1. Introduction

Alfalfa (Medicago sativa L.) is one of the most important forage crops grown worldwide in more than 80 countries on an area of over 40 million hectares. Total acres of alfalfa crops in Kazakhstan in 2022 was 2,149,774.3 hectares, and the total production of alfalfa hay was 437,455.5 tons. In the conditions of the Kyzylorda region, alfalfa is an integral and important crop of rice crop rotation, the area of which is 67,318.6 hectares, and the production of alfalfa hay in the region amounted to 25,038.3 tons and continues to increase.

The high content of nutrients and minerals in the green mass and alfalfa hay puts it among the most valuable forage crops. Alfalfa is used for making hay, herbal protein-vitamin flour, haylage, silage, as an additional green feeding. Such a variety of uses is due to the fact that it is rich in vegetable protein with a high content of essential amino acids.

In the green mass of alfalfa, harvested in the budding stage – beginning of flowering, the protein is 18%, fat - 3, fiber - 24.9, free-nitrogen extracts - 43.3, calcium - 2.12, phosphorus - 0.27, potassium - 1.1 % on absolutely dry basis. The green mass of alfalfa is a multivitamin feed for all types of livestock and birds.

The studies have found that, in addition to provitamin A (carotene), alfalfa contains vitamin В

1, which prevents diseases of the nervous system and plays an important role in regulating carbohydrate metabolism in the animal body; vitamin C - antiscorbutic; vitamin D - antirachitic; vitamin K - affecting blood composition (blood clotting); vitamin PP - preventing pellagra in animals and vitamin E - affecting the reproductive ability of the animal [

1]. Also, research by Tuantuan Cui et al., 2018 [

2] has shown that intercropping can increase plants biomass and reduce the accumulation of heavy metals in plants. At the same time, the lead content in the shoots and roots of ryegrass and alfalfa in intercropping was significantly lower than in monoculture.

In the Kyzylorda region, the gathering of wet alfalfa hay for the second and subsequent years of life can reach 150–180 c/ha [

3,

4,

5]. In the conditions of irrigated agriculture, the number of haymaking is determined mainly by the duration of the frost-free period with an air temperature of at least 10°C. Therefore, in the Kyzylorda region, where the frost-free period lasts 170-180 days, it is possible to get 3-4 haymaking. The preparation of high-quality hay, herbal protein-vitamin flour, haylage, alfalfa silage is an important reserve in creating a forage base for livestock in the region. In this regard, proper and timely harvesting, drying and storage of alfalfa is important and responsible.

It is known that when harvesting alfalfa for hay, a significant amount of the most nutritionally valuable parts of plants - leaves, flowers, is lost, since they dry out faster and easily shatter during mowing, stacking and other harvesting operations. Therefore, the main challenge in harvesting alfalfa is to minimize the loss of leaves, buds and flowers. In addition, in field conditions, physical and chemical changes occur in the feed as it dries. Primary biological or metabolic losses occur due to plant respiration [

6].

2. Materials and Methods

In order to obtain high-quality hay, it is necessary to harvest alfalfa in the best agrotechnical terms, without a gap between mowing, pressing, loading and transporting hay. It is also necessary to take into account the fact that there are big differences between the hay-making methods in wet and arid regions. In wet regions, hay growers speed up hay drying by improving hay bale ventilation and use conservants such as propionic acid to keep the product for a longer period of time in humid conditions. In arid regions, hay is only pressed after the dew has accumulated on the soft tissues of the plants to reduce leaf loss. For the same reason, researchers have developed new systems for spraying water mist on plant tissues during pressing [

7].

As is well known, the traditional methods of conservation of forage crops are haymaking and silaging. However, the loss of yield and hay quality during different periods of harvesting is 30-70% of the potential yield of alfalfa [

8,

9,

10,

11]. Until now, in the conditions of the Aral Sea region, this issue has not been given special or due attention. Therefore, more research work is needed on this particular issue to minimize losses; especially the time of haymaking according to the stages of alfalfa development. It should be noted that the ultimate goal of haymaking machinery is to maintain the highest possible nutritional value of the hay; therefore, it is important to understand the impact of harvesting methods on the quantity and quality of hay harvested. Thus, the main purpose of this research was to study the influence of the timing of haymaking on the yield and quality of alfalfa feed in the conditions of the Kazakhstan Aral Sea region.

In several farms of the region, in accordance with the methods of conducting field experiments [

21,110], studies were carried out to determine the weight gain and growth dynamics of alfalfa over time. For the accuracy of the experiments, the second haymaking period was chosen.

To carry out these studies, in accordance with the replication method, fields were selected, where 12 plots sized 1.0x1.0 m were marked with a tape measure and pegs. These studies were carried out every 5 days after the first haymaking.

In the first plot out of 12, 5 days after the first haymaking, all alfalfa was cut off with a pruner at the root. Of these, 100 measurements of the weight and growth of the stems were selectively made. At the same time, medical scales of the VNZ-2000 GOST 574-75 type were used to measure weight, and a meter ruler was used to measure growth. The measurements showed that the alfalfa cutting height ranged from 3.8 to 8.0 cm, the average weight at this growth turned out to be 0.9 g. The measurement error was: for weight gain - ± 0.2 g, for height gain - ± 1.0 mm.

Similarly, every 5 days, 100 measurements of the weight and height of the growth of the stems were carried out in all plots. If in the first plot they cut with pruners and measured the weight and height 5 days after haymaking, in the second plot a similar operation was performed 10 days after haymaking, in the third plot - 15 days after haymaking, and so on until the end.

Table 1 shows the average measurements to determine the weight gain and growth dynamics of alfalfa stem over time.

In the study of the seventh plot, the growth of the stems reached 52-76 cm, and the average weight was 8.5 g, and buds appeared in alfalfa.

On the fortieth day after haymaking, the average stem weight reached 10.9 g, while alfalfa began to bloom, and in the study of the ninth plot, the weight of alfalfa reached 12.3 g, as it turned out after measuring the tenth plot, in which the average stem weight was 11.8 g, it was maximum.

Field experiments provide an objective assessment of the options under study only if the experiment has been carried out in compliance with all the requirements of the techniques. Technical errors made at any stage of experimental work violate the comparability of options and distort their effectiveness. Errors of this kind cannot be corrected by any mathematical processing and, hence, completely invalidate the results of the experiments. Therefore, observance of all technological rules for conducting an experiment in the field is an important condition for obtaining accurate data suitable for an objective assessment of the actions studied in the experiment.

Thus, studies of many years have shown that on irrigation in the conditions of the Kyzylorda region, with timely harvesting of alfalfa for hay, you can get from 3 to 5 haymaking [

1,

3,

4]. When carrying out haymaking in the early vegetative stages, the subsequent regrowth occurs mainly from the axillary buds of the stem remaining after mowing, and when harvesting during the flowering period - from dormant and additional buds of the head (crown) of the root. Therefore, the best time for harvesting alfalfa for hay is the period from the beginning of flowering to full flowering, which covers 11-12 days. These data of agricultural scientists were laid as fundamental factors for optimizing the timing and number of alfalfa haymaking. At the same time, it should be remembered that the formation of the first haymaking requires 55-60 days, the second haymaking - 25-30 days and the third haymaking - 40-45 days.

Carrying out haymaking of alfalfa during the period of budding - beginning of flowering is justified by the fact that alfalfa at this age produces good quality hay, although it is somewhat inferior in terms of yield compared to haymaking carried out during the full flowering period. However, due to the presence of a stock of nutrients, the shortage of yield is compensated by the total collection of nutrients per unit area, especially proteins. Carrying out haymaking at the end of budding - at the beginning of flowering is justified by the fact that that at the same time alfalfa produces more yield. For the purpose of a detailed study of the timing of alfalfa haymaking on the features of growth and development in subsequent haymaking, research was carried out under irrigation conditions [

12,

13,

14,

15].

Thus, according to (Zykov Yu.D.) [

1,

3], forage alfalfa was mowed in the following periods: flower buttons probing - by 60-70%, mass budding - 60-70%, beginning of flowering - appearance of flowers - by 20- 30%, mass flowering - 60-70% of the main stems and the beginning of seed formation.

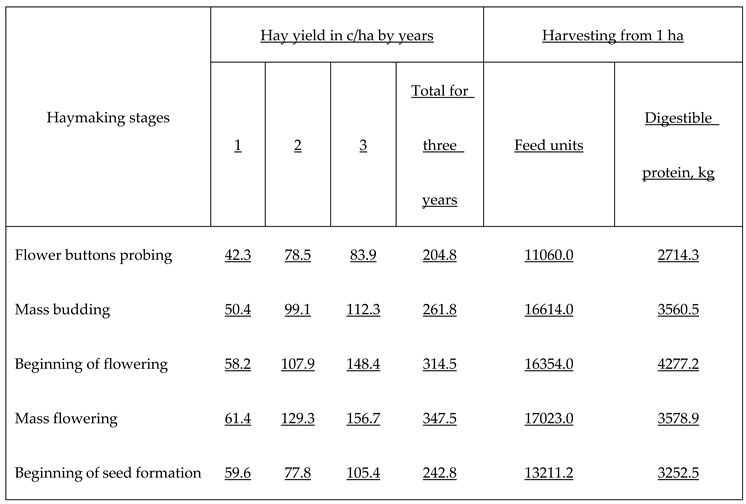

The accounting of the yield of green mass and hay during the harvesting of alfalfa in different vegetative stages has shown that the systematic mowing of alfalfa at the age of buttons probing and budding leads to a sharp decrease in yield compared to haymaking carried out at the time of flowering, which is reflected in

Table 2.

The decrease in the hay yield, and consequently in the total collection of feed units and digestible protein during the early harvesting time of alfalfa occurs due to the incomplete completion of the growth vegetative processes of plants, as well as due to the lack of plastic substances in the above-ground mass.

The growth dynamics of the mass of one alfalfa stem in the second year of life, according to the main vegetative stages, is as follows: during flower buttons probing - 5.3 g, during mass budding - 11.1 g, during flowering - 17.7 g and at the beginning of seed formation - 17 g.

As can be seen, an intensive growth of green mass in Semirechensk alfalfa occurs in the stages of flower buttons probing to beginning of flowering.

The second reason, which causes a decrease in the alfalfa yield when it is systematically harvested in the early vegetative stages, is the thinning of plants. The main reason for the high thinness of the alfalfa plant in experiments with annual haymaking in the early vegetative stages is a severe depletion of plants [

12,

13].

If we trace the dynamics of total nitrogen and phosphorus in alfalfa roots by vegetative stages, then it will be as follows: during the after growing period of alfalfa, the stocks of nutrients in the root are minimal, since they are intensively consumed for the formation of the aerial parts of the plants. At the time of flowering, when growth vegetative processes are suspended, an outflow of nutrients from the above-ground mass to the roots occurs and an increase in nitrogen and phosphorus content is observed.

During the pod formation, the stocks of nutrients in the roots decrease again, and with the beginning of seed maturation, they increase sharply again. Consequently, the systematic mowing of alfalfa herbage, in the early vegetative stages leads to a strong weakening of plants, and often to their death. Hence it is clear why options with early timing of mowing produce lower yields of green mass and hay. In addition, observations of the growth dynamics of alfalfa herbage, depending on the stage of systematic haymaking, show a certain pattern. Thus, in the options where mowing was carried out before flowering, the height of the stems 10 days after the haymaking was 10.6-12.4 cm, and when mowing was carried during the flowering period it was 20.9-21.5 cm.

This difference in the height of alfalfa plants remains even before haymaking. This is explained not only by the weakening of plants during systematic mowing before flowering, but also by the type of regrowth of new stems. When carrying out haymaking in the early vegetative stages, the subsequent regrowth occurs mainly from the axillary buds of the stem remaining after mowing, and when harvesting during the flowering period - from dormant and additional buds of the head (crown) of the root.

In addition, the bushiness of plants has a great influence on the size of the hay yield, which, in turn, is directly dependent on the development of the root head of the plant. On the other hand, the size of the root head depends on the type of regeneration of alfalfa herbage by haymaking and years of life. The low bushiness of alfalfa was observed during its systematic mowing before flowering, i.e., when the main regeneration occurs due to its axillary stem buds. The maximum bushiness was observed in plants that were systematically mowed during the flowering period, and the regeneration was mainly due to the buds located on the root head.

Based on the above, it is clear that determining the number of alfalfa haymaking depending on the yield is relevant.

In the literature we know, the number of haymaking is determined by agronomists and is carried out according to their production capabilities. There are no theoretical studies on optimizing the number of haymaking in the literature known to us. Thus, according to a number of research institutions, it has been found that it is possible to get from 3 to 5 complete haymaking of alfalfa for hay on the irrigated lands in the south and south-east of the country [

14,

15,

16,

17,

18,

19].

In the studies of the alfalfa growing intensity on irrigated lands by VASKHNIL (Lenin All-Union Academy of Agricultural Sciences) academicians K.A. Asanov and P.K. Velichko [

16,

26], it is indicated that the best time for mowing alfalfa is the stage of the beginning of budding. At this time, it contains the greatest amount of nutrients, gives a large number of haymaking and a high feed output per acre of forage. Earlier mowing of alfalfa leads to a shortage of yield, and later mowing leads to a deterioration of the feed quality, as well as to a decrease in yield. Thus, according to research at the Kazakh Research Institute of Agriculture (Almaty region, Republic of Kazakhstan) [

16], when mowing alfalfa in the budding stage, four haymaking were taken with a total green mass yield of 606 c/ha, on light chestnut soils - 714 c/ha, respectively, with three haymaking in the flowering stage, the yield was 519 and 609 c/ha.

Therefore, carrying out haymaking in different vegetative stages of alfalfa, you can get a different number of haymaking. In years with a long frost-free period, when mowing the alfalfa herbage before budding and during the budding period, 4-5 haymaking are taken, and during the flowering period one haymaking less. Applying different terms of mowing alfalfa within certain limits, it is possible to regulate the level of green mass yield and the quality of feed, its uniform supply for livestock feed throughout the warm period, from spring to the onset of frosts.

Research by Kvitko G.P. [

19] has found that the mowing regime is important for long-term use of alfalfa. First-year alfalfa should be mowed only in the flowering stage. At the same time, a sufficient amount of plastic substances that contribute to the formation of shoots accumulate in the “crown”. In its first year, 80 days pass from germination to flowering, alfalfa reaches the second flowering in 45-50 days. In two haymaking in this stage, the yield of green mass is 228 c/ha, the yield of feed units is 48 c/ha and digestible protein is 8.3 c/ha.

In the second year of life, alfalfa is mowed for the first time in the budding stage. If it is delayed, the yield is significantly lost, as the alfalfa overgrows and lodges. The second and third haymaking are best done after 30-35 days the start of flowering. Plant leaf coverage is 50-60%, as a result of which the protein yield increases by 3-4 c/ha compared to harvesting in the full flowering stage.

In the third year of life, the first haymaking in the budding stage should be carried out on the area where in the previous year the last mowing was in the budding stage, and the second haymaking - in the flowering stage. Each year, one of the haymaking is carried out in the stage of the beginning of flowering, which contributes to the accumulation of plastic substances in the “crown” and good shoot formation. The optimal interval of mowing between the first and second haymaking is 30-35 days, and between the second and third, as well as the fourth haymaking is 35-40 days. Zhunisbekov P.Zh. and Mamedalieva G.A. [

18] point out that in order to obtain the maximum gross yield with high quality feed, the number of haymaking should have not only a biological, but also a mathematical justification.

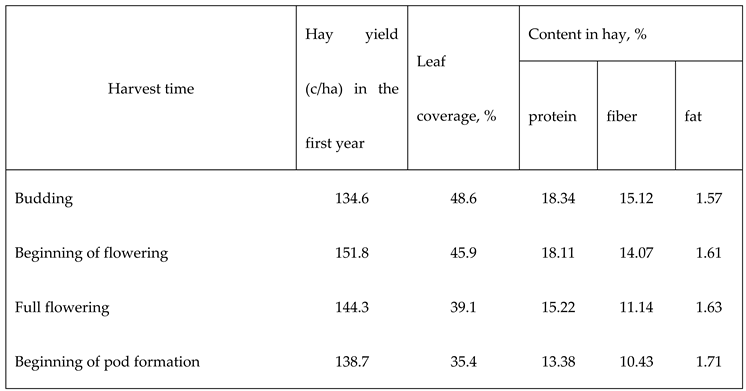

Table 3 shows the yield and quality of hay depending on the time of harvesting.

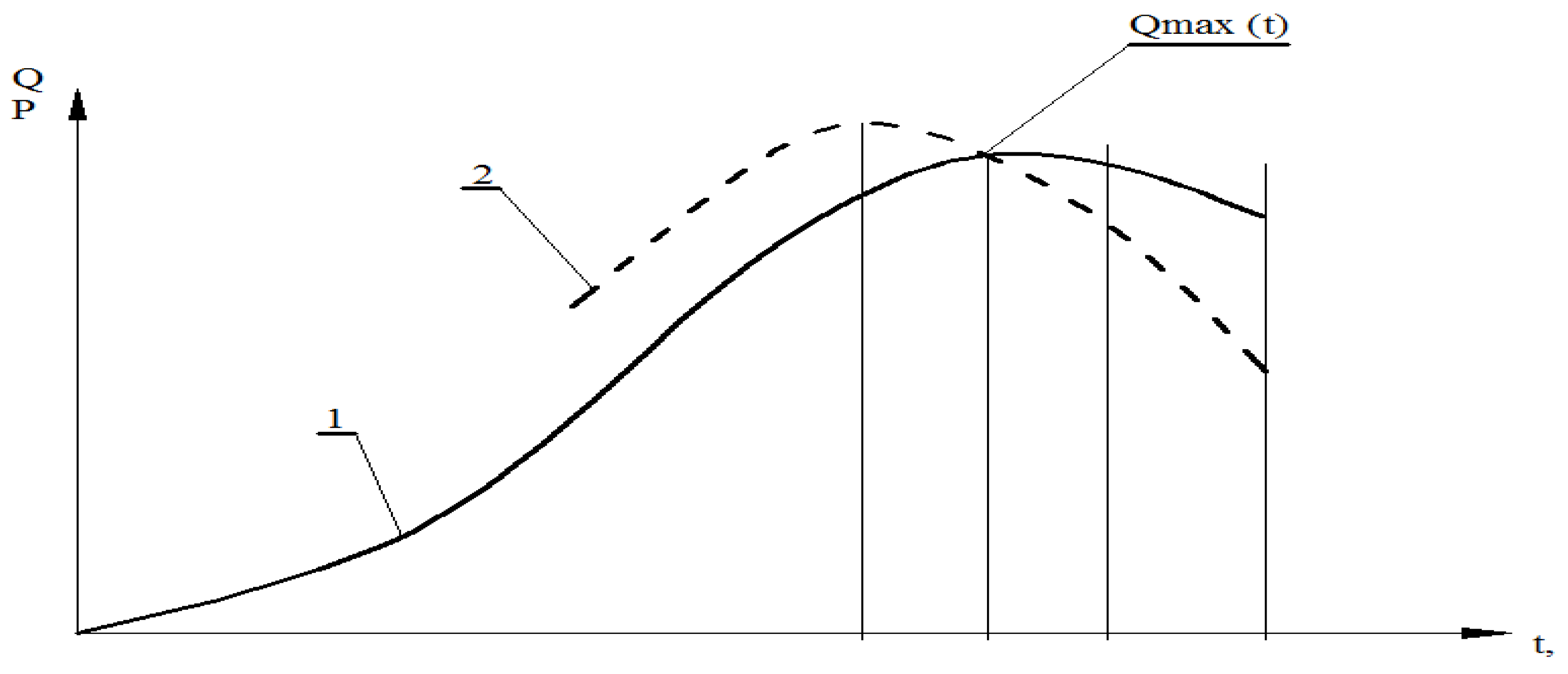

Figure 1 also shows a graph of the change in protein content, constructed taking into account the peculiarities of alfalfa weight gain according to

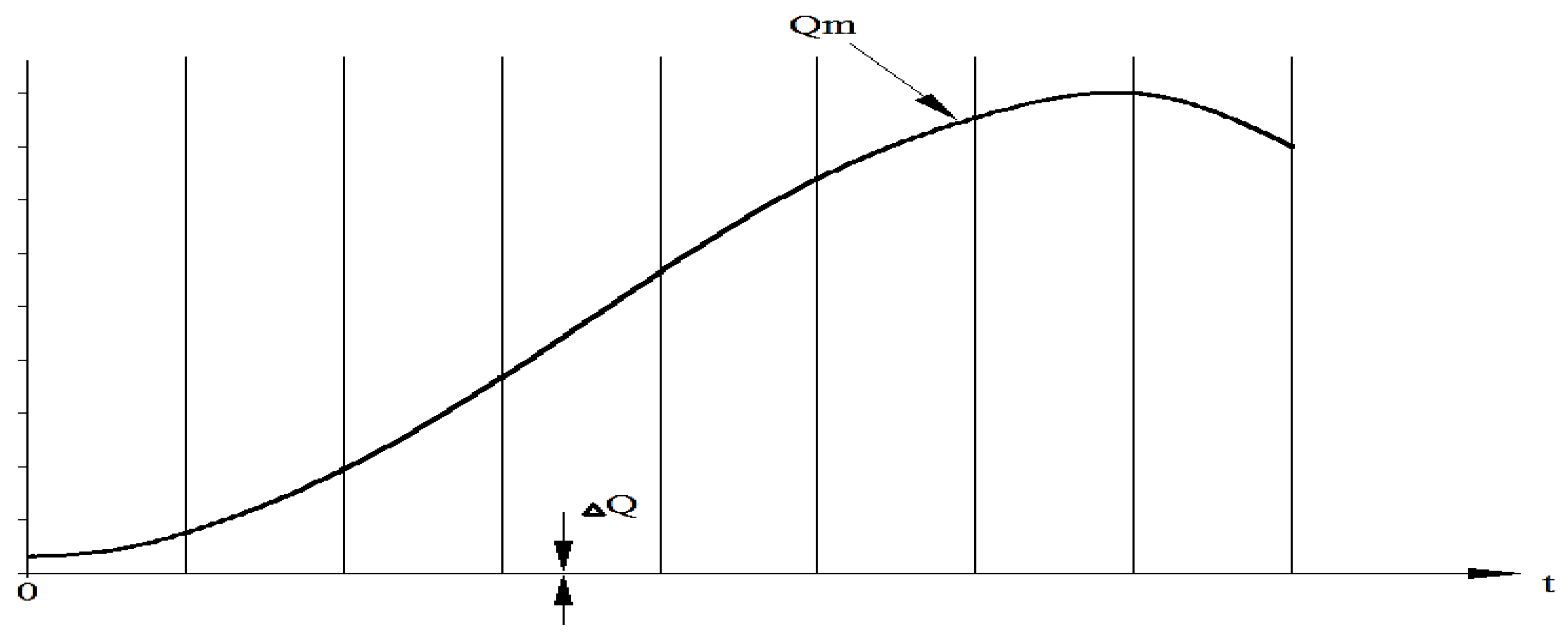

Figure 2. This graph - Q(t) is called a sigmoid curve, and by approximating it, the dependence is obtained in the form:

where

Qm is the largest biological mass of alfalfa at the end of the biological process of weight gain;

В is approximation coefficient;

t is plant growth time;

ΔQ is the unmown mass or the mass of alfalfa below the cutter bar of the mower.

Figure 1 shows a graph of the change in protein content and weight gain by height.

When carrying out haymaking in the early vegetative stages, the subsequent regrowth occurs mainly from the axillary buds of the stem remaining after mowing, and when harvesting during the flowering period - from dormant and additional buds of the head (crown) of the root.

Therefore, the best time for harvesting alfalfa for hay is the period from the beginning of flowering to full flowering, which covers 11-12 days.

Figure 1.

Graph of the change in protein content in alfalfa (Protein content P(t) 2 and weight gain, t, days).

Figure 1.

Graph of the change in protein content in alfalfa (Protein content P(t) 2 and weight gain, t, days).

Justification of the number of haymaking can provide a a set of maximum gross yield:

n

opt is determined by researching Q

gross for an extremum:

The number of haymaking n

opt is equal to

where t

seas is the length of the alfalfa vegetation period during the year; t

1 is the optimal timing of haymaking defined by the previous equation.

The main limitation of the timing of haymaking is

where

tb ,te are beginning and end of alfalfa flowering.

Figure 2.

Dependence of alfalfa weight gain Q over time t (Q - weight, c/ha; t - time, days).

Figure 2.

Dependence of alfalfa weight gain Q over time t (Q - weight, c/ha; t - time, days).

It follows from the above that the maximum gathering of alfalfa depends on the number of haymaking, yield and duration of harvesting. At the same time, it is necessary to take into account the agrotechnical requirements for harvesting alfalfa.

3. Results and Discussion

When harvesting alfalfa, the main focus is not only on its maximum gross yield, but also on the maximum preservation of the yield and increasing the content of nutrients in the feed. Violation of harvesting technology and deviation from agrotechnical requirements lead to a significant decrease in quality and increased losses of alfalfa during their haymaking, storage and use.

Table 4 shows the main rates of nutrient losses [

22].

In order to obtain high quality alfalfa with minimal losses during mowing, it is necessary to comply with agrotechnical requirements for the operations of the harvesting technology. Thus, according to agrotechnical requirements, alfalfa should be mowed in the period from the beginning of flowering to full flowering, when it contains the maximum amount of nutrients. Since the stages of alfalfa development change quickly, in order to obtain high-quality hay from it, mowing is carried out in a very short time. In the conditions of the Kyzylorda region, where the climate is dry and hot, 10-12 days are allotted for this according to agrotechnical requirements. Since the annual mowing of alfalfa in the early periods reduces the productivity of the land in subsequent years, it is necessary to establish the order of harvesting individual plots by year, as well as to organize application of mineral fertilizers.

Mowing alfalfa is the most important of all technological operations. Therefore, the cut of plants should be even and complete. The height deviation along the entire length of the cutter bar should not exceed ±5 mm [

18,

19,

20,

21]. Losses during mowing alfalfa caused by high cutting and uncut plants should not exceed 2%. Cutter bar shoes and wheels of units should not crush cut and uncut alfalfa. When mowing alfalfa, they are placed in windrows evenly along the entire length without gaps or piling up.

In areas with the most humid climate, according to agrotechnical requirements, it is advisable to fluff the cut grass in the swaths simultaneously or immediately after mowing, since it dries slowly from the soil side and even becomes moistened. The loosened turned over grass is spread evenly over the area, avoiding the formation of heaps, and kept in swaths until the moisture content of the mass decreases to 60%. Then it is gathered into uniform windrows up to 1.2 m wide [

20,

22].

To dry hay in windrows, it is better to collect it along the mowing line using side or finger-wheel rakes, it is allowed to rake hay across the swath using dump rakes, during which the total loss of hay should not exceed 2.5%. Alfalfa is dried in windrows from 60 to 35% of moisture content. To do this, the windrows are tedded and turned 180°, and when the moisture content is about 30%, it is collected in shocks [

21,

22,

23]. Wills and Bledsoe, 2015 [

24] nevertheless recommend raking plants in the same direction as the cut to allow the rake teeth to make contact with the leafy part of the plant for better plant movement to roll the leaves towards the center of the windrow. They also reported that raking in the direction opposite to mowing would result in the leafy part to be on the outside of the windrow, which could result in more damage to the plant with any further mechanical impact. Hunt and Wilson [

25] recommend raking plants in the same direction as the previous mowing, taking into account that the entire raking process is completed before the moisture drops below 40%, especially for deciduous plants such as alfalfa.

The moisture content of the mowed mass of alfalfa is determined by external features, that is, by the structure, color of leaves and stems:

- at a moisture content of the mowed mass of 50-70% - the leaves are wilted, their color has faded, and the stems are fresh and green;

- at 40-50% - the leaves are still soft, the stems are wilted, their color has faded; at 40-30% - the leaves start to crumble, the stems are still flexible, the color of the grass is faded, the petioles of the leaves start to break, and there is a real danger of losing dry mass;

- at 25-30% - the leaves have dried out, are crumbling, sap is still released from the stalks, the leaf petioles are very brittle, the loss of dry mass is great;

- at 20-25% - the stems are still soft, but sap is not released from them, the leaf petioles are very brittle, the loss of dry mass is significant;

- at less than 20% - the stems are brittle, the fracture is straight, the leaf petioles are very brittle, the loss of dry mass is very high [

22].

The quality of tedding, raking and windrowing is determined by the completeness of raking the swaths into windrows, their fluffing and moisture content of the grass in the swaths before raking, by the width and weight of 1 running meter of the windrow and field losses of grass. The completeness of raking the swaths into windrows, fluffing and moisture content of the mowed mass is determined visually 2-3 times per shift. For a more accurate determination of the moisture content of alfalfa, it is necessary to take 2 kg of new-mown grass from the windrow and spread it with a layer of the same thickness as the swath. Such areas should be laid every 10 swaths. Moisture is calculated by the formula [

26]:

where

P is initial grass weight, kg;

K is dry matter yield, %;

Pn is weight of dry grass, kg

Alfalfa hay making is carried out in loose and pressed forms. Loose alfalfa hay is made by drying the mowed mass in windrows, picking it up, transporting it to storage sites, stacking and cocking. When making loose alfalfa hay, certain agrotechnical requirements must be observed. For example, when picking up windrows, the pick-up mechanism should well follow the field surface and not clog the alfalfa hay with earth. In order not to contaminate alfalfa hay with earth and not to lose leaves, it should not be transported to the place of stacking by rope sweeps.

The optimum moisture of alfalfa hay making with stacking, picked up by spring-finger pick-ups, is 25-30%. When raking alfalfa hay with front-end loaders, the optimum moisture is 25-28%. With less moisture, alfalfa should be raked from windrows into a pile in the morning or evening hours in the dew. In this case, the total losses should not exceed 2% of the yield [

22,

27,

28].

Stacked alfalfa hay should have an optimal moisture content of 20-22%. In order to avoid losses, hay of standard moisture, which has a moisture content of 16-17%, is recommended to stack in the early morning or before sunset in the dew. Dry hay that can be stored for a long time is stacked tightly in a haystack and tamped.

The width of the stack base should be 6-8 m, the height up to 8 m and the length 10-20 m, depending on the amount of hay. To prevent the stack from getting wet to a depth of more than 0.25 m, it is necessary to tamp it well and form two slopes with an angle of 90-100°. To prevent hay from being blown up by the wind, the top of the stack is covered with waterproof material, fixed to logs 10–15 cm in diameter, and bound together with steel wire or twine [

20].

When making alfalfa hay by shocking, the moisture content should be 20-30%, and when cocking - 20-22%. Roughly the moisture content is determined visually, by the color and physical and mechanical properties of hay. If moisture content is high, the weight of the shock should not exceed 400 kg, and if moisture content is 25%, it should not exceed 600 kg. The density of a shock or cock should be at least 70 kg/m. A cock can be formed up to 7 tons with a hay moisture content of up to 20%. Shocks or cocks should have a regular, complete shape and slopes on both sides. During storage, they should not be destroyed by the wind and should not be soaked to a depth of more than 0.2 m.

The nutrient content, its feed value and moisture content are determined during storage in the laboratory. When stacked for storage, the quality of alfalfa hay is determined by color, odor, moisture content, which should be 17-18%, and the time of mowing the grass. When making pressed alfalfa hay, such works as picking from windrows, pressing into bales and transportation to storage sites or placing in stacks are carried out. The main agrotechnical requirements for hay pressing are as follows: - thus during the picking of the mass from the windrow, baling, supply to transport or unloading in the field, the work tools of the baler should not grind hay, scatter leaves and inflorescence of grass. Hay pressing is characterized as one of the main operations of hay production, which includes processing, transportation and storage of hay. Hay balers are specific agricultural machinery that is designed to collect harvested hay from windrows and press it into round or square bales. The baling process is carried out after three previous operations, namely: - cutting the feed with mowers that cut the feed and unload it in rows; - the windrowing process with a mower that collects the cut feed into larger windrows 1.0–1.5 m wide and the raking process using rakes that mix and turn the hay to ensure a complete hay drying process [

21].

The conditions of the Kazakhstan Aral Sea region are an area with a hot climate; therefore, hay baling should be done in the morning or evening hours so as not to lose the most valuable parts of the plants. The density of pressing hay into bales should be uniform, depending on climatic conditions and the mass moisture - from 100 to 200 kg/m3. In practice, the density of baled hay with the mass moisture of 20-22% can be 150-200 kg/m3. In this case, the bales are immediately loaded into vehicles and transported to storage sites. If hay is pressed from windrows with a moisture content of 25-30%, the pressing density should be 130-140 kg/m3. At the same time, the bales are dried in the field before transportation to storage.

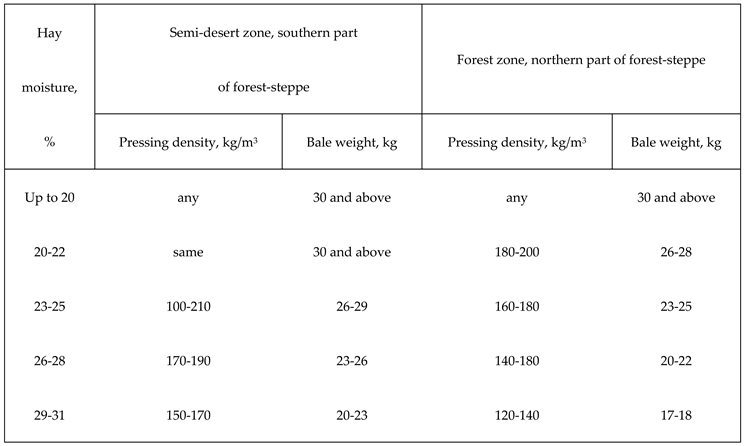

Permissible density of pressing alfalfa hay into bales of 35x45x85 cm, depending on its moisture content in different zones, is presented in

Table 5 [

22]. Overall dimensions of bales are formed within the following limits: length is 0.7-1, width is up to 0.5 and height is up to 0.36 m. This shape and basic sizes must be maintained during loading into vehicles, transportation and stacking for long-term storage.

Pressed bales are bound with two steel wires with a diameter of 1-2 mm placed in parallel or with twine made of synthetic material with the same compressive force of the mass. The non-binding of bales by the binding unit should not exceed 2%. Losses of alfalfa hay during its pickup from the windrow, baling and delivery to the transport should not exceed 2%. Losses of leaves and inflorescences are not allowed. According to agrotechnical requirements, the dimensions of stacks of baled hay should be as follows: length - 20 m; width - 5-5.5 m; and height is not more than 18-20 bales. The optimal dimensions of a stack are provided if the weight of the bales placed in it is 40-60 tons [

22].

The agrotechnical requirements for the transportation of pressed bales of alfalfa are as follows: the baler should provide 100% pick-up of normally bound bales with a pressing density of at least 100 kg/m

3 and weight of up to 40 kg, having an angle of rotation of the longitudinal axis to the movement direction within ±20°. The stockpile formed on the vehicle should not fall apart and have the correct geometric shape during transportation and stacking at the place of long-term storage. Work tools of the vehicle should not damage the binding wire or twine on the bales. Losses during loading onto the vehicle and unloading of bales from it should not exceed 0.1% [

22,

23,

24]. When transporting pressed bales, no losses are allowed.

Silage is made in a known manner, using natural plant components, and with the use of chemical preservatives and bacterial starter cultures. Silage making includes technological processes such as mowing grass into windrows, tedding and raking windrows, grinding leafy mass, transportation and stacking in storage.

According to the established agrotechnical requirements, alfalfa should be harvested in its budding stage to obtain high quality silage with minimal losses.

When filling the storage, the silage mass is evenly leveled and continuously compacted. The thickness of the layer laid per day should be at least 0.8–1.2 m in trenches and 4–5 m in silos [

22,

23,

24,

25,

26,

27].

The temperature of well-compacted mass should not exceed 30°С to ensure a normal ensilage process. If the storage is filled slowly and compacted insufficiently, then a large amount of air accumulates between the particles, the temperature of the mass rises to 60-80°C, at which butyric acid bacteria and other harmful microorganisms develop. Also, contamination of the silage mass with fuel, lubricants and soil should not be allowed.

The silage mass is put into the storage of various capacities for 3-4 days without interruption. After filling the storage, it is immediately covered to isolate it from air and precipitation. Delaying covering for 2-3 days increases feed losses by 7-10% due to warming of the entire mass.

If the requirements of alfalfa silaging technology as a result of fermentation are observed, the total loss of dry matter should not exceed: in silos -8, in large-capacity trenches -8-12% [

22,

23,

24].

The haylage making process includes the following operations: alfalfa mowing, crushing, wilting, placement in storage and unloading from storage.

When performing these operations, it is necessary to comply with agrotechnical requirements so that the haylage contains a sufficient amount of nutrients, is not acidic, has the same amount of sugar as new-mown grass, has high digestibility and is well eaten by animals.

For haylage making, alfalfa is mowed in the stage - from the beginning of budding to the beginning of flowering. The duration of mowing should not exceed 10 days, the optimal cutting height is 4-6 cm. Crushing is carried out simultaneously with mowing in settled good weather and during intermittent rains. Partially or completely crushed plants should be at least 90% of the total mass. Depending on the climatic and weather conditions, the wilting process lasts from 2 to 48 hours. Grass is wilted in swaths to a moisture content of 60-70%, and in windrows up to 55-60% [

22,

23,

26].

Plant mass is picked up when its moisture drops to 55-60%. Chopped plants up to 20 mm long are placed in silo. Plants of this length should be at least 75% of the total mass. When preserving feed in trenches, a cut length of up to 15 mm is allowed. To maximize the use of the carrying capacity of vehicles when transporting crushed grass, their sides are extended. Losses during overloading of the mass should not exceed 1%.

The optimal duration of placing haylage in trenches is no more than 4 days, in silos- 3-4 days without interruption. When placing the mass in the trench, it is continuously compacted. The temperature of the inner layer when filling the trench should not exceed 37°C. If it has increased, then the placing process is accelerated and tamping is strengthened. Haylage with a moisture content of 50% is placed with a volume weight of 450-550 kg/m3.

When the placing of haylage is completed, the surface of the trench is covered with a film, on top of which quicklime 5-10 mm thick, shredded straw with a layer of 20-30 cm and earth 15-30 cm thick are poured. In trenches, annually haylage is selected in vertical layers with a thickness of at least 50, in silos at least 30 cm over the entire open surface. In silos with bottom discharge, the one-time discharge volume is unlimited [

22,

23,

24,

25,

26,

27,

28,

29,

30]. Compliance with the above agrotechnical requirements ensures the reduction in material and financial expenses for harvesting, the quality and safety of alfalfa.