved to be the most consistent approach for the faster and more efficient measurement of the fuel in the calorimeter. For a successful test to take a heating value measurement, at least 0.1g of material was placed in a specialized container inside the calorimeter. Then the sample heats up (pre period) and combusts in a pure oxygen environment (post-period) for the calculation of the heating value in MJ / kg of fuel.

One of the by-products of hydrothermal treatment with potential pollutants is liquid residue, which can be specified through the COD value. The determination of the chemical oxygen demand, i.e. COD, in the liquid fraction of the hydrothermal treatment products, was performed with a closed reflux colorimetric method that used a High- Range reagent due to the high aggravating power of the liquids. Specifically, 1.2 ml of High Range solution and 2.8 ml of H2SO4 were added to the vials. 2 ml of a diluted 1% v/v sample was added to each vial and placed in the COD reactor for 2 hours for heating. The measurement was then performed on a spectrophotometer with the user program 978 COD-GG-HR 1000rpm.

Figure 3.

Hydrothermal Carbonization process of AD residues.

Figure 3.

Hydrothermal Carbonization process of AD residues.

3. Results

3.1. Composting

To simulate the utilization of biowaste in the first pathway through the aerobic treatment, a mixture of materials was composed of typical food residues.

Table 3 indicates two different piles, named as (K1, K2) and two identical composting bins were filled. In the first place K1 had an initial weight of 217.1 gr with a volume of 0.3 m³. On the contrary K2 had also an initial weight of 217.03 gr with a volume of 0.3 m³ but including a part of olive kernel as a testing application to valorize agro waste. for composting (FW+ Olive kernel). The physicochemical parameters were estimated to control composting as shown in

Table 4.

3.2. Anaerobic Digestate

In the final process, the anaerobic digestate residue as the main feedstock product for hydrocarbon pathway was investigated to be recovered by a mixture of organic subproducts. The above materials consisted of food waste (composition in

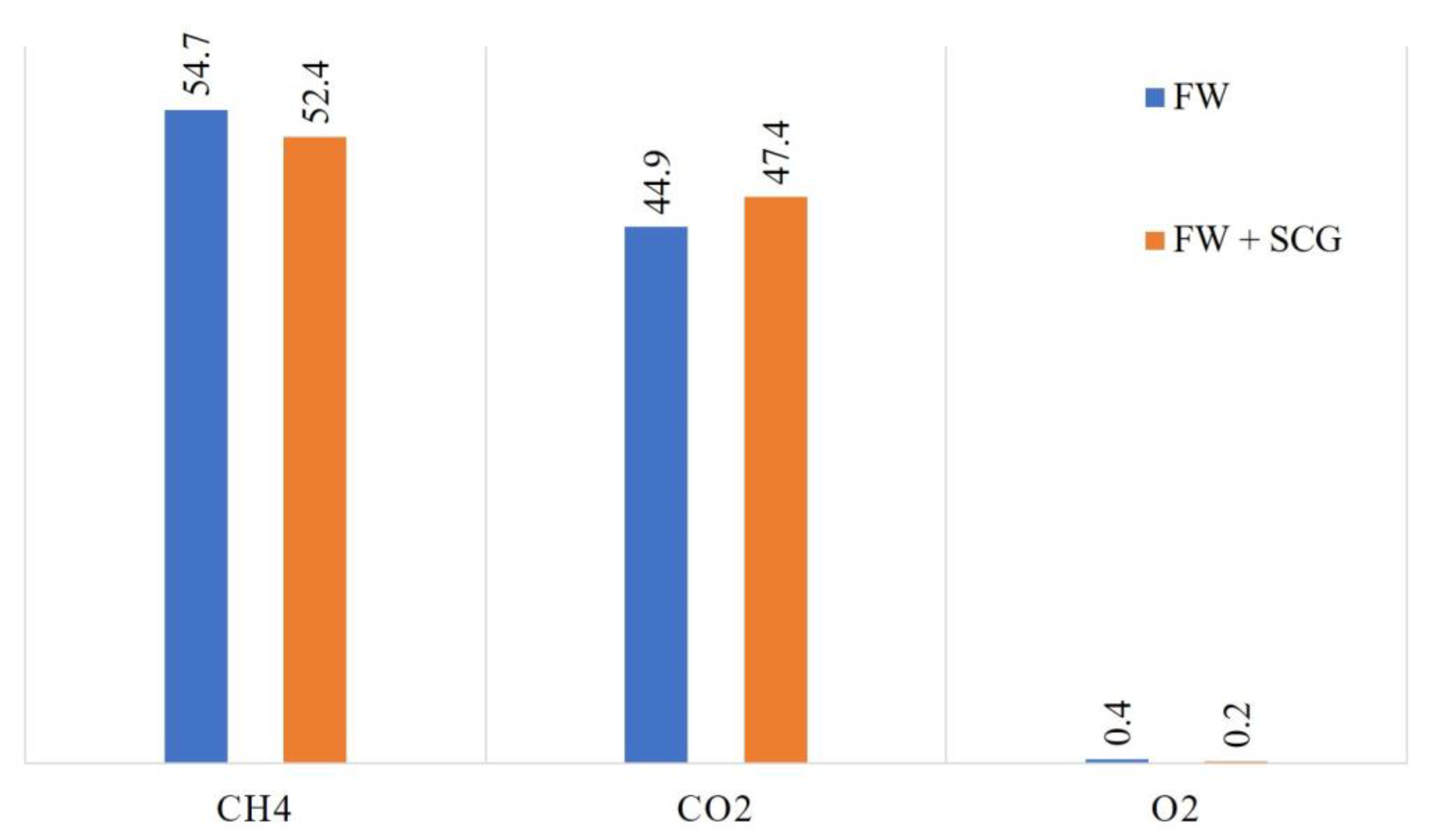

Figure 1.), olive kernels and spent coffee grounds. As presented in the section “Materials and Methods”, gas sampling bags were connected in the output of the anaerobic bottles, for the measurement of the produced biogas. The average biogas composition for the two samples is presented in

Figure 5. The solely food waste samples averaged slightly higher methane yields of 54.7% in comparison to the food waste plus spent coffee grounds samples that averaged 52.4%. The other major gas is carbon dioxide with the food waste sample having 44.9% and the other sample 47.4%. The balance gas in both cases is oxygen with values below 0.5%. The heating value of biogas is dependent on the methane composition which is low to mid- 50%. These values are not impressively high, as there are cases where the methane composition can be as high as 70%, but the values are well within the range of similar applications of approximately 40% – 60% as reported by Kapoor et al. (2020) [

23].

Figure 4.

Biogas composition analysis.

Figure 4.

Biogas composition analysis.

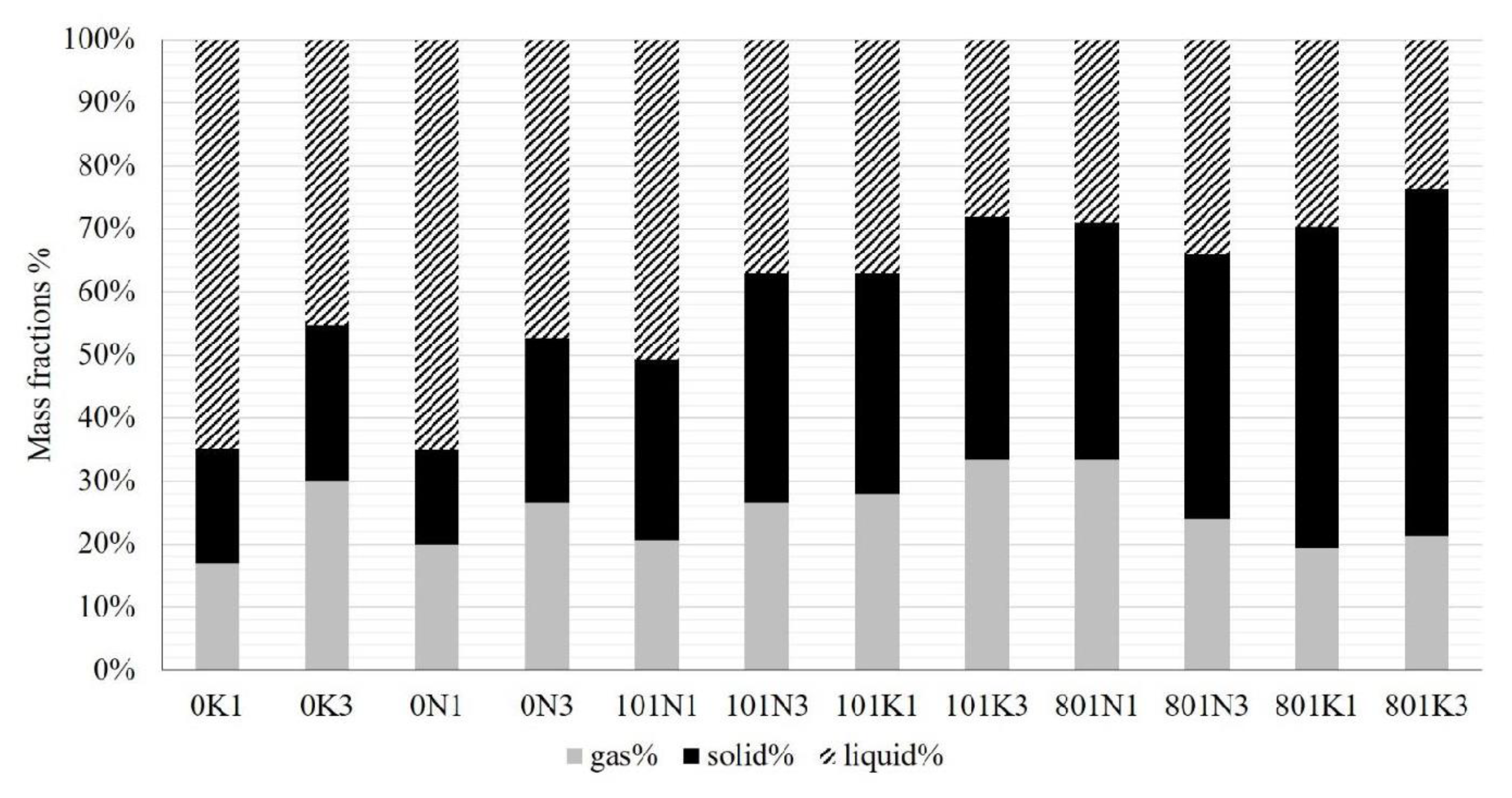

3.3. Hydrothermal Carbonisation

There were 2 different experiment recipes applied with 1 replicate for 1 day and another for 3 days of residence in the oven. In practice, the process entailed co-treating a wet solid residue with some Olive Mill Wastewater and another recipe with water. In

Figure 5, the proportions of gaseous, liquid, and solid products obtained from hydrothermal carbonization are displayed. The data reveals that when only sludge was used as the feedstock, the resulting products were mostly gaseous, accounting for more than half of the total mass in most cases. Additionally, the data shows that introducing spent coffee grounds to the feedstock led to a greater amount of solid product, specifically the hydrochar. This is an extremely interesting, but not surprising, result. As shown by Vakalis et al. (2019) spent coffee grounds have fewer volatile solids than conventional biomass (or food waste) since the coffee beans are roasted and a higher percentage of fixed carbon in the feedstock is linked to a lower proportion of volatile solids [

2].

Figure 5.

Mass fractions of HTC products.

Figure 5.

Mass fractions of HTC products.

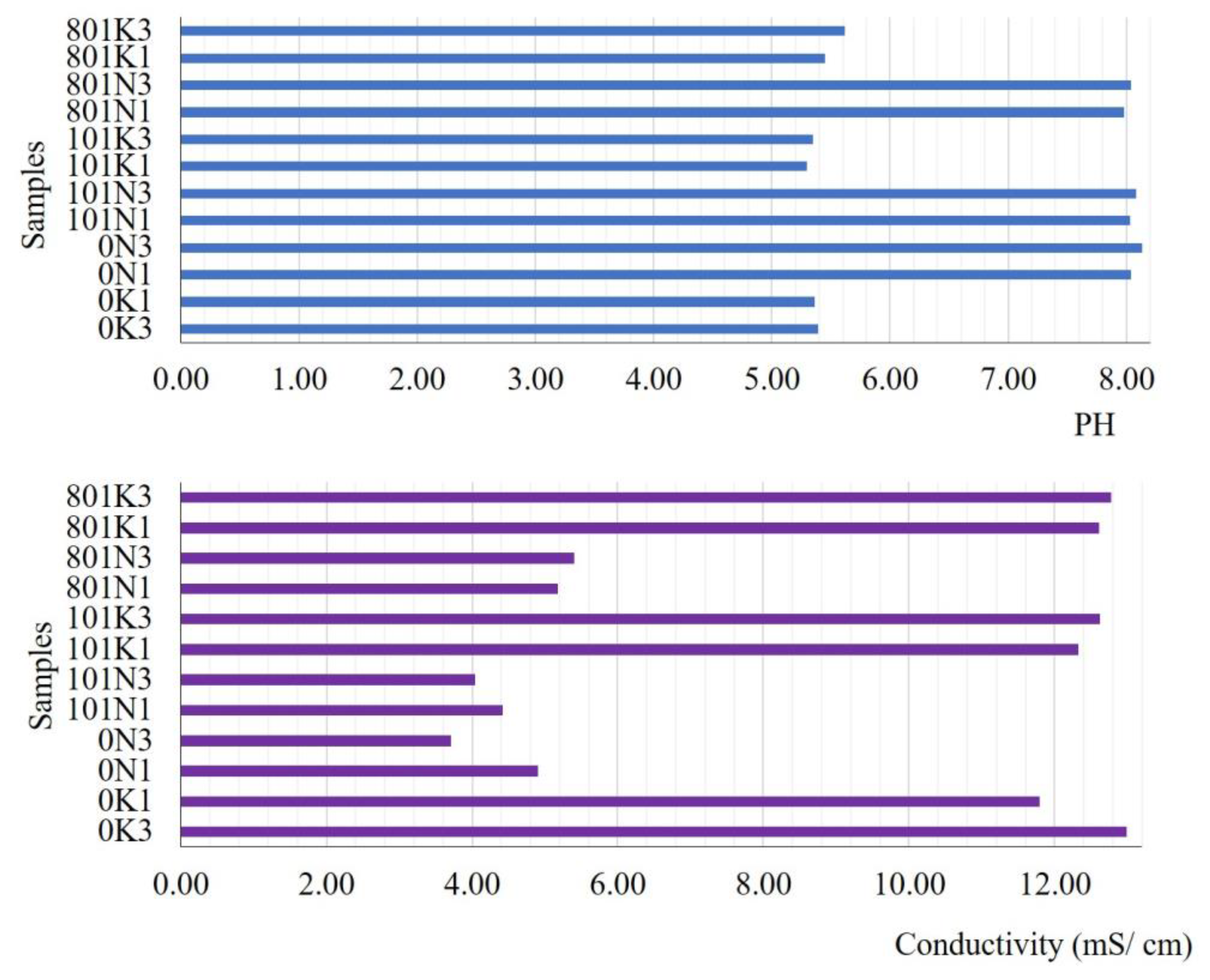

The pH and electrical conductivity of the liquid products from hydrothermal carbonization are presented in

Figure 6. The data exhibits a noticeable pattern with regards to the pH behavior of the liquid products. The samples that were treated in water medium were basic with a PH value consistently close to 8. The samples that were treated in OMWW medium were acidic with PH values close to 5.5. This significant finding can open a new cycle of future experiments including HPLC analysis, to identify the full profile of the substances of each liquid sample and affect PH.

Figure 7 presents the electrical conductivity of the liquid samples, there are two distinct groups. The samples that were treated in water have conductivities of 4 - 5 mS/ cm, contrary to the samples that were treated in OMWW that have conductivities of around 12 mS/ cm.

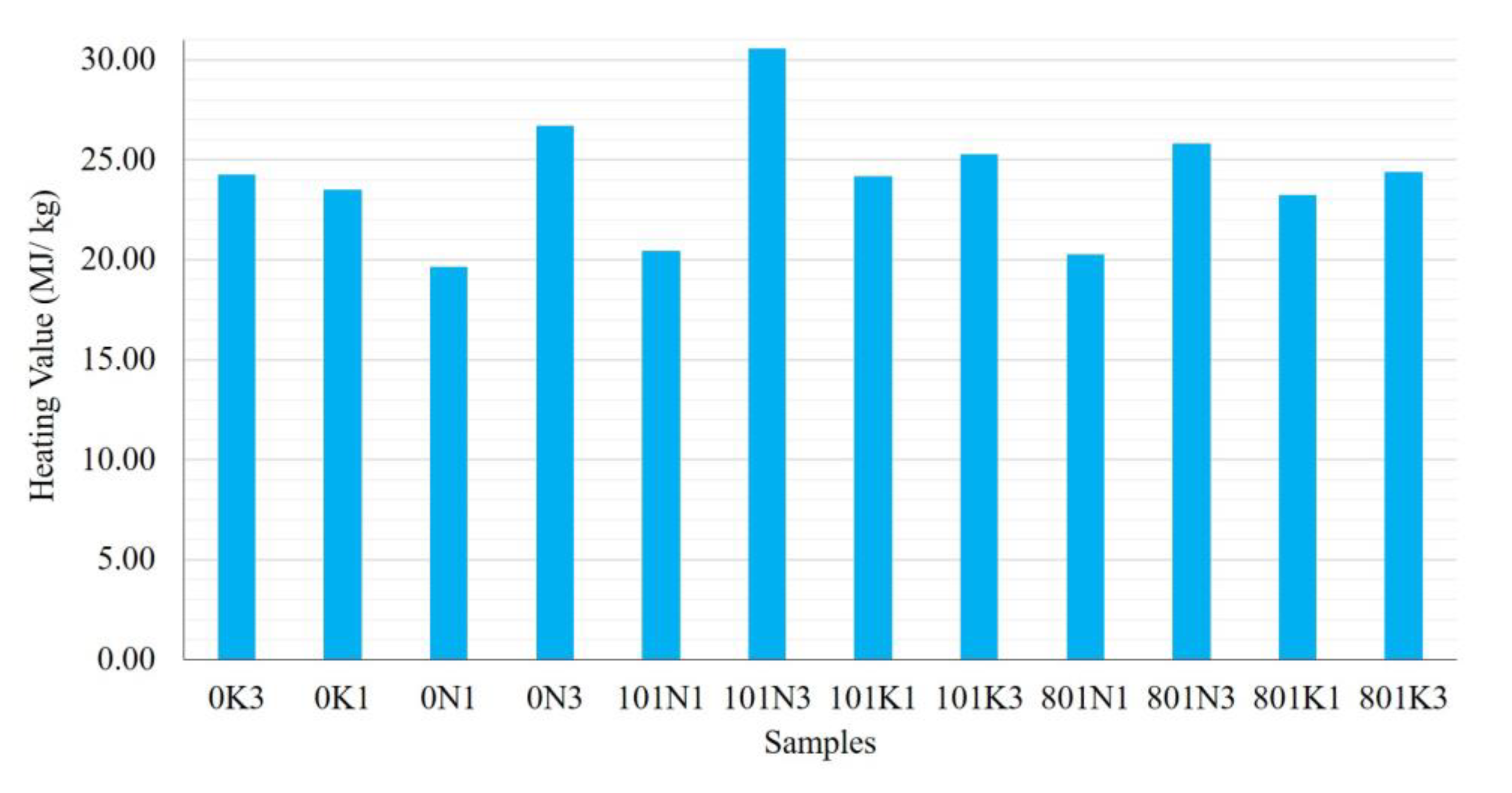

The higher heating values of the solid carbonaceous products derived from hydrothermal carbonization, specifically the hydrochars, are illustrated in

Figure 6. The data highlights two distinct trends. Firstly, the energy densities of the samples subjected to a three-day treatment are consistently greater than those of samples that underwent treatment for only one day. At a second level the samples that were reformed in water have consistently higher energy densities than the same samples that were treated in OMWW. Despite this, in nearly all cases, the heating values are substantial and surpass those found in other similar studies [

22]. This indicates that there is potential for using hydrochars derived from food waste as an energy source. The outcomes of the heating value measurements, which exceeded expectations, can be accounted for by the chosen temperature of hydrothermal carbonization (HTC) treatment. It has been demonstrated that this temperature has an optimal impact on the heating value of hydrochar, as illustrated in the work done by Shrestha et al. in 2021 [

24].

Figure 7.

Higher Heating Values of hydrochar products from HTC.

Figure 7.

Higher Heating Values of hydrochar products from HTC.

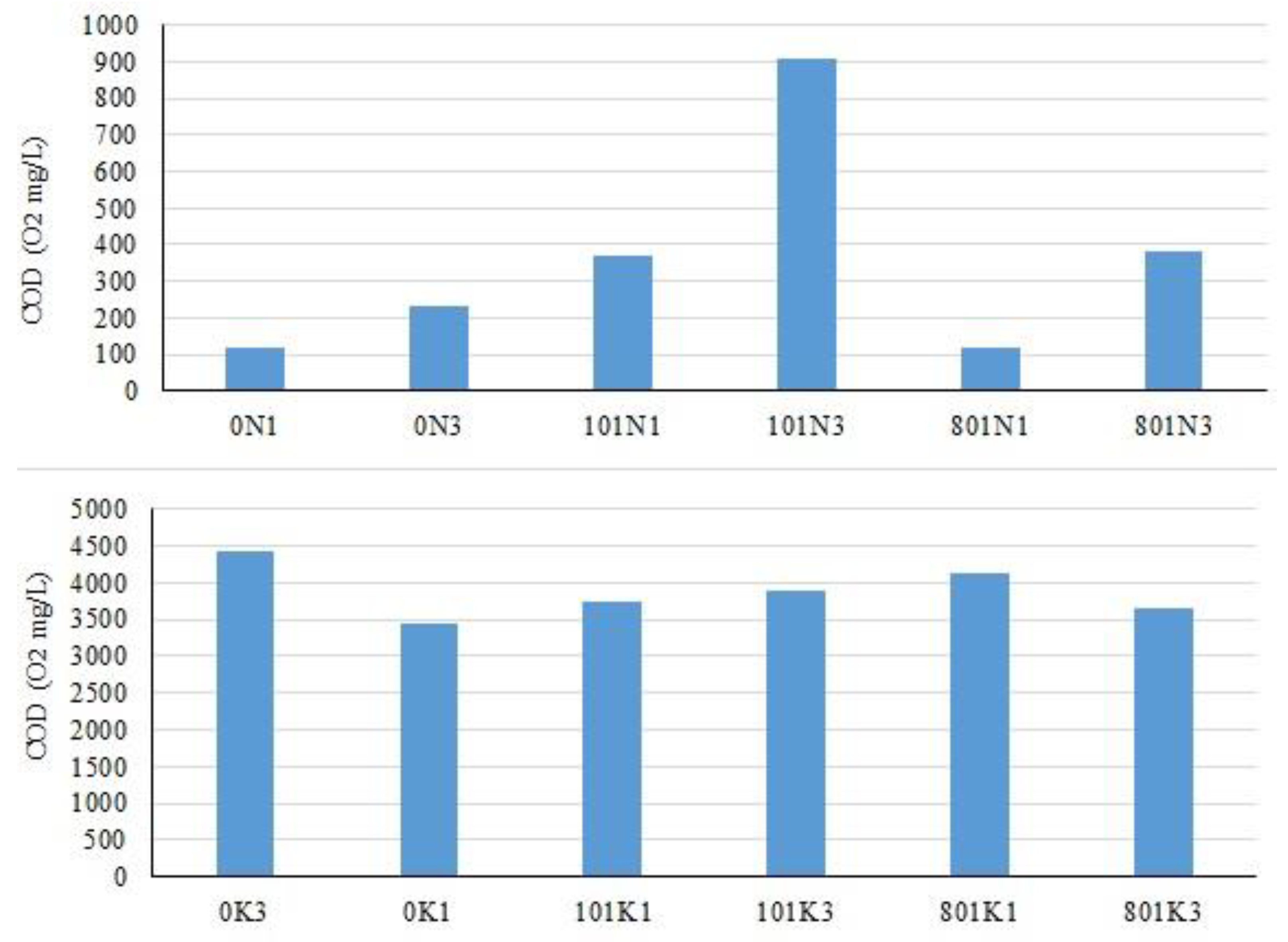

Figure 8 presents the chemical oxygen demand of the liquid fractions of the products from hydrothermal carbonization. Once again, it has to be noted that the utilization of OMWW as a hydrothermal medium directly affects the characteristics of liquid products. The samples that were treated with OMWW have chemical oxygen demand between 350 - 450 mg/ L, contrary to the samples that were treated with water that have chemical oxygen demand between 10 - 90 mg/ L. In addition, the water samples seem to have increased COD with increased duration of treatment, but there is no clear tendency for the OMWW samples. The difference in the COD levels was expected since the COD of OMWW is in the several thousands. But what is very interesting is that HTC significantly reduces the COD in OMWW samples since the release of carbon-oxides reduces the COD. This is a very interesting result which indicates a pathway for combined energetic valorization and simultaneous reduction of the environmental impact.

4. Discussion

A few final considerations on this study can be the following. The acidic profile of HTC with OMWW may have assisted the production of hydrochar. Zhang et al. (2021) denoted that acidic environments in HTC may accelerate the hydrolysis process and thus enhance the reforming [

25]. Another hypothesis could be that OMWW is more volatile than water and for the same temperatures it may have developed higher pressure profiles that can assist the production of hydrochar. A future next step is the utilization of hydrochar back inside the anaerobic bottles for assisting the AD process in a way similar to the assistance of AD by co-AD with conventional biochar. This is a step towards circular co-treatment and will elevate this work at the next level. As mentioned before, HPLC analysis will be performed in the immediate future for the identification of the full profile of the substances of each liquid sample. Finally, upcoming work will present the results from the composting experiments.

Food waste along with spent coffee grounds were treated in parallel in aerobic, i.e., composting, and anaerobic, i.e., AD, treatments. This study investigates the holistic management of biowaste and focuses on the co-treatment of AD residues by means of hydrothermal treatment. The additional feedstock that was utilized was local agro waste and liquid biowaste of Lesvos Island. A unique application that is presented is the utilization of OMWW not only as HTC feedstock but also as a hydrothermal medium for the treatment of food waste (plus some samples that contained additionally spent coffee grounds), and the results are compared with similar samples that treated with HTC and water as the main hydrothermal medium.

The utilization of OMWW as a hydrothermal medium consistently returns higher hydrochar yields in comparison to water HTC. In addition, the samples that contained spent coffee grounds had increased hydrochar yields that exceeded 50%, due to the higher fixed carbon of the feedstock. On the one hand, liquid samples from OMWW HTC had lower PH, higher COD and higher conductivity than the water HTC samples. On the other hand, the water HTC samples had higher heating values that exceeded 25 MJ/ kg in several cases, and the energy density was increased for samples that were treated for longer periods of time. Finally, HTC treatment led to a significant reduction of the COD in the liquid products, although OMWW has very high COD and OMWW HTC samples had significantly higher COD than water HTC samples.

Author Contributions

For research articles with several authors, a short paragraph specifying their individual contributions must be provided. The following statements should be used “Conceptualization, S.V. and D.L.; methodology, S.V. and D.L.; validation, S.V., I.D. and D.L.; formal analysis, P.X. and I.D.; investigation, P.X. and I.D.; resources, S.V. and D.L.; data curation, all; writing—original draft preparation, S.V.; writing—review and editing, S.V. and X.P.; visualization, S.V.; supervision, S.V. and D.L.; project administration, S.V. and D.L.; funding acquisition, D.L. All authors have read and agreed to the published version of the manuscript.”

Funding

“This research was funded by the project “Center of Sustainable and Circular Bioeconomy [Aegean_BIOECONOMY]” (MIS 5045851) which is implemented under the Action “Reinforcement of the Research and Innovation Infrastructure”, funded by the Operational Programme “Competitiveness, Entrepreneurship and Innovation” (NSRF 2014-2020) and co-financed by Greece and the European Union (European Regional Development Fund)”.

Data Availability Statement

Data are available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission. Communication from the commission to the European parliament, the council, the European economic and social committee and the committee of the regions Closing the loop - An EU action plan for the Circular Economy COM/2015/0614 final. EUROSTAT.2020. Agri-environmental indicators. 2015. Available online: https://ec.europa .eu/eurostat/data/.

- Vakalis, S.; Moustakas, K.; Benedetti, V.; Cordioli, E.; Patuzzi, F.; Loizidou, M.; Baratieri, M. Centralized collection scheme and torrefaction of spent coffee grounds – an introduction to the concept of the “COFFEE BIN”. Environmental Science and Pollution Research 2019. [Google Scholar] [CrossRef] [PubMed]

- Loizidou, M.; Vakalis, S.; Moustakas, K.; Malamis, D. Chapter 5 - Movement Towards Circular Economy and E.U. Waste Management Regulation. In Proceedings of 2018 EEC/WTERT Conference; Marco J. Castaldi, Francesco Patuzzi, Simona 383 Ciuta, Swanand Tupsakhare, Demetra Tsiamis; ASME: New York, 2019; ISBN 9780791861950. [Google Scholar] [CrossRef]

- Ojha, S.; Sara Bußler, S.; Schlüter, O.K. Food waste valorisation and circular economy concepts in insect production and processing, Waste Management 118: 600-609; Hellenic Statistical Authority, Annual agricultural statistics of the National Statistical Authority: Athens, 2020. [Google Scholar]

- Pérez, S.; Renedo, C.J.; Ortiz, A.; Mañana, M.; Delgado, F.; Tejedor, C. Energetic density of different forest species of energy crops in Cantabria (Spain). Biomass and Bioenergy 2011, 359, 4657–4664. [Google Scholar] [CrossRef]

- Castaldi, M.J. The Scientific Truth about Waste-to-Energy. Grove School of Engineering, City College of New York, 2021. Available online: https://ccnyeec.org/wp-content/uploads/2021/05/WTE-REPORT7603.pdf.

- Regional Authority of North Aegean. Strategic and Operational program of the Municipality of Lesvos 2015-2019. 2015. Available online: http://www.mytilene.gr/wp403 content/uploads/2016/09/Epixirisiako_sxedio.pdf.

- Moustakas, K.; Parmaxidou, P.; Vakalis, S. Anaerobic Digestion for energy production from agricultural biomass waste in Greece: Capacity assessment for the Region of Thessaly. Energy 2020, 191, 116556. [Google Scholar] [CrossRef]

- European Commision. Updated Bioeconomy Strategy: A sustainable bioeconomy for Europe: strengthening the connection between economy, society and the environment, Directorate-General for Research and Innovation Unit F – Bioeconomy, European Commission B-1049 Brussels. 2018; ISBN 978-92-79-94144-3. [Google Scholar]

- Katsouli, A.; Stasinakis, A.S. Production of municipal solid waste and sewage in European refugees’ camps: The case of Lesvos, Greece. Waste Management 2019, 86, 49–53. [Google Scholar] [CrossRef] [PubMed]

- Porzig, M.; Baur, F.; Wern, B.; Lekkas, D.F. SusNisia: Circular economy for biogenic residues for the North Aegean – case studies for Islands of Chios and Lesvos. 16th International Conference on Environmental Science and Technology, Rhodes, Greece, 4-7 September 2019. [Google Scholar]

- Al Seadi, T.; Owen, N.; Hellström, H.; Kang, H. Source separation of MSW: An overview of the source separation and separate collection of the digestible fraction of household waste, and of other similar wastes from municipalities, aimed to be used as feedstock for anaerobic digestion in biogas plants; IEA Bioenergy, 2013; ISBN 978-1-910154-01-4. [Google Scholar]

- Negri, C.; Ricci, M.; Zilio, M.; D'Imporzano, G.; Qiao; Dong, W. R.; Adani, F. Anaerobic digestion of food waste for bio-energy production in China and Southeast Asia: A review. Renewable and Sustainable Energy Reviews 2020, 133, 110138. [Google Scholar] [CrossRef]

- Angelidaki, I.; Treu, L.; Tsapekos, P.; Luo, G.; Campanaro, S.; Wenzel, H.; Kougias, P.G. Biogas upgrading and utilization: Current status and perspectives. Biotechnology Advances 2018, 36, 452–466. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhao, M.; Lv, C.; Yue, P. The effect of microwave pretreatment on anaerobic co-digestion of sludge and food waste: Performance, kinetics and energy recovery. Environmental Research 2020, 189, 109856. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Kuroki, A.; Loh, K.-C.; Seok, J.K.; Dai, Y.; Tong, Y.W. Highly efficient anaerobic co-digestion of food waste and horticultural waste using a three-stage thermophilic bioreactor: Performance evaluation, microbial community analysis, and energy balance assessment. Energy Conversion and Management 2020, 223, 113290. [Google Scholar] [CrossRef]

- Yuan, T.; Shi, X.; Sun, R.; Ko, J.H.; Xu, Q. Simultaneous addition of biochar and zero valent iron to improve food waste anaerobic digestion. Journal of Cleaner Production 2021, 278, 123627. [Google Scholar] [CrossRef]

- Vakalis, S.; Ahmad, J.; Heimann, R.; Patuzzi, F.; Baratieri, M. The Case of Frictional Torrefaction and the Effect of Reflux Condensation on the Operation of the Rotary Compression Unit Bioresource Technology. 2018, 268, 91–96. [Google Scholar] [CrossRef] [PubMed]

- Libra, J.A.; Ro, K.S.; Kammann, C.; Funke, A.; Berge, N.D.; Neubauer, Y.; Titirici, M.M.; Fühner, C.; Bens, O.; Kern, J.; Emmerich, K.H. Hydrothermal carbonization of biomass residuals: a comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2011, 2, 71–106. [Google Scholar] [CrossRef]

- Su, H.; Zhou, X.; Zheng, R.; Zhou, Z.; Zhang, Y.; Zhu, G.; Yu, C.; Hantoko, D.; Yan, M. Hydrothermal carbonization of food waste after oil extraction pre-treatment: Study on hydrochar fuel characteristics, combustion behavior, and removal behavior of sodium and potassium. Science of The Total Environment 2021, 754, 142192. [Google Scholar] [CrossRef] [PubMed]

- Sharma, H.B.; Dubey, B.K. Co-hydrothermal 404 carbonization of food waste with yard waste for solid biofuel production: Hydrochar characterization and its pelletization. Waste Management 2020, 118, 521–533. [Google Scholar] [CrossRef] [PubMed]

- Pawlak-Kruczek, H.; Niedzwiecki, L.; Sieradzka, M.; Mlonka-Mędrala, A.; Baranowski, M.; Serafin-Tkaczuk, M.; A Magdziarz. 2020. Hydrothermal carbonization of agricultural and municipal solid waste digestates – Structure and energetic properties of the solid products, Fuel 275:117837, ISSN 0016-2361, https://doi.org/10.1016/j.fuel.2020.117837.Author 1, A.; Author 2, B. Title of the chapter. In Book Title, 2nd ed.; Editor 1, A., Editor 2, B., Eds.; Publisher: Publisher Location, Country, 2007; Volume 3, pp. 154–196.

- Kapoor, R.; Ghosh, P.; Tyagi, B.; Vijay, V.K.; Vijay, V.; Thakur, I.S.; Kamyab, H.; Nguyen, D.D.; Kumar, A. Advances in biogas valorization and utilization systems: A comprehensive review. Journal of Cleaner Production 2020, 273, 123052. [Google Scholar] [CrossRef]

- Shrestha, A.; Acharya, B.; Farooque, A.A. Study of hydrochar and process water from hydrothermal carbonization of sea lettuce. Renewable Energy 2021, 163, 589–598. [Google Scholar] [CrossRef]

- Zhang, S.; Sheng, K.; Yan, W.; Liu, J.; Shuang, E.; Yang, M.; Zhang, X. Bamboo derived hydrochar microspheres fabricated by acid-assisted hydrothermal carbonization. Chemosphere 2021, 263, 128093. [Google Scholar] [CrossRef] [PubMed]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).