Submitted:

26 April 2023

Posted:

27 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Model description

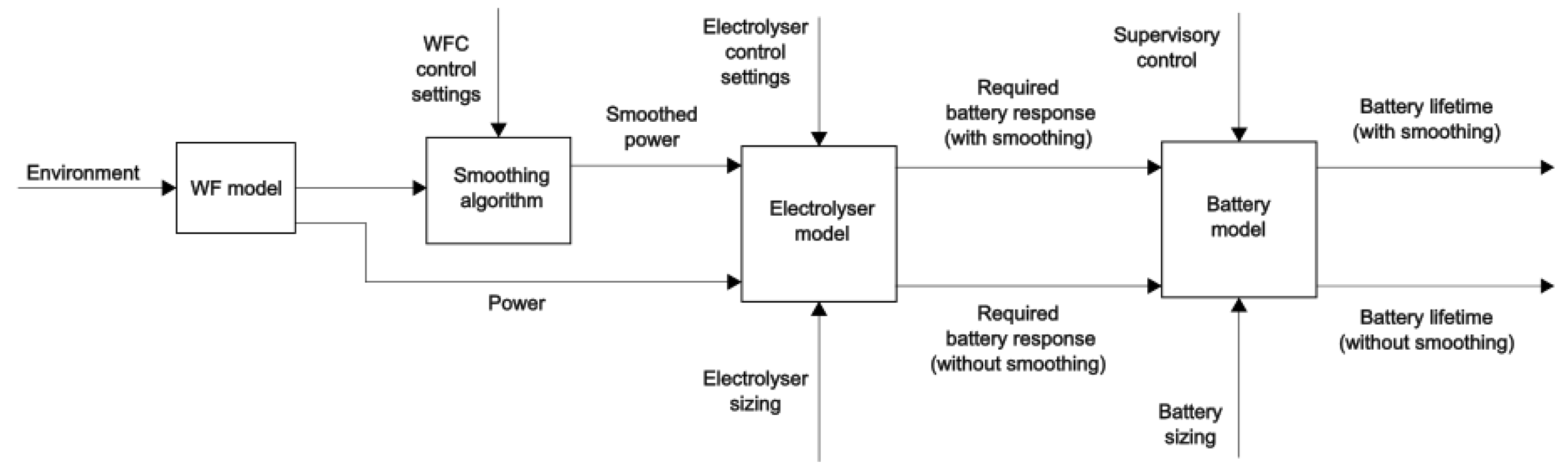

2.1. High level data flow

2.2. Wind turbine and wind farm models

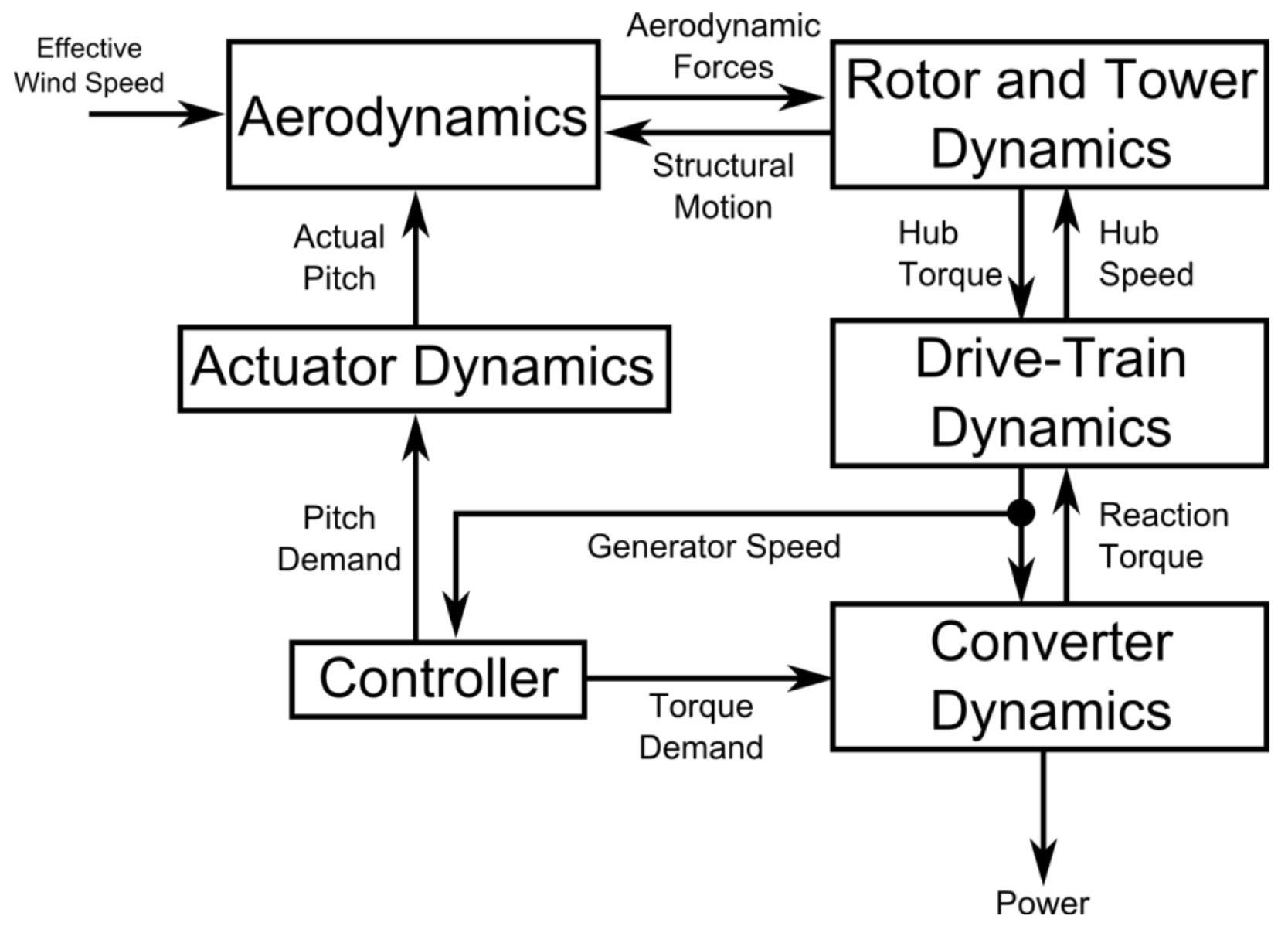

2.2.1. Wind Turbine Model

2.2.2. Wind Farm Model

2.3. Idealised control methodology

2.3.1. Available kinetic energy

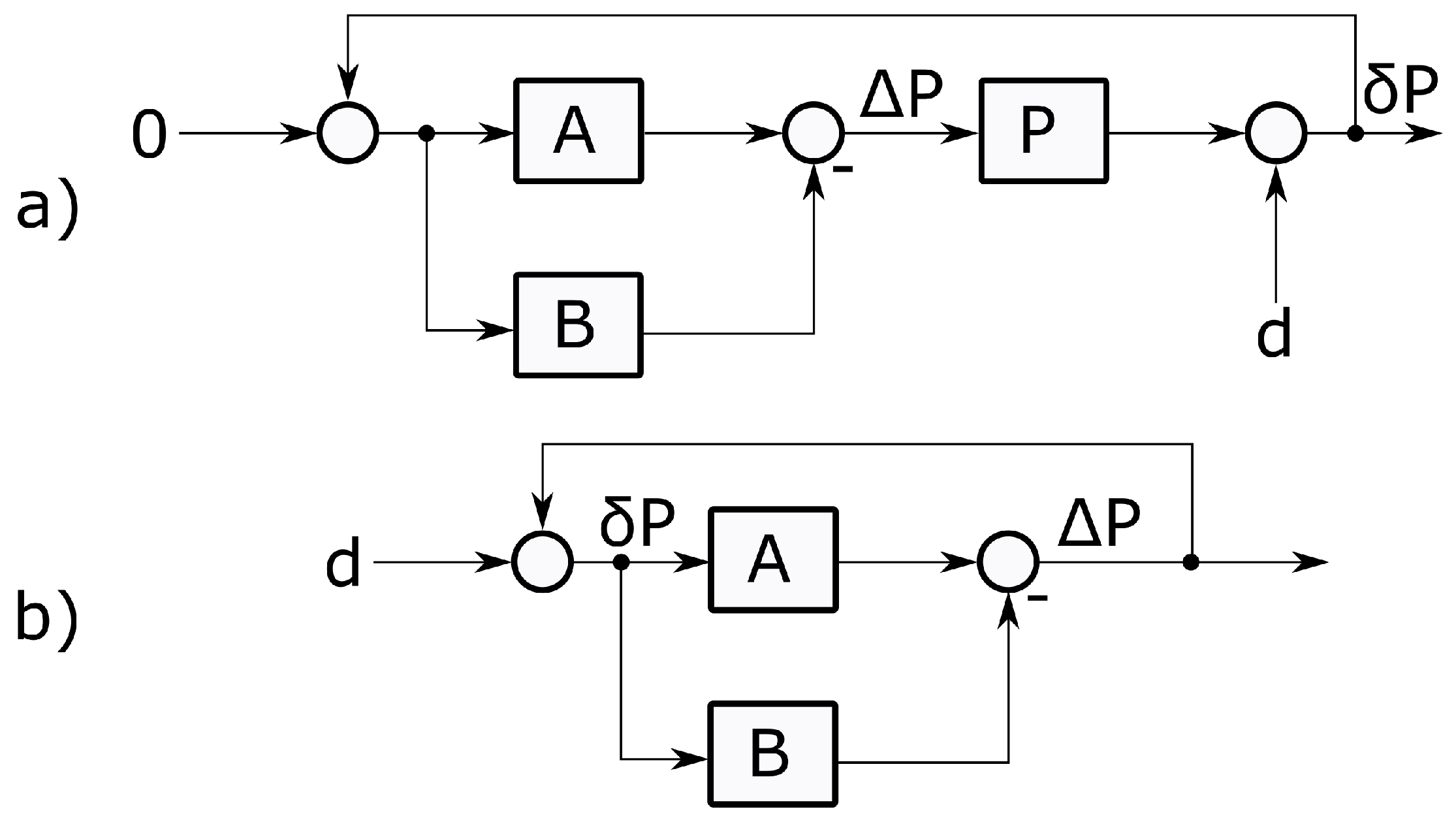

2.3.2. Wind farm control structure

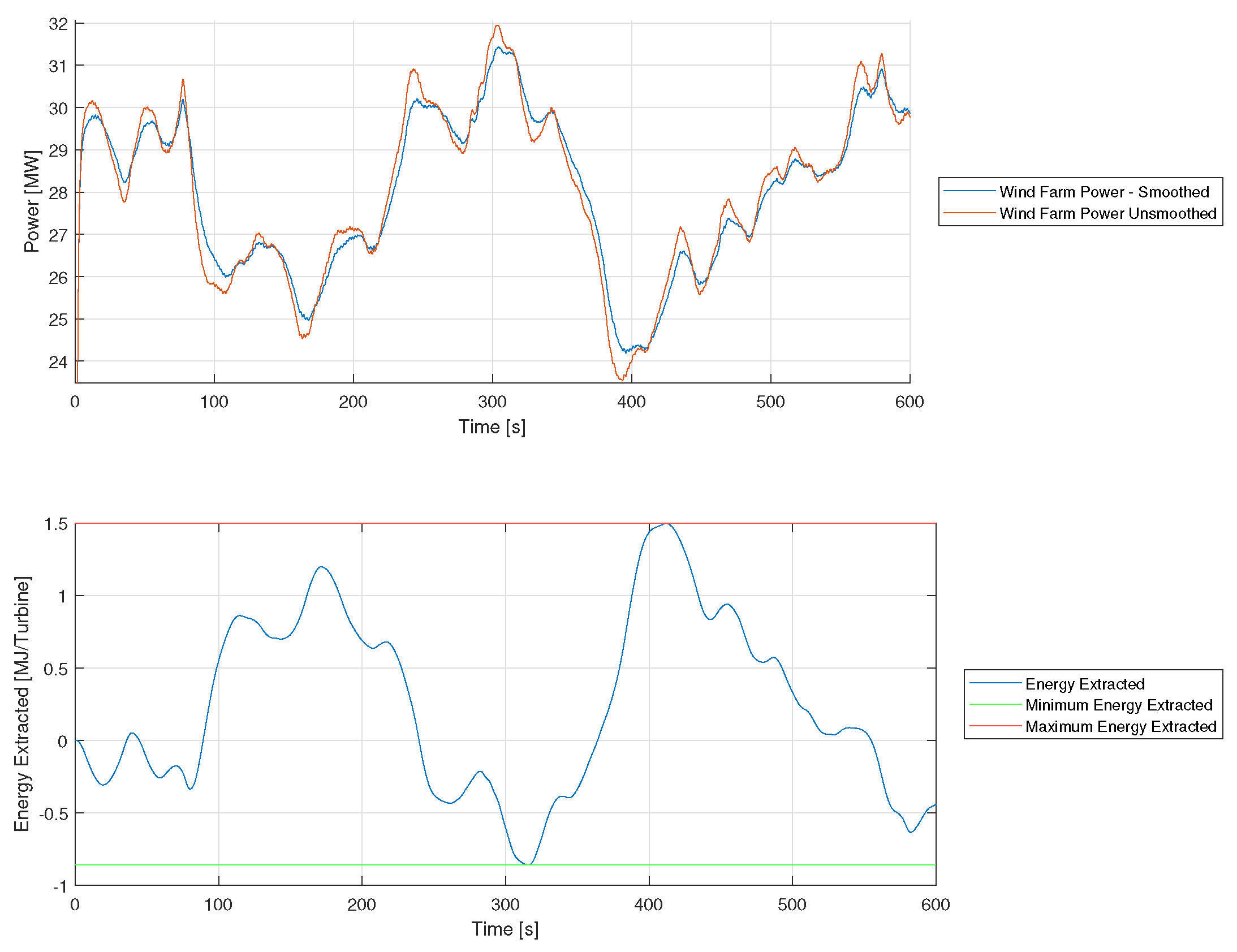

2.3.3. Example of WFC outputs

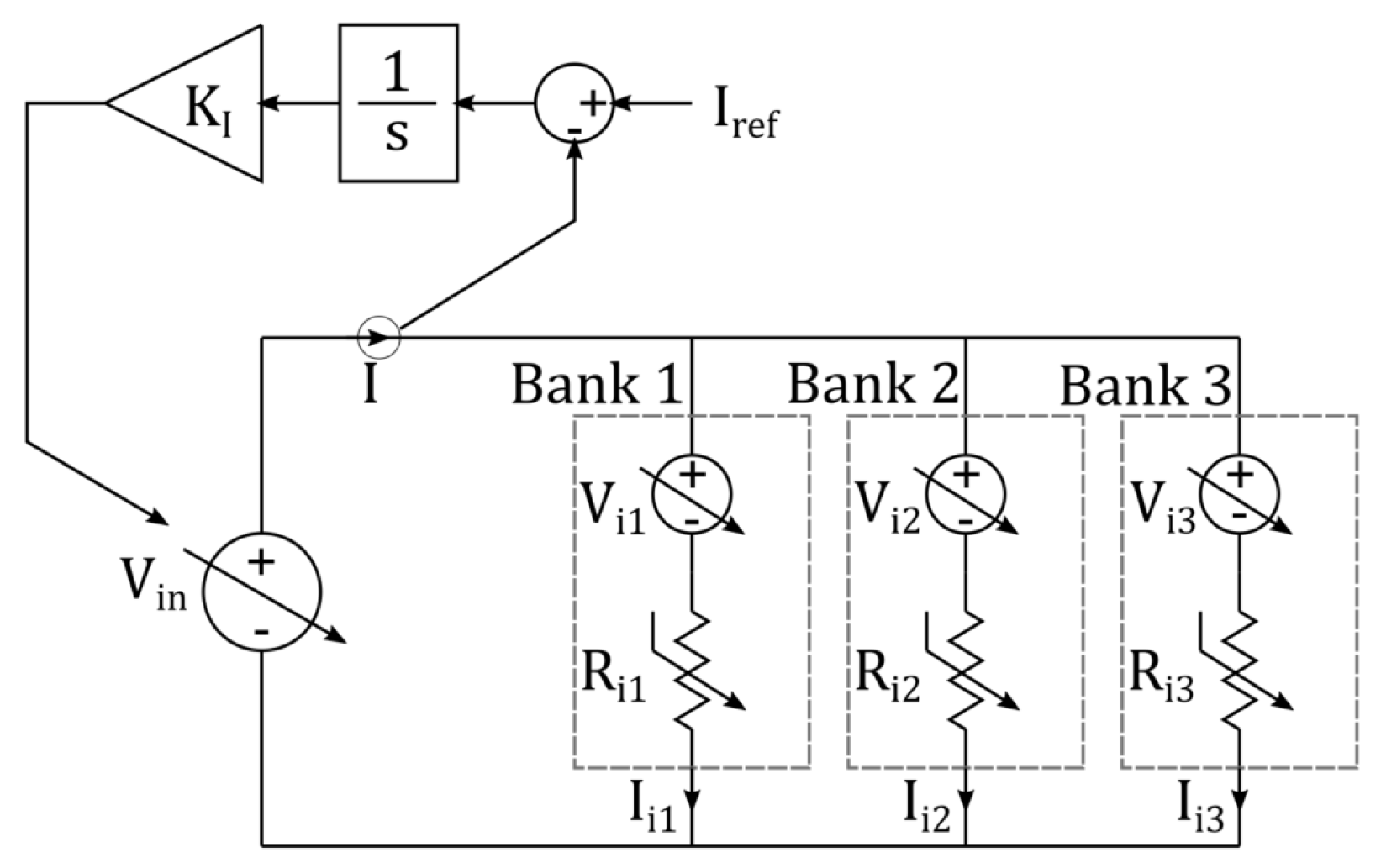

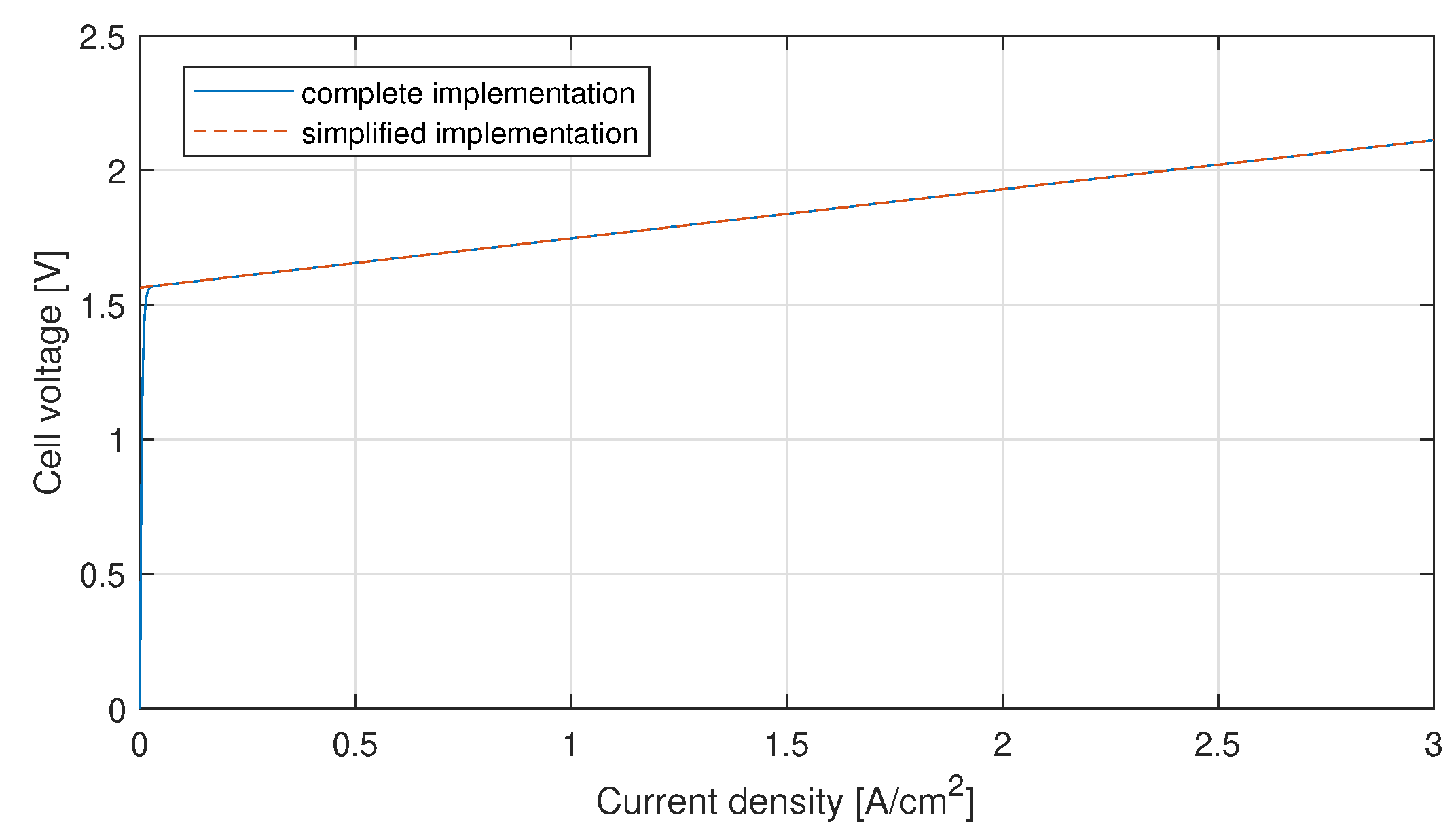

2.4. Electrolyser model

- Power consumption of supporting system is neglected.

- Isothermal operation, i.e. the system is at rated temperature throughout.

- Isobaric operation, i.e. the system is at rated pressure throughout.

- Minimal degradation of the electrolyser.

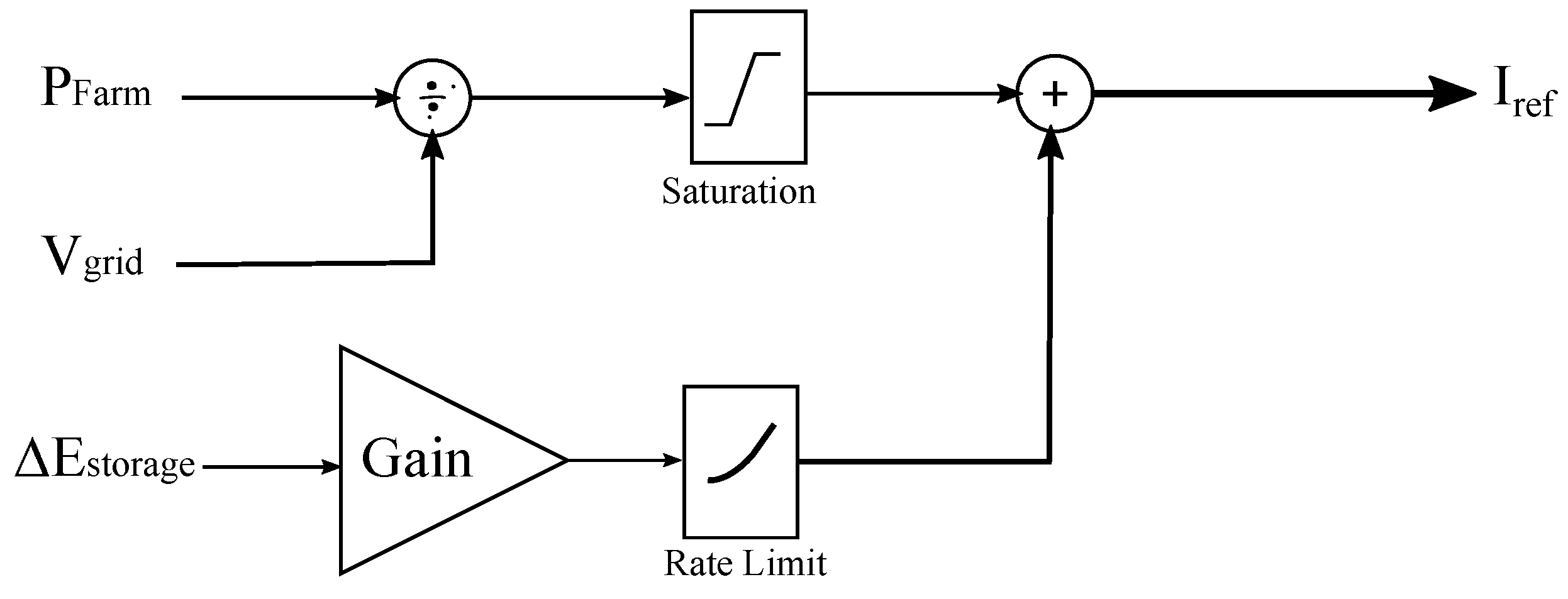

2.5. Supervisory control

2.6. Battery lifetime model

3. Case study

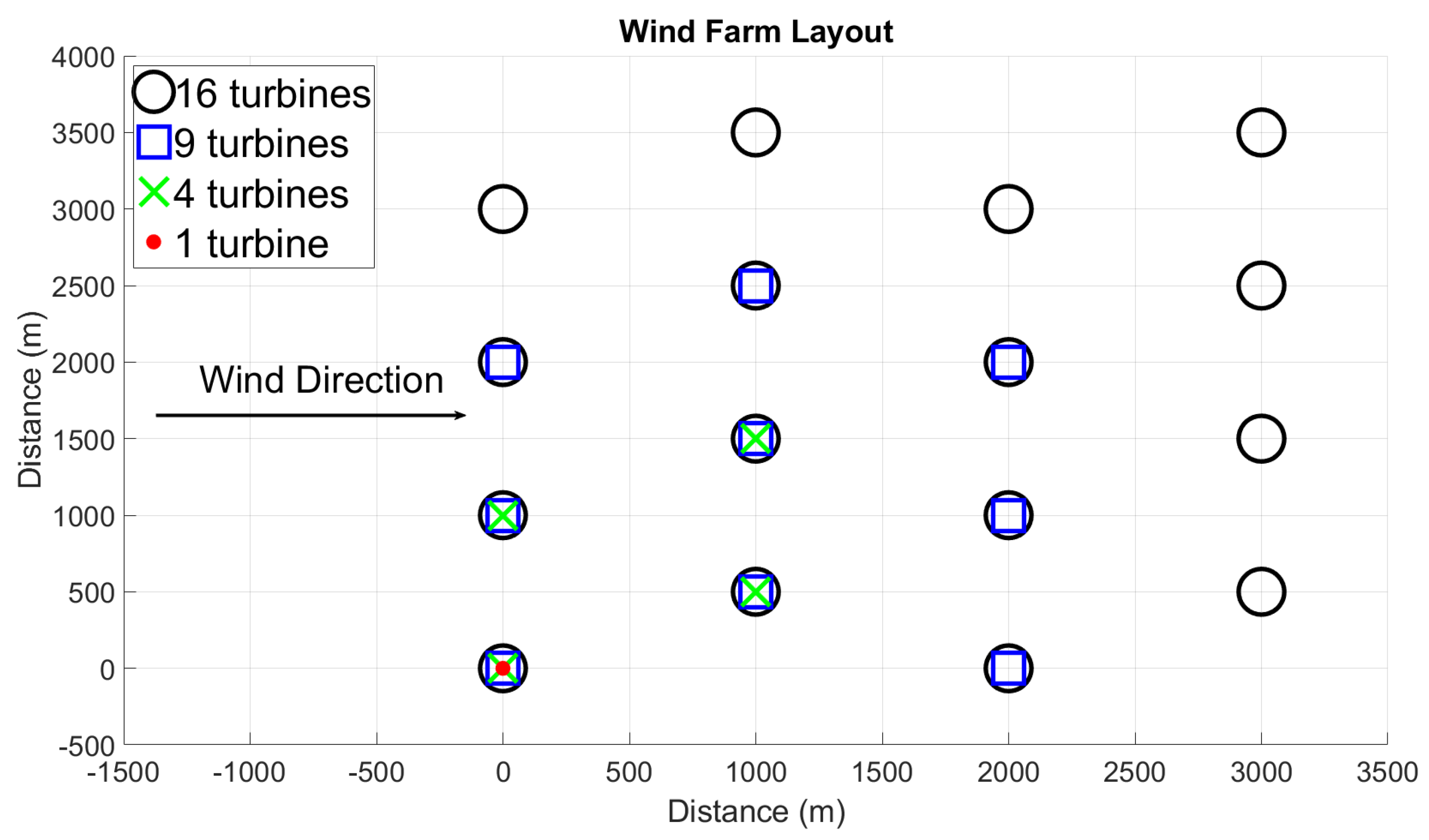

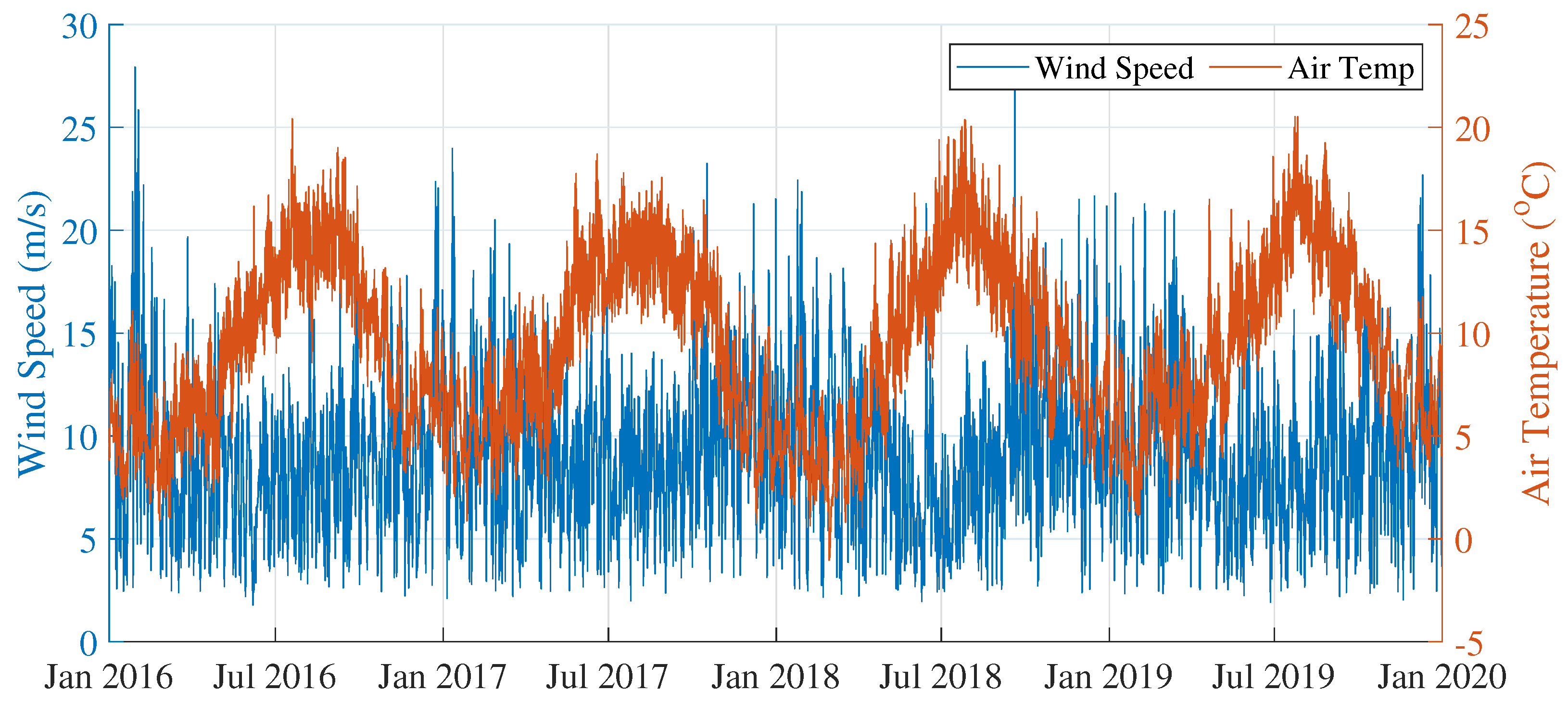

3.1. Wind farm layout and wind properties

3.2. Wind turbine model

3.3. Applying outputs from the electrolyser to the battery model

3.4. Wind Farm Control Design

3.4.1. Note on implementation for one turbine

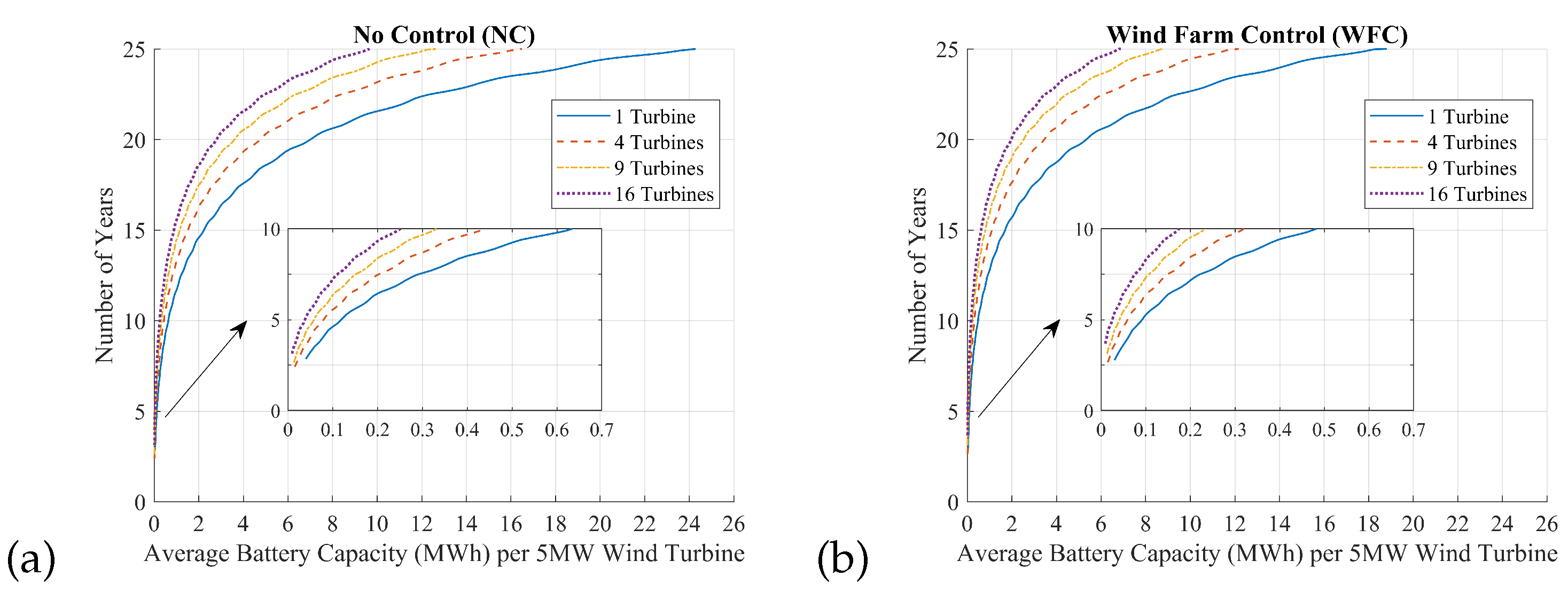

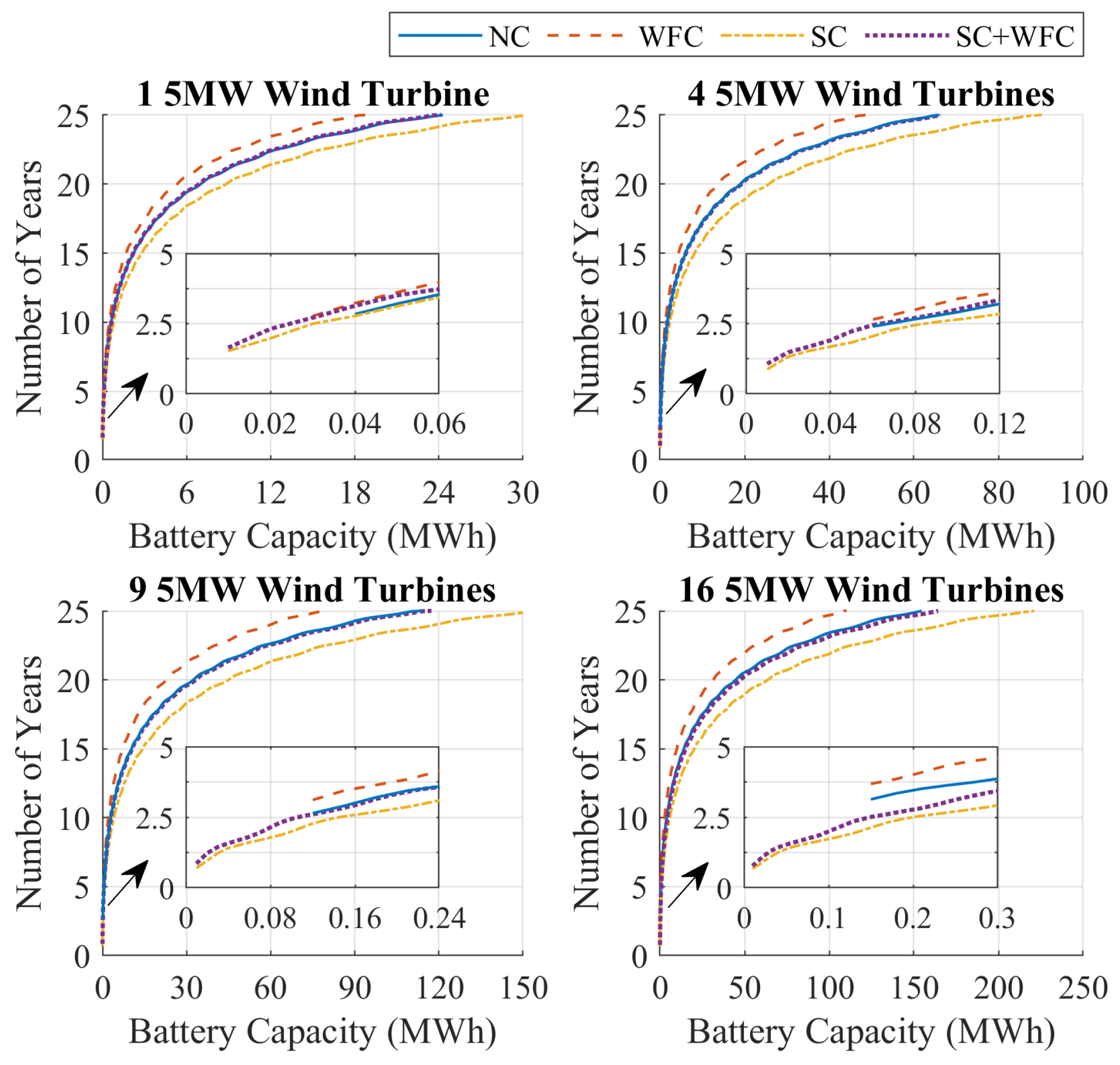

4. Results

5. Discussion

6. Conclusions

- A full implementation of the WFC and supervisory controller

- Further study in the tuning of the supervisory controller gain

- Further development of the electrolyser model to include degradation

- Further development of the battery model to include thermal considerations

- A LCOE analysis of wind to hydrogen with no grid connection

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| NC | No Control |

| WFC | Wind Farm Control |

| SC | Supervisory Control |

| DoD | Depth of Discharge |

| SoC | State of Charge |

| LMO | Lithium Manganese Oxide |

| SEI | Solid Electrolyte Interphase |

| MERRA-2 | Modern-Era Retrospective Analysis for Research and Applications, Version 2 |

| LCOE | Levelised Cost of Energy |

References

- Spyroudi, A.; Stefaniak, K.; Wallace, D.; Mann, S.; Smart, G.; Kurban, Z. Offshore wind and hydrogen: Solving the integration challenge. Technical report, ORE Catapult, UK, 2020.

- Jang, D.; Kim, K.; Kim, K.H.; Kang, S. Techno-economic analysis and Monte Carlo simulation for green hydrogen production using offshore wind power plant. Energy Conversion and Management 2022. [Google Scholar] [CrossRef]

- Oliveira, A.M.; Beswick, R.R.; Yan, Y. A green hydrogen economy for a renewable energy society. Science Direct 2021. [Google Scholar] [CrossRef]

- Song, S.; Lin, H.; Sherman, P.; Yang, X.; Nielsen, C.P.; Chen, X.; McElroy, M.B. Production of hydrogen from offshore wind in China and cost-competitive supply to Japan. Nature 2021. [Google Scholar] [CrossRef] [PubMed]

- Office of Energy Efficiency & Renewable Energy, US DOE. Hydrogen’s Role in Transportation. Available online: https://www.energy.gov/eere/vehicles/articles/hydrogens-role-transportation (accessed on 14 September 2022).

- Department of Business, Energy & Industrial Strategy. British Energy Security Strategy. Available online: https://www.energy.gov/eere/vehicles/articles/hydrogens-role-transportation (accessed on 28 April 2022).

- McKinsey & Company. How to succeed in the expanding global offshore wind market. Available online: https://www.mckinsey.com/industries/electric-power-and-natural-gas/our-insights/how-to-succeed-in-the-expanding-global-offshore-wind-market (accessed on 14 September 2022).

- International Energy Agency. Wind Power. Available online: https://www.iea.org/reports/wind-power (accessed on 14 September 2022).

- Climate Change Committee. Net Zero: The UK’s contribution to stopping global warming. Available online: https://www.theccc.org.uk/publication/net-zero-the-uks-contribution-to-stopping-global-warming/ (accessed on 28 April 2022).

- Climate Change Committee. The Sixth Carbon Budget. Available online: https://www.theccc.org.uk/publication/sixth-carbon-budget/ (accessed on 28 April 2022).

- Renewable, UK. Wind Energy Statistics. Available online: https://www.renewableuk.com/page/UKWEDhome/Wind-Energy-Statistics.htm (accessed on 14 September 2022).

- USDOE. Hydrogen Strategy: Enabling a Low-Carbon Economy. Technical report, US Department of Energy, 2020.

- Bonacina, C.N.; Gaskare, N.B.; Valenti, G. Assessment of offshore liquid hydrogen production from wind power for ship refueling. International Journal of Hydrogen Energy 2021. [Google Scholar] [CrossRef]

- Calado, C.; Castro, R. Hydrogen Production from Offshore Wind Parks: Current Situation and Future Perspectives. Applied Sciences 2021. [Google Scholar] [CrossRef]

- Schug, C. Operational characteristics of high-pressure, high-efficiency water-hydrogen-electrolysis. International journal of hydrogen energy 1998, 23, 1113–1120. [Google Scholar] [CrossRef]

- Zeng, Z.; Ouimet, R.; Bonville, L.; Niedzwiecki, A.; Capuano, C.; Ayers, K.; Soleymani, A.P.; Jankovic, J.; Yu, H.; Mirshekari, G.; et al. Degradation Mechanisms in Advanced MEAs for PEM Water Electrolyzers Fabricated by Reactive Spray Deposition Technology. Journal of the Electrochemical Society 2022. [Google Scholar] [CrossRef]

- Weiss, A.; Siebel, A.; Bernt, M.; Shen, T.H.; Tileli, V. Impact of Intermittent Operation on Lifetime and Performance of a PEM Water Electrolyzer. Journal of The Electrochemical Society 2018. [Google Scholar]

- Papakonstantinou, G.; Algara-Siller, G.; Teschner, D.; Vidaković-Koch, T.; Schlögl, R.; Sundmacher, K. Degradation study of a proton exchange membrane water electrolyzer under dynamic operation conditions. Applied Energy 2020, 280, 115911. [Google Scholar] [CrossRef]

- Xu, B.; Oudalov, A.; Ulbig, A.; Andersson, G.; Kirschen, D.S. Modeling of Lithium-Ion Battery Degradation for Cell Life Assessment. IEEE Transactions on Smart Grid 2018, 9, 1131–1140. [Google Scholar] [CrossRef]

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW reference wind turbine for offshore system development. Technical report, National Renewable Energy Lab.(NREL), Golden, CO (United States), 2009.

- Chatzopoulos, A.P. Full envelope wind turbine controller design for power regulation and tower load reduction. PhD thesis, University of Strathclyde, 2011.

- Jamieson, P. Innovation in wind turbine design; John Wiley & Sons, 2018.

- Stock, A.; Leithead, W. Providing grid frequency support using variable speed wind turbines with augmented control. In Proceedings of the European Wind Energy Conference and Exhibition 2012. WindEurope; 2012; pp. 153–160. [Google Scholar]

- Lalor, G.; Mullane, A.; O’Malley, M. Frequency control and wind turbine technologies. IEEE Transactions on Power Systems 2005, 20, 1905–1913. [Google Scholar] [CrossRef]

- Giles, A.; van der Hoek, D.; Bedon, G.; Merz, K.; Kühn, M.; Vali, M.; Anaya-Lara, O.; Kanev, S.; Petrović, V.; Trabucchi, D.; et al. Integrated Research Programme on Wind Energy: Offshore array control Work Package 6.3-Deliverable number 63.4. Technical report, University of Strathclyde, 2018.

- Hur, S.H.; Poushpas, S.; Amos, L.; Leithead, B. Supergen Wind Hub: D3. 1 Report of Wind Farm Modelling. Technical report, University of Strathclyde, 2019.

- Stock, A.; Leithead, W.; Anaya-Lara, O.; Amos, L.; Cole, M.; Taylor, P.; Pirrie, P.; Campos-Gaona, D. Wind farm control work at the University of Strathclyde, past, present and future. In Proceedings of the 5th Wind Energy Systems Engineering Workshop; 2019. [Google Scholar]

- Leithead, W.; Rogers, M. Drive-train characteristics of constant speed HAWT’s: Part I–Representation by simple dynamic models. Wind Engineering.

- Leithead, W.; Rogers, M. Drive-train characteristics of constant speed HAWT’s: Part II–Simple characterisation of dynamics. Wind Engineering.

- Neilson, V.W. Individual Blade Control for Fatigue Load Reduction of Large-scaled Wind Turbines : Theory and Modelling. Mphil, University of Strathclyde, 2010.

- Veers, P.S. Three-dimensional wind simulation. Technical report, Sandia National Labs., Albuquerque, NM (USA), 1988.

- Poushpas, S. Wind farm simulation modelling and control. PhD thesis, University of Strathclyde, 2016.

- Bastankhah, M.; Porté-Agel, F. A new analytical model for wind-turbine wakes. Renewable Energy 2014, 70, 116–123. [Google Scholar] [CrossRef]

- Gala-Santos, M.L. Aerodynamics and Wind-Field Models for Wind Turbine Control. Phd, University of Strathclyde, 2018.

- Stock, A. Augmented control for flexible operation of wind turbines. PhD thesis, University of Strathclyde, 2015.

- Stock, A.; Leithead, W. A generic approach to wind farm control and the power adjusting controller. Wind Energy 2022. [Google Scholar] [CrossRef]

- Anaya-Lara, O.; Campos-Gaona, D.; Moreno-Goytia, E.; Adam, G. Offshore wind energy generation: control, protection, and integration to electrical systems; John Wiley & Sons, 2014.

- Buttler, A.; Spliethoff, H. Current status of water electrolysis for energy storage, grid balancing and sector coupling via power-to-gas and power-to-liquids: A review. Renewable and Sustainable Energy Reviews 2018, 82, 2440–2454. [Google Scholar] [CrossRef]

- Ferguson, J.L. Technoeconomic Modelling of Renewable Hydrogen Supply Chains on Islands with Constrained Grids. PhD thesis, University of Edinburgh, 2021.

- Lee, Y.L.; Tjhung, T. Chapter 3 - Rainflow Cycle Counting Techniques. In Metal Fatigue Analysis Handbook; Lee, Y.L., Barkey, M.E., Kang, H.T., Eds.; Butterworth-Heinemann: Boston, 2012; pp. 89–114. [Google Scholar]

- IEC. IEC 61400-1: 2019: Wind energy generation systems - Part 1: Design requirements. Standard, International Electrotechnical Commission, Geneva, CH, 2019.

- Gelaro, R.; McCarty, W.; Suárez, M.J.; Todling, R.; Molod, A.; Takacs, L.; Randles, C.A.; Darmenov, A.; Bosilovich, M.G.; Reichle, R.; et al. The Modern-Era Retrospective Analysis for Research and Applications, Version 2 (MERRA-2). Journal of Climate 2017, 30, 5419–5454. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.; Zorzi, G.; Campos-Gaona, D.; Nwobu, J. Wind-plus-battery system optimisation for frequency response service: the UK perspective. Electric Power Systems Research 2022, 211, 108400. [Google Scholar] [CrossRef]

| Component | Symbol | Value | Unit |

|---|---|---|---|

| Cell area | 1000 | cm | |

| Rated current density | 3 | A/cm | |

| Rated temperature | 55 | C | |

| Rated pressure | 20 | bar | |

| Cell voltage at nominal current and temperature | 2.1 | V | |

| Voltage rating per bank | 633.5 | V | |

| Current rating per bank | 3000 | A | |

| Power rating of one electrolyser unit | 5.7 | MW | |

| Reference voltage | 1.55 | V | |

| Ideal gas constant | R | 8.314 | J/mol/K |

| Faraday constant | F | 96,485 | As/mol |

| Reference resistance | 0.34 | ||

| Gradient constant | -0.0045 | cm/C |

| Coefficient | Value | Coefficient | Value |

|---|---|---|---|

| 4.14E-10 () | 1.40E5 | ||

| 1.04 | -5.01E-1 | ||

| 6.93E-2 | -1.23E5 | ||

| 5.75E-2 | 121 |

| Wind Speed | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 18 | 20 | 22 | 24 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 Turbine | 1 | 1 | 2 | 2 | 2 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 6 | 6 | 6 | 6 |

| 4 Turbines | 1 | 1 | 2.4 | 3.3 | 3.3 | 3.9 | 3.9 | 3.9 | 9.4 | 10 | 10 | 10 | 10 | 18 | 18 | 20 |

| 9 Turbines | 1 | 1 | 3.2 | 6 | 6 | 6 | 6 | 6 | 15 | 15 | 20 | 20 | 20 | 20 | 20 | 20 |

| 16 Turbines | 1 | 1 | 3.2 | 3.2 | 3.8 | 4.7 | 4.9 | 4.9 | 5 | 5 | 5 | 5 | 20 | 20 | 20 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).