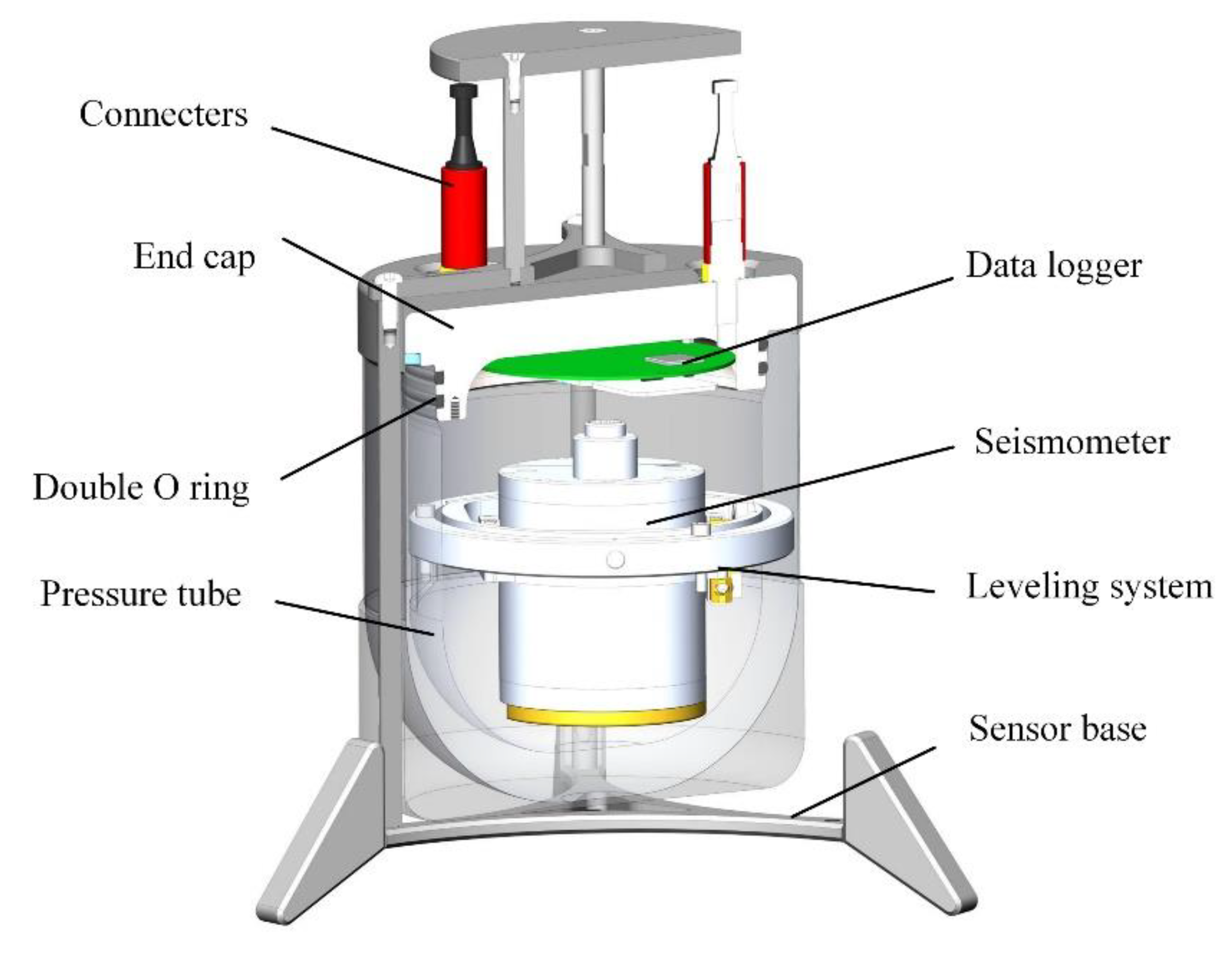

3.1. Sensor Module and the Leveling System

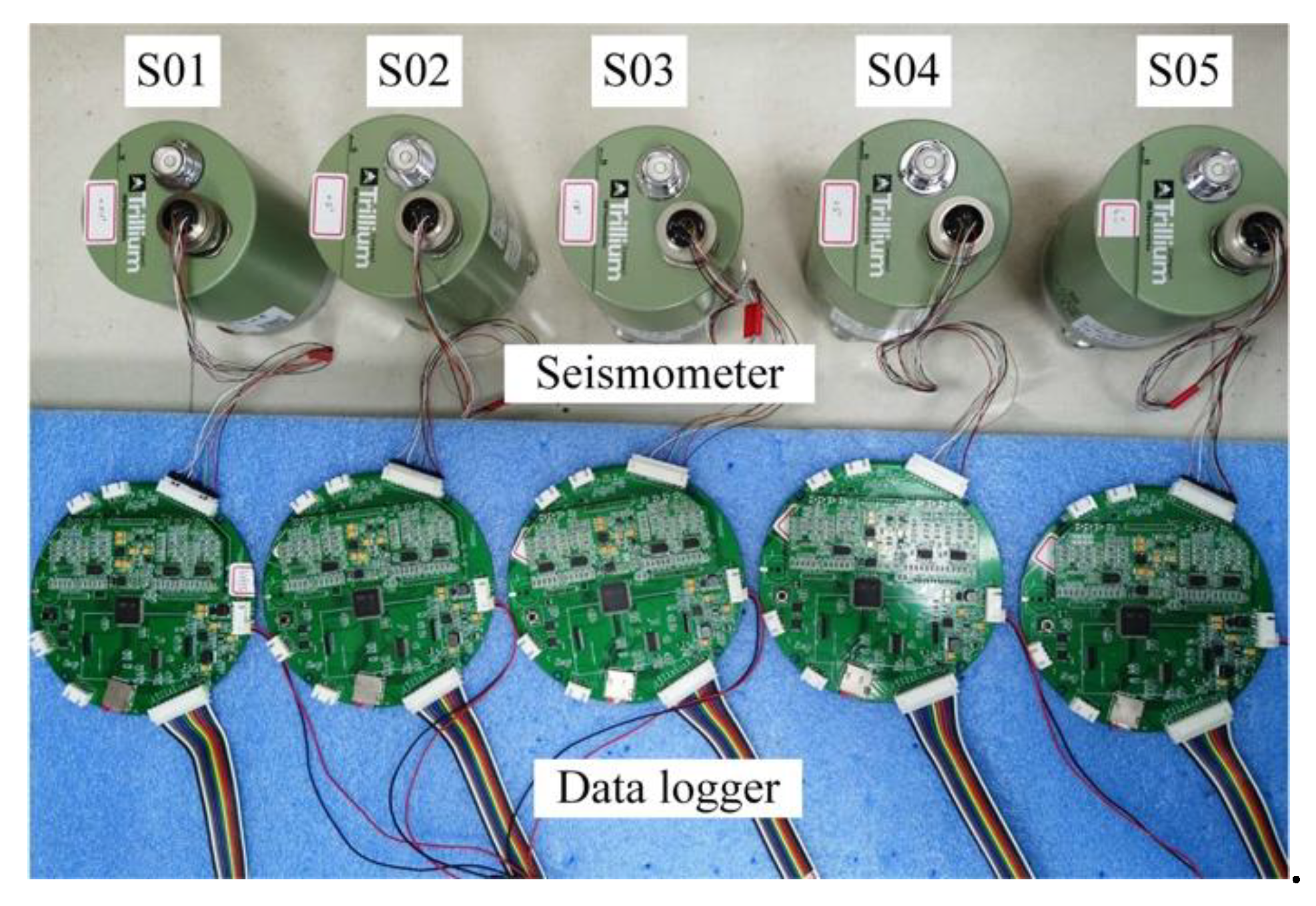

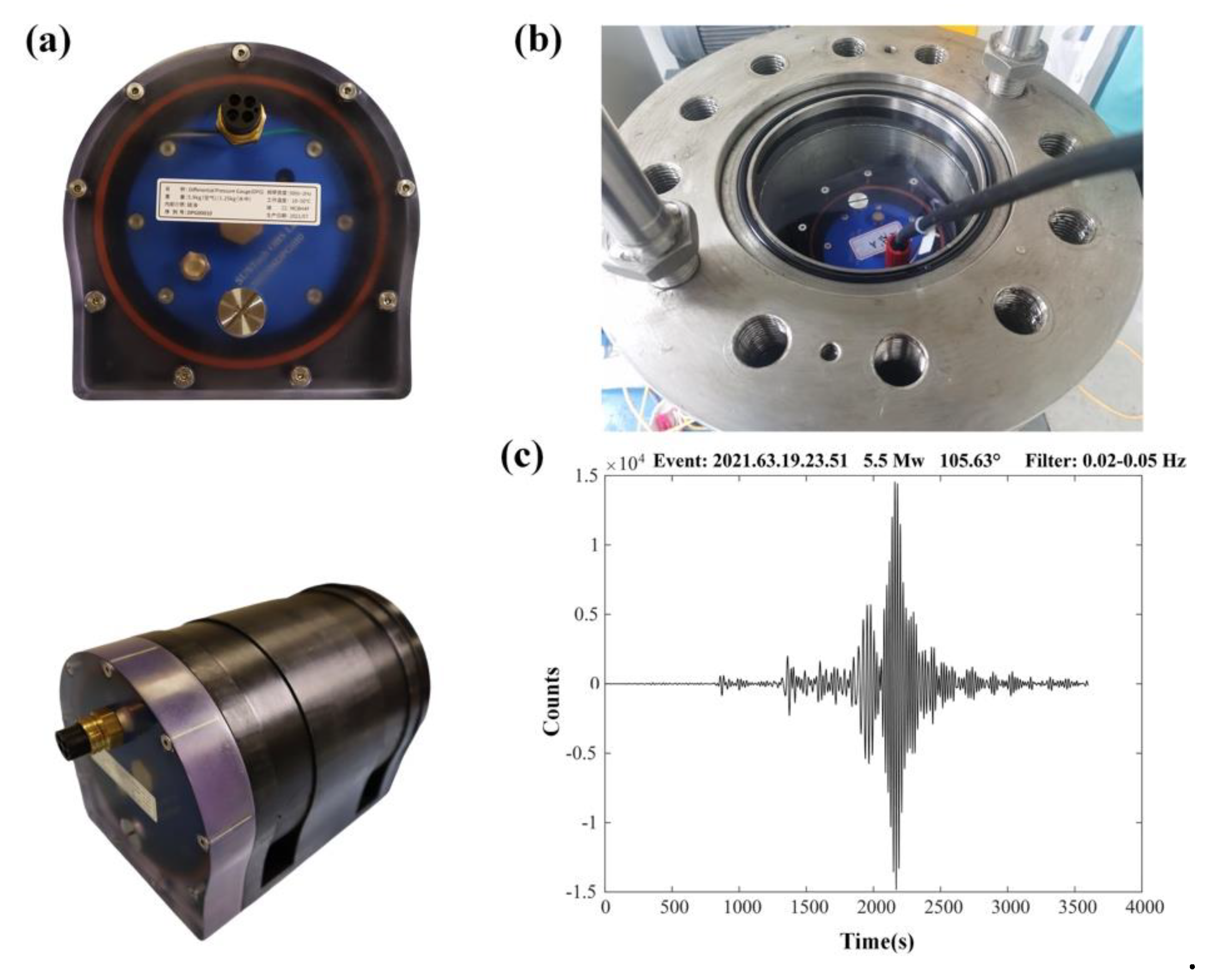

Pankun’s sensor module, which comprises a seismometer with a leveling system and data logger (

Figure 4), is one of the most critical components of the instrument. It is housed in a cylindrical pressure tube with a radius of 0.20 meters and a height of 0.25 meters, making it very compact, and smaller than that of most OBSs. The relatively small size would help it subside into the sediment, achieving a better coupling with the seabed. What is more, a small cross-section area would reduce the influence of the bottom currents and suppress the tilt noise [

13].

Pankun's seismometer is the Trillium Compact from Nanometrics, a widely-used seismometer for passive-source OBS due to its small size, low power consumption, and relatively broad frequency range (120 seconds to 100 Hz) [

17].

A seismometer must be meticulously leveled for the optimal recording of three-component seismograms. However, it is typical for a free-fall OBS to incur a tilt angle greater than the necessary 2.5° operating tilt once it reaches the seafloor. Thus, an automatic leveling system is essential for OBS’ seismometer to work properly.

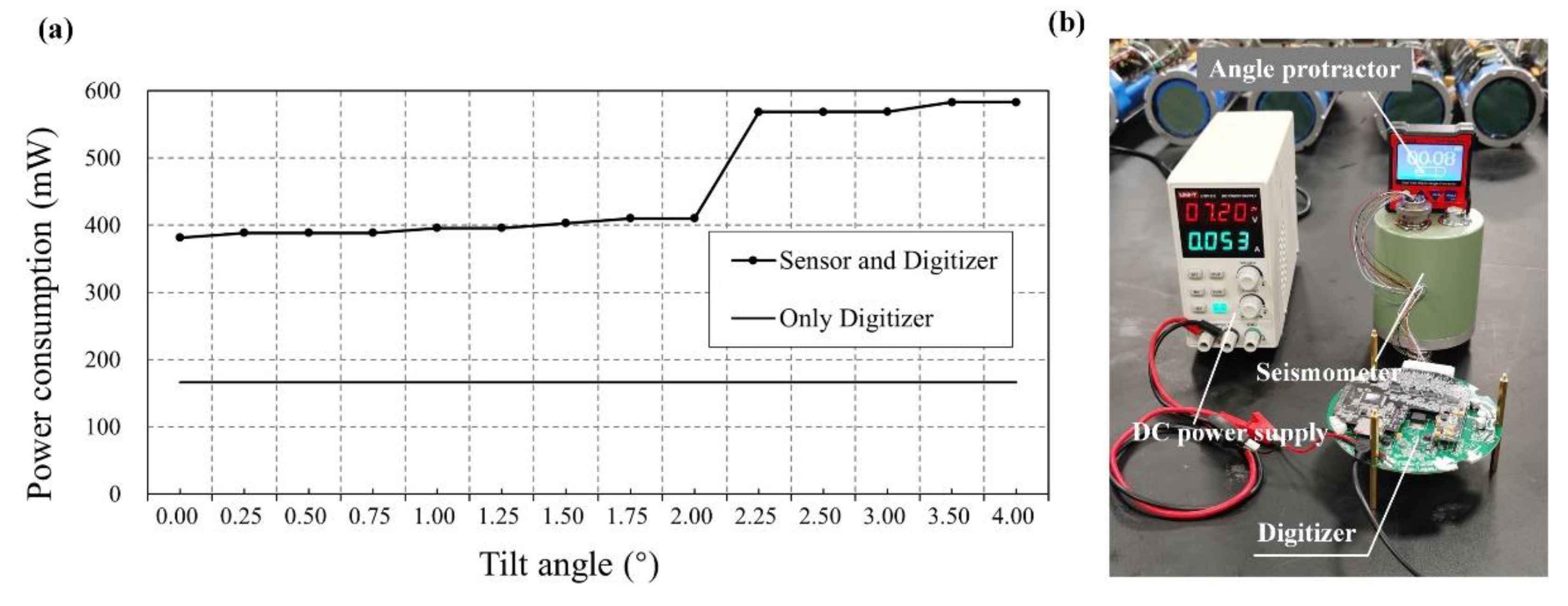

To evaluate the impact of an un-leveled seismometer on OBS performance, we conducted an experiment in the Lab. Five identical seismometers were placed on a platform with gradually increasing tilt angles. We compared the data quality and power consumption of the tilted seismometers to that without tilt using calculations of coherence and power consumption measurements (

Figure 5).

Figure 6 illustrates the coherence analysis of the three components between a tilted seismometer and a benchmark seismometer (S01). The analysis was based on one day of seismic data collected at each seismometer and was conducted using Welch's overlapped averaging periodogram method [

18]. The coherence between the recordings of the two seismometers is represented as a function of frequency, with the magnitude-squared coherence is defined as:

where

,

are the power spectral densities of the X and Y components, respectively, and

is the cross spectral density of the X and Y components.

The coherence between the first pair (S02 and S01) is the highest for all three components across the observational frequency band (

Figure 6a). As the tilt angle increases, the coherence of the other pairs decreases gradually. While the coherences of the Z and X components of S03 and S01 decrease only slightly (Fig. 6b), the decrease is more pronounced for S04 and S01 (Fig. 6c). The last pair (S05 and S01) shows the worst coherence in the entire frequency band of interest (Fig. 6d). This experiment demonstrates that tilting has a significant impact on data quality. If the tilt angle approaches or exceeds 2.5° (the tolerance of the seismometer), the recordings of the seismometer deteriorate. Therefore, the leveling system of OBS should achieve at least 2.5° leveling precision.

We also measured the instrument's power consumption for these tilted seismometers. The power consumption for S01 is 382 mW. It rises to 410 mW for S02 as the tilt angle is around 2°. However, as the tilt angle increases to 2.5°, the system's power consumption jumps to 554 mW, 45% higher than the leveled S01 (

Figure 7). Such an increase in power consumption of a tilted seismometer would significantly reduce the operating duration of OBS.

This experiment shows that the performance of the seismometer is very sensitive to tilting. To record high-quality seismograms and ensure a long operational duration, the seismometer needs to be precisely leveled. The leveling system of Pankun has a small tilt tolerance, and the leveling procedure will be activated if the control system detects the seismometer tilt exceeding 1.5°. This ensures that the seismometer is kept within the optimal tilt range, thus minimizing power consumption and maximizing data quality.

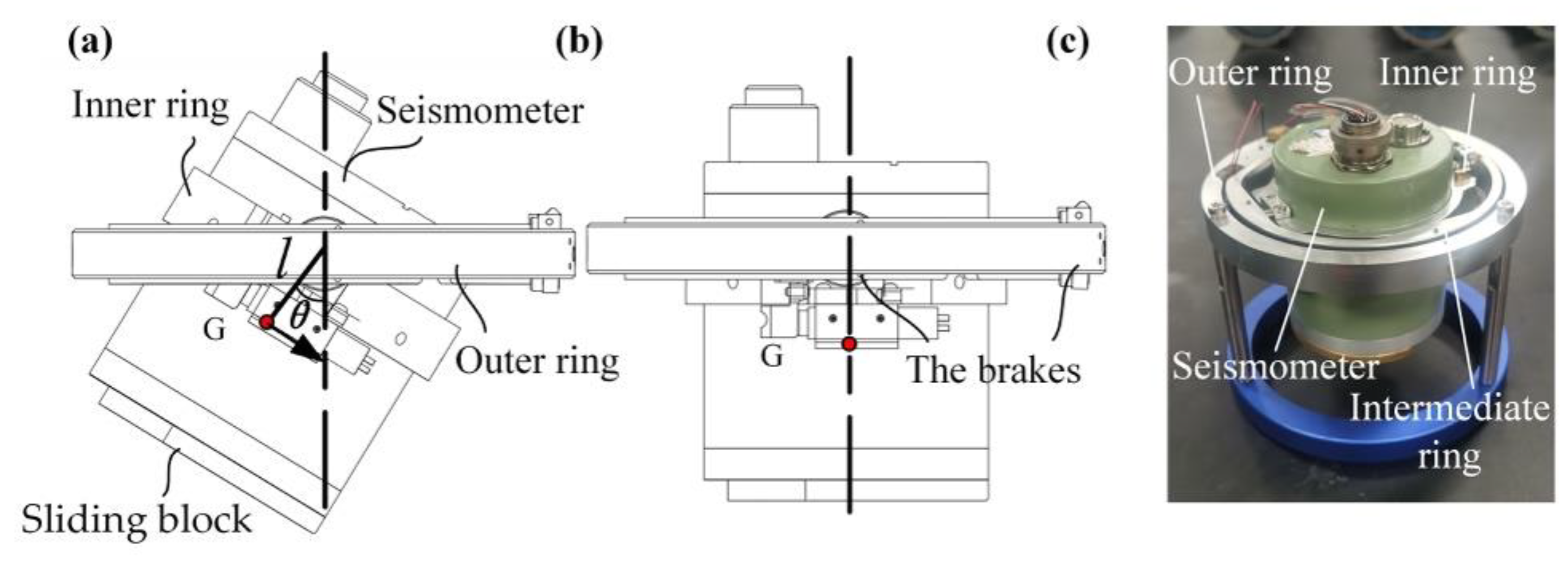

Figure 8 illustrates the leveling system designed for the Pankun OBS. It is a dual-axis device made of aluminum that allows for leveling from a maximum tilt angle of 34° in the vertical direction. The sensor module is very compact: the outer ring is 166 mm in diameter, and its overall height, including the seismometer, is 150 mm. A brake, driven by a small motor on the gimbal axis, can be unlocked to allow the seismometer to rotate passively under gravity and level itself. The brakes then lock the seismometer in place to secure its coupling with the pressure tube and sensor base. It is crucial to lock the leveling system before the operation, as any unrestricted movement during transportation and deployment can result in imperfections between the rings, brakes, and pressure tube, leading to nonlinear compliance and negatively impacting data quality. Two Maxon DCX10L brush DC motors drive the brakes, operating through a GPX10A 64:1 gear reducer. These motors are 12V with a nominal speed of 5990 rpm, stall torque of 4.36 mN·m, working current of 0.06 A, and stall current of 0.2 A.

The leveling system utilizes the self-gravity of the seismometer to achieve leveling. The sensor’s center of gravity is located at about its center, 30 mm below the gimbal axes. When the seismometer deviates from the vertical direction, a recovery torque of mg*l*sin(θ) will be generated to drive the seismometer to the level (where mg is the weight of the seismometer, l is the distance between the axis and the center of gravity position G, θ is the angle between the line from the center of gravity to the axis and the vertical direction). However, the gravity center of the leveling system does not coincide with that of the seismometer. As a result, the barycenter of this system is not located at the center of the seismometer. It is difficult to accomplish a perfect leveling based on the self-gravity of the seismometer alone. Although the tilts of the seismometer in most cases are still within the 2.5° as required for the seismometer works properly, it is not an ideal leveling. To tackle this difficulty, we attach an extra sliding block to the seismometer bottom. Its position is adjustable. By fine-tuning the extra block, the leveling system will achieve an accuracy of less than 0.5°.

After initial leveling, the seismometer's dip may enlarge over time due to its gradual sinking in sediments or the effects of bottom currents. To ensure high-quality seismograms and long operational duration, a re-leveling scheme is necessary. The control system constantly monitors the seismometer's status and, if the tilt angle exceeds 1.5°, initiates a re-leveling procedure. The brakes are unlocked, allowing the seismometer to rotate passively under gravity and level itself, and then locked again. This re-leveling process may need to be repeated several times throughout the deployment.

3.2. Data Logger

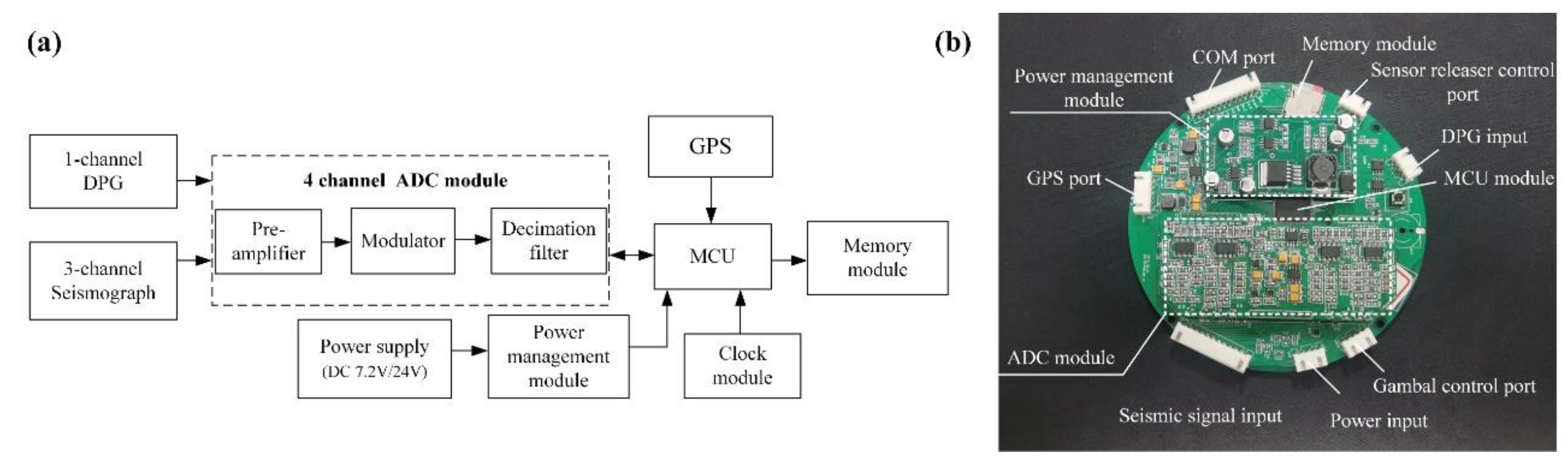

Compared to the counterparts in other passive-source OBS, Pankun's data logger is characterized by low-power consumption (only 166 mW at 7.2 V input voltage) and high precision. As shown in

Figure 9, it consists of four main modules: the Microcontroller Unit (MCU) and storage module, the analog-to-digital converter (ADC) module, the clock module, and the power management module.

The MCU and storage module is the core component of the data logger and is responsible for managing the overall system, as well as for storing seismic data in memory in the miniseed format. The MCU module is a 32-bit STM32 L4 series microcontroller from STMicroelectronics, which is based on a high-performance ARM Cortex-M4 RISC core. It has a micro-USB connector and a working frequency of up to 80 MHz. The data storage medium is a 32G micro-SD card, which is interfaced with the MCU through a software driver using a FAT-32 file system.

The ADC module is a 31-bit ADS1281 chip, which is widely used in high-accuracy instrumentation in energy exploration and seismic monitoring applications. It has a dynamic range of 130 dB at 250 Hz bandwidth and high accuracy of -122 dB (total harmonic distortion). The converter uses a 4-order delta-sigma modulator, which provides excellent low noise level and linear performance [

19]. The digital filter has a data rate that supports outputting 1 to 4000 samples per second, making it sufficient for seismic data acquisition applications. Additionally, the ADS consumes only 12 mW per channel, making it suitable for the low-power requirements of a digitizer. The photograph of the ADC module is shown in

Figure 9b.

The clock module is a circuit based on a temperature-compensated crystal oscillator (TCXO), which has a temperature range of -40°C to +85°C. It has a frequency stability of ±280 ppb (±0.28 ppm) and generates a stable clock frequency for the ADC and MCU through a phase-locked loop. Overall, the data logger has a low power consumption of only 166 mW at 7.2 V input voltage and high precision, making it suitable for use in passive-source OBS.

The power management module in Pankun OBS ensures a stable and continuous power supply to all components, including the seismometer, data logger, sensor releaser, and DPGs. Two types of batteries are used in Pankun: a lithium thionyl chloride battery pack (7.2 V) and a rechargeable Li-ion battery pack (24 V). The lithium thionyl chloride battery is chosen for its ability to provide low current and long-term discharge power for the digitizer, seismometer, and DPG. With a capacity of up to 650 Wh/kg at a low release rate, it consists of 60 DD-sized lithium thionyl chloride batteries with a single battery capacity of up to 35 Ah at 3.6V. On the other hand, the sensor releaser and brake operations require intermittent, high-current power, which is provided by the 18650 rechargeable lithium-ion (24 V) battery with an energy density of about 300 Wh/kg and consisting of 36 batteries. To generate the voltage required by different modules (12 V for the seismometer, 3.3 V for the MCU, 3.3 V and ± 2.5 V for the ADC, 24 V for the sensor releaser, 7.2 V for the DPG), a DC-DC power management module based on XL6019 is used. This module can work in the DC 5 V to 40 V input voltage with a conversion efficiency of up to 95%. The power management module is integrated into the data logger as shown in

Figure 9b.

3.3. Differential Pressure Gauge (DPG)

Earthquakes can also cause pressure changes in seawater. Pressure recordings have been an important complement to the seismometer’s recordings in various seismic applications [

20]. They recently have been used to remove the compliance noise to improve the signal-to-noise ratio for seismic recordings [

13]. Therefore, the pressure gauge has been a standard component for modern OBS. The pressure sensor in Pankun OBS is a deep-sea differential pressure gauge (DPG) developed by SUSTech OBS Lab based on the theory and method of Cox & Webb [

21] (

Figure 10).

The DPG, which is filled with silicone oil of viscosity 500 cSt and equipped with a pressure relief valve between the reference and outer chambers, is able to withstand pressures of over 66 MPa (as shown in

Figure 10b). The DPG can measure pressure signals across a wide frequency range, from 0.002 Hz to 2 Hz. It features a differential pressure sensor, with two chambers located at either end of the sensor. The outer chamber's pressure changes in response to external pressure and is insulated by a soft rubber film. A capillary leak, measuring 0.3 mm in diameter and 38 mm in length, connects the two chambers. This functions as a high pass filter [

22], with its angular frequency determined by the capillary tube's diameter and length, as well as the silicone oil's viscosity. However, accurately calibrating the DPG can be challenging due to changes in the silicone oil's viscosity with pressure and temperature [

19]. The typical power consumption of the DPG is 15 mW when using a 7.2 V input voltage, and it can be powered by the same supply as the seismometer.

3.4. The Pressure Vessels

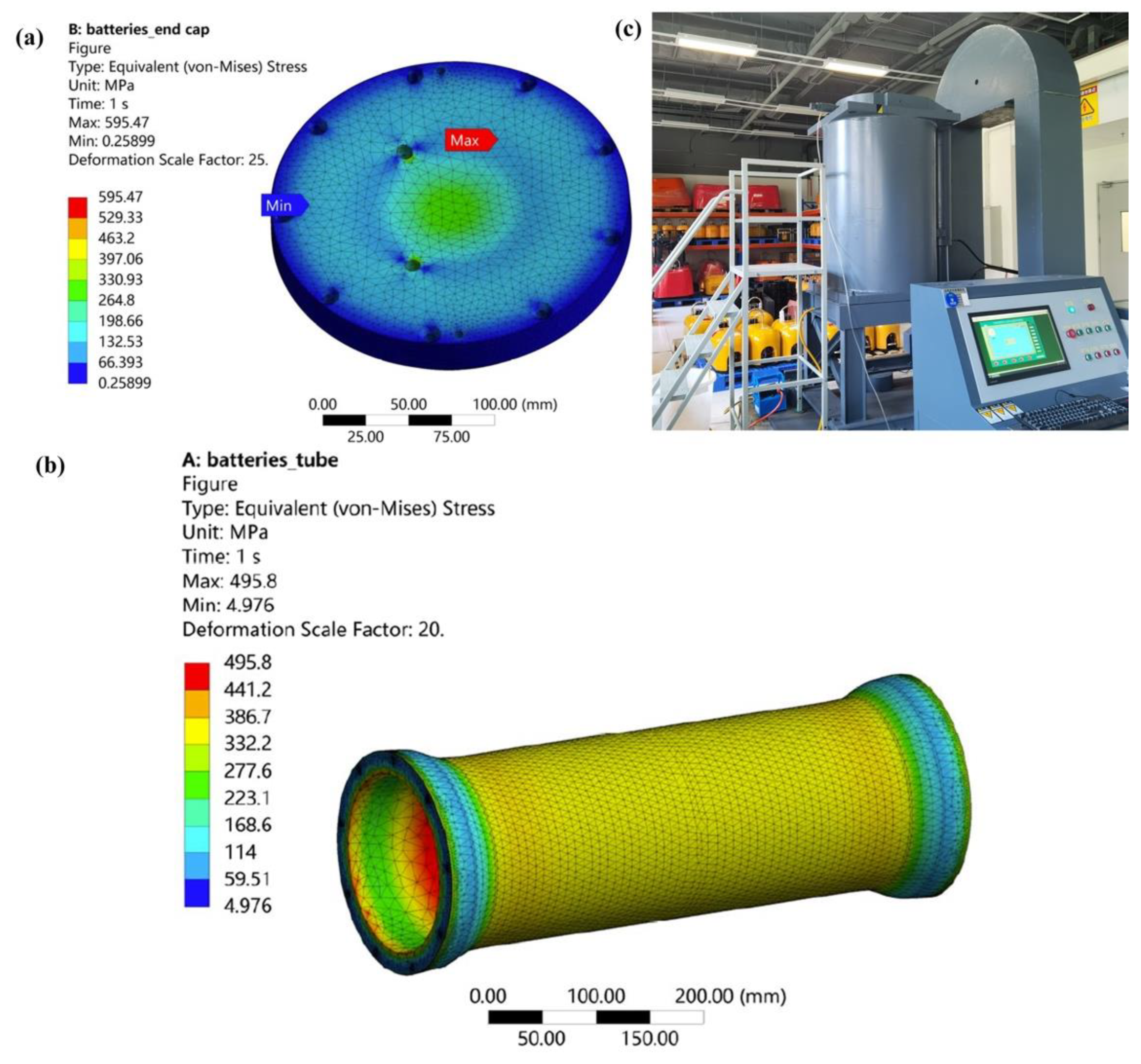

The Pankun OBS has two pressure vessels: one for the battery and the other for the sensor module. These vessels must withstand the harsh deep-sea conditions of high pressure and corrosion for the OBS's long-term operation on the seafloor. Therefore, the choice of material is crucial. Duplex stainless steel, 316 stainless steel, aluminum and titanium alloy are common materials used for making pressure vessels. The strength-to-weight ratio of stainless steel is low, which means more buoyancy materials are needed for the same strength of the structure. 7075 aluminum alloy is widely used as the pressure vessel material. The strength-weight ratio is close to that of titanium alloy, which is about twice that of stainless steel. It is a lightweight alloy, but sensitive to seawater corrosion. Because the connectors need to be installed on the end cap, if it is made of aluminum alloy, the fixed connector easily damages the anodic oxide layer, resulting in the loss of protection of the aluminum alloy structure. Taking all factors into consideration, we choose TC4 (Ti-6Al-4V) as the pressure vessel material, with a strength limit of 952 Mpa and a yield limit of 879 Mpa. The pressure vessels are designed with a safety factor of 1.8 and sealed with double sealing rings.

We simulate the pressure and analyze the strength of both vessels and the end caps using ANSYS software.

Figure 11a shows the finite element analysis results of the pressure vessel for the battery under the pressure of 66 Mpa. The two vessels have the same cylinder diameter and thickness.

To ensure that the vessels can properly function at the designed depths, we conducted a pressure test on the finished products in a pressure tank in our SUSTech OBS Lab (

Figure 11c). The static pressure of 66 Mpa was applied to the vessel for 4 hours.

Table 2 gives the detailed specifications for the pressure vessels.