Submitted:

27 April 2023

Posted:

28 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

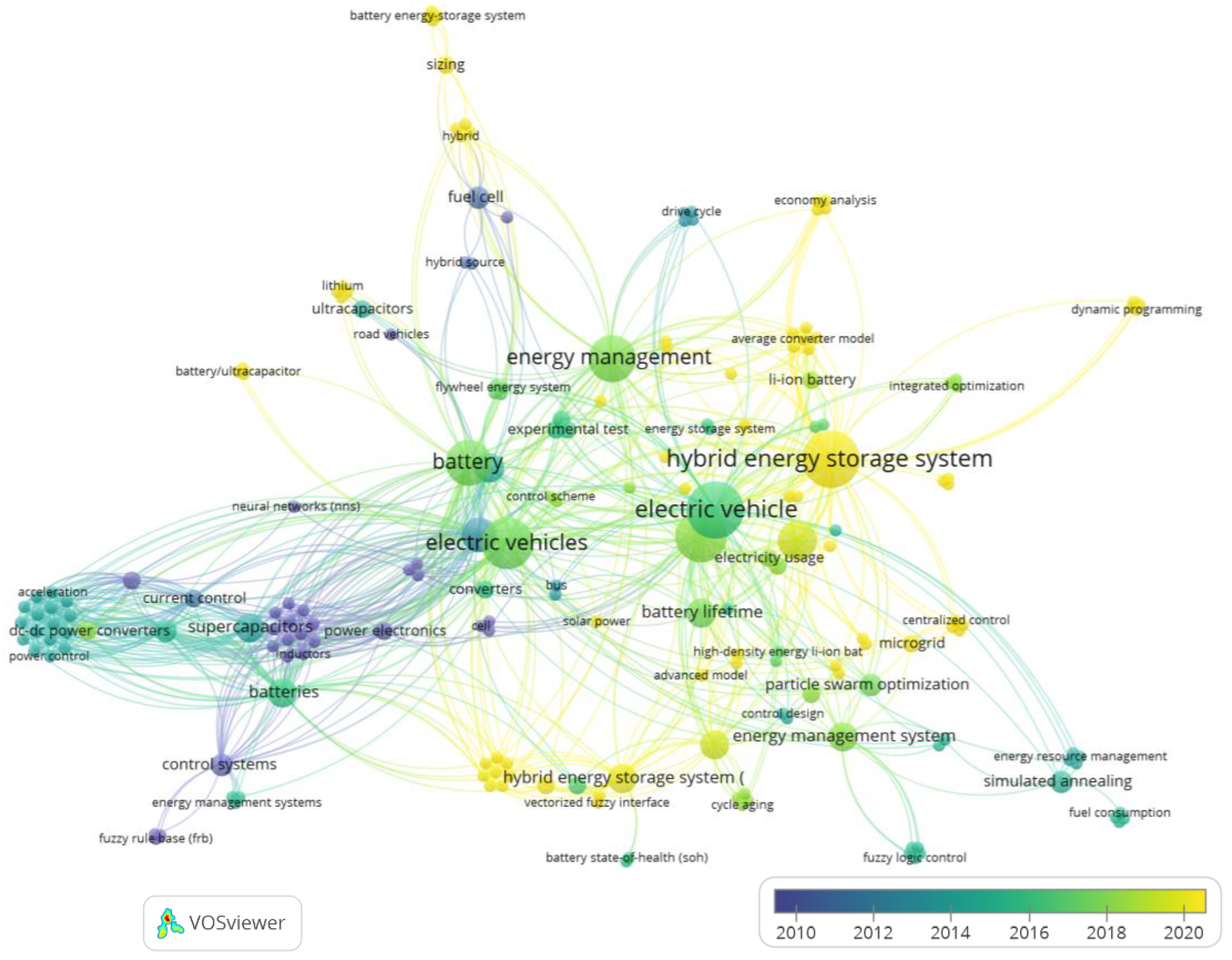

2. Research methodology

3. Battery and supercapactior in hybrid energy storage system

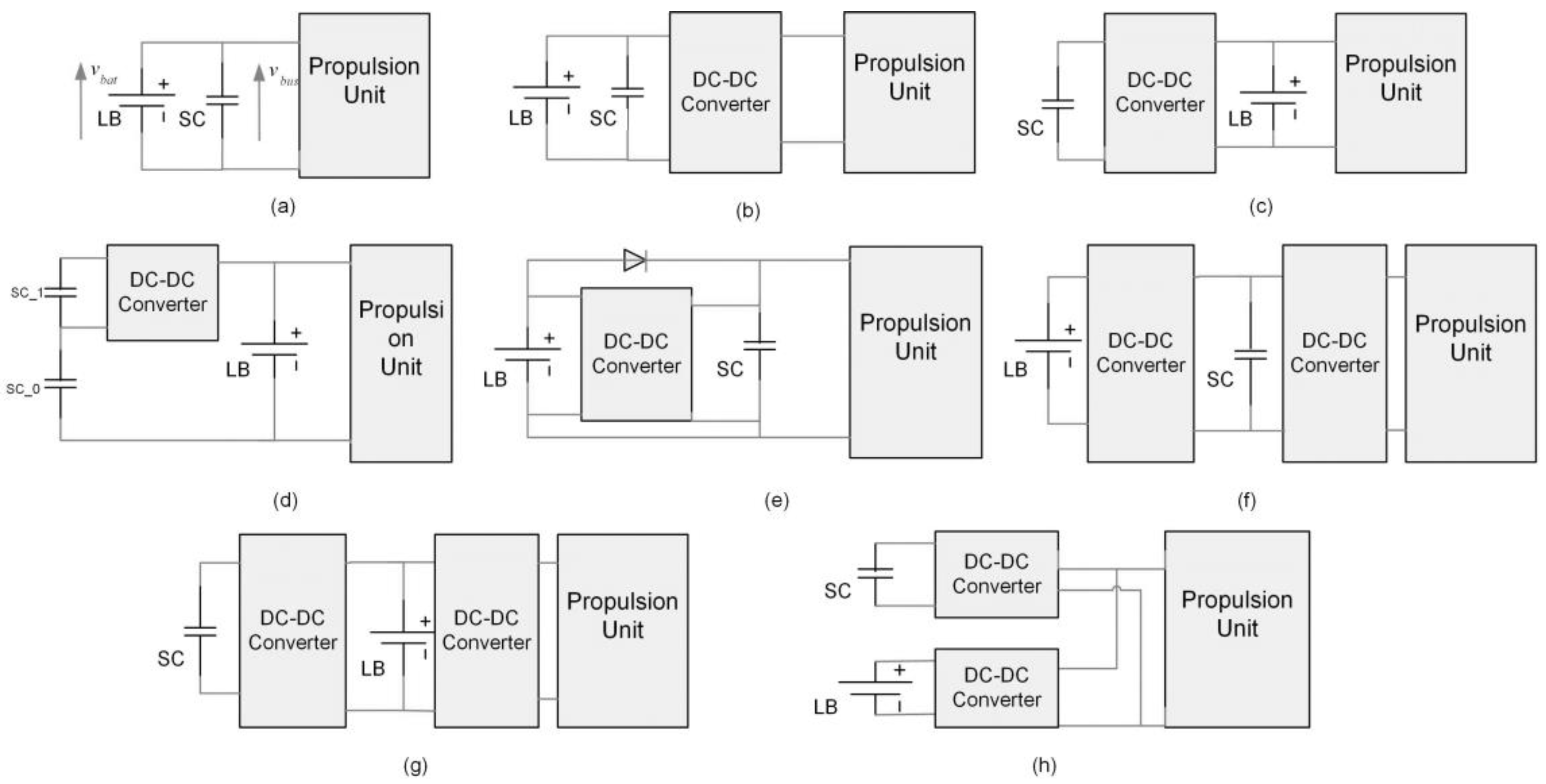

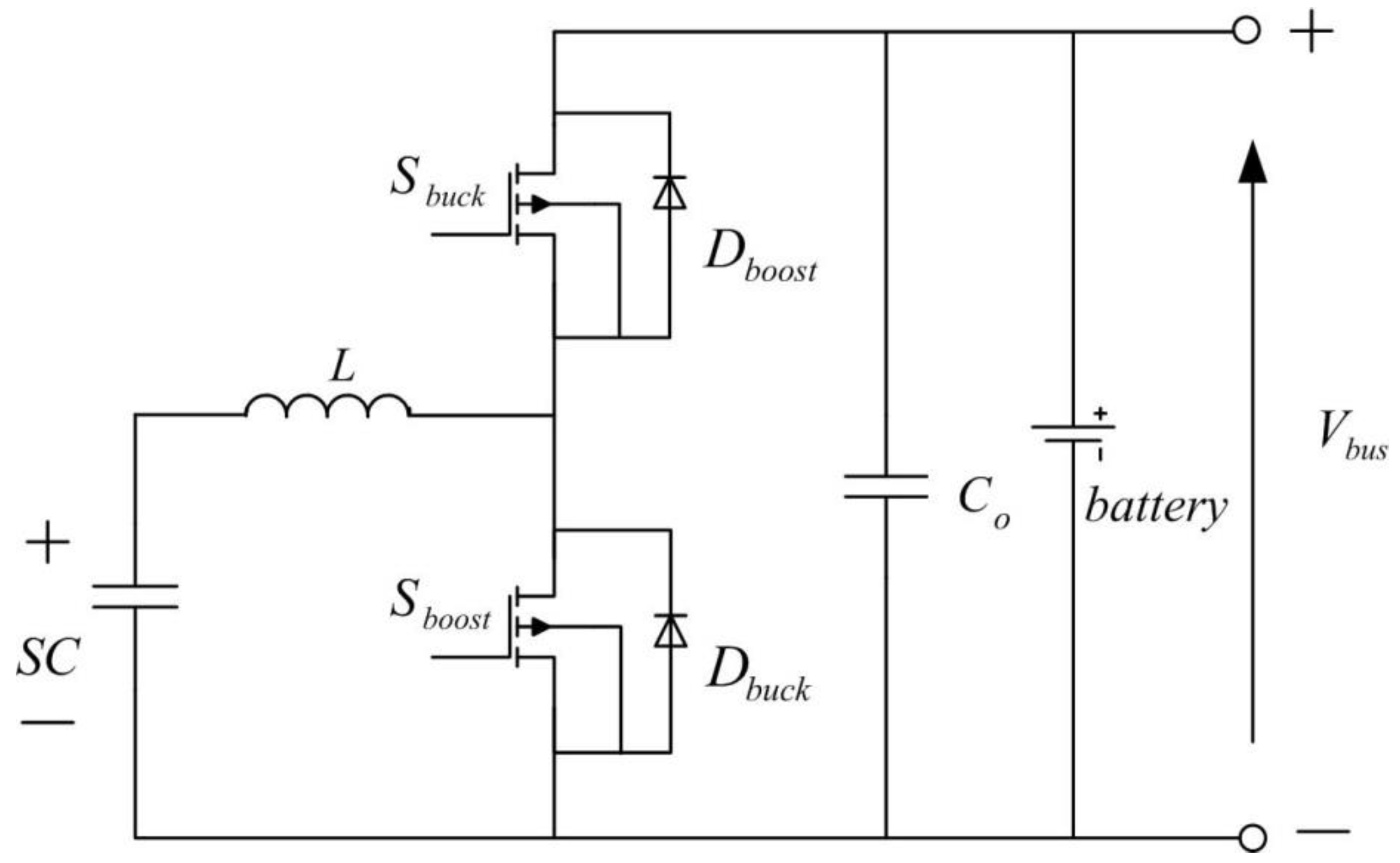

4. DC/DC converter topologies for energy source

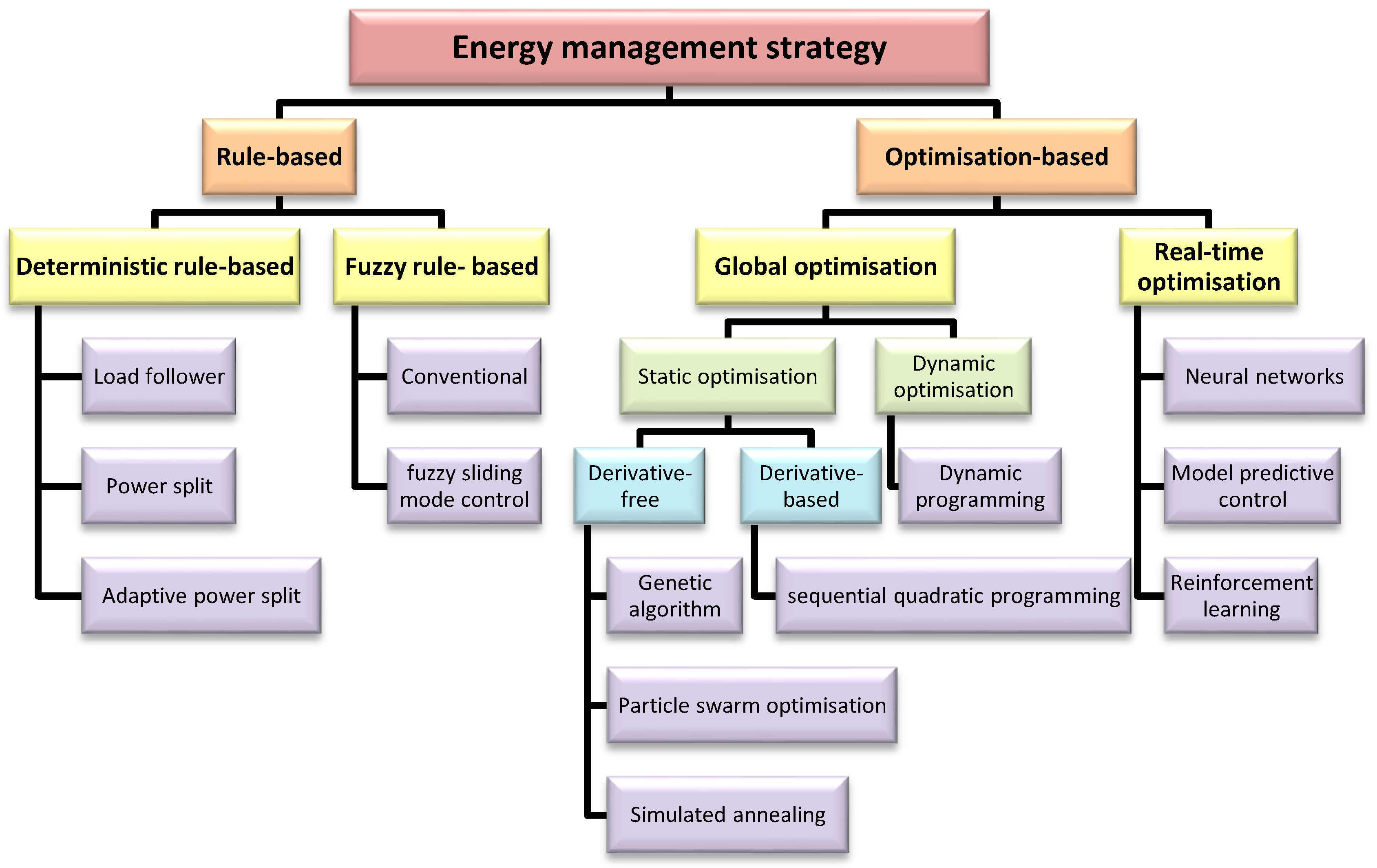

5. Energy management strategies for EV applications

5.1. Rule-based energy management strategy

5.1.1. Deterministic rule-based energy management strategy

5.1.2. Fuzzy rule-based energy management strategy

5.2. Optimization-based energy management strategy

5.2.1. Global optimization energy management strategy

- Firstly, the optimisation of the parameters of a rule-based energy management control strategy. By this method, the energy management problem turns into a parameter optimisation problem, and it is called a static optimisation problem. Thus, a derivative-free static optimisation method can be implemented, i.e., genetic algorithm (GA), particle swarm optimisation (PSO) and simulated annealing (SA). In addition, a derivative-based static optimisation method such as sequential quadratic programming (SQP) can also be applied.

- Secondly, the energy management problem of EV applications is considered as a dynamic, nonlinear, and constrained optimisation problem. This is recognised as an optimal control problem. The optimisation problem can be determined by dynamic optimisation methods such as dynamic programming.

- Thirdly, the optimal control problem is approximately modelled as a mathematical problem. After that, the problem is solved by static optimisation methods such as SQP.

- Both static and dynamic optimisation methods have been utilised in optimisation control problem of EV applications, which are described as follows.

5.2.2. Real-time optimisation energy management strategy

6. Discussion on major finding of energy management strategies

7. Conclusions

- The finding declared the significance of HESS for EV in terms of performance, cycle life, and controllability via DC-DC power converters among literatures and scoring for a suitable configuration for applications.

- A review on non-isolated half bridge bi-directional DC-DC converter is proposed for smooth operation based on the limitations of low weight, low cost, and low loss with good dependability.

- The evaluation of the energy management strategies where we found the rule-based real-time control is an acceptable solution for vehicle manufacturing. However, the performance of real-time optimization strategy is acknowledged and has a good prospect unless th economy of scale is established.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Husain, I. Electric and Hybrid Vehicles, 3rd ed.; CRC Press: Boca Raton, 2021; ISBN 9780429490927. [Google Scholar]

- Wang, Y.; Sun, Z.; Chen, Z. Energy Management Strategy for Battery/Supercapacitor/Fuel Cell Hybrid Source Vehicles Based on Finite State Machine. Appl. Energy 2019, 254, 113707. [Google Scholar] [CrossRef]

- Chemali, E.; Peindl, M.; Malysz, P.; Emadi, A. Electrochemical and Electrostatic Energy Storage and Management Systems for Electric Drive Vehicles: State-of-the-Art Review and Future Trends. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 1–1. [Google Scholar] [CrossRef]

- Pullen, K.R.; Dhand, A. Mechanical and Electrical Flywheel Hybrid Technology to Store Energy in Vehicles. In Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance; 2014; pp. 476–504 ISBN 9780857095220.

- Rimpas, D.; Kaminaris, S.D.; Aldarraji, I.; Piromalis, D.; Vokas, G.; Papageorgas, P.G.; Tsaramirsis, G. Energy Management and Storage Systems on Electric Vehicles: A Comprehensive Review. Mater. Today Proc. 2022, 61, 813–819. [Google Scholar] [CrossRef]

- ISO Win the Energy Challenge with ISO 50001. Int. Organ. Stand. 2011, 16.

- Choi, M.; Lee, J.; Seo, S. Real-Time Optimization for Power Management Systems of a Battery / Supercapacitor Hybrid Energy Storage System in Electric Vehicles. IEEE Trans. Veh. Technol. 2014, 63, 3600–3611. [Google Scholar] [CrossRef]

- Song, Z.; Hofmann, H.; Li, J.; Hou, J.; Han, X.; Ouyang, M. Energy Management Strategies Comparison for Electric Vehicles with Hybrid Energy Storage System. Appl. Energy 2014, 134, 321–331. [Google Scholar] [CrossRef]

- Aharon, I.; Kuperman, A. Topological Overview of Powertrains for Battery-Powered Vehicles with Range Extenders. IEEE Trans. Power Electron. 2011, 26, 868–876. [Google Scholar] [CrossRef]

- Ahmed, O.A.; Bleijs, J.A.M. An Overview of DC – DC Converter Topologies for Fuel Cell-Ultracapacitor Hybrid Distribution System. Renew. Sustain. Energy Rev. 2015, 42, 609–626. [Google Scholar] [CrossRef]

- Pay, S.; Baghzouz, Y.; Member, S. Effectiveness of Battery-Supercapaicitor Combination in Electric Vehicles. 2003 IEEE Bol. PowerTech - Conf. Proc. 2003. [Google Scholar]

- Lukic, S.M.S.M.; Cao, J.; Bansal, R.C.R.C.; Rodriguez, F.; Emadi, A.; Member, S.S.; Cao, J.; Bansal, R.C.R.C.; Member, S.S.; Rodriguez, F. Energy Storage Systems for Automotive Applications. Ind. Electron. IEEE Trans. 2008, 55, 2258–2267. [Google Scholar] [CrossRef]

- Iannuzzi, D.; Tricoli, P. Speed-Based State-of-Charge Tracking Control for Metro Trains With Onboard Supercapacitors. IEEE Trans. Power Electron. 2012, 27, 2129–2140. [Google Scholar] [CrossRef]

- Armenta, J.; Núñez, C.; Visairo, N.; Lázaro, I. An Advanced Energy Management System for Controlling the Ultracapacitor Discharge and Improving the Electric Vehicle Range. J. Power Sources 2015, 284, 452–458. [Google Scholar] [CrossRef]

- Dixon, J.; Nakashima, I.; Arcos, E.F.; Ortúzar, M. Electric Vehicle Using a Combination of Ultracapacitors and ZEBRA Battery. IEEE Trans. Ind. Electron. 2010, 57, 943–949. [Google Scholar] [CrossRef]

- Ortúzar, M.; Moreno, J.; Dixon, J. Ultracapacitor-Based Auxiliary Energy System for an Electric Vehicle: Implementation and Evaluation. IEEE Trans. Ind. Electron. 2007, 54, 2147–2156. [Google Scholar] [CrossRef]

- Moreno, J.; Ortuzar, M.E.; Dixon, J.W. Energy-Management System for a Hybrid Electric Vehicle, Using Ultracapacitors and Neural Networks. IEEE Trans. Ind. Electron. 2006, 53, 614–623. [Google Scholar] [CrossRef]

- Wangsupphaphol, A.; Rumzi, N.; Idris, N. Student Research Highlight : Acceleration-Based Design of Electric Vehicle Auxiliary Energy Source. IEEE Aerosp. Electron. Syst. Mag. 2016, 32–35. [Google Scholar] [CrossRef]

- Wangsupphaphol, A.; Rumzi, N.; Idris, N.; Jusoh, A.; Muhamad, N.D.; Chamchuen, S. Acceleration-Based Control Strategy and Design for Hybrid Electric Vehicle Auxiliary Energy Source. ECTI Trans. Comput. Inf. Technol. 2015, 9, 83–92. [Google Scholar] [CrossRef]

- Guidi, G.; Undeland, T.M.; Hori, Y. Optimized Power Electronics Interface for Auxiliary Power Buffer Based on Supercapacitors. In Proceedings of the 2008 IEEE Vehicle Power and Propulsion Conference, VPPC 2008; 2008; Vol. 0; pp. 0–5. [Google Scholar]

- Guidi, G.; Undeland, T.M.; Hori, Y. An Optimized Converter for Battery-Supercapacitor Interface. In Proceedings of the PESC Record - IEEE Annual Power Electronics Specialists Conference; 2007; pp. 2976–2981. [Google Scholar]

- Guidi, G.; Undeland, T.M.; Hori, Y. An Interface Converter with Reduced VA Ratings for Battery-Supercapacitor Mixed Systems. In Proceedings of the Fourth Power Conversion Conference-NAGOYA, PCC-NAGOYA 2007 - Conference Proceedings; 2007; pp. 936–941. [Google Scholar]

- Lu, S.; Corzine, K.A.; Ferdowsi, M. A New Battery/Ultracapacitor Energy Storage System Design and Its Motor Drive Integration for Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2007, 56, 1516–1523. [Google Scholar] [CrossRef]

- Kuperman, A.; Aharon, I. Battery – Ultracapacitor Hybrids for Pulsed Current Loads : A Review. Renew. Sustain. Energy Rev. 2011, 15, 981–992. [Google Scholar] [CrossRef]

- Laldin, O.; Moshirvaziri, M.; Trescases, O. Predictive Algorithm for Optimizing Power Flow in Hybrid Ultracapacitor/Battery Storage Systems for Light Electric Vehicles. IEEE Trans. Power Electron. 2013, 28, 3882–3895. [Google Scholar] [CrossRef]

- Florescu, A.; Bacha, S.; Munteanu, I.; Iuliana, A.; Rumeau, A.; Bratcu, A.I.; Rumeau, A. Adaptive Frequency-Separation-Based Energy Management System for Electric Vehicles. J. Power Sources 2015, 280, 410–421. [Google Scholar] [CrossRef]

- Source, B.P.; Hredzak, B.; Agelidis, V.G.; Member, S.; Jang, M. A Model Predictive Control System for a Hybrid. IEEE Trans. POWER Electron. 2014, 29, 1469–1479. [Google Scholar]

- Zhou, S.Q.; Guo, G.F.; Xiang, Y.Y. Multi-Objective Optimal Sizing Hybrid Power System in a Solar Electric Vehicle Using Particle Swarm Optimization Algorithm. Adv. Mater. Res. 2013, 694–697, 2699–2703. [Google Scholar] [CrossRef]

- Wong, J.H.; Sutikno, T.; Idris, N.R.N.; Anwari, M. A Parallel Energy-Sharing Control Strategy for Fuel Cell Hybrid Vehicle. Telkomnika 2011, 9, 357–364. [Google Scholar] [CrossRef]

- Schupbach, R.M.; Balda, J.C. Comparing DC-DC Converters for Power Management in Hybrid Electric Vehicles. IEEE Int. Electr. Mach. Drives Conf. 2003. IEMDC’03. 2003, 3, 1369–1374. [Google Scholar] [CrossRef]

- Amjadi, Z.; Williamson, S.S. Prototype Design and Controller Implementation for a Battery-Ultracapacitor Hybrid Electric Vehicle Energy Storage System. IEEE Trans. Smart Grid 2012, 3, 332–340. [Google Scholar] [CrossRef]

- Fernão Pires, V.; Romero-Cadaval, E.; Vinnikov, D.; Roasto, I.; Martins, J.F. Power Converter Interfaces for Electrochemical Energy Storage Systems - A Review. Energy Convers. Manag. 2014, 86, 453–475. [Google Scholar] [CrossRef]

- Wangsupphaphol, A.; Idris, N.R.N.; Jusoh, A.; Muhamad, N.D.; Alsofyani, I.M. Energy and Power Control Strategy for Battery Electric Vehicle with Supercapacitors. Energy Convers. (CENCON), 2014 IEEE Conf. 2014; 13–18. [Google Scholar] [CrossRef]

- Wangsupphaphol, A.; Idris, N.R.N.; Jusoh, A.; Muhamad, N.D.; Yao, L.W. The Energy Management Control Strategy for Electric Vehicle Applications. Green Energy Sustain. Dev. (ICUE), 2014 Int. Conf. Util. Exhib. 2014; 1–5. [Google Scholar]

- Wangsupphaphol, A.; Idris, N.R.N.; Jusoh, A.; Muhamad, N.D.; Alsofyani, I.M. Acceleration-Based Design Auxiliary Power Source for Electric Vehicle Applications. 2014 11th Int. Conf. Electr. Eng. Comput. Telecommun. Inf. Technol. 2014, 1–6. [Google Scholar] [CrossRef]

- Zhang, P.; Yan, F.; Du, C. A Comprehensive Analysis of Energy Management Strategies for Hybrid Electric Vehicles Based on Bibliometrics. Renew. Sustain. Energy Rev. 2015, 48, 88–104. [Google Scholar] [CrossRef]

- Salmasi, F.R. Control Strategies for Hybrid Electric Vehicles: Evolution, Classification, Comparison, and Future Trends. IEEE Trans. Veh. Technol. 2007, 56, 2393–2404. [Google Scholar] [CrossRef]

- Trovão, J.P.; Antunes, C.H. A Comparative Analysis of Meta-Heuristic Methods for Power Management of a Dual Energy Storage System for Electric Vehicles. Energy Convers. Manag. 2015, 95, 281–296. [Google Scholar] [CrossRef]

- Tie, S.F.; Tan, C.W. A Review of Power and Energy Management Strategies in Electric Vehicles. 2012, 412–417.

- Tie, S.F.; Tan, C.W. A Review of Energy Sources and Energy Management System in Electric Vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar] [CrossRef]

- Dixon, J.W.; Ortúzar, M.E. Ultracapacitors + DC-DC Converters in Regenerative Braking System. IEEE Aerosp. Electron. Syst. Mag. 2002, 17, 16–21. [Google Scholar] [CrossRef]

- Thounthong, P.; Sethakul, P.; Raël, S.; Davat, B. Performance Evaluation of Fuel Cell / Battery / Supercapacitor Hybrid Power Source for Vehicle Applications. IEEE Ind. Appl. Soc. Annu. Meet. IAS 2009 2009, 1–8. [Google Scholar]

- Thounthong, P.; Raël, S.; Davat, B. Energy Management of Fuel Cell/Battery/Supercapacitor Hybrid Power Source for Vehicle Applications. J. Power Sources 2009, 193, 376–385. [Google Scholar] [CrossRef]

- Faggioli, E.; Rena, P.; Danel, V.; Andrieu, X.; Mallant, R.; Kahlen, H. Supercapacitors for the Energy Management of Electric Vehicles. J. Power Sources 1999, 84, 261–269. [Google Scholar] [CrossRef]

- Ortuzar, M.; Dixon, J.; Moreno, J. Design, Construction and Performance of a Buck-Boost Converter for an Ultracapacitor-Based Auxiliary Energy System for Electric Vehicles. IECON’03. 29th Annu. Conf. IEEE Ind. Electron. Soc. (IEEE Cat. No.03CH37468) 2003, 3, 2889–2894. [Google Scholar] [CrossRef]

- Dixon, J.W.; Ortúzar, M.; Wiechmann, E. Regenerative Braking for an Electric Vehicle Using Ultracapacitores and a Buck-Boost Converter. In Proceedings of the 17th Electric Vehicle Symposium (EVS17), (Canada); 2000. [Google Scholar]

- Wangsupphaphol, A.; Idris, N.R.N.; Jusoh, A.; Muhamad, N.D. Power Converter Design for Electric Vehicle Applications. J. Teknol. (Sciences Eng. 2014, 67, 25–31. [Google Scholar] [CrossRef]

- Wangsupphaphol, A.; Rumzi, N.; Idris, N.; Jusoh, A.; Muhamad, N.D.; Chaitusaney, S. Design and Development of Auxiliary Energy Storage for Battery Hybrid Electric Vehicle. J. Energy Storage 2022, 51, 104533. [Google Scholar] [CrossRef]

- Karunarathne, E.; Wijesekera, A.; Samaranayake, L.; Binduhewa, P.; Ekanayake, J. On the Implementation of Hybrid Energy Storage for Range and Battery Life Extension of an Electrified Tuk-Tuk. J. Energy Storage 2022, 46. [Google Scholar] [CrossRef]

- Wang, G.; Yang, P.; Zhang, J. Fuzzy Optimal Control and Simulation of Battery-Ultracapacitor Dual-Energy Source Storage System for Pure Electric Vehicle. Proc. 2010 Int. Conf. Intell. Control Inf. Process. ICICIP 2010 2010, 555–560. [Google Scholar] [CrossRef]

- Xiaoliang, H.; Curti, J.M.A.; Yoichi, H. Energy Management Strategy with Optimized Power Interface for the Battery Supercapacitor Hybrid System of Electric Vehicles. IECON Proc. (Industrial Electron. Conf. 2013; 4635–4640. [Google Scholar] [CrossRef]

- Zandi, M.; Payman, A.; Martin, J.; Pierfederici, S.; Davat, B.; Meibody-Tabar, F. Energy Management of a Fuel Cell / Supercapacitor / Battery Power Source for Electric Vehicular Applications. IEEE Trans. Veh. Technol. 2011, 60, 433–443. [Google Scholar] [CrossRef]

- Cao, J.; Cao, B.; Bai, Z.; Chen, W. Energy-Regenerative Fuzzy Sliding Mode Controller Design for Ultracapacitor-Battery Hybrid Power of Electric Vehicle. In Proceedings of the 2007 International Conference on Mechatronics and Automation; 2007; pp. 1570–1575. [Google Scholar]

- Li, Q.; Chen, W.; Liu, Z.; Li, M.; Ma, L. Development of Energy Management System Based on a Power Sharing Strategy for a Fuel Cell-Battery-Supercapacitor Hybrid Tramway. J. Power Sources 2015, 279, 267–280. [Google Scholar] [CrossRef]

- Sampathnarayanan, B.; Onori, S.; Yurkovich, S. ; Ieee An Optimal Regulation Strategy for Energy Management of Hybrid Electric Vehicles. 2012 Ieee 51st Annu. Conf. Decis. Control 2012, 50, 7063–7068. [Google Scholar]

- Dellnitz, M.; Eckstein, J.; Flaßkamp, K.; Friedel, P.; Horenkamp, C.; Köhler, U.; Ober-Blöbaum, S.; Peitz, S.; Tiemeyer, S. Development of an Intelligent Cruise Control Using Optimal Control Methods. Procedia Technol. 2014, 15, 285–294. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Yang, C.; Jiao, X. Hybrid Genetic Algorithm-Based Optimization of Powertrain and Control Parameters of Plug-in Hybrid Electric Bus. J. Franklin Inst. 2015, 352, 776–801. [Google Scholar] [CrossRef]

- Ren, Y.; Zhong, Z. A Combined Particle Swarm Optimization-Wavelet Transform Based Strategy for Power Management of PEM Fuel Cell Powered Hybrid System. Adv. Mater. Res. 2014, 973, 954–957. [Google Scholar] [CrossRef]

- Chen, Z.; Mi, C.C.; Xia, B.; You, C. Energy Management of Power-Split Plug-in Hybrid Electric Vehicles Based on Simulated Annealing and Pontryagin ’ s Minimum Principle. J. Power Sources 2014, 272, 160–168. [Google Scholar] [CrossRef]

- Sousa, T.; Vale, Z.; Carvalho, J.P.; Pinto, T.; Morais, H. A Hybrid Simulated Annealing Approach to Handle Energy Resource Management Considering an Intensive Use of Electric Vehicles. Energy 2014, 67, 81–96. [Google Scholar] [CrossRef]

- Jain, M.; Desai, C.; Williamson, S.S. Genetic Algorithm Based Optimal Powertrain Component Sizing and Control Strategy Design for a Fuel Cell Hybrid Electric Bus. 2009 IEEE Veh. Power Propuls. Conf. 2009, 980–985. [Google Scholar]

- Chen, Z.; Xia, B.; You, C.; Mi, C.C. A Novel Energy Management Method for Series Plug-in Hybrid Electric Vehicles. Appl. Energy 2015, 145, 172–179. [Google Scholar] [CrossRef]

- Zhang, S.; Xiong, R. Adaptive Energy Management of a Plug-in Hybrid Electric Vehicle Based on Driving Pattern Recognition and Dynamic Programming. Appl. Energy 2015, 155, 68–78. [Google Scholar] [CrossRef]

- Samanta, C.K.; Hota, M.K.; Nayak, S.R.; Panigrahi, S.P.; Panigrahi, B.K. Energy Management in Hybrid Electric Vehicles Using Optimized Radial Basis Function Neural Network. Int. J. Sustain. Eng. 2014, 7, 352–359. [Google Scholar] [CrossRef]

- Anubi, O.M.; Clemen, L. Energy-Regenerative Model Predictive Control. J. Franklin Inst. 2015, 352, 2152–2170. [Google Scholar] [CrossRef]

- Borhan, H. a.; Vahidi, A. Model Predictive Control of a Power-Split Hybrid Electric Vehicle with Combined Battery and Ultracapacitor Energy Storage. Am. Control Conf. (ACC), 2010 2010, 5031–5036. [Google Scholar] [CrossRef]

- Thounthong, P.; Davat, B. Control Strategy of Fuel Cell / Supercapacitors Hybrid Power Sources for Electric Vehicle. 2006, 158, 806–814. [CrossRef]

- Thounthong, P.; Chunkag, V.; Sethakul, P.; Davat, B.; Hinaje, M. Comparative Study of Fuel-Cell Vehicle Hybridization with Battery or Supercapacitor Storage Device. IEEE Trans. Veh. Technol. 2009, 58, 3892–3904. [Google Scholar] [CrossRef]

- Shen, J.; Khaligh, A. Design and Real-Time Controller Implementation for a Battery-Ultracapacitor Hybrid Energy Storage System. IEEE Trans. Ind. Informatics 2016, 12, 1910–1918. [Google Scholar] [CrossRef]

- Zhai, C.; Luo, F.; Liu, Y. A Novel Predictive Energy Management Strategy for Electric Vehicles Based on Velocity Prediction. IEEE Trans. Veh. Technol. 2020, 69, 12559–12569. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, J.; Zhao, W. Deep Reinforcement Learning Based Energy Management Strategy for Fuel Cell/Battery/Supercapacitor Powered Electric Vehicle. Green Energy Intell. Transp. 2022, 1, 100028. [Google Scholar] [CrossRef]

| Configuration | Converter size (score 0-3) | DC bus voltage (score 0-2) | Reliability (score 0-1) | Total score |

|---|---|---|---|---|

| (a) | None (0) | Follow battery (1) | High (1) | 2 |

| (b) | 1 full size (1) | Constant (2) | Low (0) | 3 |

| (c) | 1 medium size (2) | Follow battery (1) | High (1) | 4 |

| (d) | 1 small size (3) | Follow battery (1) | High (1) | 5 |

| (e) | 1 medium size (2) | Follow SC (0) | High (1) | 3 |

| (f)-(h) | 1 full 1 medium size (1) | Constant (2) | Low (0) | 3 |

| Paper | EMS | Control structure | Main Contributions | Validation | Limitations | Year |

|---|---|---|---|---|---|---|

| [15,16,17,41,45,46] | Rule-based; Load follower | SC converter for current control within bandwidth |

|

|

|

2000-2010 |

| [42,67,68] | SC converter for current control based on energy and power-SC converter |

|

Experimental validation |

|

2006-2009 | |

| [29] | SC converter for voltage and current control |

|

Experimental validation |

|

2011 | |

| [14] | SC converter for power control based on vehicle dynamic |

|

Simulation |

|

2015 | |

| [48] | SC converter for current control based on vehicle dynamic |

|

Simulation and lab-scale experiment | Real-vehicle experiement | 2022 | |

| [8] | Rule-based; power split | SC converter for power control based on vehicle kinetic energy |

|

Simulation |

|

2014 |

| [26] | Rule-based; adaptive power split | SC converter for curent and voltage control | Less complex of SC control reference generation | Real-time simulation | Slow control response causes inefficient use of the battery and SC. | 2019 |

| [49] | Rule-based; power split using Kalman filter | Battery and SC converter for SOC control |

|

Real-vehicle experiment |

|

2022 |

| [50] | Rule-based; conventional fuzzy logic | Battery and SC converter for power control |

|

Simulation in ADVISOR 2002 |

|

2010 |

| [52] | Battery and SC converter for energy and power control |

|

Simulation and experiment |

|

2011 | |

| [53] | Rule-based; fuzzy sliding mode | Battery and SC converter for SOC control |

|

Micro EV experiment |

|

2007 |

| [54] | Rule-based harr-wavelet fuzzy logic | Battery and SC converter for power control |

|

Tramway experiment |

|

2015 |

| [56] | Off-line optimization; sequential quadratic programming | Minimised battery’s SOC and velocity variation |

|

Simulation |

|

2014 |

| [61] | Off-line optimization; non-dominated sorting genetic algorithm | Minimised fuel economy and cost |

|

Simulation |

|

2009 |

| [58] | Off-line optimization; PSO-wavelet-transform | Estimation of battery and SC SOC and optimization of PID parameters |

|

Simulation |

|

2014 |

| [62] | Off-line optimization; Simulated annealing | Optimal battery power |

|

Simulation in Autonomie |

|

2015 |

| [63] | Off-line optimization; dynamic programming | optimal power distribution |

|

Simulation |

|

2015 |

| [15],[69] | Real-time optimization; neural network | SC converter for current control |

|

Real-vehicle experimet, real-time experiment |

|

2010, 2016 |

| [66],[70] | Real-time optimization; model predictive | Battery and SC converter for SOC control |

|

Simulation |

|

2010,2020 |

| [71] | Real-time optimization; deep-reinforcement learning | Fuel cell/battery/SC converter |

|

Simulation |

|

2022 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).