Submitted:

21 April 2023

Posted:

23 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

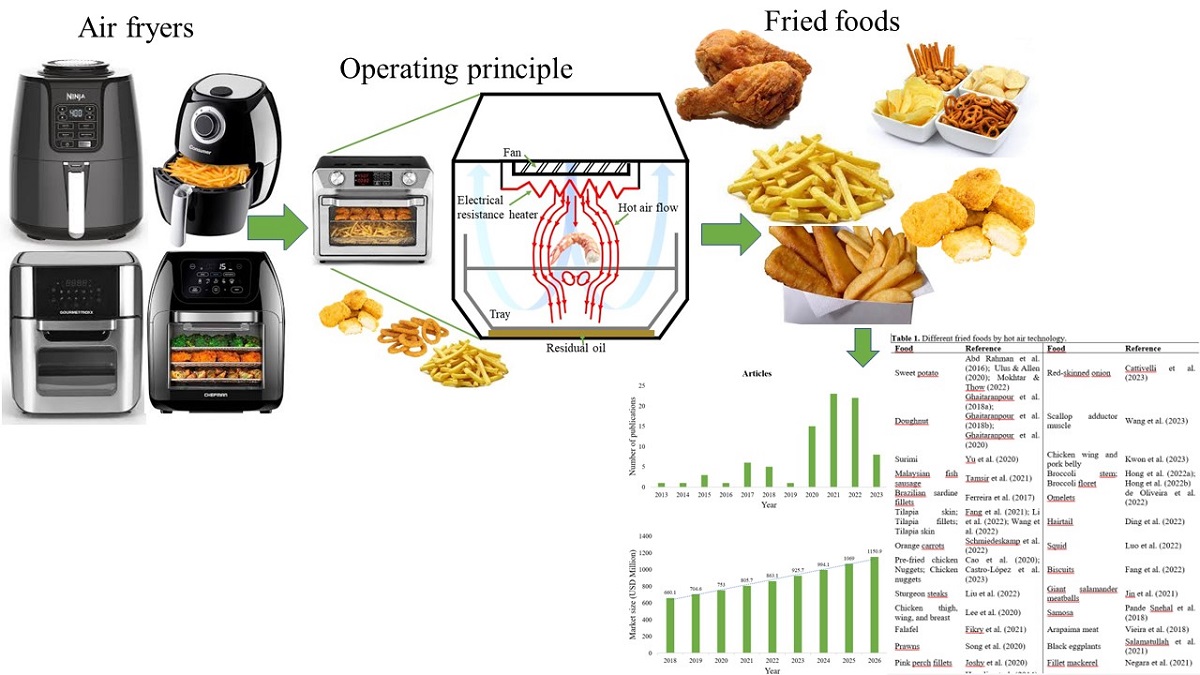

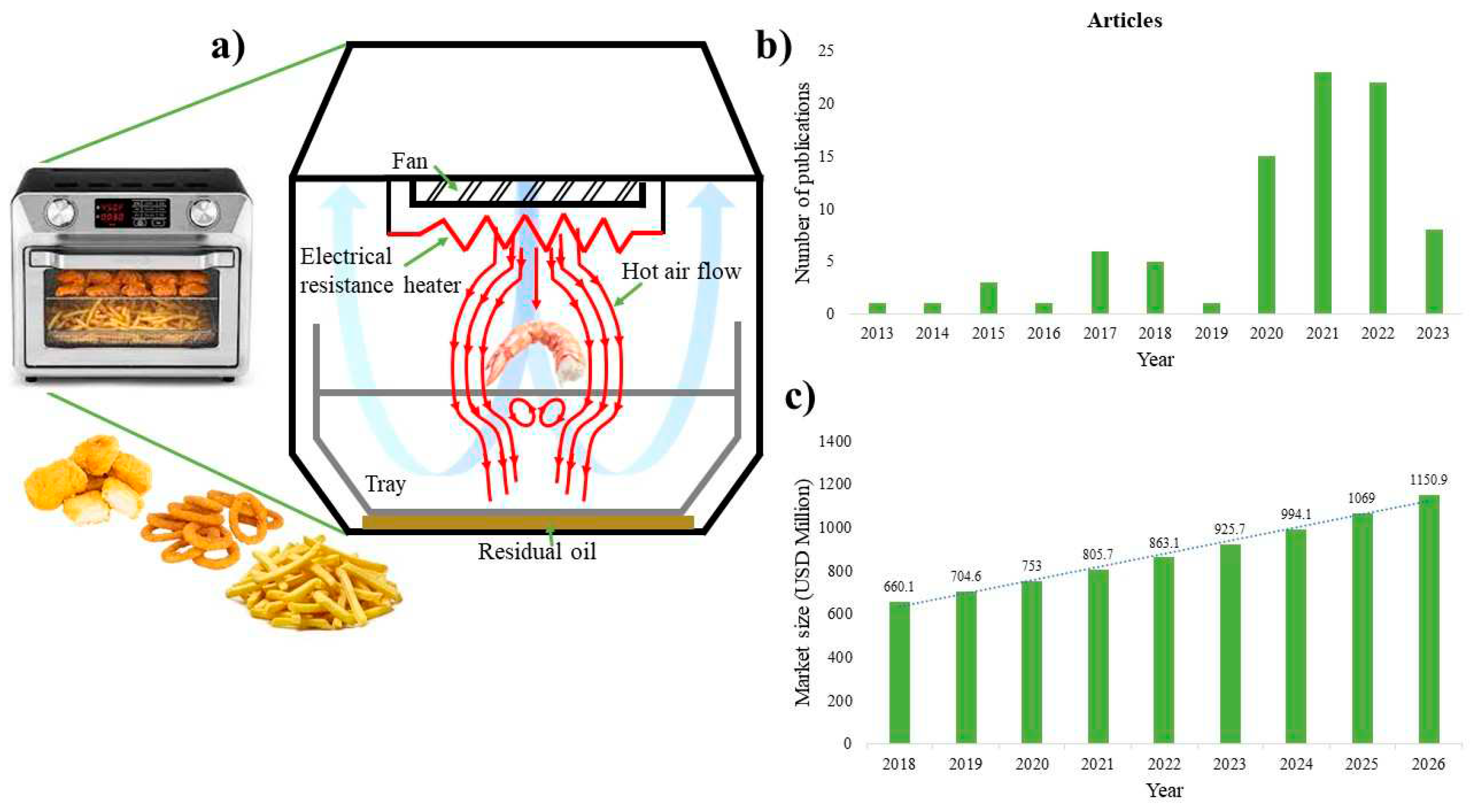

2. How Hot Air Frying Technology Works

3. Trends in Hot Air Frying Technology

4. Conclusions and Suggestions for Further Research

Conflicts of Interest

References

- Abd Rahman, N. A., Abdul Razak, S. Z., Lokmanalhakim, L. A., Taip, F. S., & Mustapa Kamal, S. M. (2016). Response surface optimization for hot air-frying technique and its effects on the quality of sweet potato snack. Journal of Food Process Engineering, 40(4). [CrossRef]

- Andrés, A., Arguelles, Á., Castelló, M. L., & Heredia, A. (2013). Mass transfer and volume changes in french fries during air frying. Food and Bioprocess Technology, 6(8), 1917–1924. [CrossRef]

- Bachir, N., Haddarah, A., Sepulcre, F., & Pujola, M. (2023). Study the interaction of amino acids, sugars, thermal treatment and cooking technique on the formation of acrylamide in potato models. Food Chemistry, 408, 135235. [CrossRef]

- Basuny, A. M. M., & Oatibi, H. H. A. (2016). Effect of a novel technology (air and vacuum frying) on sensory evaluation and acrylamide generation in fried potato chips. Banat’s Journal of Biotechnology, 7(14), 101–112. [CrossRef]

- Cao, Y., Wu, G., Zhang, F., Xu, L., Jin, Q., Huang, J., & Wang, X. (2020). A comparative study of physicochemical and flavor characteristics of chicken nuggets during air frying and deep frying. Journal of the American Oil Chemists’ Society, 97(8), 901–913. [CrossRef]

- Castro-López, R., Mba, O. I., Gómez-Salazar, J. A., Cerón-García, A., Ngadi, M. O., & Sosa-Morales, M. E. (2023). Evaluation of chicken nuggets during air frying and deep-fat frying at different temperatures. International Journal of Gastronomy and Food Science, 31, 100631. [CrossRef]

- Cattivelli, A., Di Lorenzo, A., Conte, A., Martini, S., & Tagliazucchi, D. (2023). Red-skinned onion phenolic compounds stability and bioaccessibility: A comparative study between deep-frying and air-frying. Journal of Food Composition and Analysis, 115, 105024. [CrossRef]

- Ciccone, M., Chambers, D., Chambers IV, E., & Talavera, M. (2020). Determining which cooking method provides the best sensory differentiation of potatoes. Foods, 9(4), 451-466. [CrossRef]

- de Oliveira, V. S., Chávez, D. W. H., Paiva, P. R. F., Gamallo, O. D., Castro, R. N., Sawaya, A. C. H. F., ... & Saldanha, T. (2022). Parsley (Petroselinum crispum Mill.): A source of bioactive compounds as a domestic strategy to minimize cholesterol oxidation during the thermal preparation of omelets. Food Research International, 156, 111199. [CrossRef]

- Dehghannya, J., & Ngadi, M. (2021). Recent advances in microstructure characterization of fried foods: Different frying techniques and process modeling. Trends in Food Science & Technology, 116, 786–801. [CrossRef]

- Devi, S., Zhang, M., Ju, R., & Bhandari, B. (2021). Recent development of innovative methods for efficient frying technology. Critical Reviews in Food Science and Nutrition, 61(22), 3709–3724. [CrossRef]

- Ding, Y., Zhou, T., Liao, Y., Lin, H., Deng, S., & Zhang, B. (2022). Comparative Studies on the Physicochemical and Volatile Flavour Properties of Traditional Deep Fried and Circulating-Air Fried Hairtail (Trichiurus lepturus). Foods, 11(17), 2710. [CrossRef]

- Fang, M., Huang, G. J., & Sung, W. C. (2021). Mass transfer and texture characteristics of fish skin during deep-fat frying, electrostatic frying, air frying and vacuum frying. LWT, 137, 110494. [CrossRef]

- Fang, M., Ting, Y. S., & Sung, W. C. (2022). Effects of Sodium Alginate, Pectin and Chitosan Addition on the Physicochemical Properties, Acrylamide Formation and Hydroxymethylfurfural Generation of Air Fried Biscuits. Polymers, 14(19), 3961. [CrossRef]

- Ferreira, F. S., Sampaio, G. R., Keller, L. M., Sawaya, A. C. H. F., Chávez, D. W. H., Torres, E. A. F. S., & Saldanha, T. (2017). Impact of air frying on cholesterol and fatty acids oxidation in sardines: Protective effects of aromatic herbs. Journal of Food Science, 82(12), 2823–2831. [CrossRef]

- Fikry, M., Khalifa, I., Sami, R., Khojah, E., Ismail, K. A., & Dabbour, M. (2021). Optimization of the frying temperature and time for preparation of healthy falafel using air frying technology. Foods, 10(11), 2567–2582. [CrossRef]

- Ghaitaranpour, A., Koocheki, A., Mohebbi, M., & Ngadi, M. O. (2018a). Effect of deep fat and hot air frying on doughnuts physical properties and kinetic of crust formation. Journal of Cereal Science, 83, 25–31. [CrossRef]

- Ghaitaranpour, A., Mohebbi, M., & Koocheki, A. (2018b). Characterizing the cellular structure of air and deep fat fried doughnut using image analysis techniques. Journal of Food Engineering, 237, 231–239. [CrossRef]

- Ghaitaranpour, A., Mohebbi, M., Koocheki, A., & Ngadi, M. O. (2020). An agent-based coupled heat and water transfer model for air frying of doughnut as a heterogeneous multiscale porous material. Innovative Food Science & Emerging Technologies, 61, 102335. [CrossRef]

- Giovanelli, G., Torri, L., Sinelli, N., & Buratti, S. (2017). Comparative study of physico-chemical and sensory characteristics of French fries prepared from frozen potatoes using different cooking systems. European Food Research and Technology, 243(9), 1619–1631. [CrossRef]

- Gouyo, T., Mestres, C., Maraval, I., Fontez, B., Hofleitner, C., & Bohuon, P. (2020). Assessment of acoustic-mechanical measurements for texture of French fries: Comparison of deep-fat frying and air frying. Food Research International, 131, 108947. [CrossRef]

- Gouyo, T., Rondet, É., Mestres, C., Hofleitner, C., & Bohuon, P. (2021). Microstructure analysis of crust during deep-fat or hot-air frying to understand French fry texture. Journal of Food Engineering, 298, 110484. [CrossRef]

- Haddarah, A., Naim, E., Dankar, I., Sepulcre, F., Pujolà, M., & Chkeir, M. (2021). The effect of borage, ginger and fennel extracts on acrylamide formation in French fries in deep and electric air frying. Food Chemistry, 350, 129060. [CrossRef]

- Heredia, A., Castelló, M. L., Argüelles, A., & Andrés, A. (2014). Evolution of mechanical and optical properties of French fries obtained by hot air-frying. LWT, 57(2), 755–760. [CrossRef]

- Hong, S. J., Jeong, H., Yoon, S., Jo, S. M., Lee, Y., Park, S. S., & Shin, E. C. (2022a). A comprehensive study for taste and odor compounds using electronic tongue and nose in broccoli stem with different thermal processing. Food Science and Biotechnology, 31(2), 191-201. [CrossRef]

- Hong, S. J., Yoon, S., Lee, J., Jo, S. M., Jeong, H., Lee, Y., ... & Shin, E. C. (2022b). A comprehensive study for taste and odor characteristics using electronic sensors in broccoli floret with different methods of thermal processing. Journal of Food Processing and Preservation, 46(4), e16435. [CrossRef]

- Jin, W., Pei, J., Chen, X., Geng, J., Chen, D., & Gao, R. (2021). Influence of frying methods on quality characteristics and volatile flavor compounds of giant salamander (Andrias Davidianus) meatballs. Journal of Food Quality, 2021, 1-10. [CrossRef]

- Joshy, C. G., Ratheesh, G., Ninan, G., Ashok Kumar, K., & Ravishankar, C. N. (2020). Optimizing air-frying process conditions for the development of healthy fish snack using response surface methodology under correlated observations. Journal of Food Science and Technology, 57(7), 2651–2658. [CrossRef]

- Kwon, J., Kim, I., Moon, B., Lee, K. W., Jung, M., & Lee, J. (2023). The effects of different cooking methods and spices on the formation of 11 HCAs in chicken wing and pork belly. Food Control, 147, 109572. [CrossRef]

- Lee, J. S., Han, J. W., Jung, M., Lee, K. W., & Chung, M. S. (2020). Effects of thawing and frying methods on the formation of acrylamide and polycyclic aromatic hydrocarbons in chicken meat. Foods, 9(5), 573–586. [CrossRef]

- Li, R., Sun, Z., Zhao, Y., Li, L., Yang, X., Chen, S., ... & Wang, Y. (2022). Effect of different thermal processing methods on water-soluble taste substances of tilapia fillets. Journal of Food Composition and Analysis, 106, 104298. [CrossRef]

- Liu, L., Huang, P., Xie, W., Wang, J., Li, Y., Wang, H., Xu, H., Bai, F., Zhou, X., Gao, R., & Zhao, Y. (2022). Effect of air fryer frying temperature on the quality attributes of sturgeon steak and comparison of its performance with traditional deep fat frying. Food Science & Nutrition, 10(2), 342–353. [CrossRef]

- Luo, X., Hu, S., Xu, X., Du, M., Wu, C., Dong, L., & Wang, Z. (2022). Improving air-fried squid quality using high internal phase emulsion coating. Journal of Food Measurement and Characterization, 16(5), 3844-3854. [CrossRef]

- Mokhtar, W. M. F. W., & Thow, Z. Y. (2022). Effect of osmotic dehydration as a pre-treatment on air fried sweet potato (Ipomoea batatas) chips. Journal Of Agrobiotechnology, 13(1S), 64-73. [CrossRef]

- Negara, B. F. S. P., Lee, M. J., Tirtawijaya, G., Cho, W. H., Sohn, J. H., Kim, J. S., & Choi, J. S. (2021). Application of deep, vacuum, and air frying methods to fry chub mackerel (Scomber japonicus). Processes, 9(7), 1225–1239. [CrossRef]

- Pande Snehal, D., Deo Shrutika, K., Bhope Pritish, S., & Pande Sayali, D. (2018). Comparative study of deep fat fried samosa and oxyair fried samosa. International Journal of Science, Engineering and Management, 3(4), 146–148.

- Salamatullah, A. M., Ahmed, M. A., Alkaltham, M. S., Hayat, K., Aloumi, N. S., Al-Dossari, A. M., Al-Harbi, L. N., & Arzoo, S. (2021). Effect of air-frying on the bioactive properties of eggplant (Solanum melongena L.). Processes, 9(3), 435–446. [CrossRef]

- Sansano, M., Juan-Borrás, M., Escriche, I., Andrés, A., & Heredia, A. (2015). Effect of pretreatments and air-frying, a novel technology, on acrylamide generation in fried potatoes. Journal of Food Science, 80(5), T1120–T1128. [CrossRef]

- Santos, C. S. P., Cunha, S. C., & Casal, S. (2017). Deep or air frying? A comparative study with different vegetable oils. European Journal of Lipid Science and Technology, 119(6). [CrossRef]

- Schmiedeskamp, A., Schreiner, M., & Baldermann, S. (2022). Impact of cultivar selection and thermal processing by air drying, air frying, and deep frying on the carotenoid content and stability and antioxidant capacity in carrots (Daucus carota L.). Journal of Agricultural and Food Chemistry, 70(5), 1629–1639. [CrossRef]

- Scopus. (2023). Retrieved February 11, 2023, from https://www.scopus.com/search/form.uri?display=basic#basic.

- Shaker, M. A. (2014). Air frying a new technique for produce of healthy fried potato Strips. Journal of Food and Nutrition Sciences, 2(4), 200–206. [CrossRef]

- Song, G., Li, L., Wang, H., Zhang, M., Yu, X., Wang, J., Xue, J., & Shen, Q. (2020). Real-time assessing the lipid oxidation of prawn (Litopenaeus vannamei) during air-frying by iKnife coupling rapid evaporative ionization mass spectrometry. Food Control, 111, 107066. [CrossRef]

- Stratview Research. (2023). Global air fryer market, dynamics, trends, and market analysis. Retrieved February 12, 2023, from https://www.stratviewresearch.com/1864/air-fryer-market.html.

- Tamsir, M. M., Shazini Ramli, N., Nor-Khaizura, M. A. R., Shukri, R., & Ismail-Fitry, M. R. (2021). Comparison of boiling, steaming, air frying, deep-frying, microwaving and oven-cooking on quality characteristics of Keropok lekor (Malaysian fish sausage). Malaysian Applied Biology, 50(3), 77–85.

- Teruel, M. del R., Gordon, M., Linares, M. B., Garrido, M. D., Ahromrit, A., & Niranjan, K. (2015). A comparative study of the characteristics of french fries produced by deep fat frying and air frying. Journal of Food Science, 80(2), E349–E358. [CrossRef]

- Tian, J., Chen, S., Shi, J., Chen, J., Liu, D., Cai, Y., Ogawa, Y., & Ye, X. (2017). Microstructure and digestibility of potato strips produced by conventional frying and air-frying: An in vitro study. Food Structure, 14, 30–35. [CrossRef]

- Ulus, H., & Allen, J. (2020). Nutrient degradation in baked or air-fried sweet potato chips. Current Developments in Nutrition, 4(2), 783. [CrossRef]

- Verma, V., Singh, V., Chauhan, O. P., & Yadav, N. (2023). Comparative evaluation of conventional and advanced frying methods on hydroxymethylfurfural and acrylamide formation in French fries. Innovative Food Science & Emerging Technologies, 83, 103233. [CrossRef]

- Vieira, E. C. S., Mársico, E. T., Conte-Junior, C. A., Damiani, C., Canto, A. C. V. da C. S., Monteiro, M. L. G., & Silva, F. A. da. (2018). Effects of different frying techniques on the color, fatty acid profile, and lipid oxidation of Arapaima gigas. Journal of Food Processing and Preservation, 42(11), e13820. [CrossRef]

- Wang, L., Chen, W., Zhou, R., Ren, Y., Wang, K., Jiang, N., & Gao, R. (2022). Physicochemical and sensory properties of a tilapia skin-based ready-to-eat snack prepared by infrared drying and air frying. Applied Food Research, 2(2), 100155. [CrossRef]

- Wang, Y., Wu, X., McClements, D. J., Chen, L., Miao, M., & Jin, Z. (2021). Effect of new frying technology on starchy food quality. Foods, 10(8), 1852–1871. [CrossRef]

- Wang, Z. Y., Wu, Z. X., Zhao, G. H., Li, D. Y., Liu, Y. X., Qin, L., ... & Zhou, D. Y. (2023). Effect of air frying and baking on physicochemical properties and digestive properties of scallop (Patinopecten yessoensis) adductor muscle. Food Bioscience, 52, 102460. [CrossRef]

- Yu, X., Li, L., Xue, J., Wang, J., Song, G., Zhang, Y., & Shen, Q. (2020). Effect of air-frying conditions on the quality attributes and lipidomic characteristics of surimi during processing. Innovative Food Science and Emerging Technologies, 60, 102305. [CrossRef]

- Zaghi, A. N., Barbalho, S. M., Guiguer, E. L., & Otoboni, A. M. (2019). Frying process: From conventional to air frying technology. Food Reviews International, 35(8), 763–777. [CrossRef]

| Food | Reference | Food | Reference |

|---|---|---|---|

| Sweet potato | Abd Rahman et al. (2016); Ulus & Allen (2020); Mokhtar & Thow (2022) | Red-skinned onion | Cattivelli et al. (2023) |

| Doughnut | Ghaitaranpour et al. (2018a, 2018b); Ghaitaranpour et al. (2020) | Scallop adductor muscle | Wang et al. (2023) |

| Surimi | Yu et al. (2020) | Chicken wing and pork belly | Kwon et al. (2023) |

| Malaysian fish sausage | Tamsir et al. (2021) | Broccoli stem; Broccoli floret | Hong et al. (2022a); Hong et al. (2022b) |

| Brazilian sardine fillets | Ferreira et al. (2017) | Omelets | de Oliveira et al. (2022) |

| Tilapia skin; Tilapia fillets; Tilapia skin | Fang et al. (2021); Li et al. (2022); Wang et al. (2022) | Hairtail | Ding et al. (2022) |

| Orange carrots | Schmiedeskamp et al. (2022) | Squid | Luo et al. (2022) |

| Pre-fried chicken Nuggets; Chicken nuggets | Cao et al. (2020); Castro-López et al. (2023) | Biscuits | Fang et al. (2022) |

| Sturgeon steaks | Liu et al. (2022) | Giant salamander meatballs | Jin et al. (2021) |

| Chicken thigh, wing, and breast | Lee et al. (2020) | Samosa | Pande Snehal et al. (2018) |

| Falafel | Fikry et al. (2021) | Arapaima meat | Vieira et al. (2018) |

| Prawns | Song et al. (2020) | Black eggplants | Salamatullah et al. (2021) |

| Pink perch fillets | Joshy et al. (2020) | Fillet mackerel | Negara et al. (2021) |

| Potatoes | Heredia et al. (2014); Teruel et al. (2015); Gouyo et al. (2020); Tian et al. (2017); Shaker (2014); Basuny & Oatibi (2016); Sansano et al. (2015); Andrés et al. (2013) | Potatoes | Giovanelli et al. (2017); Haddarah et al. (2021); Gouyo et al. (2021); Ciccone et al. (2020); Santos et al. (2017); Verma et al. (2023); Bachir et al. (2023) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).