1. Introduction

A single definition of Industry 4.0 does not exist. However, a starting point could be the concept standardized by UNE, a set of Spanish technical standards developed by the Spanish Association for Standardization and Certification (AENOR), which establish minimum quality and safety requirements in different fields such as construction, energy, environment, health, etc.

The UNE standardizes the definition of "Industry 4.0" as the extensive inclusion of information technology in all processes related to the value chain of the manufacturing industry, which represents the fourth industrial revolution. The implementation of this technology will improve the coordination and optimization of research and development, design, production, logistics, and associated services processes, in general optimization product lifecycle management [

1,

2,

3,

4].

The complexity and interest in the 4.0 concept have led to the creation of numerous reports, platforms, and initiatives to lay the foundations for its understanding and proper application, the most prominent of which are referenced throughout this article. The complexity of the concept and the need for a stable context have certainly been demonstrated.

In the same way, the link is established with the need to create appropriate strategies, as well as trying to focus attention on certain issues, such as security or the development of an adapted legal framework. At a similar level, a large amount of technical literature has been developed on the main technological agents, including Cloud Computing [

5,

6,

7,

8] and Big Data [

9,

10,

11,

12] as a compendium of tools and resources for the collection, processing, and storage of large amounts of data [

13,

14,

15] or Cybersecurity [

16,

17], as the set of tools necessary to protect cyber environments, due to aggressions and cybercrime, among many others.

At the same time, it must be said that since practically the end of the 20th century, attention has been focused on the environment, which until then had been practically non-existent. This attention has turned into what could be expressed as concern in the present century. The main factor that the socio-political and cultural environment has been stimulating this observance is the exponential standard of living that the vast majority of countries are experiencing. A need arises to ensure the maintenance of these standards of living, which include issues such as the quality of air, water, as well as the quality of the products consumed by individuals.

The implementation of all these changes produces alterations both in factories and in their production processes and even in the life cycles of products. And beyond this, the changes also reach political, economic, and social levels.

The purpose of this study is to shed light on the critical aspect of Industry 4.0, known as Sustainability 4.0, with a specific focus on the energy sector. To achieve this aim, an in-depth analysis of the concept will be conducted, exploring its fundamental characteristics and scope. Additionally, this study will examine various quantitative indicators to evaluate the Spanish case and provide a comprehensive conclusion. To accomplish this, the paper will begin with an introduction that will present the context and significance of the topic, emphasizing the importance of Industry 4.0 and its implications for the energy sector.

Next, a literature review related to Industry 4.0 and the energy sector will be conducted, including definitions, key concepts, models, and relevant theories. Critical aspects will be developed, such as Industry 4.0 technologies applied to the energy sector (IoT, artificial intelligence, big data, etc.), the impact of Industry 4.0 on energy efficiency and sustainability, or the opportunities and challenges of Industry 4.0 in the energy sector.

Finally, the most relevant conclusions of the review will be presented, summarising the main ideas and contributions.

2. Theoretical Foundations of Energy's Role in Industry 4.0: an in-depth examination of materials and methods.

The objective of this review is to analyze the current situation of the energy sector in the context of Industry 4.0 and determine future trends and perspectives. To achieve this, a systematic search was conducted in electronic databases, including DIALNET, SCOPUS, SPI, and WoS. Relevant studies published in the last 10 years were selected using keywords such as "Industry 4.0," "energy," "digital technologies," and "energy efficiency." Inclusion and exclusion criteria were applied to select the most relevant articles, and a critical synthesis of the results was performed.

The review's findings are presented in different sections, including Industry 4.0 technologies, impact on energy efficiency and sustainability, and opportunities and challenges in the energy sector. It is expected that this review will contribute to a better understanding of the interaction between the energy sector and Industry 4.0 and identify areas for future research.

This paper is based on the review and study of numerous research literature, all of which are referenced in the bibliography section. According to the current state of the art, the object of the present work is developed.

An essential part is the specialized literature of both national and international nature, being these resources used both in physical and digital format. For the search of the resources in digital format it is worth mentioning that different digital sources have been used: ProQuest, EBSCOhost or ResearchGate, among others. These databases stand out for their extensive catalogue of articles, reviews, and scientific and academic publications by authors from all over the world.

However, for the collection of the data necessary for the quantitative analysis, different databases have been used, including INE (National Institute of Statistics of Spain), OECD (Organization for Economic Co-operation and Development), World Bank Open Data, and EUROSTAT (the statistical office of the European Union), whose routes used for data extraction are cited throughout the article. Although, in general terms, data items on innovation, energy, pollution and taxes have been used.

Energy is a critical component of the Industry 4.0 landscape [

18], as it plays a vital role in powering the technologies and systems that drive this new era of manufacturing. As companies move towards greater automation and digitization, they will require more energy to power their operations, as well as to support the increased demand for data processing and storage.

To meet these needs, companies will need to adopt new and innovative approaches to energy management, including the use of renewable energy sources, energy storage systems, and advanced energy management technologies. This will require significant investment and collaboration between industry, government, and academia, as well as the development of new policies and regulations to support the transition to a more sustainable energy future.

Overall, energy will be a critical factor in the success of Industry 4.0 [

19], and companies that are able to adopt and implement innovative energy solutions will be well positioned to thrive in the years ahead.

Manufacturing is nothing more than the production of objects composed of interlocking parts, which are made by different manufacturing processes. The passage from a raw material to a product is one of the manifestations of manufacturing [

20], but production is also the use of already manufactured products, whose mission is the development of new products. These production systems require the implementation of modern technologies to evolve. And along with these, energy is required to produce [

21].

Production systems must observe their general and specific objectives, as economic, political, and social situations mark the main points of attention of production [

22]. A correct system must address purely technical issues such as design needs, product standards and specifications, but beyond that it must address standards of sustainability and respect for the environment [

23].

The Industrial Revolution has influenced the way goods are produced. However, the term "Industrial Revolution" may be inappropriate as it does not adequately reflect the gradual progression of changes that occurred [

24]. Furthermore, the importance of other factors beyond changes in industrial production has been demonstrated when analyzing national income and its corresponding variables.

Industry 4.0 has roots in the first industrial revolution, which began in 18th century Britain and spread throughout Europe and North America in the 19th century. The revolution brought about the steam engine and other production techniques, resulting in greater production and reduced costs. The use of steam and water as energy sources created mechanized production systems and new social classes like the industrial bourgeoisie and proletariat [

25]. The first industrial revolution also led to the creation of modern factories and specialization of tasks, as well as significant economic and social changes.

So, the Second Industrial Revolution began in the late 19th century and lasted until the first half of the 20th century. It brought about significant socio-economic and technological changes [

26] such as electrification, assembly-line production [

27], mass production, automation of production processes [

28], the invention of the automobile and airplane [

29], emergence of oil, introduction of new materials, and expansion of international trade. These changes led to greater efficiency in production and an increase in material well-being. The labor movement played a strong role in defending workers' rights and fighting for social protection. This period of innovation and scientific research generated significant changes in the industrial, economic [

30], and social realms [

31].

The third industrial revolution, also known as the digital revolution, occurred in the mid to late 20th century with the introduction of electronics and computing. This revolution has been marked by the development of information and communication technologies (ICT) [

32], which have allowed for greater connectivity and access to information.

The third industrial revolution, also known as the digital revolution, was marked by the development of information and communication technologies. The scientific-technical revolution, or intelligence revolution, is a concept coined by Jeremy Rifkin, who argues that the second industrial revolution based on fossil fuels is declining due to rising energy and food prices, high unemployment, increasing debt, and climate change caused by industrial activity based on fossil fuels [

33]. This era of digital revolution includes advances such as the World Wide Web (WWW), created in 1989 [

34,

35].

This is how we arrive at the fourth industrial revolution, also known as Industry 4.0, which involves the integration of digital and physical technologies to transform production and economic systems [

36,

37]. It entails the utilization of technologies such as artificial intelligence (AI) and the implementation of machine learning algorithms to AI, thereby unlocking a plethora of application options, including energy management control of systems [

38,

39,

40,

41,

42,

43,

44], the Internet of Things (IoT) [

45], advanced robotics, and additive manufacturing (3D printing) to improve the efficiency, cost, and flexibility of production processes [

46,

47].

Industry 4.0 refers to the integration of digital technologies in manufacturing industry and the transformation of production processes. There are various definitions of the concept, including those of the University of Aachen, the German Ministry of Economics and Energy, the German Ministry of Education and Research, the Organization for Economic Co-operation and Development (OECD) and the World Economic Forum [

48,

49]. They all highlight the importance of integrating cyber-physical systems into production to create more efficient, flexible, and customized processes [

47,

50].

Industry 4.0 is a term that encompasses technologies and concepts for organizing the value chain. It integrates cyber-physical systems, the Internet of things, and online services to create a smart factory. This approach optimizes production, logistics, and maintenance through intelligent interconnection of machines and processes. Industry 4.0 represents an evolution in industrial automation, creating an intelligent and connected ecosystem of people, machines, and objects. The main goal is to create a smart factory where cyber-physical systems monitor and make decentralized decisions to improve efficiency and customization [

51,

52,

53,

54,

55,

56].

The concept of Industry 4.0 was officially presented at the Hannover-Messe 2011, where the digitalization, automation, and connectivity of production were championed, paving the way for smart factories and connected industry [

57]. Germany is leading the 4.0 initiative due to its vast experience in complex industrial processes, which has positioned the country as a pioneer in this field [

58].

During the Hannover industrial fair in 2013, the German government presented its official Industry 4.0 initiative. ACATECH, DFKI, and major German companies published a foundational document highlighting how Industry 4.0 can improve business, infrastructure, and work ("Recommendations for implementing the strategic initiative Industrie 4.0", which included the associated platform "Platform Industrie 4.0"). Solid strategies are provided to implement the transition to 4.0, including examples of customized manufacturing.

The report emphasizes that Germany must integrate ICT into its traditional strategies to maintain its leadership in the global market [

59]. The main purpose of this report is to present Germany as a state with sufficient potential and the right technological and production bases for the development of a new type of industrialization. It points out how the country must strive to include ICTs in "traditional" strategies on an ongoing basis to maintain its global market leadership [

60].

The document said that Germany, as a leader, must implement three critical points: vertical and horizontal integration, networked manufacturing systems, and digital integration of engineering factor in the value chain. [

51,

61,

62].

The German Industry 4.0 initiative has received support from several countries. For example, the United States developed the initiative "2010-Plan Advanced Manufacturing", with the aim of developing its manufacturing industry and digital transformation. It creates the network of institutes (IMIs). For its part, and by way of illustration, France has the "2013-La Nouvelle France Industrielle" initiative, with specific plans and the development of priority technologies (cloud computing, cybersecurity, etc.) with the aim of boosting innovation and competitiveness.

The European level has also shown interest in the Industry 4.0 concept, which has led, among others, to the Europe 2020 Framework - Innovation Union/ a digital agenda for Europe/ an industrial policy for the globalization era. Europe has been declared to lead and promote the digital transformation of its companies and the modernization of its infrastructures to maintain its competitiveness in the global market, and there are different reports that express it, such as "Industry 4.0, The New Industrial Revolution” [

63]. Similarly, Europe must address issues of privacy and security, studying the limits of cybersecurity in a context of 4.0 development [

64].

In the case of Spain, the " Connected Industry 4.0." platform should be highlighted, which seeks to improve the competitiveness and economic growth of national industry through the integration of advanced digital technologies in production processes and the value chain. It seeks to increase the efficiency and productivity of companies, promote skilled employment, and generate new business and export opportunities.

To achieve these objectives, different measures are being conducted, such as the creation of research and development centers, the promotion of training in digital skills, the financing of innovative projects and public-private collaboration. The initiative has received the support of both sectors and is expected to have a significant impact on the economy and the competitiveness of Spanish companies in the global market.

It is important to consider that the adoption of Industry 4.0 will not solely bring benefits, and it is crucial to have a clear understanding of the underlying factors and prerequisites for successful implementation. Technology and knowledge generate wealth, and there is a positive relationship between a country's hidden wealth and its GDP [

65]. The adaptation of a complex concept such as Industry 4.0 entails both opportunities and challenges for countries. Therefore, countries must make efforts to understand its defining features and how they can adapt, including attention to fiscal policies and addressing issues such as tax evasion and the lack of adaptation of factors such as human capital in terms of education and the labor market, among others [

66].

The impact of Industry 4.0 may not be entirely positive, and it is therefore necessary to comprehensively assess the factors that facilitate or hinder its success [

67]. In general terms, it can be summarized that the technological basis of 4.0. in the elements: Cloud computing [

68], big data [

9,

69,

70,

71,

72], cybersecurity [

73], IoT, Simulation [

74] and 3D printing [

75] and robotic [

76]. And alongside the enablers of 4.0. are the factors that play a decisive role in its implementation. One of these is energy, which is the subject of this article.

3. The nexus between energy and Industry 4.0 in Spain: insights from a comprehensive analysis.

Energy is a key factor in Industry 4.0, as it is necessary to drive the production processes and technologies used in it [

77]. Industry 4.0 is characterized by increased automation and digitalization of industrial processes, which requires a higher demand for electricity [

78]. In general terms, 4.0. should aim to reduce energy consumption and increase energy efficiency in industrial processes. To this end, technologies such as sensors and energy control systems are used to monitor and optimize energy consumption in real time [

79,

80].

Another important aspect of energy in Industry 4.0 is the use of renewable energy sources such as solar, wind and hydropower. These energy sources are becoming increasingly important in Industry 4.0, as they make it possible to reduce energy costs and improve the environmental sustainability of production processes.

Globally, the energy sector is in a process of transition towards Industry 4.0. In Europe, various initiatives and strategies are being implemented to drive the digital transformation of the energy sector. For example, the European Union has established the Horizon 2020 program, which funds research and innovation projects in energy and technology. Initiatives such as the European Green Pact, which seeks to achieve climate neutrality in Europe by 2050, have also been launched.

And in the case of Spain, the energy sector is also undergoing a transformation towards Industry 4.0. In 2019, the Just Transition Strategy was approved, which lays the foundations for a sustainable and just energy transition in Spain. In addition, initiatives such as the National Integrated Energy and Climate Plan 2021-2030 have been implemented, which sets out the objectives and measures needed to achieve a low-carbon economy. On the business side, several Spanish energy companies are implementing digital technologies in their production processes. For example, the Spanish company Endesa has developed digitalization projects in its power plants and in the management of smart grids. Another Spanish company, Acciona, has implemented technologies such as virtual and augmented reality in the construction of wind farms.

In Spain, the arrival of 4.0 could be marked in 2015, when the "

Industria conectada 4.0" (Connected Industry 4.0) initiative was launched at state level, with the collaboration of private entities such as Telefónica. In this year, the platform published the report "

The digital transformation of the Spanish manufacturing sector”, which seeks to highlight the importance of industry for the growth of the entire Spanish economy. Already in this report [

81], the concept of guaranteeing the sustainability of the production process only appears in the appendix and in any case not in a long-term projection.

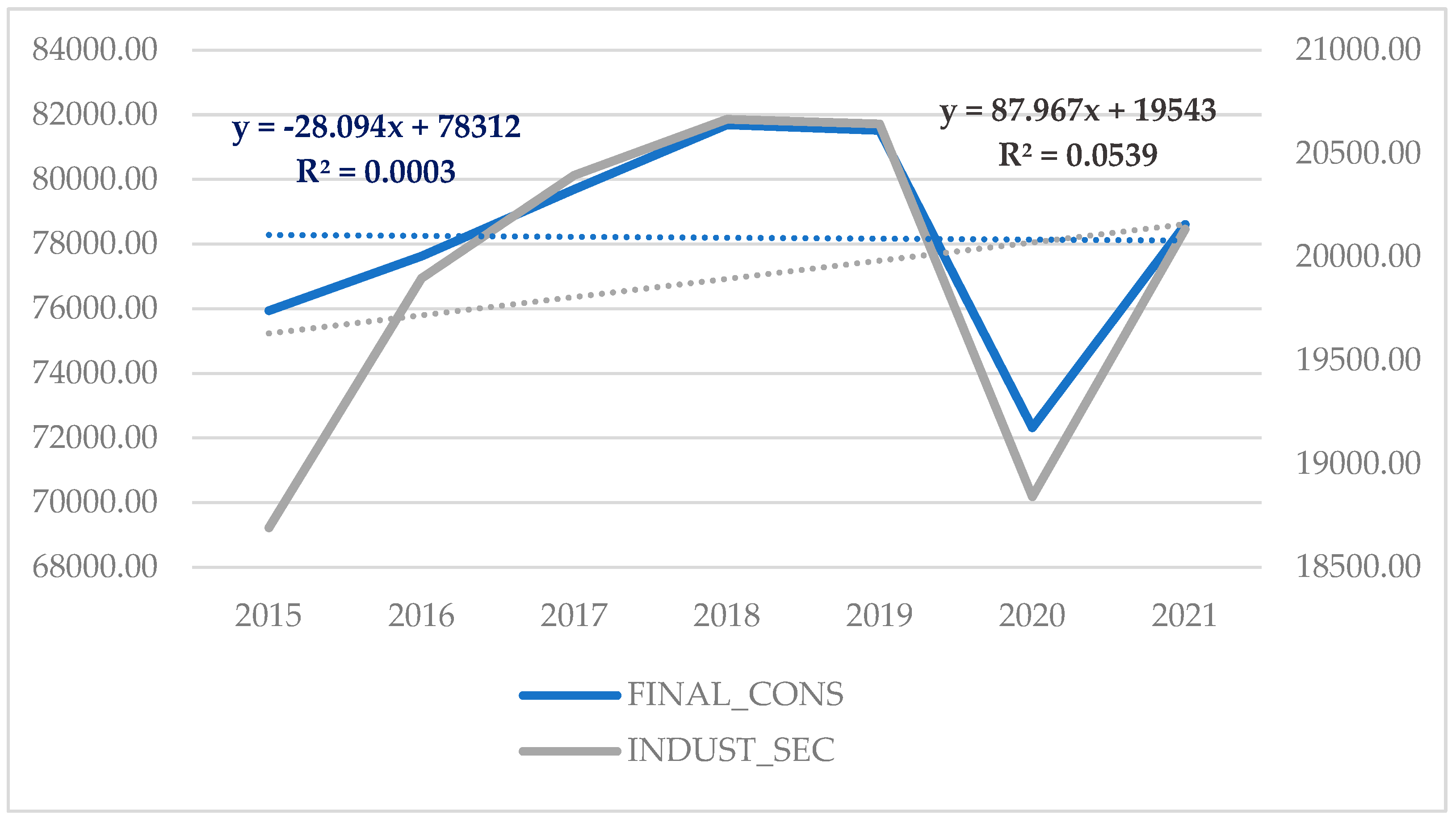

Furthermore, we can observe the following trend when comparing the final energy consumption data for Spain to the total consumption of the Spanish industrial sector since the beginning of 4.0. (

Figure 1, based on data from Energia.gob.es).

Since the introduction of the 4.0., the trend in energy consumption by both the Spanish economy as a whole and the industrial sector has shown a rise to 2020, a cause attributed, among others, to the impact of the health crisis Covid 19. A closer examination of Spain's economic growth reveals a startling reality.

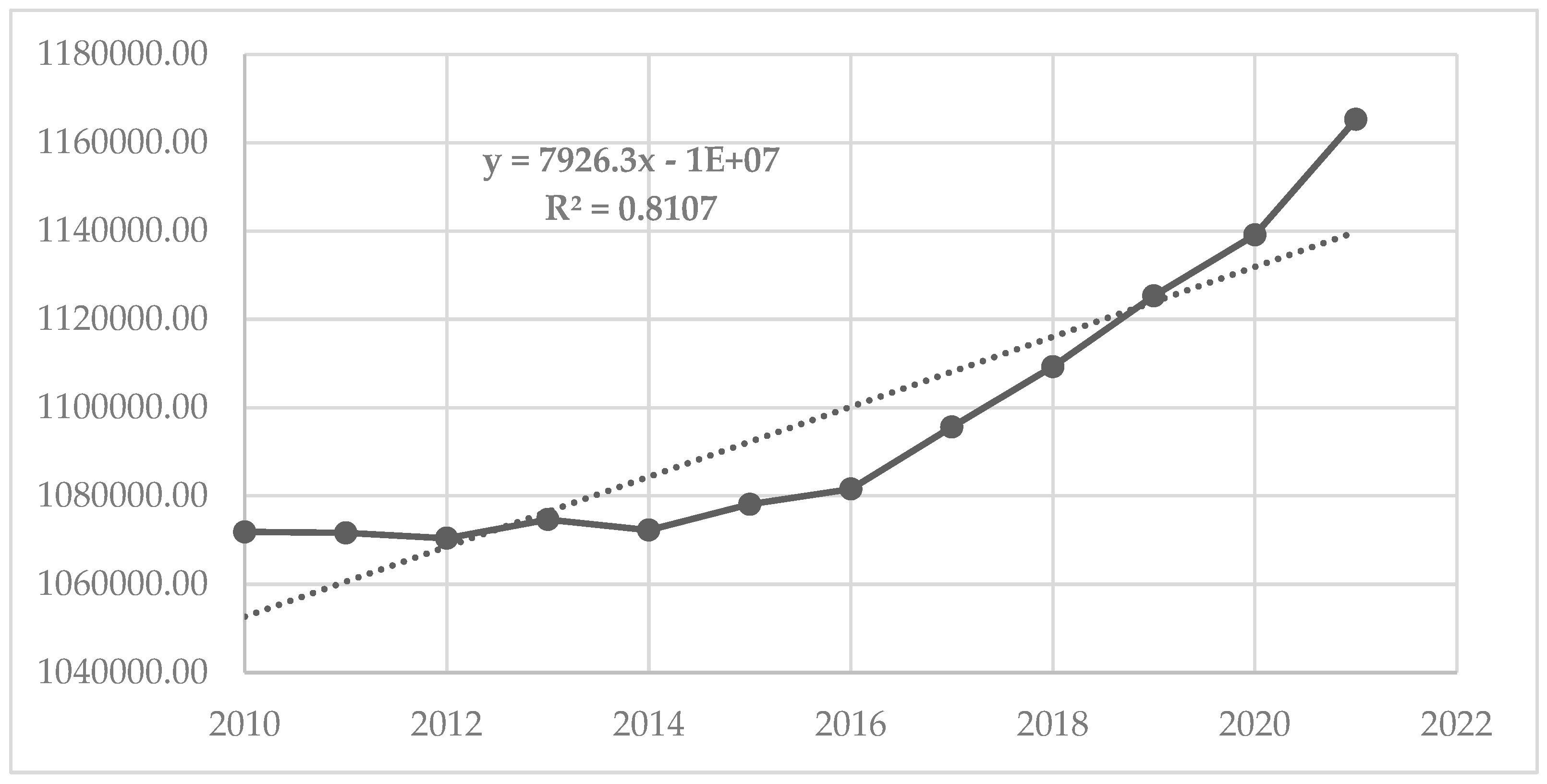

Figure 2 shows Spanish economic growth in terms of GDP at constant prices, deflated based on 2015 (based on data from INEbase).

Regarding the country's economic growth, the health crisis caused by Covid-19 initially did not lead to a decrease in growth levels. By observing the linear correlation coefficient (LCC) between the GDP variable at constant prices and analyzing its correlation with respect to final energy expenditure, as well as with final energy expenditure of the industrial sector, two models emerge which are described below.

This expression is likely from a study that examines the relationship between the levelized cost of energy (LCC), gross domestic product (GDP, constant prices), and final energy consumption. The value of -0.05 indicates that there is a negative correlation between LCC and GDP (constant prices) -final energy consumption, which means that as the LCC decreases, GDP (constant prices) and final energy consumption tend to increase. The value in brackets, [R

2], indicates the coefficient of determination, which measures how well the model fits the data. In this case, an R

2 of 0.05 means that the model explains only 5% of the variance in the data.

This expression is like the first one, but it focuses specifically on the relationship between LCC, GDP (constant prices), final energy consumption, and the industrial sector. The value of 0.16 indicates a positive correlation between LCC and GDP (constant prices) -final energy consumption industry, which means that as the LCC increases, GDP (constant prices) and final energy consumption in the industrial sector tend to increase as well. The value in brackets, [R2], represents the coefficient of determination, which in this case is 0.16, meaning that the model explains 16% of the variance in the data.

The research examined the correlation between the levelized cost of energy (LCC), gross domestic product (GDP, constant prices), and final energy consumption, with a specific focus on the industrial sector. The outcomes of our analysis revealed that LCC and GDP were positively correlated with the final energy consumption in the industrial sector (LCC (GDP-final energy consumption industry) = 0.16 [R2]). This result implies that an increase in LCC would lead to an increase in GDP and final energy consumption in the industrial sector. Nonetheless, a negative relationship was also detected between LCC and GDP (constant prices) -final energy consumption in all sectors (LCC (GDP-final energy consumption) = -0.05 [R2]), suggesting that a decrease in LCC would lead to an increase in GDP and final energy consumption across all industries. In summary, the findings indicate that a reduction in LCC could have significant implications in promoting economic growth and decreasing energy consumption in diverse sectors.

So initially energy consumption and growth do not seem to have a satisfactory level of relationship. This may have an impact on policies and measures to be taken in the energy sector as what happens will not result in further growth of the economy. This may discourage the development of new and better energy policies and energy consumption.

3.1. Sustainability 4.0. Types of energy used in Spain.

Globally, there is a trend from high to low carbon emissions, just as there is a trend from fossil to non-fossil energy [

82]. The application of technology also enables energy to be harnessed and energy-efficient and low-emission production methods to be generated. Thanks to this 4.0 technology, among other benefits, there are better safety protocols [

83] that seek to prevent incidents affecting the environment [

84]. However, due to the production activity itself, the probability of suffering these incidents is still high. Therefore, the consumption of this non-green energy will perpetuate a problem of industrial sustainability.

Energy consumption in Spain is high compared to other EU countries. According to data from the European Environment Agency, energy consumption per capita in Spain is about 10%, according to the data published by eea.europa.eu on the energy consumption of the EU, higher than the European average. The transport and residential sectors are the largest consumers of energy in Spain, followed by industry and the services sector. In terms of the source of energy used, oil and its derivatives are the most widely used in the country, followed by electricity and natural gas.

The study of the data relating to the several types of energy currently used by Spanish industry provides a snapshot of the state of this issue and the level of progress made since the advent of the 4.0 concept.

Table 1 are presented. In which it can be seen how Spain has not modified its levels of fossil energy consumption at all. These being absolutely majority in the common use of the industrial fabric. According to official data from energia.gob.es (energy balance), petrol and natural gas make up 61% of the energy used by industry, neither of which is green energy nor a driver of sustainability.

If we analyze the data on the consumption of fossil fuels and bioenergy in the period between 2015 (the start of the 4.0. in Spain) to 2021, the following can be observed (

Table 1, based on data from Energy.gob.es):

There is a subtle trend towards reducing the presence of fossil fuels in Spanish industry. However, the percentage of fossil fuels is extremely high and is still a long way from sustainability standards, as it is still 2021, six years after the start of 4.0, and practically two decades since the changes in the consumption of these energies began to be considered.

It is evident that a truly effective economic and political plan is necessary for the gradual elimination of the use of fossil fuels, as was done in Germany with the

Energiewende initiative [

58], and periodic monitoring of data is necessary to evaluate whether this transition is taking place.

3.2. Policies on renewable energies. Green taxes.

The features of the industry and the company in Spain should be considered. Thus, there is a high presence of small and medium-sized enterprises, so policies should focus on innovation and promotion of cleaner technologies, considering the size, knowledge intensity, and inter-company cooperation of the Spanish fabric [

85].

Sustainable development aims to balance economic growth, environmental protection, and social welfare to ensure that future generations can meet their needs [

86]. According to other authors, the importance of a rigorous analysis of energy sectors is highlighted for planning and decision-making in energy policies [

87].

However, economic growth has led to the exploitation of natural resources and pollution, which is a challenge for sustainable development. Environmental taxes can contribute to sustainable development by internalizing environmental costs in the price of goods and services, encouraging the adoption of more sustainable practices, and generating revenue for environmental protection policies and sustainable development programs [

86]. Related to the above is a change in business culture, as well as a need for investment in resources and infrastructure [

88].

By way of illustration, the case of European small and medium-sized enterprises in terms of the adoption of clean technologies and recycling is discussed. Studies indicate that energy prices have a strong influence on the adoption of clean technologies and recycling by SMEs. In addition, the capacity of SMEs to innovate and the existence of supportive policies also influence their adoption of clean technologies and recycling [

89].

This indicates that EU energy and environmental policy must be coherent and coordinated to support sustainable development and the adoption of clean technologies by SMEs.

Thus, it is argued that environmental taxes can be an effective tool for tackling climate change and promoting sustainable development, as they allow environmental costs to be included in the price of goods and services, providing incentives for the adoption of more sustainable practices [

90]. In addition, revenues generated by environmental taxes can be used to finance environmental protection policies and sustainable development programs.

The implementation of environmental fiscal policies should be accompanied by measures to support and promote sustainable practices and technologies, as well as environmental education and awareness programs [

91].

However, the definition of environmental taxes and their application, specifying their objectives and design criteria (such as their tax base), as well as the relationship between environmental taxes and other environmental policy instruments, need to be properly studied and precisely defined [

91].

In this context, the reality is that the Spanish industry, despite adapting changes in terms of technology, connectivity and managing increasingly smart factory units, has not applied protocols for switching from traditional energy sources.

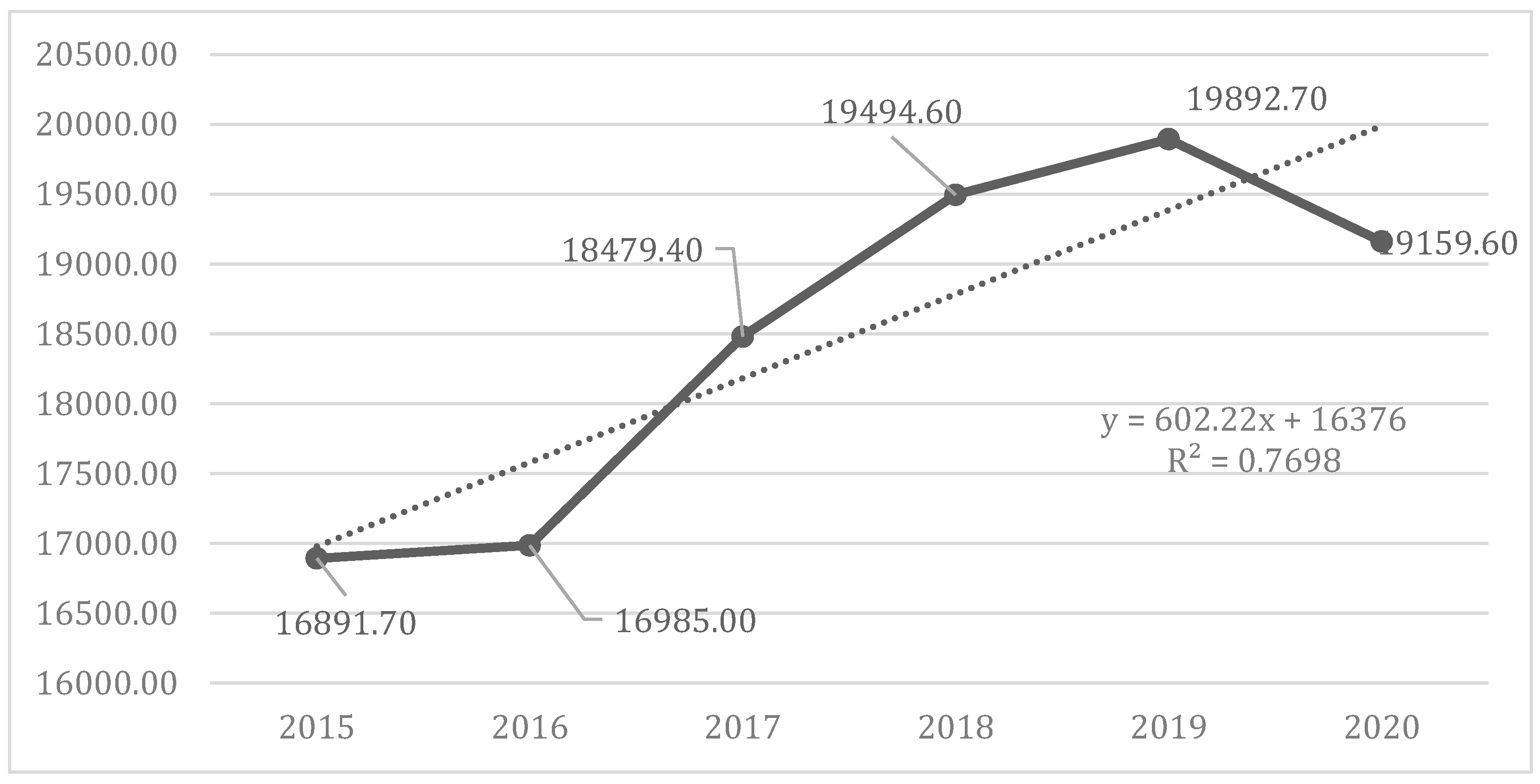

One of the causes may be the lack of economic return in the short and medium term of applying these changes. On the contrary, they imply economic and human costs that make companies decide not to implement the changes. National expenditure on environmental protection applied to the industrial sector in Spain in 2010 amounted to 18,636.50 million euros, according to the data published by the OECD (about environmental protection expenditure accounts).

It is true that since the implementation of 4.0. in Spain there has been an increase in this type of expenditure, rising by more than 13.00 % (

Figure 3, based on data from OECD STAT). The use of modern technologies together with European environmental policies can therefore justify this.

In this sense, to give an overall picture of the attention paid to the environment, it is worth contrasting these data with Spain's attitude towards measures to control the negative externalities that affect the environment. On the one hand,

Table 2 shows the millions of euros that have been paid up to 2021 in energy taxes.

On the other hand, it shows the data corresponding to pollution and resource taxes. There is no change in the taxes paid for pollution. This indicates that on the one hand the industry has not changed its attitude and way of production. On the other hand, it seems that all the effort to generate an environmental culture among the agents involved in the industry is not yielding results.

The use of taxation tools comes to tax certain behaviors. Already in the neoclassical approach to growth, with authors such as Solow in 1956 [

92] or later visions of endogenous growth with authors such as Romer [

93,

94], the intervention of the public sector is the object of study.

Although historically public intervention has had the objective of stable economic growth (in addition to others such as the correct distribution of income or equity) [

95]. However, when it comes to environmental taxes (green taxes), the focus is on the behavior of the agents. The presence of both positive and negative externalities must be analyzed, as far as it marks the existence of both economic and non-economic (or extra-economic) consequences. In the case of environmental externalities, public intervention is a political decision, not an economic one.

As these externalities are not measured in terms of costs and benefits for market actors, other issues must be addressed. One option is to apply the Polluter Pays-Principle (PPP) [

96], which has been widely applied by the European Community in cases such as A. Stanley [

97], the case deals with Directive 91/676/EEC which aims to protect waters from pollution caused by nitrates from agricultural sources. The case focuses on the identification and designation of vulnerable zones to pollution and their validity in relation to principles such as the PPP, the principle of rectification of environmental damage at source, and the principle of proportionality. This case has been used as a basis for subsequent decisions, but difficulties in its application have been noted due to problems of identification and proportionality in the risk relationship.

Although this method suffers from problems such as the proportionality of the sanction, the standards of liability for both the risks of pollution and the damage caused must be very well defined. The limitations of the PPP approach have led to the exploration of new options. These include the use of market-based instruments such as subsidies or taxes. In the case of environmental taxes, their objective is to penalize negative externalities. The purpose of this type of tax is to modify behavior, to correct the negative externalities of the activity.

It is true that despite the above, Spain is making efforts to adjust the tax system, as the "

Libro Blanco para la Reforma del Sistema Tributario"(

White Paper for Tax System Reform) [

98], should be cited. In which a diagnosis of the Spanish tax system is made, by which a series of recommendations are articulated and on the other hand the text offers different proposals on several areas, among which is the environmental taxation. With proposals such as the abolition of the Tax on the Value of Electricity Production, or the reform of the special tax on electricity to promote electrification and energy efficiency.

In the same sense, attention must be paid to the situation of Spanish fiscal decentralization, as it has usually had a negative impact on environmental taxation (e.g., in the case of water taxes [

99]) and has resulted in a lack of coordination between the different public administrations involved in management and a lack of coherence in the related tax policies.

Considering the structure of the tax itself, and the percentage of impact that this type of tax has, the conclusion is that it is inefficient. It does not incentivize behavioral change because it treats all products in an excessively generic way.

4. Discussion. Final issues.

Industry 4.0, also known as the fourth industrial revolution, refers to the implementation of advanced digital technologies in manufacturing and industrial process automation. Its arrival presents opportunities and challenges. It is revealed as fundamental that stakeholders make efforts to create models that allow for the evaluation of the implementation of Industry 4.0 technology, to study its real impact [

100].

On the one hand, it presents an opportunity to achieve greater efficiency, as the implementation of advanced technologies such as the IoT, artificial intelligence, and robotics can enhance the efficiency and productivity of industrial operations, leading to cost reduction and increased competitiveness. Additionally, it offers other opportunities such as mass customization of products, stimulation of innovation by unlocking new opportunities for business models, services, and products. Furthermore, real-time data access, including real-time data collection and analysis, can assist companies in making informed decisions and improving the decision-making process.

On the other hand, its arrival also brings challenges that require a proper understanding of the factors that define and shape the fourth industrial revolution. These challenges include the need for significant investment in infrastructure and personnel training, as well as others such as the rise of cyberattacks and security breaches. Another challenge is the need for cultural change, as Industry 4.0 requires a business culture focused on innovation, collaboration, and experimentation, among other things.

Thus, the optimization of factory production systems, as well as affecting the machinery and human factor involved in the product production process, also affects the external level. These include the environment. The dimension of affectation is absolute, as it has an impact on production, as well as on the other main agents of interest, which is none other than the client or end consumer [

101]. This is because if an environment is not sustainable, beyond the product produced, basic issues such as water or air quality will be affected, and this will have a direct impact on the quality of life of the agents.

It is a reality that there are many initiatives to implement an industry based on technology, digitalization, and connectivity within a context of environmental sustainability. The policies implemented seem to result in economic growth for the country. When this is related to the level of performance and emissions, it is observed that it has been reduced by 14.94% in Spain in 2021 compared to the levels existing in 2015. The calculation is based on official data from the INE, specifically on emissions of gases into the atmosphere (annual levels for the Spanish economy).

On the other side, if the level of hazardous waste generated by the Spanish industry is analyzed, it is observed that the variation from 2014 to 2020 is 8.23% (1310 to 10201 units). The author's calculation is based on official data from the INE, specifically on waste generated by the industry considered dangerous (annual levels). There does not seem to be a reduction in the emission of environmentally hazardous waste. This behavior has remained at remarkably similar levels.

The previous section explained how this problem is connected to the main tool for correcting behavior, which is the environmental tax. However, the design of this tax in Spain falls short of achieving its objectives. Additionally, the PPP principle is still in effect, which, combined with penalties and the high cost of changing production fundamentals, hinders the transition to cleaner energy and the optimization of processes to decrease pollution levels.

The creation of policies and tools for environmental sustainability in industry has taken place at European level (e.g., Next Generation EU, as a temporary palliative, with a strong economic envelope proposed for repair at two levels, economic and social [

102], national (

Connected Industry 4.0), autonomous community and local. In this regard, the case of Castilla-La Mancha, region of Spain, serves as an example, with the "

Plan Adelante 2020 - 2023" [

103] plans for investment and innovation, among others.

As it happens in other cases [

99,

104], in this one, an analysis of energy taxation and pollution in Spain, and its impact on the management of energy resources at different levels of administrative organization in the country, is configured as a fundamental step, which must always be a constant and transparent study to be useful.

Beyond these tools, Spain is trying to stimulate Industry 4.0 and "Sustainability 4.0.” Through regulations. On the one hand, specific tax rates are created for environmental protection, which tax both energy and waste. The impact of these taxes does not meet the objective, because industry continues to use mostly fossil fuels and, on the other hand, there has been no real reduction in atmospheric emissions or waste.

Therefore, to develop an energy sector in line with current sustainability policies, and on the other hand, a set of consumers who understand and adopt this culture of sustainability, it is necessary to review the tools, beyond attending to the macroeconomic levels of technological investment, with its relevant study of economic growth.

On the one hand, tools and plans are nothing if there is no investment in innovation and R&D expenditure (Research and Development expenditure), and on the other hand, behavior cannot be corrected if there are no effective sanction systems, so in this sense one of the first issues that should be reviewed is the structure of the green tax base, as the taxpayer cannot "run away" from their responsibility.

In short, it is a matter of creating a sufficiently coercive barrier for industry to opt for a shift towards sustainability.

Sustainability 4.0 presents limitations, as do green taxes, as advanced technologies such as IoT or artificial intelligence may require significant initial investment. This may be a challenge for small and medium-sized enterprises without the necessary budget. Additionally, the complexity of the technology and the need to hire specialized and trained personnel can be an additional challenge. Furthermore, there is a real lack of regulation and standardization, as regulations have proved to be ineffective in changing agent behavior.

There has been a growing interest in promoting sustainable practices within industries in recent years, and one strategy is to create a coercive enough barrier for industries to adopt sustainable production methods. However, it is important to note that this strategy has its limitations, and the effectiveness of these coercive measures, especially in terms of achieving long-term and sustainable results, can be difficult to quantify. Furthermore, these measures can have unintended consequences, such as the displacement of the industry to regions with weaker environmental regulations or the ineffectiveness of the measures themselves.

To further explore the effectiveness of these coercive measures and address these limitations, a future research project could involve a comparative analysis of industries in different regions or countries. The study could examine the effectiveness of diverse types of coercive measures, such as economic incentives, fines and penalties, and regulatory requirements.

By analyzing and comparing the results of these strategies, the study could offer ideas on the most effective strategies for promoting sustainable practices within industries. Additionally, the study could explore possible unintended consequences and identify strategies to mitigate these risks. Ultimately, this research could help guide policymakers and industry leaders to make more informed decisions about sustainable production methods.

Author Contributions

Conceptualization, Sonia García Moreno; methodology, Sonia García Moreno; formal analysis, Sonia García Moreno; investigation, Sonia García Moreno.; resources Sonia García Moreno.; data curation, Sonia García Moreno, and Victor Raul Lopez Ruiz; writing—original draft preparation. Sonia García Moreno.; writing—review and editing, Sonia García Moreno; supervision, Victor Raul Lopez Ruiz.; project administration, Victor Raul Lopez Ruiz. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mussomeli, A., Gish, D. and Laaper, S. The rise of the digital supply network: Industry 4.0 enables the digital transformation of supply chains. Deloitte Insights, 2016, December 1.

- Pasi, B. N., Mahajan, S. K., and Rane, S. B. Smart supply chain management: a perspective of industry 4.0. In Supply Chain Management, 29(5), 2020, 3016-3030.

- Shao, X.-F.; Liu, W.; Li, Y.; Chaudhry, H.R.; Yue, X.-G. Multistage implementation framework for smart supply chain management under industry 4.0. Technol. Forecast. Soc. Chang. 2020, 162, 120354–120354. [CrossRef]

- Stark, J. Product lifecycle management (PLM). In Product Lifecycle Management (Volume 1) 21st Century Paradigm for Product Realization, Springer International Publishing, 2022, Volume 1, pp. 1-32.

- Hayes, B. (2008). Cloud computing.

- Armbrust, M., Fox, A., Griffith, R., Joseph, A. D., Katz, R., Konwinski, A., and Zaharia, M. (2010). A view of cloud computing. In Communications of the ACM, 53(4), 50-58.

- Mell, P., and Grance, T. (2011). The NIST definition of cloud computing. National Institute of Standards and Technology, 53(6), 50.

- Xu, X. (2012). From cloud computing to cloud manufacturing. In Robotics and computer-integrated manufacturing, 28(1), 75-86.

- Agrawal, D.; Bernstein, P.; Bertino, E.; Davidson, S.; Dayal, U.; Franklin, M.; Widom, J. Challenges and opportunities with Big Data. 2011-1.

- Davenport, T. H.; Barth, P.; Bean, R. How 'big data' is different. In Big Data Analytics, 1st ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 11-32.

- Chen, M.; Mao, S.; Liu, Y. Big data: a survey. Mobile networks and applications 2014, 19, 171-209.

- Kitchin, R. Big Data, new epistemologies and paradigm shifts. Big Data Soc. 2014, 1, 2053951714528481. [CrossRef]

- Roblek, V.; Meško, M.; Krapež, A. A Complex View of Industry 4.0. SAGE Open 2016, 6, 2158244016653987. [CrossRef]

- Zhou, K., Liu, T., & Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), IEEE, August 2015, pp. 2147-2152.

- Rojko, A. Industry 4.0 Concept: Background and Overview. Int. J. Interact. Mob. Technol. (iJIM) 2017, 11, 77–90. [CrossRef]

- Singer, P. W., and Friedman, A. Cybersecurity: What everyone needs to know. OUP USA, 2014.

- Radanliev, P., De Roure, D., Nurse, J. R., Nicolescu, R., Huth, M., Cannady, S., and Montalvo, R. M. Integration of cyber security frameworks, models, and approaches for building design principles for the internet-of-things in industry 4.0. In Proceedings of the Living in the Internet of Things: Cybersecurity of the IoT-2018 Conference, London, UK, 28-29 March 2018.

- Nienke, S.; Frölian, H.; Zeller, V.; Schuh, G. Energy-management 4.0: roadmap towards the self-optimising production of the future. In Proceedings of the 6th International Conference on Informatics, Environment, Energy, and Applications; Location of Conference, Country; March 2017 (Day Month Year); pp. 6–10.

- Sony, M.; Naik, S. Critical factors for the successful implementation of Industry 4.0: a review and future research direction. Prod. Plan. Control. 2019, 31, 799–815. [CrossRef]

- López Martínez, A. Tecnología de la fabricación: apuntes de teoría. Tecnología de la fabricación 2019, 1-194.

- Rüßmann, M., Lorenz, M., Gerbert, P., Waldner, M., Justus, J., Engel, P. and Harnisch, M. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consulting Group 2015, 9(1), 54-89.

- Sniderman, B., Mahto, M. and Cotteleer, M. J. Industry 4.0 and manufacturing ecosystems: Exploring the world of connected enterprises. Deloitte Consulting, 2016.

- Grau Ríos, M. Riesgos ambientales en la industria, 2010. ES: UNED.

- Cameron, R. E.; Neal, L. Historia económica mundial, desde el paleolítico hasta el presente. In Historia económica mundial, 2nd ed.; Cameron, R. E.; Neal, L., Eds.; Alianza Editorial, Oxford University Press: Madrid, Spain, 2010; pp. 185-188.

- Ashton, T.S. The Industrial Revolution 1760-1830. OUP Catalogue, 1997.

- Jevons, H. S. The second industrial revolution. The Economic Journal 1931, 41(161), 1-18.

- Kanji, G.K. Total quality management: the second industrial revolution. Total. Qual. Manag. 1990, 1, 3–12. [CrossRef]

- Mokyr, J., & Strotz, R. H. The second industrial revolution, 1870-1914. Storia dell’economia Mondiale 1998, 21, 945(1).

- Universidad Politécnica Madrid, Miríadax. Curso Industria 4.0. Nosotros y las tecnologías para la industria del futuro, 2018. Available online: https://miriadax.net/web/industria-40-nosotros-y-las-tecnologias-para-la-industria-del-futuro/ (accessed on 07 March 2019).

- Atkeson, A. and Kehoe, P. J. The transition to a new economy after the second industrial revolution. National Bureau of Economic Research, 2001, w8676.

- Cole, G. D. Historia del pensamiento socialista, IV: La Segunda Internacional, 1889-1914. Segunda parte. Fondo de Cultura Económica, 2021.

- Joyanes L. Industria 4.0 la cuarta revolución industrial. (1). Alfaomega Marcombo, 2017, pp. 45-72.

- Rifkin J. La tercera revolución industrial, cómo el poder lateral está transformando la energía, la economía y el mundo, 2011; Grupo Planeta Spain Paidós: España.

- Berners-Lee, T. J. Information management: A proposal, CERN-DD-89-001-OC, 1989.

- Powell, J.; Clarke, A. The WWW of the World Wide Web: Who, What, and Why?. J. Med Internet Res. 2002, 4, e4. [CrossRef]

- Windelband, L. and Dworschak, B. "Veränderungen in der industriellen Produktion–Notwendige Kompetenzen auf dem Weg vom Internet der Dinge zu Industrie 4.0." Berufsbildung in Wissenschaft und Praxis (BWP) 2015, 44(6), 26-29.

- Trzaska, R.; Sulich, A.; Organa, M.; Niemczyk, J.; Jasiński, B. Digitalization Business Strategies in Energy Sector: Solving Problems with Uncertainty under Industry 4.0 Conditions. Energies 2021, 14, 7997. [CrossRef]

- Breiman, L. Bagging predictors. Machine Learning 1996, 24, pp. 123-140.

- LeCun, Y., Bengio, Y., & Hinton, G. Deep learning. Nature 2015, 521, pp. 436-444.

- Dopico, M., Gomez, A., De la Fuente, D., García, N., Rosillo, R. and Puche, J. A vision of industry 4.0 from an artificial intelligence point of view. In Proceedings of the International Conference on Artificial Intelligence (ICAI), The Steering Committee of The World Congress in Computer Science, Computer Engineering and Applied Computing (WorldComp), Las Vegas, Nevada, USA, 25-28 July 2016.

- Heaton, J. Ian Goodfellow, Yoshua Bengio, and Aaron Courville: Deep learning: The MIT Press, 2016, 800 pp, ISBN: 0262035618. Genetic Programming and Evolvable Machines 2018, 19(1-2), pp. 305-307.

- Breiman, L. Random forests. Machine learning, 2001, 45, pp. 5-32.

- Mostafaeipour, A.; Rafsanjani, A.J.; Ahmadi, M.; Dhanraj, J.A. Investigating the performance of Hadoop and Spark platforms on machine learning algorithms. J. Supercomput. 2020, 77, 1273–1300. [CrossRef]

- Abdolrasol, M.G.M.; Hannan, M.A.; Hussain, S.M.S.; Ustun, T.S.; Sarker, M.R.; Ker, P.J. Energy Management Scheduling for Microgrids in the Virtual Power Plant System Using Artificial Neural Networks. Energies 2021, 14, 6507. [CrossRef]

- Ashton, K. That ‘internet of things’ thing. RFID journal 2009, 22(7), pp. 97-114.

- Lasi, H., Fettke, P., Kemper, H. G., Feld, T., & Hoffmann, M. Industrie 4.0. Wirtschaftsinformatik 2014, 56, pp. 261-264.

- Guo, D., Li, M., Lyu, Z., Kang, K., Wu, W., Zhong, R. Y., and Huang, G. Q. Synchroperation in industry 4.0 manufacturing. International Journal of Production Economics 2021, 238, pp.108 171.

- World Economic Forum. The Fourth Industrial Revolution: what it means, how to respond. Klaus Schwab, Founder and Executive Chairman, World Economic Forum. 2016. Available online: https://www.weforum.org/agenda/2016/01/the-fourth-industrial-revolution-what-it-means-and-how-to-respond/ (accessed on 09 April 2023).

- World Economic Forum. Centre for the Fourth Industrial Revolution. 2019. Available online: https://www.weforum.org/centre-for-the-fourth-industrial-revolution/about (accessed on 9 April 2023).

- Schlick, J., Stephan, P., Loskyll, M., & Lappe, D. Industrie 4.0 in der praktischen Anwendung. Industrie 4.0 in Produktion, Automatisierung und Logistik: Anwendung· Technologien· Migration, 2014, pp. 57-84.

- Kagermann, H., Wahlster, W., and Helbig, J. Deutschlands Zukunft als Produktionsstandort sichern Umsetzungsempfehlungen für das Zukunftsprojekt Industrie 4.0. Abschlussbericht des Arbeitskreises Industrie 4.0. Forschungsunion im Stifterverband für die Deutsche Wirtschaft e.V., 2013.

- Wahlster, W. Industrie 4.0: Das Internet der Dinge kommt in die Fabriken. In Zukunft der Arbeit in Industrie 4.0. Herausforderungen und Chancen für die Arbeitswelt der Zukunft, 1st ed.; Wolter, S., Spath, D., Eds.; Springer Gabler: Berlin/Heidelberg, Germany, 2016, pp. 23.

- Brühl, V., & Brühl, V. Industrie 4.0. Wirtschaft des 21. Jahrhunderts: Herausforderungen in der Hightech-Ökonomie, 2015, pp. 61-107.

- Porter, M.E., and Heppelmann, J.E. How smart, connected products are transforming companies. Harvard business review 2015, 93(10), pp. 96-114.

- Hermann, M., Pentek, T., and Otto, B. Design principles for industrie 4.0 scenarios. IEEE, 2016, pp. 3928-3937.

- Lucks, K. Grundlagen und Definitionen einer Industrie 4.0. Praxishandbuch Industrie 2017, 4, pp. 1-16.

- Drath, R., & Horch, A. Industrie 4.0: Hit or hype? [industry forum]. IEEE Industrial Electronics Magazine, 2014, 8(2), pp. 56-58.

- Federal Foreign Office of Germany. Industrie 4.0 auf der Hannover Messe Der Weg zur „intelligenten Fabrik“führt über die Hannover Messe. Deutsche Messe - Industry 4.0. 2014. Available online: https://www.deutschland.de/de/topic/wirtschaft/globalisierung-welthandel/industrie-40-auf-der-hannover-messe (accessed on 20 March 2023).

- Weyer, S., Schmitt, M., Ohmer, M. and Gorecky, D. Towards Industry 4.0-Standardization as the crucial challenge for highly modular, multi-vendor production systems. Ifac-Papersonline 2015, 48(3), pp. 579-584.

- Ministry of Industry, Energy and Tourism, Santander, Telefónica and Indra. La Transformación digital de la industria española. In Industria Conectada 4.0, 2015: http://www6.mityc.es/IndustriaConectada40/informe-industria-conectada40.pdf (accessed on 1 February 2023).

- Kagermann, H. Speech at the Hannover Fair, Hannover, Germany, 7-11 April 2014. In Proceedings of the Hannover Fair, Hannover, Germany, 7-11 April 2014.

- Balasingham, K. Industry 4.0: securing the future for German manufacturing companies. Master's thesis, University of Twente, Enschede, The Netherlands, 2016.

- Roland Berger Strategy Consultants. Industry 4.0, The New Industrial Revolution: How Europe Will Succeed. In Proceedings of the International Conference the Next Industrial Revolution Manufacturing and Society in the XXI Century, Turin, Italy, 14-15 November 2014.

- Wegener, H. La ciberseguridad en la Unión Europea. Boletín Electrónico del Instituto español de Estudios Estratégicos, 2014, pp. 1-22.

- Ruiz, V.R.L.; Navarro, J.L.A.; Peña, D.N. Relationship between Gross Domestic Product (GDP) and Hidden Wealth over the period 2000 2008: An International Study. Electronic Journal of Knowledge Management 2011, 9(3), pp. 259-270.

- Kergroach, S.; Industry 4.0: New Challenges and Opportunities for the Labour Market. Foresight STI Gov. 2017, 11, 6–8. [CrossRef]

- Schwab, K. The Fourth Industrial Revolution, by Klaus Schwab. World Economic Forum: Geneva, Switzerland, 2016.

- Kim, J.H. A Review of Cyber-Physical System Research Relevant to the Emerging IT Trends: Industry 4.0, IoT, Big Data, and Cloud Computing. J. Ind. Integr. Manag. 2017, 2, 1750011. [CrossRef]

- Manyika, J., Chui, M., Brown, B., Bughin, J., Dobbs, R., Roxburgh, C. and Byers, A. H. "Big data: The next frontier for innovation, competition, and productivity." McKinsey Global Institute, 2011, pp. 1-156.

- Gokalp, M. O., Kayabay, K., Akyol, M. A., Eren, P. E., and Koçyiğit, A. "Big data for industry 4.0: A conceptual framework." In 2016 international conference on computational science and computational intelligence (CSCI), IEEE, 2016, pp. 431-434.

- Khan, M., Wu, X., Xu, X. Big Data Challenges and Opportunities in Industry 4.0. In Proceedings of the 2017 International Conference on Big Data Analytics and Data Mining, Beijing, China, 5-8 October 2017.

- Brödner, P. Industrie 4.0 und Big Data–wirklich ein neuer Technologieschub?. In Digitalisierung industrieller Arbeit, January 2018, pp. 323-346.

- CISCO. What Is Cybersecurity? Products & Services. Available online: https://www.cisco.com/c/en/us/products/security/what-is-cybersecurity.html (accessed on 16 February 2023).

- De Paula Ferreira, W., Armellini, F., and De Santa-Eulalia, L. A. Simulation in industry 4.0: A state-of-the-art review. Computers & Industrial Engineering 2020, 149, 106 868.

- Chaney, D.; Gardan, J.; De Freyman, J. A framework for the relationship implications of additive manufacturing (3D printing) for industrial marketing: servitization, sustainability and customer empowerment. J. Bus. Ind. Mark. 2021, 37, 91–102. [CrossRef]

- Ribeiro, J.; Lima, R.; Eckhardt, T.; Paiva, S. Robotic Process Automation and Artificial Intelligence in Industry 4.0 – A Literature review. Procedia Comput. Sci. 2021, 181, 51–58. [CrossRef]

- Marinakis, V., Doukas, H., and Psarras, J. Energy management 4.0. In Handbook of Research on Artificial Intelligence, Innovation and Entrepreneurship, 1st ed.; Edward Elgar Publishing: Cheltenham, UK, 2023; pp. 121-134.

- Nia, A.R.; Awasthi, A.; Bhuiyan, N. Industry 4.0 and demand forecasting of the energy supply chain: A literature review. Comput. Ind. Eng. 2021, 154, 107128. [CrossRef]

- DFKI. Newsletter Deutsches Forschungszentrum Für Künstliche Intelligenz Gmbh, Forschungsprojekt RES-COM: Erster Baustein zur ressourcenschonenden Produktion für Industrie 4.0, 2/2011.

- Munsamy, M., Telukdarie, A., and Dhamija, P. Logistics 4.0 energy modelling. International Journal of Business Analytics (IJBAN) 2020, 7(1), pp. 98-121.

- Alcántara, V.; Roca, J. Energy and CO2 emissions in Spain: Methodology of analysis and some results for 1980–1990. Energy Econ. 1995, 17, 221–230. [CrossRef]

- Zou, C.; Zhao, Q.; Zhang, G.; Xiong, B. Energy revolution: From a fossil energy era to a new energy era. Nat. Gas Ind. B 2016, 3, 1–11. [CrossRef]

- Porfiryev, B.N.; Tulupov, A.S. Environmental hazard assessment and forecast of economic damage from industrial accidents. Stud. Russ. Econ. Dev. 2017, 28, 600–607. [CrossRef]

- Malhotra, R. Fossil Energy; Springer: Berlin/Heidelberg, Germany, 2020.

- Triguero, A.; Moreno-Mondéjar, L.; Davia, M. Eco-innovation by small and medium-sized firms in Europe: from end-of-pipe to cleaner technologies. Innovation 2015, 17, 24–40. [CrossRef]

- Ezcurra, M. V. Desarrollo sostenible y tributos ambientales. Crónica tributaria 2003, 107, 123-137.

- Alcántara, V.; Padilla, E. “Key” sectors in final energy consumption: an input–output application to the Spanish case. Energy Policy 2003, 31, 1673-1678.

- Herrero H. Digitalizar para Ganar. In Hewlett Packard Enterprise, 1st ed.; Publisher: Bilbao, Spain, 2014, e-article number.

- Triguero, A.; Moreno-Mondéjar, L.; Davia, M.A. The influence of energy prices on adoption of clean technologies and recycling: Evidence from European SMEs. Energy Econ. 2014, 46, 246–257. [CrossRef]

- Ezcurra, M.V. Cambio climático, desarrollo sostenible y fiscalidad ambiental. Madrid: CEU Ediciones, DL 2010. pp. 11-27.

- Herrera Molina, P.M. Derecho Tributario Ambiental (Envirommental tax law). La introducción del interés ambiental en el ordenamiento tributario. In Marcial Pons-Ministerio de Medio Ambiente, Madrid-Barcelona; 2000; pp. 37 and following.

- Solow, R.M. A Contribution to the Theory of Economic Growth. Q. J. Econ. 1956, 70, 65–94, doi:10.2307/1884513.

- Romer, P.M. Increasing Returns and Long-Run Growth. J. Politi- Econ. 1986, 94, 1002–1037. [CrossRef]

- Romer, P. M. El cambio tecnológico endógeno. El trimestre económico 1991, 58(231), 441-480.

- Rivero, F. J. D., and Jiménez, J. S. Impuestos y crecimiento económico: Una panorámica. RAE: Revista Asturiana de Economía 2008, (42), 9-30.

- Bleeker, A. Does the Polluter Pay? The Polluter-Pays Principle in the Case Law of the European Court of Justice. Eur. Energy Environ. Law Rev. 2009, 18, 289–306. [CrossRef]

- Case C-293/97, ECR I-04775. 1999.

- White Paper on Tax Reform (2022) Fiscal Studies Institute, Committee Of Experts To Develop The White Paper On Tax Reform Spanish Ministry of Finance and Public Administrations. https://www.ief.es/docs/investigacion/comiteexpertos/LibroBlancoReformaTributaria_2022.pdf.

- Marco, A.Z., Giménez, J.V., and Cortés, C.T. "Descentralización fiscal y tributación ambiental: el caso del agua en España". Instituto de Estudios Fiscales, 2007, pp. 1-32.

- Dalenogare, L. S., Benitez, G. B., Ayala, N. F., and Frank, A. G. The expected contribution of Industry 4.0 technologies for industrial performance. International Journal of production economics 2018, 204, 383-394.

- Hood, J., Brady, A. and Dhanasri, R. Industry 4.0 engages customers: The digital manufacturing enterprise powers the customer life cycle. Deloitte Insights 2016, 15, Available online: https://www2.deloitte.com/content/dam/insights/us/articles/3452-industry4-0-engages-customers/DUP_industry4-0-engages-customer.pdf (accessed on 1 April 2023).

- Picek, O. Spillover Effects From Next Generation EU. Intereconomics 2020, 55, 325–331. [CrossRef]

- Junta de Comunidades de Castilla-La Mancha. Adelante 2020-2023 [Economic and social development plan, registration number 20200325]. Available online: https://www.jccm.es/adelante2020-2023 (accessed on 20 March 2023).

- Terrapon-Pfaff, J.C., Ortiz, W., Viebahn, P., Kynast, E., and Fl ̈orke, M. Water demand scenarios for electricity generation at the global and regional levels. Water 2020, 12, 2482.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).