Submitted:

11 May 2023

Posted:

11 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental

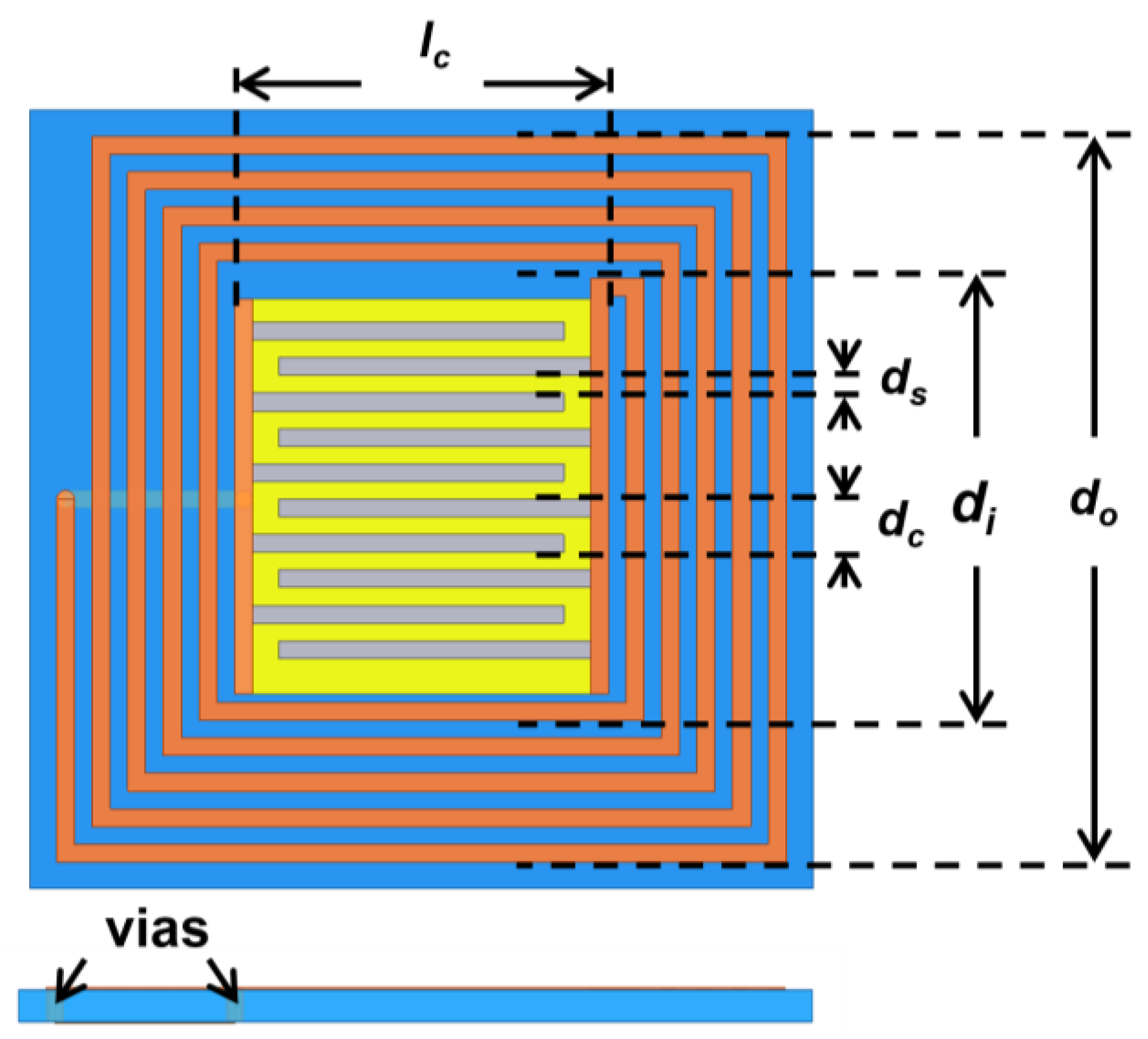

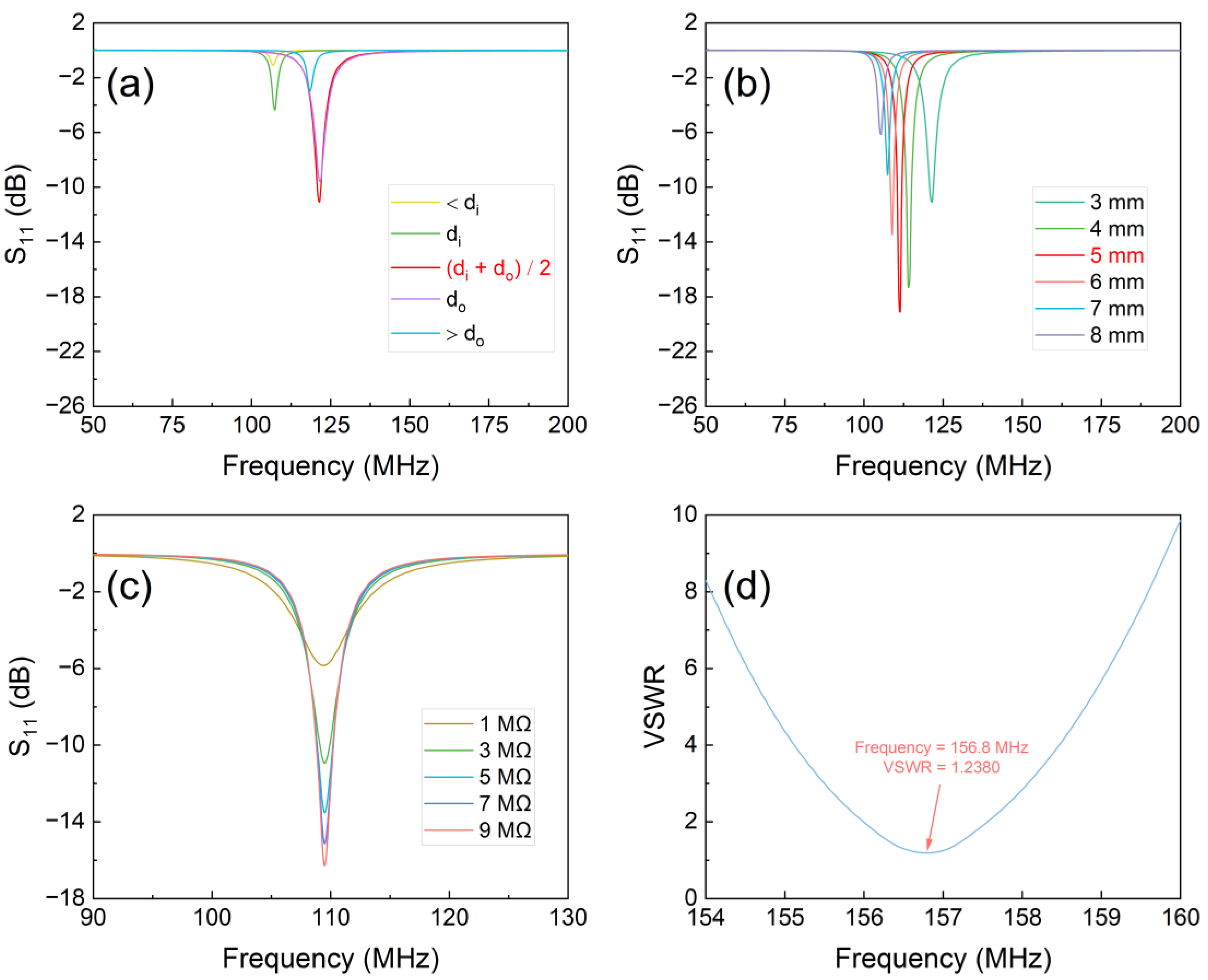

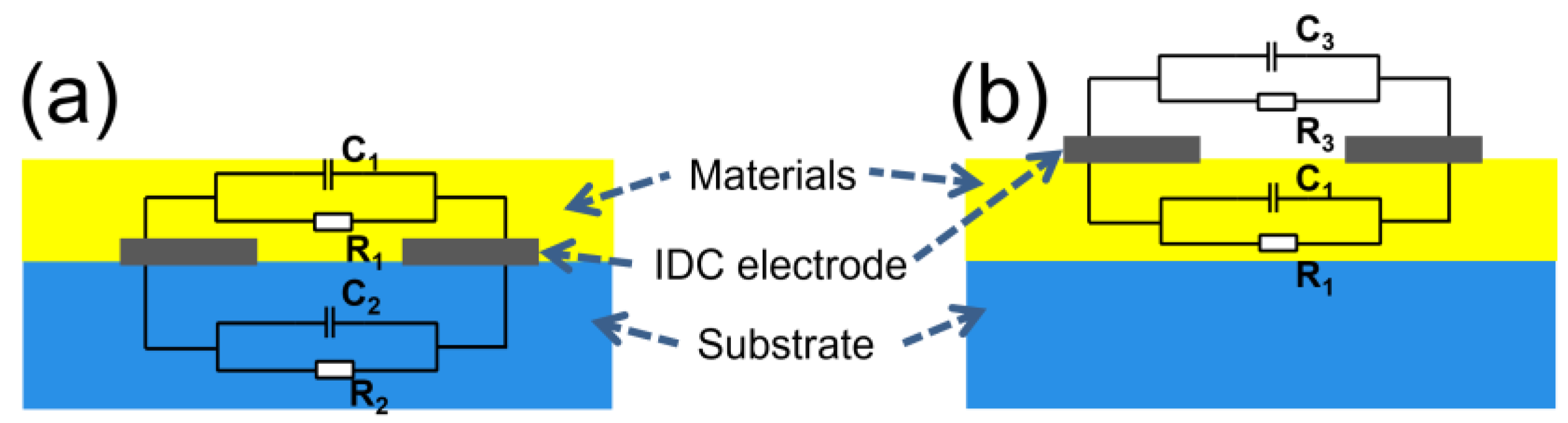

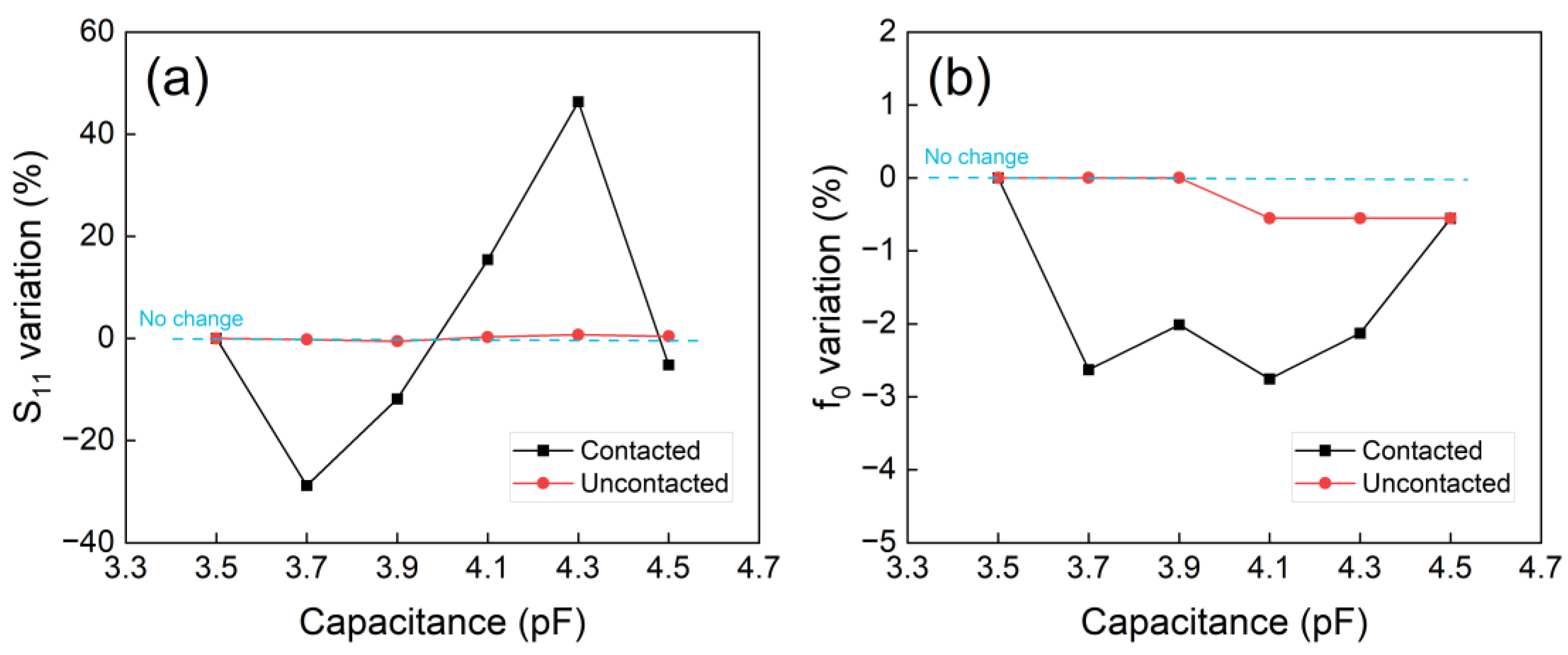

2.1. Design and Optimization of Antennas

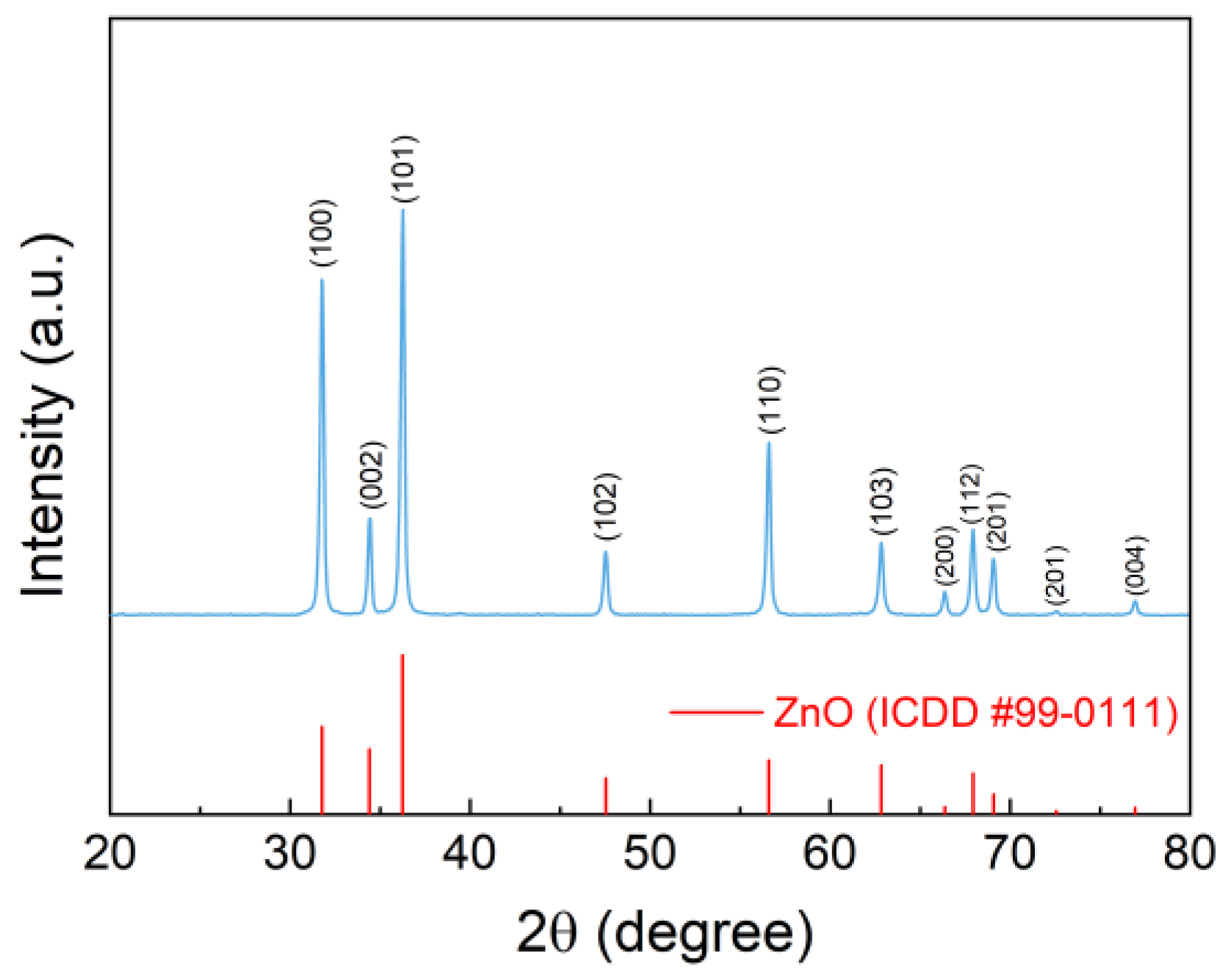

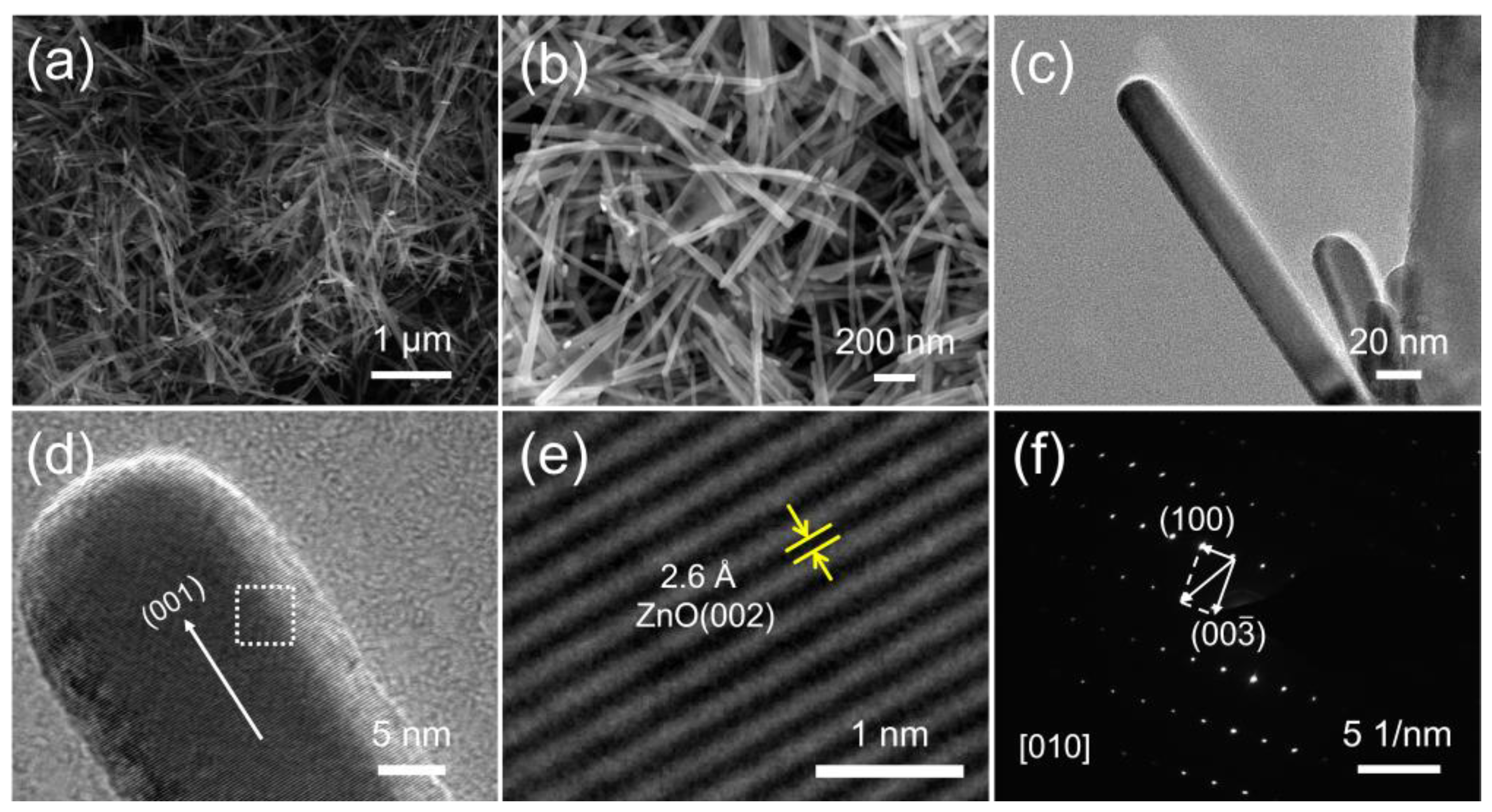

2.2. Synthesis and Characterization of ZnO NWs

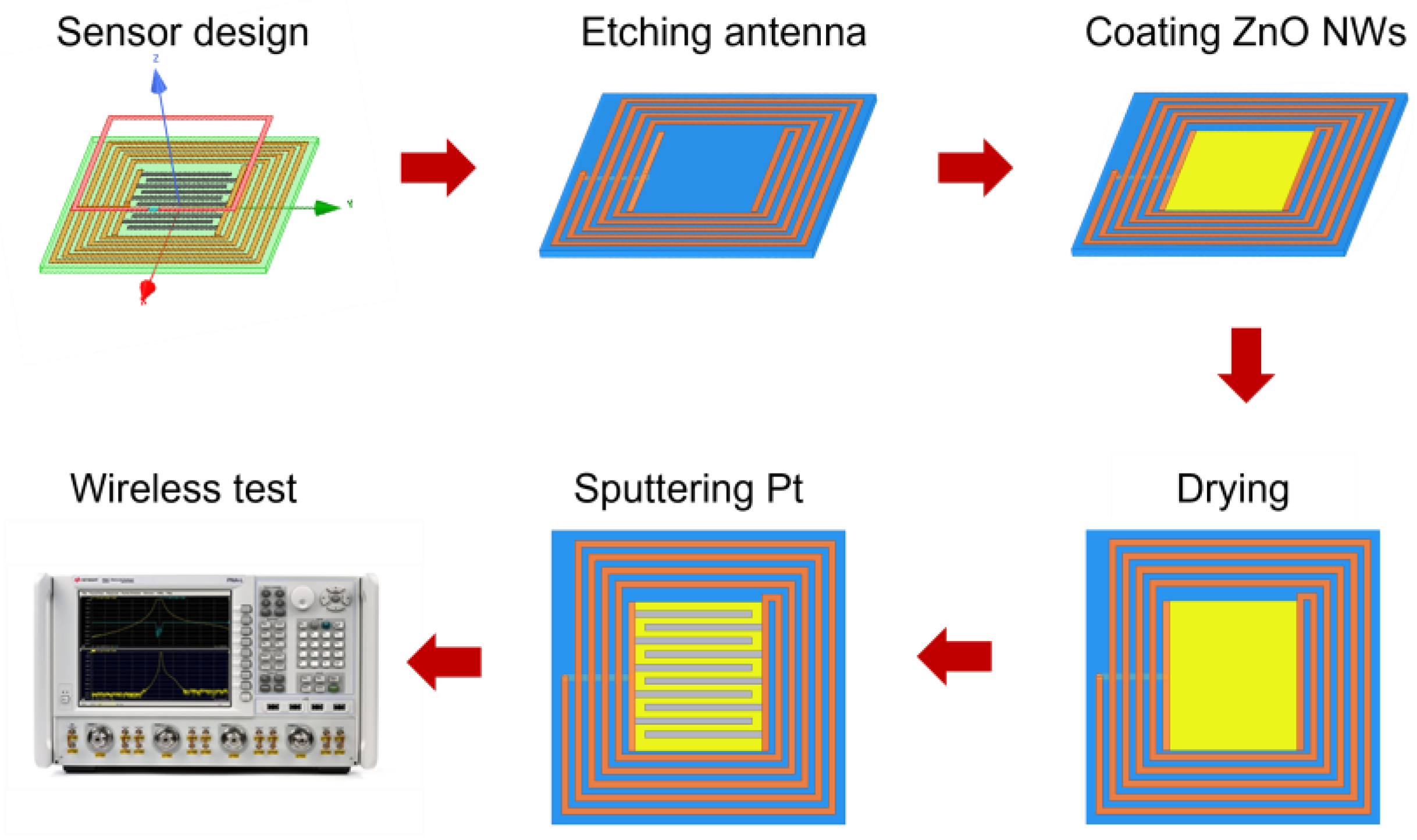

2.3. LC Sensor Fabrication and Gas Sensing Measurement

3. Results and Discussion

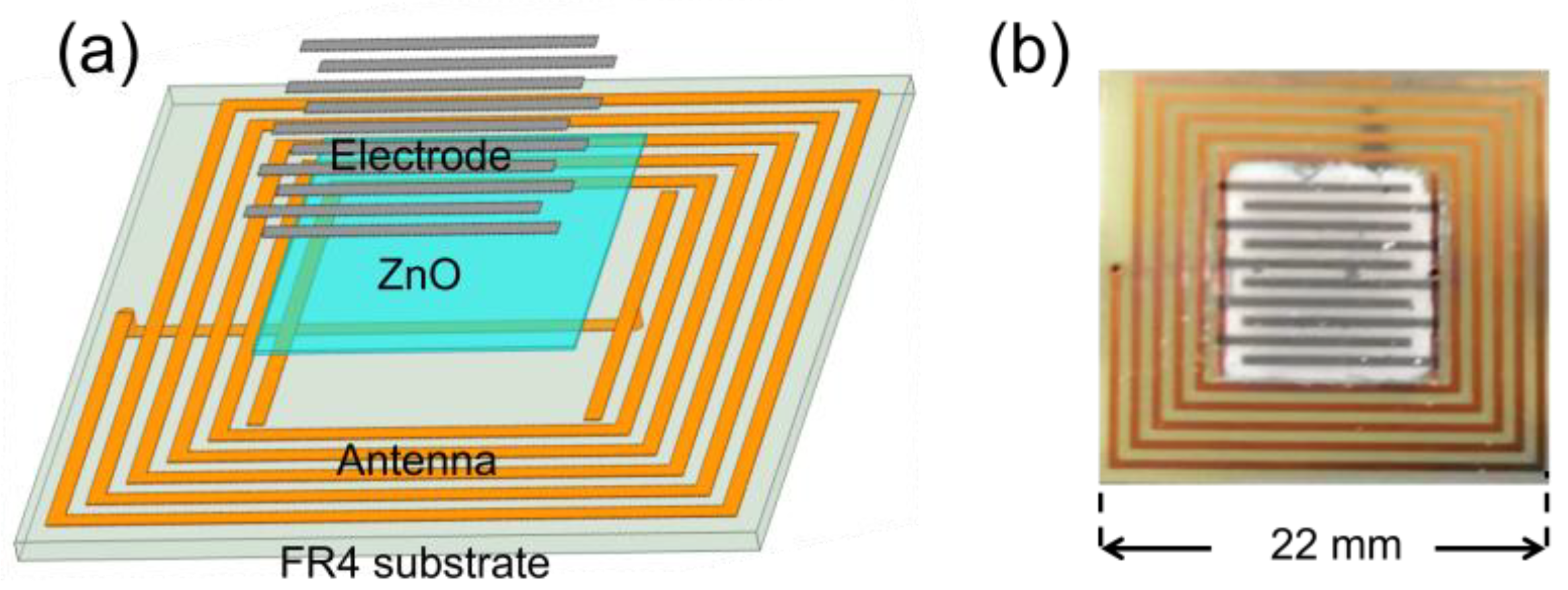

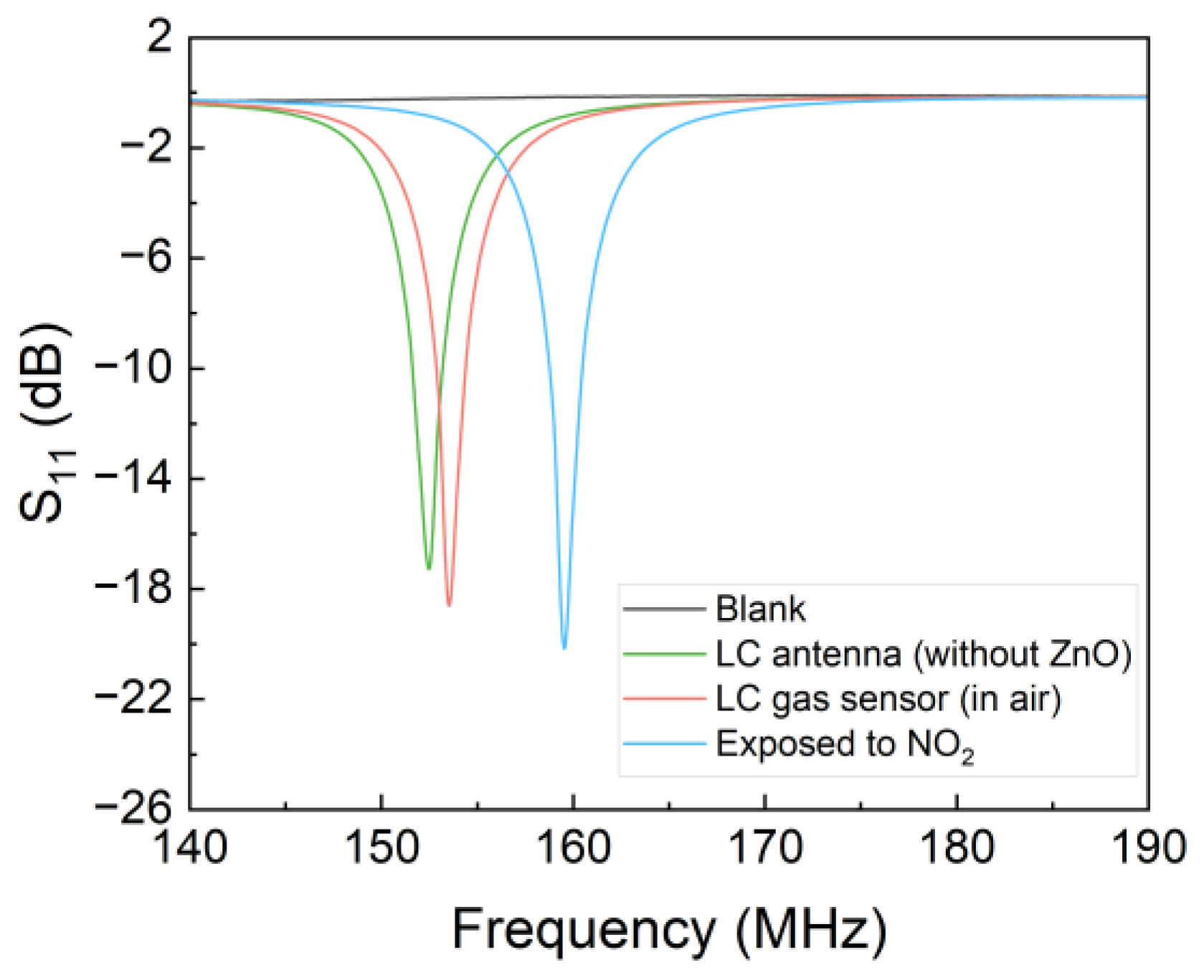

3.1. Novel Structure of the LC Sensor

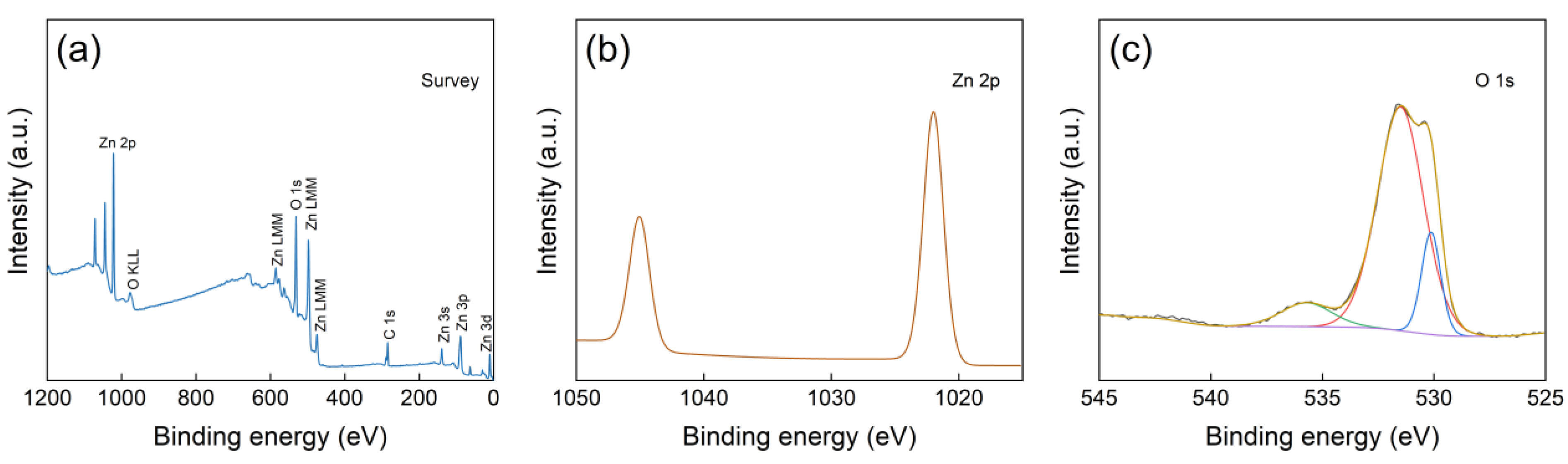

3.2. Characterizations of ZnO NWs

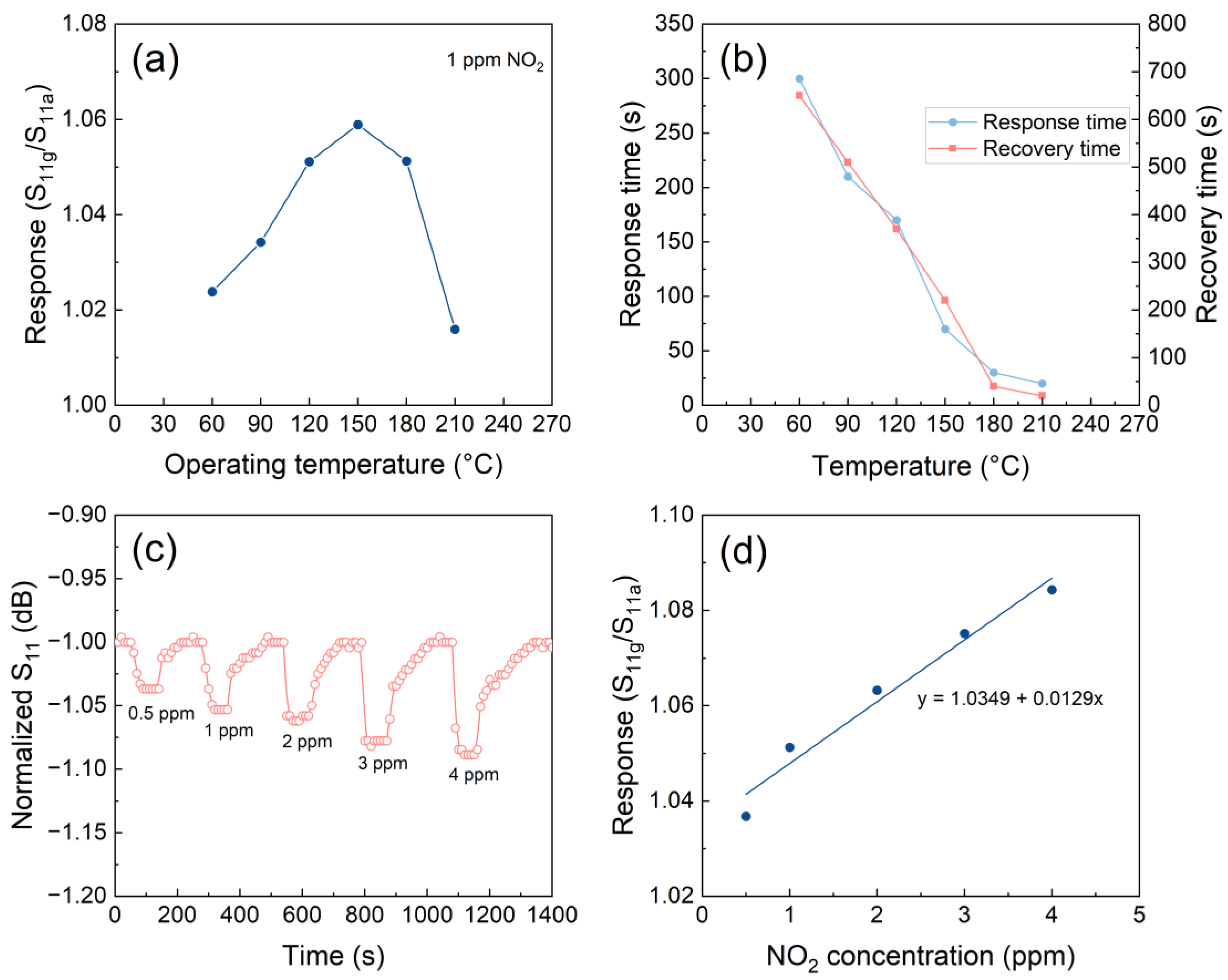

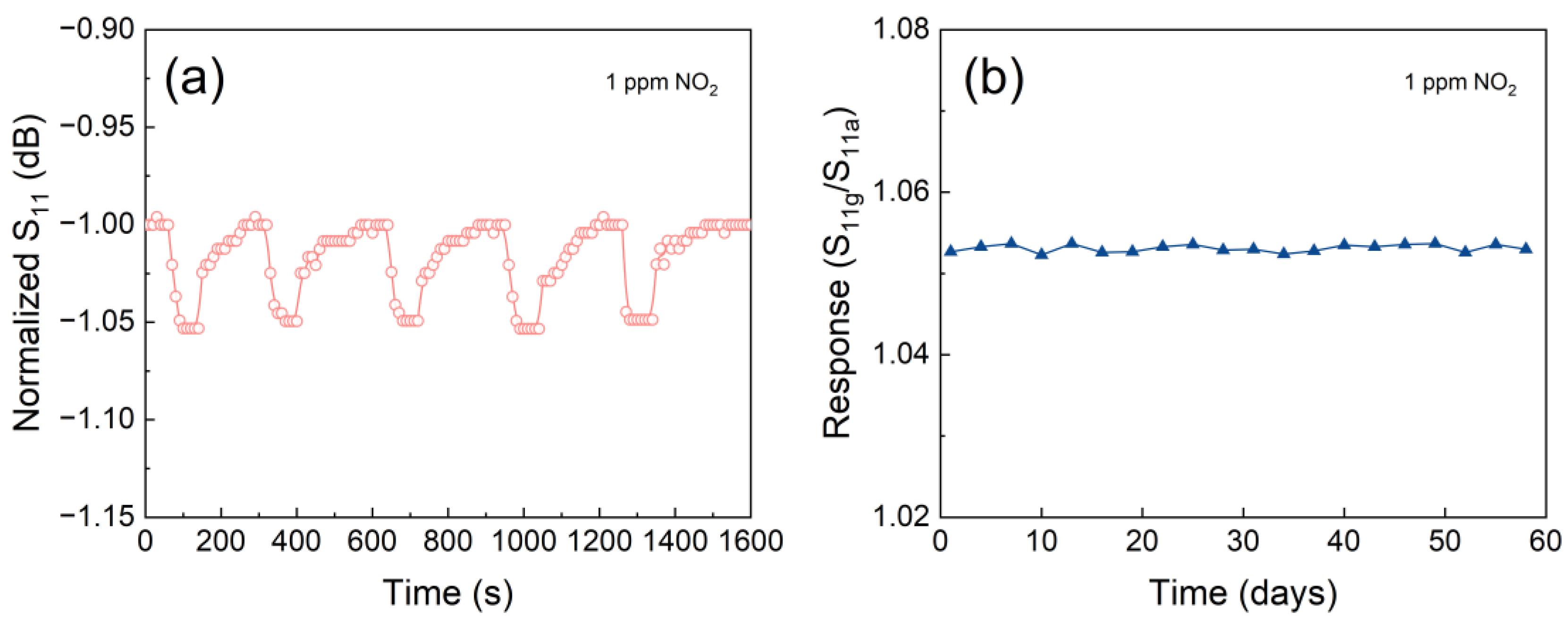

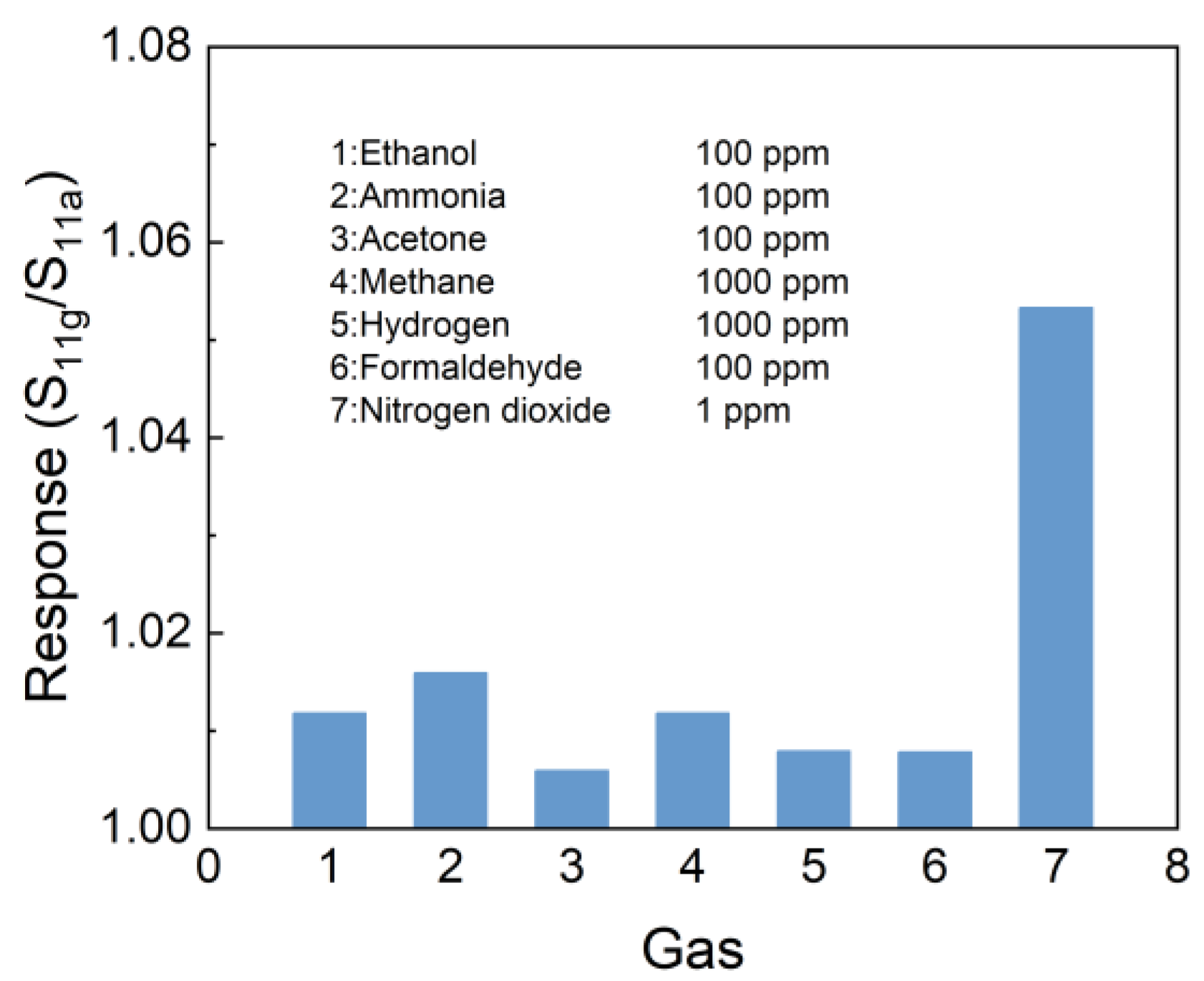

3.3. NO2 Sensing Properties of the LC Sensor

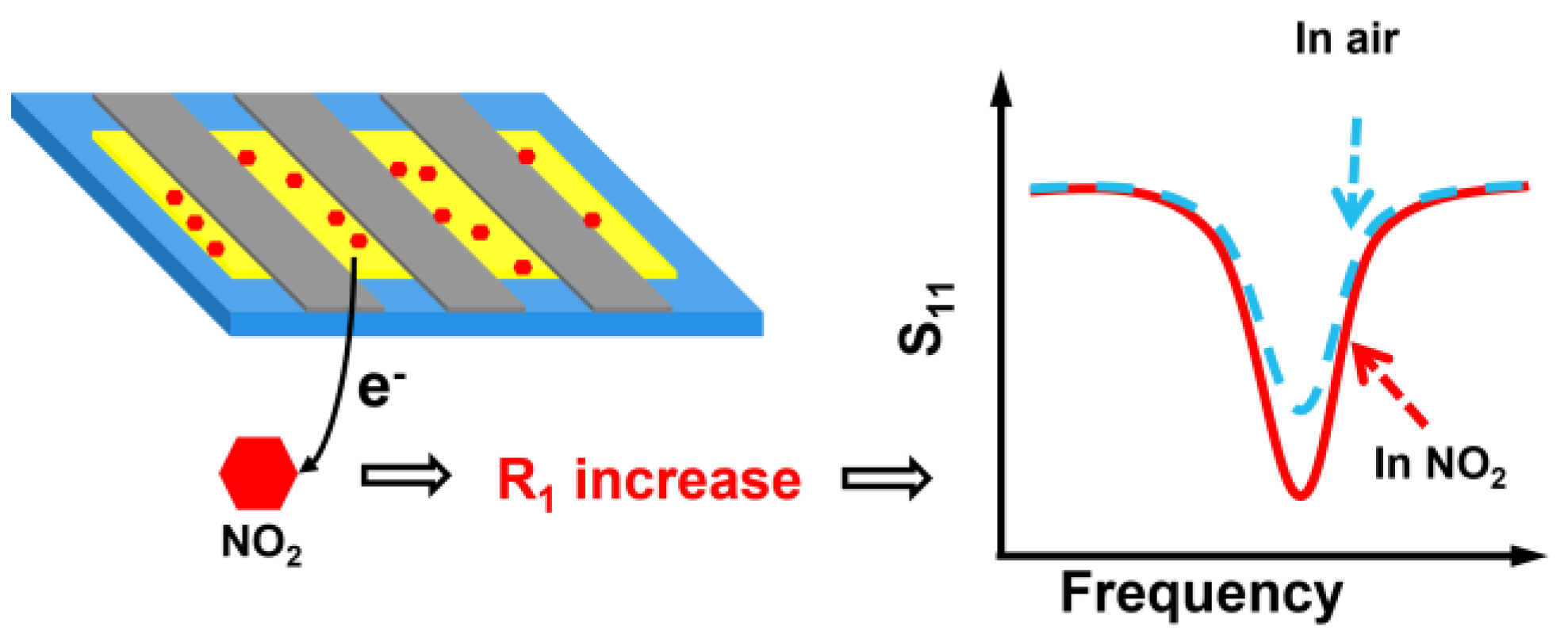

3.4. Gas Sensing Mechanism of the LC Sensor

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Samerjai, T.; Tamaekong, N.; Liewhiran, C.; Wisitsoraat, A.; Phanichphant, S. NO2 gas sensing of flame-made Pt-loaded WO3 thick films. Journal of Solid State Chemistry 2014, 214, 47-52. [CrossRef]

- Zhao, S.; Shen, Y.; Maboudian, R.; Carraro, C.; Han, C.; Liu, W.; Wei, D. Facile synthesis of ZnO-SnO2 hetero-structured nanowires for high-performance NO2 sensing application. Sensors and Actuators B: Chemical 2021, 333. [CrossRef]

- Liu, W.; Xu, L.; Sheng, K.; Chen, C.; Zhou, X.; Dong, B.; Bai, X.; Zhang, S.; Lu, G.; Song, H. APTES-functionalized thin-walled porous WO3 nanotubes for highly selective sensing of NO2 in a polluted environment. Journal of Materials Chemistry A 2018, 6, 10976-10989. [CrossRef]

- Qin, Y.; Wang, F.; Shen, W.; Hu, M. Mesoporous three-dimensional network of crystalline WO3 nanowires for gas sensing application. Journal of Alloys and Compounds 2012, 540, 21-26. [CrossRef]

- Shen, Y.; Bi, H.; Li, T.; Zhong, X.; Chen, X.; Fan, A.; Wei, D. Low-temperature and highly enhanced NO2 sensing performance of Au-functionalized WO3 microspheres with a hierarchical nanostructure. Applied Surface Science 2018, 434, 922-931. [CrossRef]

- Ghosh, A.; Zhang, C.; Shi, S.; Zhang, H. High temperature CO2 sensing and its cross-sensitivity towards H2 and CO gas using calcium doped ZnO thin film coated langasite SAW sensor. Sensors and Actuators B: Chemical 2019, 301. [CrossRef]

- Luo, J.; Feng, X.; Kan, H.; Li, H.; Fu, C. One-Dimensional Bi2S3 Nanobelts-Based Surface Acoustic Wave Sensor for NO2 Detection at Room Temperature. IEEE Sensors Journal 2021, 21, 1404-1408. [CrossRef]

- Wen, C.B.; Ju, Y.F.; Li, W.L.; Sun, W.Z.; Xu, X.; Shao, Y.; Li, Y.M.; Wen, L.M. Carbon Dioxide Gas Sensor Using SAW Device Based on ZnO Film. Applied Mechanics and Materials 2011, 135-136, 347-352. [CrossRef]

- Kamada, T.; Ueda, T.; Fukuura, S.; Yumura, T.; Hosokawa, S.; Tanaka, T.; Kan, D.; Shimakawa, Y. Ultralong Distance Hydrogen Spillover Enabled by Valence Changes in a Metal Oxide Surface. J Am Chem Soc 2023, 145, 1631-1637. [CrossRef]

- Zhang, C.; Wang, L.-F.; Huang, J.-Q.; Huang, Q.-A. An LC-Type Passive Wireless Humidity Sensor System With Portable Telemetry Unit. Journal of Microelectromechanical Systems 2015, 24, 575-581. [CrossRef]

- Jang, C.; Park, J.K.; Yun, G.H.; Choi, H.H.; Lee, H.J.; Yook, J.G. Radio-Frequency/Microwave Gas Sensors Using Conducting Polymer. Materials (Basel) 2020, 13. [CrossRef]

- Wang, N.; Zhang, N.; Wang, T.; Liu, F.; Wang, X.; Yan, X.; Wang, C.; Liu, X.; Sun, P.; Lu, G. Microwave gas sensor for detection of ammonia at room-temperature. Sensors and Actuators B: Chemical 2022, 350. [CrossRef]

- Tan, Q.; Luo, T.; Wei, T.; Liu, J.; Lin, L.; Xiong, J. A Wireless Passive Pressure and Temperature Sensor via a Dual LC Resonant Circuit in Harsh Environments. Journal of Microelectromechanical Systems 2017, 26, 351-356. [CrossRef]

- Huang, Q.-A.; Dong, L.; Wang, L.-F. LC Passive Wireless Sensors Toward a Wireless Sensing Platform: Status, Prospects, and Challenges. Journal of Microelectromechanical Systems 2016, 25, 822-841. [CrossRef]

- Potyrailo, R.A.; Surman, C.; Nagraj, N.; Burns, A. Materials and Transducers Toward Selective Wireless Gas Sensing. Chemical Reviews 2011, 111, 7315-7354. [CrossRef]

- Azzarelli, J.M.; Mirica, K.A.; Ravnsbaek, J.B.; Swager, T.M. Wireless gas detection with a smartphone via rf communication. Proceedings of the National Academy of Sciences of the United States of America 2014, 111, 18162-18166. [CrossRef]

- Ma, M.; Khan, H.; Shan, W.; Wang, Y.; Ou, J.Z.; Liu, Z.; Kalantar-zadeh, K.; Li, Y. A novel wireless gas sensor based on LTCC technology. Sensors and Actuators B: Chemical 2017, 239, 711-717. [CrossRef]

- Ma, Z.; Chen, P.; Cheng, W.; Yan, K.; Pan, L.; Shi, Y.; Yu, G. Highly Sensitive, Printable Nanostructured Conductive Polymer Wireless Sensor for Food Spoilage Detection. Nano Lett 2018, 18, 4570-4575. [CrossRef]

- Tang, N.; Zhou, C.; Xu, L.; Jiang, Y.; Qu, H.; Duan, X. A Fully Integrated Wireless Flexible Ammonia Sensor Fabricated by Soft Nano-Lithography. ACS Sens 2019, 4, 726-732. [CrossRef]

- Zhang, L.; Yang, H.; Tan, Q.; Jing, L.; Zhang, W.; Xiong, J.; Chen, P.-Y. Wireless Detection of Biogenic Amines Using a Split-Ring Resonator with Silver Nanoparticles-Decorated Molybdenum Disulfide. Sensors and Actuators B: Chemical 2021, 343. [CrossRef]

- Li, W.; Liang, T.; Liu, W.; Jia, P.; Chen, Y.; Xiong, J.; Lei, C.; Hong, Y.; Li, Y. Wireless passive pressure sensor based on sapphire direct bonding for harsh environments. Sensors and Actuators a-Physical 2018, 280, 406-412. [CrossRef]

- Kim, S.-Y.; Kim, J.; Cheong, W.H.; Lee, I.J.; Lee, H.; Im, H.-G.; Kong, H.; Bae, B.-S.; Park, J.-U. Alcohol gas sensors capable of wireless detection using In2O3/Pt nanoparticles and Ag nanowires. Sensors and Actuators B: Chemical 2018, 259, 825-832. [CrossRef]

- Zhang, D.; Yang, Z.; Li, P.; Pang, M.; Xue, Q. Flexible self-powered high-performance ammonia sensor based on Au-decorated MoSe2 nanoflowers driven by single layer MoS2-flake piezoelectric nanogenerator. Nano Energy 2019, 65. [CrossRef]

- Zhao, S.; Shen, Y.; Zhou, P.; Hao, F.; Xu, X.; Gao, S.; Wei, D.; Ao, Y.; Shen, Y. Enhanced NO2 sensing performance of ZnO nanowires functionalized with ultra-fine In2O3 nanoparticles. Sensors and Actuators B: Chemical 2020, 308. [CrossRef]

- Zhao, S.; Shen, Y.; Yan, X.; Zhou, P.; Yin, Y.; Lu, R.; Han, C.; Cui, B.; Wei, D. Complex-surfactant-assisted hydrothermal synthesis of one-dimensional ZnO nanorods for high-performance ethanol gas sensor. Sensors and Actuators B: Chemical 2019, 286, 501-511. [CrossRef]

- Fiddes, L.K.; Yan, N. RFID tags for wireless electrochemical detection of volatile chemicals. Sensors and Actuators B: Chemical 2013, 186, 817-823. [CrossRef]

- Hasan, N.; Noordin, N.H.; Karim, M.S.A.; Rejab, M.R.M.; Ma, Q.J. Dielectric properties of epoxy–barium titanate composite for 5 GHz microstrip antenna design. SN Applied Sciences 2019, 2. [CrossRef]

- Zhang, L.; Tan, Q.; Kou, H.; Wu, D.; Zhang, W.; Xiong, J. Highly Sensitive NH3 Wireless Sensor Based on Ag-RGO Composite Operated at Room-temperature. Sci Rep 2019, 9, 9942. [CrossRef]

- Mao, S.; Cui, S.; Lu, G.; Yu, K.; Wen, Z.; Chen, J. Tuning gas-sensing properties of reduced graphene oxide using tin oxide nanocrystals. Journal of Materials Chemistry 2012, 22. [CrossRef]

- Wilson, W.C.; Atkinson, G.M. Passive Wireless Sensor Applications for NASA’s Extreme Aeronautical Environments. IEEE Sensors Journal 2014, 14, 3745-3753. [CrossRef]

- Klingshirn, C. ZnO: material, physics and applications. Chemphyschem 2007, 8, 782-803. [CrossRef]

- Liu, B.; Zeng, H.C.J.J.a.c.s. Hydrothermal synthesis of ZnO nanorods in the diameter regime of 50 nm. 2003, 125, 4430.

- Shimpi, N.G.; Jain, S.; Karmakar, N.; Shah, A.; Kothari, D.C.; Mishra, S. Synthesis of ZnO nanopencils using wet chemical method and its investigation as LPG sensor. Applied Surface Science 2016, 390, 17-24. [CrossRef]

- Choi, K.-I.; Hwang, S.-J.; Dai, Z.; Chan Kang, Y.; Lee, J.-H. Rh-catalyzed WO3 with anomalous humidity dependence of gas sensing characteristics. RSC Adv. 2014, 4, 53130-53136. [CrossRef]

- Li, W.; Ma, S.; Li, Y.; Yang, G.; Mao, Y.; Luo, J.; Gengzang, D.; Xu, X.; Yan, S. Enhanced ethanol sensing performance of hollow ZnO–SnO2 core–shell nanofibers. Sensors and Actuators B: Chemical 2015, 211, 392-402. [CrossRef]

- Li, G.; Shen, Y.; Zhao, S.; Bai, J.; Gao, S.; Liu, W.; Wei, D.; Meng, D.; San, X. Construction of rGO-SnO2 heterojunction for enhanced hydrogen detection. Applied Surface Science 2022, 585. [CrossRef]

- Zhao, S.; Shen, Y.; Hao, F.; Kang, C.; Cui, B.; Wei, D.; Meng, F. P-n junctions based on CuO-decorated ZnO nanowires for ethanol sensing application. Applied Surface Science 2021, 538. [CrossRef]

- Shen, Y.; Wang, W.; Chen, X.; Zhang, B.; Wei, D.; Gao, S.; Cui, B.J.J.o.M.C.A. Nitrogen dioxide sensing using tungsten oxide microspheres with hierarchical nanorod-assembled architectures by a complexing surfactant-mediated hydrothermal route. 2016, 4, 1345-1352.

- Barreca, D.; Bekermann, D.; Comini, E.; Devi, A.; Fischer, R.A.; Gasparotto, A.; Maccato, C.; Sberveglieri, G.; Tondello, E. 1D ZnO nano-assemblies by Plasma-CVD as chemical sensors for flammable and toxic gases. Sensors and Actuators B: Chemical 2010, 149, 1-7. [CrossRef]

- Chang, S.C. Oxygen chemisorption on tin oxide: Correlation between electrical conductivity and EPR measurements. Journal of Vacuum Science and Technology 1980, 17, 366-369. [CrossRef]

- Mizokawa, Y.; Nakamura, S.J.O.B. ESR study of adsorbed oxygen on tin dioxide. 1977, 46, 580-584.

- Belysheva, T.V.; Bogovtseva, L.P.; Kazachkov, E.A.; Serebryakova, N.V. Gas-Sensing Properties of Doped In2O3 Films as Sensors for NO2 in Air. Journal of Analytical Chemistry 2003, 58, 583-587. [CrossRef]

- Ferro, R.; Rodríguez, J.A.; Bertrand, P. Peculiarities of nitrogen dioxide detection with sprayed undoped and indium-doped zinc oxide thin films. Thin Solid Films 2008, 516, 2225-2230. [CrossRef]

| lc | dc | ds | Ni | do | di | Nc |

|---|---|---|---|---|---|---|

| 10.5 mm | 1.5 mm | 0.5 mm | 4.75 | 20.5 mm | 12.5 mm | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).