Submitted:

20 April 2023

Posted:

21 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental

2.1. Reagents and Instruments

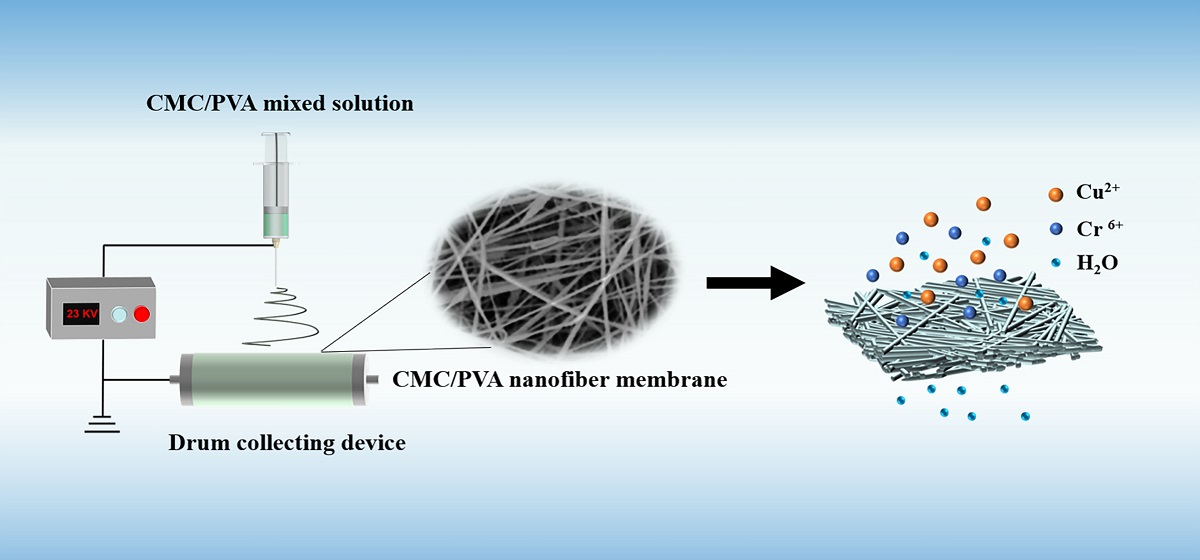

2.2. Preparation of CMC/PVA Nanofiber Membrane

2.3. Characterization of CMC/PVA Nanofiber Membranes

2.4. Filtration Tests of CMC/PVA Nanofiber Membranes

3. Results and Discussion

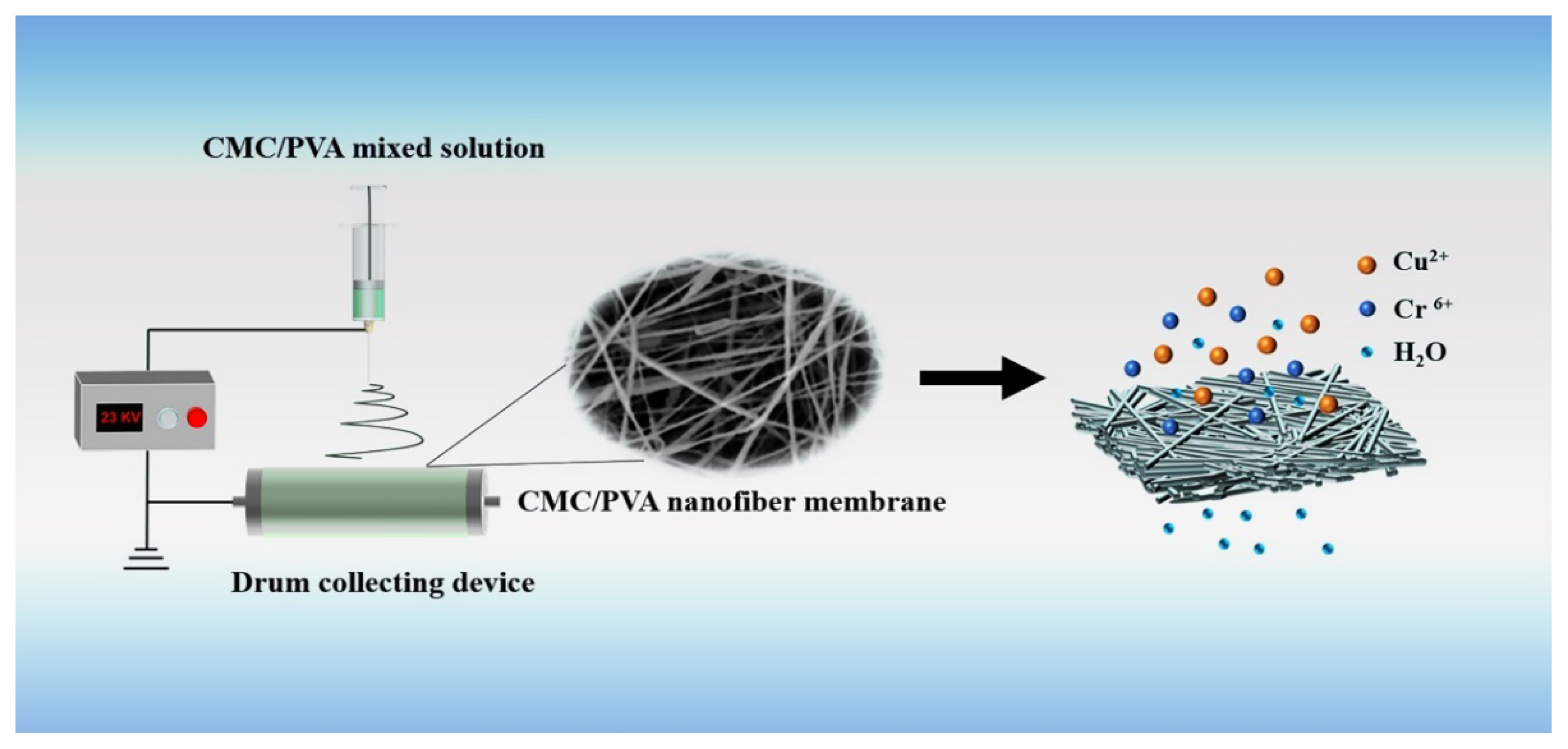

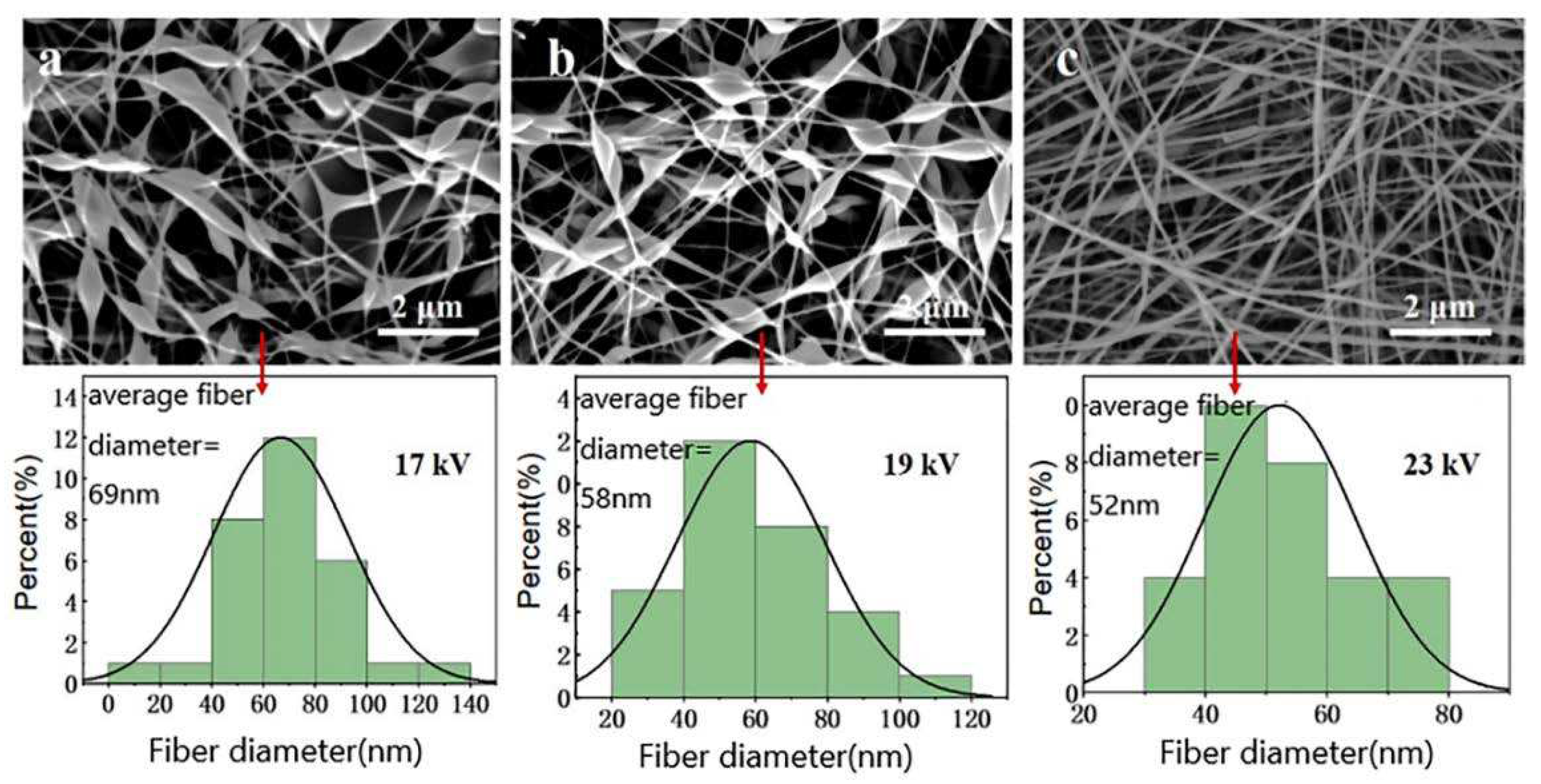

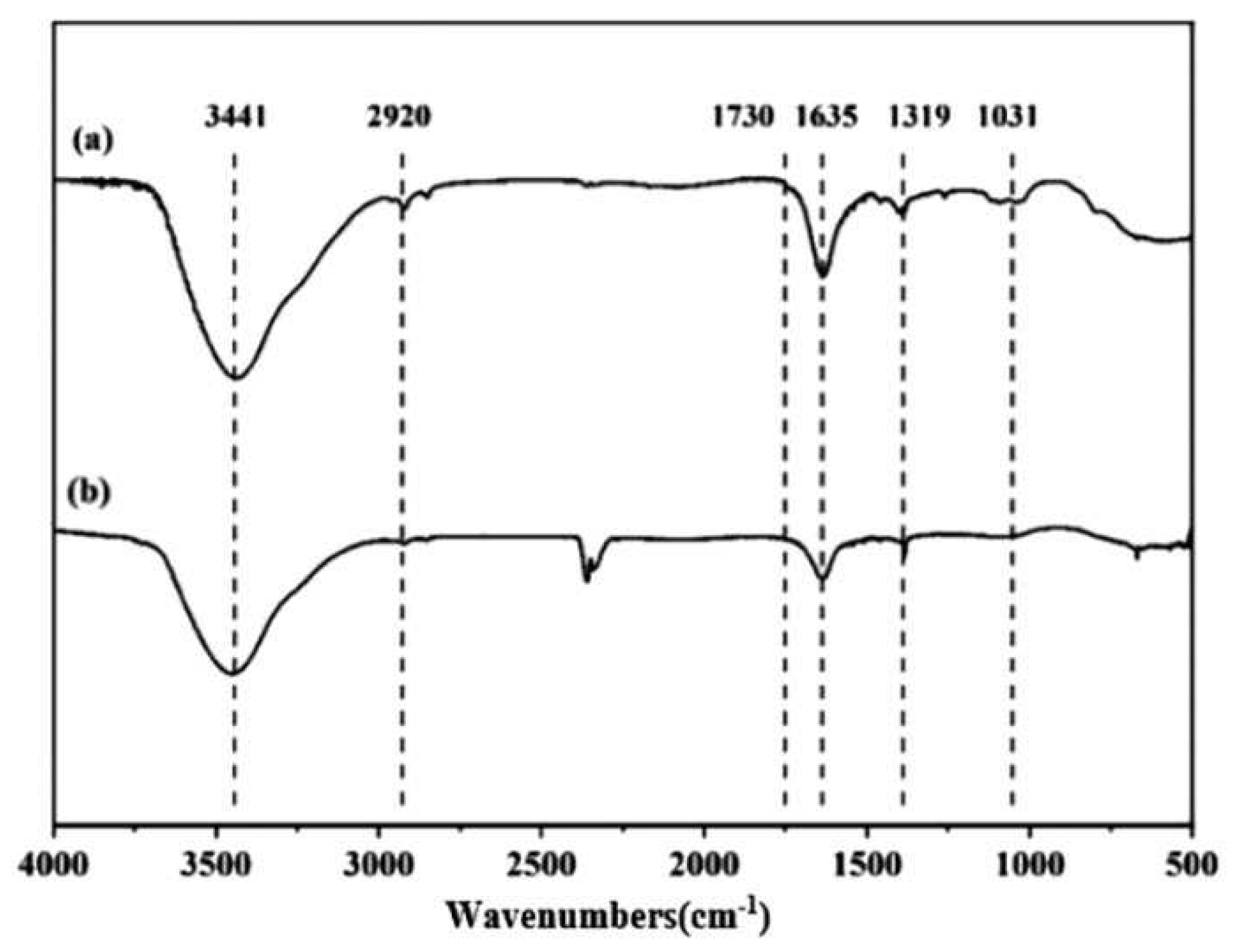

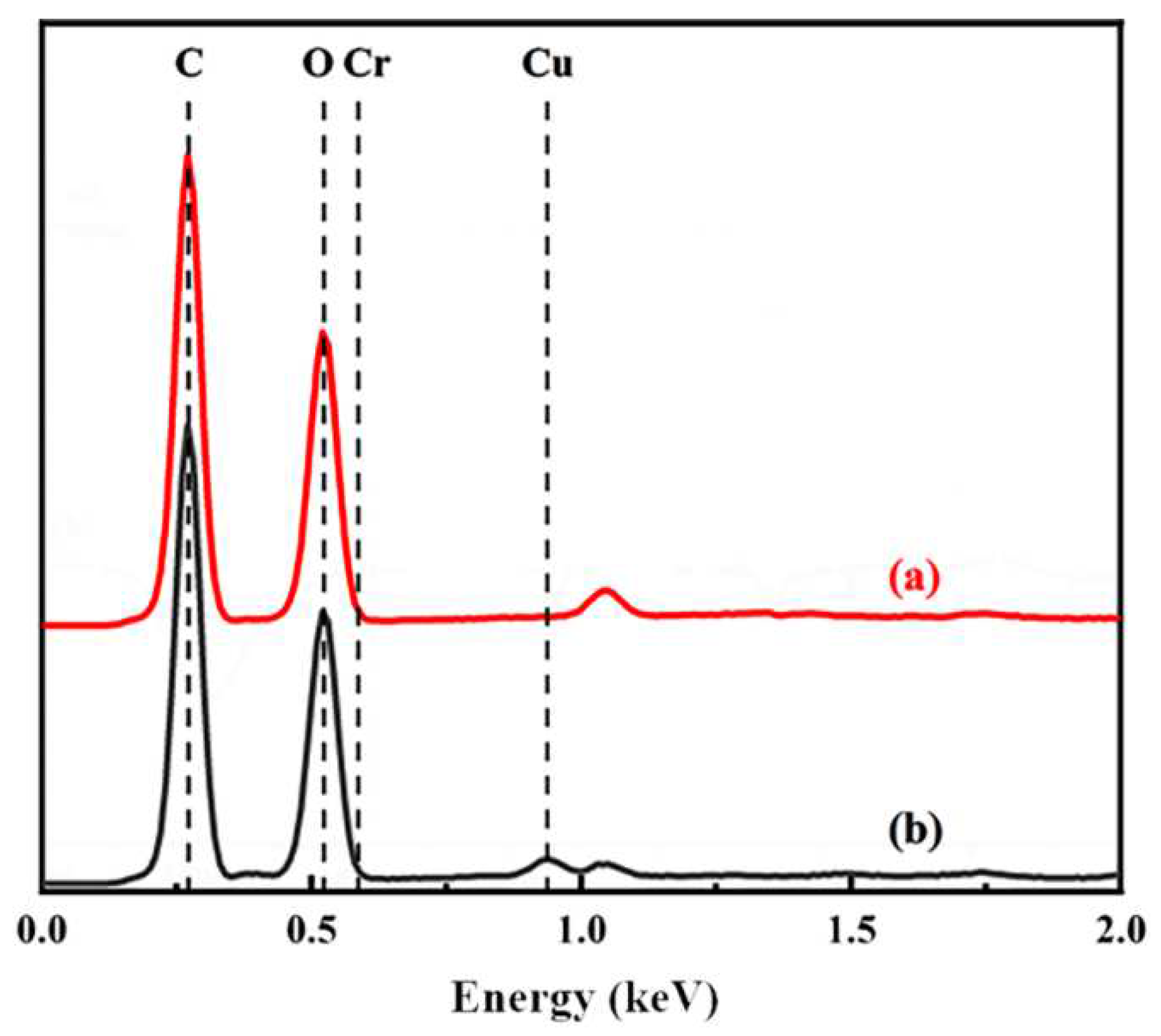

3.1. Characteristics of Nanofiber Membranes

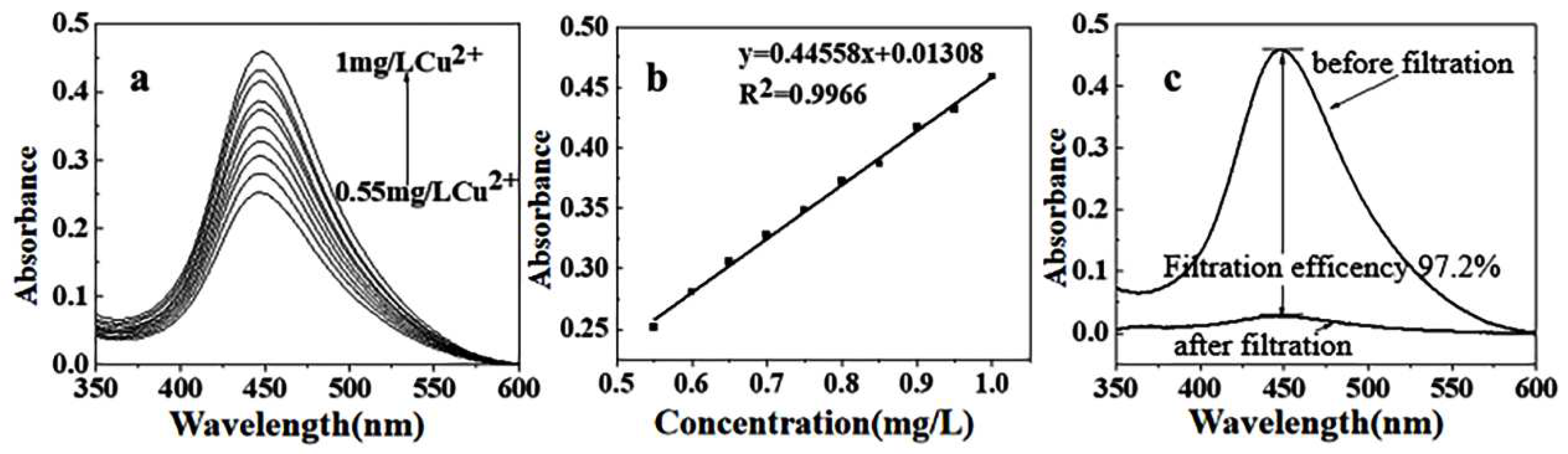

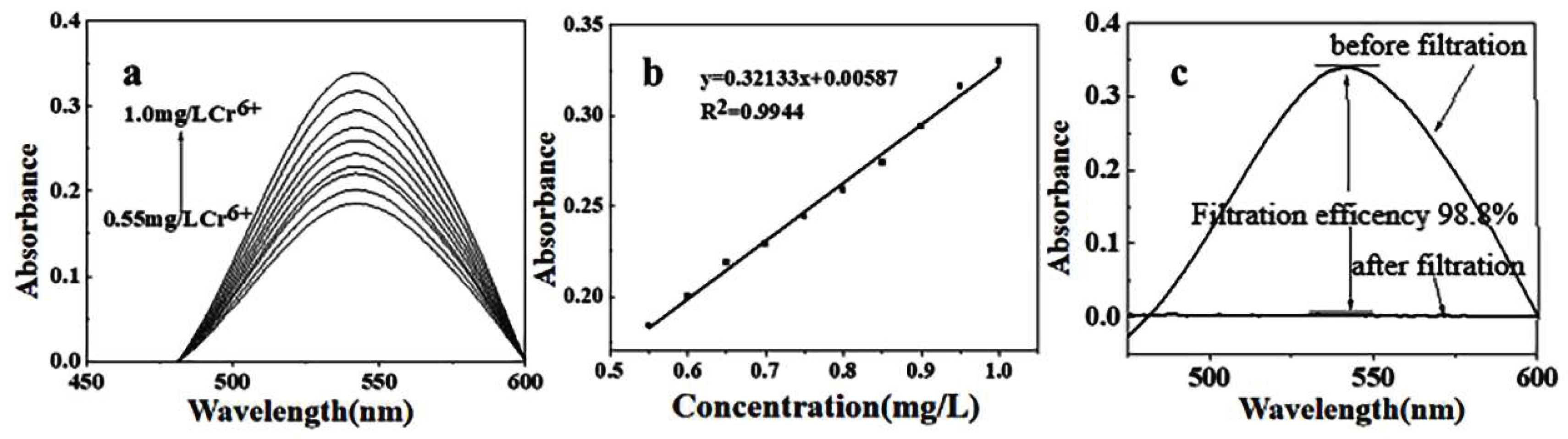

3.2. Separation Properties of Nanofiber Membranes

4. Conclusions

Acknowledgments

References

- Mishra, S.; Bharagava, R. N.; More, N.; Yadav, A.; Zainith, S.; Mani, S.; Chowdhary, P. , Heavy metal contamination: an alarming threat to environment and human health. Environmental biotechnology: For sustainable future 2019, 103–125. [Google Scholar]

- Han, R.; Zhou, B.; Huang, Y.; Lu, X.; Li, S.; Li, N. , Bibliometric overview of research trends on heavy metal health risks and impacts in 1989–2018. J. Cleaner Prod. 2020, 276, 123249. [Google Scholar] [CrossRef]

- Kapoor, D.; Singh, M. P. , Heavy metal contamination in water and its possible sources. In Heavy metals in the environment, Elsevier: 2021; pp 179-189.

- Ali, H.; Khan, E.; Ilahi, I. , Environmental chemistry and ecotoxicology of hazardous heavy metals: environmental persistence, toxicity, and bioaccumulation. J chem 2019, 2019. [Google Scholar] [CrossRef]

- Vardhan, K. H.; Kumar, P. S.; Panda, R. C. , A review on heavy metal pollution, toxicity and remedial measures: Current trends and future perspectives. J. Mol. Liq. 2019, 290, 111197. [Google Scholar] [CrossRef]

- Qasem, N. A.; Mohammed, R. H.; Lawal, D. U. , Removal of heavy metal ions from wastewater: A comprehensive and critical review. Npj Clean Water 2021, 4, 36. [Google Scholar] [CrossRef]

- Qi, Y.; Zhu, L.; Shen, X.; Sotto, A.; Gao, C.; Shen, J. , Polythyleneimine-modified original positive charged nanofiltration membrane: removal of heavy metal ions and dyes. Sep. Purif. Technol. 2019, 222, 117–124. [Google Scholar] [CrossRef]

- Merino-Garcia, I.; Velizarov, S. , New insights into the definition of membrane cleaning strategies to diminish the fouling impact in ion exchange membrane separation processes. Sep. Purif. Technol. 2021, 277, 119445. [Google Scholar] [CrossRef]

- Velusamy, S.; Roy, A.; Sundaram, S.; Kumar Mallick, T. , A review on heavy metal ions and containing dyes removal through graphene oxide-based adsorption strategies for textile wastewater treatment. Chem Rec 2021, 21, 1570–1610. [Google Scholar] [CrossRef]

- Liang, B.; He, X.; Hou, J.; Li, L.; Tang, Z. , Membrane separation in organic liquid: technologies, achievements, and opportunities. Adv. Mater. 2019, 31, 1806090. [Google Scholar] [CrossRef]

- Tijing, L. D.; Dizon, J. R. C.; Ibrahim, I.; Nisay, A. R. N.; Shon, H. K.; Advincula, R. C. , 3D printing for membrane separation, desalination and water treatment. Appl Mater Today 2020, 18, 100486. [Google Scholar] [CrossRef]

- Ni, J.; Yuan, C.; Zheng, J.; Liu, Y. , Distributions, contamination level and ecological risk of heavy metals in surface sediments from intertidal zone of the Sanmen Bay, East China. J. Sea Res. 2022, 190, 102302. [Google Scholar] [CrossRef]

- Pronk, W.; Ding, A.; Morgenroth, E.; Derlon, N.; Desmond, P.; Burkhardt, M.; Wu, B.; Fane, A. G. , Gravity-driven membrane filtration for water and wastewater treatment: a review. Water Res. 2019, 149, 553–565. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Cai, N.; Chan, V.; Yu, F. , Development and applications of MOFs derivative one-dimensional nanofibers via electrospinning: a mini-review. Nanomater. 2019, 9(9), 1306. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Li, F.; Wang, Y.; Zhang, Q.; Ma, W.; Huang, C. , Electrospun nanofiber membranes for wastewater treatment applications. Sep. Purif. Technol. 2020, 250. [Google Scholar] [CrossRef]

- Wu, S.; Li, K.; Shi, W.; Cai, J. , Chitosan/polyvinylpyrrolidone/polyvinyl alcohol/carbon nanotubes dual layers nanofibrous membrane constructed by electrospinning-electrospray for water purification. Carbohydr. Polym. 2022, 294, 119756. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Cheng, S.; Lu, W.; Wang, Y.; Zhang, P.; Yao, Q. , Electrospun fibers and their application in drug controlled release, biological dressings, tissue repair, and enzyme immobilization. RSC. Adv. 2019, 9, 25712–25729. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Zhang, Z.; Zhou, W.; Liang, X.; Zhou, G.; Han, C. C.; Xu, S.; Liu, Y. , Mechanism of a long-term controlled drug release system based on simple blended electrospun fibers. J. Controlled. Release. 2020, 320, 337–346. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, Y.; Zhang, M.; Feng, Z.; Yu, D.-G.; Wang, K. , Electrospun nanofiber membranes for air filtration: A review. Nanomater. 2022, 12, 1077. [Google Scholar] [CrossRef]

- Farokhi, M.; Mottaghitalab, F.; Reis, R. L.; Ramakrishna, S.; Kundu, S. C. , Functionalized silk fibroin nanofibers as drug carriers: Advantages and challenges. J. Controlled. Release. 2020, 321, 324–347. [Google Scholar] [CrossRef]

- Wu, W.; Zhang, X.; Qin, L.; Li, X.; Meng, Q.; Shen, C.; Zhang, G. , Enhanced MPBR with polyvinylpyrrolidone-graphene oxide/PVDF hollow fiber membrane for efficient ammonia nitrogen wastewater treatment and high-density Chlorella cultivation. Chem. Eng. J. 2020, 379, 122368. [Google Scholar] [CrossRef]

- Zou, P.; Lee, W.-H.; Gao, Z.; Qin, D.; Wang, Y.; Liu, J.; Sun, T.; Gao, Y. , Wound dressing from polyvinyl alcohol/chitosan electrospun fiber membrane loaded with OH-CATH30 nanoparticles. Carbohydr. Polym. 2020, 232, 115786. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Lu, T.; Cui, J.; Samal, S. K.; Xiong, R.; Huang, C. , Bio-based electrospun nanofiber as building blocks for a novel eco-friendly air filtration membrane: A review. Sep. Purif. Technol. 2021, 277, 119623. [Google Scholar] [CrossRef]

- Yang, D.; Li, L.; Chen, B.; Shi, S.; Nie, J.; Ma, G. , Functionalized chitosan electrospun nanofiber membranes for heavy-metal removal. Polymer. 2019, 163, 74–85. [Google Scholar] [CrossRef]

- Deng, S.; Liu, X.; Liao, J.; Lin, H.; Liu, F. , PEI modified multiwalled carbon nanotube as a novel additive in PAN nanofiber membrane for enhanced removal of heavy metal ions. Chem. Eng. J. 2019, 375. [Google Scholar] [CrossRef]

- Rahman, M. M.; Alam, M.; Rahman, M. M.; Susan, M. A. B. H.; Shaikh, M. A. A.; Nayeem, J.; Jahan, M. S. , A novel approach in increasing carboxymethylation reaction of cellulose. Carbohydr. Polym. Technol. Appl. 2022, 4, 100236. [Google Scholar] [CrossRef]

- Hamdan, M. A.; Ramli, N. A.; Othman, N. A.; Amin, K. N. M.; Adam, F. , Characterization and property investigation of microcrystalline cellulose (MCC) and carboxymethyl cellulose (CMC) filler on the carrageenan-based biocomposite film. Mater. Today: Proc. 2021, 42, 56–62. [Google Scholar] [CrossRef]

- Mohamadpour, F. , Carboxymethyl cellulose (CMC) as a recyclable green catalyst promoted eco-friendly protocol for the solvent-free synthesis of 1 H-pyrazolo [1, 2-b] phthalazine-5, 10-dione derivatives. Polycyclic. Aromat. Compd. 2022, 42, 1091–1102. [Google Scholar] [CrossRef]

- Allafchian, A.; Hosseini, H.; Ghoreishi, S. M. , Electrospinning of PVA-carboxymethyl cellulose nanofibers for flufenamic acid drug delivery. Int. J. Biol. Macromol. 2020, 163, 1780–1786. [Google Scholar] [CrossRef]

- Shen, H.; Li, Y.; Yao, W.; Yang, S.; Yang, L.; Pan, F.; Chen, Z.; Yin, X. , Solvent-free cellulose nanocrystal fluids for simultaneous enhancement of mechanical properties, thermal conductivity, moisture permeability and antibacterial properties of polylactic acid fibrous membrane. Compos. Part B: Eng. 2021, 222, 109042. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, J.; Liu, L.; Zhang, P.; Wang, X.; Yu, J.; Ding, B. , Transformation of fibrous membranes from opaque to transparent under mechanical pressing. Eng. 2021. [Google Scholar] [CrossRef]

- Mazuki, N.; Majeed, A. A.; Nagao, Y.; Samsudin, A. , Studies on ionics conduction properties of modification CMC-PVA based polymer blend electrolytes via impedance approach. Polym. Test. 2020, 81, 106234. [Google Scholar] [CrossRef]

- Al-Shamari, A.; Abdelghany, A.; Alnattar, H.; Oraby, A. , Structural and optical properties of PEO/CMC polymer blend modified with gold nanoparticles synthesized by laser ablation in water. J. Mater. Res. Technol. 2021, 12, 1597–1605. [Google Scholar] [CrossRef]

- Behdarvand, F.; Valamohammadi, E.; Tofighy, M. A.; Mohammadi, T. , Polyvinyl alcohol/polyethersulfone thin-film nanocomposite membranes with carbon nanomaterials incorporated in substrate for water treatment. J. Environ. Chem. Eng. 2021, 9(1), 104650. [Google Scholar] [CrossRef]

- Cui, Z.; Zheng, Z.; Lin, L.; Si, J.; Wang, Q.; Peng, X.; Chen, W. , Electrospinning and crosslinking of polyvinyl alcohol/chitosan composite nanofiber for transdermal drug delivery. Adv. Polym. Tech. 2018, 37, 1917–1928. [Google Scholar] [CrossRef]

- Raksa, A.; Numpaisal, P.-o.; Ruksakulpiwat, Y. , The effect of humidity during electrospinning on morphology and mechanical properties of SF/PVA nanofibers. Mater. Today: Proc. 2021, 47, 3458–3461. [Google Scholar] [CrossRef]

- Unal, B.; Yalcinkaya, E. E.; Demirkol, D. O.; Timur, S. , An electrospun nanofiber matrix based on organo-clay for biosensors: PVA/PAMAM-Montmorillonite. Appl. Surf. Sci. 2018, 444, 542–551. [Google Scholar] [CrossRef]

- Khan, M. Q.; Kharaghani, D.; Ullah, S.; Waqas, M.; Abbasi, A. M. R.; Saito, Y.; Zhu, C.; Kim, I. S. , Self-cleaning properties of electrospun PVA/TiO2 and PVA/ZnO nanofibers composites. Nanomater. 2018, 8, 644. [Google Scholar] [CrossRef]

- Hashmi, M.; Ullah, S.; Ullah, A.; Saito, Y.; Haider, M. K.; Bie, X.; Wada, K.; Kim, I. S. , Carboxymethyl Cellulose (CMC) Based Electrospun Composite Nanofiber Mats for Food Packaging. Polym. 2021, 13(2). [Google Scholar] [CrossRef]

- Duran-Guerrero, J. G.; Martinez-Rodriguez, M. A.; Garza-Navarro, M. A.; Gonzalez-Gonzalez, V. A.; Torres-Castro, A.; De La Rosa, J. R. , Magnetic nanofibrous materials based on CMC/PVA polymeric blends. Carbohydr. Polym. 2018, 200, 289–296. [Google Scholar] [CrossRef]

- Angel, N.; Guo, L.; Yan, F.; Wang, H.; Kong, L. , Effect of processing parameters on the electrospinning of cellulose acetate studied by response surface methodology. J. Agric. Food Res. 2020, 2. [Google Scholar] [CrossRef]

- Bakar, S. S. S.; Fong, K. C.; Eleyas, A.; Nazeri, M. F. M. , Effect of Voltage and Flow Rate Electrospinning Parameters on Polyacrylonitrile Electrospun Fibers. IOP Conf. Ser.: Mater. Sci. Eng. 2018, 318. [Google Scholar] [CrossRef]

- Liu, W.; Wang, D.; Soomro, R. A.; Fu, F.; Qiao, N.; Yu, Y.; Wang, R.; Xu, B. , Ceramic supported attapulgite-graphene oxide composite membrane for efficient removal of heavy metal contamination. J. Membr. Sci. 2019, 591, 117323. [Google Scholar] [CrossRef]

- Elessawy, N. A.; Gouda, M. H.; Elnouby, M.; Ali, S. M.; Salerno, M.; Youssef, M. E. , Sustainable Microbial and Heavy Metal Reduction in Water Purification Systems Based on PVA/IC Nanofiber Membrane Doped with PANI/GO. Polym. 2022, 14, 1558. [Google Scholar] [CrossRef] [PubMed]

- Hezarjaribi, M.; Bakeri, G.; Sillanpaa, M.; Chaichi, M. J.; Akbari, S.; Rahimpour, A. , Novel adsorptive PVC nanofibrous/thiol-functionalized TNT composite UF membranes for effective dynamic removal of heavy metal ions. J. Environ. Manage. 2021, 284, 111996. [Google Scholar] [CrossRef]

- Wang, H.; Xu, H.; Li, H.; Liu, X.; Du, Z.; Yu, W. , Electrospun Polyurethane/Zeolitic Imidazolate Framework Nanofibrous Membrane with Superior Stability for Filtering Performance. ACS Appl. Polym. Mater. 2020, 3, 710–719. [Google Scholar] [CrossRef]

- Zhang, X.; Jin, P.; Xu, D.; Zheng, J.; Zhan, Z.-M.; Gao, Q.; Yuan, S.; Xu, Z.-L.; Van der Bruggen, B. , Triethanolamine modification produces ultra-permeable nanofiltration membrane with enhanced removal efficiency of heavy metal ions. J. Membr. Sci. 2022, 644, 120127. [Google Scholar] [CrossRef]

- Abdulkarem, E.; Ibrahim, Y.; Kumar, M.; Arafat, H. A.; Naddeo, V.; Banat, F.; Hasan, S. W. , Polyvinylidene fluoride (PVDF)-α-zirconium phosphate (α-ZrP) nanoparticles based mixed matrix membranes for removal of heavy metal ions. Chemosphere. 2021, 267, 128896. [Google Scholar] [CrossRef]

- Pei, X.; Gan, L.; Tong, Z.; Gao, H.; Meng, S.; Zhang, W.; Wang, P.; Chen, Y. , Robust cellulose-based composite adsorption membrane for heavy metal removal. J. Hazard. Mater. 2021, 406, 124746. [Google Scholar] [CrossRef]

- Kamari, S.; Shahbazi, A. , High–performance nanofiltration membrane blended by Fe3O4@ SiO2–CS bionanocomposite for efficient simultaneous rejection of salts/heavy metals ions/dyes with high permeability, retention increase and fouling decline. Chem. Eng. J. 2021, 417, 127930. [Google Scholar] [CrossRef]

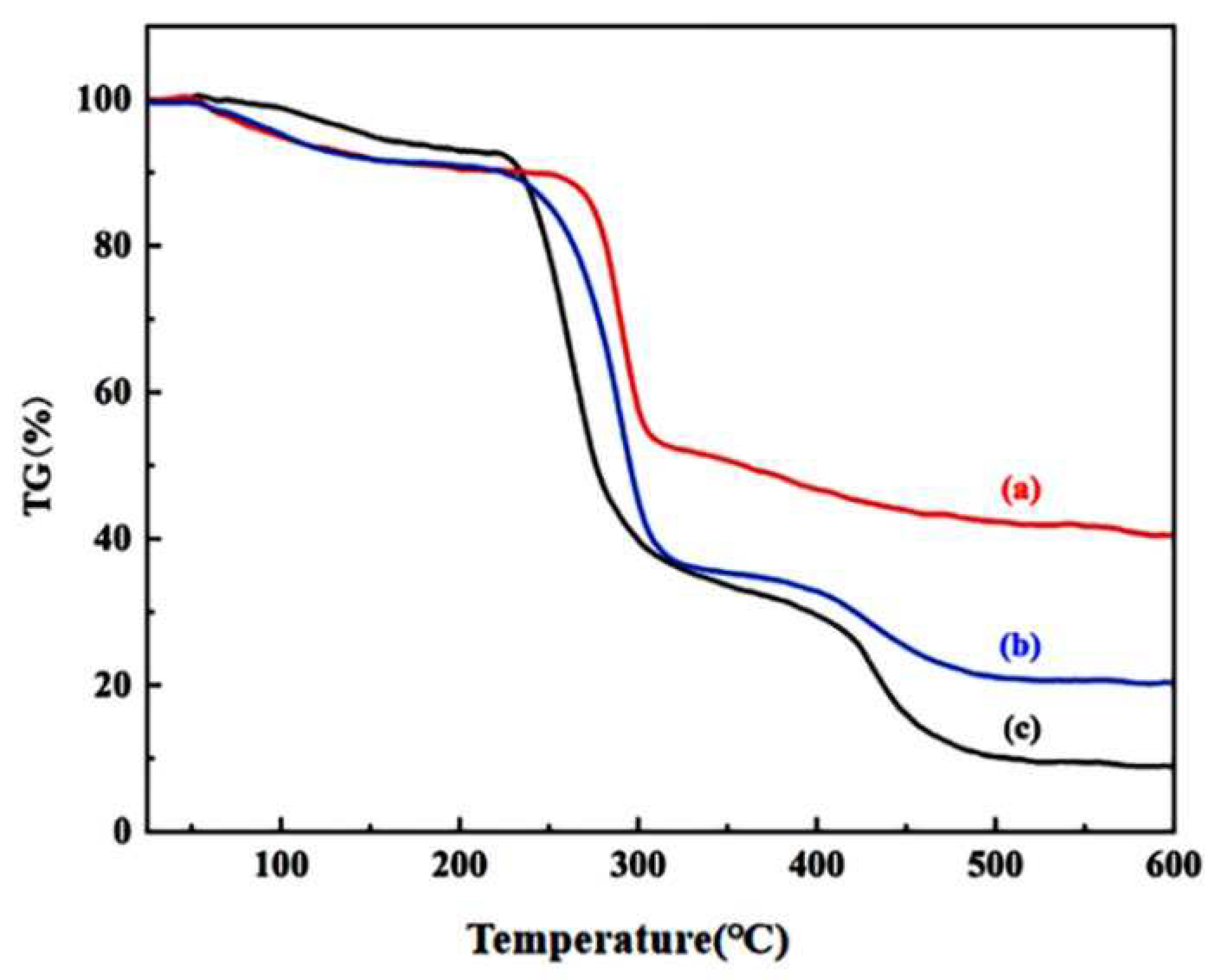

| Membrane type | Heavy metal ion | Rejection rate | Reference |

|---|---|---|---|

| GO/Attapulgite/ Al2O3 | Cu2+ | 99.9% | [43] |

| PVA/IC/PANI/GO | Pb2+、Cd2+ | 97.19%、91.4% | [44] |

| PVC/TNT | Cu2+、Ni2+ | 90%、86.7% | [45] |

| PU/ZIF | Cr6+ | 85% | [46] |

| PEI/TMC | Zn2+、Cd2+、Ni2+、Cu2+ | 97% | [47] |

| PVDF/α-ZrP | Cu2+ 、Pb2+ | 93.1%、91.2% | [48] |

| CA/ P(MA-co-AA)/PEI | Cu2+ | 97.4% | [49] |

| CS/Fe3O4@SiO2 | Cu2+ 、Pb2+ | 98.61%、98.11% | [50] |

| CMC/PVA | Cu2+、Ni2+ | 97.2%、98.8% | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).