1. Introduction

Energy conversion from heat to sound is desired in thermoacoustic engines [

1,

2,

3], because there are no or fewer moving parts and non-exotic materials involved. When this occurs in most modern combustion equipment with high energy densities (such as in liquid/solid rocket engines [

4,

5,

6], aero-engines [

7,

8,

9], or land-based gas turbines [

10,

11,

12]), intense thermoacoustic oscillations may occur, which pose a significant risk due to destructive damage [

13,

14,

15]. This may include, structural vibration fatigue, overloaded heating to the combustor walls, and even explosion. Generally, thermoacoustic instabilities are caused by coupling between the unsteady combustion process, acoustic waves, and turbulence flow inside the combustors, which are characterized by large-amplitude pressure or heat oscillations. To avoid or at least suppress these detrimental oscillations, it is necessary to achieve a better understanding of the process responsible for transitions to instability [

16,

17,

18].

Many previous researches have focused on deterministic stability analyses of thermoacoustic systems [

19,

20,

21]. However, the combustion systems in propulsion instruments are inherently noisy, and measured acoustic signals and heat release rates present some obvious random characteristics [

22,

23], especially when the thermoacoustic system is configured near stability boundaries. For example, the responses of a linearly stable thermoacoustic system are no longer a single state, as shown in deterministic analyses, but exhibit random pressure bursts. In such a case, the deterministic analysis of the thermoacoustic system cannot explain the stochastic behaviors. Furthermore, it is difficult to predict the onset of thermoacoustic instability in a deterministic framework.

Random disturbances in thermoacoustic systems may be generated directly by the unsteady combustion processes or indirectly by flow separation and turbulence [

24]. It has been found that [

25,

26] these random disturbances occurring in the combustion response, frequency, and damping rate may work as additive or multiplicative excitation sources to the acoustic propagation system inside the combustors. At the early stage for easy implementation, the assumption of white noise is often used to represent these random disturbances. Interestingly, it is found that increasing the noise intensity can induce a drift in the stability boundary and narrows down the combustor stability margin [

27,

28,

29]. Lieuwen [

27] numerically illustrated that the stable region of the combustor decreases as the intensity of the white noise grows. Some small-amplitude random noise can even lead to noise-induced transitions (NIT) [

30,

31,

32,

33] and noise-induced coherence resonances [

34,

35,

36], which have been evidenced experimentally in prototypical thermoacoustic systems.

However, such assumptions of white noise only work in the limited situation of rapidly varying fluctuations. That is, stochastic disturbances are assumed to be serially uncorrelated with a constant power spectral density. By comparison, colored noise with some finite correlation time would be closer to reality [

37], as spectra for unsteady heat release have been experimentally evidenced as having a low-pass nature [

38]. The non-vanishing correlation time in these disturbances is often called the `color’ of the noise. The influence of the colored noise on the thermoacoustic system have been investigated by Waugh et al. [

39] and they found that the colored noise with the low-pass characteristics is more effective in triggering large-amplitude thermoacoustic oscillations than white noise. Bonciolini et al. [

40] evaluated the influence of the autocorrelation time of colored noise on the probability density function (PDF) of thermoacoustic systems and observed strong deviations from the white noise forcing case. Li et al. [

41] utilized stochastic nonlinear dynamic theories to analytically study the influence of additive colored noise on the coherence behaviors of thermoacoustic systems, and found that the optimal noise intensity corresponding to the maximum the signal-to-noise ratio (SNR) is strongly dependent on the variations in the correlation time. In addition, the role of the additive and multiplicative colored noise on the stability behaviors of a Rijke-type thermoacoustic system [

21] was also studied and identified. Most relevant works about the influence of colored noise on thermoacoustic systems are constrained in analytic and numerical frameworks with a lack of experimental data, which motivates this work.

The rest of this paper is divided into three main sections. Firstly, an experimental configuration of the Rijke-type standing-wave thermoacoustic system and the external colored noise is introduced in

Section 2. The colored noise is generated by solving the corresponding governing equation, and a random signal is produced from the signal generators before reaching the loudspeakers. Secondly, the effects of colored noise on the response of thermoacoustic systems are evaluated with relevant results discussed in

Section 3. Finally, the key findings are summarized in

Section 4.

2. Experimental Configuration of the Rijke-type Thermoacoustic System Driven by Colored Noise

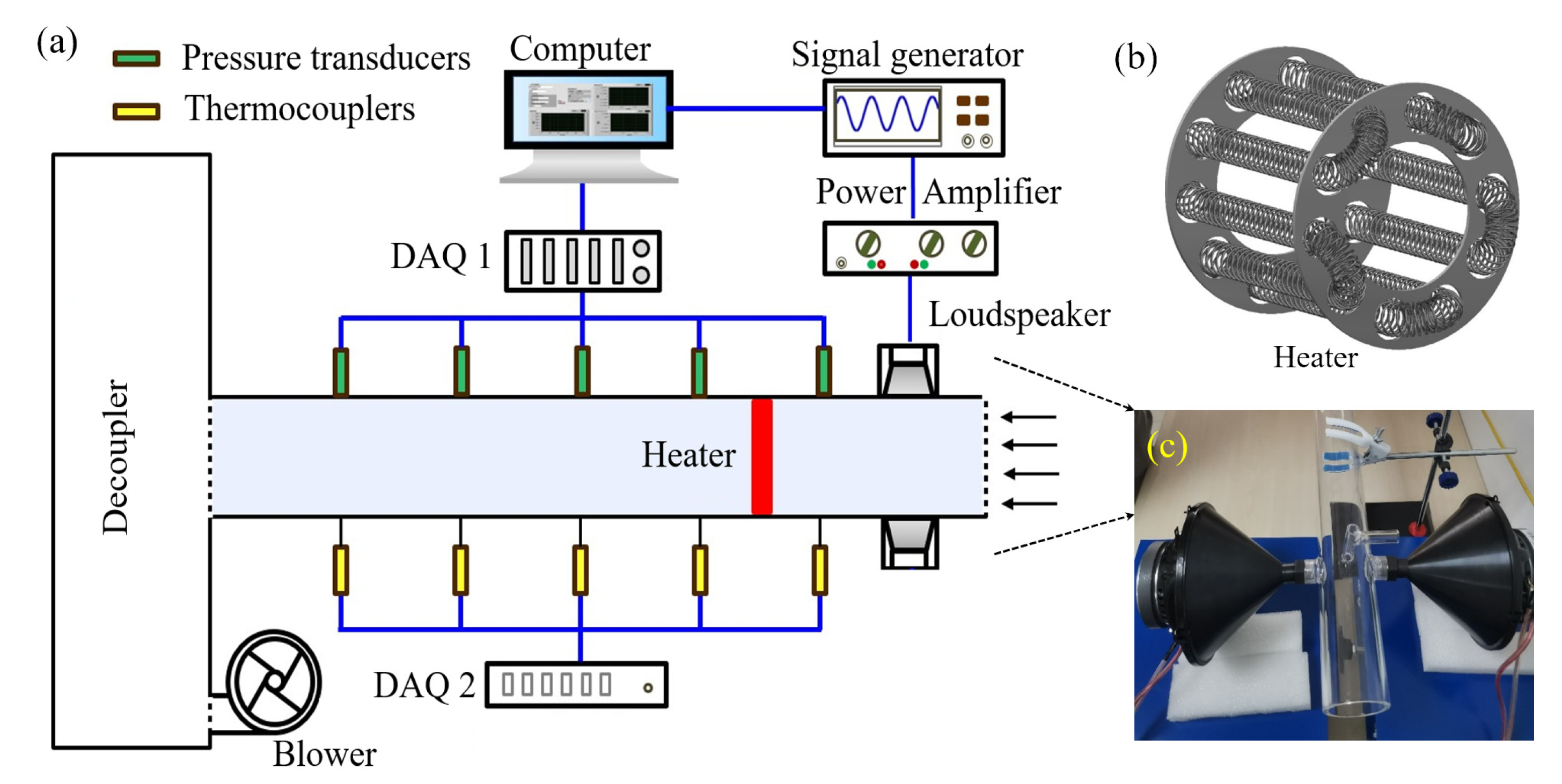

A schematic diagram of the experimental setup for the stochastic Rijke-type standing-wave thermoacoustic system is shown in

Figure 1. The acoustic resonator is made of silicon with an overall length of 1 m and it is placed horizontally so that the interaction between the mean flow and heat power in the vertical Rijke tube is decoupled. The cross section of the resonator is circular with a radius of 50 mm, and both ends are acoustically open, where the acoustic pressure equals zero. Through operating a blower (Model JABSCO-35440 with a voltage range of 0–24 V) in the suction mode, a mean flow can be constructed. A hot wire anemometer (SMART Testo) is used to measure the volume flow rate, and a decoupler (1200 mm × 600 mm × 600 mm) is placed between the the blower and the Rijke tube, where some absorbing material is installed inside to stop the flow disturbances and noise pollution from the blower.

The heat source is provided by an axially-distributed electrical heater, as shown in

Figure 1(b). It is made of nichrome, and the heating coils are wound over two ceramic rings such that each ring of wires cannot touch the adjacent structure. This heater has the benefit of releasing large amounts of thermal power without geometry changes, which is a convenient approach to modify the characteristics of the heat source. The electrical energy is supplied by DC-stabilized power, which produces 100 V at 100 A. The power supplied is controlled by changing the loaded voltage of the heater.

Two loudspeakers are used to introduce noisy disturbances in the Rijke tube, as is shown in

Figure 1(c). These loudspeakers are mounted diametrically opposite to each other along the circumference of the tube and located upstream of the heater. To model the turbulence-induced fluctuations, these loudspeakers are excited by the colored noise signals. It is assumed that [

36,

41] the random disturbance with low-pass filter properties is characterized by Ornstein–Uhlenbeck (OU)-type colored noise

, which is governed by the following equation [

42,

43]:

where

is the autocorrelation time of the stochastic forcing

, and it is a measure of the extent of the current process depending on the past.

D denotes the noise intensity.

is Gaussian white noise, which has zero mean and unit variance. The statistical properties of the OU-type colored noise is given as follows:

where

denotes the operator of expectation for the stochastic signals. It is noted that as

, this OU-type colored noise degenerates into white noise.

The colored noise signal is generated by solving Equation (

1) with the stochastic second-order Euler method. These stochastic signals are then transmitted to TTi TGF4042 arbitrary waveform generators to create an electrical signal, and amplified by the Crown XTi-1002A amplifier before driving the two JBL CLUB-6522 loudspeakers. To record the system response, several K-type thermocouples are utilized to measure the gas temperature inside the tube, and they has the measuring ranges of -

and an accuracy of

. In addition, some pressure transducers (BSWA-MP401) are installed along the duct with sensitivities of 5 mV/Pa to measure the acoustic pressure inside the tube. These sensors are placed such that the first two eigenmodes of the thermoacoustic oscillations can be identified. The measured signals are recorded simultaneously via Labview and National Instruments PXIe-4464 data acquisition cards which has a sample rate of 10 kHz.

3. Results and Discussions

The effects of the colored noise on the Rijke-type standing-wave thermoacoustic system are studied. The nonlinear dynamic behaviors of the Rijke-type thermoacoustic system are first evaluated in the absence of noisy disturbances.

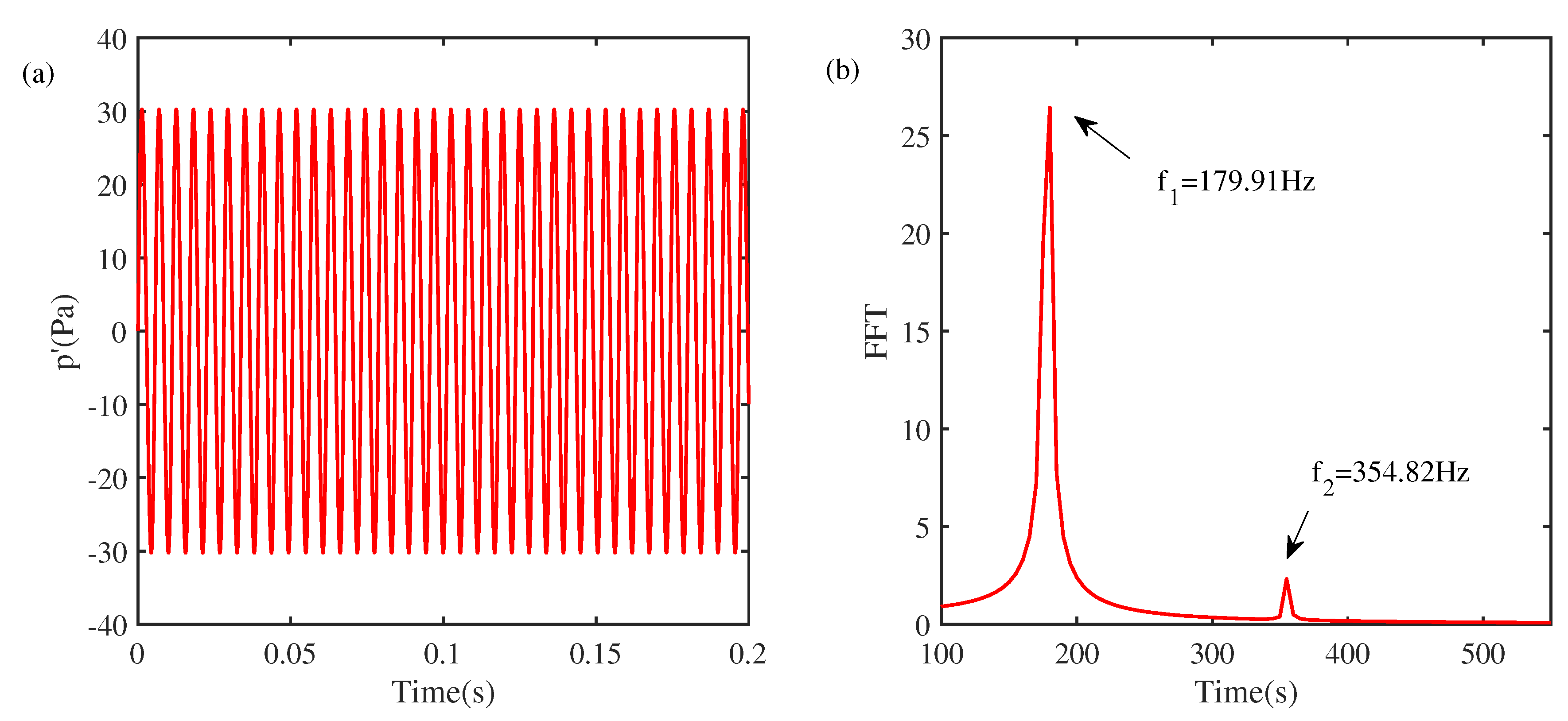

Figure 2 shows the measured acoustic pressure oscillations and the corresponding frequency spectrum. When thermoacoustic instability occurs in the experimental system, the large-amplitude regular acoustic limit cycle is observed, as is shown in

Figure 2(a). Here, all the local maxima and minima have the same amplitude.

Figure 2(b) shows the acoustic pressure signal in the frequency domain using a fast Fourier transformation (FFT). The frequency at the peak is around 179.9 Hz, which is close to the first-order acoustic frequency of the Rijke tube with

Hz.

Based on the previous studies [

34], external white noise significantly influences the system response when configured near the stability boundary. Similarly, the stability boundaries of the Rijke-type thermoacoustic system are also explored for various heater powers. Two different transition behaviors are obtained in Figure . When the incoming flow velocity is around 0.41 m/s, Figure (a) shows that increasing the heater power makes the system unstable at around 242 W. Further increasing the heater power leads to an increased acoustic pressure, as denoted by the red-starred curve. If the heater power decreases, the acoustic pressure oscillations also decrease, and the system becomes stabilized at the original transition point. Therefore, the Rijke thermoacoustic system becomes unstable via supercritical Hopf bifurcation. When the incoming flow velocity is 0.36 m/s, an obvious hysteresis region is observed between 328 and 338 W, which is where the heater power increases initially to destabilize the system and then decreases continuously to reach the stable state. Therefore, the thermoacoustic system becomes unstable via subcritical Hopf bifurcation. The effects of colored noise on the response of the thermoacoustic system are considered near this supercritical bifurcation point.

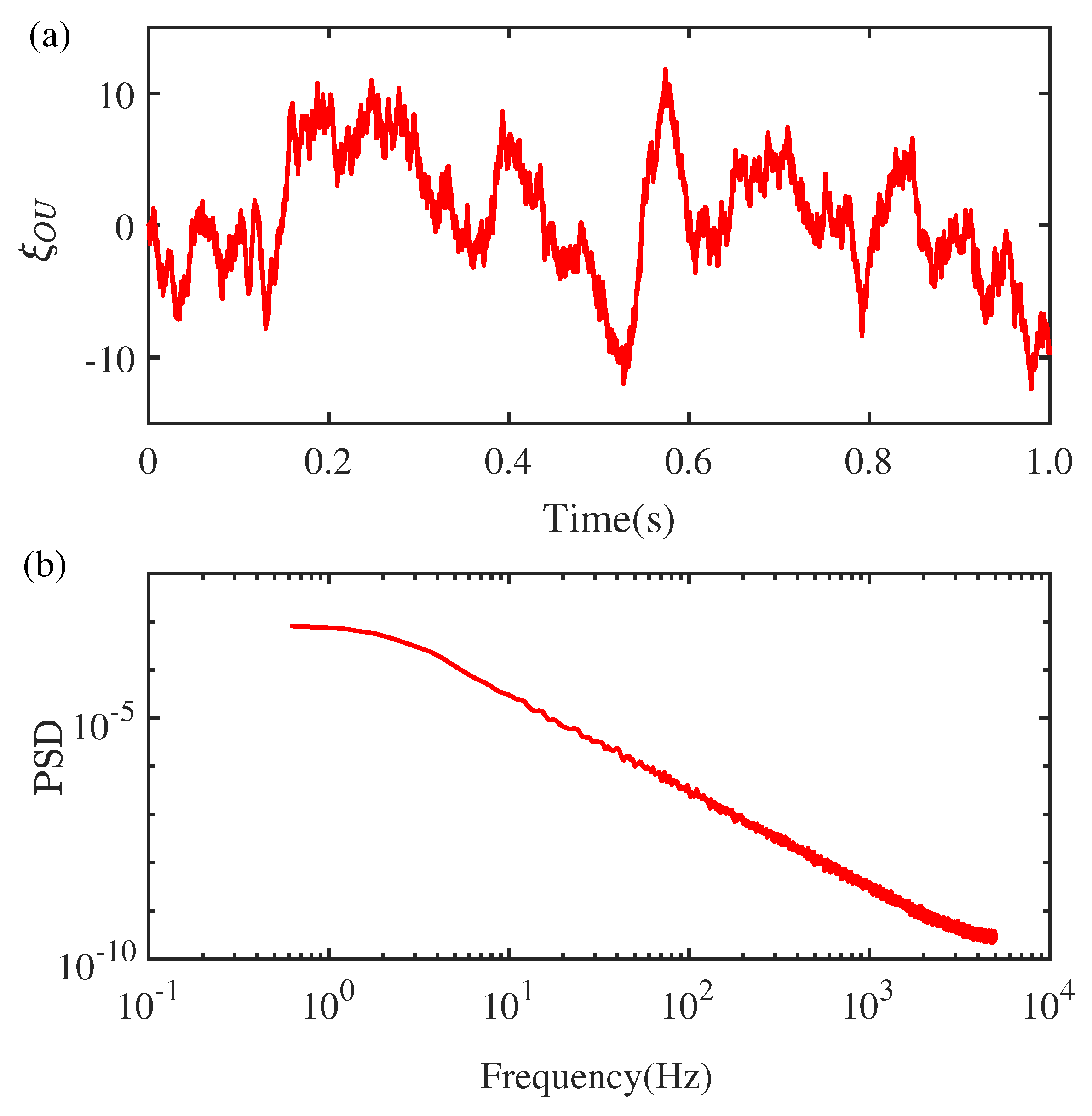

Figure 3(a) illustrates a time series of Gaussian colored noise

as obtained by solving Equation (

1), and the corresponding power spectral density is shown in

Figure 3(b). The response of

depends on the past time, and the power spectrum density has low-pass filtering properties. When random colored noise

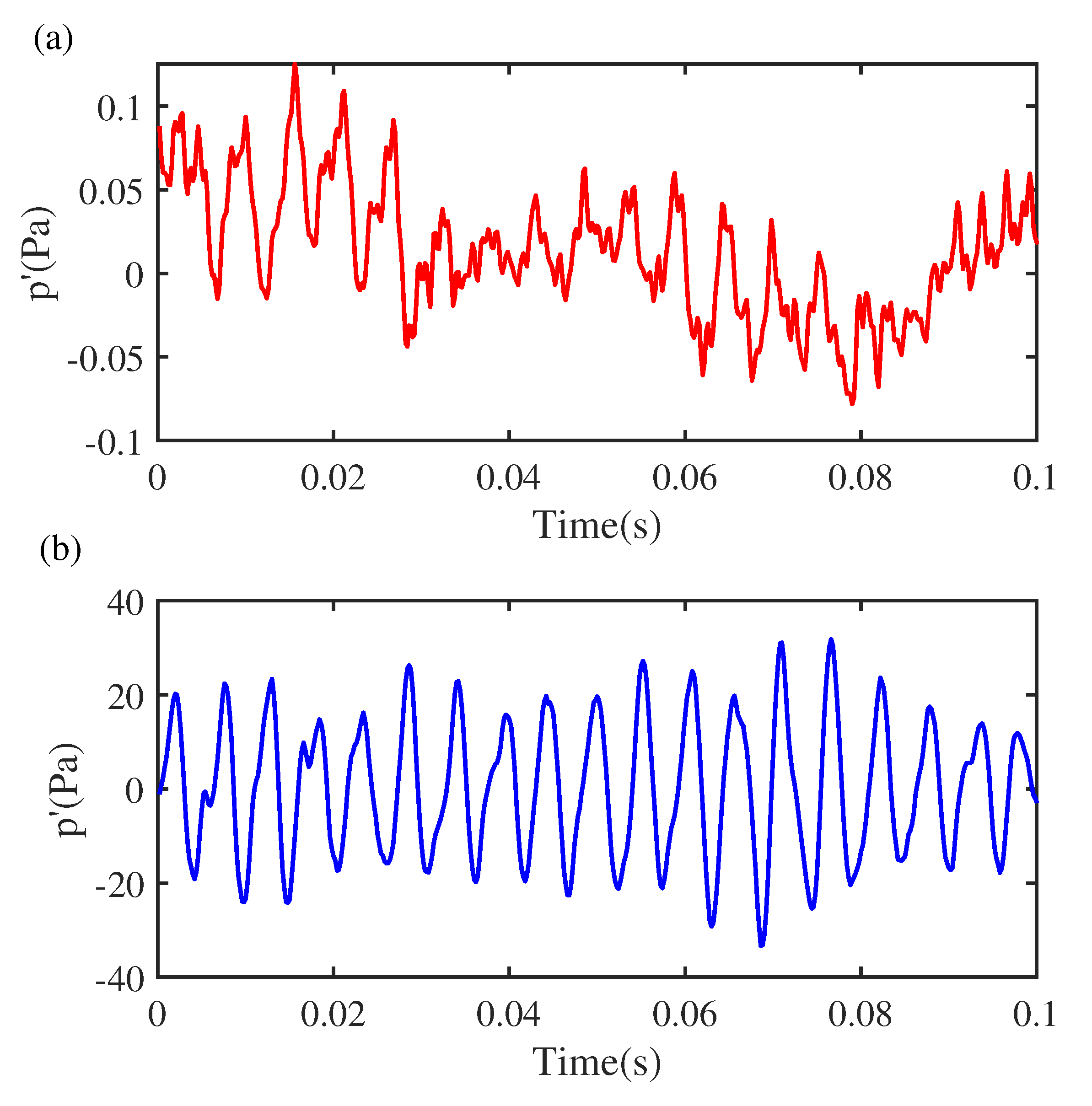

is added to the thermoacoustic system,

Figure 4 shows that the original unregular acoustic pressure oscillations become organized in the sub-threshold region, and the amplitude of the acoustic pressure increases from 0.1 to 20 Pa.

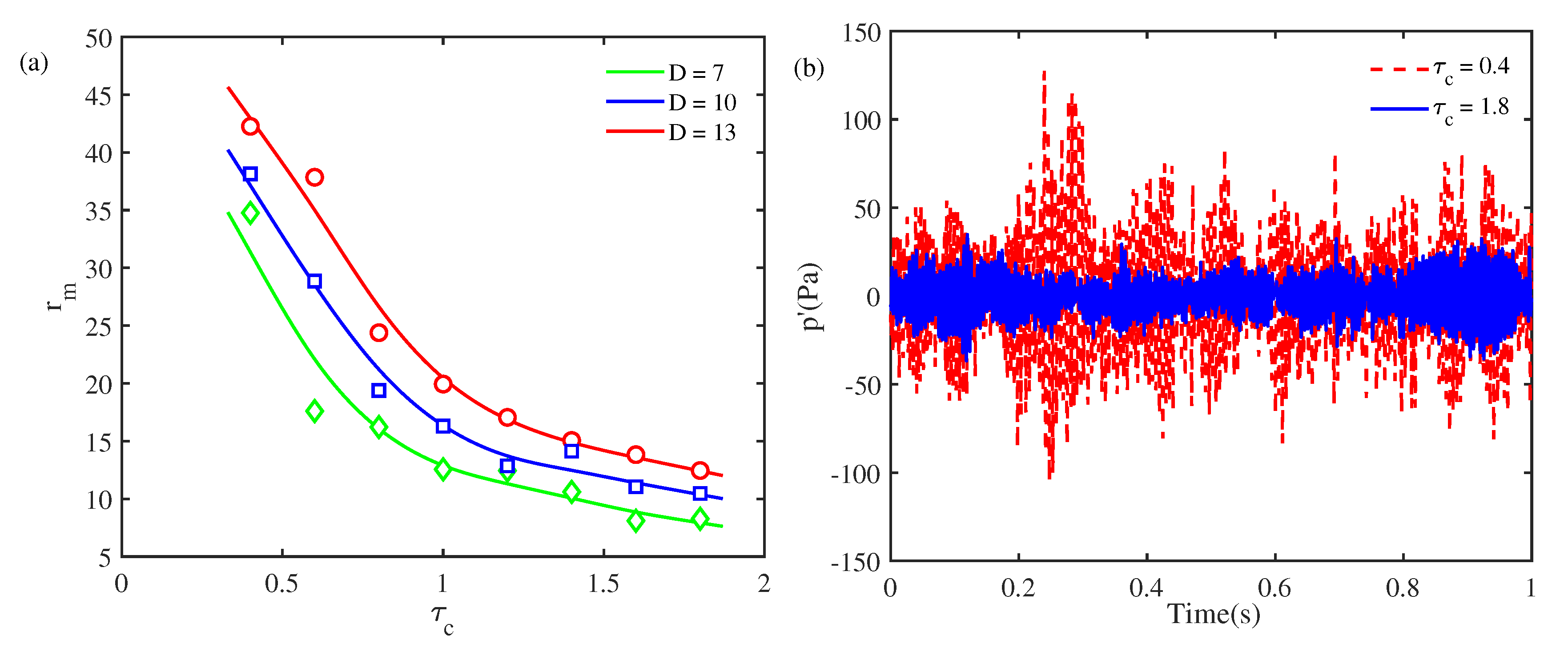

The amplitude of the measured stochastic acoustic pressure is obtained to investigate the statistical properties of the thermoacoustic system, as is shown in

Figure 5(a). The corresponding PDF of the amplitude

is given in

Figure 5(b). The most probable amplitude corresponds to a maximized stationary PDF.

Figure 6 shows the effects of colored noise (including the noise intensity

D and the autocorrelation time

) on the most probable amplitude of Rijke-type thermoacoustic systems. When the noise intensity

D is fixed,

Figure 6(a) shows that an increased autocorrelation time

causes the most probable amplitude

to drop sharply at the initial stage, and when the autocorrelation time

is larger than 1, the most probable amplitude

decrease slowly.

Figure 6(b) shows the time evolutions of the thermoacoustic system at two different autocorrelation times. As the autocorrelation time increases from

to

, although the noise intensity

D remains unchanged, the acoustic pressure fluctuations increase significantly. For any autocorrelation time

in

Figure 6(a), increasing the noise intensity

D causes the most probable amplitude to increase and generate more intense oscillations in the system.

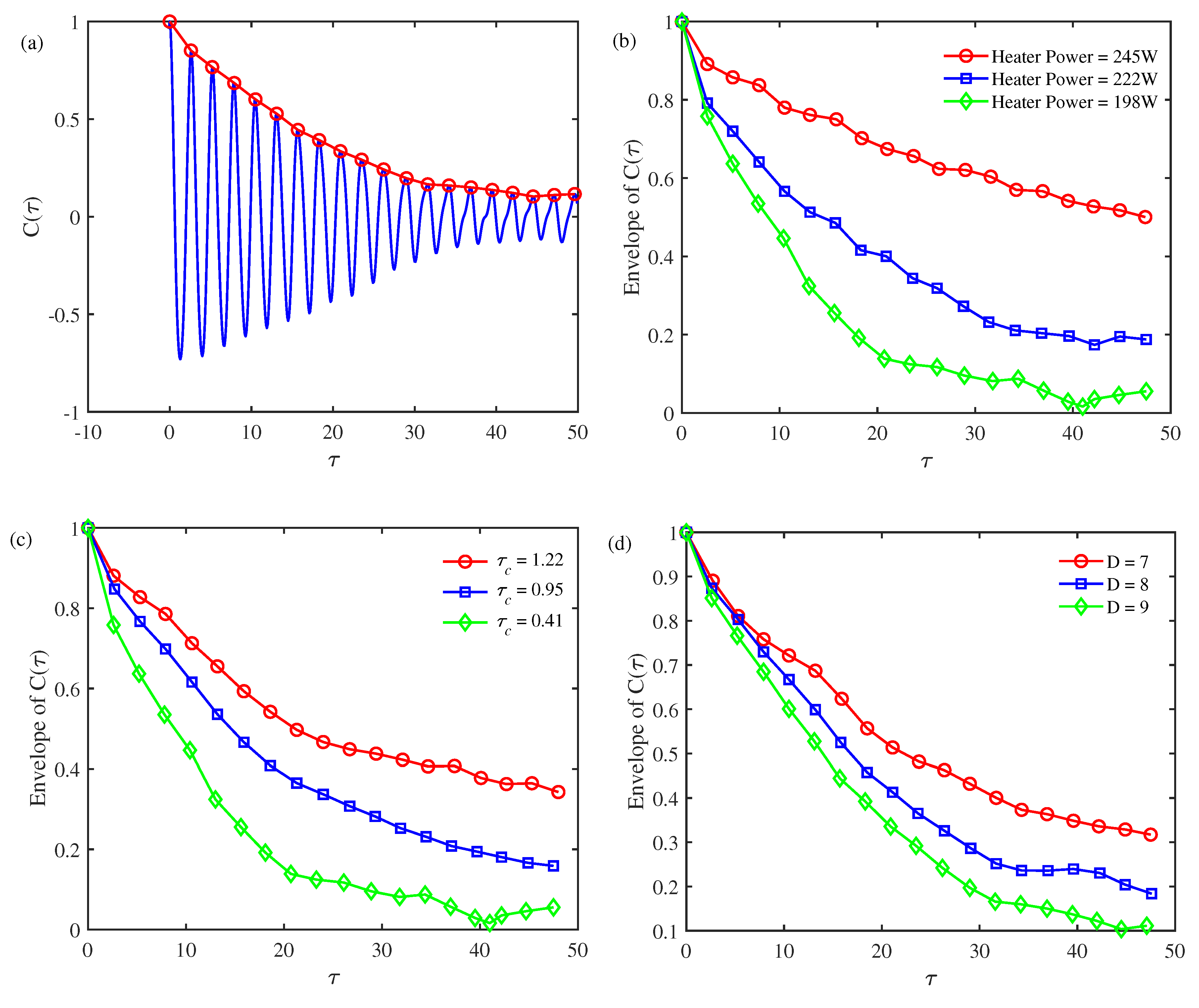

The stochastic properties of the Rijke-type thermoacoustic system can be evaluated based on the autocorrelation function

of the measured stochastic pressure.

Figure 7(a) shows variations in the autocorrelation function when the time lag of the two acoustic pressure signals increases. When

,

, which agrees with intuition. In addition, a strong oscillatory property is observed, and the envelope of the autocorrelation function

initially decreases exponentially. When the time lag

is larger than approximately 35,

oscillates with a nearly constant amplitude. Figures.

Figure 7(b)–

Figure 7(d) study the roles of the operation condition (heater power) and the colored noise disturbance (

and

D) on the envelope of the autocorrelation function

. As the heater power increases from 198 to 245 W, the thermoacoustic system is more prone to instability, and

Figure 7(b) shows that the autocorrelation function

decreases more slowly. That is, the correlation of the acoustic pressure oscillations at different times intensifies when the stochastic Rijke-type thermoacoustic system is configured closer to the supercritical bifurcation point. Figures.

Figure 7(c) and

Figure 7(d) illustrate that increasing the autocorrelation time of colored noise or decreasing its noise intensity can slow the decreasing trend of

in terms of the time lag, which enhances the correlation of the thermoacoustic response in the time domain.

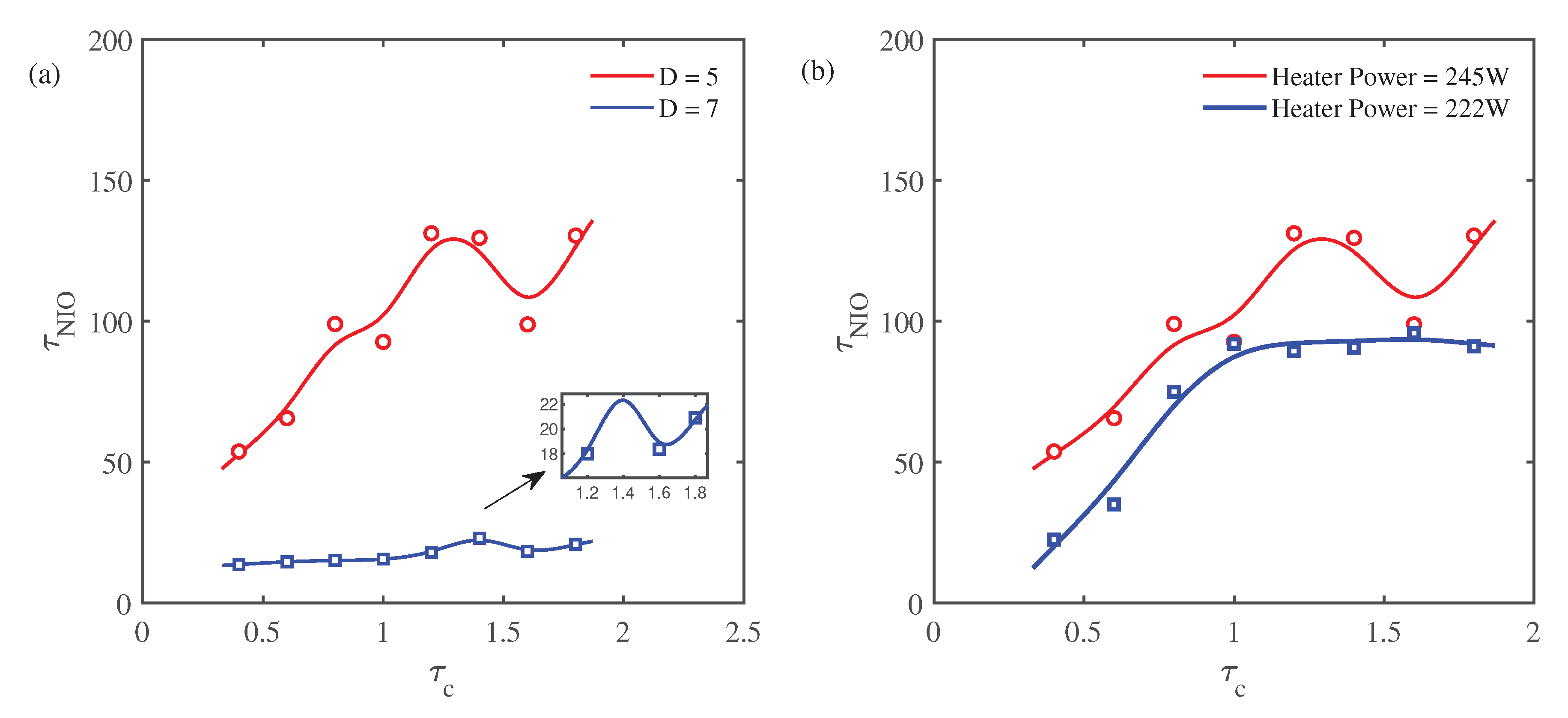

The correlation time of the acoustic pressure

is evaluated in

Figure 8. When the heater power is around 245 W, the correlation time of the acoustic pressure

increases linearly with respect to the autocorrelation time of the colored noise

and becomes nonlinearly when

is greater than 1.4, as seen in

Figure 8(a). Increasing the colored noise intensity

D from 5 to 7 leads to a significant decrease in the correlation time. When the thermoacoustic system is configured to be further from the bifurcation point, i.e.,

222 W,

Figure 8(b) shows that both the correlation time

and saturation point for

decrease. Therefore, colored noise with a larger autocorrelation time and smaller noise intensity creates more intense oscillations in the Rijke-type thermoacoustic system, especially when configured to be closer to the stability boundary.

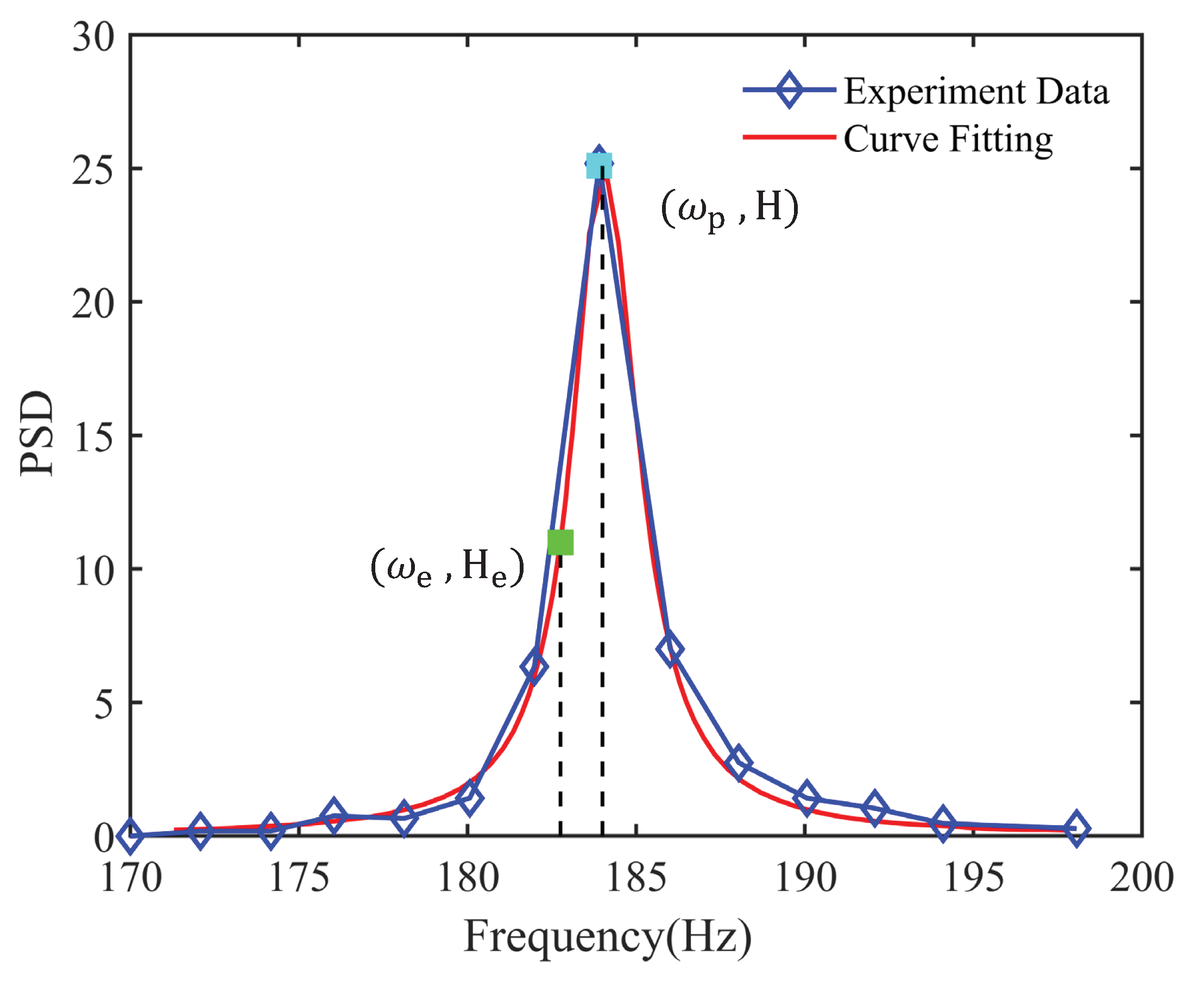

The SNR of the acoustic pressure fluctuations is utilized to characterize the regularity of the noise-induced motion in the Rijke-type thermoacoustic system. This is defined by the power spectral density of the stochastic signal [

43], as shown in

Figure 9.

In the figure,

H represents the peak height of the power spectrum,

is the corresponding peak frequency, and

is the width of the frequency between the peak and the frequency for the SNR value of

. In

Figure 9, the blue curve denotes the experimentally-obtained power spectral density, while the red curve is obtained via curve fitting. The power spectrum density of the noise-induced oscillation (NIO) exhibits a distinguishable peak, and the corresponding frequency is close to the theoretical prediction of the first-order acoustic frequency of the Rijke tube.

The dependencies of the SNR for the Rijke-type thermoacoustic system response on the autocorrelation time of the colored noise

at different noise intensities are studied in

Figure 10. The dots represent the experimental data, and the smooth curves are obtained via curve fitting. For a fixed noise intensity

D,

Figure 10(a) shows that the SNR of the thermoacoustic system response increases initially and then decreases with the autocorrelation time

. Thus, there is an optimal autocorrelation time

for which the SNR is maximized. When the noise intensity

D varies, all three SNR curves show bell-shaped variations, which indicates coherence resonance. In addition, a stronger colored noise intensity

D corresponds to a larger optimal autocorrelation time

. These findings are consistent with Li’s analytical predictions in annular gas turbine systems [

41].

Figure 10(b) shows the sound pressure time series signals at different SNRs with a fixed colored noise intensity of

. The red dashed line for the maximum SNR value has more intense oscillations than the blue curve for the system with a lower SNR.

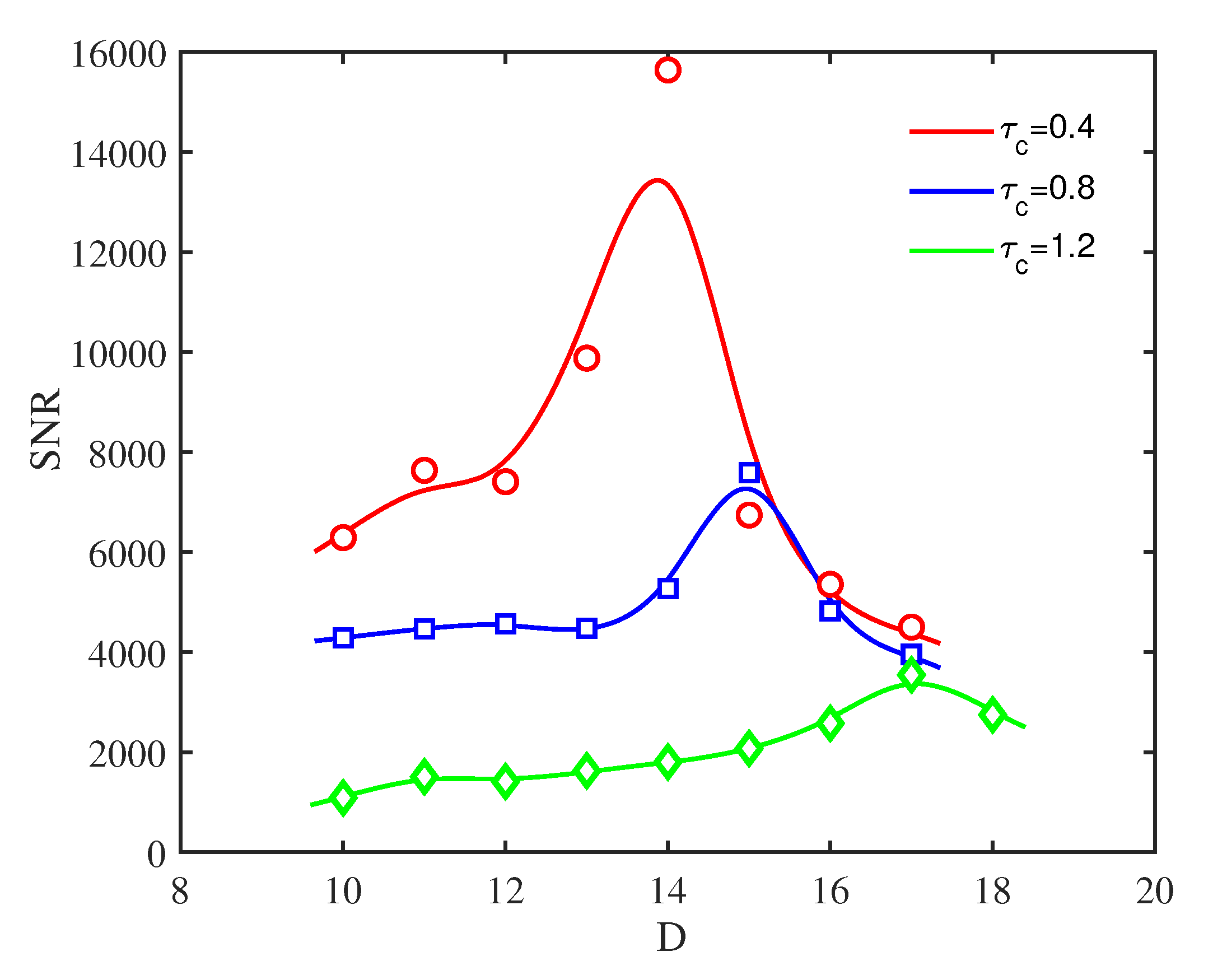

The dependence of the SNR on the noise intensity

D is evaluated in

Figure 11. With an increased colored noise intensity

D, the SNRs of the thermoacoustic system have resonance-like behaviors, and there is an optimal noise intensity where the SNR is maximized. Therefore, coherence resonance also occurs with respect to the noise intensity. Meanwhile, a larger

corresponds to a greater optimal noise intensity for coherence resonance.

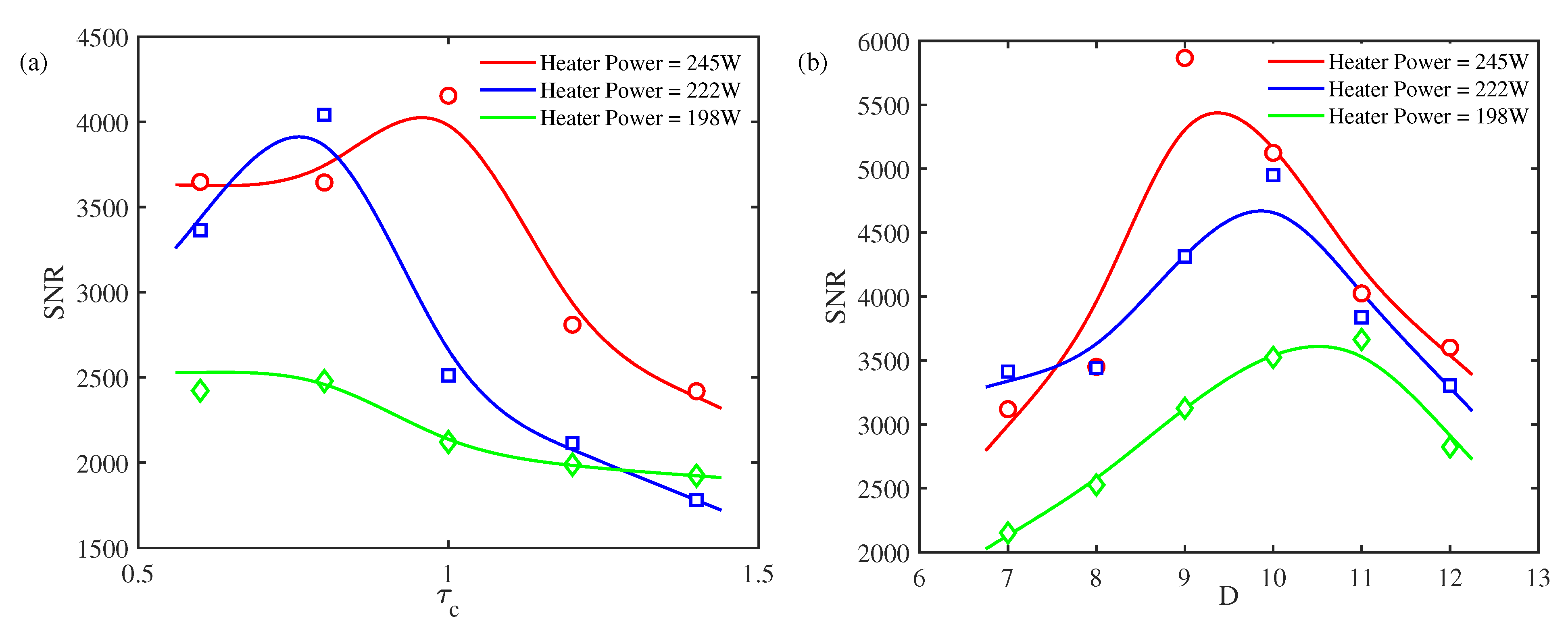

Finally, the dependence of the thermoacoustic system response SNR on the operating conditions (i.e., heating power) is evaluated in

Figure 12.

Figure 12(a) shows variations in the SNR with respect to the autocorrelation time

of the colored noise when the noise intensity is fixed at

. When the heating power is 198 W, the system is away from the bifurcation point, and an increased autocorrelation time for the colored noise leads to a nearly monotonic decrease in the SNR of the thermoacoustic system response. Thus, no coherence resonance is observed. By comparison, when the heating power is increased, a greater autocorrelation time

causes the blue and red SNR curves to increase first and then decrease. Both bell-shaped curves are observed when the system is close to the supercritical bifurcation point. That is, obvious coherence resonance behaviors in terms of

appear near the bifurcation point. The closer the system is configured to the supercritical bifurcation point, the larger the optimal autocorrelation time.

Figure 12(b) shows variations in the SNR with respect to the noise intensity

D with an autocorrelation time of the colored noise fixed at

. The three curves all exhibit the behaviors of coherence resonance. Similarly, as the autocorrelation time

is fixed and the system is configured to be closer to the supercritical bifurcation point, the maximum SNR increases and the optimal noise intensity decreases, which is consistent with the influence of white noise.