Submitted:

24 April 2023

Posted:

24 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methods

2.1. Plasmid and strain

2.2. Determination of dry cell weight

2.3. Quantification of total proteins and RBD

2.4. Medium composition for flask cultures and bioreactor fermentations

2.5. Inoculum preparation

2.6. Cultivation in Erlenmeyer flask

2.7. Fermentations in stirred-tank bioreactor

2.8. Purification of recombinant RBD and quality control

3. Results

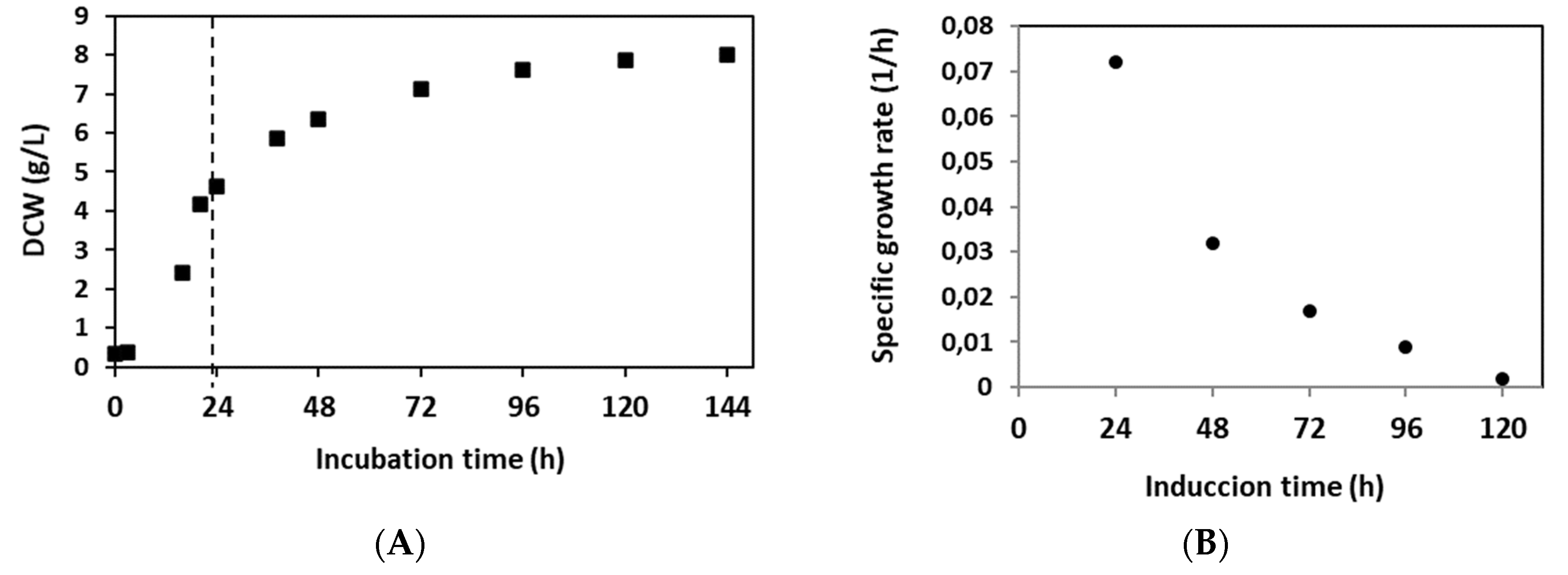

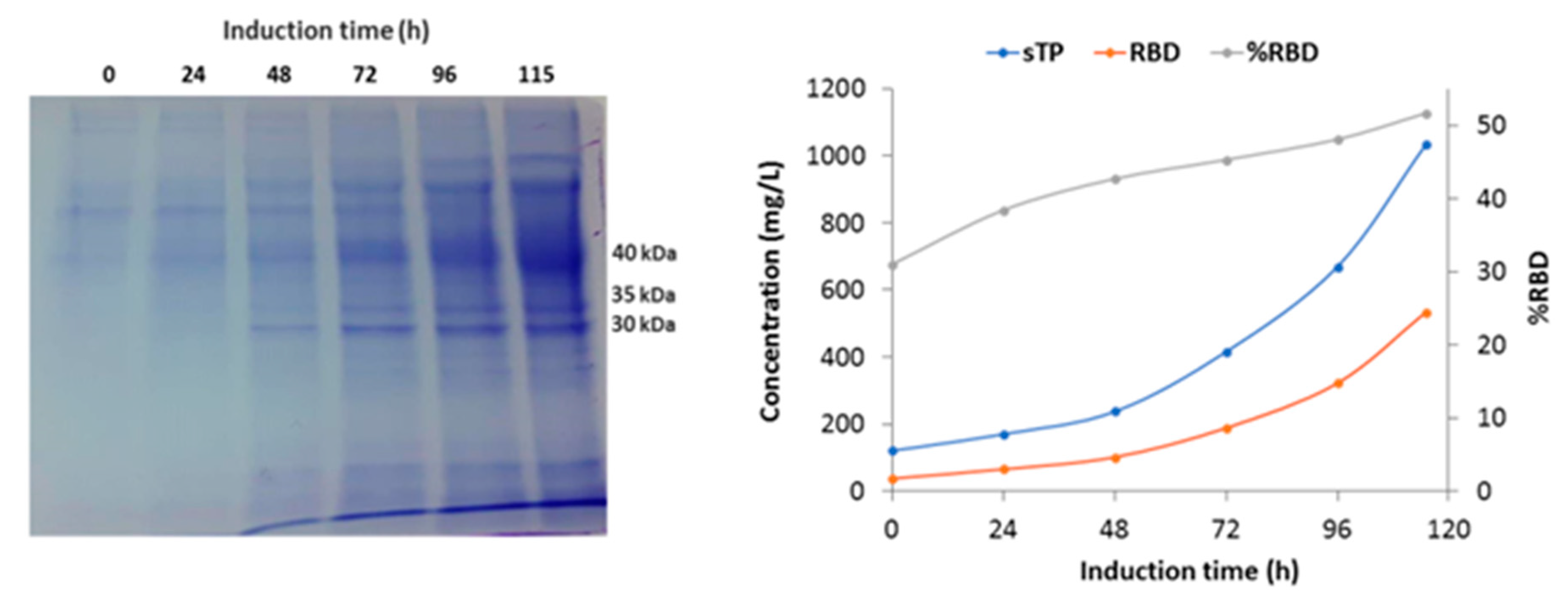

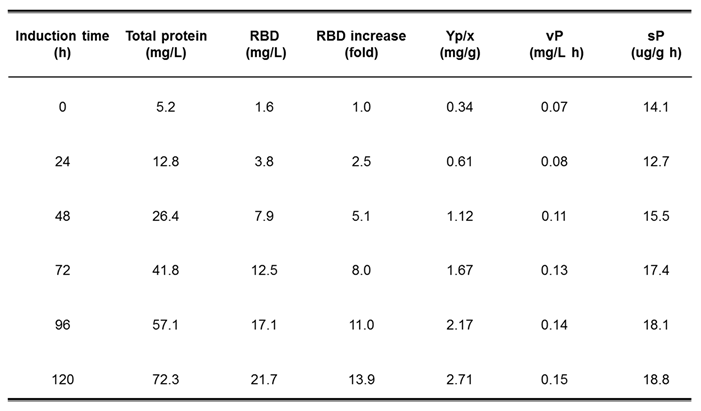

3.1. Growth kinetics and RBD expression at flask level

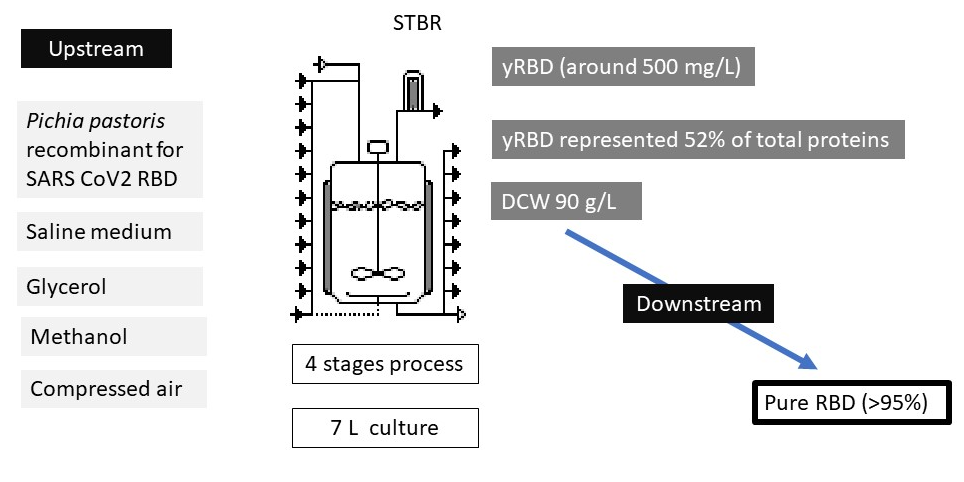

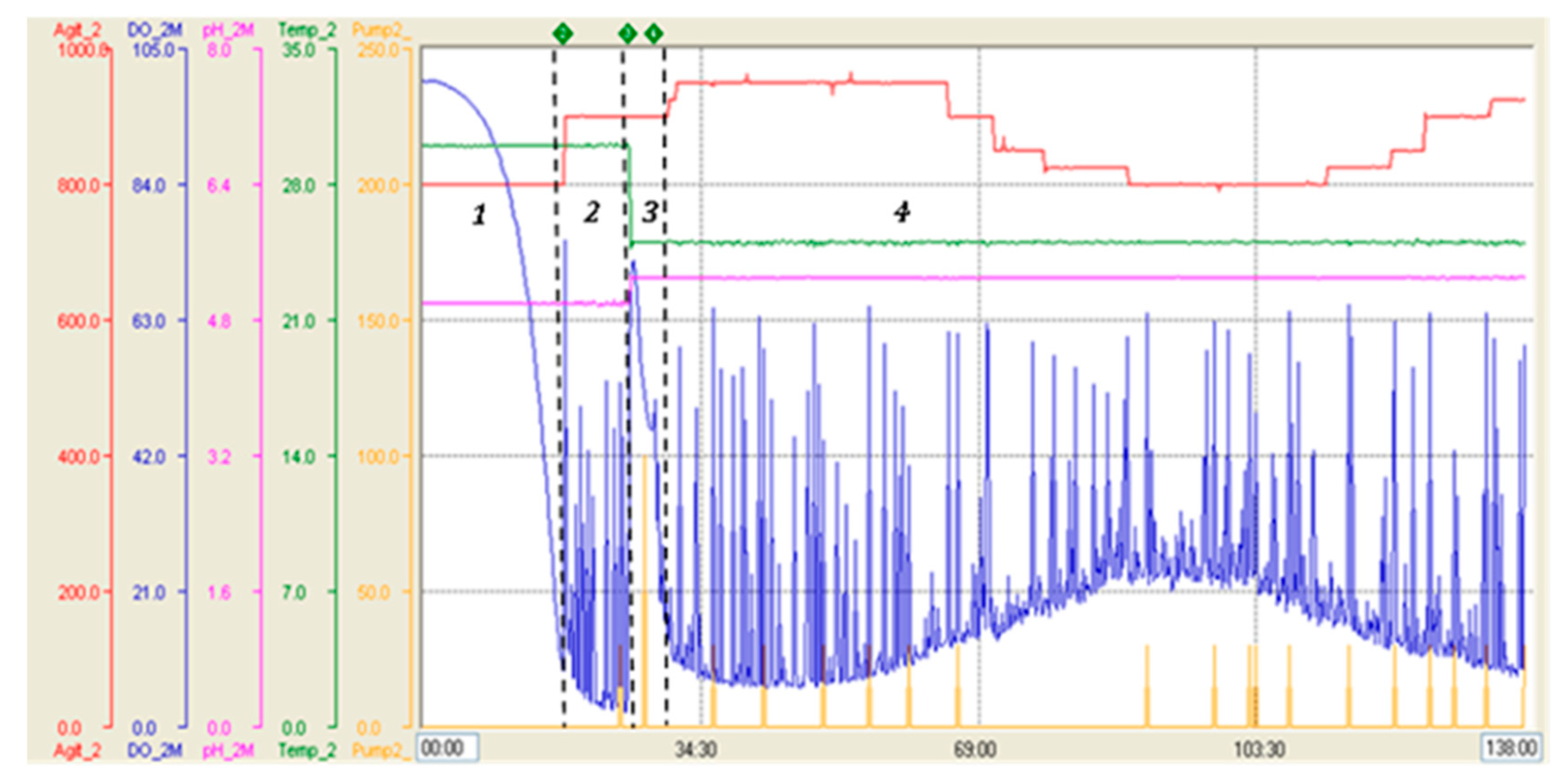

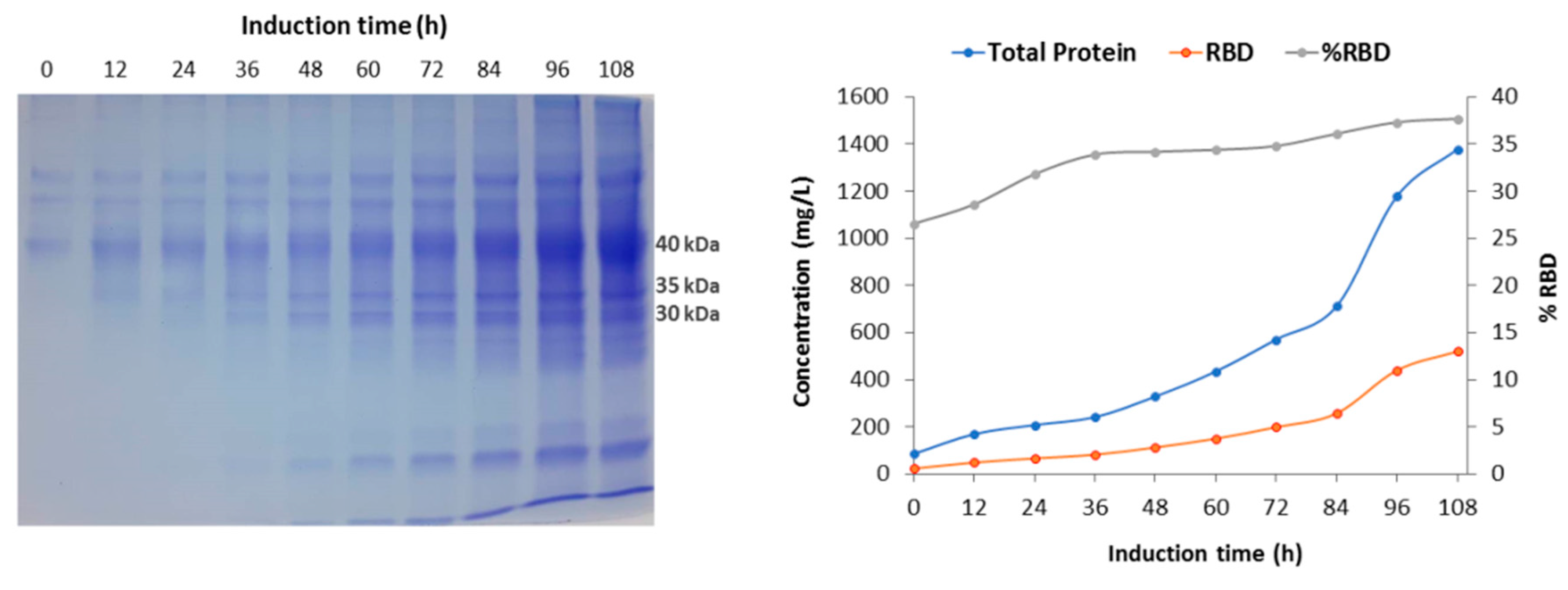

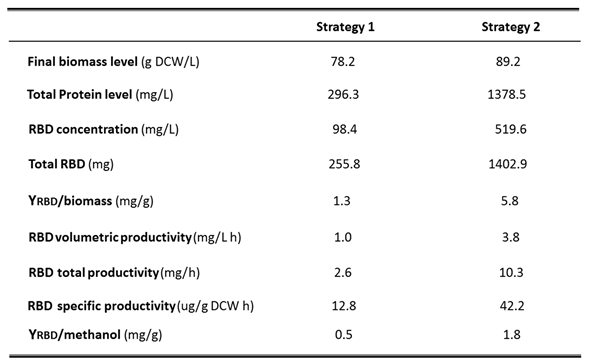

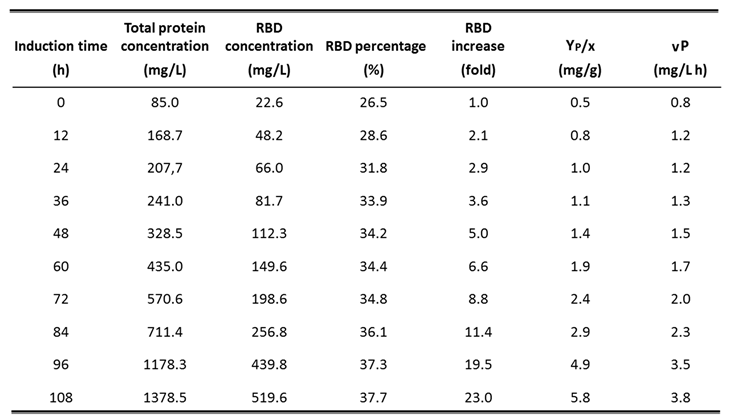

3.2. Production of recombinant RBD in 7-L stirred bioreactor

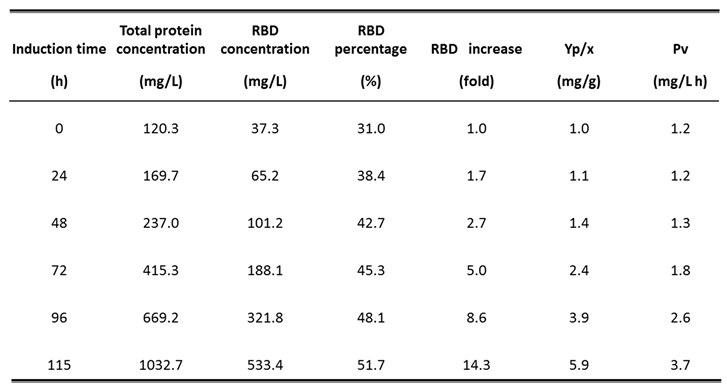

3.3. Scale-up of recombinant RBD production in a 14-L stirred tank bioreactor

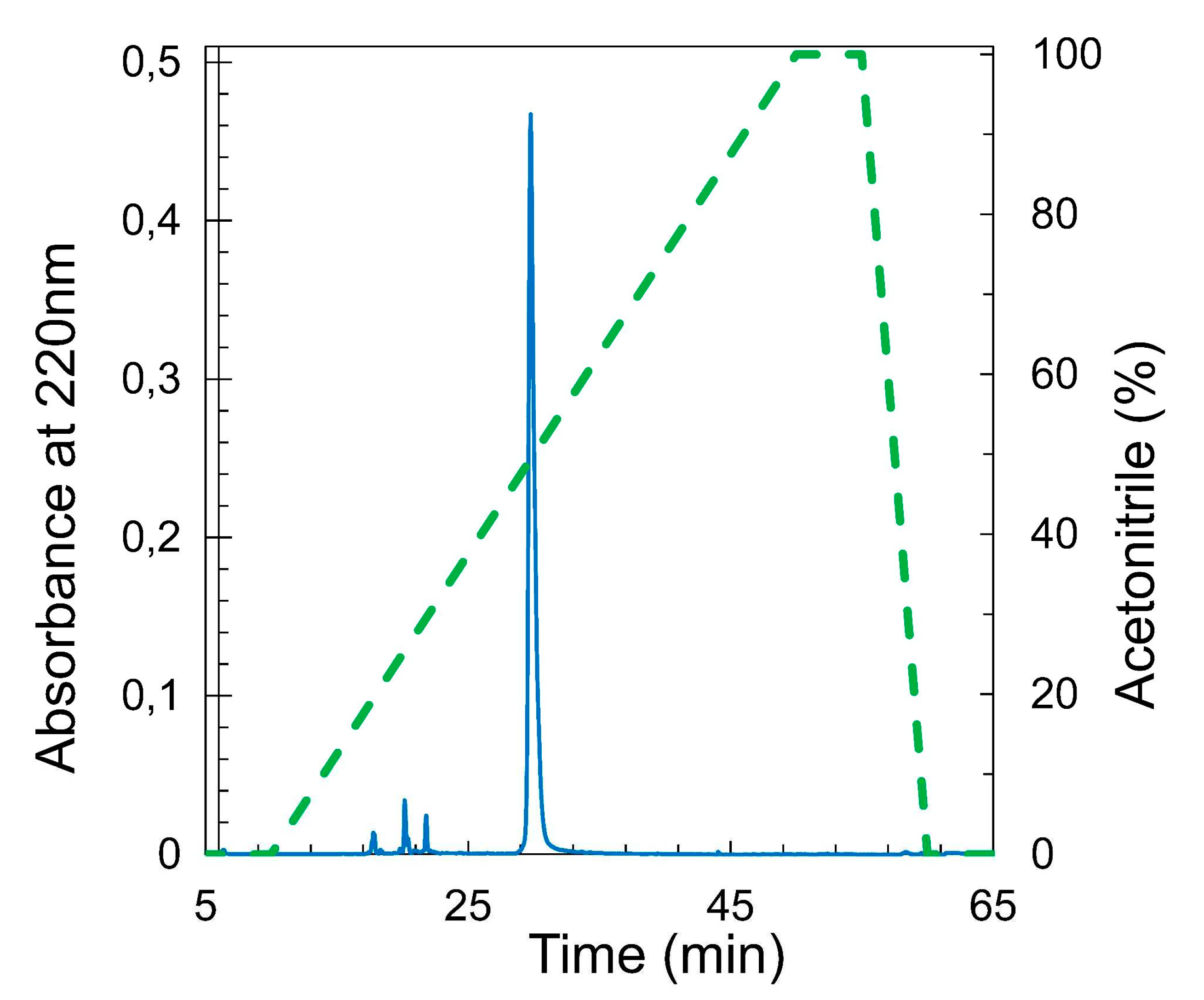

3.4. Purification and analysis of RBD

4. Discussion

5. Conclusion

Author Contributions

Funding

Data availability

Acknowledgements

Declaration of Competing Interest

References

- Dennehy, J.J.; Gupta, R.K.; Hanage, W.P.; Johnson, M.C.; Peacock, T.P. Where is the next SARS-CoV-2 variant of concern? Lancet 2022, 399, 1938–1939. [Google Scholar] [CrossRef] [PubMed]

- Forster, P.; Forster, L.; Renfrew, C.; Forster, M. Phylogenetic Network Analysis of SARS-CoV-2 Genomes. Proceedings of the National Academy of Sciences 2020, 117, 9241–9243. [Google Scholar] [CrossRef]

- Wang, X.-M.; Mannan, R.; Xiao, L.; Abdulfatah, E.; Qiao, Y.; Farver, C.; Myers, J.L.; Zelenka-Wang, S.; McMurry, L.; Su, F.; et al. Characterization of SARS-CoV-2 and Host Entry Factors Distribution in a COVID-19 Autopsy Series. Communications Medicine 2021, 1. [Google Scholar] [CrossRef] [PubMed]

- Arimori, T.; Takagi, J. Structure of SARS-CoV-2 Spike Receptor-Binding Domain Complexed with High Affinity ACE2 Mutant 3N39 2020.

- Xu, Z.P.; Liu, K.F.; Han, P.; Qi, J.X. Structure of SARS-CoV-2 Spike Receptor-Binding Domain Complexed with Its Receptor Equine ACE2 2022.

- Wang, X.; Lan, J.; Ge, J.; Yu, J.; Shan, S. Crystal Structure of SARS-CoV-2 Spike Receptor-Binding Domain Bound with ACE2 2020.

- Lan, J.; Ge, J.; Yu, J.; Shan, S.; Zhou, H.; Fan, S.; Zhang, Q.; Shi, X.; Wang, Q.; Zhang, L.; et al. Structure of the SARS-CoV-2 Spike Receptor-Binding Domain Bound to the ACE2 Receptor. Nature 2020, 581, 215–220. [Google Scholar] [CrossRef]

- Shamsi, A.; Mohammad, T.; Anwar, S.; Amani, S.; Khan, M.S.; Husain, F.M.; Rehman, M.T.; Islam, A.; Hassan, M.I. Potential Drug Targets of SARS-CoV-2: From Genomics to Therapeutics. International Journal of Biological Macromolecules 2021, 177, 1–9. [Google Scholar] [CrossRef]

- Ju, B.; Zhang, Q.; Ge, J.; Wang, R.; Sun, J.; Ge, X.; Yu, J.; Shan, S.; Zhou, B.; Song, S.; et al. Human neutralizing antibodies elicited by SARS-CoV-2 infection. Nature 2020, 584, 115–119. [Google Scholar] [CrossRef]

- Greaney, A.J.; Starr, T.N.; Barnes, C.O.; Weisblum, Y.; Schmidt, F.; Caskey, M.; Gaebler, C.; Cho, A.; Agudelo, M.; Finkin, S.; et al. Mapping mutations to the SARS-CoV-2 RBD that escape binding by different classes of antibodies. Nat. Commun. 2021, 12, 1–14. [Google Scholar] [CrossRef]

- Liu, L.; Wang, P.; Nair, M.S.; Yu, J.; Rapp, M.; Wang, Q.; Luo, Y.; Chan, J.F.; Sahi, V.; Figueroa, A.; et al. Potent neutralizing antibodies against multiple epitopes on SARS-CoV-2 spike. Nature 2020, 584, 450–456. [Google Scholar] [CrossRef] [PubMed]

- Fujita, R.; Hino, M.; Ebihara, T.; Nagasato, T.; Masuda, A.; Lee, J.M.; Fujii, T.; Mon, H.; Kakino, K.; Nagai, R.; et al. Efficient production of recombinant SARS-CoV-2 spike protein using the baculovirus-silkworm system. Biochem. Biophys. Res. Commun. 2020, 529, 257–262. [Google Scholar] [CrossRef]

- Argentinian AntiCovid Consortium; Berguer, P. M.; Blaustein, M.; Bredeston, L.M.; Craig, P.O.; D’alessio, C.; Elias, F.; Farré, P.C.; Fernández, N.B.; Gentili, H.G.; et al. Covalent coupling of Spike’s receptor binding domain to a multimeric carrier produces a high immune response against SARS-CoV-2. Sci. Rep. 2022, 12, 1–16. [Google Scholar] [CrossRef]

- Argentinian AntiCovid Consortium; Arbeitman, C. R.; Auge, G.; Blaustein, M.; Bredeston, L.; Corapi, E.S.; Craig, P.O.; Cossio, L.A.; Dain, L.; D’alessio, C.; et al. Structural and functional comparison of SARS-CoV-2-spike receptor binding domain produced in Pichia pastoris and mammalian cells. Sci. Rep. 2020, 10, 1–18. [Google Scholar] [CrossRef]

- Smith, I.; Mc Callum, G.J.; Sabljic, A.V.; Marfia, J.I.; Bombicino, S.S.; Trabucchi, A.; Iacono, R.F.; Birenbaum, J.M.; Vazquez, S.C.; Minoia, J.M.; et al. Rapid and cost-effective process based on insect larvae for scale-up production of SARS-COV-2 spike protein for serological COVID-19 testing. Biotechnol. Bioeng. 2021, 118, 4129–4137. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Zheng, Q.; Yu, H.; Wu, D.; Xue, W.; Xiong, H.; Huang, X.; Nie, M.; Yue, M.; Rong, R.; et al. SARS-CoV-2 spike produced in insect cells elicits high neutralization titres in non-human primates. Emerg. Microbes Infect. 2020, 9, 2076–2090. [Google Scholar] [CrossRef] [PubMed]

- Shajahan, A.; Supekar, N.T.; Gleinich, A.S.; Azadi, P. Deducing the N- and O-glycosylation profile of the spike protein of novel coronavirus SARS-CoV-2. Glycobiology 2020, 30, 981–988. [Google Scholar] [CrossRef]

- Azad, T.; Singaravelu, R.; Taha, Z.; Jamieson, T.R.; Boulton, S.; Crupi, M.J.F.; Martin, N.T.; Brown, E.E.F.; Poutou, J.; Ghahremani, M.; et al. Nanoluciferase Complementation-Based Bioreporter Reveals the Importance of N-Linked Glycosylation of SARS-CoV-2 S for Viral Entry. Molecular Therapy 2021, 29, 1984–2000. [Google Scholar] [CrossRef]

- Jenkins, N.; Curling, E.M. Glycosylation of recombinant proteins: Problems and prospects. Enzym. Microb. Technol. 1994, 16, 354–364. [Google Scholar] [CrossRef]

- Brooks, S.A. Appropriate Glycosylation of Recombinant Proteins for Human Use: Implications of Choice of Expression System. Mol. Biotechnol. 2004, 28, 241–256. [Google Scholar] [CrossRef]

- Lingg, N.; Zhang, P.; Song, Z.; Bardor, M. The sweet tooth of biopharmaceuticals: Importance of recombinant protein glycosylation analysis. Biotechnol. J. 2012, 7, 1462–1472. [Google Scholar] [CrossRef]

- Goh, J.B.; Ng, S.K. Impact of host cell line choice on glycan profile. Crit. Rev. Biotechnol. 2017, 38, 851–867. [Google Scholar] [CrossRef]

- Casalino, L.; Gaieb, Z.; Goldsmith, J.A.; Hjorth, C.K.; Dommer, A.C.; Harbison, A.M.; Fogarty, C.A.; Barros, E.P.; Taylor, B.C.; McLellan, J.S.; et al. Beyond Shielding: The Roles of Glycans in the SARS-CoV-2 Spike Protein. ACS Central Sci. 2020, 6, 1722–1734. [Google Scholar] [CrossRef] [PubMed]

- Gomes, A.M.V.; Carmo, T.S.; Carvalho, L.S.; Bahia, F.M.; Parachin, N.S. Comparison of Yeasts as Hosts for Recombinant Protein Production. Microorganisms 2018, 6, 38. [Google Scholar] [CrossRef] [PubMed]

- Bernauer, L.; Radkohl, A.; Lehmayer, L.G.K.; Emmerstorfer-Augustin, A. Komagataella phaffii as Emerging Model Organism in Fundamental Research. Front. Microbiol. 2021, 11. [Google Scholar] [CrossRef] [PubMed]

- Ata. ; Ergün, B.G.; Fickers, P.; Heistinger, L.; Mattanovich, D.; Rebnegger, C.; Gasser, B. What makes Komagataella phaffii non-conventional? FEMS Yeast Res. 2021, 21. [Google Scholar] [CrossRef]

- Wegner, G.H. Emerging applications of the methylotrophic yeasts. FEMS Microbiol. Lett. 1990, 87, 279–284. [Google Scholar] [CrossRef] [PubMed]

- Daly, R.; Hearn, M.T.W. Expression of heterologous proteins inPichia pastoris: a useful experimental tool in protein engineering and production. J. Mol. Recognit. 2005, 18, 119–138. [Google Scholar] [CrossRef] [PubMed]

- Ergün, B.G.; Berrios, J.; Binay, B.; Fickers, P. Recombinant protein production in Pichia pastoris: from transcriptionally redesigned strains to bioprocess optimization and metabolic modelling. FEMS Yeast Res. 2021, 21. [Google Scholar] [CrossRef]

- Hartner, F.S.; Glieder, A. Regulation of methanol utilisation pathway genes in yeasts. Microb. Cell Factories 2006, 5, 39–39. [Google Scholar] [CrossRef]

- Hartner, F.S.; Ruth, C.; Langenegger, D.; Johnson, S.N.; Hyka, P.; Lin-Cereghino, G.P.; Lin-Cereghino, J.; Kovar, K.; Cregg, J.M.; Glieder, A. Promoter library designed for fine-tuned gene expression in Pichia pastoris. Nucleic Acids Res. 2008, 36, e76–e76. [Google Scholar] [CrossRef] [PubMed]

- Cereghino, G.P.L.; Lin Cereghino, G.P.; Sunga, A.J.; Cereghino, J.L.; Cregg, J.M. Expression of Foreign Genes in the Yeast Pichia Pastoris. Genetic Engineering: Principles and Methods 157–169.

- Cregg, J.M.; Cereghino, J.L.; Shi, J.; Higgins, D.R. Recombinant protein expression in Pichia pastoris. Mol. Biotechnol. 2000, 16, 23–52. [Google Scholar] [CrossRef] [PubMed]

- Cereghino, G.P.; Cereghino, J.L.; Ilgen, C.; Cregg, J.M. Production of recombinant proteins in fermenter cultures of the yeast Pichia pastoris. Curr. Opin. Biotechnol. 2002, 13, 329–332. [Google Scholar] [CrossRef] [PubMed]

- Cereghino, J.L.; Cregg, J.M. Heterologous protein expression in the methylotrophic yeast Pichia pastoris. FEMS Microbiol. Rev. 2000, 24, 45–66. [Google Scholar] [CrossRef] [PubMed]

- Shental-Bechor, D.; Levy, Y. Effect of glycosylation on protein folding: A close look at thermodynamic stabilization. Proc. Natl. Acad. Sci. 2008, 105, 8256–8261. [Google Scholar] [CrossRef] [PubMed]

- Jayaprakash, N.G.; Surolia, A. Role of glycosylation in nucleating protein folding and stability. 2017, 474, 2333–2347. [CrossRef]

- Roth, J.; Zuber, C.; Park, S.; Jang, I.; Lee, Y.; Kysela, K.G. Protein N-Glycosylation, Protein Folding, and Protein Quality Control. Molecules 2010. [CrossRef]

- Gao, J.; Jiang, L.; Lian, J. Development of synthetic biology tools to engineer Pichia pastoris as a chassis for the production of natural products. Synth. Syst. Biotechnol. 2021, 6, 110–119. [Google Scholar] [CrossRef]

- Gaboardi, G.C.; Alves, D.; Santos, D.G.d.L.; Xavier, E.; Nunes, A.P.; Finger, P.; Griep, E.; Roll, V.; Oliveira, P.; Silva, A.; et al. Influence of Pichia pastoris X-33 produced in industrial residues on productive performance, egg quality, immunity, and intestinal morphometry in quails. Sci. Rep. 2019, 9, 1–14. [Google Scholar] [CrossRef]

- Sturmberger, L.; Chappell, T.; Geier, M.; Krainer, F.; Day, K.J.; Vide, U.; Trstenjak, S.; Schiefer, A.; Richardson, T.; Soriaga, L.; et al. Refined Pichia pastoris reference genome sequence. J. Biotechnol. 2016, 235, 121–131. [Google Scholar] [CrossRef]

- Sinha, J.; Plantz, B.A.; Zhang, W.; Gouthro, M.; Schlegel, V.; Liu, C.; Meagher, M.M. Improved Production of Recombinant Ovine Interferon-τ by Mut+ Strain of Pichia pastoris Using an Optimized Methanol Feed Profile. Biotechnol. Prog. 2003, 19, 794–802. [Google Scholar] [CrossRef]

- Files, D.; Ogawa, M.; Scaman, C.H.; A Baldwin, S. A Pichia pastoris fermentation process for producing high-levels of recombinant human cystatin-C. Enzym. Microb. Technol. 2001, 29, 335–340. [Google Scholar] [CrossRef]

- Cos, O.; Ramón, R.; Montesinos, J.L.; Valero, F. Operational strategies, monitoring and control of heterologous protein production in the methylotrophic yeast Pichia pastoris under different promoters: A review. Microb. Cell Factories 2006, 5, 17–17. [Google Scholar] [CrossRef] [PubMed]

- Yamawaki, S.; Matsumoto, T.; Ohnishi, Y.; Kumada, Y.; Shiomi, N.; Katsuda, T.; Lee, E.K.; Katoh, S. Production of Single-Chain Variable Fragment Antibody (scFv) in Fed-Batch and Continuous Culture of Pichia pastoris by Two Different Methanol Feeding Methods. J. Biosci. Bioeng. 2007, 104, 403–407. [Google Scholar] [CrossRef] [PubMed]

- Looser, V.; Bruhlmann, B.; Bumbak, F.; Stenger, C.; Costa, M.; Camattari, A.; Fotiadis, D.; Kovar, K. Cultivation strategies to enhance productivity of Pichia pastoris: A review. Biotechnol. Adv. 2015, 33, 1177–1193. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, A.R.; Ataíde, F.; von Stosch, M.; Dias, J.M.L.; Clemente, J.J.; Cunha, A.E.; Oliveira, R. Application of adaptive DO-stat feeding control to Pichia pastoris X33 cultures expressing a single chain antibody fragment (scFv). Bioprocess Biosyst. Eng. 2012, 35, 1603–1614. [Google Scholar] [CrossRef]

- Trinh, L.B.; Phue, J.N.; Shiloach, J. Effect of methanol feeding strategies on production and yield of recombinant mouse endostatin fromPichia pastoris. Biotechnol. Bioeng. 2003, 82, 438–444. [Google Scholar] [CrossRef]

- Liu, W.; Xiang, H.; Zhang, T.; Pang, X.; Su, J.; Liu, H.; Ma, B.; Yu, L. Development of a New High-Cell Density Fermentation Strategy for Enhanced Production of a Fungus β-Glucosidase in Pichia pastoris. Front. Microbiol. 2020, 11. [Google Scholar] [CrossRef]

- Dalvie, N.C.; Rodriguez-Aponte, S.A. Engineered SARS-CoV-2 Receptor Binding Domain Improves Manufacturability in Yeast and Immunogenicity in Mice. Proceedings of the 2021. [CrossRef]

- Liu, Y.; Ye, Q. Nucleic Acid Vaccines against SARS-CoV-2. Vaccines 2022, 10, 1849. [Google Scholar] [CrossRef]

- Jain, S.; Venkataraman, A.; Wechsler, M.E.; Peppas, N.A. Messenger RNA-based vaccines: Past, present, and future directions in the context of the COVID-19 pandemic. Adv. Drug Deliv. Rev. 2021, 179, 114000–114000. [Google Scholar] [CrossRef]

- Heidary, M.; Kaviar, V.H.; Shirani, M.; Ghanavati, R.; Motahar, M.; Sholeh, M.; Ghahramanpour, H.; Khoshnood, S. A Comprehensive Review of the Protein Subunit Vaccines Against COVID-19. Front. Microbiol. 2022, 13, 927306. [Google Scholar] [CrossRef] [PubMed]

- Dalvie, N.C.; Tostanoski, L.H.; Rodriguez-Aponte, S.A.; Kaur, K.; Bajoria, S.; Kumru, O.S.; Martinot, A.J.; Chandrashekar, A.; McMahan, K.; Mercado, N.B.; et al. SARS-CoV-2 receptor binding domain displayed on HBsAg virus–like particles elicits protective immunity in macaques. Sci. Adv. 2022, 8, eabl6015. [Google Scholar] [CrossRef] [PubMed]

- Ghasemiyeh, P.; Mohammadi-Samani, S.; Firouzabadi, N.; Dehshahri, A.; Vazin, A. A focused review on technologies, mechanisms, safety, and efficacy of available COVID-19 vaccines. Int. Immunopharmacol. 2021, 100, 108162–108162. [Google Scholar] [CrossRef] [PubMed]

- Kruger, N.J. The Bradford Method for Protein Quantitation. Protein Protocols Handbook, The 15–22.

- Kruger, N.J. The Bradford Method for Protein Quantitation. In Springer Protocols Handbooks; Humana Press: Totowa, NJ, 2009; ISBN 9781603274746. [Google Scholar]

- Chen, W.-H.; Chag, S.M.; Poongavanam, M.V.; Biter, A.B.; Ewere, E.A.; Rezende, W.; Seid, C.A.; Hudspeth, E.M.; Pollet, J.; McAtee, C.P.; et al. Optimization of the Production Process and Characterization of the Yeast-Expressed SARS-CoV Recombinant Receptor-Binding Domain (RBD219-N1), a SARS Vaccine Candidate. J. Pharm. Sci. 2017, 106, 1961–1970. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Xiong, F.; Lin, Q.; D'Anjou, M.; Daugulis, A.J.; Yang, D.S.; Hew, C.L. Low-Temperature Increases the Yield of Biologically Active Herring Antifreeze Protein in Pichia pastoris. Protein Expr. Purif. 2001, 21, 438–445. [Google Scholar] [CrossRef]

- Shi, X.; Karkut, T.; Chamankhah, M.; Alting-Mees, M.; Hemmingsen, S.M.; Hegedus, D. Optimal conditions for the expression of a single-chain antibody (scFv) gene in Pichia pastoris. Protein Expr. Purif. 2003, 28, 321–330. [Google Scholar] [CrossRef]

- Çelik, E.; Çalık, P. Production of recombinant proteins by yeast cells. Biotechnol. Adv. 2012, 30, 1108–1118. [Google Scholar] [CrossRef]

- Noseda, D.G.; Recúpero, M.N.; Blasco, M.; Ortiz, G.E.; Galvagno, M.A. Cloning, expression and optimized production in a bioreactor of bovine chymosin B in Pichia (Komagataella) pastoris under AOX1 promoter. Protein Expr. Purif. 2013, 92, 235–244. [Google Scholar] [CrossRef]

- Noseda, D.G.; Recúpero, M.; Blasco, M.; Bozzo, J.; Galvagno, M. Production in stirred-tank bioreactor of recombinant bovine chymosin B by a high-level expression transformant clone of Pichia pastoris. Protein Expr. Purif. 2016, 123, 112–121. [Google Scholar] [CrossRef] [PubMed]

- Picotto, L.; Sguazza, G.; Tizzano, M.; Galosi, C.; Cavalitto, S.; Pecoraro, M. An effective and simplified DO-stat control strategy for production of rabies glycoprotein in Pichia pastoris. Protein Expr. Purif. 2017, 132, 124–130. [Google Scholar] [CrossRef] [PubMed]

- Westwood, M.-M.; Rieley, W. Medical gases, their storage and delivery. Anaesth. Intensiv. Care Med. 2012, 13, 533–538. [Google Scholar] [CrossRef]

- Malayaman, S.N.; Mychaskiw, G., II; Berry, J.M.; Ehrenwerth, J. Medical Gases: Storage and Supply. In Anesthesia Equipment; Elsevier, 2021; pp. 3–24.

- Farnós, O.; Venereo-Sánchez, A.; Xu, X.; Chan, C.; Dash, S.; Chaabane, H.; Sauvageau, J.; Brahimi, F.; Saragovi, U.; Leclerc, D.; et al. Rapid High-Yield Production of Functional SARS-CoV-2 Receptor Binding Domain by Viral and Non-Viral Transient Expression for Pre-Clinical Evaluation. Vaccines 2020, 8, 654. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Fan, Z.; Lin, Y.; Wang, T.-Y. Serum-Free Medium for Recombinant Protein Expression in Chinese Hamster Ovary Cells. Front. Bioeng. Biotechnol. 2021, 9. [Google Scholar] [CrossRef]

- Zhang, J.; Greasham, R. Chemically defined media for commercial fermentations. Appl. Microbiol. Biotechnol. 1999, 51, 407–421. [Google Scholar] [CrossRef]

- Orman, M.A.; Çalık, P.; Özdamar, T.H. The Influence of Carbon Sources on Recombinant-human-growth-hormone Production by Pichia Pastoris Is Dependent on Phenotype: A Comparison of Muts and Mut+ …. Biotechnol. Appl. Biochem. 2009. [CrossRef]

- Pla, I.; Damasceno, L.; Vannelli, T.; Ritter, G.; Batt, C.; Shuler, M. Evaluation of Mut+ and MutS Pichia pastoris Phenotypes for High Level Extracellular scFv Expression under Feedback Control of the Methanol Concentration. Biotechnol. Prog. 2006, 22, 881–888. [Google Scholar] [CrossRef]

- Singh, A.; Narang, A. The Mut+ strain of Komagataella phaffii (Pichia pastoris) expresses PAOX1 5 and 10 times faster than Muts and Mut− strains: evidence that formaldehyde or/and formate are true inducers of PAOX1. Appl. Microbiol. Biotechnol. 2020, 104, 7801–7814. [Google Scholar] [CrossRef]

- Barrigón, J.M.; Montesinos, J.L.; Valero, F. Searching the best operational strategies for Rhizopus oryzae lipase production in Pichia pastoris Mut+ phenotype: Methanol limited or methanol non-limited fed-batch cultures? Biochem. Eng. J. 2013, 75, 47–54. [Google Scholar] [CrossRef]

- Garrigós-Martínez, J.; Nieto-Taype, M.A. Specific Growth Rate Governs AOX1 Gene Expression, Affecting the Production Kinetics of Pichia Pastoris (Komagataella Phaffii) PAOX1-Driven Recombinant …. Microb. Cell Fact. 2019.

- Mayson, B.E.; Kilburn, D.G.; Zamost, B.L.; Raymond, C.K.; Lesnicki, G.J. Effects of methanol concentration on expression levels of recombinant protein in fed-batch cultures of Pichia methanolica. Biotechnol. Bioeng. 2002, 81, 291–298. [Google Scholar] [CrossRef] [PubMed]

- Katakura, Y.; Zhang, W.; Zhuang, G.; Omasa, T. Effect of Methanol Concentration on the Production of Human β2-Glycoprotein I Domain V by a Recombinant Pichia Pastoris: A Simple System for the Control of Methanol …. J. Ferment. Bioeng. 1998.

- Guarna, M.M.; Lesnicki, G.J.; Tam, B.M.; Robinson, J.; Radziminski, C.Z.; Hasenwinkle, D.; Boraston, A.; Jervis, E.; MacGillivray, R.T.A.; Turner, R.F.B.; et al. On-line monitoring and control of methanol concentration in shake-flask cultures ofPichia pastoris. Biotechnol. Bioeng. 1997, 56, 279–286. [Google Scholar] [CrossRef]

- Schenk, J.; Marison, I.W.; Vonstockar, U. A simple method to monitor and control methanol feeding of Pichia pastoris fermentations using mid-IR spectroscopy. J. Biotechnol. 2007, 128, 344–353. [Google Scholar] [CrossRef]

- Chen, W.-H.; Du, L.; Chag, S.M.; Ma, C.; Tricoche, N.; Tao, X.; Seid, C.A.; Hudspeth, E.M.; Lustigman, S.; Tseng, C.-T.K.; et al. Yeast-expressed recombinant protein of the receptor-binding domain in SARS-CoV spike protein with deglycosylated forms as a SARS vaccine candidate. Hum. Vaccines Immunother. 2013, 10, 648–658. [Google Scholar] [CrossRef]

- Chen, W.H.; Hotez, P.J.; Bottazzi, M.E. Potential for Developing a SARS-CoV Receptor-Binding Domain (RBD) Recombinant Protein as a Heterologous Human Vaccine against Coronavirus Infectious Disease …. Hum. Vaccin. 2020. [CrossRef]

- Limonta-Fernández, M.; Chinea-Santiago, G.; Martín-Dunn, A.M.; Gonzalez-Roche, D.; Bequet-Romero, M.; Marquez-Perera, G.; González-Moya, I.; Canaan-Haden-Ayala, C.; Cabrales-Rico, A.; Espinosa-Rodríguez, L.A.; et al. An engineered SARS-CoV-2 receptor-binding domain produced in Pichia pastoris as a candidate vaccine antigen. New Biotechnol. 2022, 72, 11–21. [Google Scholar] [CrossRef]

- Cardoso, V.M.; Campani, G.; Santos, M.P.; Silva, G.G.; Pires, M.C.; Gonçalves, V.M.; Giordano, R.d.C.; Sargo, C.R.; Horta, A.C.; Zangirolami, T.C. Cost analysis based on bioreactor cultivation conditions: Production of a soluble recombinant protein using Escherichia coli BL21(DE3). Biotechnol. Rep. 2020, 26, e00441. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Qi, J.; Xiao, L.; Shen, L.; Yu, W.; Hu, T. Purification and characterization of the receptor-binding domain of SARS-CoV-2 spike protein from Escherichia coli. Eng. Life Sci. 2021, 21, 453–460. [Google Scholar] [CrossRef] [PubMed]

- Meena, J.; Singhvi, P.; Srichandan, S.; Dandotiya, J.; Verma, J.; Singh, M.; Ahuja, R.; Panwar, N.; Wani, T.Q.; Khatri, R.; et al. RBD decorated PLA nanoparticle admixture with aluminum hydroxide elicit robust and long lasting immune response against SARS-CoV-2. Eur. J. Pharm. Biopharm. 2022, 176, 43–53. [Google Scholar] [CrossRef] [PubMed]

- Hossler, P.; Khattak, S.F.; Li, Z.J. Optimal and consistent protein glycosylation in mammalian cell culture. Glycobiology 2009, 19, 936–949. [Google Scholar] [CrossRef]

- Dumont, J.; Euwart, D.; Mei, B.; Estes, S.; Kshirsagar, R. Human cell lines for biopharmaceutical manufacturing: history, status, and future perspectives. Crit. Rev. Biotechnol. 2015, 36, 1110–1122. [Google Scholar] [CrossRef]

- Kiss, B.; Gottschalk, U.; Pohlscheidt, M. New Bioprocessing Strategies: Development and Manufacturing of Recombinant Antibodies and Proteins; Springer, 2018; ISBN 9783319971100.

|

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).